Method for improving corrosion resistance of magnesium alloy surface through short-pulse laser

A short-pulse laser and corrosion-resistant technology, which is applied in the field of short-pulse laser to improve the corrosion resistance of magnesium alloy surfaces, can solve the problems of large thermal impact and affect the performance of metal substrates, achieve small thermal impact, improve production efficiency, and improve processing speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

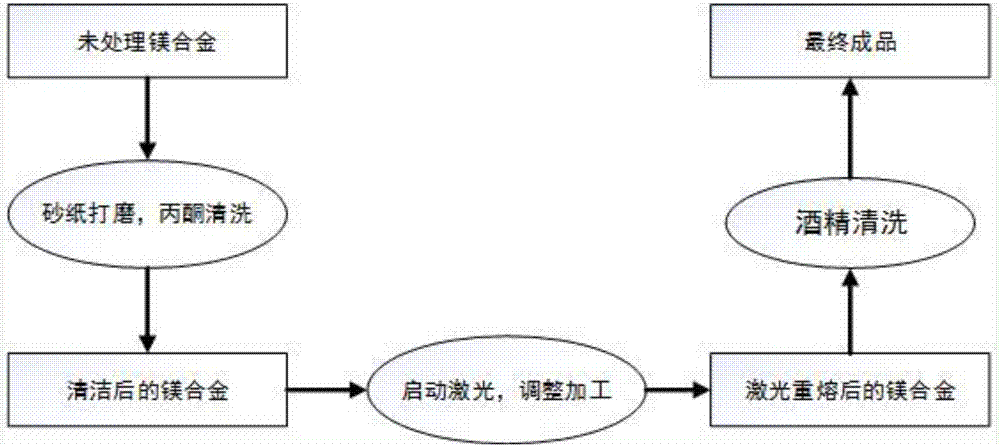

[0035] (1) Take a Mg-Gd-Ca magnesium alloy block with a thickness of 5 mm, polish it with sandpaper to remove the oxide film on the processed surface, and place it in anhydrous acetone for cleaning.

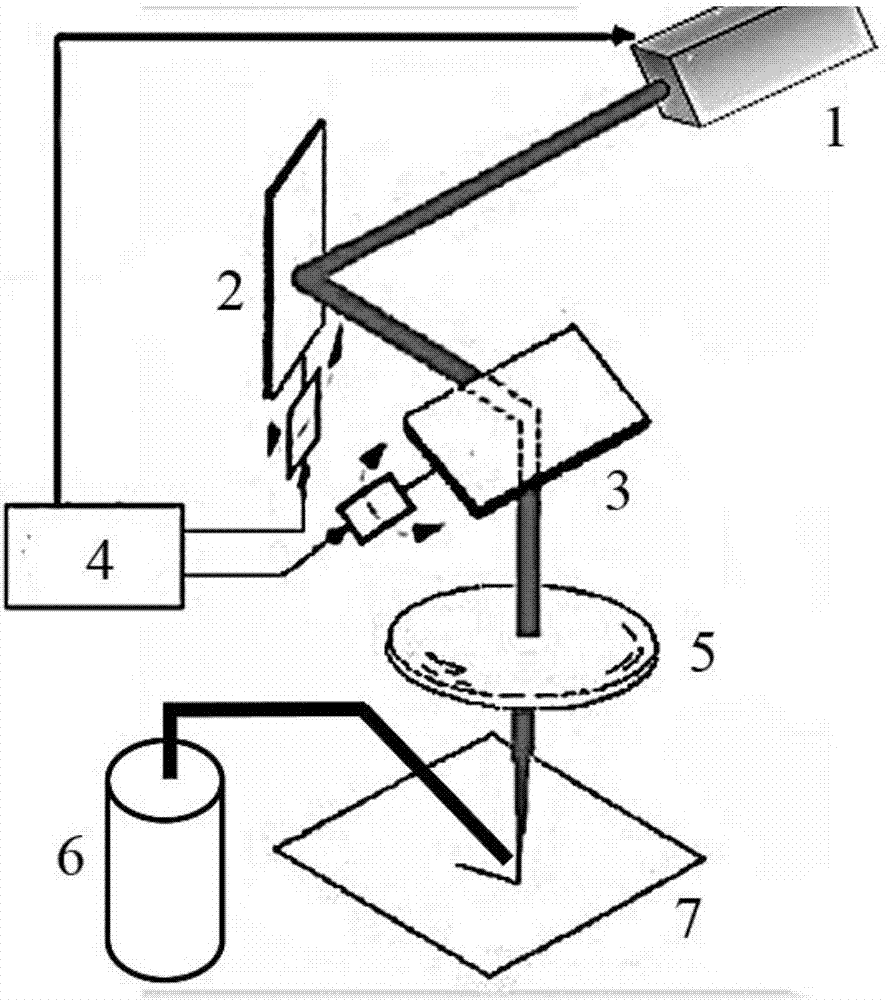

[0036] (2) Put the sample in such as figure 2 The nanosecond laser processing system of SPI company shown (using 1060nm wavelength of CO 2 On the workbench of the laser), set the laser power to 70W, the frequency to 500kHz, the scanning speed to 200mm / s, set the scanning area size to 10mm×10mm, adjust the spot overlap rate to 20%, and start the laser processing system to start processing.

[0037] (3) Remove the processed magnesium alloy block from the workbench and wipe it with absolute alcohol.

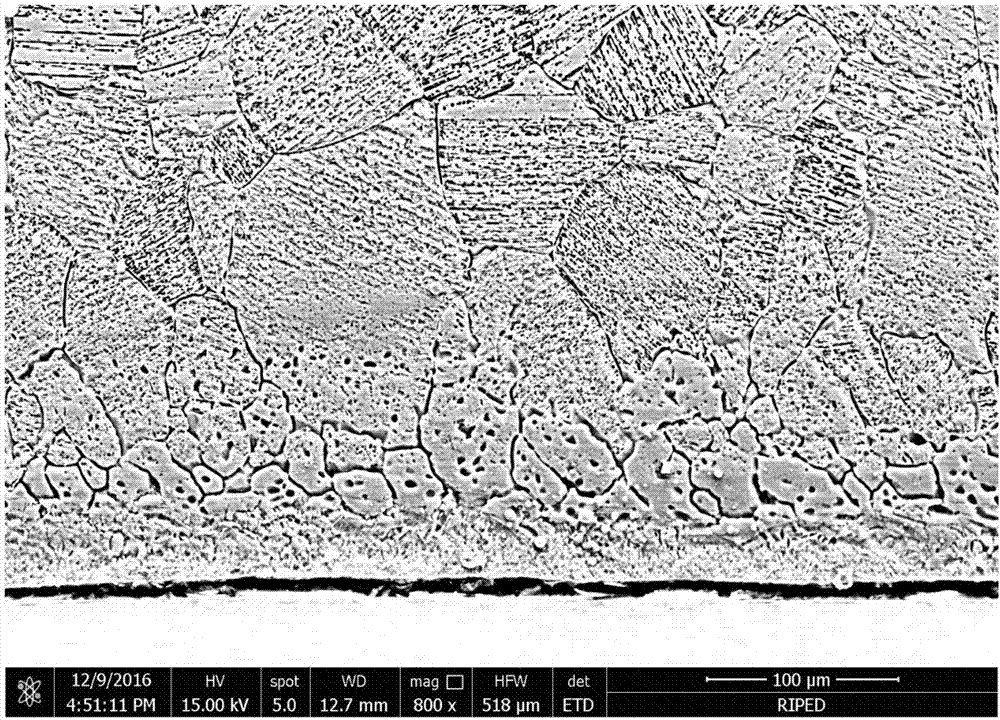

[0038] Such as image 3 Shown is the metallography of the longitudinal section near the surface of the Mg-Gd-Ca magnesium alloy obtained after processing in Example 1. As shown in the figure, there is a remelted layer with a thickness of about 20 μm on the metal surface after short-...

Embodiment 2

[0040] (1) Take a Mg-Gd-Ca magnesium alloy block with a thickness of 5mm, sand it to remove the oxide film on the processed surface, and place it in anhydrous acetone for cleaning.

[0041] (2) Put the sample in such as figure 2 On the workbench of the nanosecond laser processing system of SPI Company shown (using a CO2 laser with a wavelength of 1060nm), the laser power is set to 80W, the frequency is 500kHz, the scanning speed is 50mm / s, and the scanning area is set to 10mm×10mm. The spot overlap rate is adjusted to 40%, and the laser processing system is started to start processing.

[0042] (3) Remove the processed magnesium alloy block from the workbench and wipe it with absolute alcohol.

[0043] Such as Figure 5 Shown is the electrode polarization curve of the Mg-Gd-Ca magnesium alloy obtained after processing in Example 2 and the untreated sample. As shown in the figure, the self-corrosion potential of the alloy after remelting is improved relative to the untreated...

Embodiment 3

[0045] (1) Take a ZK60 magnesium alloy block with a thickness of 5mm, sand it to remove the oxide film on the processed surface, and place it in anhydrous acetone for cleaning.

[0046] (2) Put the sample in such as figure 2On the workbench of the nanosecond laser processing system of SPI Company shown (using a CO2 laser with a wavelength of 1060nm), the laser power is set to 120W, the frequency is 20kHz, the scanning speed is 50mm / s, and the scanning area is set to 10mm×10mm. The spot overlap rate is adjusted to 50%, and the laser processing system is started to start processing.

[0047] (3) Remove the processed magnesium alloy block from the workbench and wipe it with absolute alcohol.

[0048] Such as Figure 6 Shown is the electrode polarization curve of the ZK60 magnesium alloy obtained after processing in Example 3 and the untreated sample. As shown in the figure, the self-corrosion potential of the alloy after remelting is improved compared with the untreated sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com