Low-wear abrasive capable of improving corrosion resistance capability of stainless steel surface and preparation method of low-wear abrasive

A stainless steel, low-wear technology, used in chemical instruments and methods, other chemical processes, etc., can solve problems such as incomplete passivation film and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

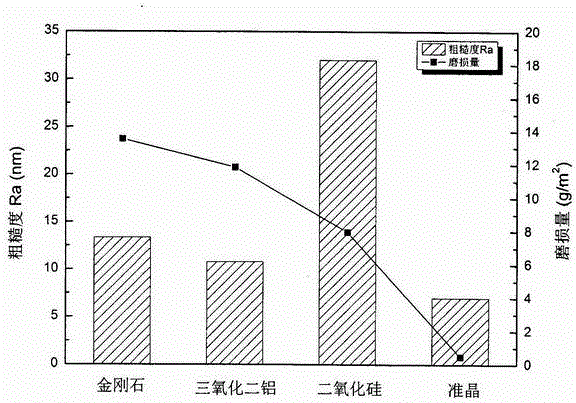

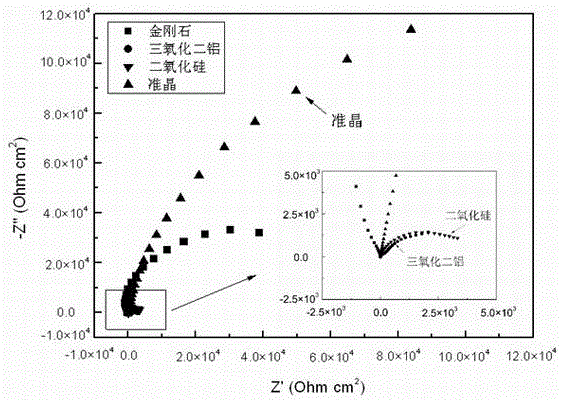

Image

Examples

Embodiment 1

[0018] Example 1: Al 62 Cu 25.5 Fe 12.5 quasicrystalline abrasive

[0019] Step 1. Ingredients

[0020] According to Al 62 Cu 25.5 Fe 12.5 The atomic percentage is used for batching;

[0021] Step 2. Smelting

[0022] The raw material in step 1 is repeatedly smelted by non-consumable electric arc in a water-cooled copper mold to prepare an alloy ingot with uniform composition;

[0023] Step 3, preparation of quasicrystals with a purity greater than 50%

[0024] The alloy ingot in step 2 was annealed in vacuum at 800°C for 8 hours, and then air-cooled to obtain a high-purity icosahedral quasicrystalline single-phase alloy. The quasicrystalline characteristic peak and its quasicrystalline phase content were determined to be greater than 75% by X-ray diffraction testing technology;

[0025] Step 4. Flour making

[0026] Put the high-purity quasi-crystalline ingot in step 3 into a planetary ball mill, under the protection of argon, set the speed at 200r / min, ball mill fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com