Modification method for improving corrosion resistance and surface functionalization of biomedical magnesium-based metal material

A surface functionalization, magnesium-based metal technology, applied in the field of biomedical engineering functional materials, can solve problems such as excessive degradation, achieve high research and application value, hinder electron transfer, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A modification method for improving the corrosion resistance and surface functionalization of biomedical magnesium-based metal materials is obtained by the following steps:

[0031] A. Polish, clean and dry the pure magnesium material that needs to be modified;

[0032] B. Place the sample obtained in step A in a buffer system with pH=7, then add epigallocatechin gallate EGCG with a concentration of 0.5 mg / ml to the system, and react at 10°C for 1 hour;

[0033] C. For the sample obtained in step B, immerse it in deionized water, clean it ultrasonically for 3 times, each time for 5min, and then wash it in N 2 The target material can be obtained by drying under the conditions.

Embodiment 2

[0035] A modification method for improving the corrosion resistance and surface functionalization of biomedical magnesium-based metal materials is obtained by the following steps:

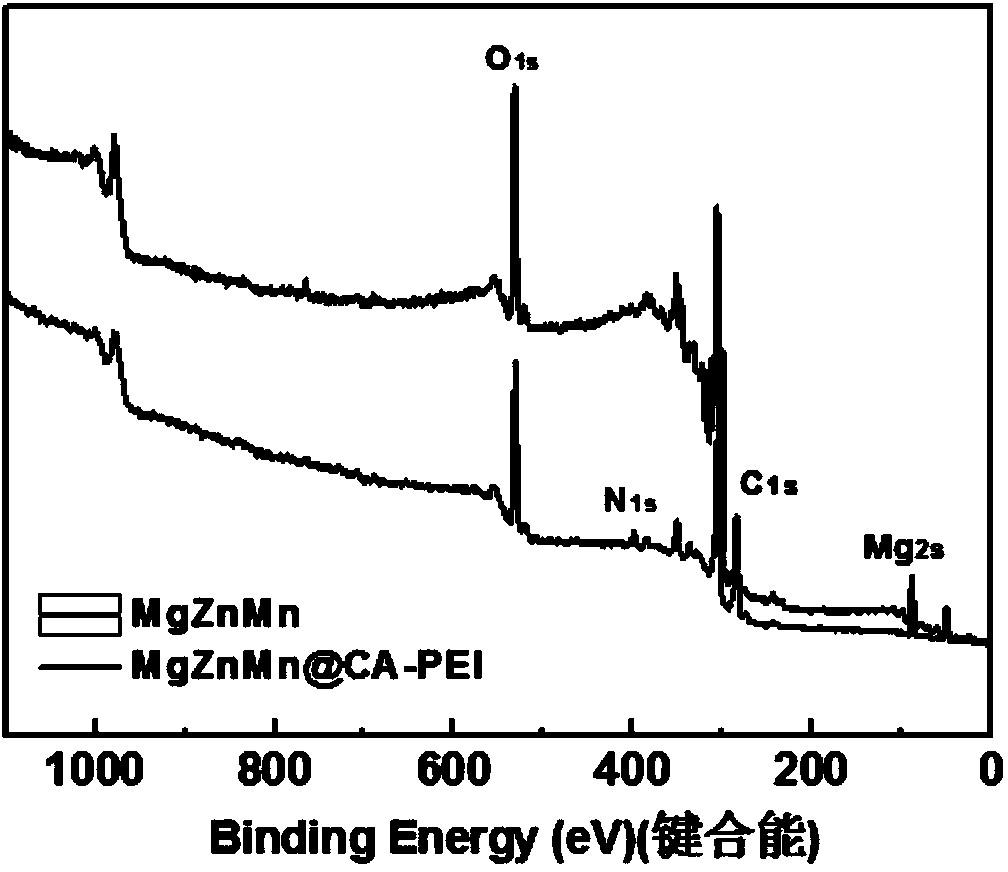

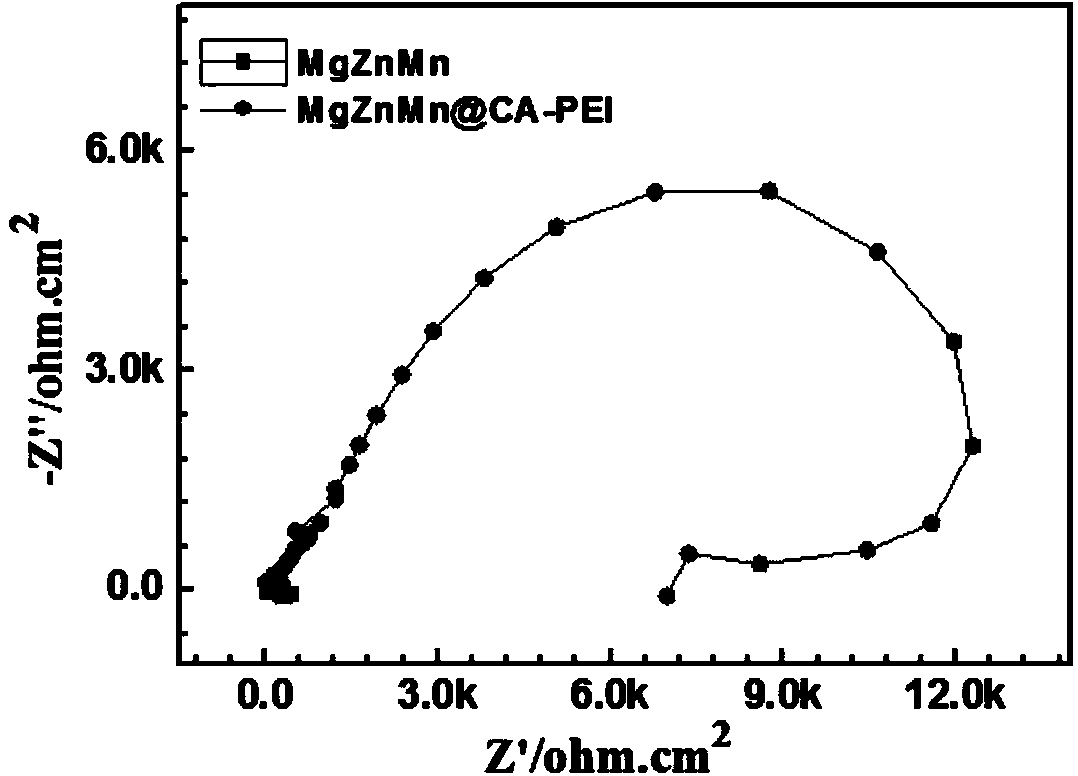

[0036] A. Polish, clean and dry the magnesium-zinc-manganese alloy material that needs to be modified;

[0037]B. Place the sample obtained in step A in a buffer system of pH=12, then add epigallocatechin gallate (EGCG) with a concentration of 10 mg / ml and selenocystamine with a concentration of 10 mg / ml to the system, At 30°C, react for 6h;

[0038] C. For the sample obtained in step B, immerse it in deionized water, clean it ultrasonically for 3 times, each time for 5min, and then wash it in N 2 The target material can be obtained by drying under the conditions.

Embodiment 3

[0040] A modification method for improving the corrosion resistance and surface functionalization of biomedical magnesium-based metal materials is obtained by the following steps:

[0041] A. Polish, clean and dry the WE43 magnesium alloy that needs to be modified;

[0042] B. Place the sample obtained in step A in a Tris-buffer buffer system with pH = 7, then add tannic acid with an o-phenolic hydroxyl structure with a concentration of 0.1 mg / ml into the system, and simultaneously add acetonitrile with a concentration of 1 mg / ml. Diamine, at 10°C, react for 1h;

[0043] C. For the sample obtained in step B, immerse it in deionized water, clean it ultrasonically for 3 times, each time for 5min, and then wash it in N 2 The target material can be obtained by drying under the conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com