Low-temperature Ge-containing Sn-Bi solder used for photovoltaic solder strip and preparation method thereof

A photovoltaic ribbon and low-temperature solder technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as increasing alloy brittleness, improve corrosion resistance, ensure accuracy, and prevent metal oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

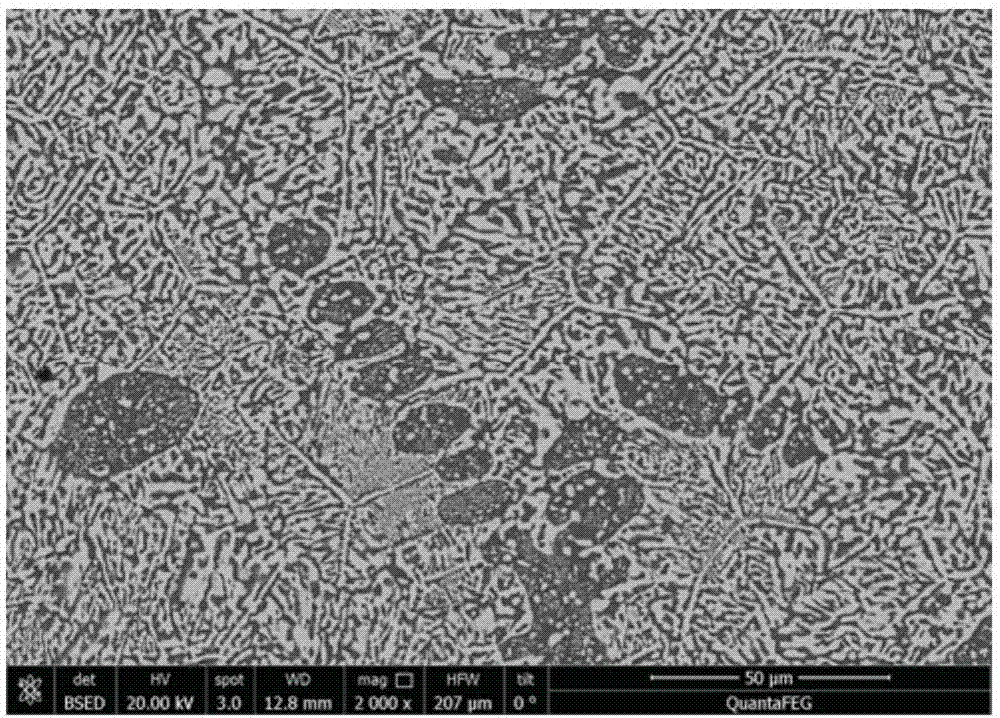

Embodiment 1

[0048]When smelting, first mechanically stir metal powders such as pure tin (Sn), pure bismuth (Bi) and pure germanium (Ge) with mass ratios of 54.975wt%, 45wt%, and 0.025wt%, respectively, and mix the metal powders evenly placed in a quartz crucible. Cover the surface of the metal powder with KCl and LiCl mixed salt with a mass ratio of 1.3:1, and then place the quartz crucible in a resistance furnace at 500°C for heating until the metal powder and mixed salt are melted to form molten solder, and stir once every 15 minutes. The tissue is homogenized to form liquid solder. The liquid solder was cooled to room temperature, and the mixed salts were washed away by ultrasonic cleaning to obtain Ge-containing low-temperature Sn-Bi solder, and the solder prepared in this embodiment was made into a solder ribbon. According to the national standard GB / T 228.1-2010, the as-cast alloy was prepared into a tensile sample, and the mechanical properties of the alloy were measured at a tens...

Embodiment 2

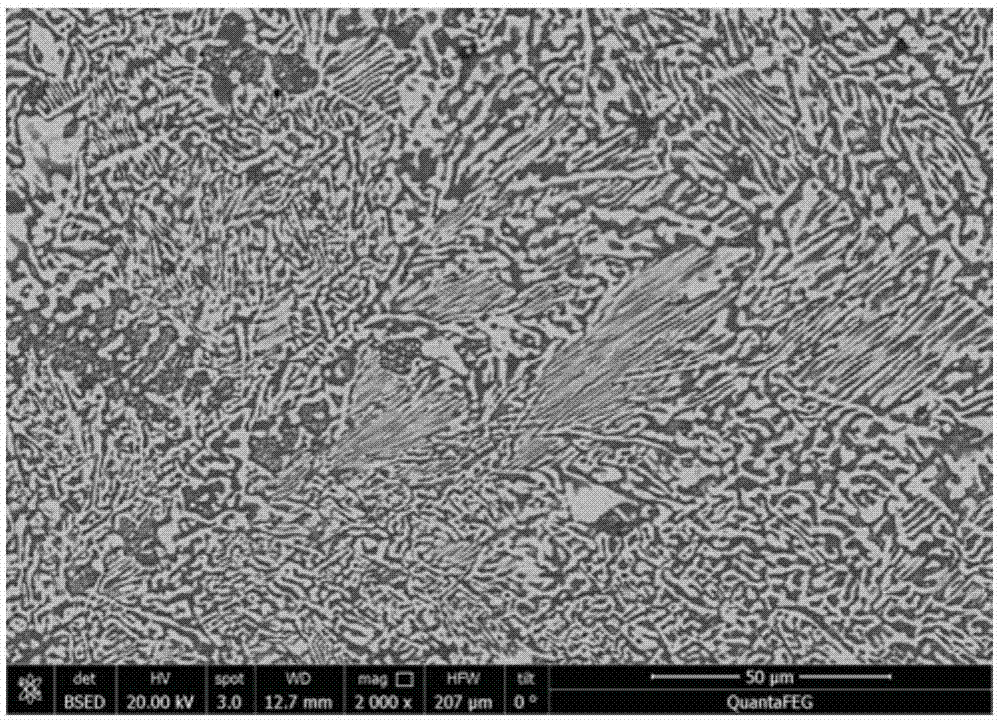

[0052] During smelting, the pure tin, pure bismuth and pure germanium powders with mass ratios of 54.9wt%, 45wt%, and 0.1wt% were mechanically stirred, and the obtained uniformly mixed metal powders were placed in a quartz crucible. Cover the mixed salt of KCl and LiCl with a mass ratio of 1.3:1 on the surface of the uniformly mixed metal powder, place the quartz crucible in a resistance furnace at 550°C for heating, and wait for the metal powder and mixed salt to melt to form molten solder, 15 Stir once every minute to homogenize the tissue and form liquid solder. The liquid solder was cooled to room temperature, and the salts were washed away by ultrasonic cleaning to obtain Ge-containing low-temperature Sn-Bi solder, and the solder prepared in this embodiment was made into a solder strip. According to the national standard GB / T 228.1-2010, the as-cast alloy was prepared into a tensile sample, and the mechanical properties of the alloy were measured at a tensile rate of 6mm / ...

Embodiment 3

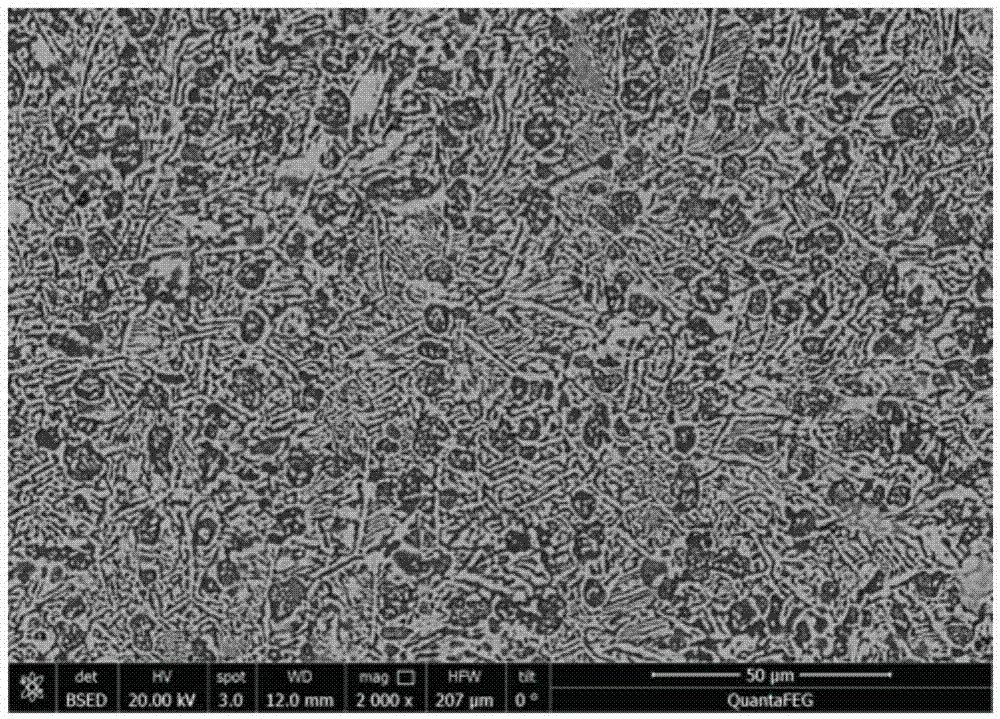

[0056] During smelting, the metal powders of pure tin, pure bismuth and pure germanium with a mass ratio of 49.75wt%, 52wt%, and 0.05wt% were mechanically stirred, and the obtained uniformly mixed metal powders were placed in a quartz crucible. Cover the surface of the uniformly mixed metal powder with KCl and LiCl mixed salt with a mass ratio of 1.3:1, place the quartz crucible in a resistance furnace at 600°C for heating, and wait for the metal powder and mixed salt to melt to form molten solder, 15 Stir once every minute to homogenize the tissue and form liquid solder. The liquid solder was cooled to room temperature, and the salts were washed away by ultrasonic cleaning to obtain Ge-containing low-temperature Sn-Bi solder, and the solder prepared in this embodiment was made into a solder strip. According to the national standard GB / T 228.1-2010, the as-cast alloy was prepared into a tensile sample, and the mechanical properties of the alloy were measured at a tensile rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com