Method for improving corrosion resistance of surface of magnesium alloy on basis of micro-arc oxidation and laser remelting

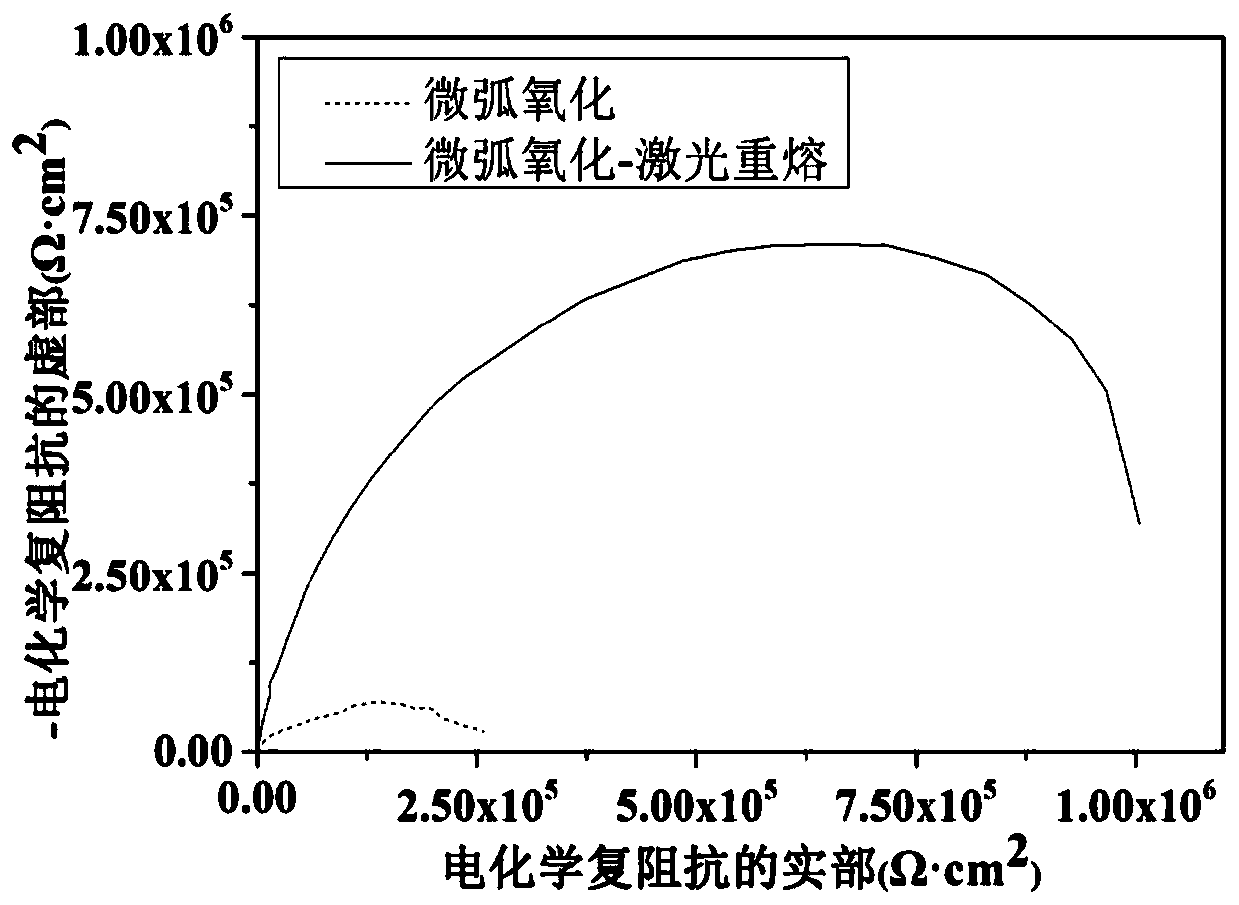

A technology of micro-arc oxidation and laser remelting, which is used in devices for coating liquid on the surface, anodizing, surface reaction electrolytic coating, etc. Limited improvement, etc., to avoid cracking, improve corrosion resistance, and achieve the effect of fine crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] A method for improving the surface corrosion resistance of magnesium alloys based on micro-arc oxidation and laser remelting, comprising the steps of:

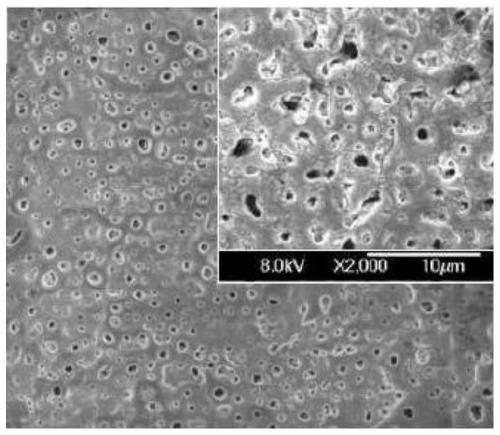

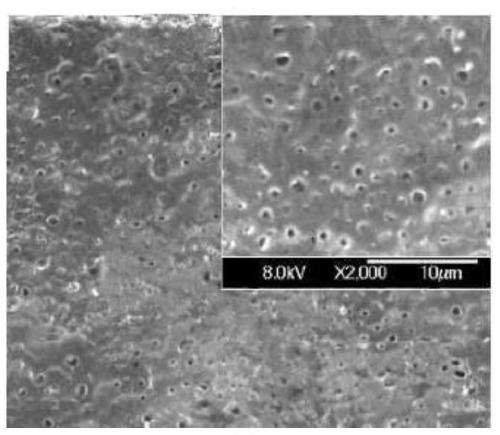

[0025] Step 1: Preparation of micro-arc oxidation film: Polish the surface of the WE43 rare earth magnesium alloy substrate with a size of 60mm×40mm×20mm sequentially with 600-1200# SiC water sandpaper, wash the polished magnesium alloy substrate with water for 8 minutes, and then Put the washed magnesium alloy base material in absolute ethanol, clean it with ultrasonic waves with a frequency of 40KHz for 10 minutes, and finally wash it in deionized water for 8 minutes, then dry it with cold air and set it aside; Sodium metaphosphate, 8g / L sodium fluoride, and 12g / L potassium hydroxide were sequentially added to a stainless steel tank filled with distilled water, and stirred evenly. The stainless steel tank was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com