Titanium/graphene/oxide combined electrode

A composite electrode and graphene technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of reducing energy consumption, improving surface corrosion resistance, and uniform and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

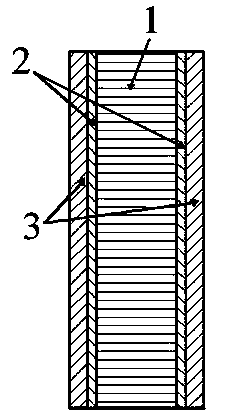

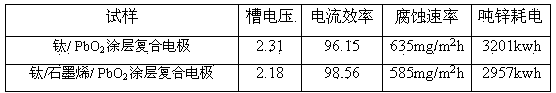

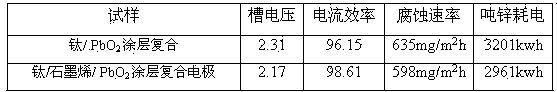

[0020] Implementation mode one: if figure 1 As shown, the structure of the composite electrode in this embodiment is that the substrate is coated with graphene 1 and oxide coating 3 in sequence, the oxide coating is Pb oxide, and the substrate is a titanium alloy plate (titanium substrate 1). The graphene coated on the substrate has three layers, the thickness of each layer is 0.4mm, and the conductivity of graphene reaches 10 6 S / m, ultra-light weight (area density 0.77mg / m 2 ). The thickness of the oxide coating is 150 μm. The plate thickness of the titanium alloy was 1 mm. The titanium alloy is titanium alloy grade TA4.

[0021] The preparation method of the composite electrode in this embodiment: select an industrial grade titanium plate and cut it into a rectangle of 80 × 60 × 1mm, and sequentially treat with corrosive solution, purification solution, cleaning solution, etc. to remove the oxide film layer on the surface; suspend the prepared graphene Brush evenly on ...

Embodiment approach 2

[0024] Embodiment 2: The structure of the composite electrode in this embodiment is that the substrate is coated with graphene and oxide coating in sequence, the oxide coating is Pb oxide, and the substrate is a plate of titanium or titanium alloy. The graphene coated on the substrate has two layers, the thickness of each layer is 1.0mm, and the conductivity of graphene reaches 10 6 S / m, ultra-light weight (area density 0.77mg / m 2 ). The thickness of the oxide coating is 300 μm. The plate thickness of the titanium alloy was 1 mm. The titanium alloy is titanium alloy grade TA4.

[0025] The preparation method of this embodiment: select an industrial-grade titanium plate and cut it into a rectangle of 80×60×1mm, and sequentially treat with corrosion solution, purification solution, cleaning solution, etc. to remove the oxide film layer on the surface; put the pretreated titanium substrate into The main part is the chemical vapor deposition device of the resistance furnace, a...

Embodiment approach 3

[0028] Embodiment 3: The structure of the composite electrode of this embodiment is that the substrate is coated with graphene and an oxide coating in sequence, the oxide coating is an oxide of Mn, Pb or La, and the substrate is a plate or titanium alloy. Stencil. The graphene coated on the substrate has four layers, the thickness of each layer is 0.8mm, and the conductivity of graphene reaches 10 6 S / m, ultra-light weight (area density 0.77mg / m2 ). The thickness of the oxide coating is 700 μm. The plate thickness of the titanium alloy was 1 mm. The titanium alloy is titanium alloy grade TA4.

[0029] The preparation method of this embodiment: select an industrial-grade titanium plate and cut it into a rectangle of 80×60×1 mm, and sequentially treat with corrosive solution, purification solution, cleaning solution, etc. to remove the oxide film layer on the surface; at the same time, the organic macromolecule (C 42 h 18 etc.) ionization, purified by mass spectrometer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com