A kind of preparation method of nickel alloy 200um coating

A nickel alloy and alloy layer technology, which is applied in the field of nickel alloy 200um coating preparation, can solve problems such as cracking, and achieve the effects of low melting point, excellent spray weldability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

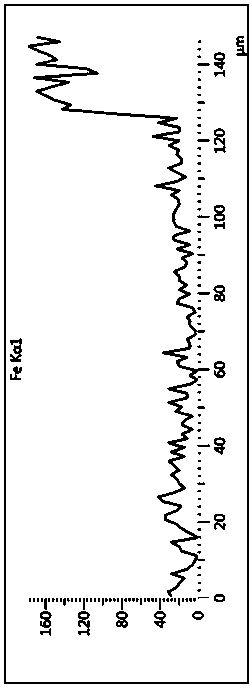

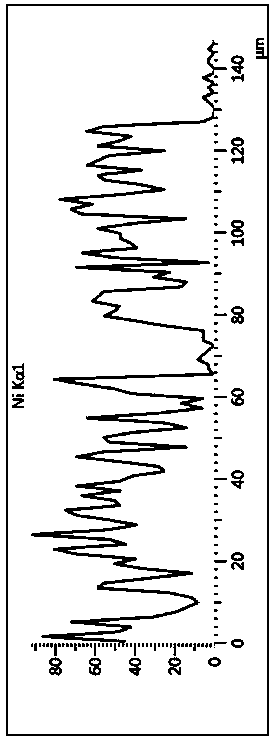

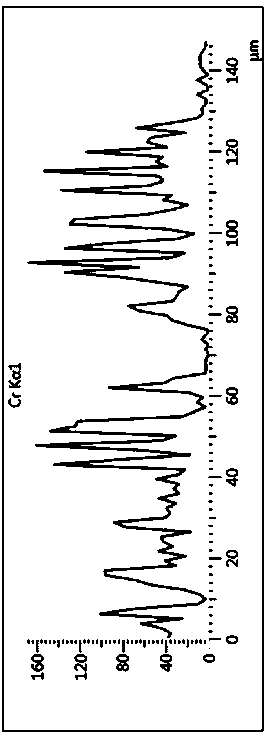

Image

Examples

Embodiment 1

[0033] A kind of preparation method of nickel alloy 200um coating, concrete steps are as follows:

[0034] 1. Use 200 on the surface of the automobile gear shaft (alloy steel 20CrMnTi) ## Sandpaper grinding, and then sandblasting;

[0035] 2. Take metal nickel powder, metal cobalt powder, metal molybdenum powder and metal chromium powder and mix uniformly in proportion to configure alloy powder, wherein each component is calculated by mass percentage: metal chromium powder 6%, metal cobalt powder 15%, metal molybdenum powder 12% and metal nickel powder 67%; metal nickel powder 150-320 mesh, metal cobalt powder 150-320 mesh, metal molybdenum powder 150-320 mesh and metal chromium powder 150-320 mesh;

[0036] 3. The prepared alloy powder is sprayed with a layer of alloy layer on the surface of the treated workpiece by plasma spraying method. The process parameters of plasma spraying are: working voltage 50V, working current 550A, main gas (Ar) 48 / L min -1 , secondary gas (H ...

Embodiment 2

[0038] A kind of preparation method of nickel alloy 200um coating, concrete steps are as follows:

[0039] 1. Use 200 on the surface of the automobile gear shaft (carburized steel 20CrMnTi) # Sanding and then sandblasting;

[0040]2. Take metallic nickel powder, metallic cobalt powder, and metallic molybdenum powder and mix uniformly in proportion to configure alloy powder, wherein each component is calculated by mass percentage: metallic cobalt powder 9%, metallic molybdenum powder 3%, and the rest is metallic nickel powder; alloy The powder size is: metal nickel powder 150-320 mesh, metal cobalt powder 150-320 mesh, metal molybdenum powder 150-320 mesh;

[0041] 3. Spray a layer of alloy layer on the surface of the treated workpiece with the prepared alloy powder by plasma spraying. The process parameters of plasma spraying are: working voltage 50V, working current 550A, main gas (Ar) 48 / L min -1 , secondary gas (H 2 )4.5 / L·min -1 , powder feeding rate 25 / g·min -1 , sp...

Embodiment 3

[0043] A kind of preparation method of nickel alloy 200um coating, concrete steps are as follows:

[0044] 1. Use 200 on the surface of the automobile gear shaft (alloy steel 20CrMnTi) # sanding, followed by sandblasting;

[0045] 2. Take metal nickel powder, metal cobalt powder, metal molybdenum powder and metal chromium powder and mix uniformly in proportion to configure alloy powder, wherein each component is calculated by mass percentage: metal chromium powder 6%, metal cobalt powder 15%, metal molybdenum powder 12%, the rest is metal nickel powder; the particle size of alloy powder is: metal nickel powder 150-320 mesh, metal cobalt powder 150-320 mesh, metal molybdenum powder 150-320 mesh and metal chromium powder 150-320 mesh;

[0046] 3. Spray a layer of alloy layer on the surface of the treated workpiece with the prepared alloy powder by plasma spraying. The process parameters of plasma spraying are: working voltage 50V, working current 550A, main gas (Ar) 48 / L min -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com