Patents

Literature

38results about How to "High fusion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

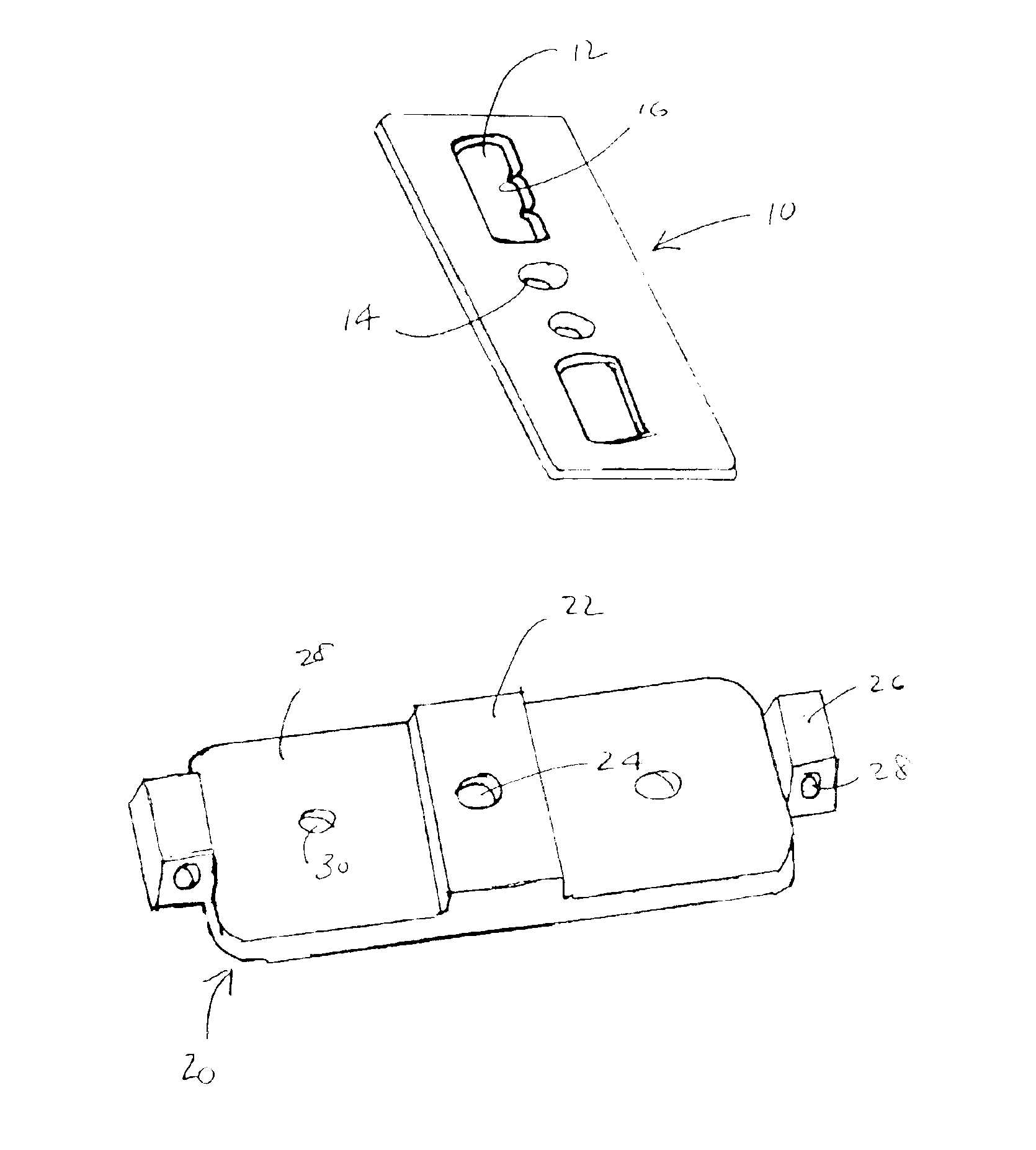

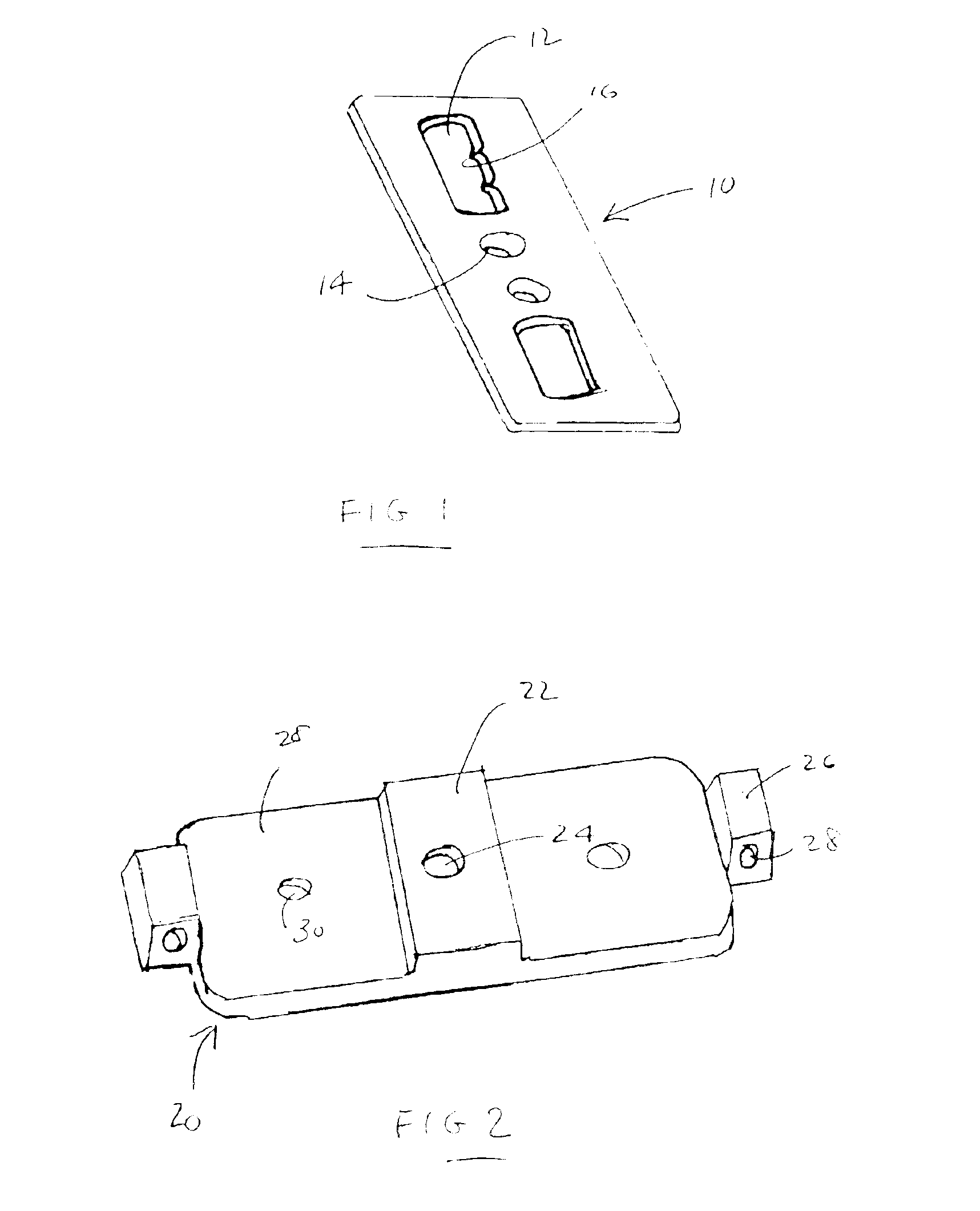

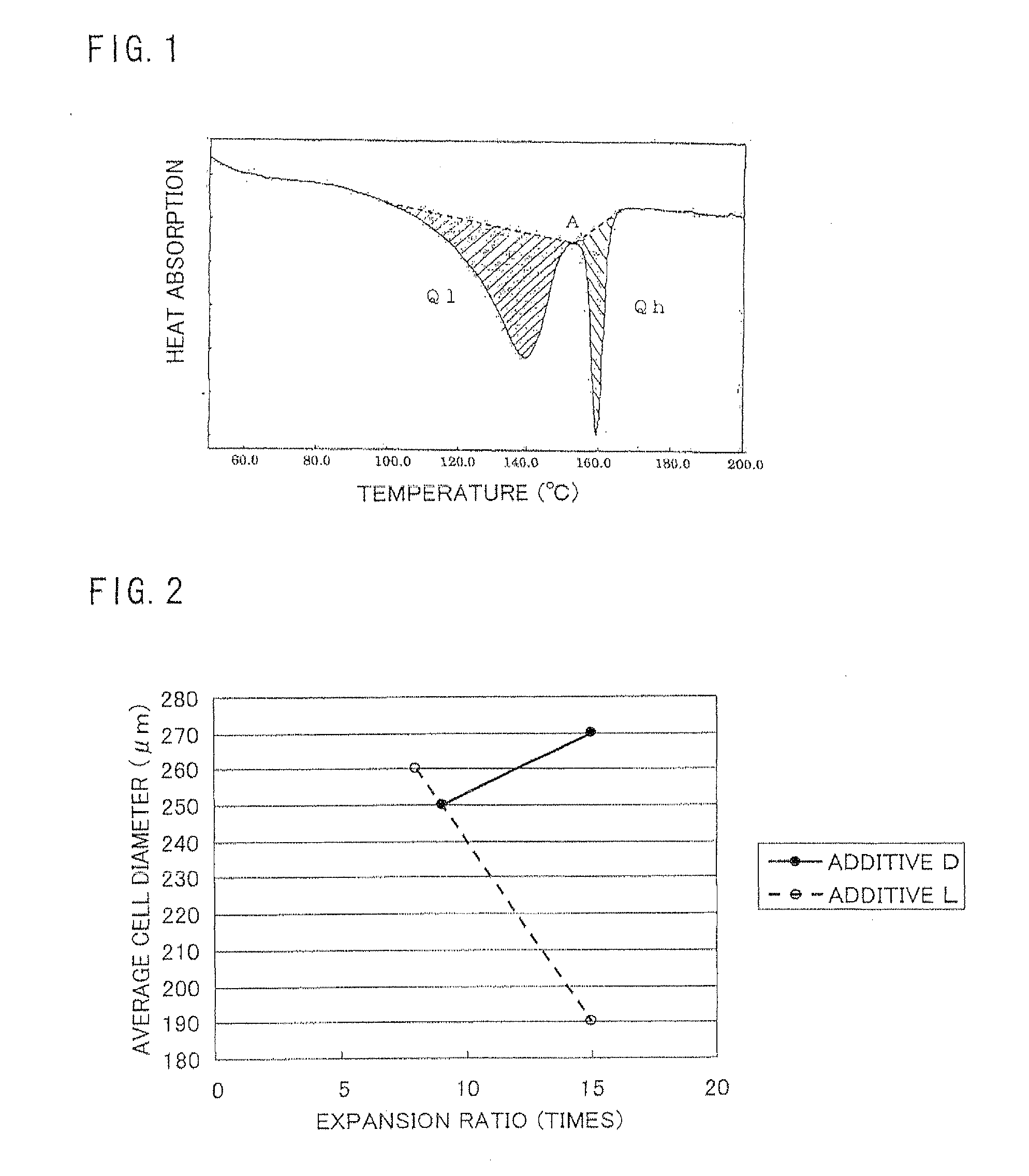

Modular anterior cervical plate

InactiveUS6855147B2Reducing of errant screw insertionReduce surgical complicationsInternal osteosythesisJoint implantsCervical vertebral bodyEngineering

An anterior cervical plate system consists of a base plate and a connecting plate movably connected to the base plate. The base plate can be inserted into any number of cervical vertebral bodies in any one construct. The base plate contains holes for two unicortical bone screws and a third hole to accommodate a rather large diameter, but short screw that movably secures the connecting plate, and raised middle portion to strengthen screw purchase and fit of the connecting plate. The connecting plate has a central trough opening to accommodate this screw.

Owner:HARRINGTON JR JAMES FREDERICK

Laser repair method for abraded centrifugal fan bearing block

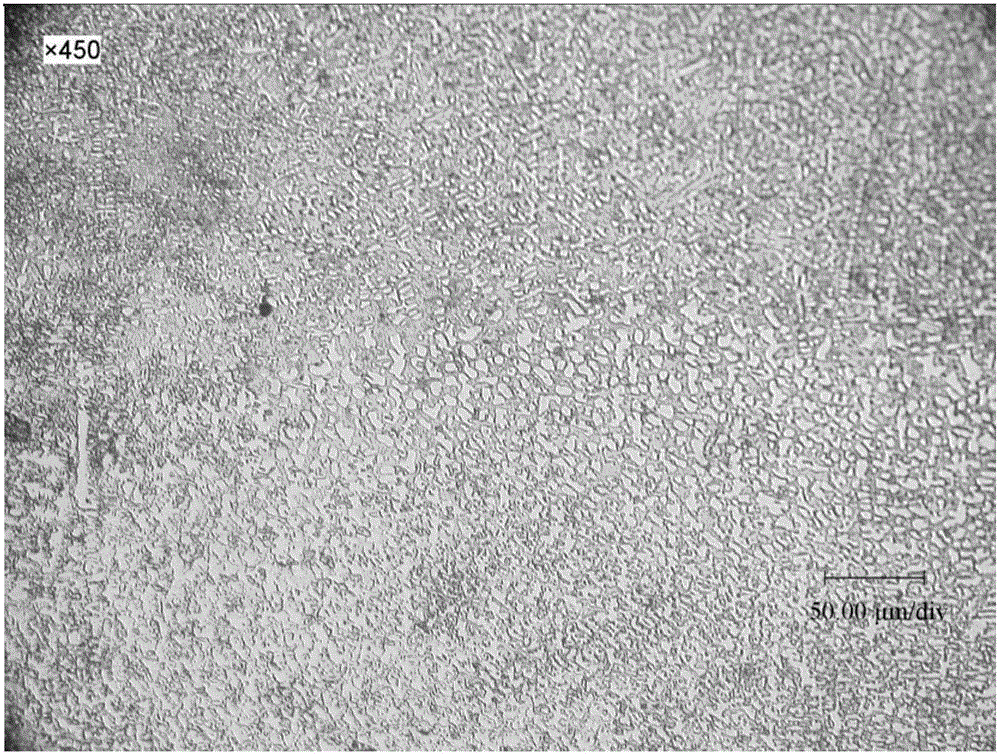

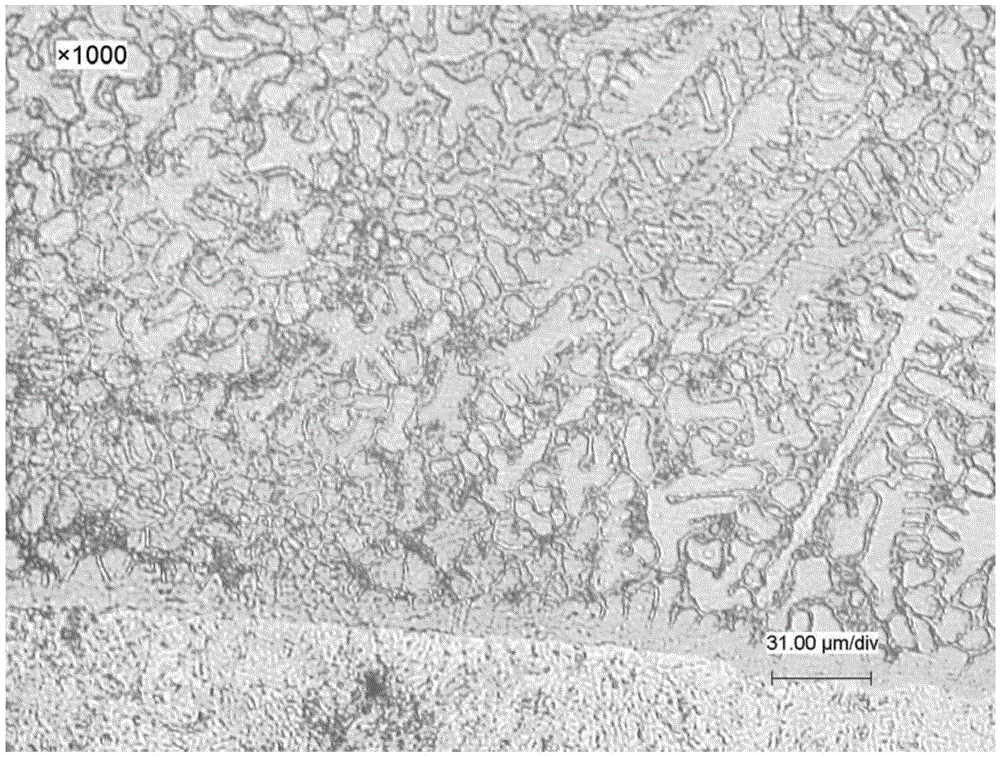

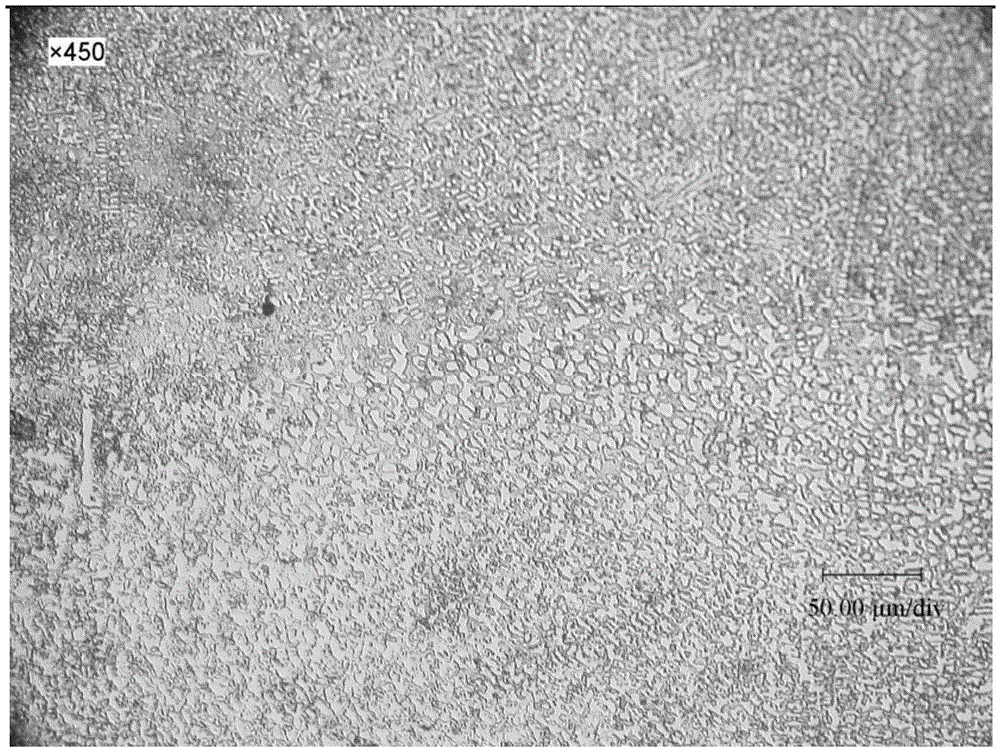

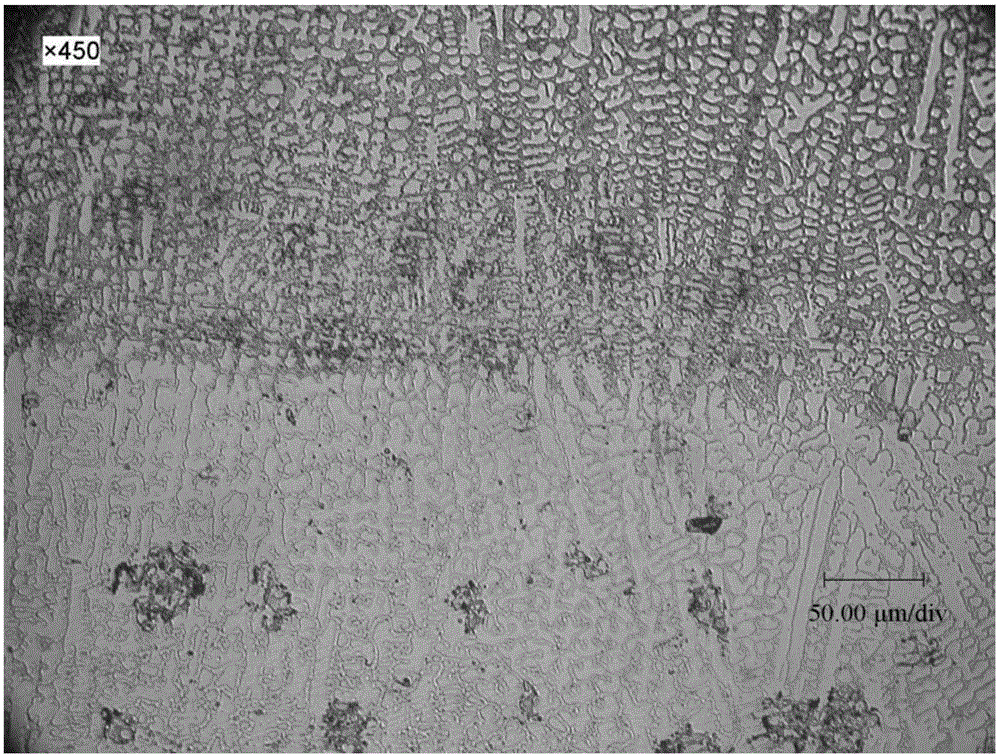

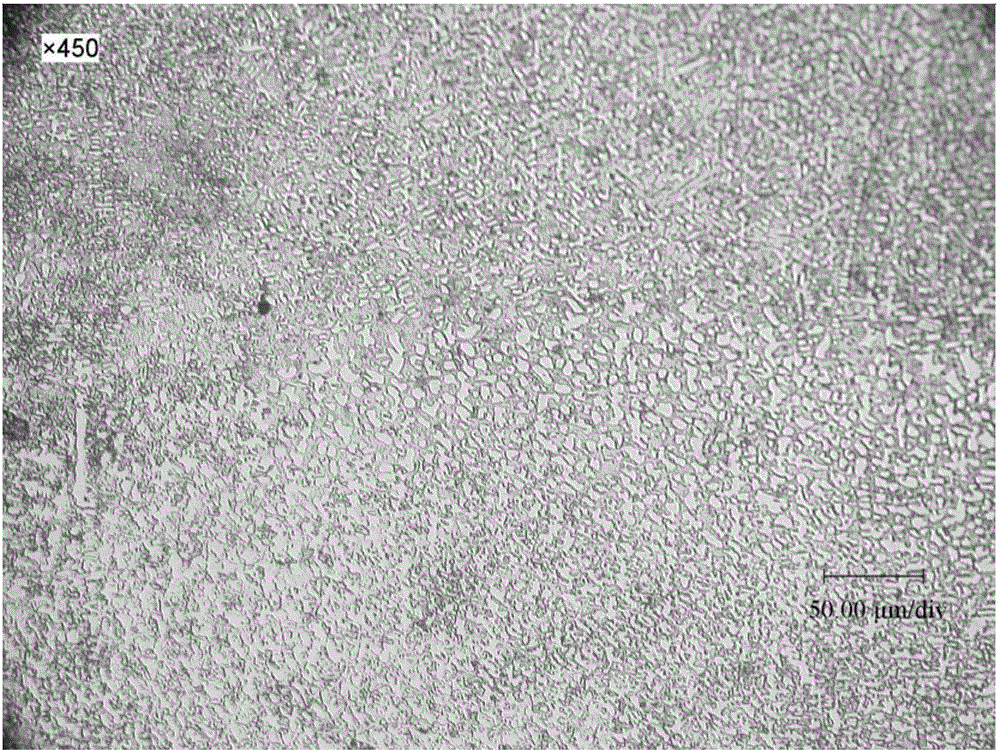

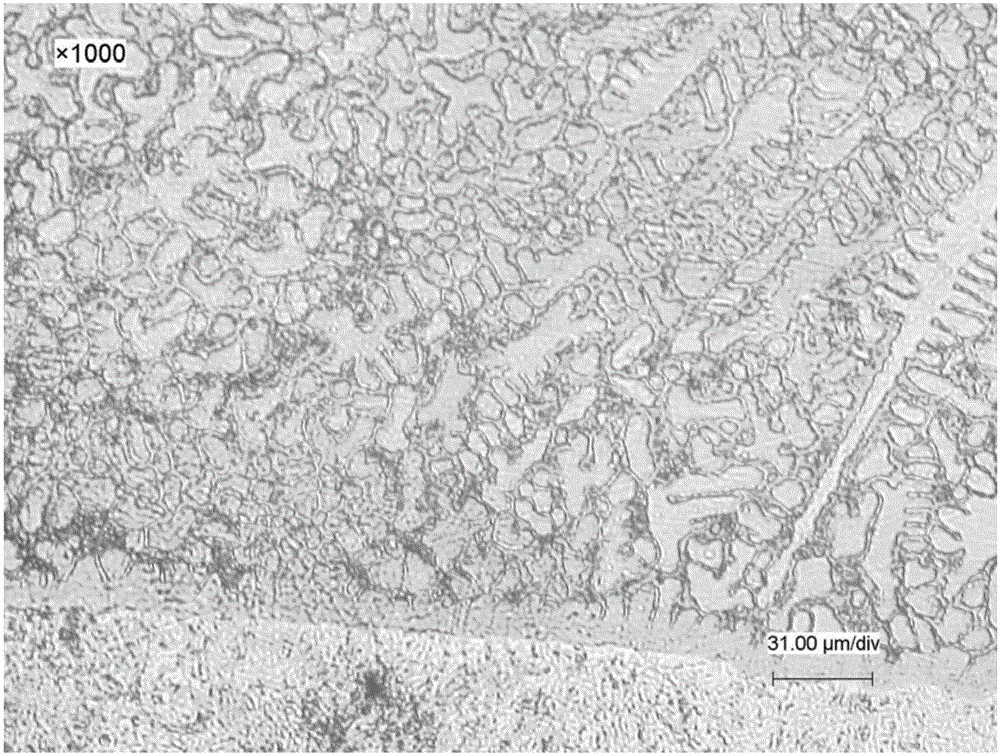

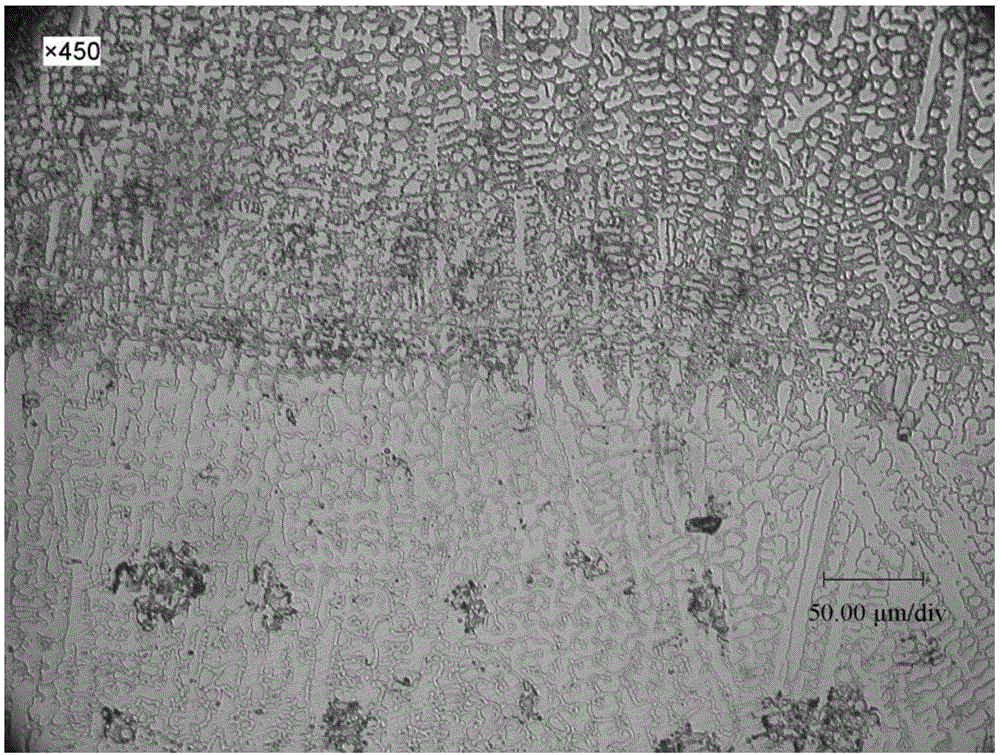

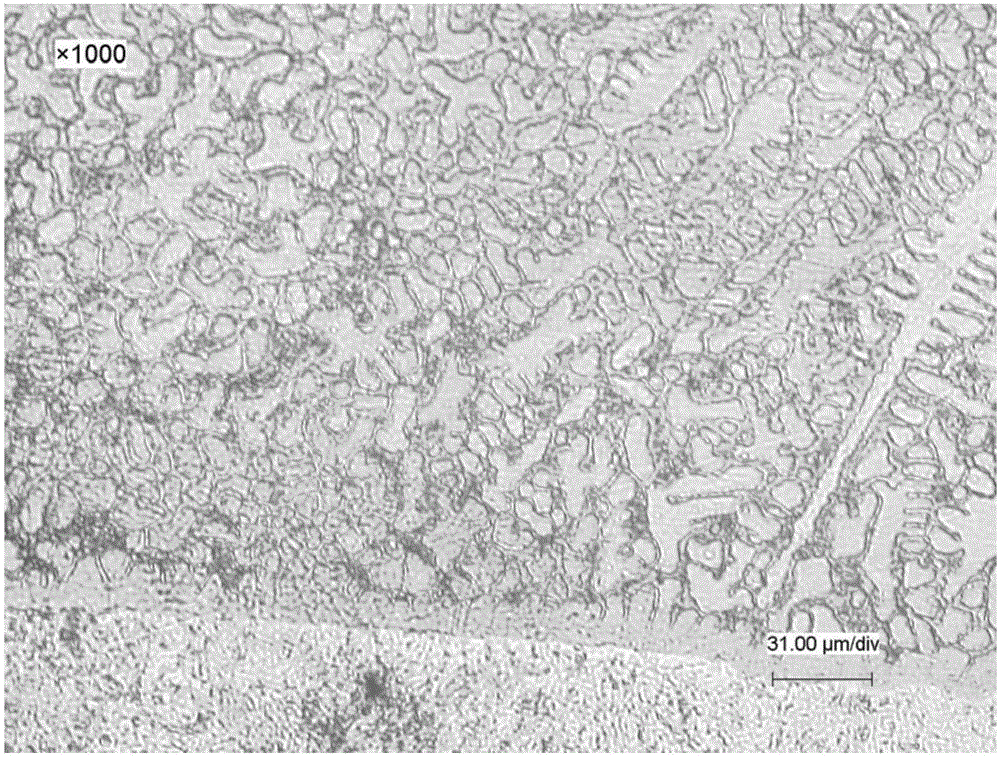

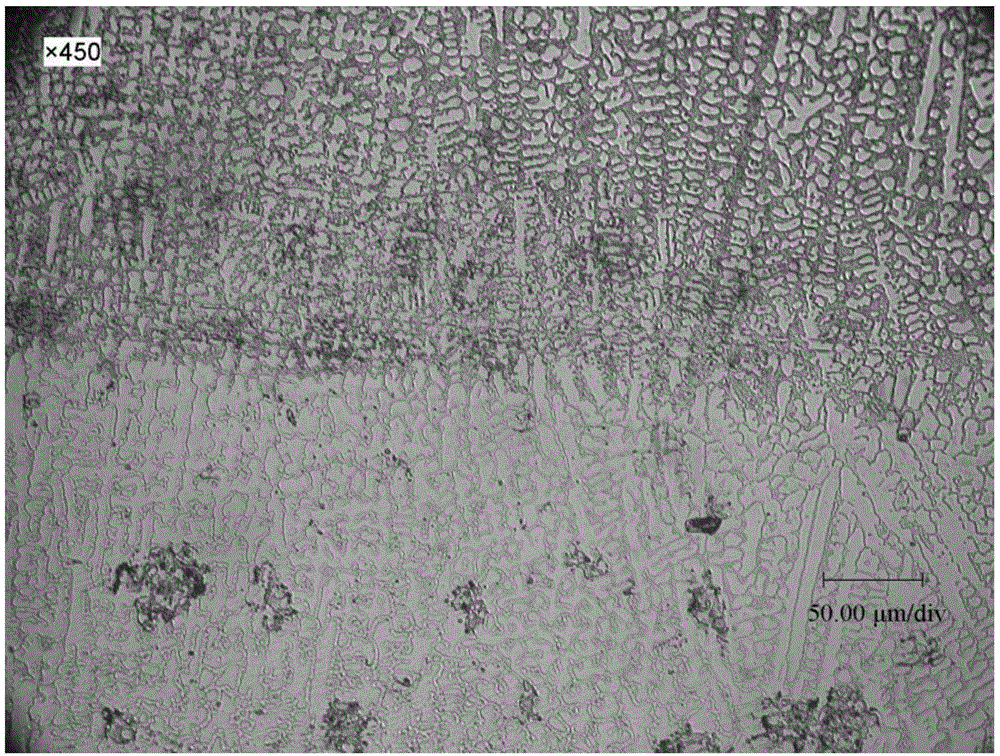

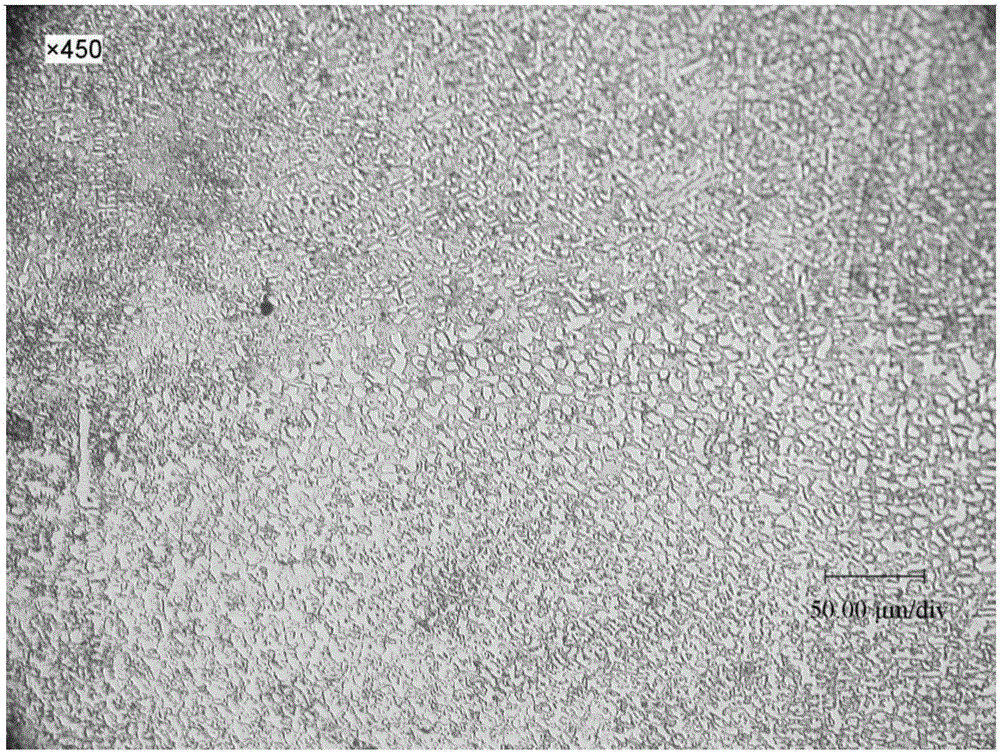

ActiveCN102031519AReduce distortionStrong fusion rateMetallic material coating processesLaser beam welding apparatusEngineeringHardness

The invention relates to a laser repair method of the mechanical repair field, in particular to a laser repair method for an abraded centrifugal fan bearing block. The laser repair method comprises the following steps of: cleaning a workpiece, detecting the dimensions of each part and determining a damaged part and the abrasion loss thereof; carrying out circular runout and end face runout detection on the workpiece; carrying out failure analysis and service life evaluation on the workpiece; removing the fatigue layer of the damaged part of the centrifugal fan bearing block and washing clean; detecting the hardness and the component of the parent material of the centrifugal fan bearing block; according to a detection result, preparing cladding powder, regulating the operating data of a laser device, setting a laser cladding technical parameters and carrying out laser cladding on the damaged part of the centrifugal fan bearing block by adopting a synchronous powder feeding mode; carrying out mechanical processing according to the requirement; carrying out surface colouration flaw detection on the processed workpiece, and detecting the processing precision of the centrifugal fan bearing block; and checking the centrifugal fan bearing block. The method has the advantages of high abrasion resistance, high hardness, high fusing rate of a cladding layer and the parent material of the bearing block, small deformation of the bearing block and the like.

Owner:河北瑞兆激光再制造技术股份有限公司

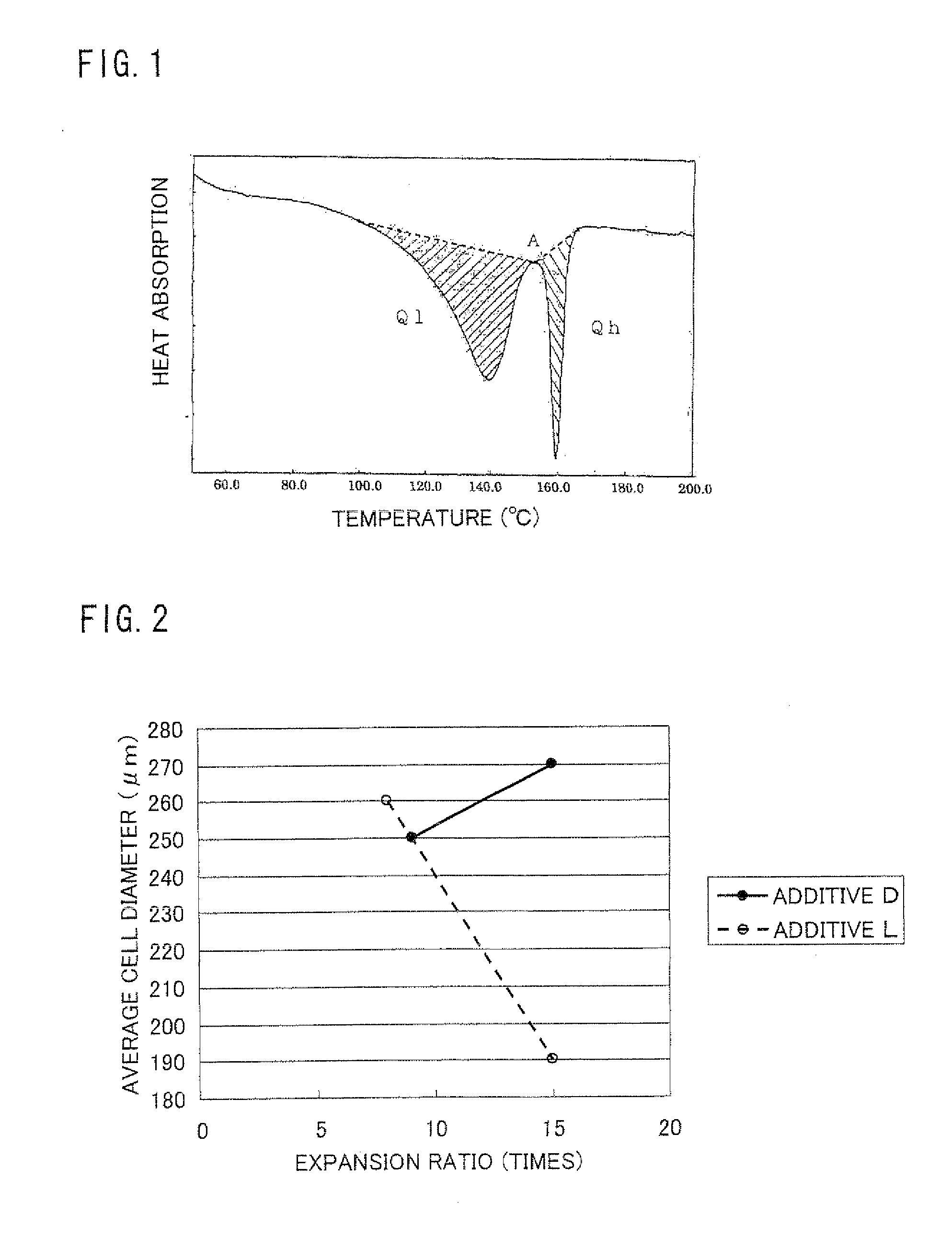

Process for producing expanded polyolefin resin particles and expanded polyolefin resin particles

ActiveUS20100267850A1High expansion ratioHigh dimensional accuracyThin material handlingPolyolefinPolyethylene glycol

Provided is a process for producing expanded polyolefin resin particles whose cells are not made nonuniform or extremely smaller as seen in conventional expanded particles, whose cell diameter and expansion ratio can be easily controlled independently, and which, when subjected to in-mold expansion molding, give in-mold expanded molded products satisfactory in fusibility and excellent in surface properties. The process is a process for producing expanded polyolefin resin particles by: dispersing polyolefin resin particles together with an aqueous dispersion medium into a closed vessel; heating the polyolefin resin particles up to or above a softening temperature of the polyolefin resin particles; and releasing the polyolefin resin particles into a zone whose pressure is lower than an internal pressure of the closed vessel, with use as a foaming agent of water serving as the dispersion medium, the polyolefin resin particles being composed of a polyolefin resin composition including: polyolefin resin; a substance selected from among polyethylene glycol, polyvalent alcohol having a carbon number of not less than 3 to not more than 6, and a water-absorbing substance having no function of forming foaming nuclei; and a foam nucleating agent.

Owner:KANEKA CORP

Laser cladding repair process for cross shafts

InactiveCN102828181AImprove wettabilityImprove wear resistanceMetallic material coating processesOptoelectronicsHardness

The invention relates to a laser cladding repair process for cross shafts. The process comprises the following steps of: A. carrying out treatment on the surface of the cross shaft, and carrying out failure analysis; B. carrying out 80-150 DEG C overall preheating on the cross shaft; C. according to failure analysis results of the cross shaft, optimizing process parameters, and carrying out laser cladding, wherein adopted alloy powder comprises the following components in percentage by weight: less than or equal to 0.1% of C, 10-13% of Cr, 1.5-2.5% of B, 1-2% of Si, 0.5-1.2% of Mo, 8-12% of Mn, 6-12% of W, 5-15% of TiO2, and the balance of Fe; and D. carrying out detection. According to the laser cladding repair process for the cross shafts, disclosed by the invention, through carrying out the laser cladding on the surface of the cross shaft, the size of the cross shaft can meet the application requirements, and the hardness and the wear resistance of the cross shaft subjected to repair exceed the original hardness and the original wear resistance of the cross shaft.

Owner:DANYANG HONGTU LASER TECH

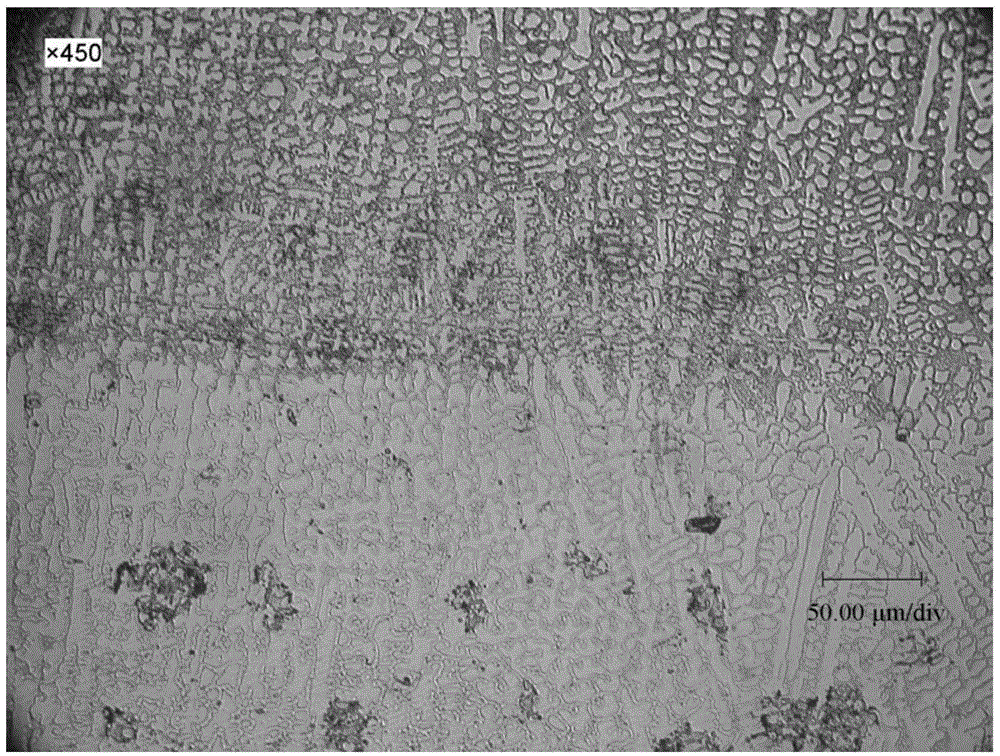

Manual arc welding repair method for centrifugal blower after impeller blade abrasion

ActiveCN104014903AReduce distortionHigh fusion rateArc welding apparatusStructural engineeringCentrifugal fan

The invention discloses a manual arc welding repair method for a centrifugal blower after impeller blade abrasion. The method comprises a preparation step before repair and a repair step, wherein the repair method comprises the following steps: cleaning a workpiece, detecting the workpiece; disassembling a damaged impeller; analyzing the workpiece; installing a special tooling; removing a fatigue layer after the abraded part of the impeller blade is removed, and detecting a base material; selecting a welding material, and welding the repaired damaged part in manners of small current, short arc operation and symmetry welding; then carrying out destressing heat treatment, and removing residual stress; carrying out surface coloring flaw detection on the processed workpiece surface, and assembling as a whole, so as to achieve the traditional design standard of a manufacturer. The repaired part has the advantages of good abrasive resistance, large hardness, high fusion rate of a cladding layer and an impeller blade base material, small impeller deformation and the like.

Owner:河北瑞兆激光再制造技术股份有限公司

Gear laser cladding repair process beneficial to improve hardness and wear resistance

ActiveCN103668176AGood self-fluxingIncrease contentMetallic material coating processesGear wheelAlloy

The invention relates to a gear laser repair process which comprises the following steps: A. treating the surface of a gear, and performing failure analysis on the gear; B, integrally preheating the gear at 80-120 DEG C, and locally preheating the to-be-repaired part of the gear at 180-220 DEG C at the same time; C, optimizing process parameters according to the failure analysis result of gear, performing layer-by-layer laser cladding, wherein the thickness of each cladding layer is less than or equal to 0.4 mm, the edge of the next cladding layer is extended outwards from the edge of the previous cladding layer by 4-6mm, and the used alloy powder comprises the following components in percentage by weight: no more than 0.5% of C, 38-52% of Cr, 1.5-2.5% of B, 0.5-1.5% of Si and the balance of Fe; and D, detecting. According to the gear laser repair process, the surface of the gear is subjected to laser cladding, so that the size meets the use requirements, and the hardness and wear resistance of the repaired gear exceed the original properties.

Owner:XINJIANG HUIXIANG LASER TECH

Laser repairing technology for aluminum foil roll crack

InactiveCN102677047AImprove tissue uniformityAvoid it happening againMetallic material coating processesLaser beam welding apparatusAlcladOptoelectronics

The invention relates to a laser repairing technology for an aluminum foil roll crack. The laser repairing technology for the aluminum foil roll crack comprises the following steps: A, cleaning up a roll; B, preheating the roll at a low temperature; C, optimizing technical parameters, and performing laser cladding on polished and cleaned pits on the roll, wherein in the process, the roll is vibrated, the temperature of the roll is kept to be 180-250 DEG C until the pits are filled, a cladding layer is higher than the roll surface, and used alloy powder comprises the following components by weight percent: 10-15% of Cr, 1-2% of B, 0.5-1.5% of Si and Fe in balancing amount; and D. detecting. The laser repairing technology for the aluminum foil roll crack can perform laser cladding on the roll crack and can effectively fill a very deep crack to making the deep crack meet a using requirement; the structural uniformity of the cladding layer is good; and the fusion rate of the cladding layer and a matrix is high.

Owner:DANYANG HONGTU LASER TECH

Aluminum electrolysis cell riser bus bar electrified repairing method

The invention discloses an aluminum electrolysis cell riser bus bar electrified repairing method which comprises the following steps of: treating a damaged surface, mounting a graphite bar, calculating the addition amount of a flux for aluminum electrolysis cell riser bus bar electrified repairing, mounting a mould, welding, opening the mould and treating the metal surface of a weld seam. According to the aluminum electrolysis cell riser bus bar electrified repairing method disclosed by the invention, a riser bus bar and an insulation intersection can be repaired in an electrified manner without experiencing interference of the high-intensity magnetic field of an electrolytic plant; the fusion rate of the side wall of the weld joint of the riser bus bar is high, and the performance of the welded joint is similar to that of a parent material; and moreover, the method has safe and reliable technology, is simple and quick to operate and is suitable for popularization and application to the aluminum electrolysis industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

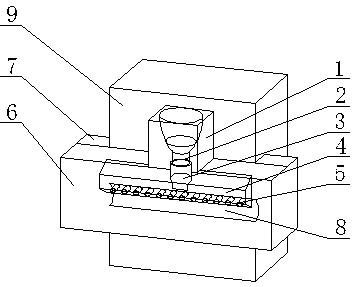

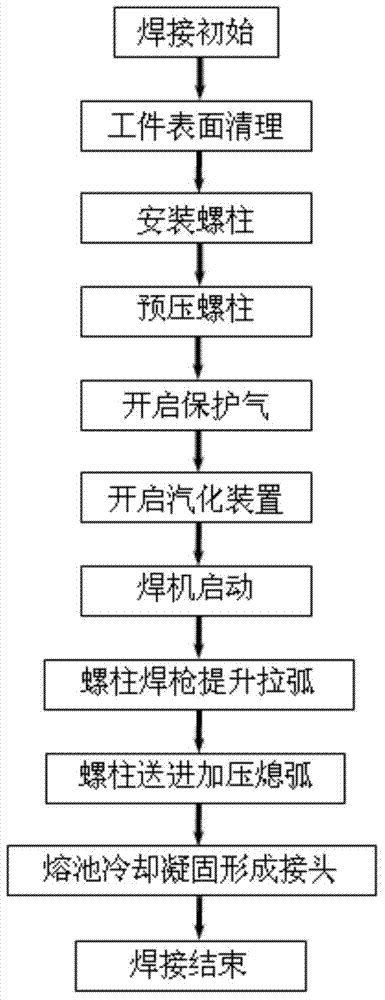

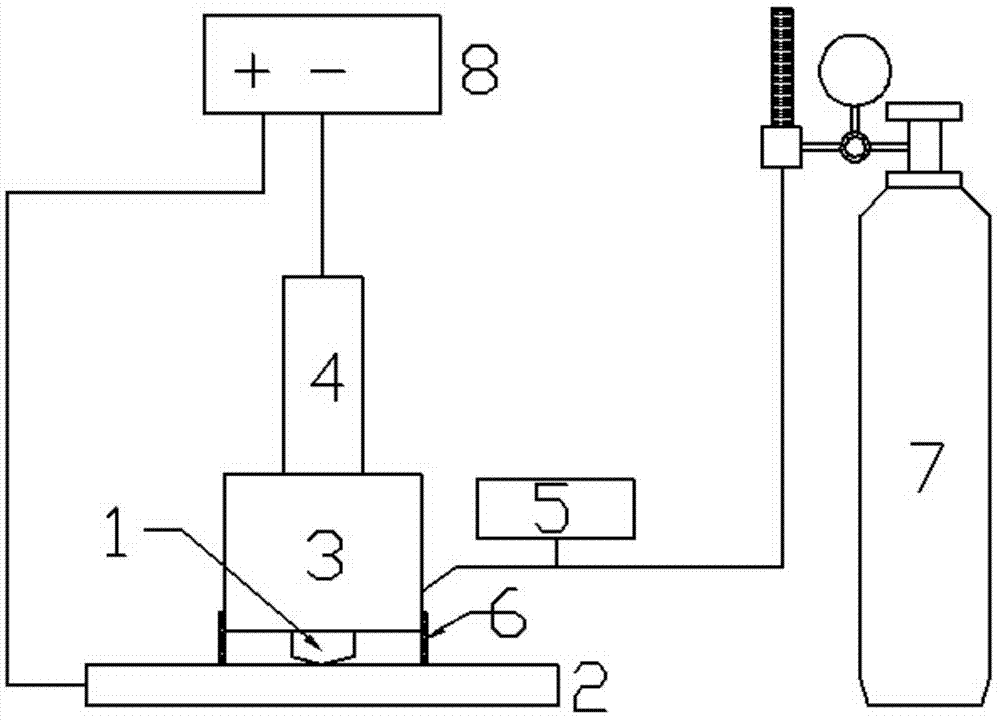

Aluminum alloy stud welding method to remove oxidation film with vapor state brazing flux

InactiveCN104741746AGood removal effectThorough protectionArc welding apparatusWelding/soldering/cutting articlesShielding gasCarbon Dioxide / Helium

The invention discloses an aluminum alloy stud welding method to remove an oxidation film with the vapor state brazing flux. The aluminum alloy stud welding method comprises the steps that the end portion of an aluminum alloy stud is machined into a face with a 150 degrees taper angle, and clearing on the end portion and the portion of an aluminum plate to be welded is conducted; a self-designed sealing air hood is installed outside a welding gun stud jacket, and a vaporizing device is joined up at the entrance position of the air course of the sealing air hood; the aluminum plate is arranged horizontally and is connected to the ground, the stud is installed, and the welding gun are compressed at the position to be welded vertically downward; the shielding gas is opened, arc striking is prepared to conduct after normal air delivering is finished, the vapor state brazing flux is jetted through a control circuit before the moment of arc striking, and welding is completed. The aluminum alloy stud welding method has the advantages that middle and large diameter aldural stud can be welded, the application range on plate thickness is wide, the operation of the welding process is easy, the intensity of the a welded joint can reaches to 90 % that of the stud, and the fusing rate of the welding joint reaches to 100 %.

Owner:NANJING UNIV OF SCI & TECH

Flux for electrified maintenance of riser bus bars of aluminum cells

ActiveCN103286476ASmooth responseHigh fusion rateWelding/cutting media/materialsSoldering mediaSolderingBus

The invention discloses a flux for electrified maintenance of riser bus bars of aluminum cells. The flux comprises self-fluxing soldering flux and blasting powder. The blasting powder covers on the surface layer of the self-fluxing soldering flux, and by mass percentage, the blasting powder and the self-fluxing soldering flux range from 0.15:100 to 0.25:100. The flux can be used for maintaining the riser bus bars in the electrified aluminum cells, the self-fluxing soldering flux and the blasting powder are stable in reaction and high in safety, fusing rate of side walls of soldering joints is high, performances of soldering joints can be similar to base materials, and using is facilitated.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

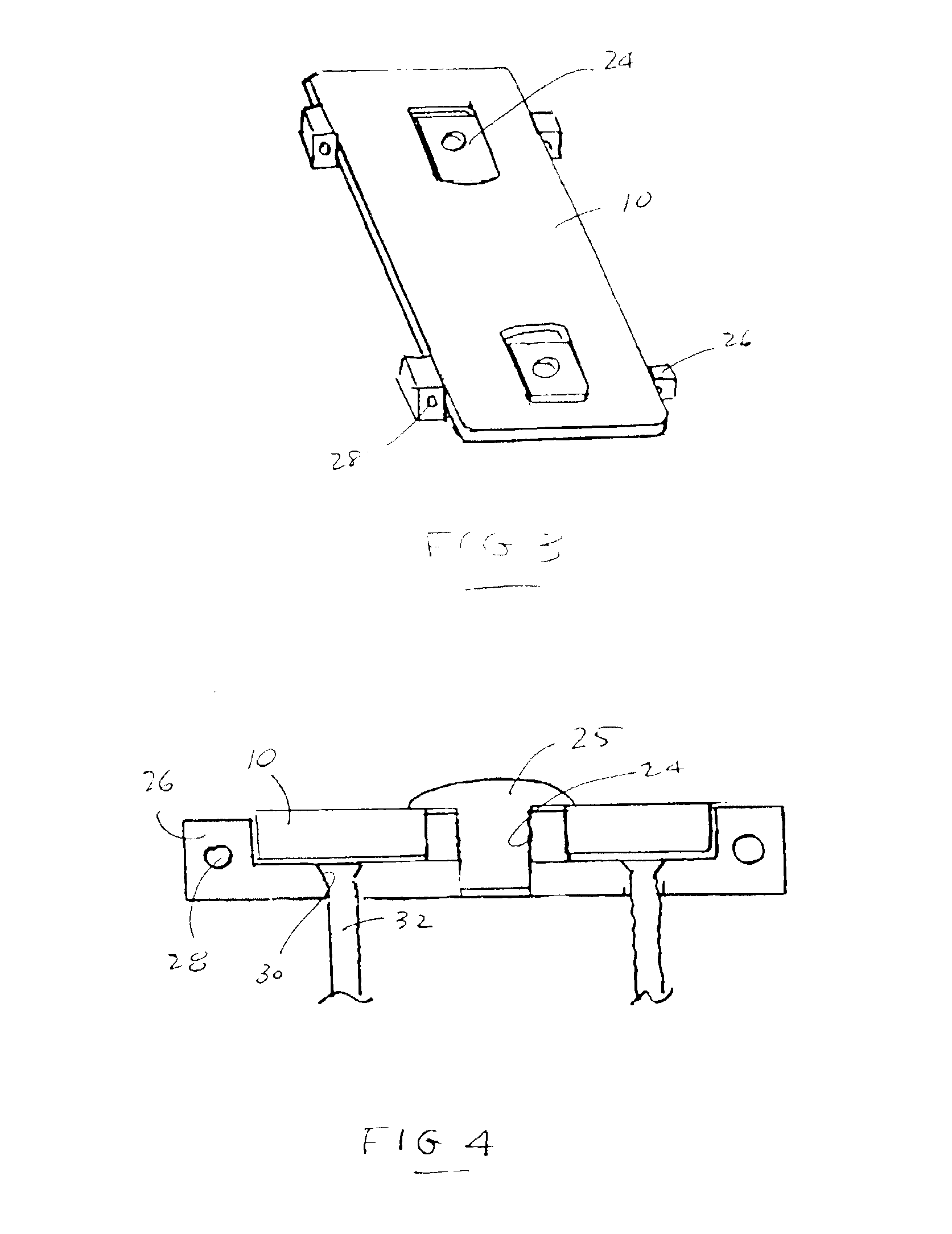

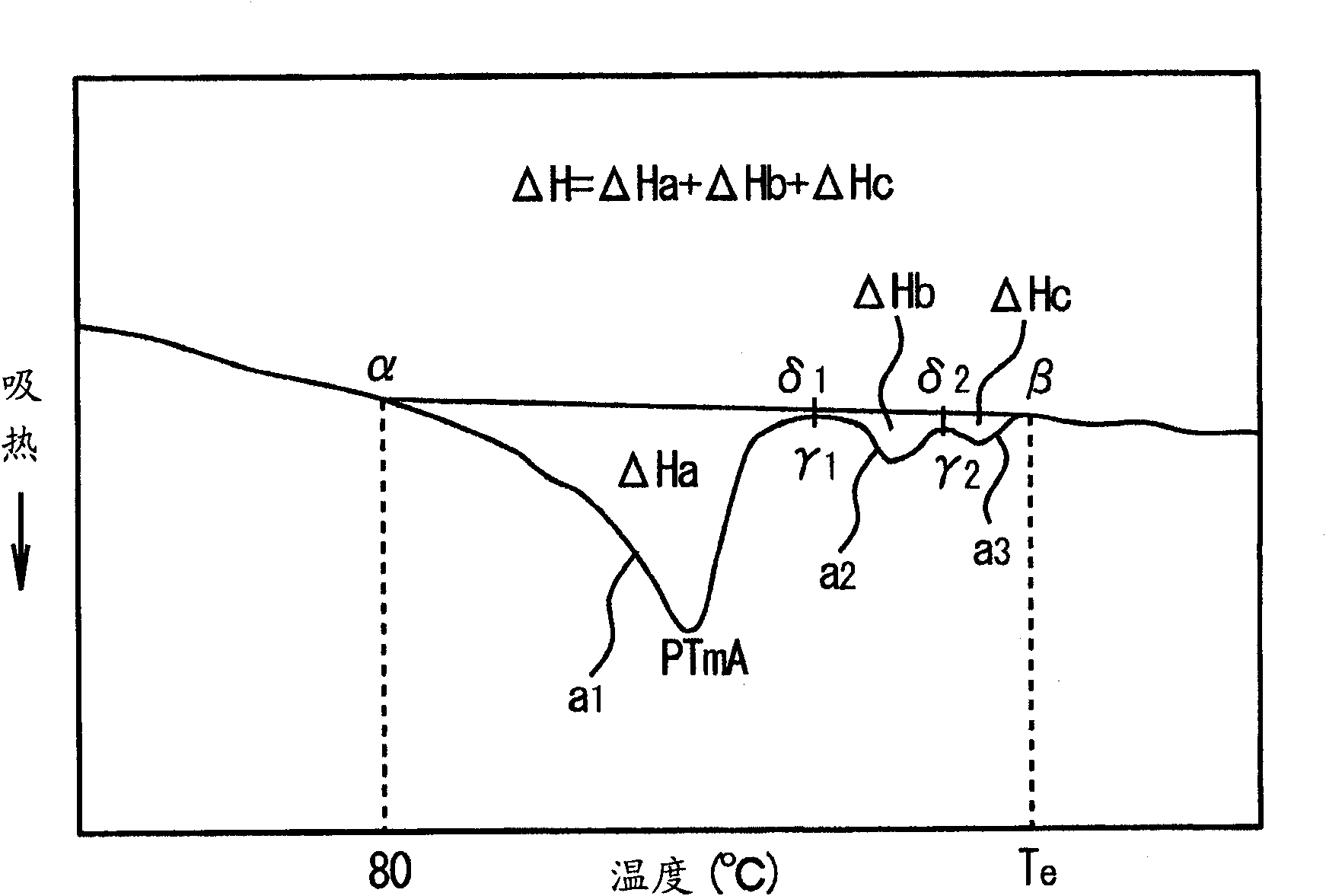

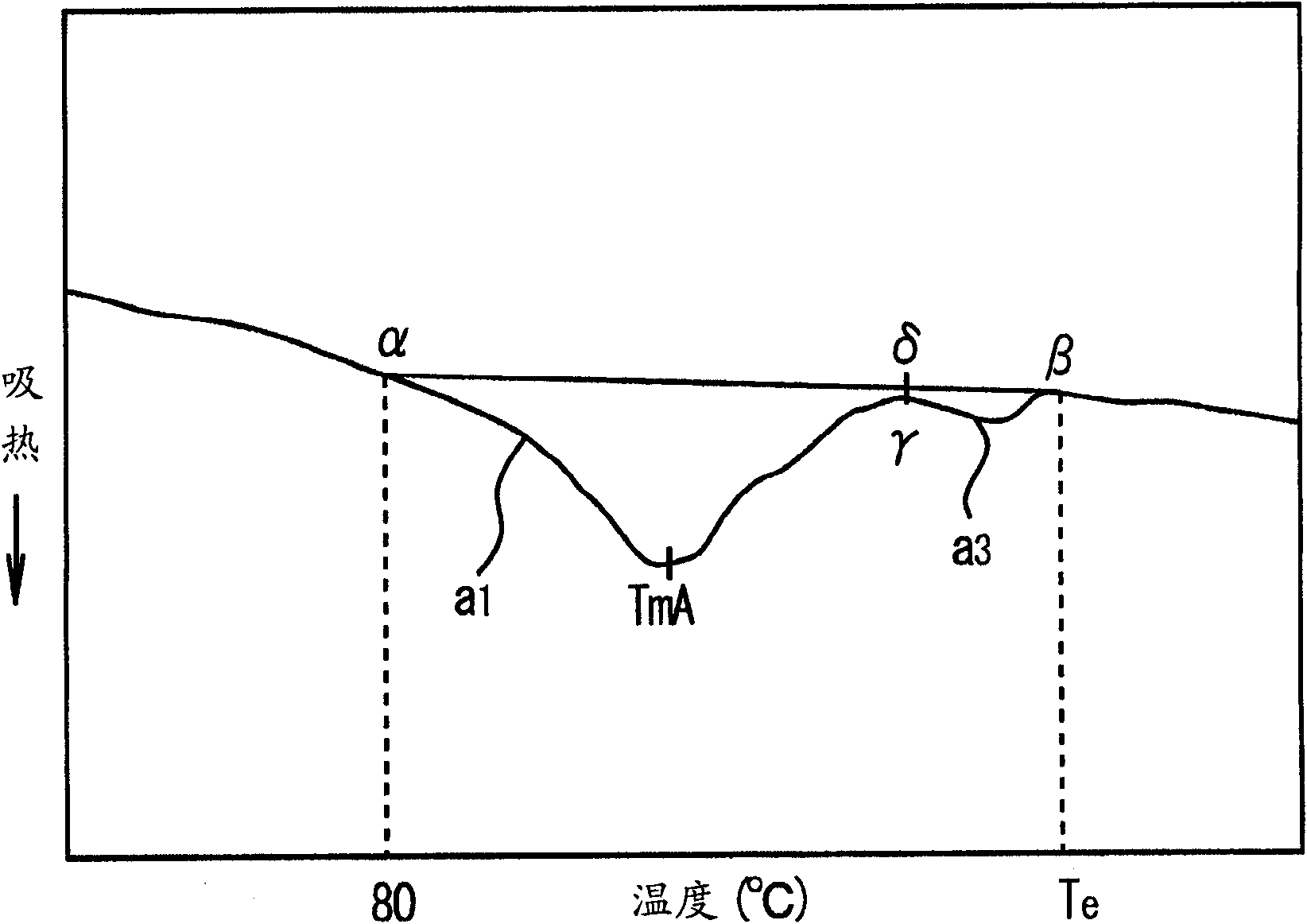

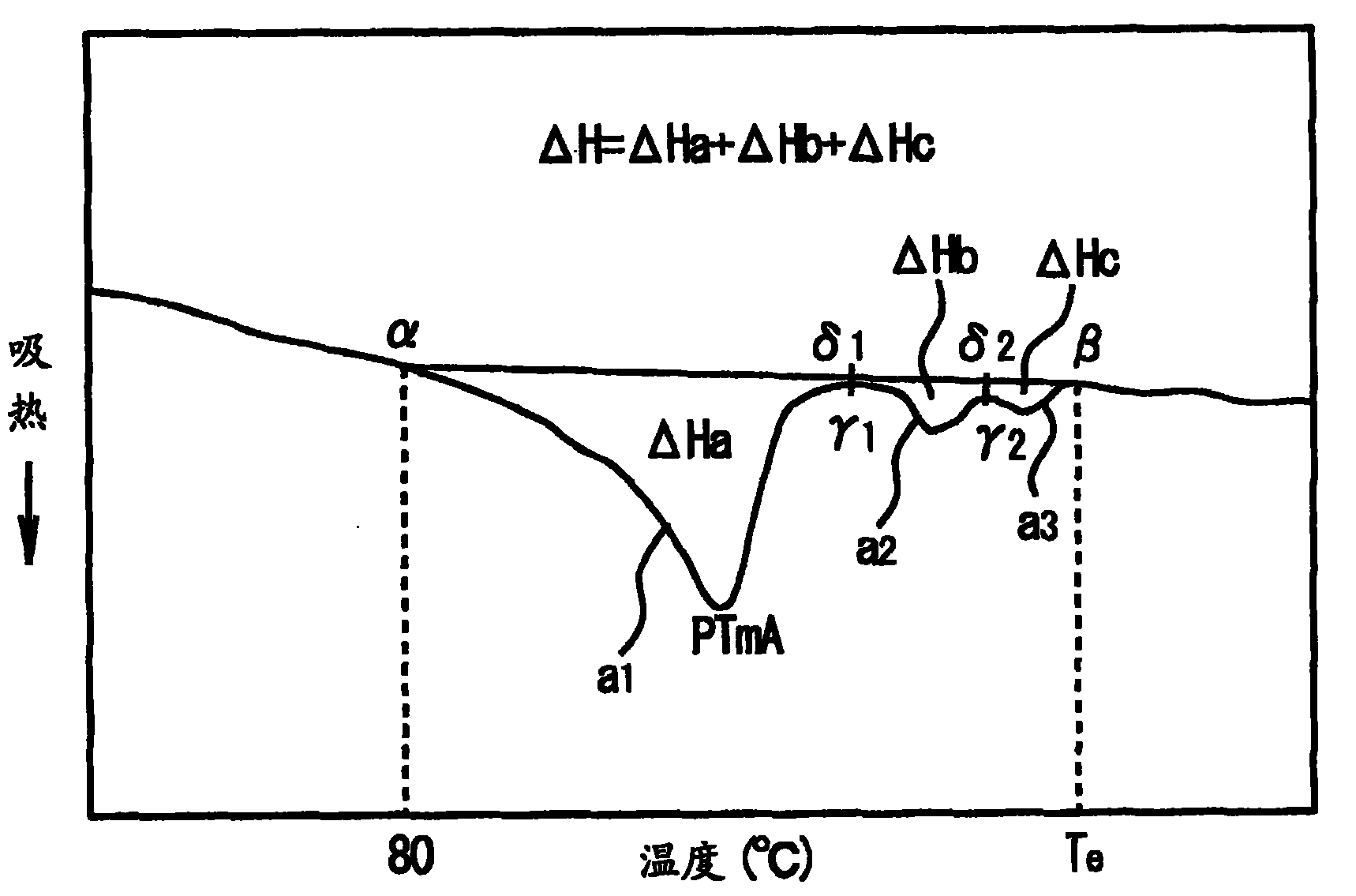

Molded product of a polypropylene-based resin expanded particle and method for producing the same

ActiveCN101875739ALow expansion ratioHigh compressive strengthApparent densityVolumetric Mass Density

The invention relates to a molded product of a polypropylene-based resin expanded particle and a method for producing the same. The object of the invention is to provide a molded product of a polypropylene-based resin expanded particle with a low expansion ratio having excellent fusibility between expanded particles mutually, small density difference between a surface part and an inner part of the molded product, better mechanical properties, such as compressive strength, compared with a conventional one, and also excellent appearance. In an in-mold molding method with the polypropylene-based resin expanded particle, the expanded particle has apparent density of 60-450 g / L, the welding rate of the polypropylene-based resin expanded particle is above 50%, the ratio between the apparent density of the expanded particle molded body to the inner density of the molded body is 1-2 and the molded product of the polypropylene-based resin expanded particle is preferably molded when satisfying the special conditions.

Owner:JSP CORP

Process for Producing Expanded Polyolefin Resin Particles and Expanded Polyolefin Resin Particles

ActiveUS20130197112A1High expansion rateEasy to controlThin material handlingInternal pressurePolymer science

Process for producing expanded polyolefin resin particles with use as a foaming agent in water contained in an aqueous dispersion medium. The process includes dispersing polyolefin resin particles with use as a foaming agent of water contained in an aqueous dispersion medium. The process includes dispersing polyolefin resin particles together with the aqueous dispersion medium into a closed vessel, heating the polyolefin resin particles up to or above a softening temperature of the polyolefin resin particles and pressurizing the polyolefin resin particles, and releasing the polyolefin resin particles into a zone whose pressure is lower than an internal pressure of the closed vessel. The polyolefin resin particles are composed of a polyolefin resin composition including a polyolefin resin, polyethylene glycol homopolymer and a foam nucleating agent.

Owner:KANEKA CORP

Flux for electrified maintenance of riser bus bars of aluminum cells

ActiveCN103286476BSmooth responseHigh fusion rateWelding/cutting media/materialsSoldering mediaSolderingBus

The invention discloses a flux for electrified maintenance of riser bus bars of aluminum cells. The flux comprises self-fluxing soldering flux and blasting powder. The blasting powder covers on the surface layer of the self-fluxing soldering flux, and by mass percentage, the blasting powder and the self-fluxing soldering flux range from 0.15:100 to 0.25:100. The flux can be used for maintaining the riser bus bars in the electrified aluminum cells, the self-fluxing soldering flux and the blasting powder are stable in reaction and high in safety, fusing rate of side walls of soldering joints is high, performances of soldering joints can be similar to base materials, and using is facilitated.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Laser cladding repairing process of valve seat with high hardness and less deformation

ActiveCN103668036AImprove corrosion resistanceImprove wear resistanceMolten spray coatingLaser beam welding apparatusHardnessAlloy

The invention relates to a laser cladding repairing process of a valve seat. The process comprises the following steps: A, treating the surface of the valve seat, and carrying out failure analysis on the valve seat; B, optimizing the technical parameters for laser cladding according to the failure analysis results of the valve seat, wherein the alloy powder adopted comprises the following components in percentage by weight: 0.5-1% of C, 19-23% of Cr, 1.5-2% of B, 1-3% of Si, 0.05-0.5% of Mo, 0.05-0.5% of Mn, 7-9% of W, 2.5-4% of Ni and the balance of C; and C, detecting. According to the laser cladding repairing process of the valve seat, laser cladding is carried out on the surface of the valve seat, so that the size of the valve seat is recovered to meet the using demands, and the corrosion resistance and wear resistance of the repaired valve seat exceed the original performances.

Owner:临沂人才数字科技集团有限公司

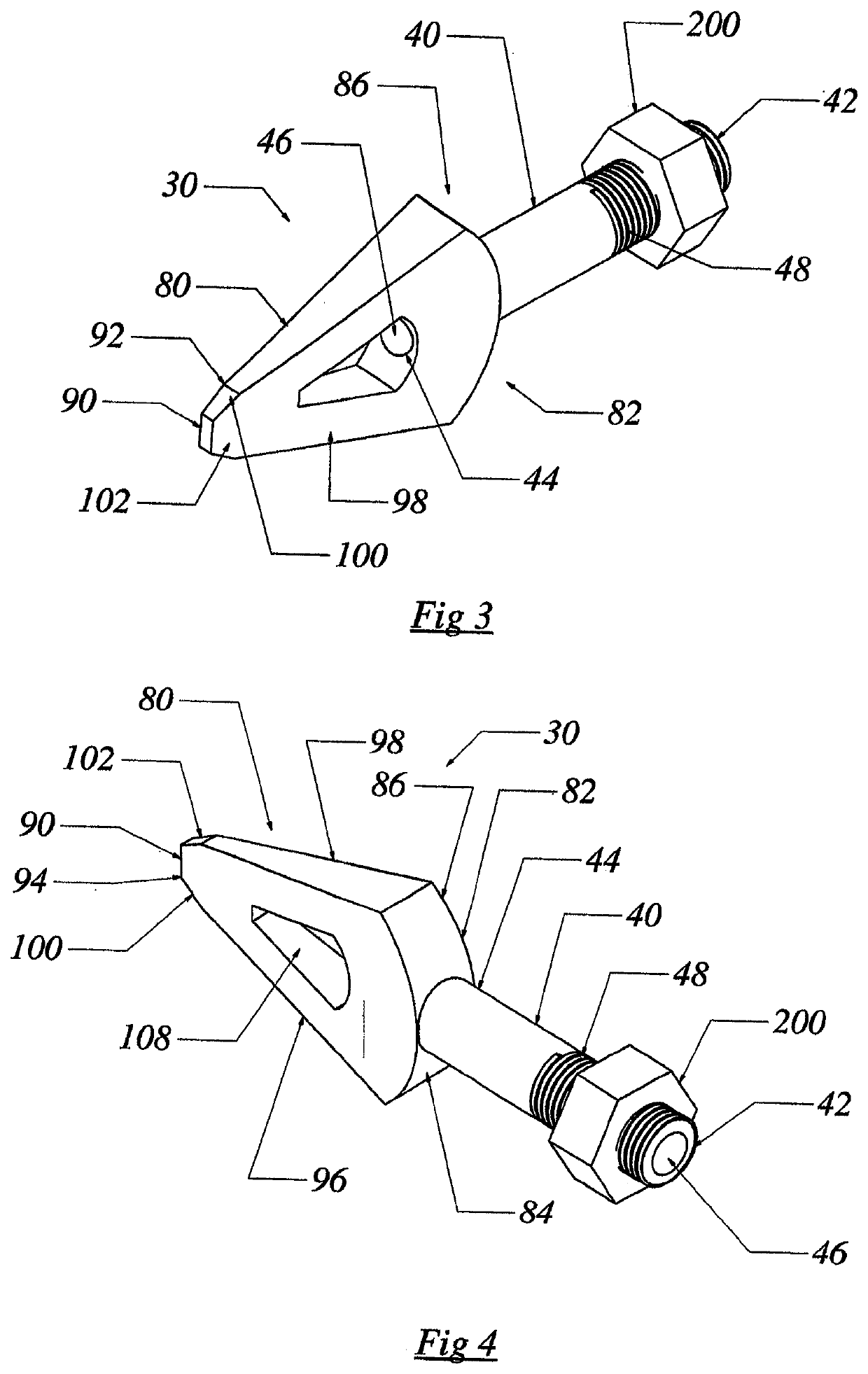

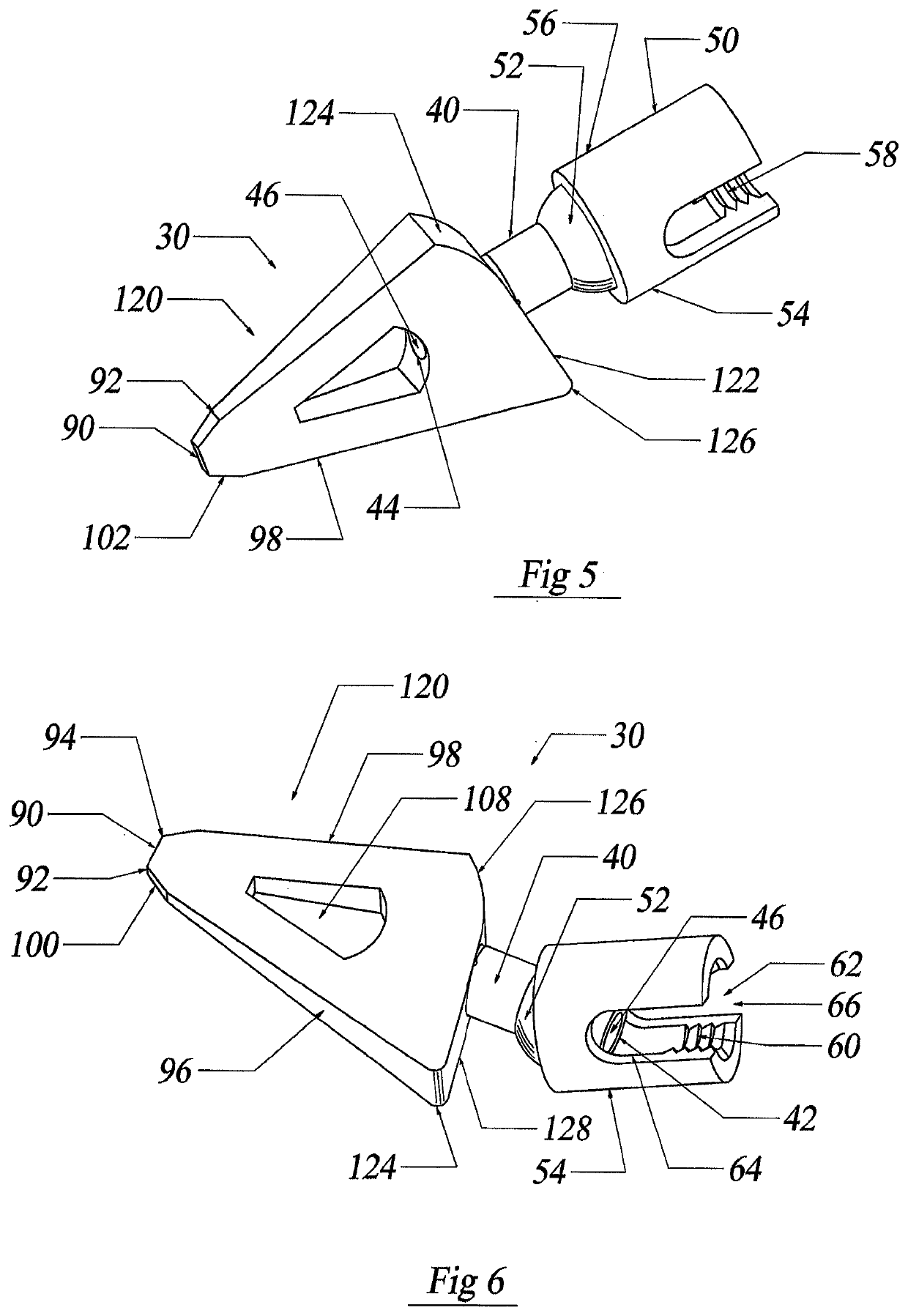

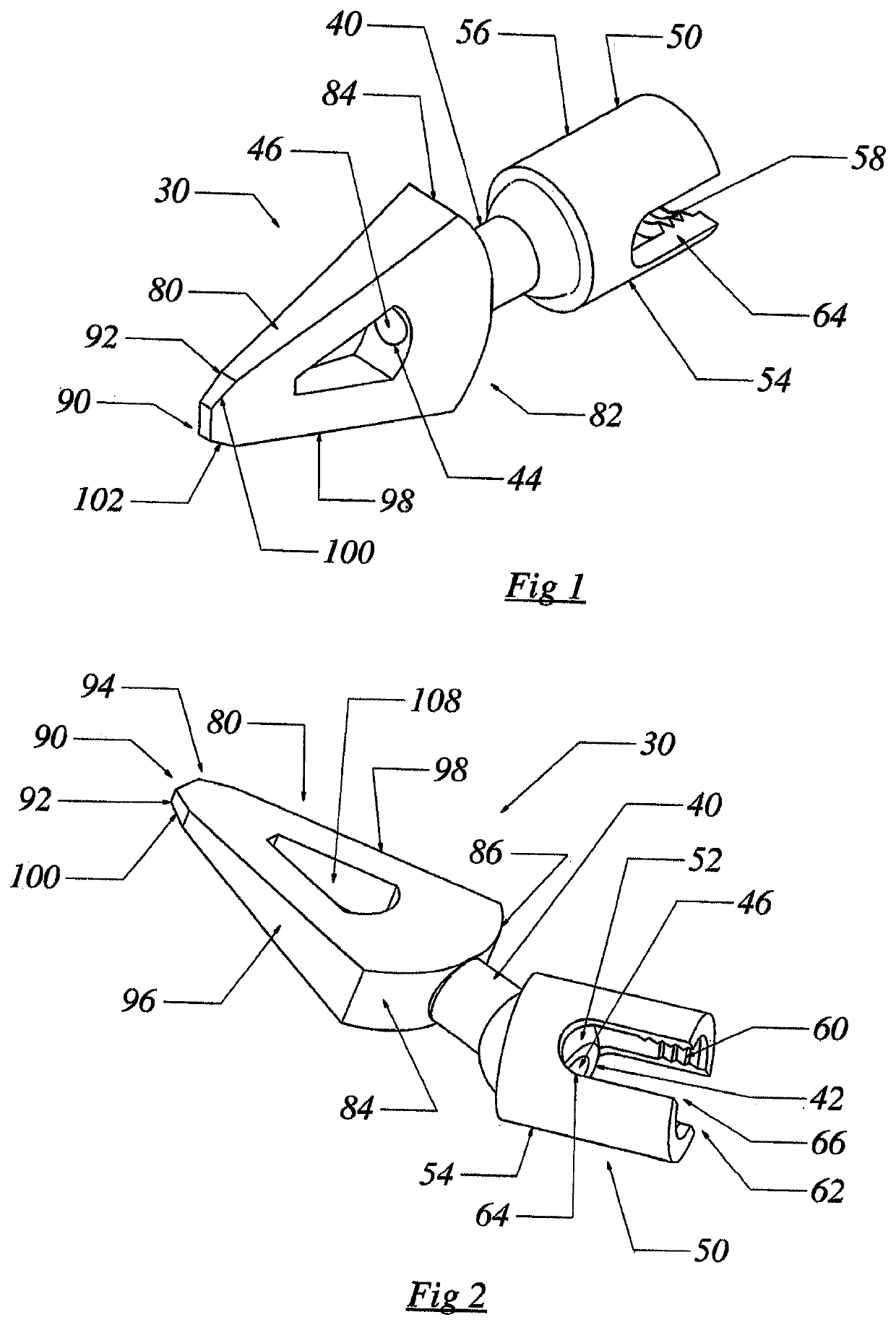

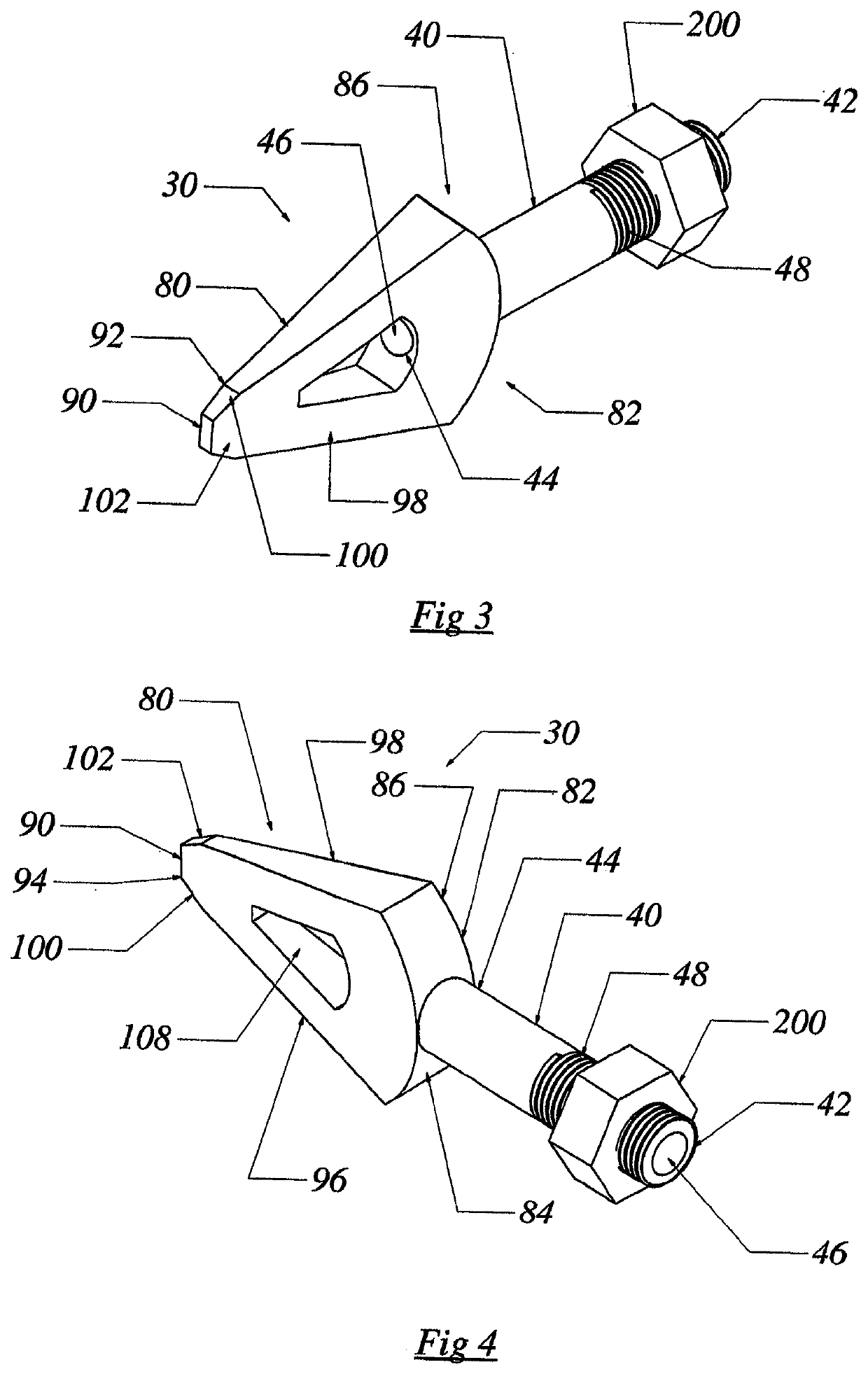

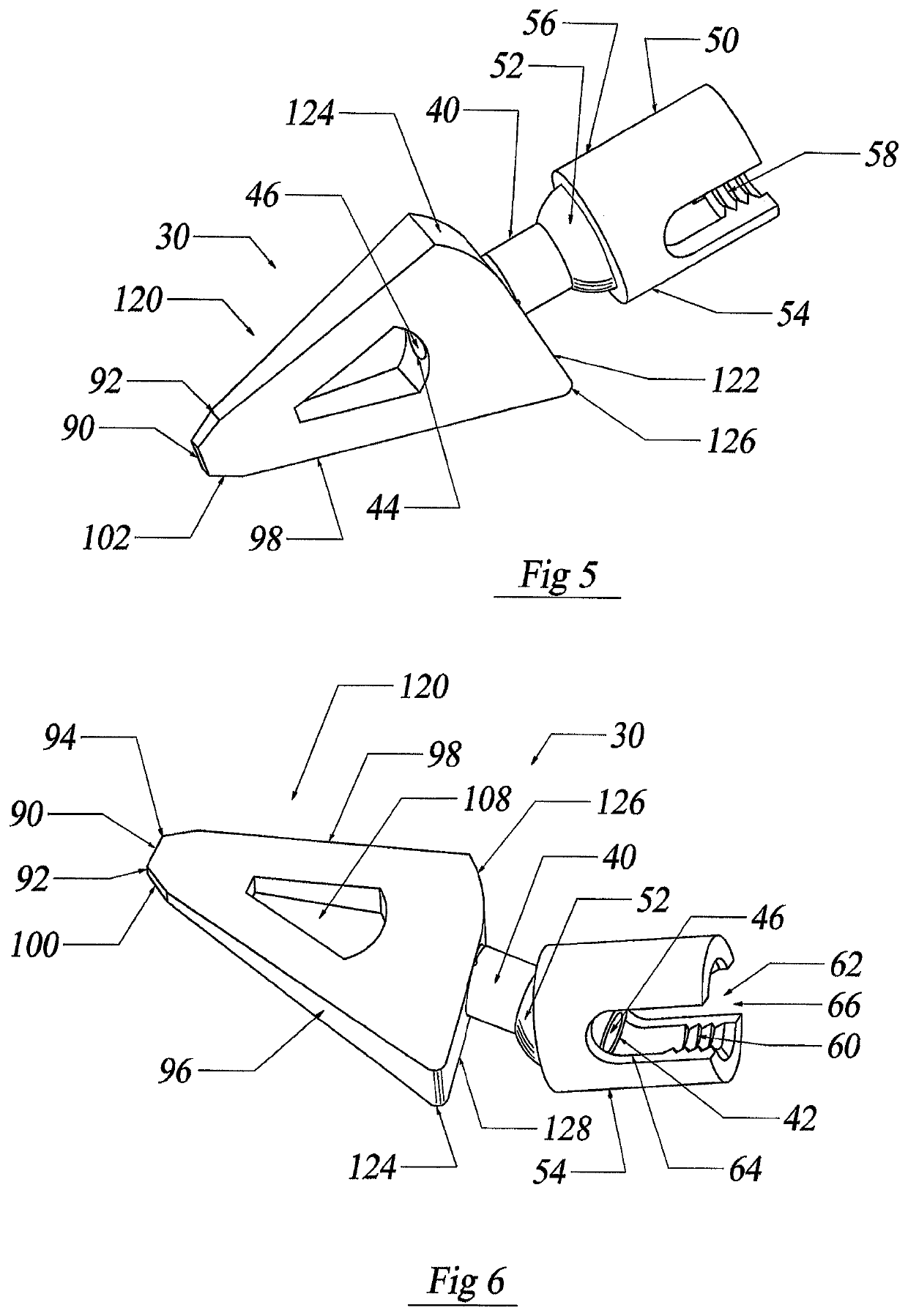

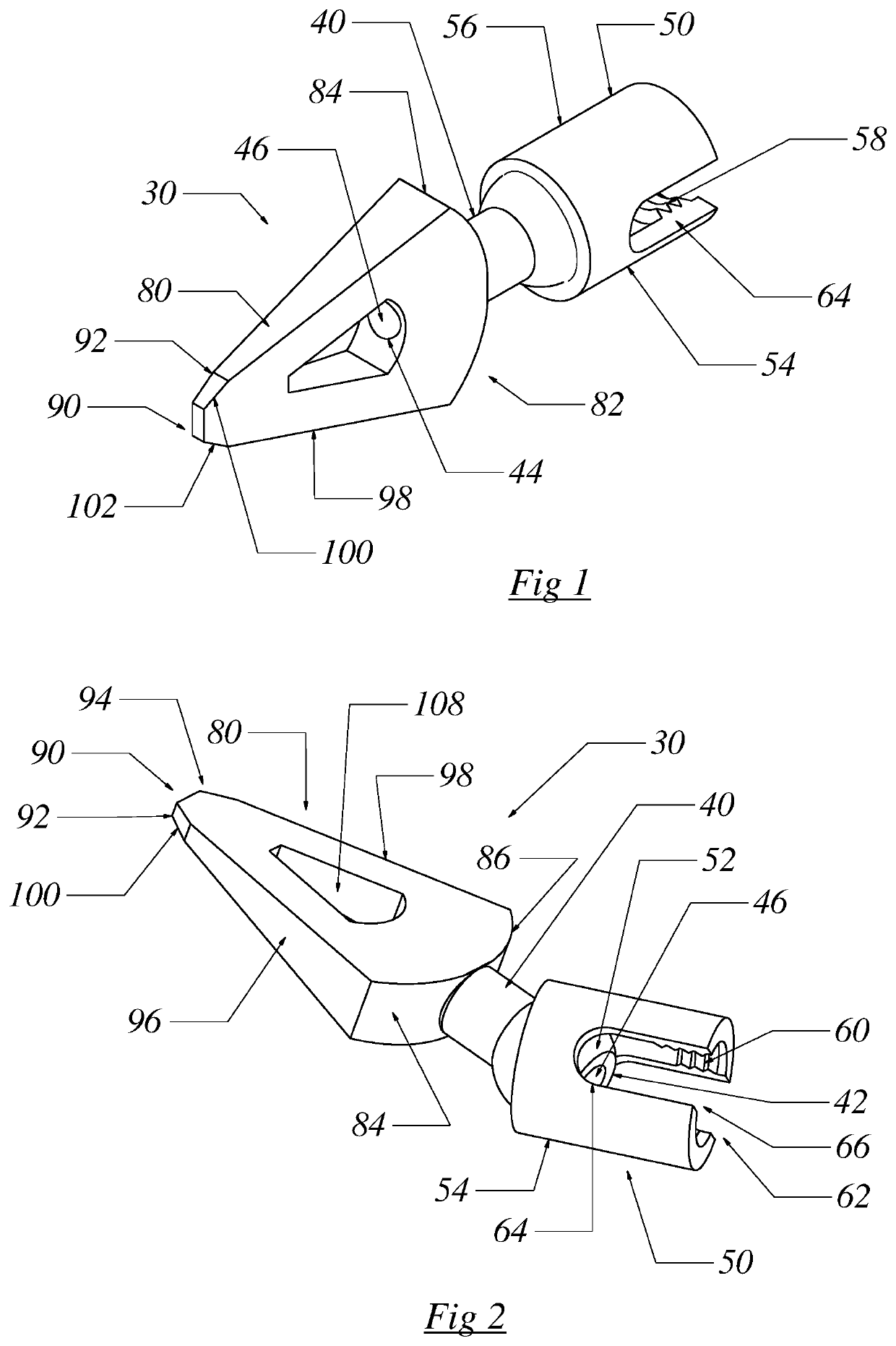

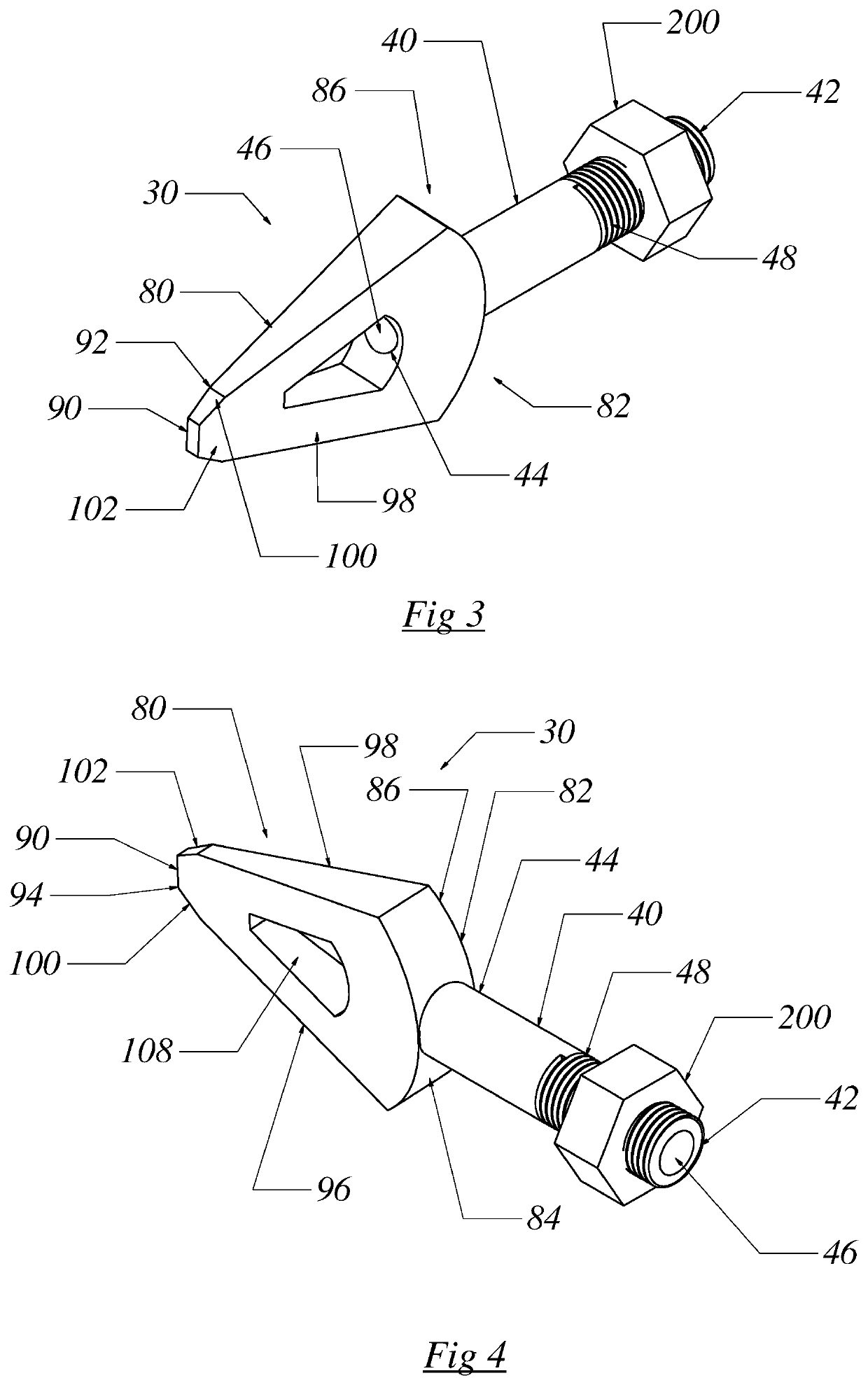

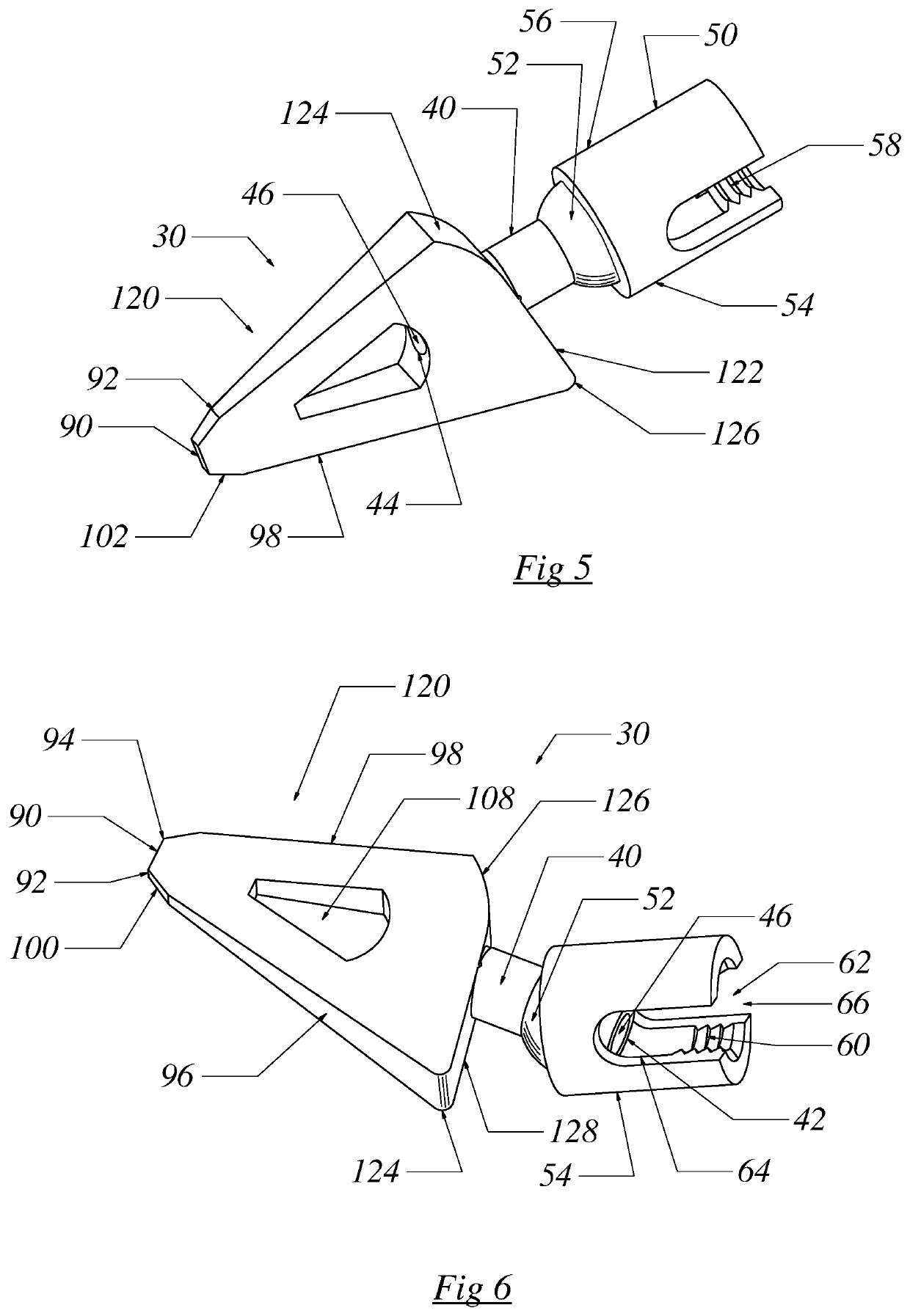

Implant for Bone

ActiveUS20200305896A1Easy to attachEnhanced attachmentInternal osteosythesisFastenersSpinal columnSurgical operation

The present invention is an implant for bone. The current implant is particularly useful in spinal surgical procedures.

Owner:BLUE SKY TECHNOLOGIES LLC

Laser repairing method for allowing roller surface of hot roller to have good thermal hardness after repairing

InactiveCN106567065APositive effectSmall amount of deformationMetallic material coating processesAlloyHardness

The invention relates to a laser repairing method for allowing the roller surface of a hot roller to have good thermal hardness after repairing. A transitional alloy layer, an intermediate alloy layer and a surface alloy layer are arranged on the surface of the hot roller in a laser cladding mode from inside one by one. The alloy powder adopted by the transitional alloy layer comprises, by mass, 0.21%-0.31% of C, 3.2%-3.6% of Si, 1.0%-1.1% of B, 2.2%-2.6% of Fe, 7%-8% of Cr and the balance Ni. The alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4%-0.5% of C, 3.8%-4.3% of Si, 11.2%-11.93% of B, 2.5%-3.2% of Fe, 10%-12% of Cr and the balance Ni. The alloy powder adopted by the surface alloy layer comprises, by mass, 0.05%-0.1% of C, 3.2%-3.6% of Si, 2%-4% of Fe, 16%-19% of Cr, 27%-30% of Mo and the balance Co. The surface of the hot roller repaired by using the laser repairing method for the hot roller has good abrasion resistance, corrosion resistance and thermal hardness, toughness and strength are taken into account in the interior, and the effect of laser cladding is good.

Owner:DANYANG HONGTU LASER TECH

Low roller deformation hot roller laser repair method

InactiveCN106567071APositive effectSmall amount of deformationMetallic material coating processesAlloyUltimate tensile strength

The present invention relates to a low roller deformation hot roller laser repair method, wherein a transition alloy layer, an intermediate alloy layer and a surface alloy layer are sequentially subjected to laser cladding on the surface of a hot roller from the inner layer, the components of the alley powder used by the transition alloy layer comprise, by mass, 0.2-0.3% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance of Ni, the components of the alley powder used by the intermediate alloy layer comprise, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance of Ni, and the components of the alley powder used by the surface alloy layer comprise, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo, and the balance of Co. According to the present invention, the hot roller repaired by using the hot roller laser repair method of the present invention has good abrasion resistance, good corrosion resistance and good thermal rigidity of the surface, has good toughness and good strength of the internal, and has good laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

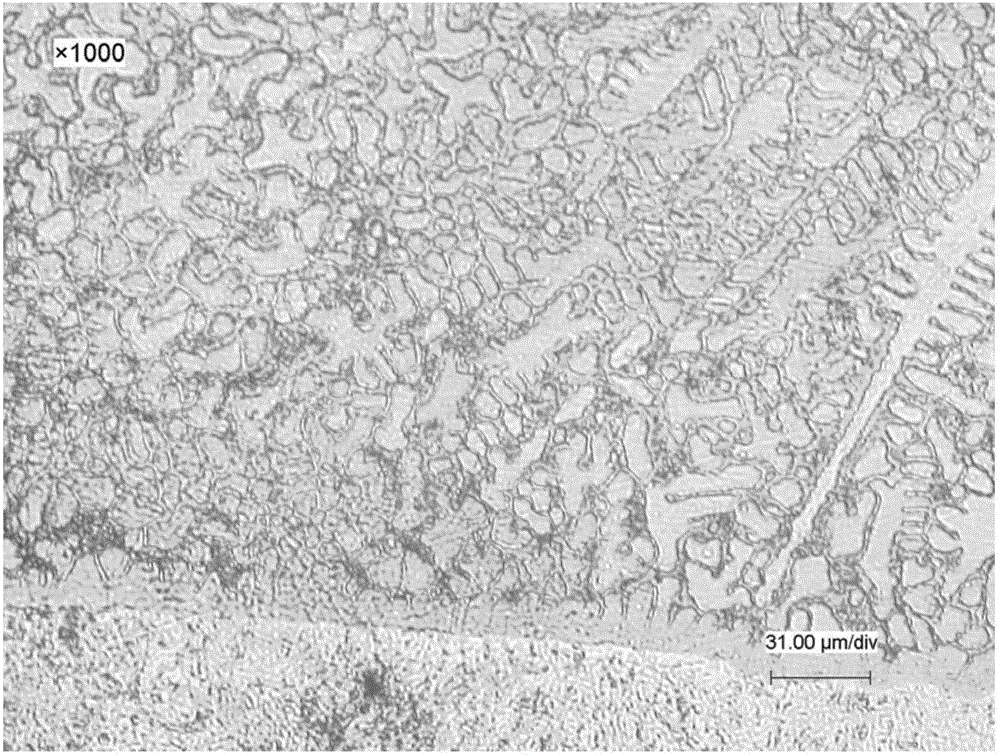

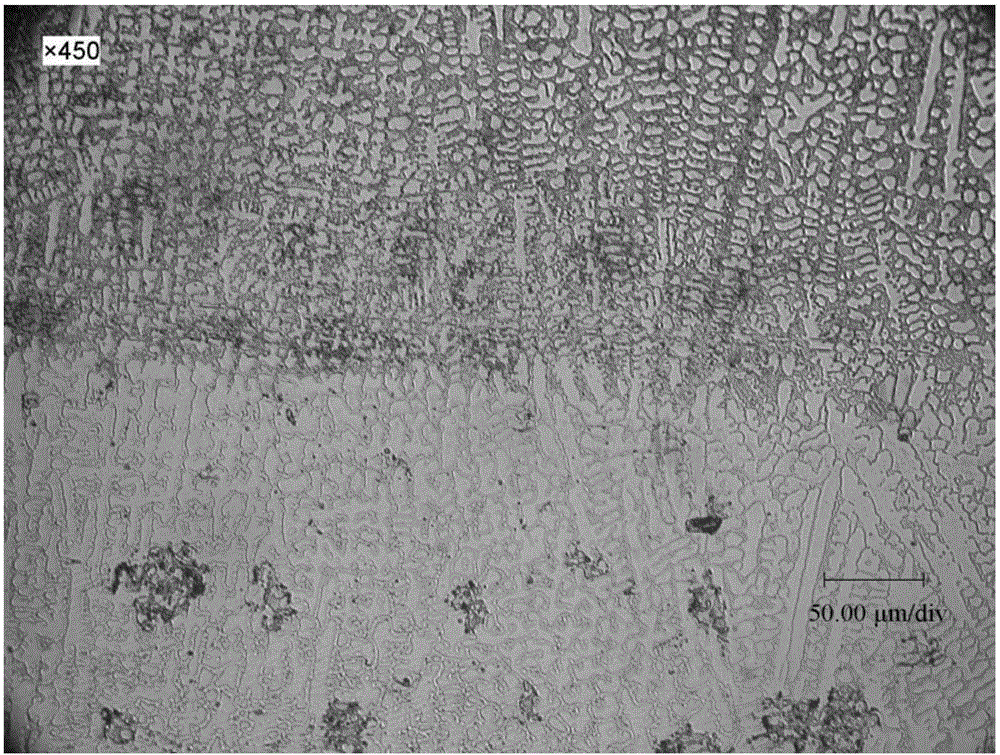

Bone-anchoring or bone-connecting device that induces a strain stimulus

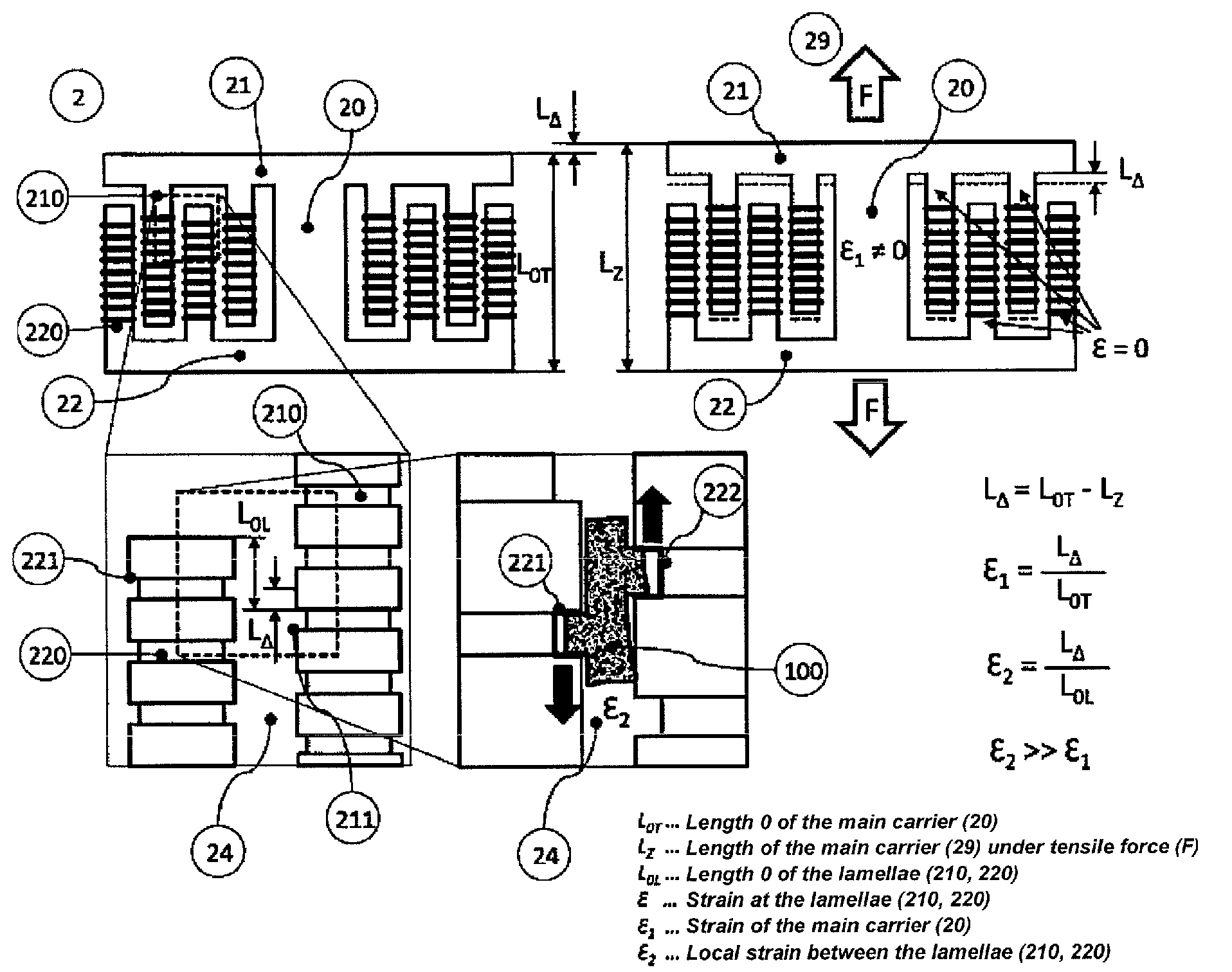

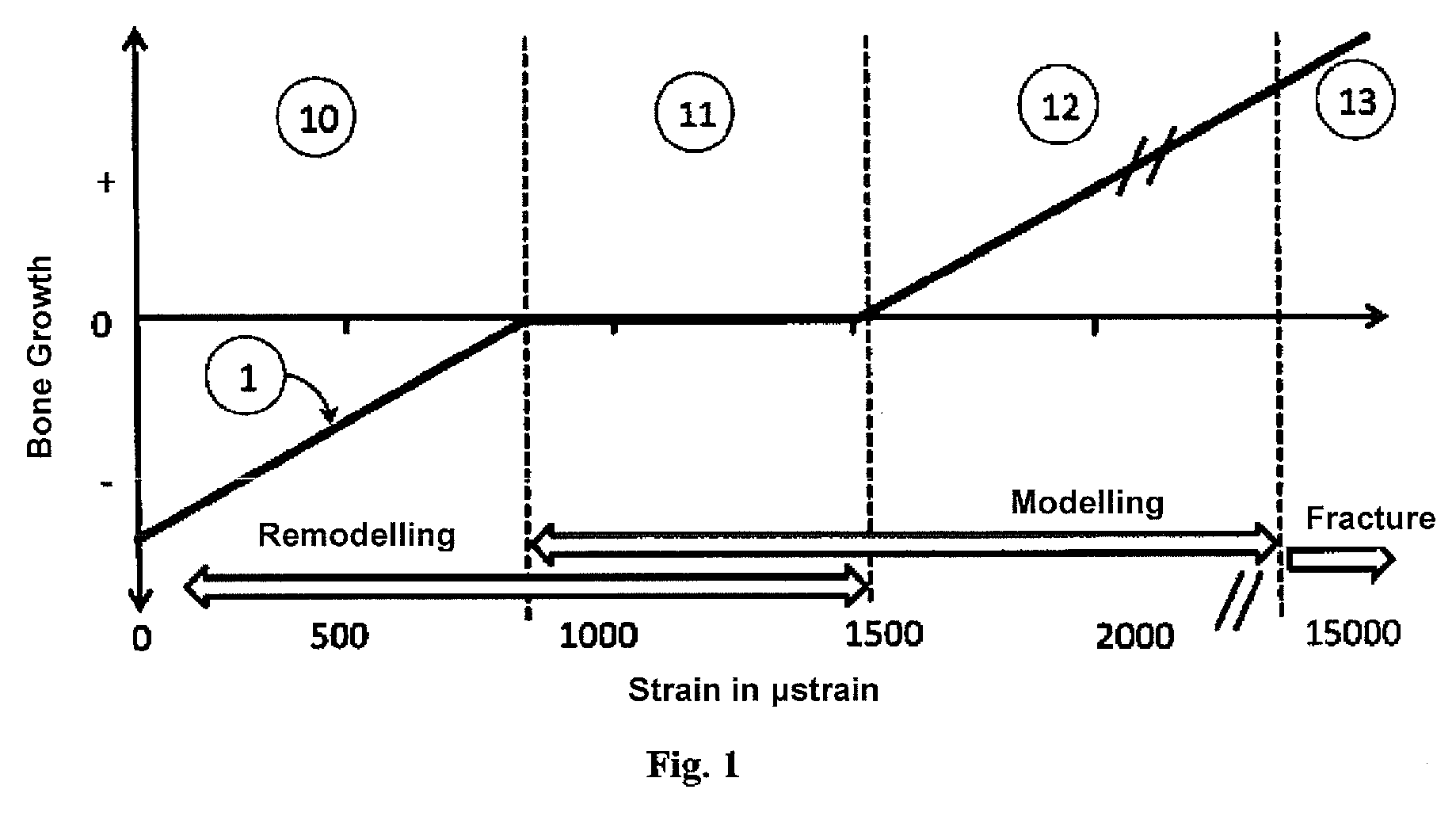

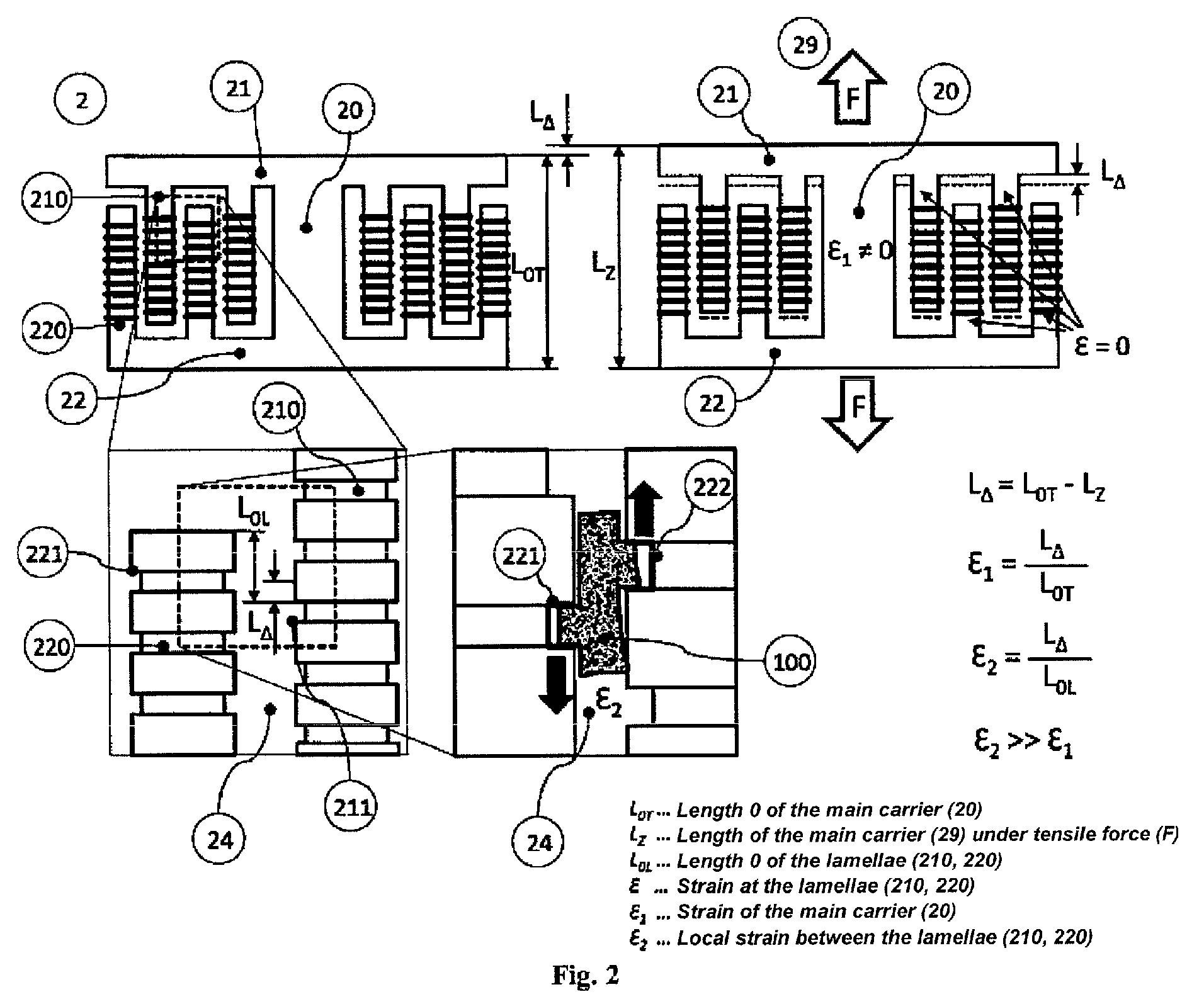

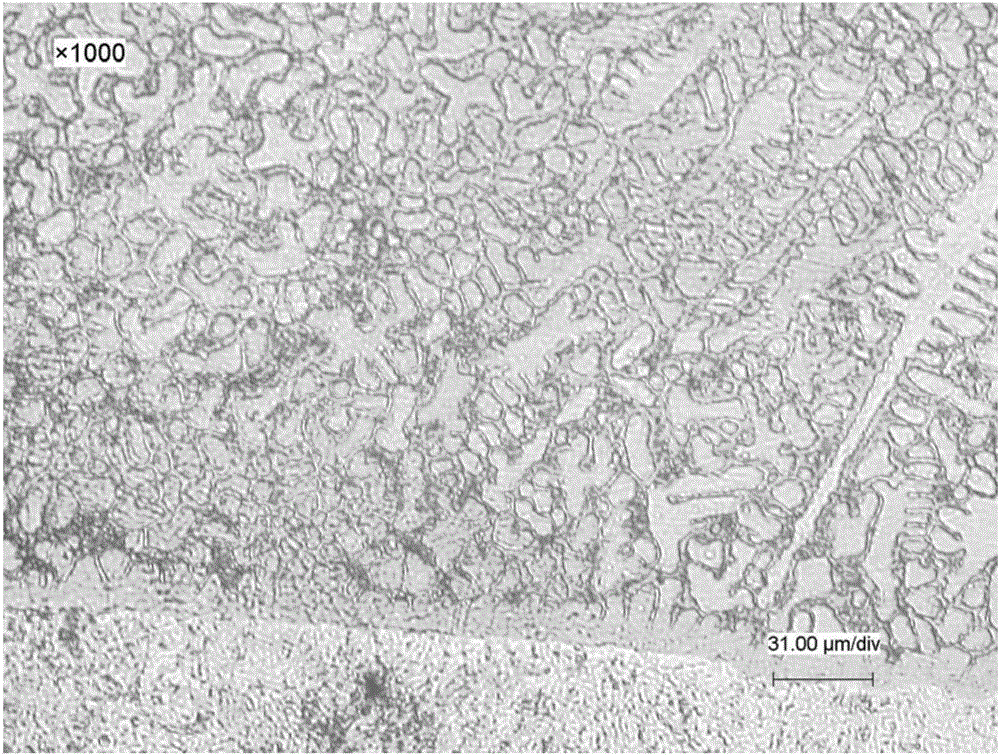

ActiveUS9283011B2Improve anchor strengthHigh, physiologically effective strainsSuture equipmentsBone implantBone growthStructuring element

The invention relates to an implant in the form of a bone-connecting device with an implant carrier, having at least two structure carriers for stimulating bone growth, the structure carriers can move relative to one another so that, due to a loading of the implant, a relative movement of the structure carriers occurs, the structure carriers furthermore contain structure elements that are arranged so that they define a plurality of partially open intermediate spaces, wherein a volume defined by these intermediate spaces and an immediate environment is deformed by the implant load, and a strain in the intermediate spaces and its immediate environment resulting from the deformation lies in the physiological range for bone growth.

Owner:ACES

A hot roller laser restoration method capable of prolonging the service lifetime of a hot roller

InactiveCN106567064APositive effectSmall amount of deformationMetallic material coating processesRestoration methodWear resistance

The invention relates to a hot roller laser restoration method capable of prolonging the service lifetime of a hot roller. A transitional alloy layer, a middle alloy layer and a surface alloy layer are cladded with laser layer by layer from the inside on the surface of the hot roller. Alloy powder adopted by the transitional alloy layer includes components by mass: 0.12-0.19% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, and 7-8% of Cr, with the balance being Ni. Alloy powder adopted by the middle alloy layer includes components by mass: 0.4-0.5 % of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, and 10-12% of Cr, with the balance being Ni. Alloy powder adopted by the surface alloy layer includes components by mass: 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr and 27-30% of Mo, with the balance being Co. The surface of the hot roller restored by the method has good wear resistance, corrosion resistance and hot hardness, both toughness and strength of the inside of the hot roller are taken into account, and laser cladding effects are good.

Owner:DANYANG HONGTU LASER TECH

Laser repairing method of hot roll good in laser cladding effect

InactiveCN106567069APositive effectSmall amount of deformationSuperimposed coating processToughnessRepair method

The invention relates to a laser repairing method of a hot roll good in laser cladding effect. The surface of the hot roll is laser-cladded with a transition alloy layer, an intermediate alloy layer and a surface alloy layer from the inside layer by layer; alloy powder adopted by the transition alloy layer comprises, by mass, 0.21-0.31% of C, 3.2-3.6% of Si, 1.0-1.1% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance Ni; alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 11.2-11.93% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance Ni; and alloy powder adopted by the surface alloy layer comprises, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo and the balance Co. The hot roll repaired by the laser repairing method of the hot roll good in laser cladding effect has good abrasion resistance, corrosion resistance and hot hardness in surface, integrates toughness and strength inside, and is good in laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

Manual Arc Welding Repair Method for Worn Impeller Blades of Centrifugal Fan

ActiveCN104014903BReduce distortionHigh fusion rateArc welding apparatusImpellerStructural engineering

The invention discloses a manual arc welding repair method for a centrifugal blower after impeller blade abrasion. The method comprises a preparation step before repair and a repair step, wherein the repair method comprises the following steps: cleaning a workpiece, detecting the workpiece; disassembling a damaged impeller; analyzing the workpiece; installing a special tooling; removing a fatigue layer after the abraded part of the impeller blade is removed, and detecting a base material; selecting a welding material, and welding the repaired damaged part in manners of small current, short arc operation and symmetry welding; then carrying out destressing heat treatment, and removing residual stress; carrying out surface coloring flaw detection on the processed workpiece surface, and assembling as a whole, so as to achieve the traditional design standard of a manufacturer. The repaired part has the advantages of good abrasive resistance, large hardness, high fusion rate of a cladding layer and an impeller blade base material, small impeller deformation and the like.

Owner:河北瑞兆激光再制造技术股份有限公司

Implant for bone

ActiveUS11432829B2Enhanced attachmentGreat resistance against pulling-out and backing-outInternal osteosythesisFastenersSpinal columnSurgical operation

The present invention is an implant for bone. The current implant is particularly useful in spinal surgical procedures.

Owner:BLUE SKY TECHNOLOGIES LLC

Laser repair method for abraded centrifugal fan bearing block

ActiveCN102031519BReduce distortionStrong fusion rateMetallic material coating processesLaser beam welding apparatusEngineeringHardness

Owner:河北瑞兆激光再制造技术股份有限公司

A hot roller laser restoration method allowing a restored surface to have good wear resistance

InactiveCN106567070ASmall amount of deformationExtended service lifeMetallic material coating processesRestoration methodWear resistance

The invention relates to a hot roller laser restoration method allowing a restored surface to have good wear resistance. A transition alloy layer, a middle alloy layer and a surface alloy layer are cladded with laser layer by layer from the inside on the surface of a hot roller. Alloy powder adopted by the transition alloy layer includes components by mass: 0.31-0.35% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, and 7-8% of Cr, with the balance being Ni. Alloy powder adopted by the middle alloy layer includes components by mass: 0.4-0.5 % of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, and 10-12% of Cr, with the balance being Ni. Alloy powder adopted by the surface alloy layer includes components by mass: 0.05-0.1% of C, 3.2-3.6% of Si, 2-4% of Fe, 16-19% of Cr and 27-30% of Mo, with the balance being Co. The surface of the hot roller restored by the method has good wear resistance, corrosion resistance and hot hardness, both toughness and strength of the inside of the hot roller are taken into account, and laser cladding effects are good.

Owner:DANYANG HONGTU LASER TECH

Implant for Bone

ActiveUS20210393298A1Enhanced attachmentGreat resistance against pulling-out and backing-outInternal osteosythesisFastenersSpinal columnSurgical operation

The present invention is an implant for bone. The current implant is particularly useful in spinal surgical procedures.

Owner:BLUE SKY TECHNOLOGIES LLC

Spinal fusion cage

The invention is directed to a spinal fusion cage for implantation between two adjacent vertebrae, wherein the total cage has, under a load, a maximum compression that is higher than 0.05% of the original height of the spinal fusion cage and the maximum compression does not change the structural integrity of the cage.

Owner:DSM IP ASSETS BV

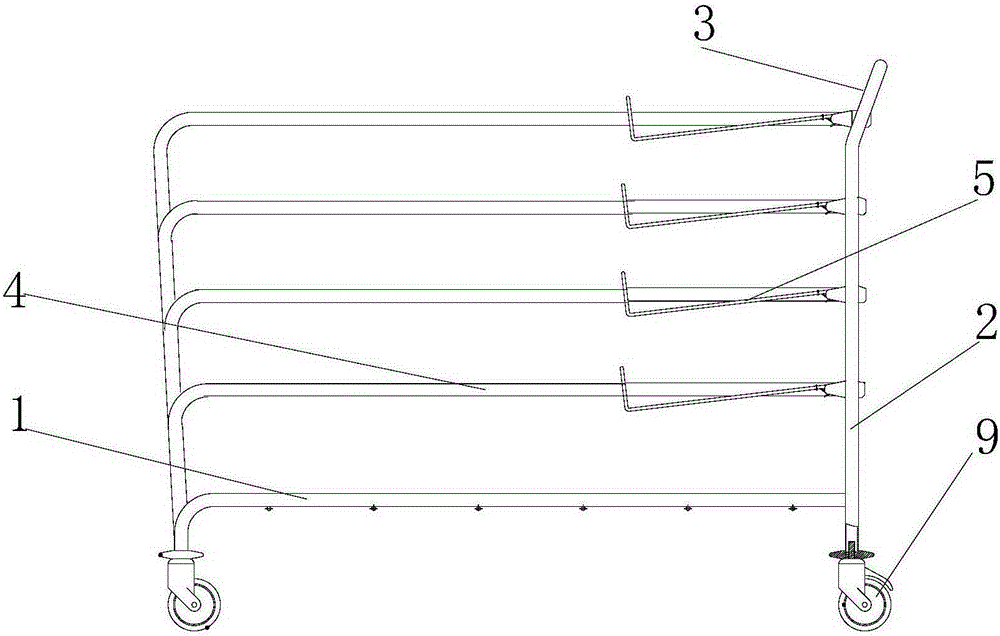

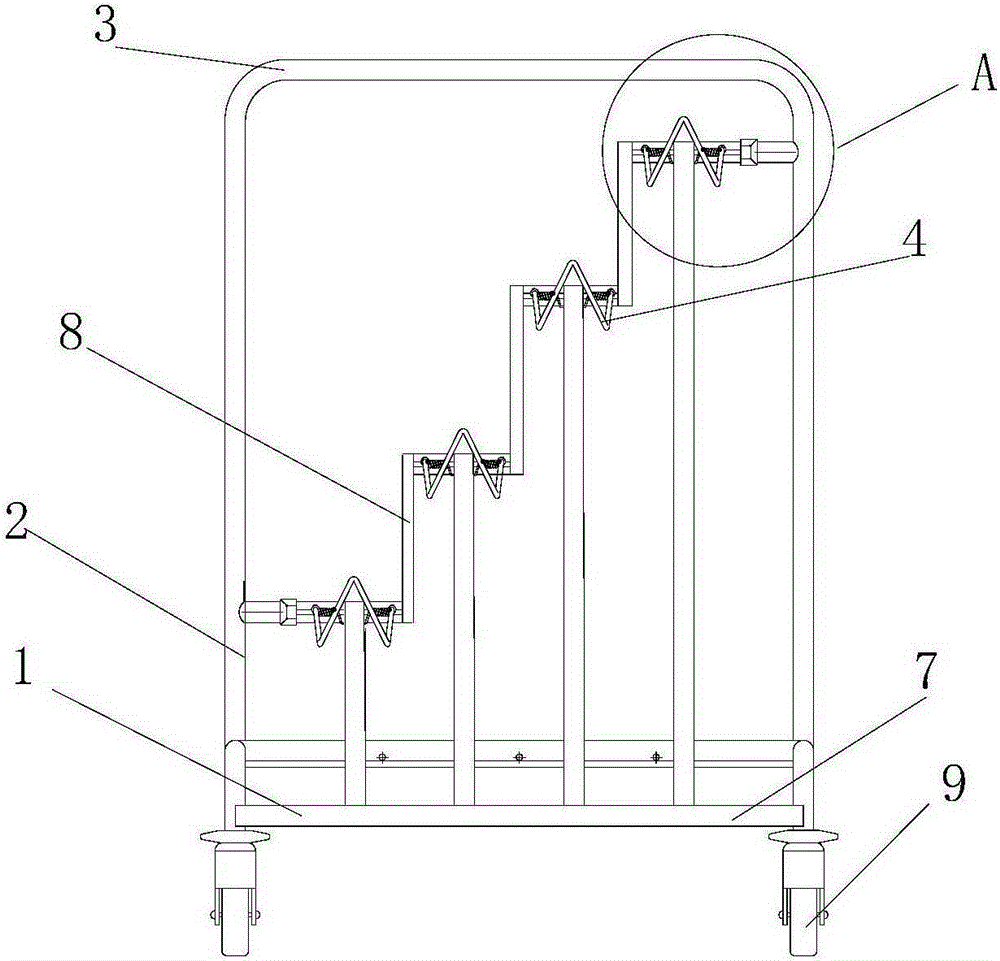

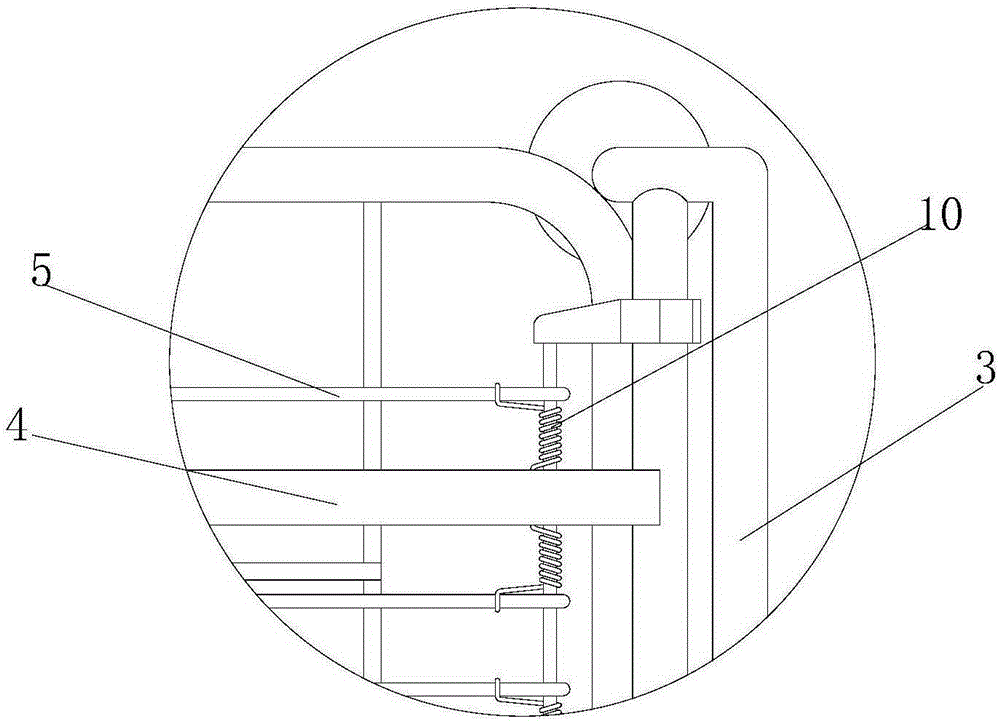

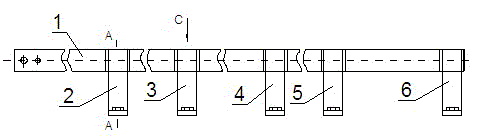

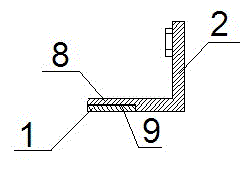

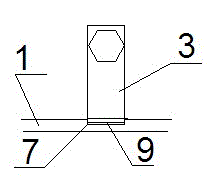

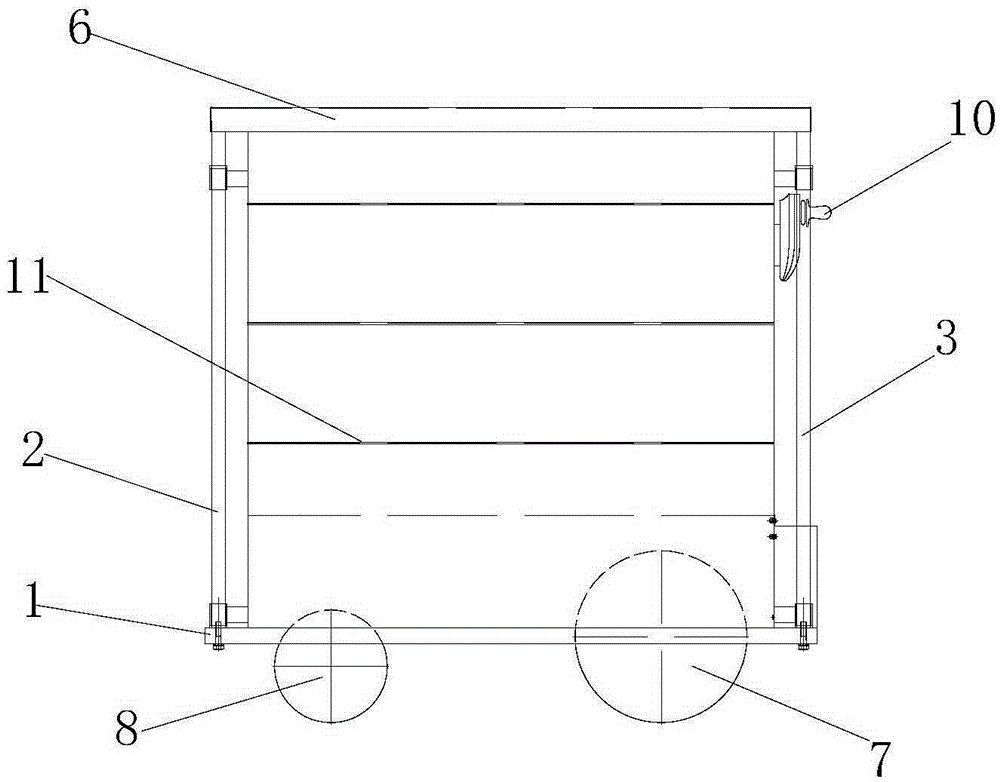

Wrapping cloth storage and transportation trolley and maintenance method thereof

InactiveCN106551769ASmall amount of deformationSuitable for noise control requirementsMetallic material coating processesNursing accommodationCoatingBreathing

The invention relates to a wrapping cloth storage and transportation trolley and a maintenance method thereof. The wrapping cloth storage and transportation trolley comprises an underframe, a trolley body arranged on the underframe, a push handle arranged on the rear side of the trolley body, a plurality of wrapping cloth pipes which are arranged on the trolley body and distributed in a stepped mode, wrapping cloth clamps arranged at the tail ends of the wrapping cloth pipes, and trundles which are arranged at the four ends of the underframe and provided with brakes. The tail ends of every two adjacent wrapping cloth pipes are connected through an inverted L-shaped connecting support. The wrapping cloth pipes are distributed in the stepped mode, so that aired wrapping cloth receives sunshine by a larger area, ventilation is facilitated, and the airing effect is remarkably improved. The wrapping cloth pipes are square pipes so that the wrapping cloth pipes and the wrapping cloth clamps can be matched more firmly and reliably. The trundles are arranged at the four ends, and thus transportation of the wrapping cloth is facilitated. The surfaces of the underframe, the trolley body, the push handle, fence assemblies, the wrapping cloth pipes, a lower transverse bracket and the inverted L-shaped connecting supports are coated with Teflon coatings, so that firmness and durability are achieved, dust is not liable to adhere to the surfaces, and cleaning and disinfection are easy.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

Method for preparing integral type multi-branch structure copper-bus busbar and busbar

ActiveCN102592712BHigh shape accuracyHigh dimensional accuracySingle bars/rods/wires/strips conductorsCable/conductor manufactureBusbarEngineering

The invention relates to a method for preparing an integral type multi-branch structure copper-bus busbar and the busbar. The method comprises the following steps of: dividing the integral type multi-branch structure copper-bus busbar into a parent part and sub-parts, wherein the sub-parts are branches of the parent part, are connected to the parent part respectively, and are pressed into the parent part through pressure; assembling and welding the parent part and the sub-parts together through polymer diffusion welding, wherein pressure tanks, the width of each of which is equal to that of each of the sub-parts, are formed on the parent part according to the distribution positions of the sub-parts, and a part of each joint of each sub-part and the parent part is cut off by milling to ensure that the sub-parts are step-shaped; pressing the sub-parts into the sub-part pressure tanks of the parent part through a pressing machine, and padding a welding assistant layer between two contact surfaces of pressure welding parts of the sub-parts and the parent part; and performing polymer diffusion pressure welding on the composite part of the sub-parts and the parent part in polymer diffusion pressure welding equipment, keeping the pressure of a welding machine to ensure that welding joints of the sub-parts and the parent part are cooled to the natural temperature, and then releasing the pressure.

Owner:ZHUZHOU BOYA TECH

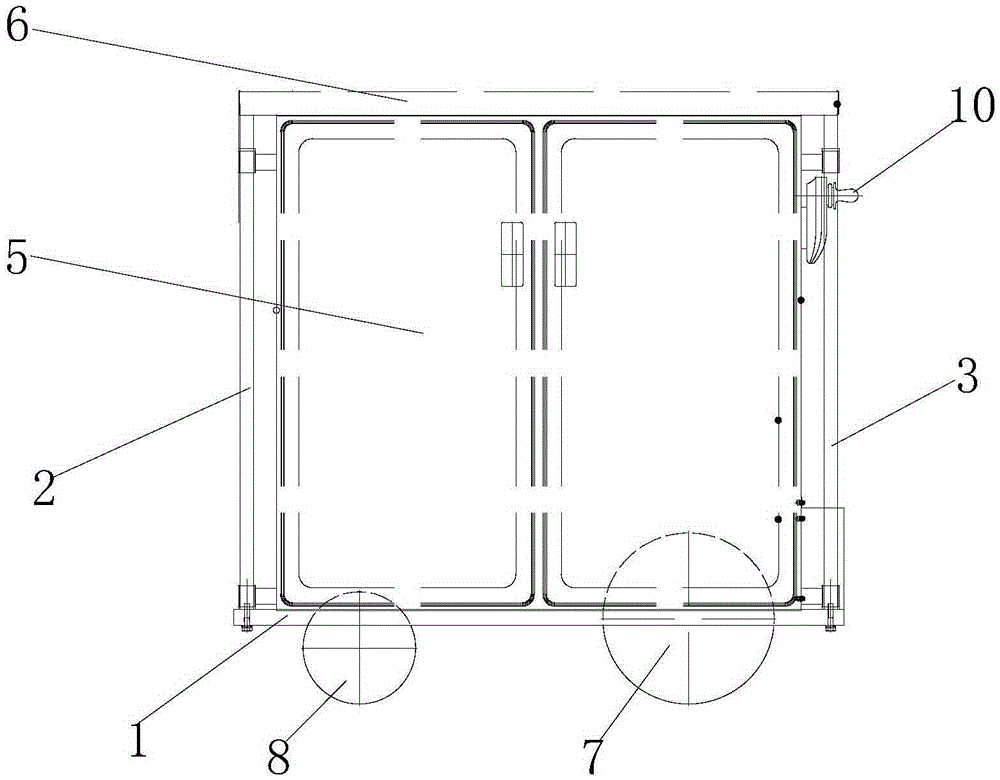

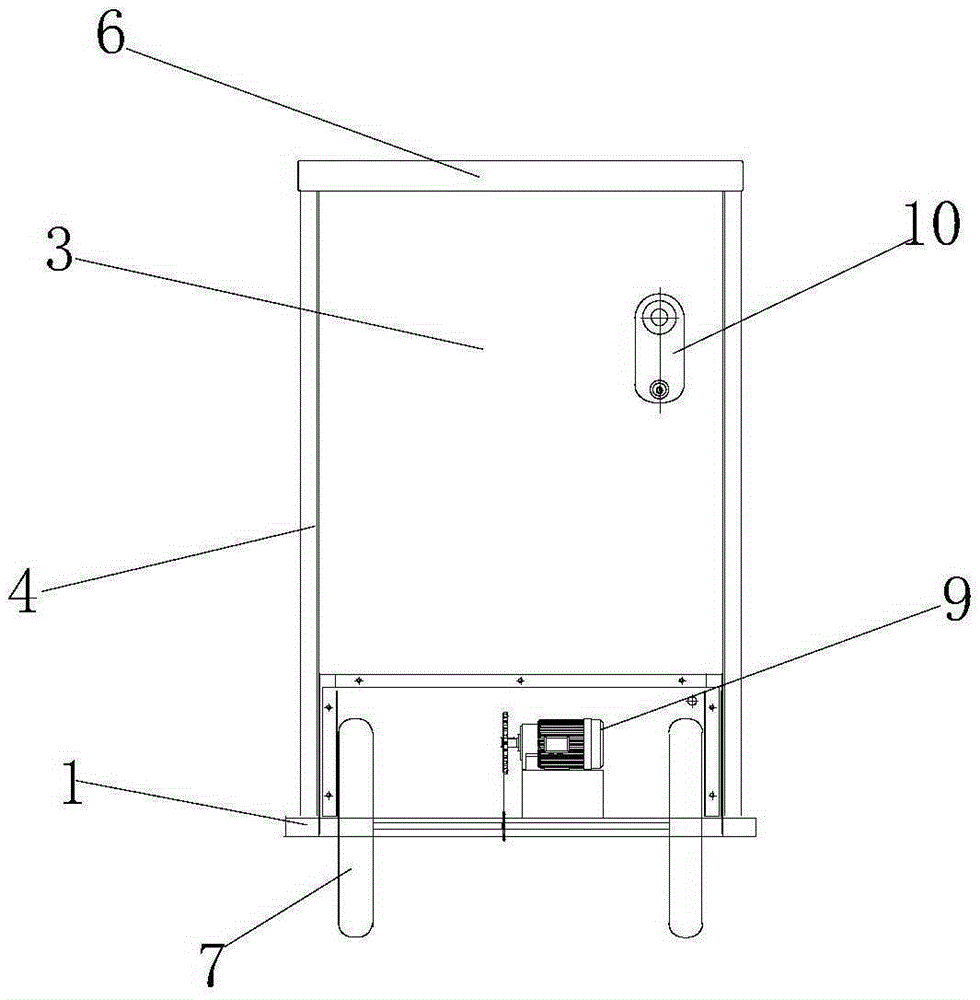

Sealed distributing and collecting trolley and maintaining method thereof

InactiveCN106553672AEasy to cleanEasy to disinfectMetallic material coating processesHand carts with multiple axesDrive wheelEngineering

The invention relates to a sealed distributing and collecting trolley and a maintaining method thereof. The trolley comprises a left side plate assembly, a right side plate assembly, a back plate, a double door assembly and a top cover assembly, wherein the left side plate assembly, the right side plate assembly, the back plate and the double door assembly are arranged on the four sides of a bottom plate assembly, the top cover assembly is arranged on the tops of the left side plate assembly, the right side plate assembly, the back plate and the double door assembly, and a sealed box body is jointly formed by the left side plate assembly, the right side plate assembly, the back plate, the double door assembly and the top cover assembly. The inner side face of the sealed box body is coated with a Teflon coating. Inner partition plates with the height capable of being freely adjusted are arranged in the sealed box body and made of stainless steel with the surface coated with the Teflon coating, dust staining is not likely to happen, and cleaning is easy. Multiple drive wheels connected with a motor driving system are arranged at the bottom of the right side of the bottom plate assembly. Multiple driven wheels are arranged at the bottom of the left side of the bottom plate assembly. A waterproof direct current motor is selected as a motor of the motor driving system, whole trolley cleaning and disinfecting are convenient, sanitation safety of equipment is ensured, the motor is used for driving the sealed distributing and collecting trolley, original manpower driving is replaced, and the labor intensity of medical workers is greatly lowered.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

Laser cladding repair process for gears with improved hardness and wear resistance

ActiveCN103668176BGood self-fluxingIncrease contentMetallic material coating processesEngineeringHardness

The invention relates to a laser cladding repair process for gear, which comprises the following steps: (A) treating the surface of the valve seat and performing failure analysis on the valve seat; (B) integrally preheating the gear at 80-120 DEG C and locally preheating the portion to be repaired of the gear at 80-220 DEG C at the same time; (C) optimizing technological parameter according to the failure analysis result of the gear, and performing laser cladding on the valve seat layer by layer, the thickness of each cladding layer is less than or equal to 0.4 mm, the edge of the later cladding layer extends out of the edge of the former cladding layer by 4 mm to 6 mm, the powdered alloy adopted is prepared from the following components in percentage by weight: less than or equal to 0.5% of carbon, 38-52% of chromium, 1.5-2.5% of boron, 0.5-1.5% of silicon and the balance of ferrum; and (D) performing detection. The surface of the gear is subjected to laser cladding through the laser repair process for gear, so that the size of the valve seat is recovered to operating requirement, and the hardness and abrasive resistance of the valve seat repaired exceed its original performance.

Owner:XINJIANG HUIXIANG LASER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com