Aluminum electrolysis cell riser bus bar electrified repairing method

A technology of column busbar and aluminum electrolytic cell, which is applied in the field of aluminum smelting, can solve the problems of poor wetting effect, difficult fusion, poor side wall fusion effect, etc., and achieves the effect of simple and rapid operation, safe and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

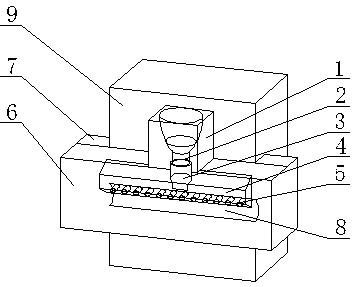

Image

Examples

Embodiment 1

[0023] Due to the breakdown of the insulation board at the short-circuit opening of the 200KA aluminum electrolytic cell, the surface of the column bus and the short-circuit bus are blasted. The dimensions of the damaged surface of the column bus are: length 420mm, width 150mm, depth 80mm.

[0024] The live repair method of the column busbar of the aluminum electrolytic cell, the repair steps are as follows:

[0025] 1. Damage surface treatment:

[0026] Use insulating paper to wrap the short-circuit busbar on the opposite side, and lay insulating boards on the grid ground near the column busbar on the side of the electrolytic cell, mainly for the purpose of insulation and ensuring the safety of personnel. The operator stands on the insulation board, burns off the rubber rod in the connection hole between the column busbar and the short-circuit busbar with an oxyacetylene flame, saws off the large solidified aluminum block on the surface of the column busbar with a sawing mach...

Embodiment 2

[0059] The column busbar of 120KA aluminum electrolytic cell is washed out due to the leak. The size of the damaged surface of the column busbar is: length 300mm, width 200mm, depth 120mm.

[0060] The live repair method of the column busbar of the aluminum electrolytic cell, the repair steps are as follows:

[0061] 1. Damage surface treatment:

[0062] Use insulating paper to wrap the short-circuit busbar on the opposite side, and lay insulating boards on the grid ground near the column busbar on the side of the electrolytic cell, mainly for the purpose of insulation and ensuring the safety of personnel. The operator stands on the insulation board, burns off the rubber rod in the connection hole between the column busbar and the short-circuit busbar with an oxyacetylene flame, saws off the large solidified aluminum block on the surface of the column busbar with a sawing machine, and removes the column with a pneumatic grinder Use a straight grinder and a high-speed electric...

Embodiment 3

[0088] 200KA aluminum electrolytic cell due to the arc discharge at the short-circuit opening, the surface of the column bus and the short-circuit bus are blasted, and the size of the damaged surface of the column bus is: length 250mm, width 180mm, depth 100mm.

[0089] The live repair method of the column busbar of the aluminum electrolytic cell, the repair steps are as follows:

[0090] 1. Damage surface treatment:

[0091] Use insulating paper to wrap the short-circuit busbar on the opposite side, and lay insulating boards on the grid ground near the column busbar on the side of the electrolytic cell, mainly for the purpose of insulation and ensuring the safety of personnel. The operator stands on the insulation board, burns off the rubber rod in the connection hole between the column busbar and the short-circuit busbar with an oxyacetylene flame, saws off the large solidified aluminum block on the surface of the column busbar with a sawing machine, and removes the column w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com