Patents

Literature

70results about How to "Low expansion ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

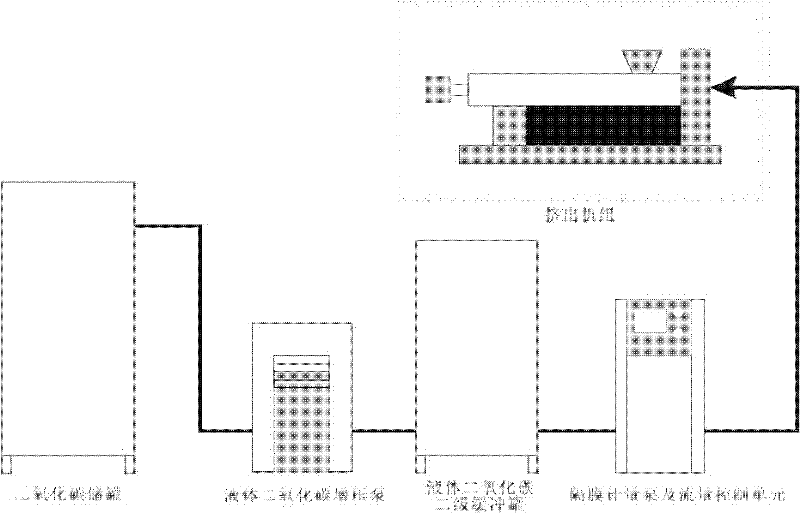

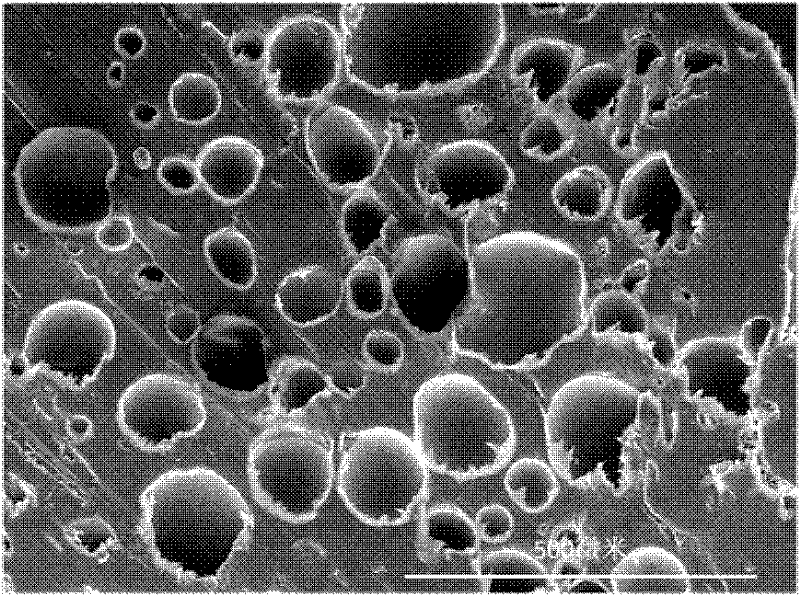

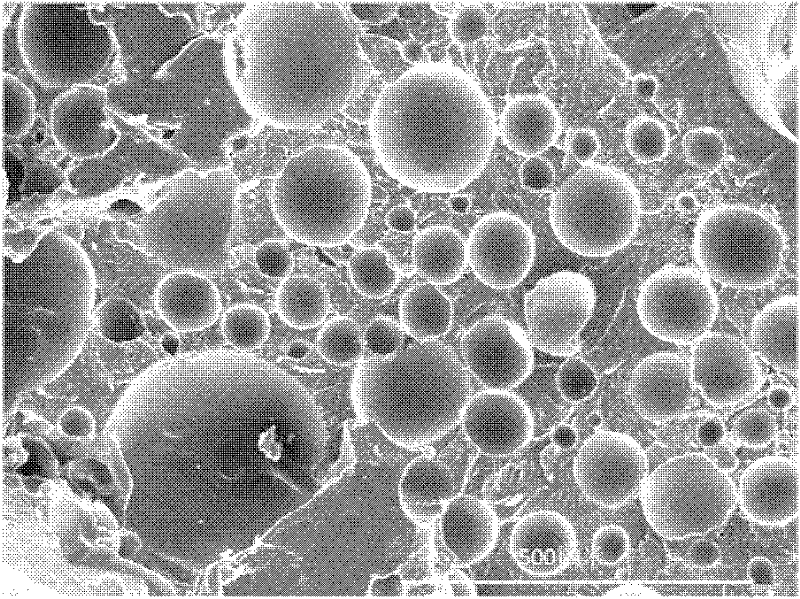

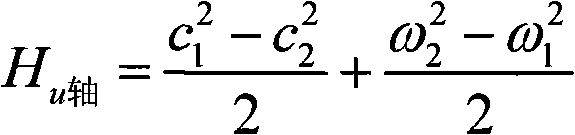

Foaming PET (Polyethylene Terephthalate) sheet and preparation method thereof

InactiveCN102504498ALow expansion ratioGood mechanical propertiesPolyethylene terephthalate glycolFoaming agent

The invention relates to a foaming PET (Polyethylene Terephthalate) sheet and a preparation method of the foaming PET sheet; the sheet is composed of the following components according to part by weight: 100 parts of PET resin, 0.1-10 parts of nucleating agent, 0.1-10 parts of foaming stabilizer and 1.5-18 parts of composite foaming agent; after being mixed by an extruding machine, the componentsare extruded, foamed and molded, so PET foam sheet is obtained, wherein the composite foaming agent comprises 1-10 parts of liquid carbon dioxide, 0.5-5 parts of second component foaming agent and 0-3 parts of third component foaming agent according to part by weight. In comparison with the prior art, the advantages are as follows: PET foaming packaging sheets with medium-low foaming ratio and good mechanical property can be prepared; the production process is highly continuous, steady and safe without environment pollution, so the production process is suitable for industrial production. Thefoaming ratio, cell size distribution and mechanical property of products have good comprehensive evaluation; and the main foaming agent is carbon dioxide so as not to affect the usability and safetyof products.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

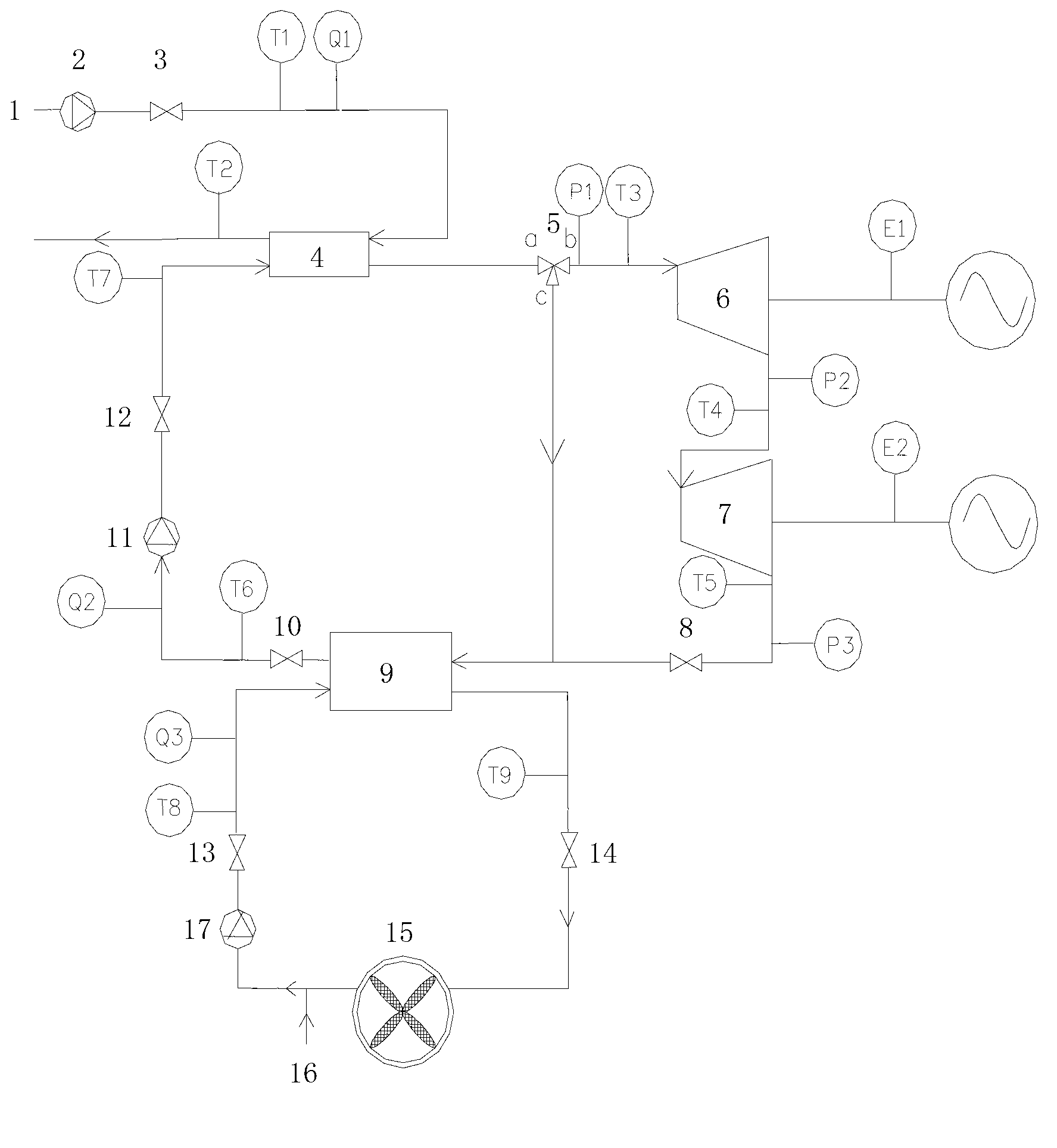

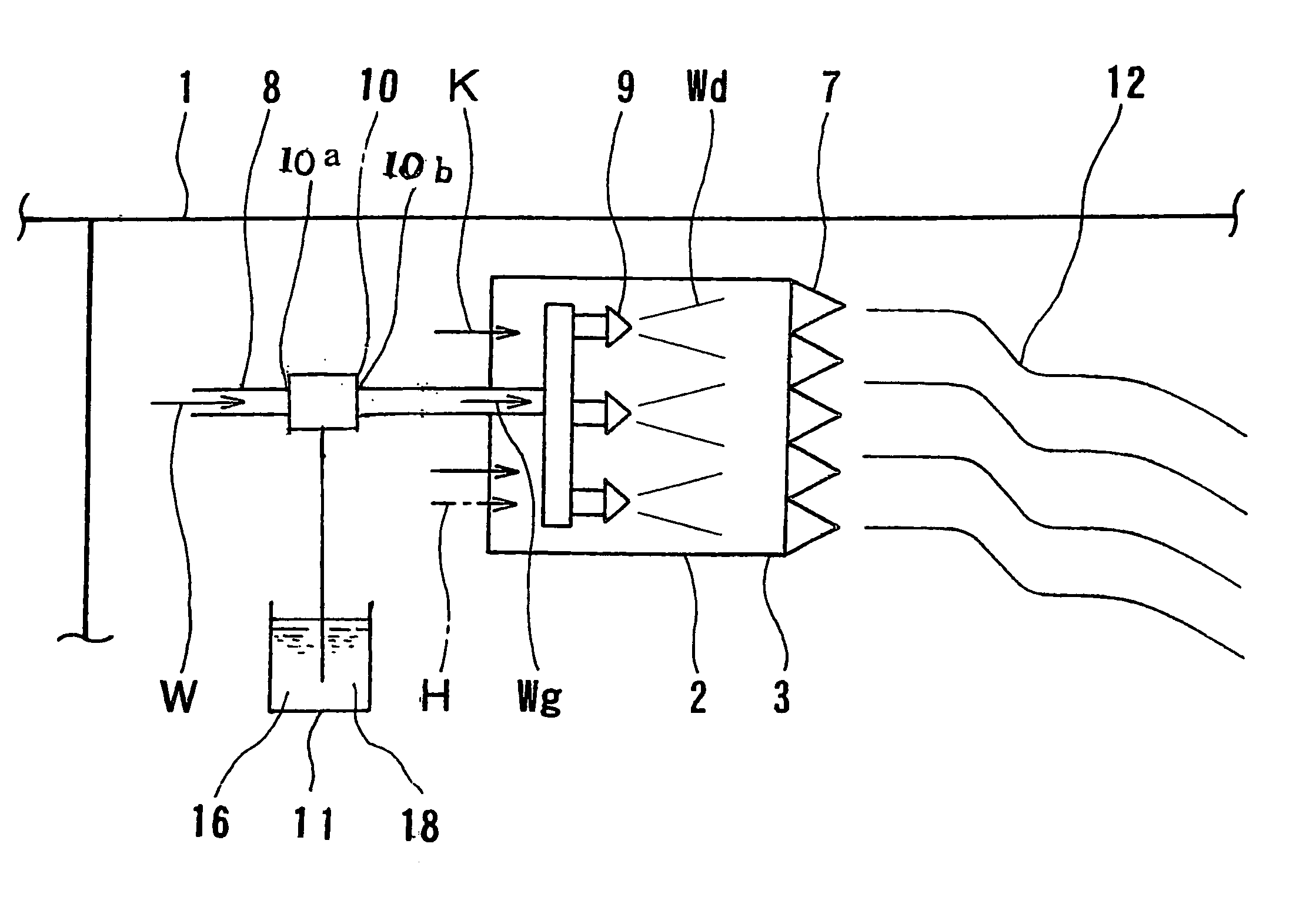

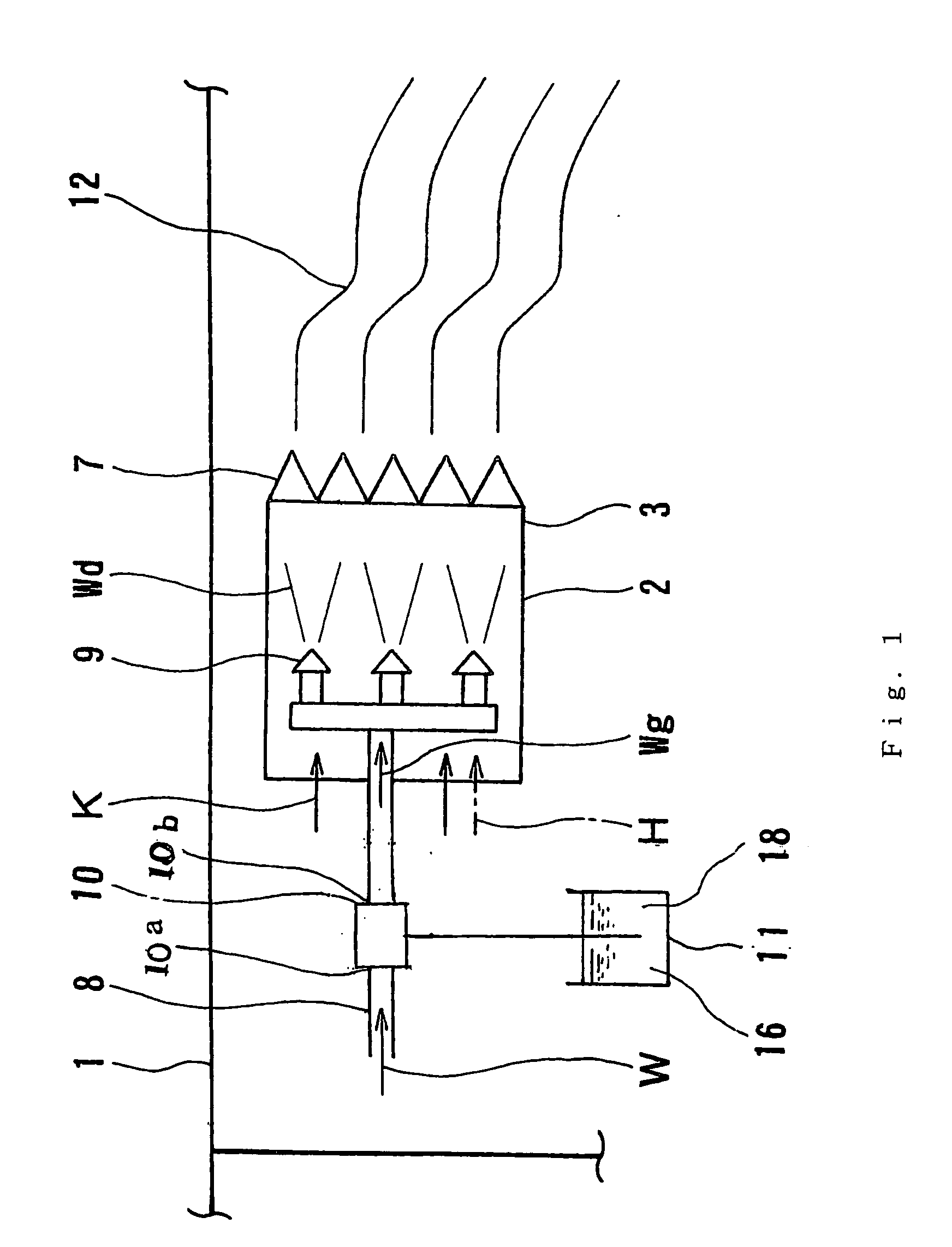

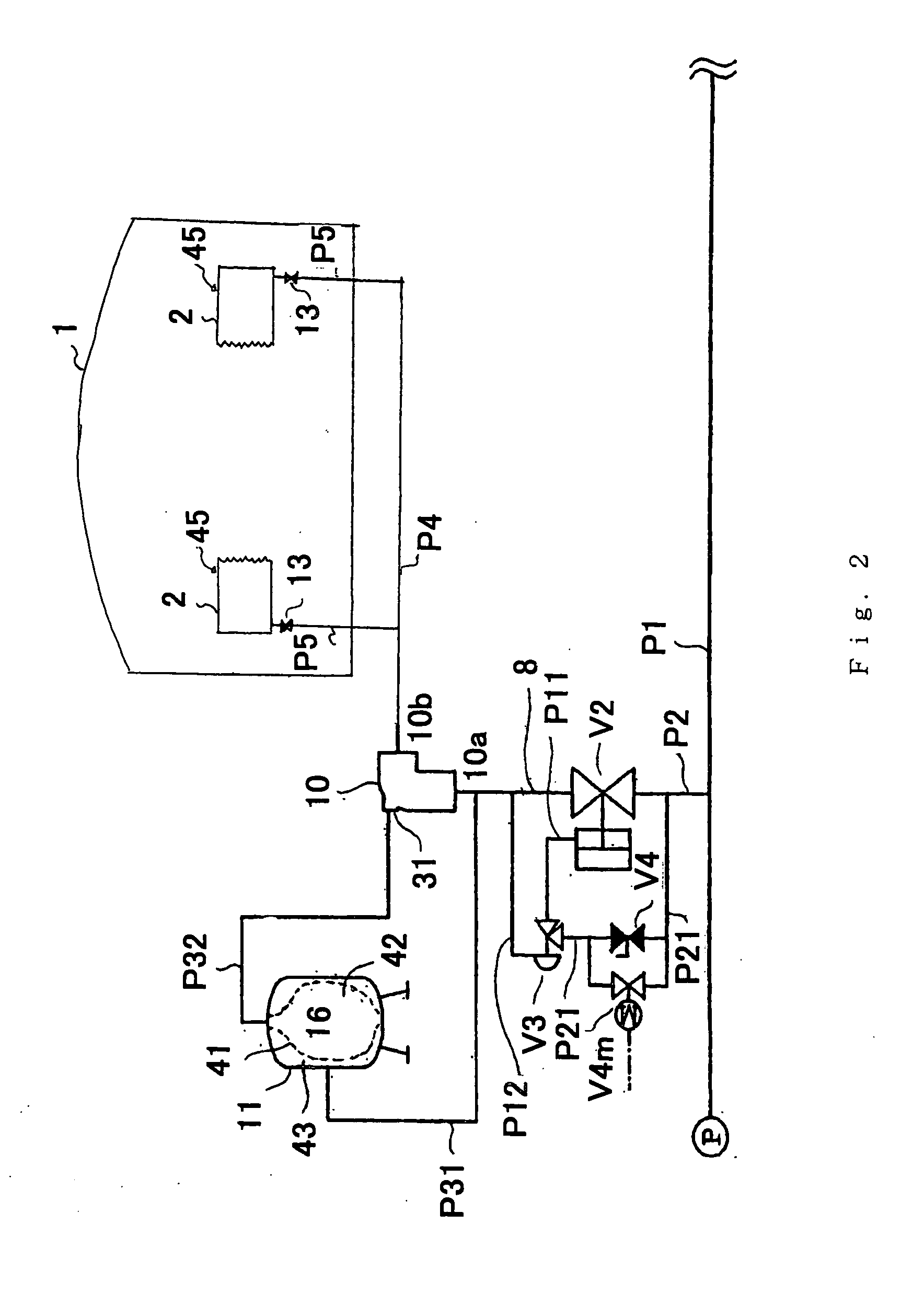

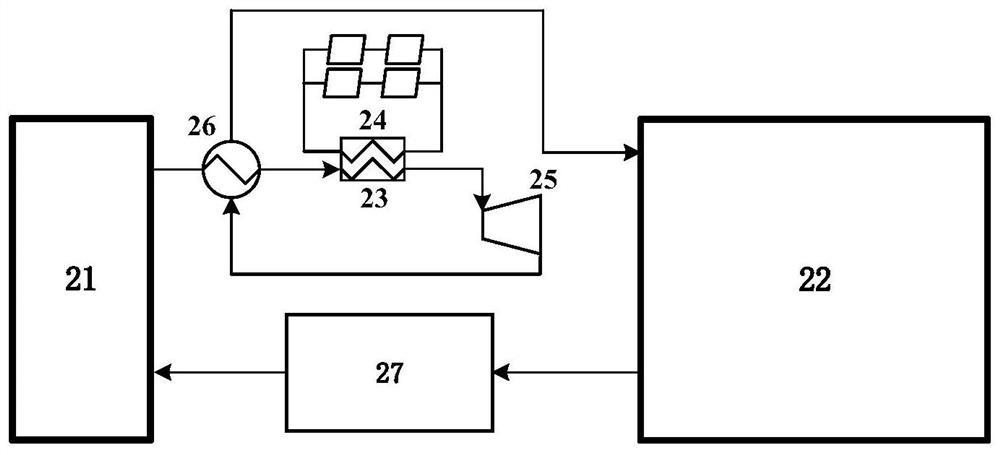

Overlapped organic rankine cycle efficient heat machine

InactiveCN103061835AEasy to passReduce transmission lossCombination enginesSteam engine plantsThermal energyOrganic Rankine cycle

The invention discloses an overlapped organic rankine cycle efficient heat machine which solves the problem that a single-stage organic rankine cycle expansion machine component is oversize in expansion ratio and achieves purposes of reducing expansion ratio through two-stage expansion, improving safety and durability of operation of an expansion machine and simultaneously improving efficiency of the heat machine. The organic rankine cycle efficient heat machine is mainly composed of a residue temperature heat source system (comprising renewable energy sources such as solar thermal power, various industrial waste heat, terrestrial heat, biomass energy, ocean thermal gradient and the like), a working medium pump, a cooling water system, a heat exchanger (respectively serving as an evaporator and a condenser on an evaporation side and a condensation side) and the expansion machine. The overlapped organic rankine cycle efficient heat machine is based on organic rankine cycle, uses the high-low-two-stage expansion machine, and uses superheated steam coming from the evaporator to drive the expansion machine to have expansion work to push a generator to generate electricity. Reclamation of energy is achieved on one hand, environmental protection can be favorably achieved on the other hand, and the overlapped organic rankine cycle efficient heat machine has good practical applicability and economical efficiency.

Owner:SOUTHEAST UNIV

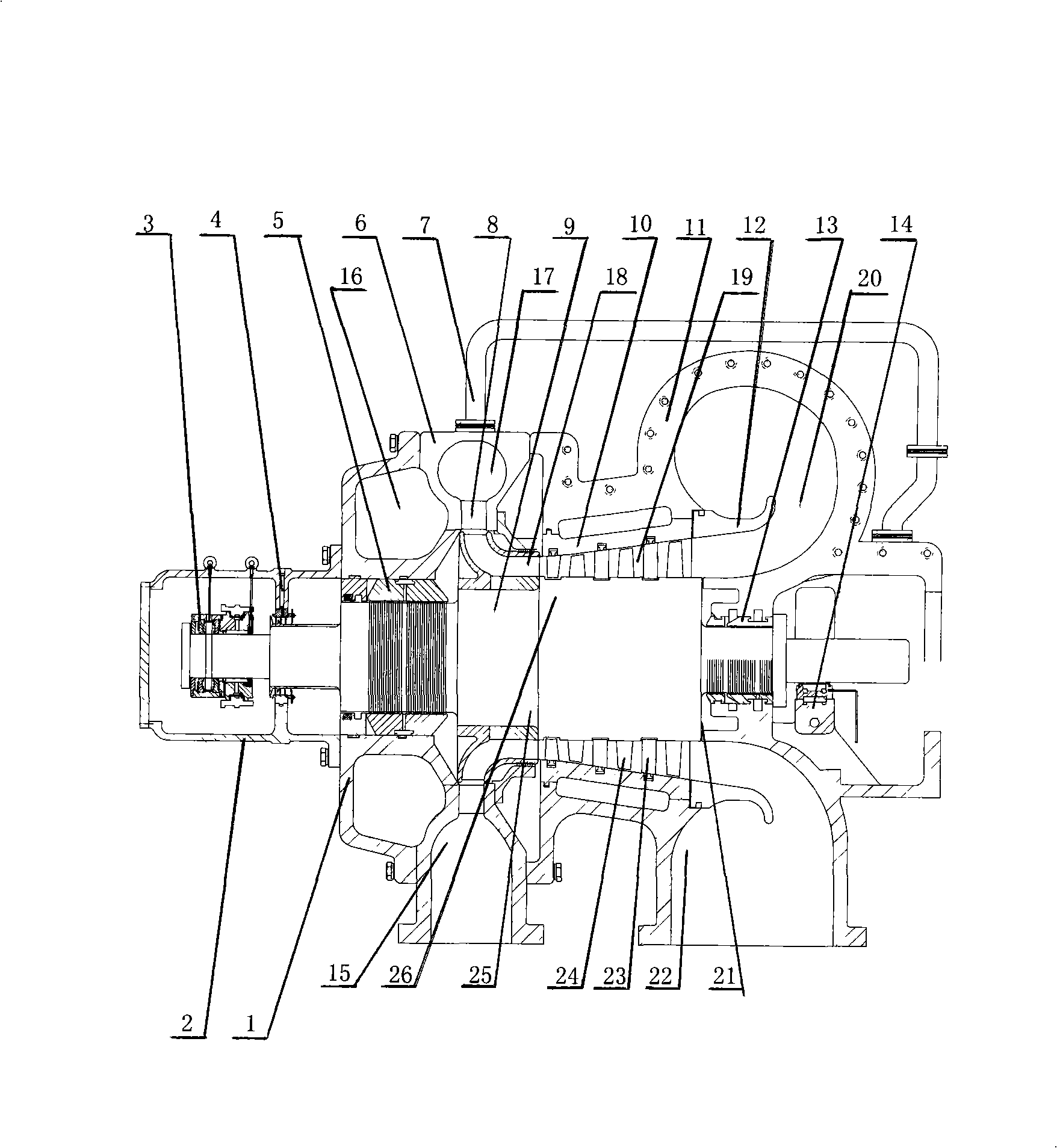

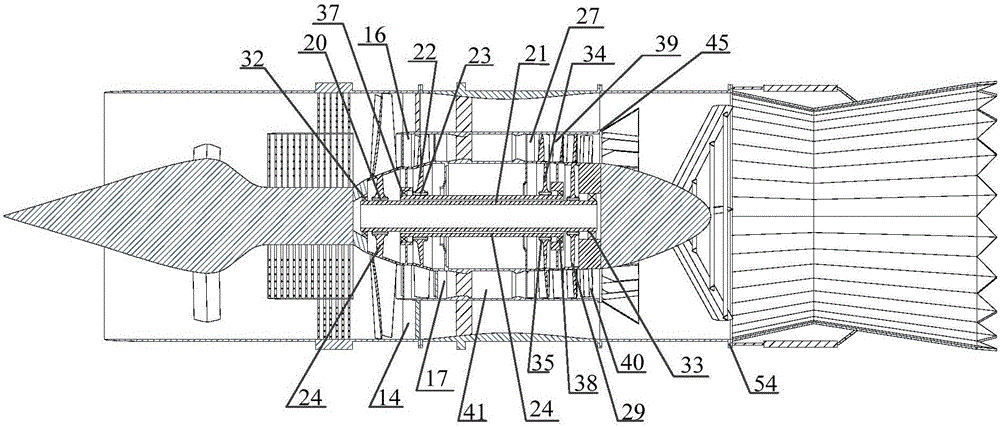

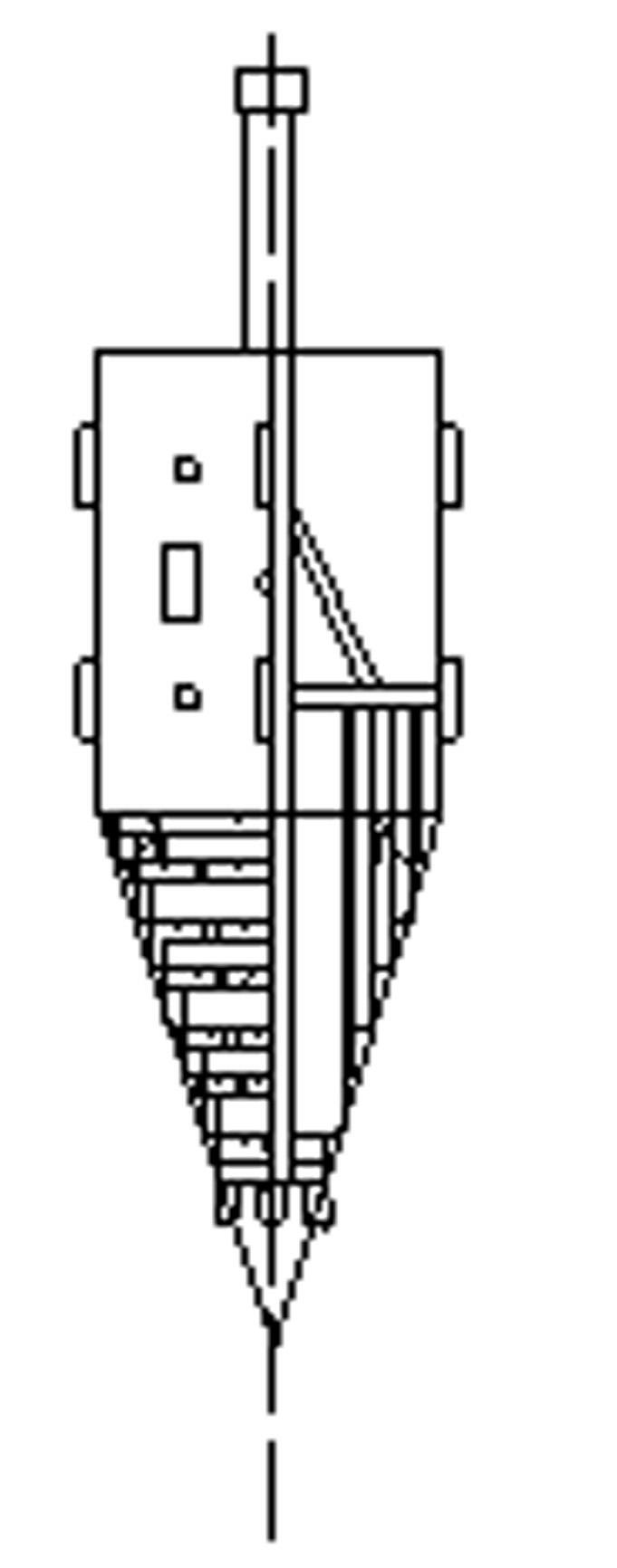

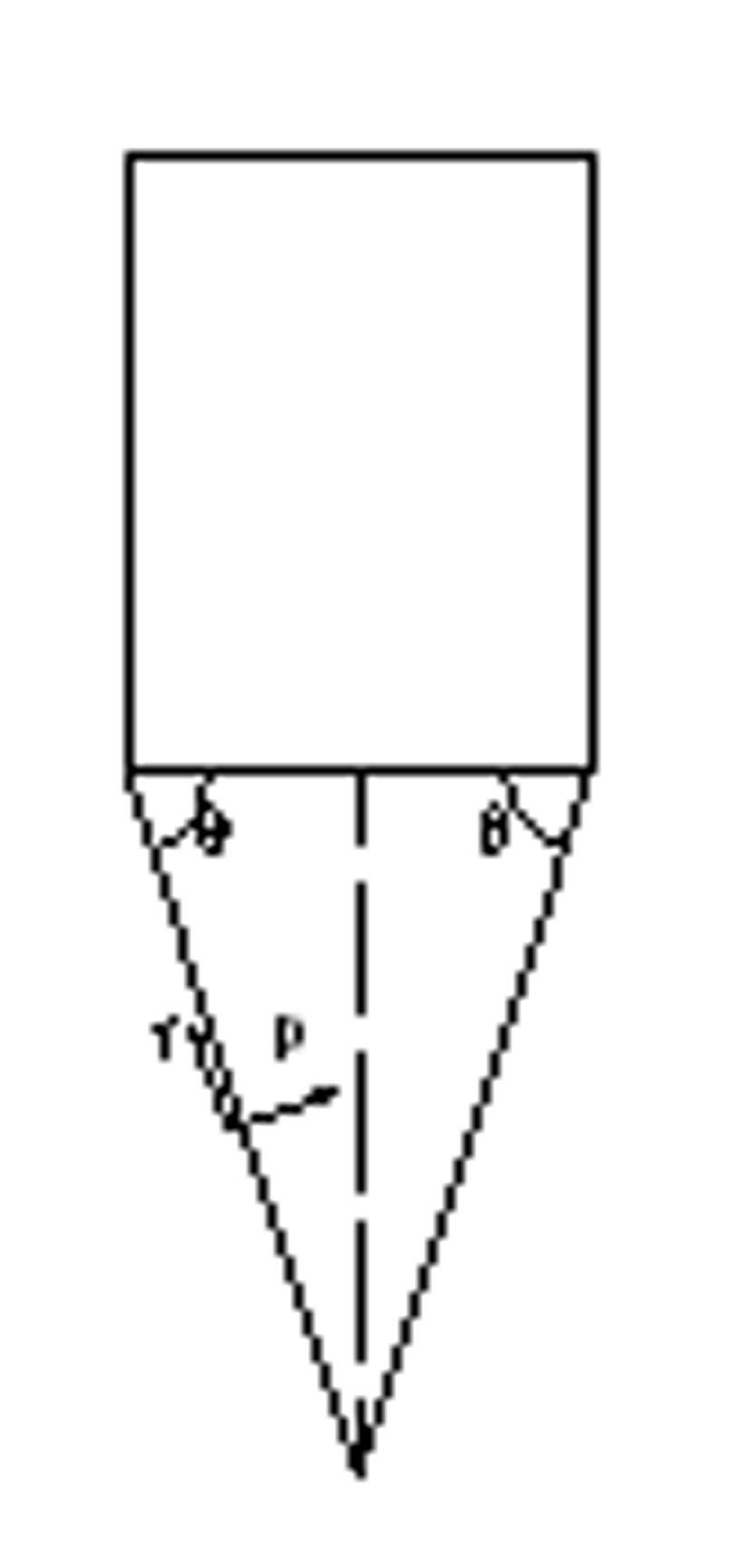

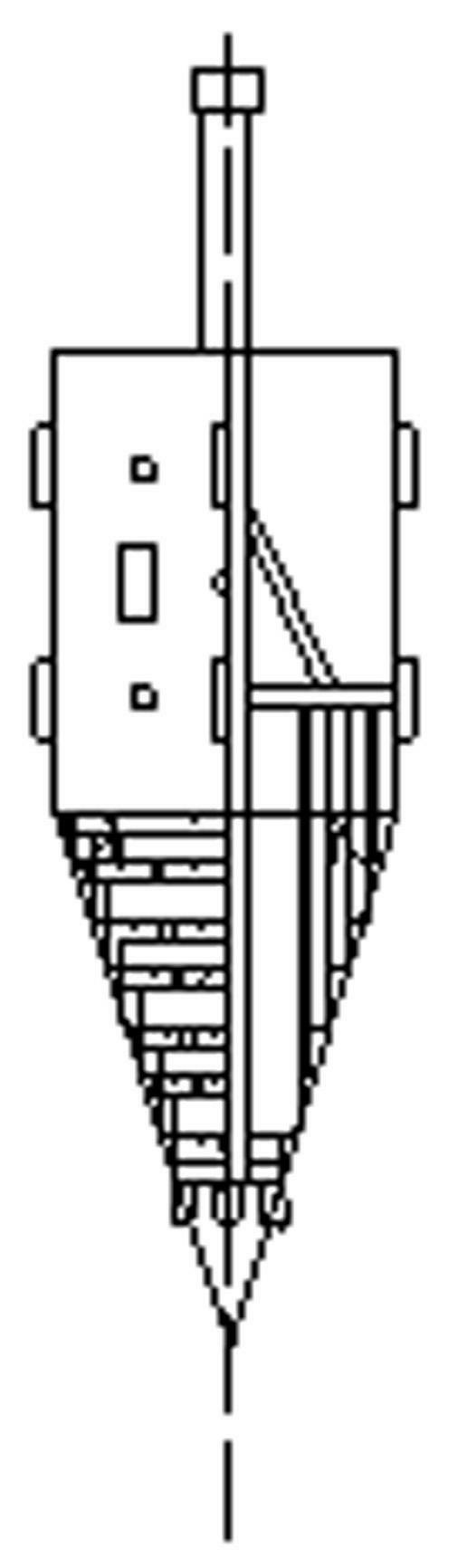

Combined turbine expansion machine

InactiveCN101265814AIncreased volume flowIncrease the expansion ratioBlade accessoriesNon-positive displacement enginesImpellerEngineering

The invention provides a composite turboexpander, which comprises a rotor. The rotor is arranged in a shell consisting of a high-pressure section casing and a low-pressure section casing; the high-pressure section casing is provided with an inlet pipe, and the inlet pipe communicates with an adjustable nozzle through a volute chamber; the high-pressure section of the rotor is provided with a radial impeller that communicates with the adjustable nozzle; the low-pressure section casing is provided with a blade carrier cylinder; the outlet of the blade carrier cylinder is provided with a flow deflecting ring, and the blade carrier cylinder is provided with a static blade; the low-pressure section casing is also provided with a volute chamber for exhausting and a vent-pipe; the low-pressure section of the rotor is provided with a moving blade; an axial flow stage comprises a first-stage static blade and a first-stage moving blade and communicates with the radial impeller and the flow deflecting ring; the pressure of the working medium decreases after going through the first-stage endocentric grade, the circumferential direction is changed into axial direction after the volume flow rate increases, and the axial flow stage is finally reached. The composite turboexpander has the advantages of simple structure, small volume flow rate for first-stage entry, high expansion rate, high expanding efficiency, convenient installation and maintenance, steady operation, etc.

Owner:冀江 +1

Expandable polystyrene particles with high foaming ratio and preparation method thereof

The invention relates to expandable polystyrene particles with high foaming ratio and a preparation method thereof, and particularly relates to raw materials for producing cushion packaging materials for electronics, building insulation materials and ocean floating products and a preparation method thereof. The expandable polystyrene particles with high foaming ratio are characterized by being prepared from styrene, soft water, nucleating agent, calcium phosphate, benzoyl peroxide, tert-butyl perbenzoate, white oil, a molecular chain acting force regulating agent, pentane, a surface lubricant and the like as raw materials by the steps of mixing, reacting, filtering and drying. The foam plastic prepared from the expandable polystyrene particles has low production cost; and used as a packaging material, the foam plastic is hard to break and can prevent the packed material from being damaged.

Owner:无锡兴达泡塑新材料股份有限公司 +5

Low dialectric composite material and laminate and printed circuit board thereof

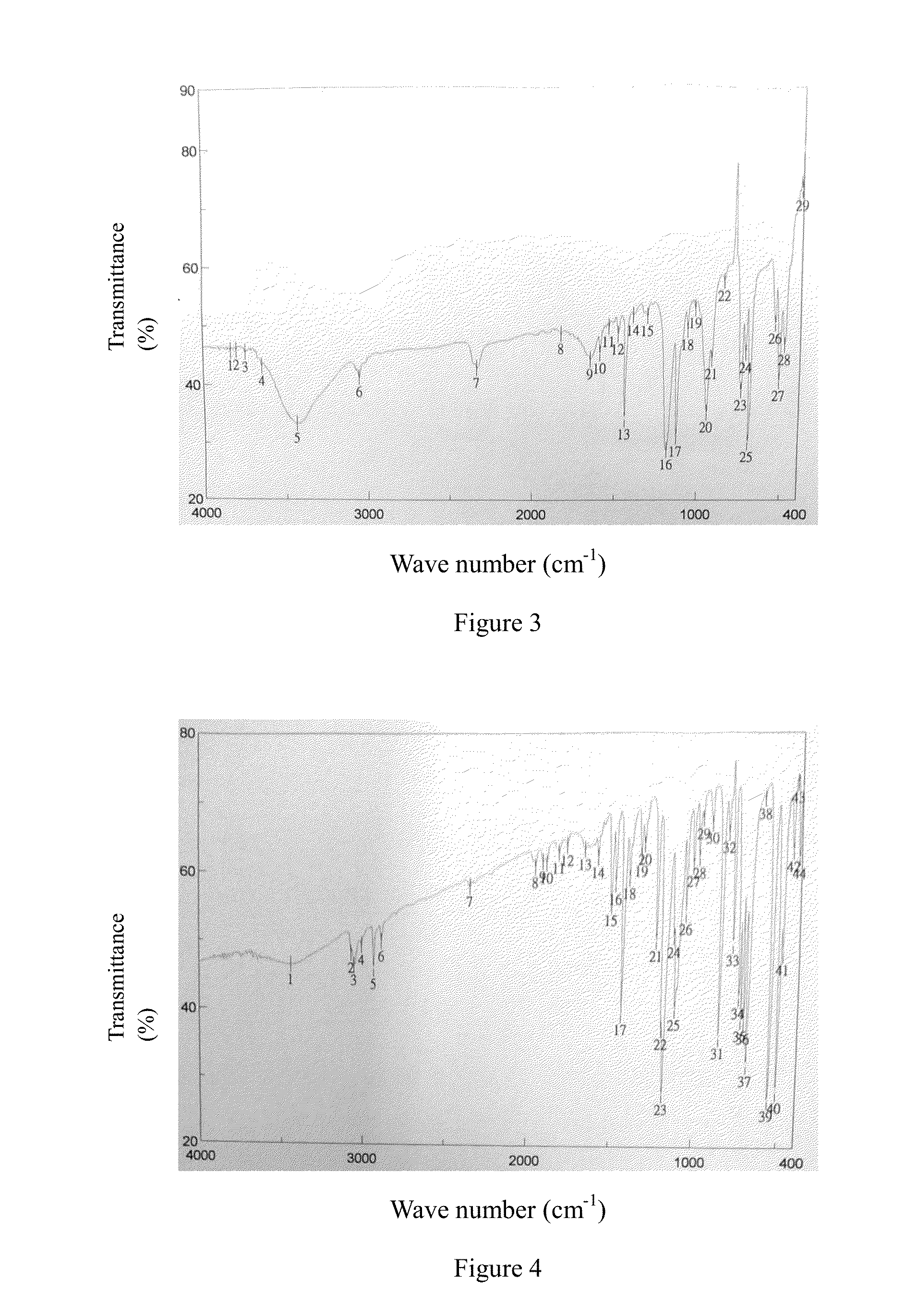

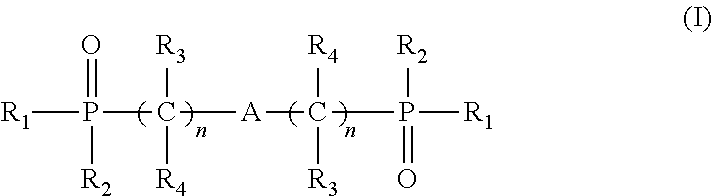

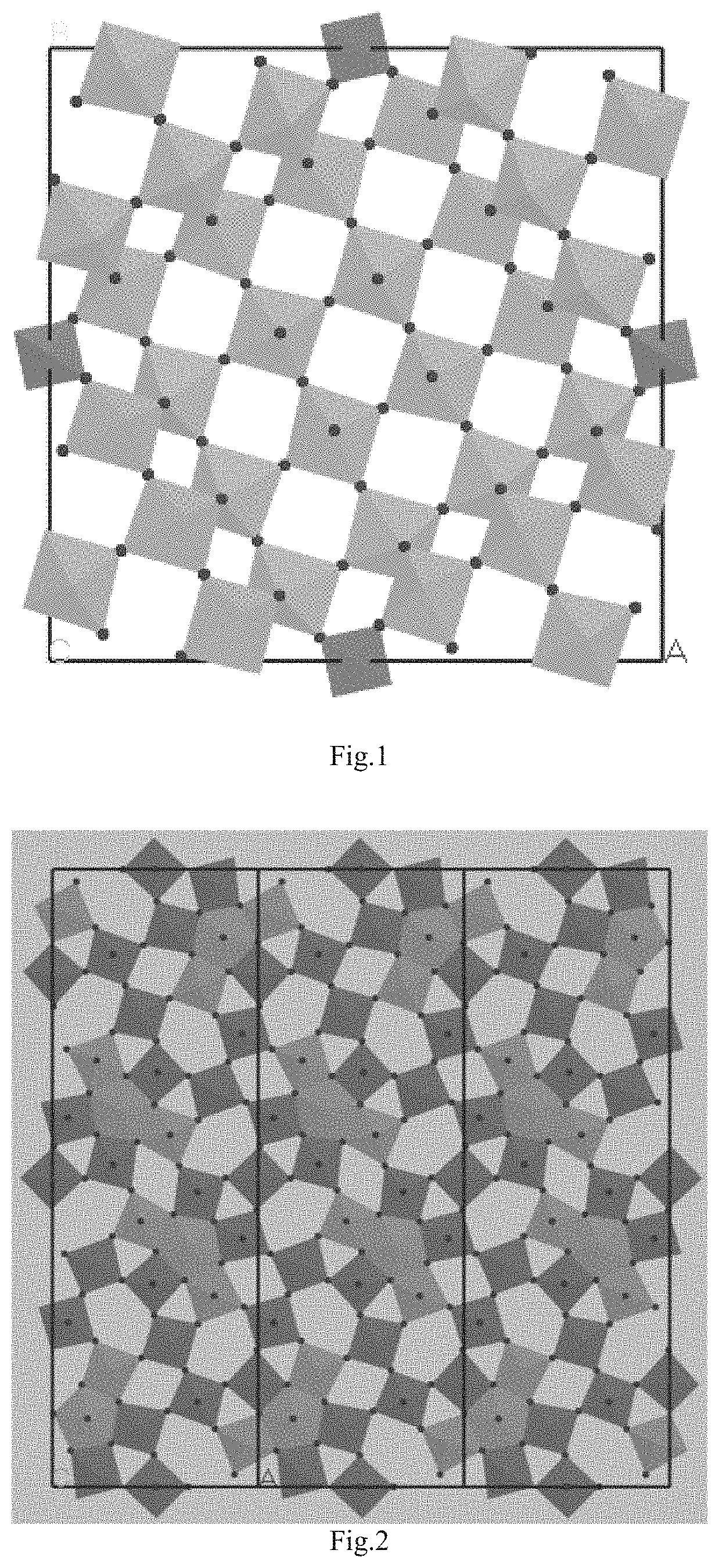

ActiveUS20160021739A1High glass transition temperatureLow expansion ratioGroup 5/15 element organic compoundsDecorative surface effectsDiphenylphosphine oxideThermal expansion

The present invention belongs to the technical field of resin composite materials, in particular relates to a low dielectric composite material and a laminate and printed circuit board prepared therefrom. The composite material is obtained by adhering a low dielectric resin composition with phosphorus-containing flame retardant onto a substrate; the composition comprises the following components: (A) phosphorus-containing flame retardant; (B) vinyl compound. The phosphorus-containing flame retardant has a structure as shown in formula (I).In the present invention, diphenylphosphine oxide is derivatized, and prepared a phosphorus-containing flame retardant, which has no reactive functional groups, has better dielectric properties, and has high melting point, and upon combining with a vinyl compound, a resin composition is obtained, and a composite material having low thermal expansion ratio, high heat resistance, high glass transition temperature, and low dielectric constant and dissipation factor, can be made from the resin composition, and a laminate and printed circuit board having the properties of high glass transition temperature, low dielectric properties, halogen-free flame retardancy, low thermal expansion coefficient of the laminate, etc., can be made from the composite material.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

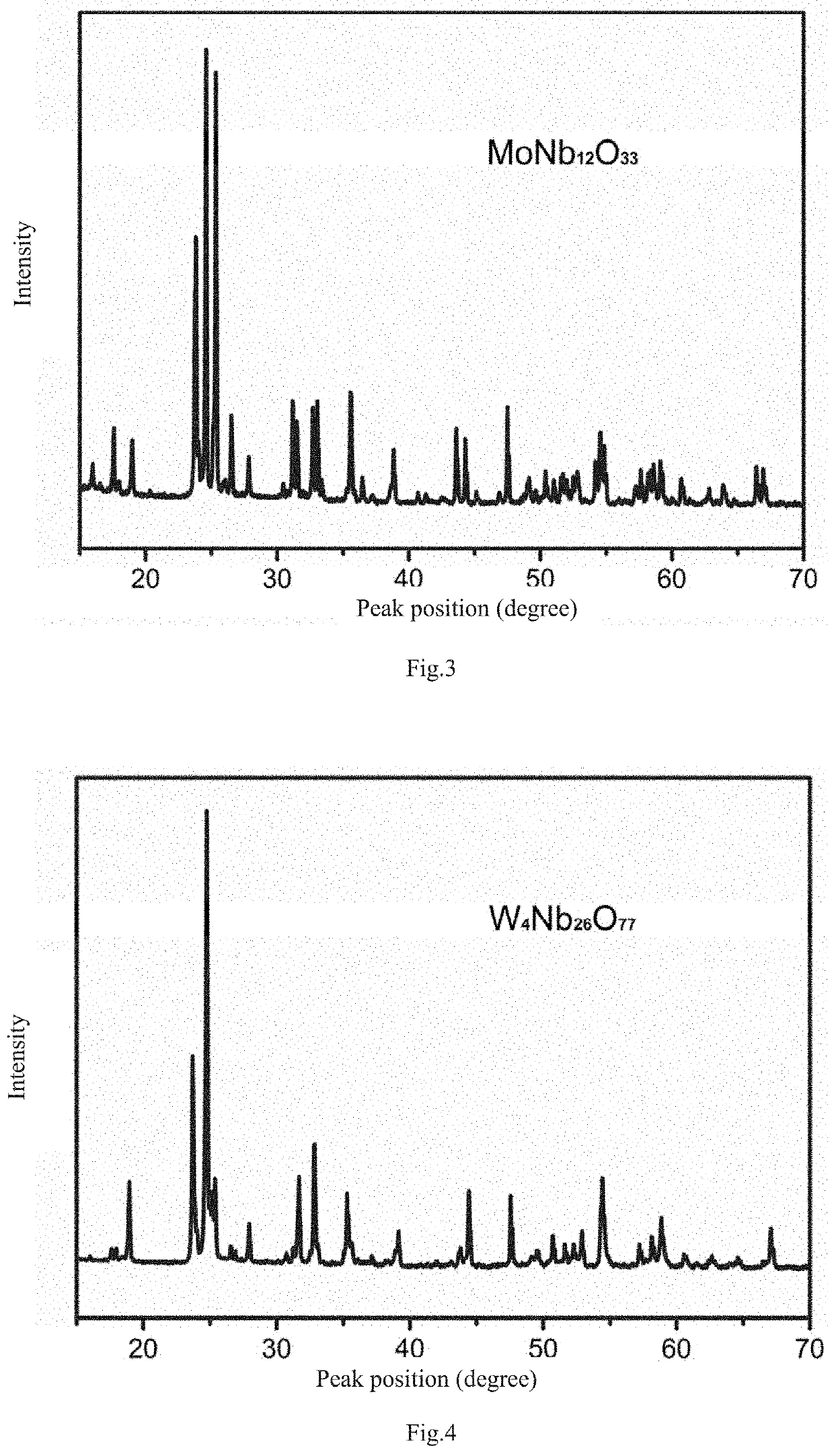

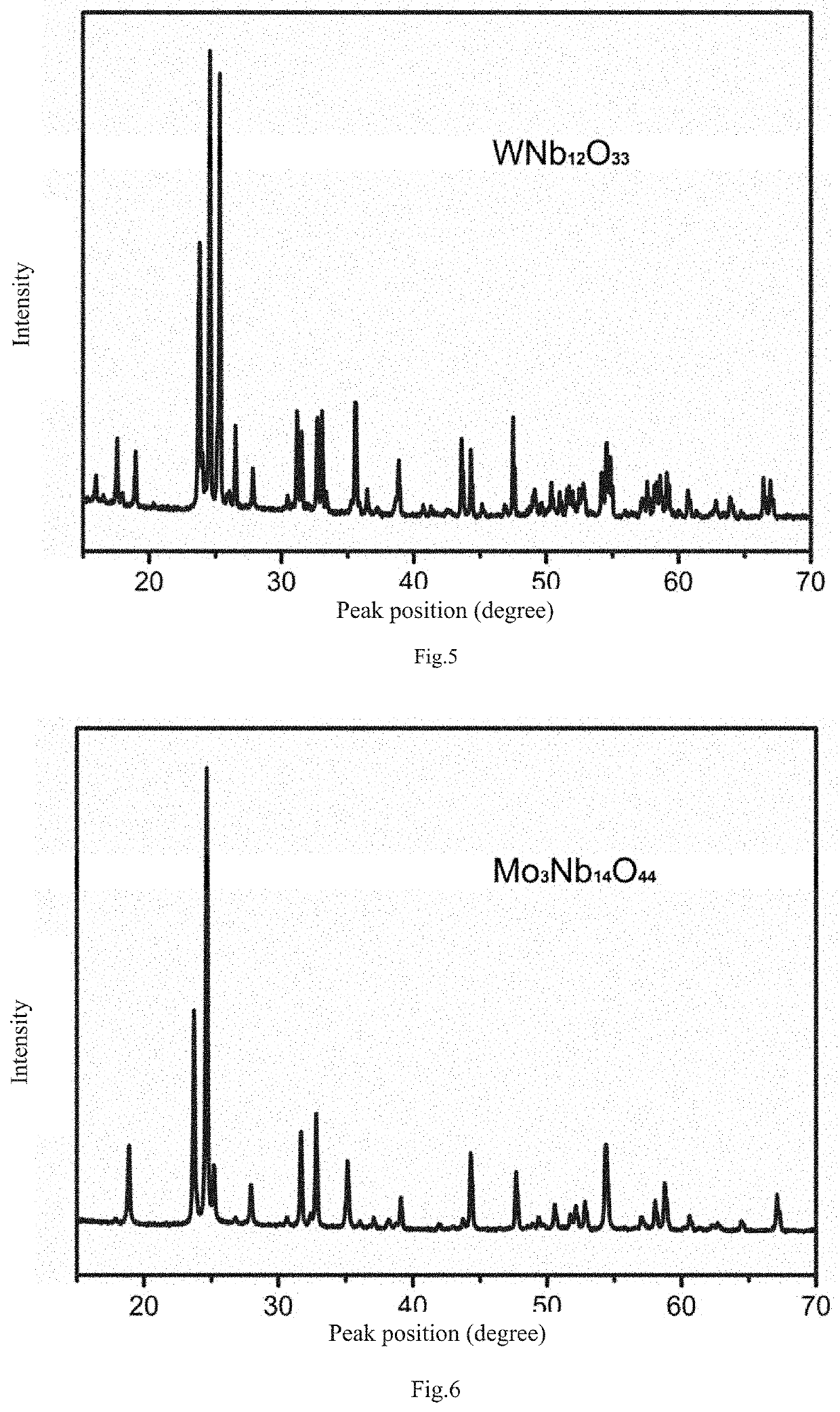

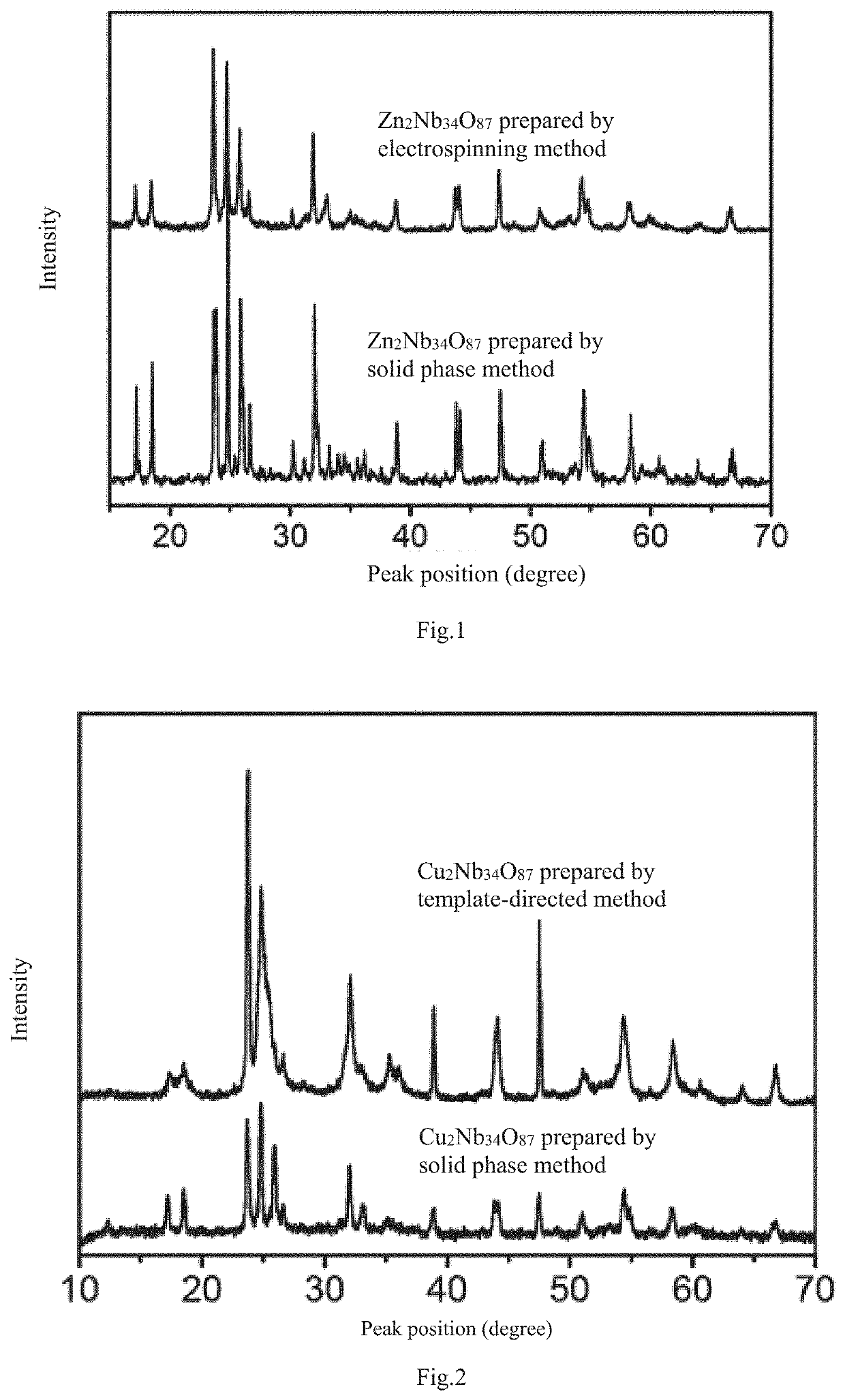

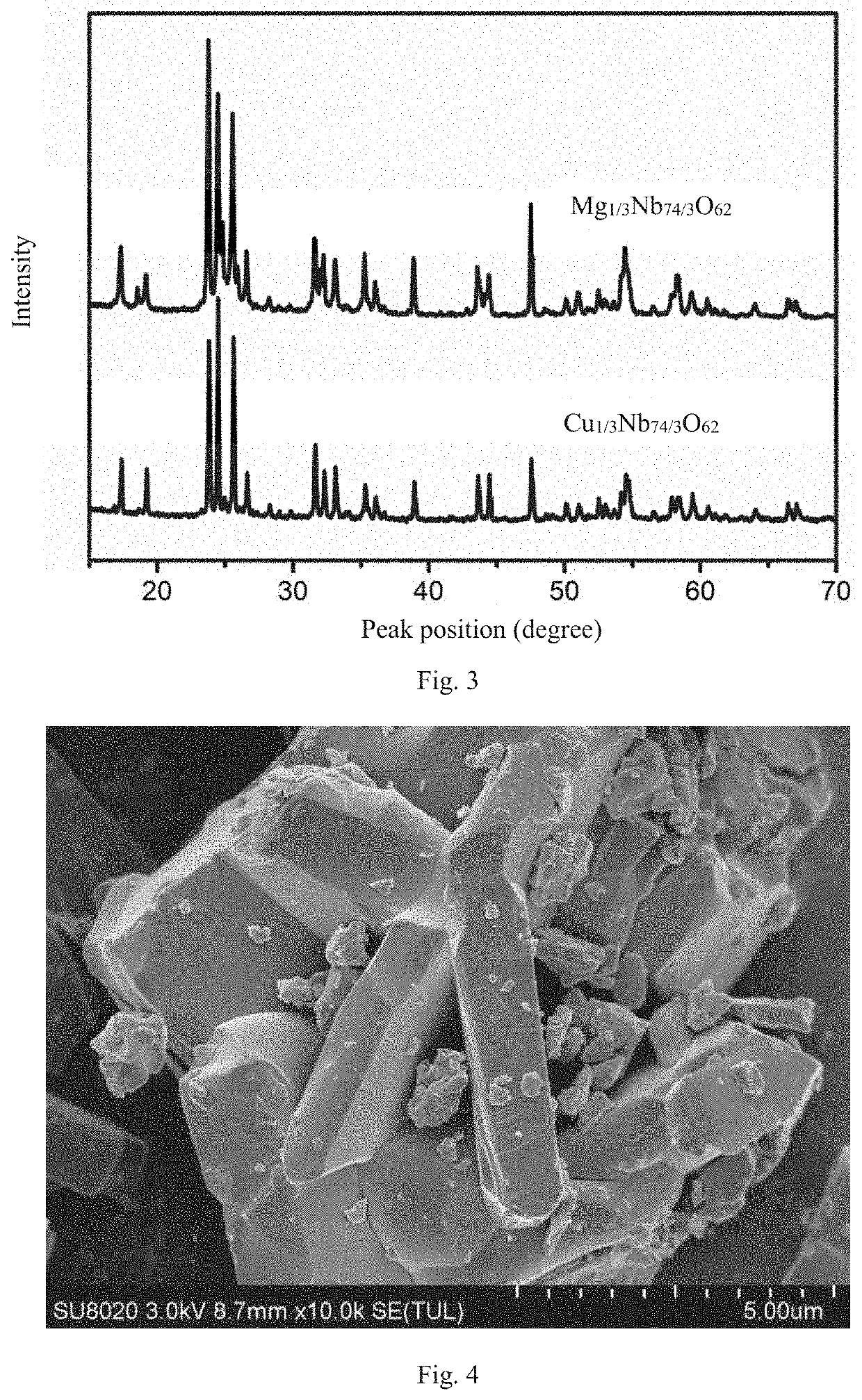

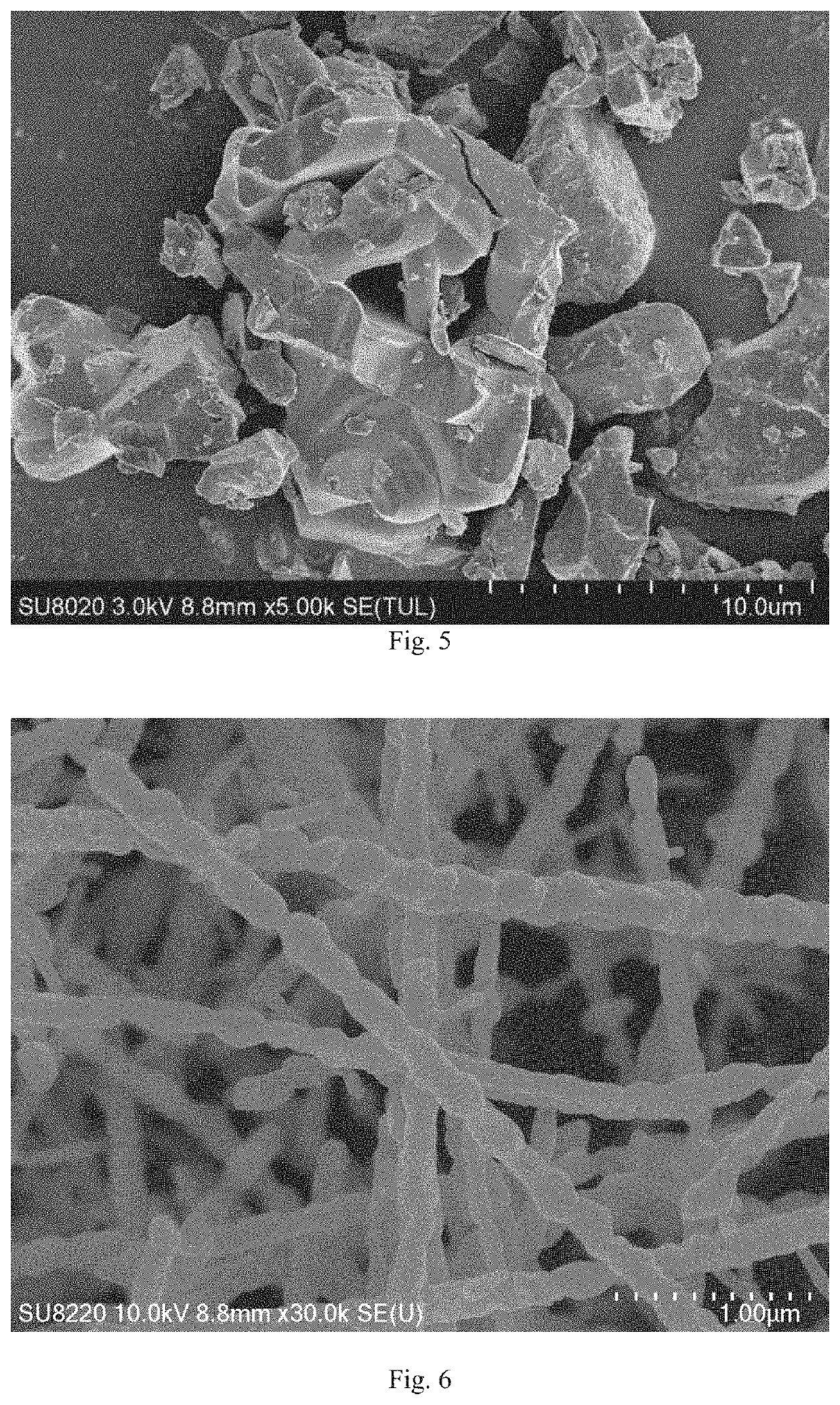

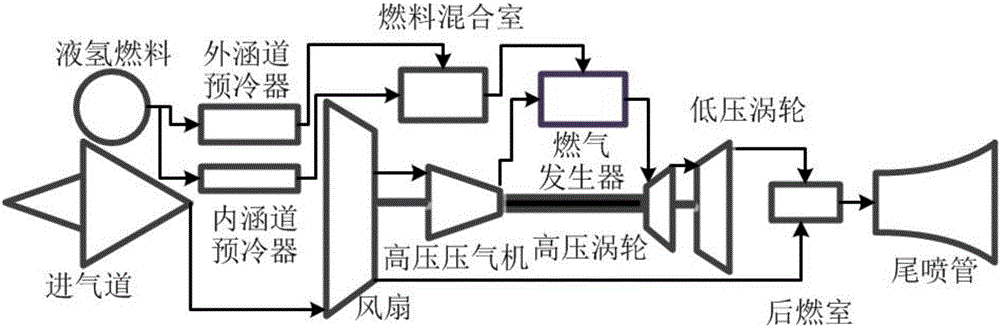

Anode Material of Lithium Ion Battery And Non-aqueous Electrolyte Battery

InactiveUS20200152963A1Improve charge rate performanceImprove performanceNegative electrodesElectrode collector coatingPhysical chemistryAqueous electrolyte

An anode material of a lithium-ion battery according to the present invention is disclosed. A chemical formula of the anode material of the lithium-ion battery is MxNbyOz, wherein, M is a pentavalent non-niobium metal ion or a hexavalent non-niobium metal ion, and x, y, z satisfy the following conditions: 1<x≤16, 2≤y≤28, and 13≤z≤94.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

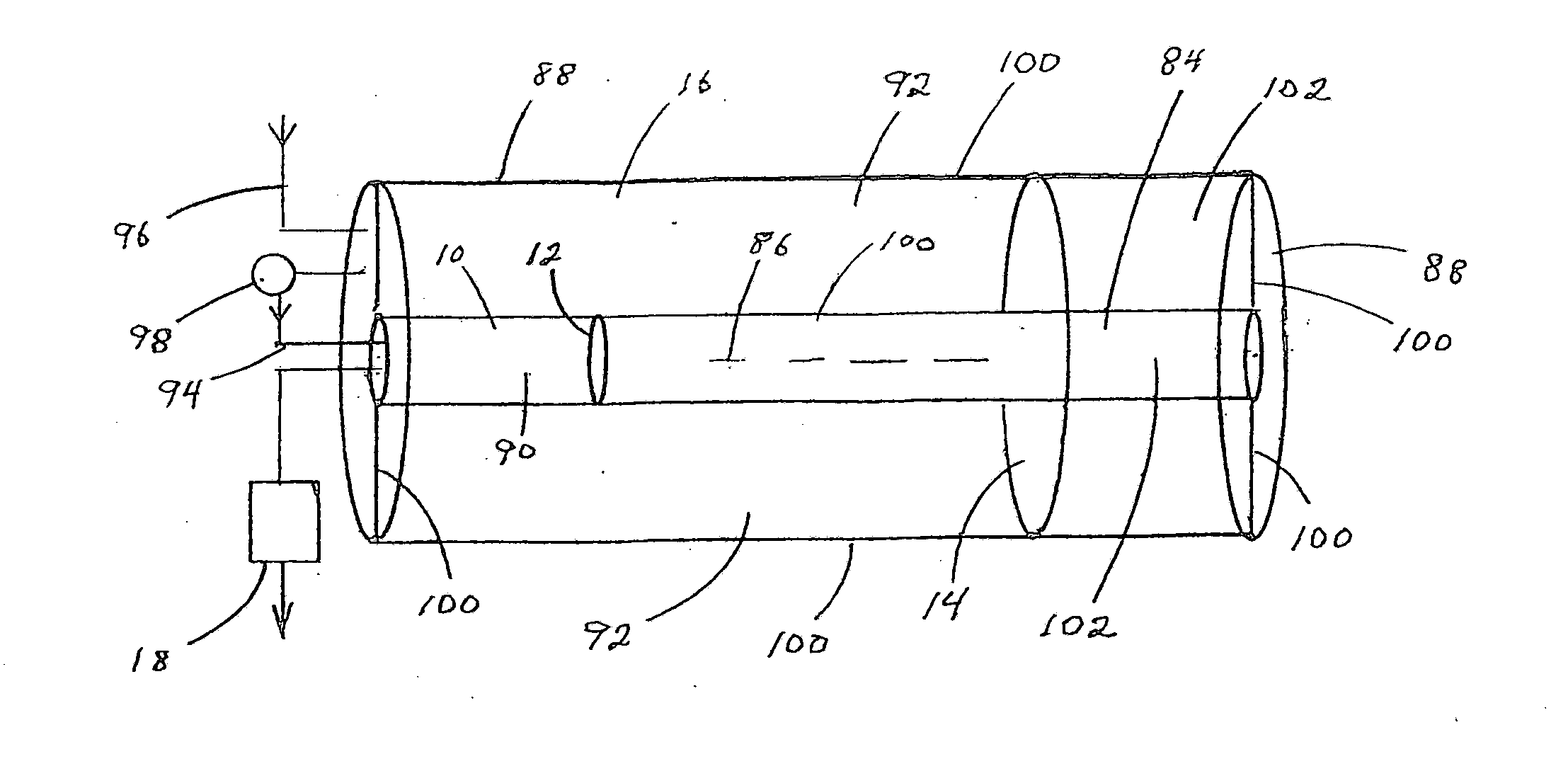

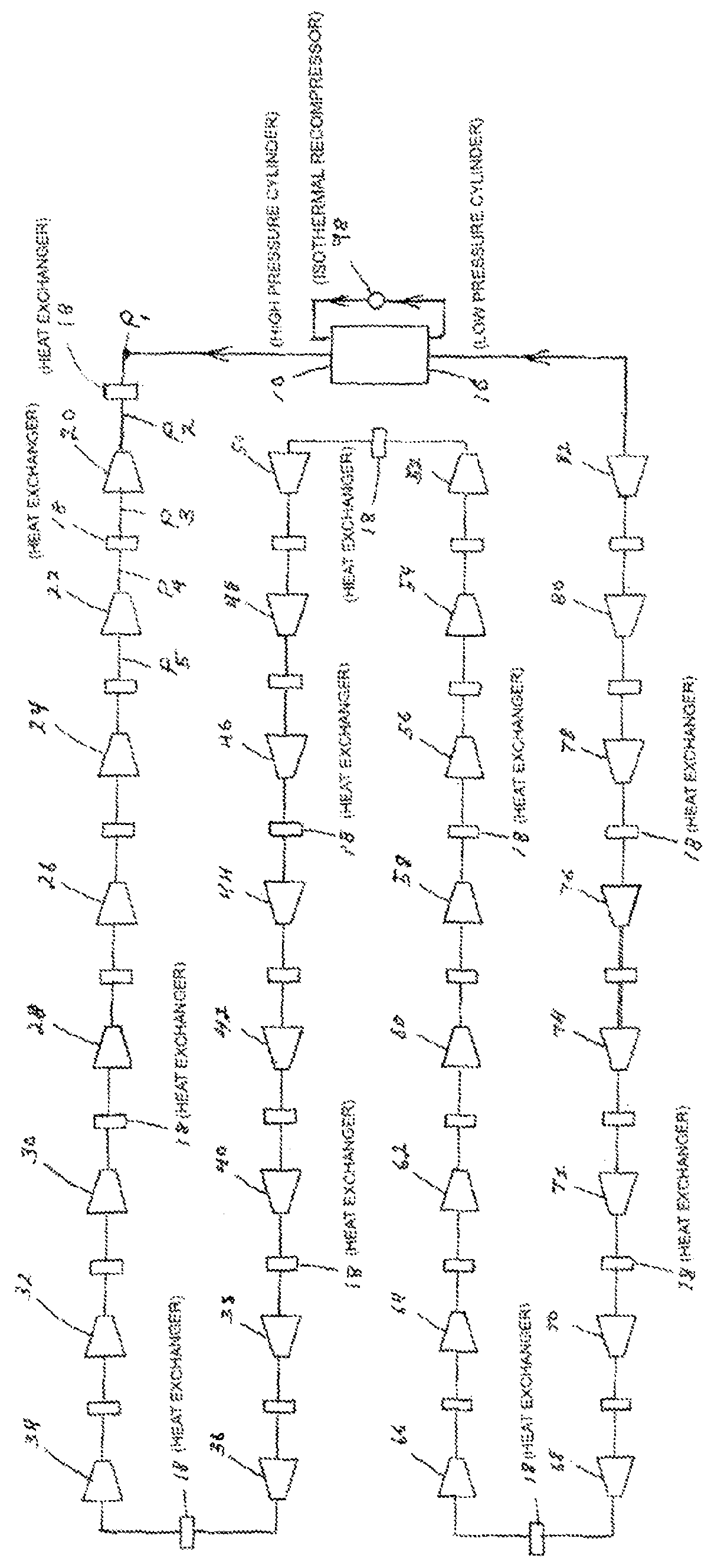

Closed-cycle cryogenic engine and operating method for propelling vehicles and generating electricity

ActiveUS20150369221A1Enormous propulsive powerImprove power densityFrom solar energyLighting and heating apparatusElectricityWorking fluid

A closed-cycle cryogenic engine is provided for propelling vehicles or generating electricity at high power densities without consuming any working fluid. The engine comprises a working fluid having a high specific heat that remains in a gaseous phase. The high temperature heat reservoir is the natural environment and the low temperature heat reservoir is created artificially by evaporating water. By isothermally compressing the working fluid at low temperature by absorbing the heat of compression by evaporating water, it is possible to extract a large amount of natural heat energy from the environment and convert a large fraction of it into net output work. Since the latent heat of evaporating water is very high, very little water is consumed which represents the engine's only fuel.

Owner:MINOVITCH MICHAEL

High expansion foam fire-extinguishing system

InactiveUS20080128141A1Perform reliability and efficientlyLow lipophilic natureDomestic plumbingSpray nozzlesSurface-active agentsExpansion ratio

Owner:NOHMI BOSAI LTD

Method for sealing closed gas drainage hole in soft coal bed areas

ActiveCN103244073ASolve the problem of air leakageReasonable designSealing/packingFree wallCement paste

The invention relates to the technical field of mine ventilation and safety-type coal bed gas drainage, particularly to a method for sealing soft coal bed gas drainage hole areas, and solves the problem of severe air leakage of soft coal bed gas drainage hole areas. The method comprises the steps of (1), sealing gas drainage holes on a roadway lane; (2), evenly distributing 2-4 closed short holes which are 6-8m in depth within a range with the circle center of each gas drainage hole serving as the center and the radius of 1-1.5m; (3), filling each closed short hole with low-consistence high-expansion cement which permeates into coal bed fracture areas until cement paste seeps from a coal wall; (4), standing for 20-24h for solidification of cement paste to form a fracture-free wall composed of coal bodies and cement. According to the method, the design is reasonable, the hole sealing technology is improved, the defects of existing hole sealing technologies are overcome, and the problem of air leakage of coal walls is solved thoroughly.

Owner:JINCHENG MINGSHI COAL LAYER USING

Anode Material of Lithium Ion Battery And Non-aqueous Electrolyte Battery

ActiveUS20200112018A1Improve charge rate performanceImprove performanceSolid electrolytesSecondary cellsPhysical chemistryAqueous electrolyte

An anode material of a lithium-ion battery and a non-aqueous electrolyte lithium-ion battery are disclosed in the present invention. The anode material of a lithium-ion battery, wherein, a chemical formula of the anode material of the lithium-ion battery is MxNbyOz, wherein, M is a bivalent non-niobium metal ion, and x,y,z satisfy the following conditions: 0<x≤3, 1≤y≤34, and 3≤z≤87.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

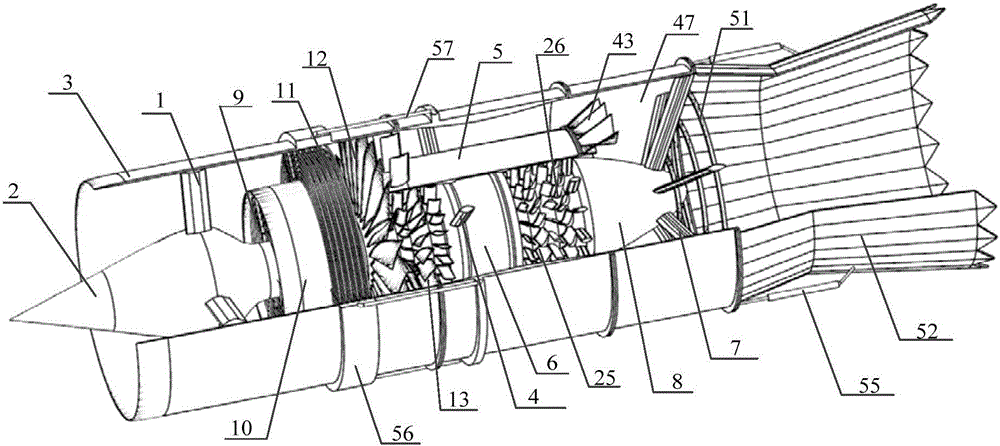

Fuel-rich pre-burning turbofan engine

ActiveCN106438104AImprove specific impulseIncrease thrust-to-weight ratioJet propulsion plantsAviationAir compressor

The invention discloses a fuel-rich pre-burning turbofan engine and relates to an aero-engine technology. An inner duct precooler is located in an inner duct at the back part of an air inlet channel and is located in the upstream position of a fan, and air enters an inner duct of a cooling fan. An outer duct precooler is located in an outer duct at the back part of the air inlet channel and is located in the upstream position of the fan, and air enters an outer duct of the cooling fan. Inner duct air discharged by the fan is continuously compressed in a high-pressure air compressor. The inner duct precooler and the outer duct precooler adopt fuel as cooling media, and fuel heated by the air is mixed in a fuel mixing chamber. The mixed fuel and the air discharged by the high-pressure air compressor are subjected to fuel-rich burning in a gas generator. Fuel-rich gas discharged by the gas generator works in a high-pressure turbine and a low-pressure turbine, and the fan and the high-pressure air compressor are driven to compress the air. The fuel-rich gas discharged by the turbines and outer duct air discharged by the fan are mixed and burnt in an after-burning chamber. High-temperature gas discharged by the after-burning chamber enters an exhaust nozzle to expand to produce thrust force. Thus, the high-specific-impulse and high-Mach-number flight can be realized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

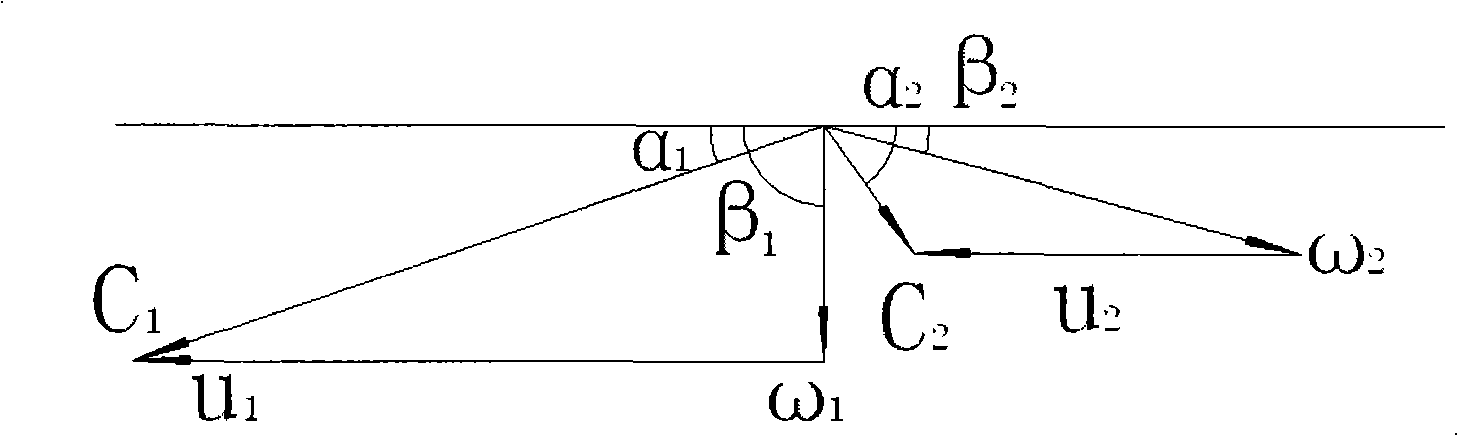

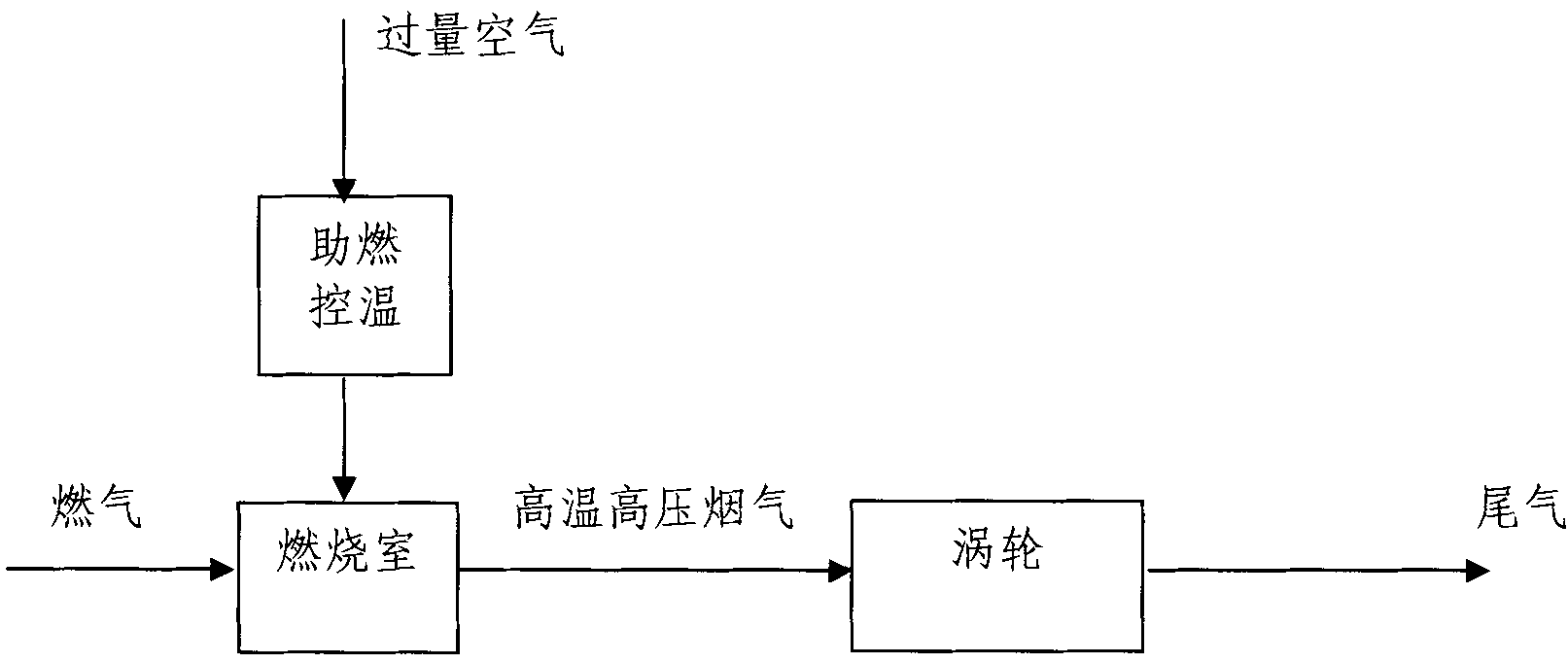

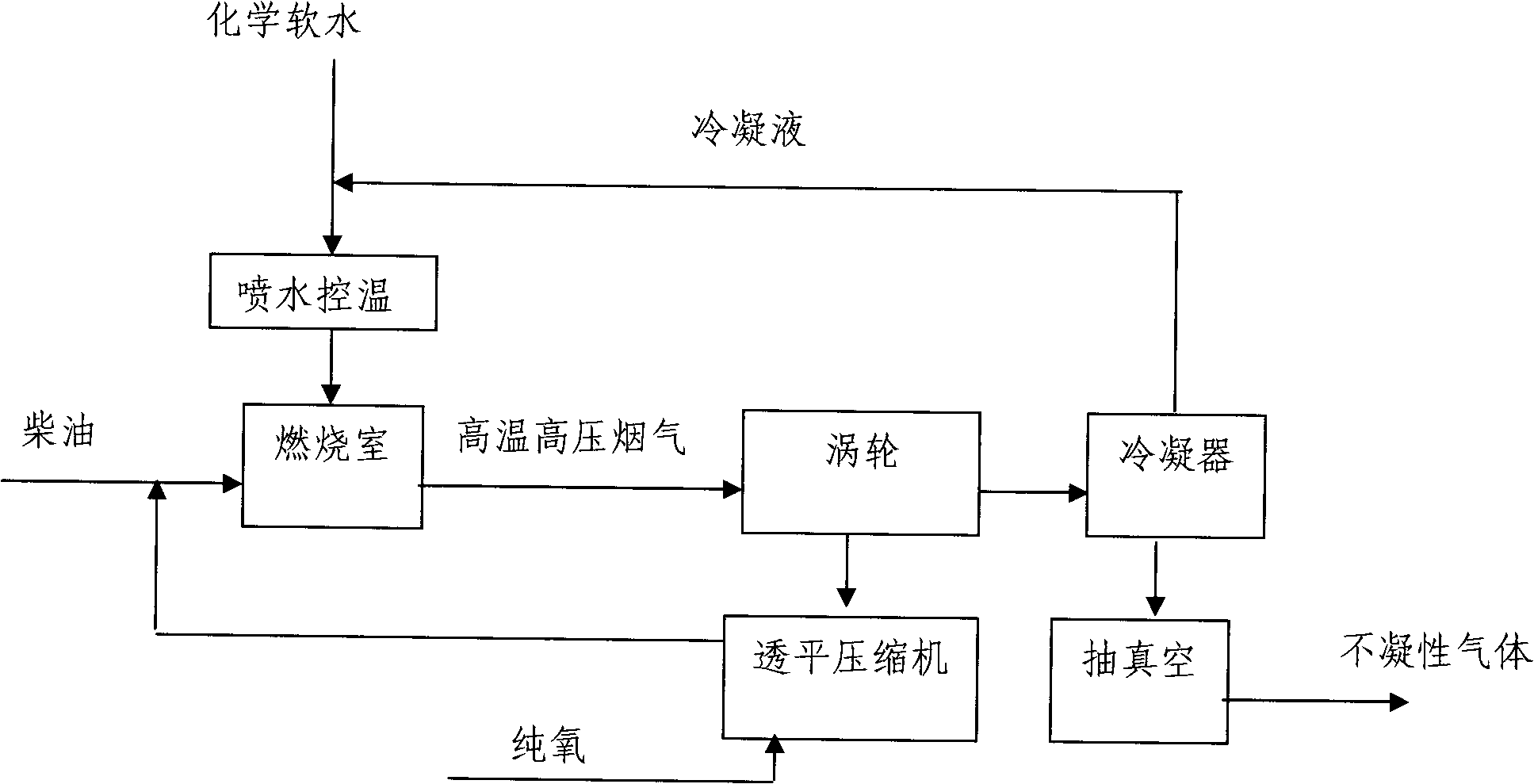

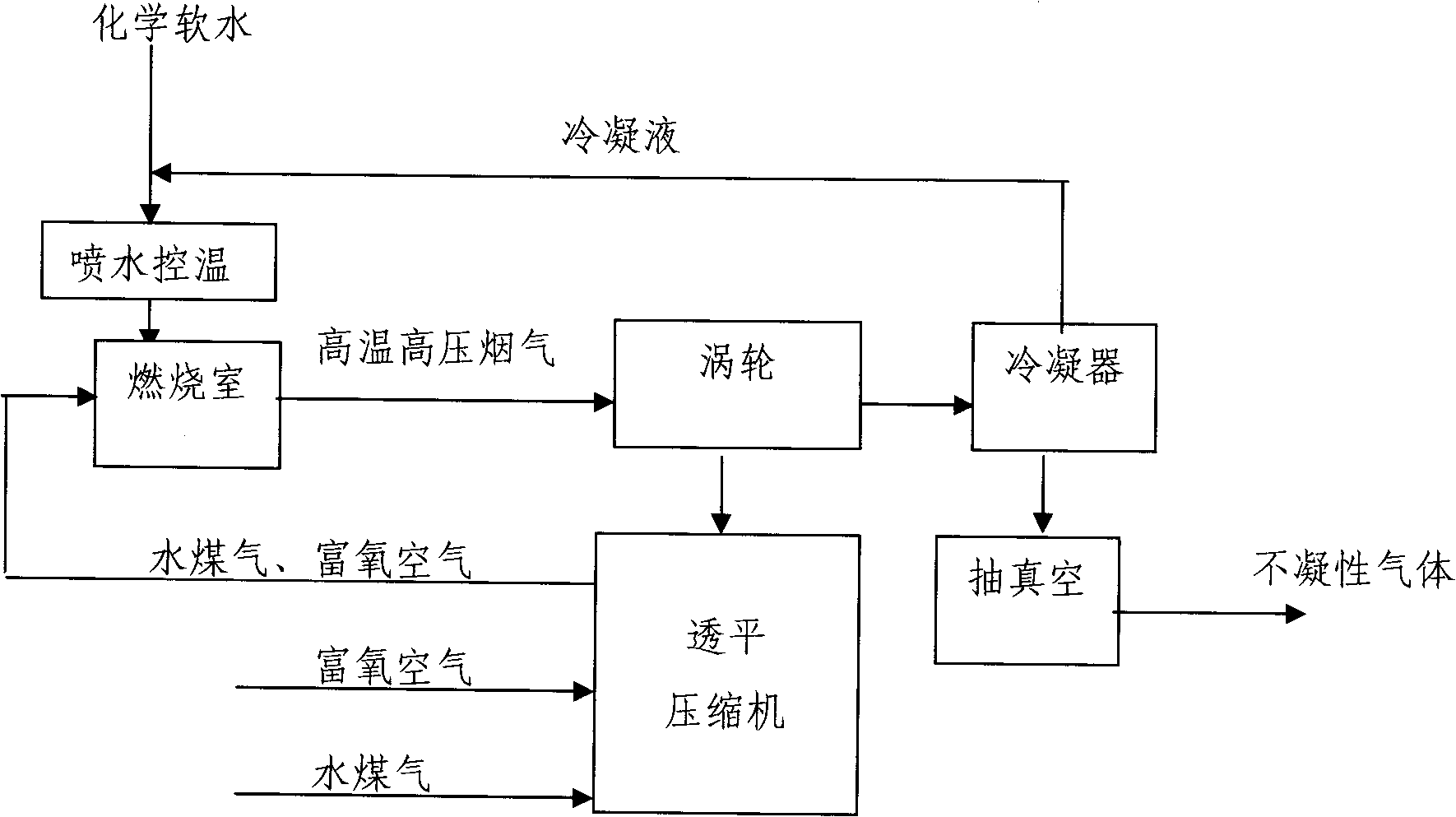

Thermal circulation process of gas turbine based on pure oxygen or oxygen-enriched combustion

InactiveCN101787930AIncrease temperatureIncrease intake pressureTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWater vapor

The invention discloses a thermal circulation process of a gas turbine based on pure oxygen or oxygen-enriched combustion, which comprises the following steps: compressing liquid fuel or gas; compressing oxygen gas or oxygen-enriched air; carrying out mixed combustion of the liquid fuel or the gas and the oxygen gas or the oxygen-enriched air; spraying water for controlling temperature; expanding high temperature and high pressure flue gas after combustion in the gas turbine for applying work; cooling most of water vapor in tail gas with circulating water in a condenser, wherein the condensed water circulates to a combustion chamber to be used for spraying water for controlling temperature, and the non-condensable gas is extracted by a vacuum pump; or exhausting gas under normal pressure without the use of the vacuum pump. By adopting direct combustion of the pure oxygen or the oxygen-enriched air and adopting the water spraying mode to replace excess air for controlling temperature, the air inflow is small, the amount of compression of a compressor is small, the restriction of the optimal pressure gas ratio is eliminated, the circulating intake pressure is improved, the non-condensable gas in the tail gas is little, and the exhaust pressure can be reduced through vacuum condensation. Because the process has high circulating intake pressure and low exhaust pressure, the expansion ratio of the gas turbine is improved, thereby improving the generating efficiency.

Owner:北京名都厚德科技有限公司

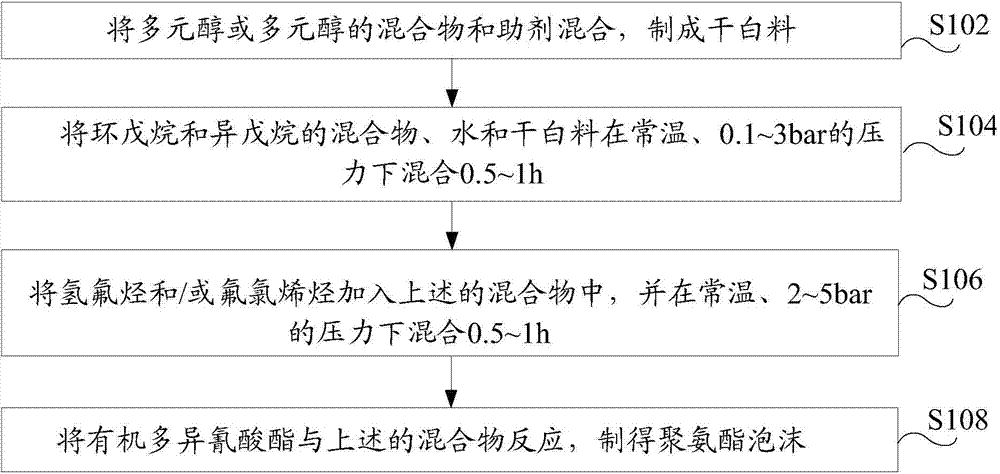

Foaming agent composition, polyurethane foam and manufacturing method thereof

The invention provides a foaming agent composition, a polyurethane foam and a manufacturing method thereof. The foaming agent composition comprises a cyclopentane-isopentane mixture, hydrofluorocarbon and / or fluorochloroalkene and water. The polyurethane foam prepared from the foaming agent composition has greatly lower molding density; and in the process of manufacturing equivalent polyurethane foam, the mass of the required foaming agent composition and other materials for manufacturing the polyurethane foam is reduced, thereby lowering the manufacturing cost of the polyurethane foam. Besides, the ODP (ozone depletion potential) of the foaming agent composition is zero, so the foaming agent composition is harmless to the ozone and is more environment-friendly. In addition, the polyurethane foam prepared from the foaming agent composition has the advantages of lower heat conductivity coefficient, favorable thermal-insulation property, favorable flowability, uniform density distribution, smooth surface, higher foam compression strength and higher dimensional stability, so that the performance of the polyurethane foam can be enhanced.

Owner:HEFEI HUALING CO LTD

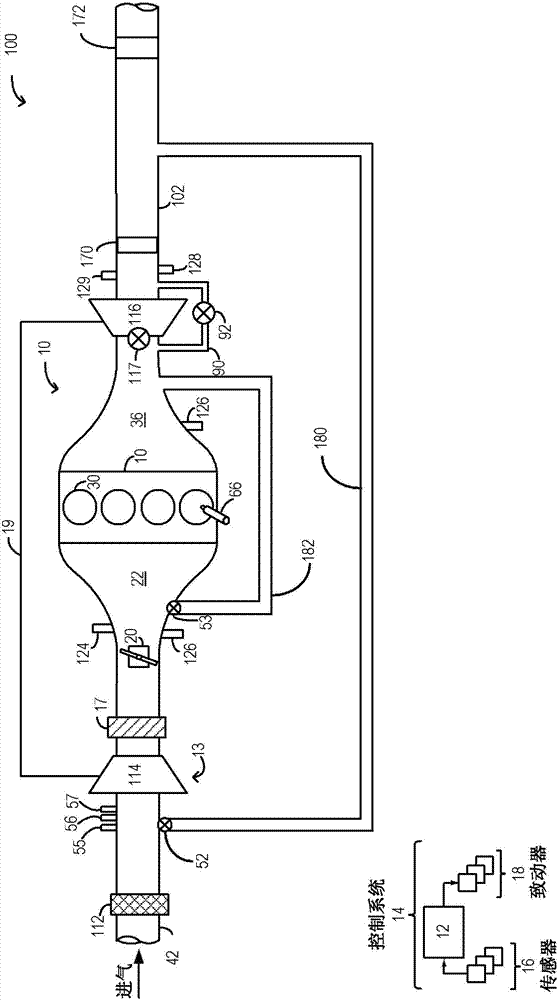

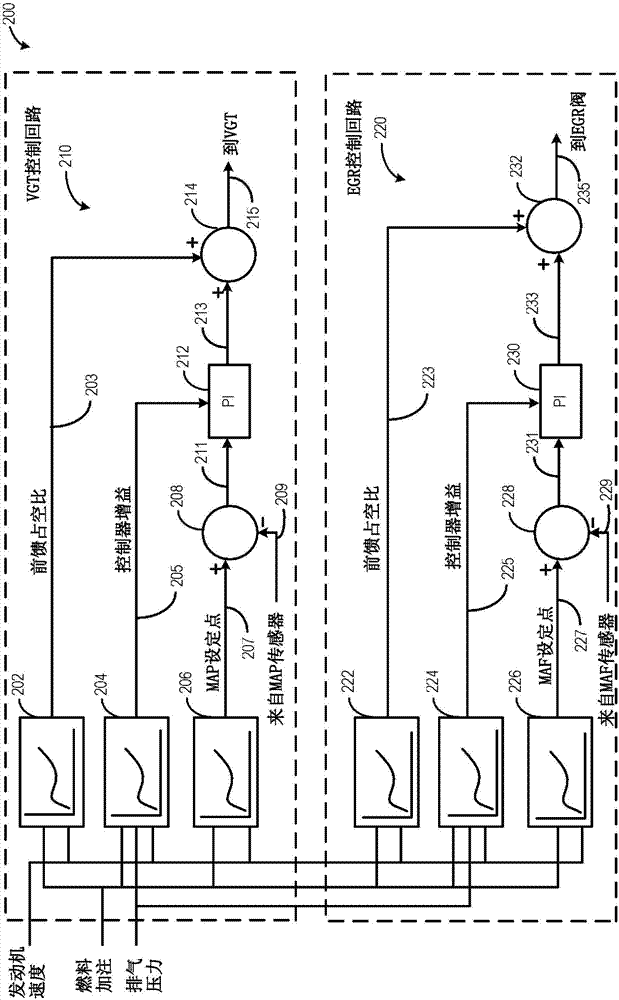

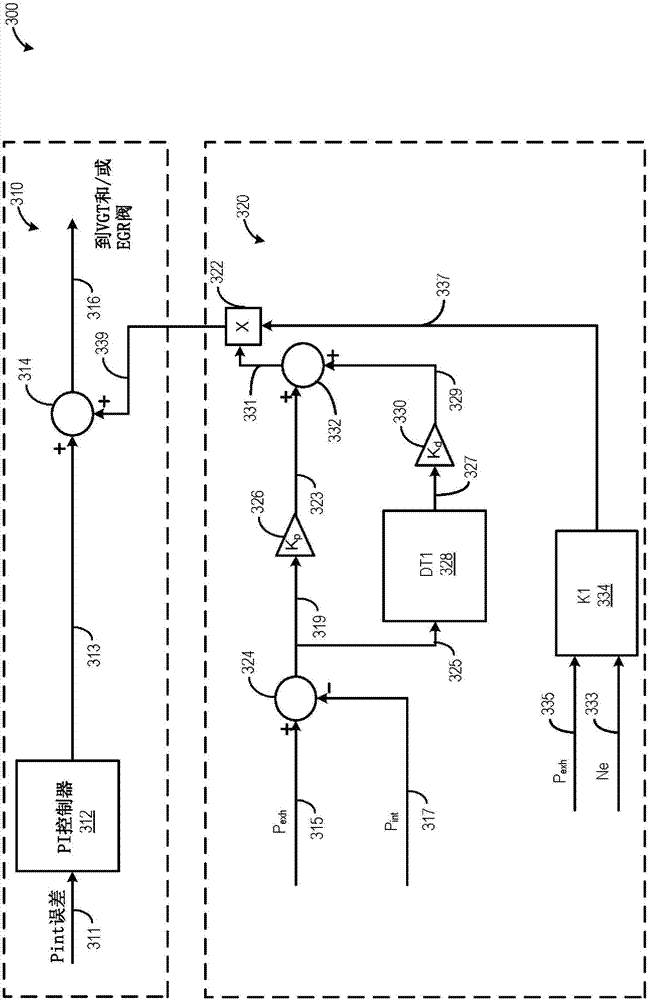

Methods and systems for boost control

ActiveCN107228026AReduce pump qigongRelieve pressureElectrical controlInternal combustion piston enginesIntake pressureValve opening

The invention discloses methods and systems for boost control. Methods and systems are provided for pressure control in a boosted engine system. A variable geometry turbine (VGT) geometry, and / or wastegate (WG), and / or an exhaust gas recirculation (EGR) valve opening is adjusted based a difference between the exhaust pressure and an intake pressure, and optionally other signals (e.g., engine speed, exhaust pressure) in order to reduce the difference between exhaust and intake manifold pressures, thereby reducing pumping work losses.

Owner:FORD GLOBAL TECH LLC

Phenolic foam heat insulation board of core-shell structure and preparing method thereof

The invention relates to a heat insulation board and a preparing method thereof, in particular to a phenolic foam heat insulation board of a core-shell structure and a preparing method thereof. Surface layers of the phenolic foam heat insulation board are made of phenolic foam, the core layer of the phenolic foam heat insulation board is made of polyurethane foam, a phenolic resin system accounts for 100 parts, and a polyurethane prepolymer system accounts for 20 parts by mass. The materials are foamed in a mold according to a preset synthetic process, solidified, cured and formed to obtain the phenolic aldehyde foam heat insulation board with good tenacity, and the defect that a phenolic foam board with certain tenacity is obtained through a traditional toughening method at the cost of fire resistance reduction is overcome. Phenolic resin is endowed with softness of the core layer polyurethane foam, the heat conductivity coefficient is further reduced, and the waterproof performance of the phenolic aldehyde foam board is improved. The phenolic aldehyde foam heat insulation board can be used as heat insulation and sound insulation materials.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

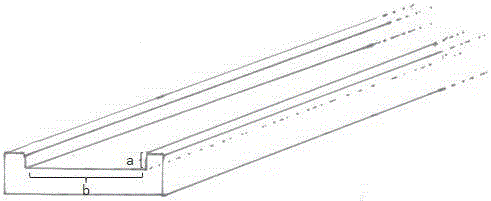

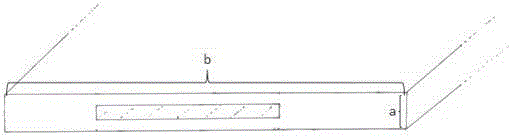

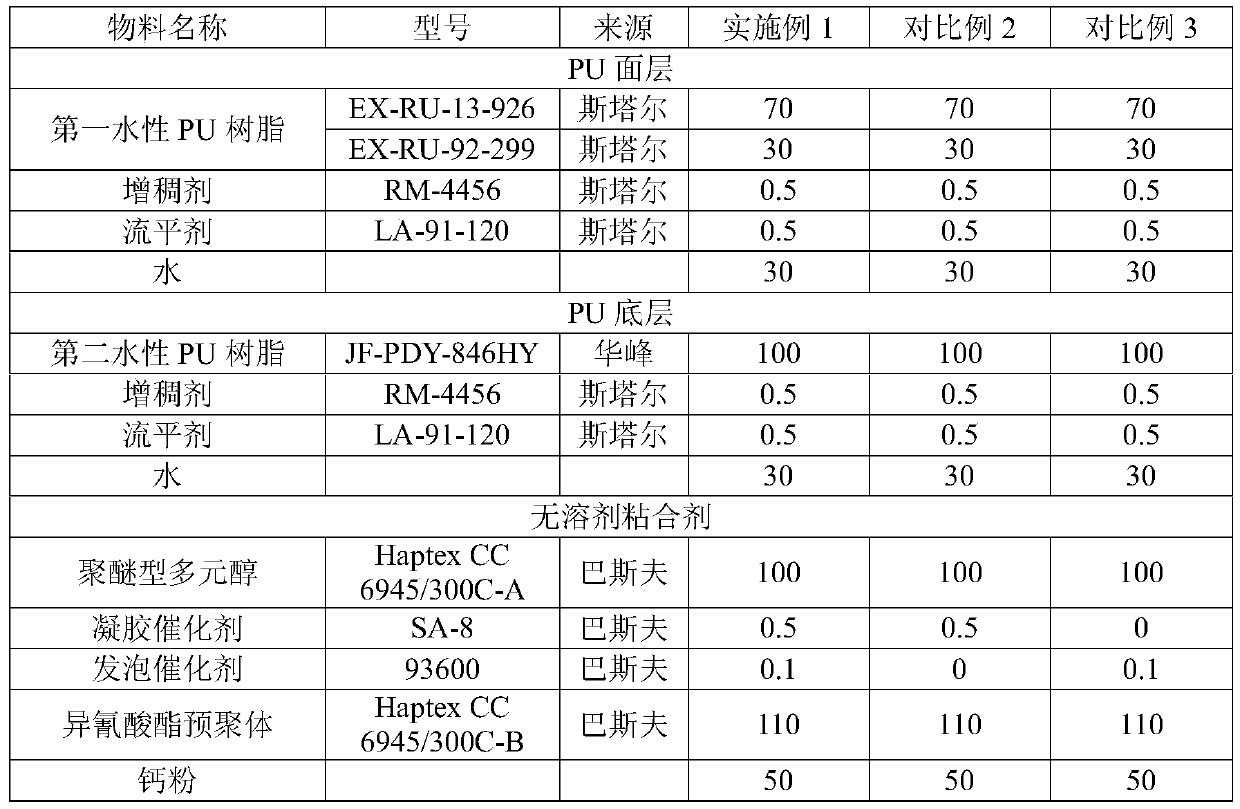

Preparation method of shoe lining leather

ActiveCN111169123AHigh peel strengthImprove folding resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceFolding endurance

The invention relates to a preparation method of shoe lining leather. The preparation method comprises the following steps: (1) uniformly mixing and stirring PU resin, a thickener, a leveling agent and water to prepare mixed slurry; (2) coating the surface of release paper with the mixed slurry, carrying out drying to obtain a PU surface layer, coating the surface layer with the mixed slurry, carrying out drying, and forming a PU bottom layer on the PU surface layer to obtain a PU dry film; (3) impregnating base cloth with water-based wet resin, and carrying out drying to obtain a base; and (4) coating the PU bottom layer of the PU dry film with a solvent-free adhesive, carrying out pre-drying, laminating the PU dry film with the base, and conducting drying and curing to obtain the shoe lining leather. According to the invention, the PU dry film and the base are compounded by adopting the specific solvent-free adhesive, a formula of the solvent-free adhesive is optimized, and proper raw materials are selected to prepare the PU bottom layer and the PU surface layer, so the peel strength of the shoe lining leather is greatly improved, and the folding resistance and the wear resistance of the shoe lining leather are improved; and the DMF content of the shoe lining leather meets requirements prescribed by the ZDHC organization according to detection results.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

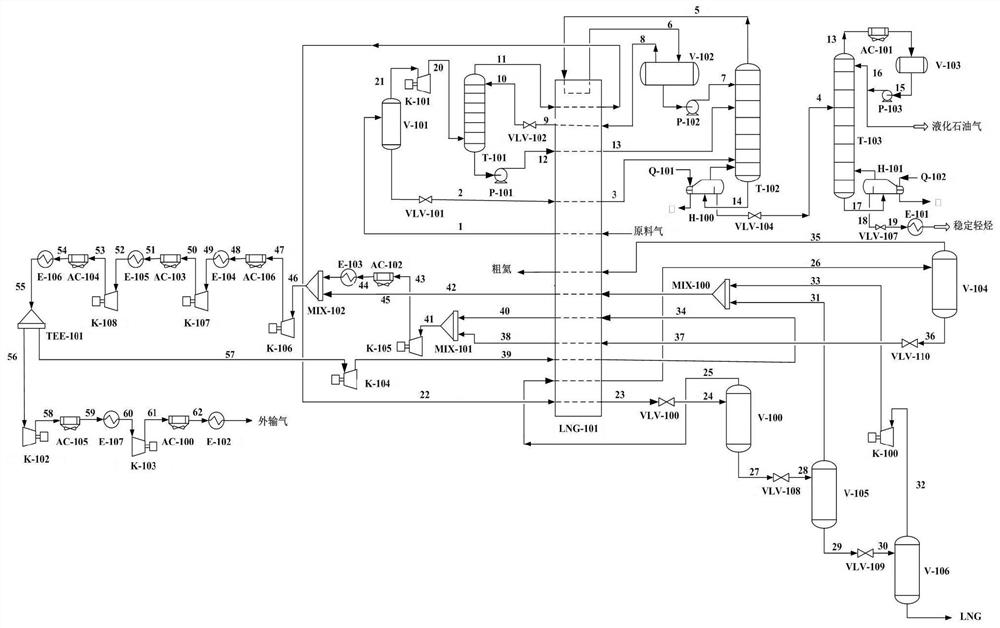

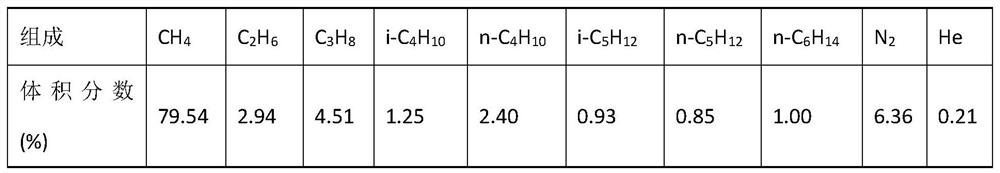

Recycling and helium-extracting co-production system and method for light hydrocarbons of helium-poor natural gas

ActiveCN112179048ALow costReduce energy consumptionSolidificationLiquefactionProcess engineeringEnvironmental geology

The invention discloses a recycling and helium-extracting co-production system and method for light hydrocarbons of helium-poor natural gas. The co-production system mainly comprises a heat exchanger,a low-temperature separator, a heavy contact tower, an ethane-removal device, a butane removal device, four flash tanks, three mixers, a plurality of compressors and a plurality of expanders. The co-production process utilizes an agent capable of automatically generating cold to refrigerate and expand a cold box to integrate heat exchange, and liquefied petroleum gas and stable light hydrocarbonsare obtained from raw material gas in the light hydrocarbon recycling device; dry gas of the light hydrocarbon recycling device enters a flash-evaporating helium-extracting device to gradually liquefy and separate to obtain LNG, externally conveyed gas and rough helium; and a low-temperature liquid-state natural gas product separated from the flash-evaporating helium-extracting device is taken asan agent capable of automatically generating cold through cascade cycle. Helium extracting and light hydrocarbon recycling are integrated, the heat exchanger is designed with high integrity, and theagent capable of automatically generating cold is adopted for cycle refrigeration; and compared with an existing process, the method overcomes the bottleneck of singe line production capacity, reducesliquefying cost and comprehensive energy consumption, improves performance, and has a practical application value.

Owner:KUNMING INST OF PRECIOUS METALS +1

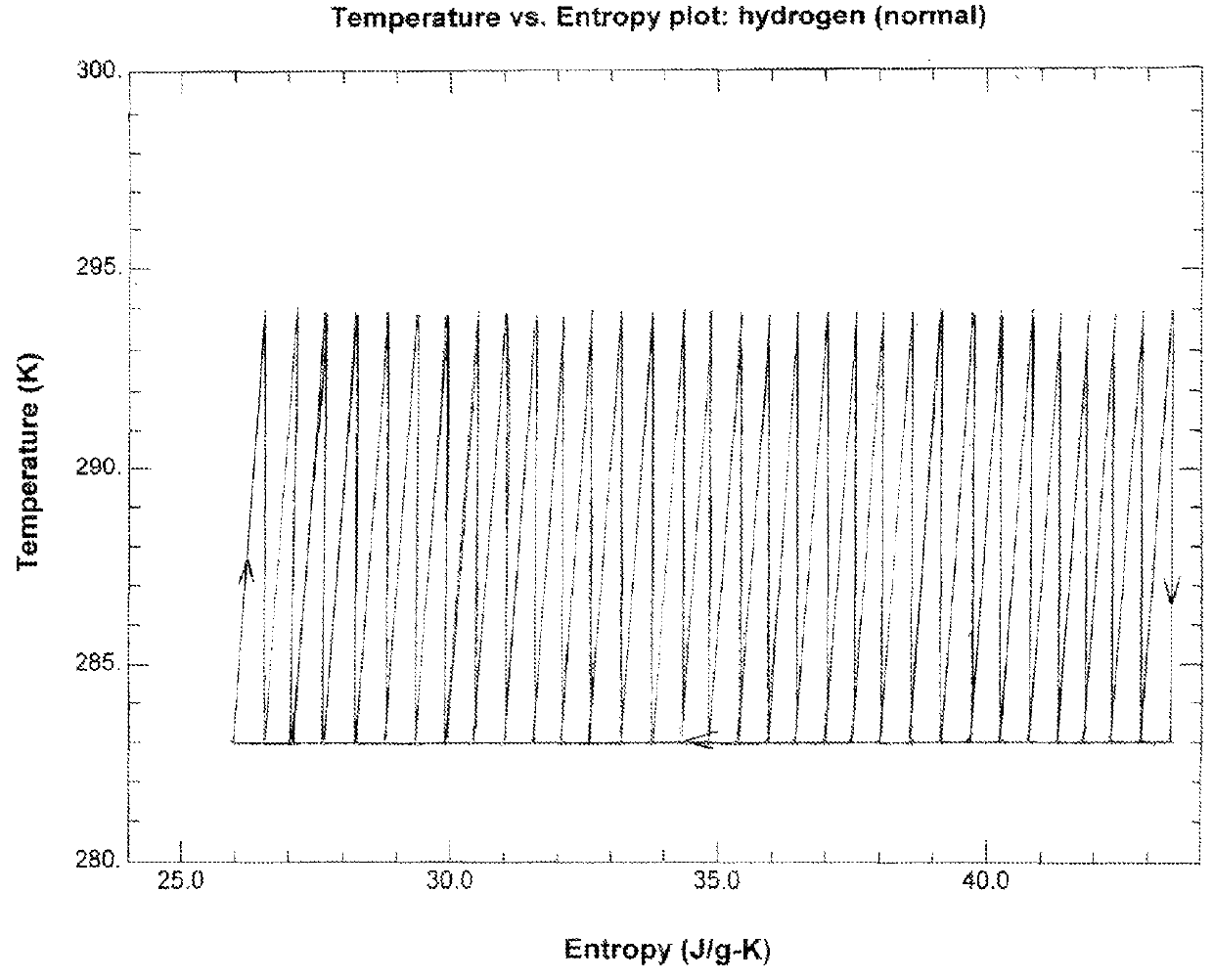

Closed-cycle cryogenic engine and operating method for propelling vehicles and generating electricity

ActiveUS9334854B2Low expansion ratioIncrease the number ofFrom solar energyOther heat production devicesThermal energyWorking fluid

A closed-cycle cryogenic engine includes a high specific heat working fluid remaining in a gaseous phase. The high temperature heat reservoir is the natural environment and the low temperature heat reservoir is created artificially by evaporating water. Isothermally compressing the working fluid at low temperature by absorbing compression heat by evaporating water extracts heat energy from the environment, converting it into net output. A plurality of serially connected isentropic expanders is interposed with a like plurality of re-heating stages. The temperature difference between the high and low temperature heat reservoirs is a few degrees, allowing expansion operation with low expansion ratios, enabling a large number of expanding and reheating steps Each engine cycle extracts natural heat energy from the environment, converting a large fraction into high density net output work. Very little water, the engine's only fuel, is consumed since evaporating water's latent heat is high.

Owner:MINOVITCH MICHAEL

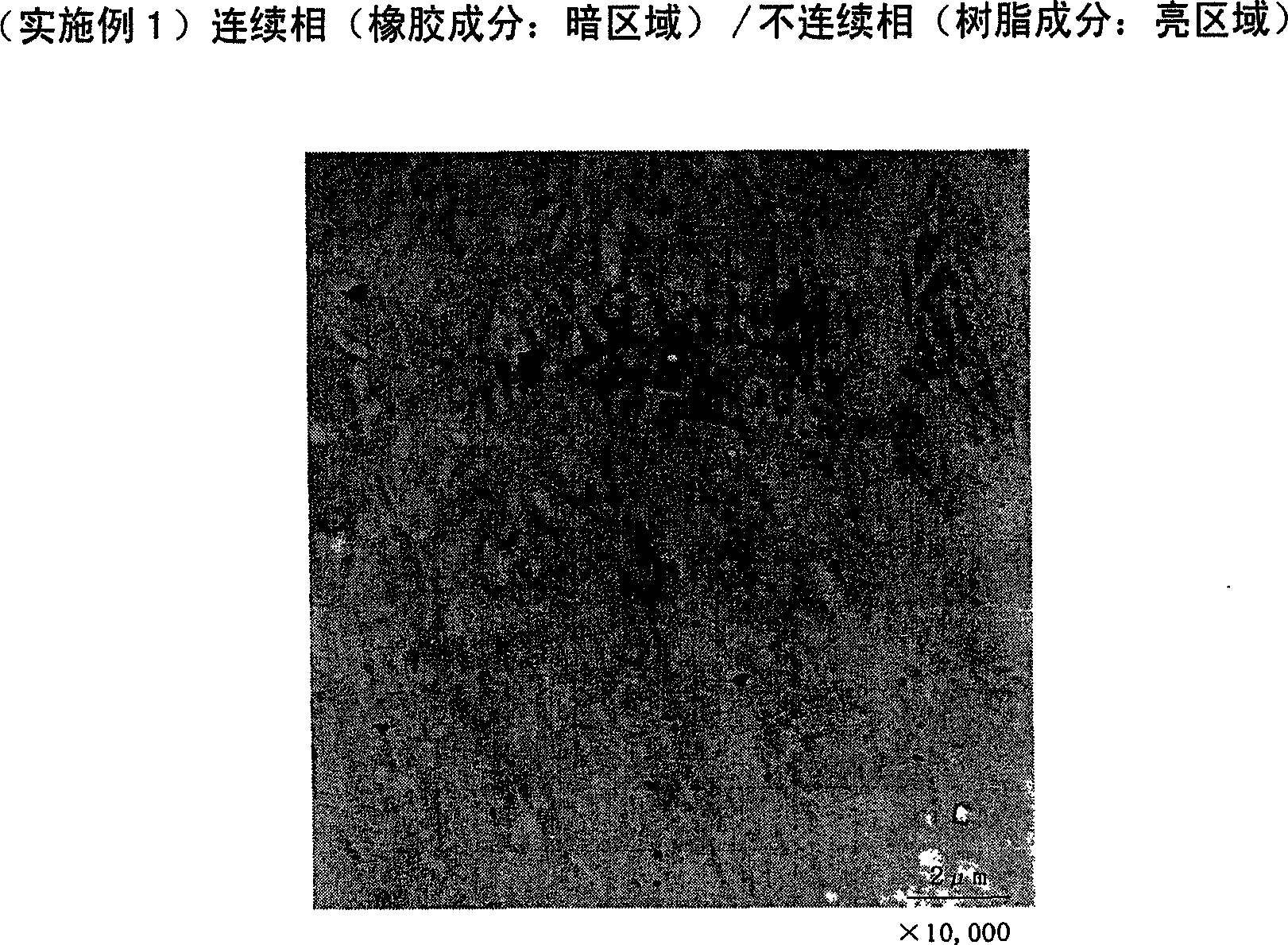

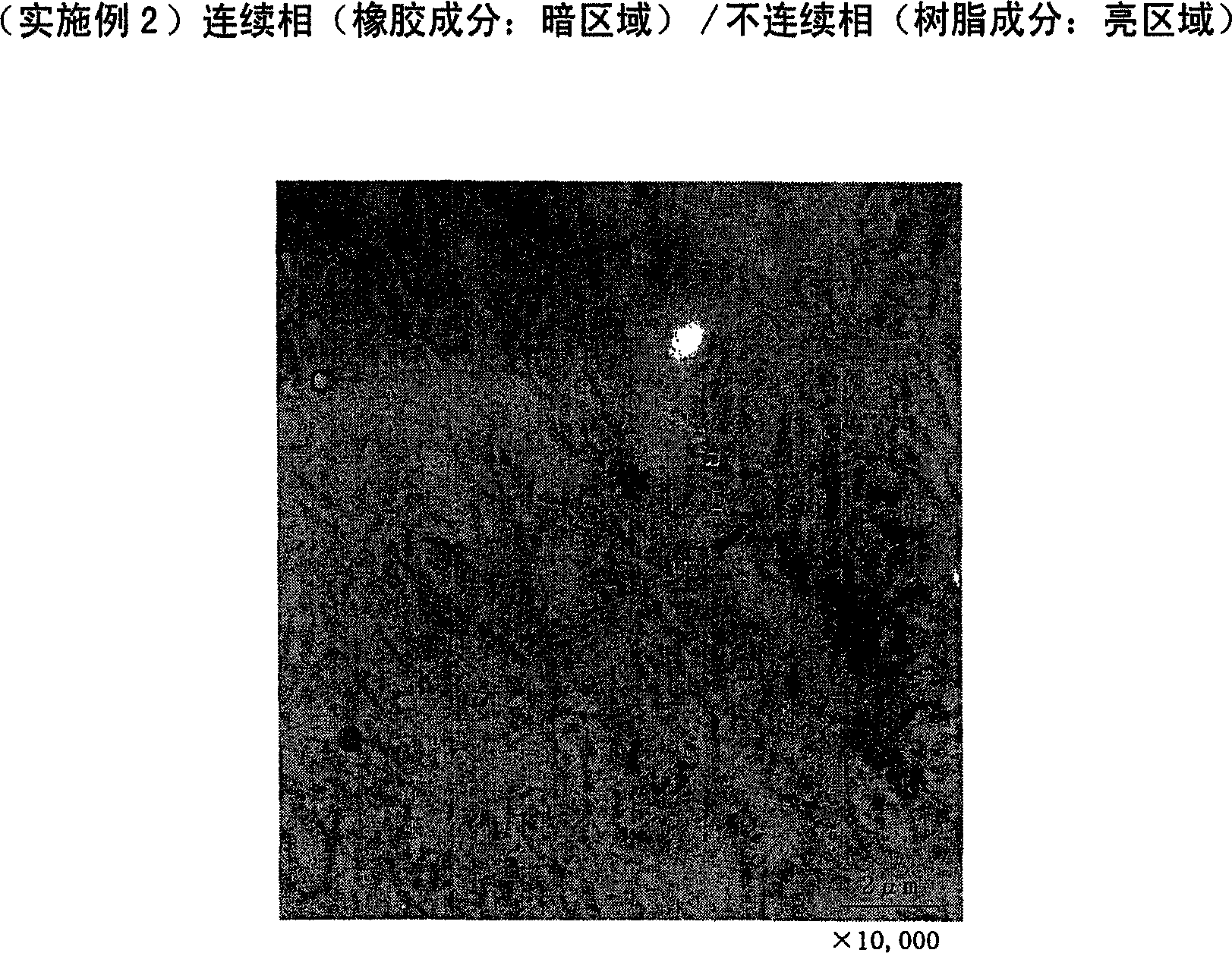

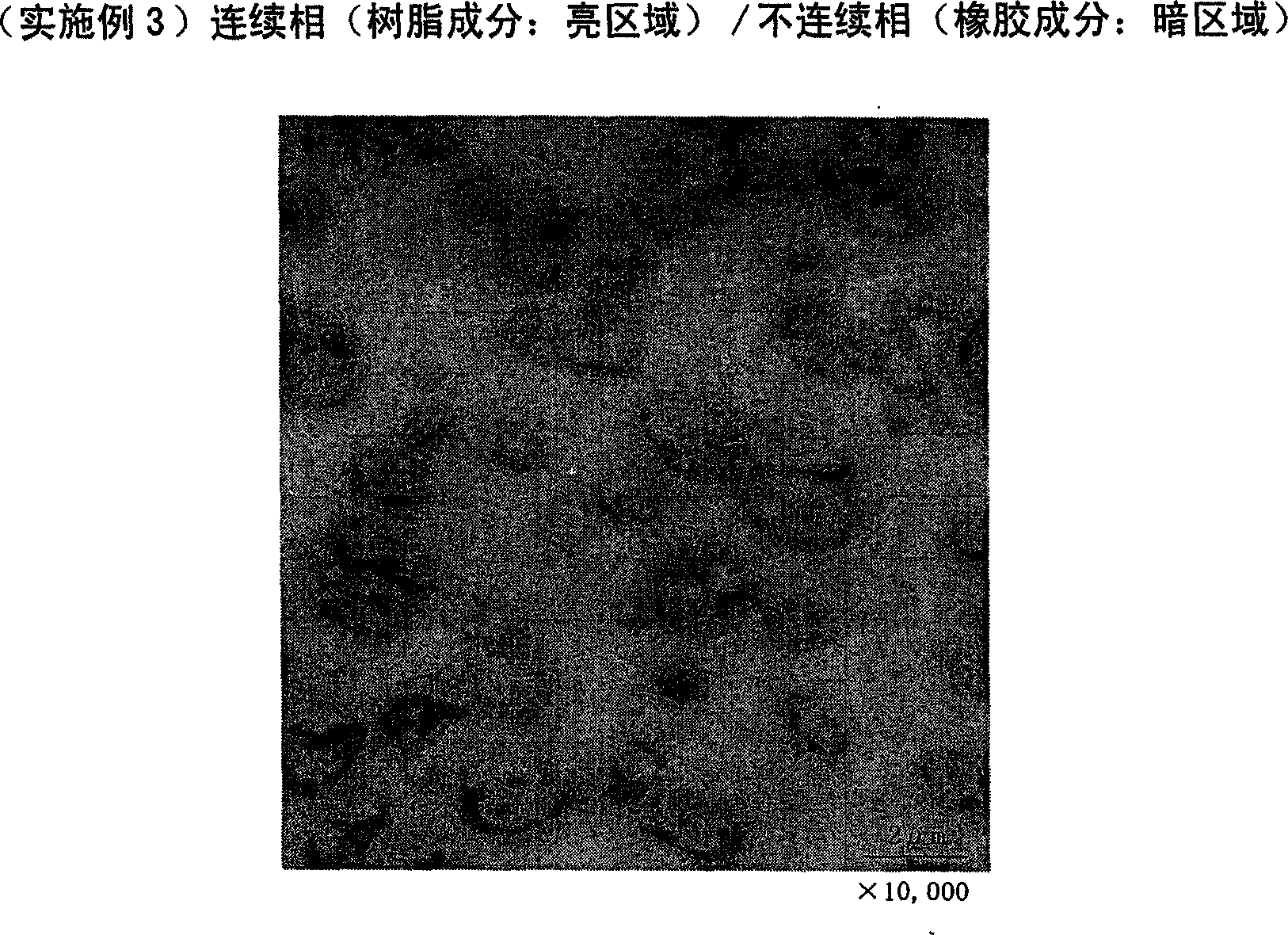

Resin composition for foam molding, foam, and process for producing foam

A resin composition for foams which comprises a branched rubbery olefin-based flexible resin (C) obtained by reacting an organic-peroxide-crosslinkable olefin copolymer rubber (A) with an organic-peroxide-decomposable crystalline olefin resin (B) through kneading, the resin (C) having a microcoagulated structure in which the organic-peroxide-crosslinkable olefin copolymer rubber (A) is present as a continuous phase and the organic-peroxide-decomposable crystalline olefin resin (B) is present as a discontinuous phase in the continuous phase. Use of this resin composition can provide foamed articles which are usable as, e.g., interior automotive parts, can have expansion ratios ranging from a high to a low value, are flexible, are excellent in cushioning properties, heat-insulating properties, and in-mold foamability, and have suitability for recycling.

Owner:NHK SPRING CO LTD

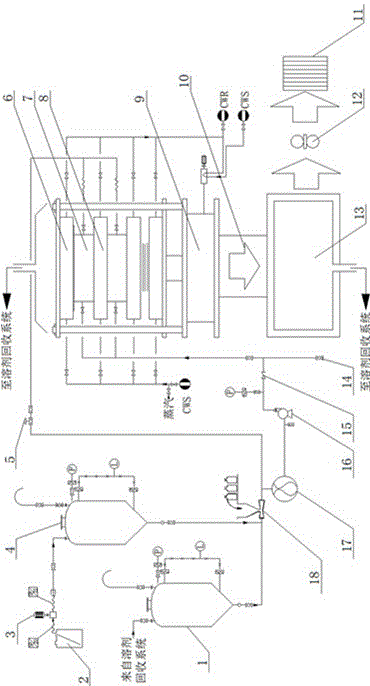

Production technology for hard PVC high foaming plate

The invention discloses a production technology for a hard PVC high foaming plate. A fresh solvent barrel, a diaphragm pump, a fresh solvent storage groove, a charging tank, a kneader, a charge pump, a foaming machine, an automatic conveyor, a hot air circulation oven and a cutting machine, all of which are sequentially connected are included. A solvent recycling storage groove is further formed in front of the charging tank. A heating plate I, a die and a heating plate II are arranged in the foaming machine. The bottom of the heating plate I is connected with the top of the die, and the bottom of the die is connected with the top of the heating plate II. An inlet of the die is connected with an outlet of the charge pump, and an outlet of the die is connected with the kneader. Each of the heating plate I and the heating plate II is provided with a steam heating and circulation water cooling device. According to the production technology, the hardness and foaming ratio of the PVC foaming plate are greatly improved, and the problem that hard high foaming plate materials are unavailable for PVC in China at present is solved.

Owner:TIANWEI CHEM +1

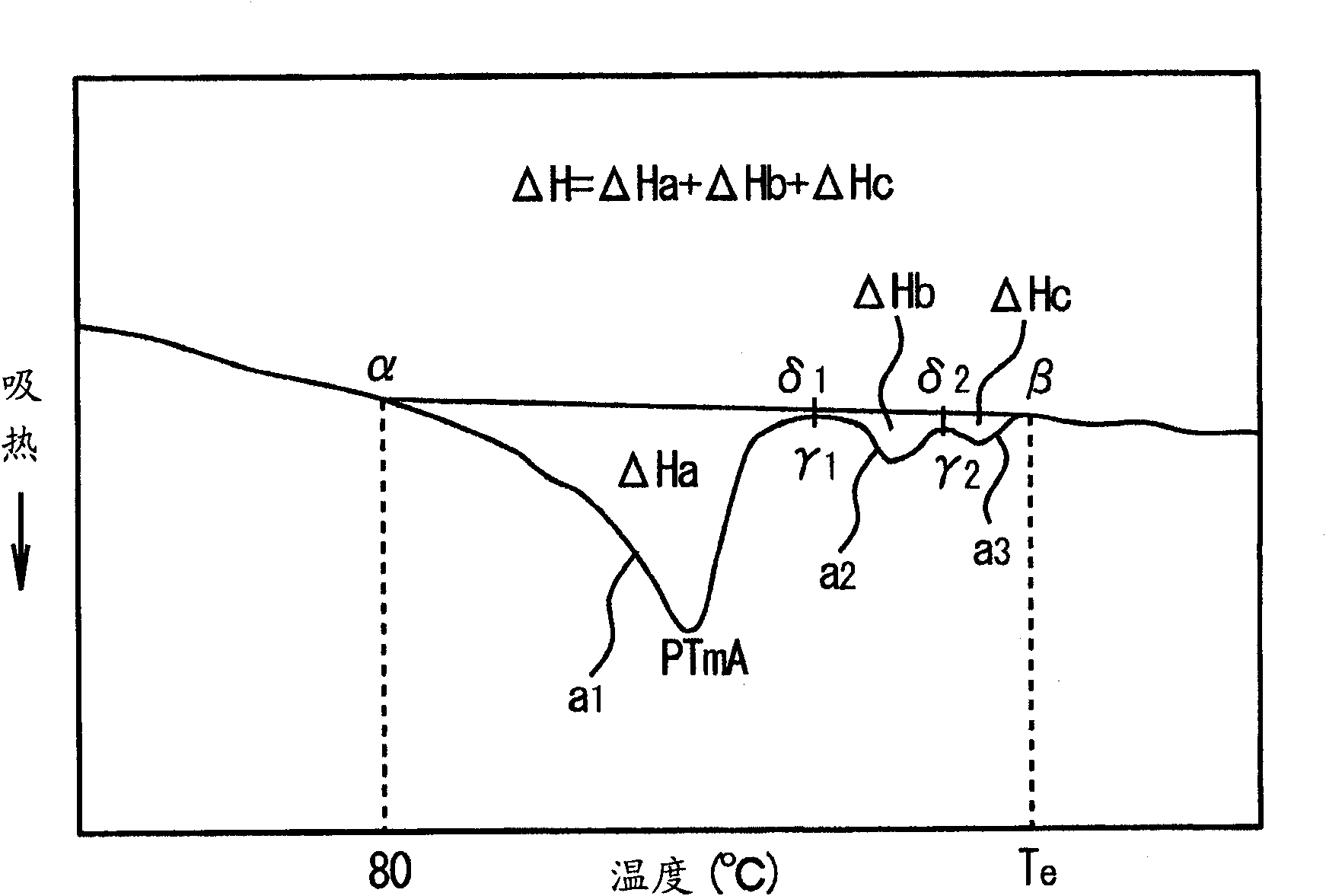

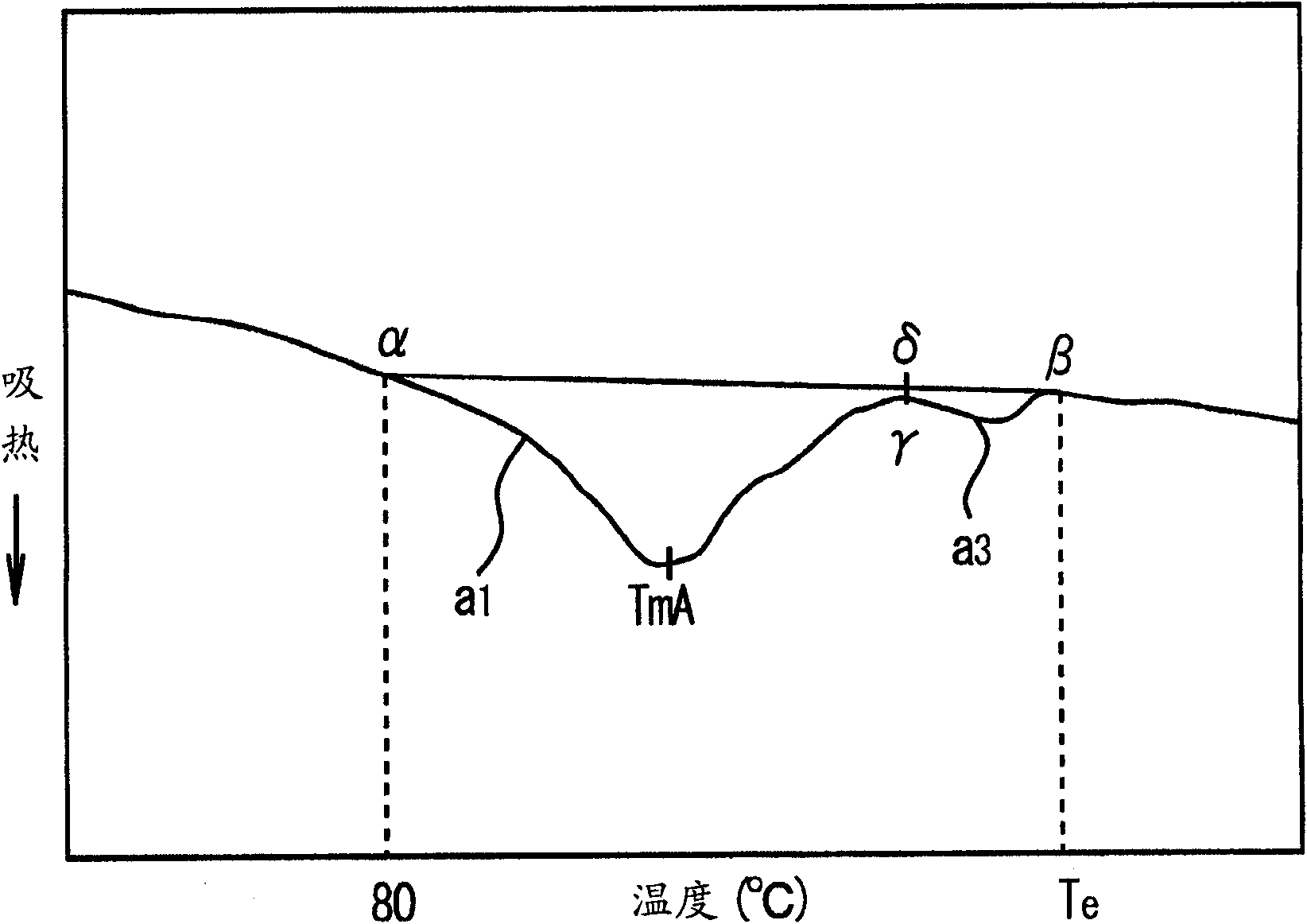

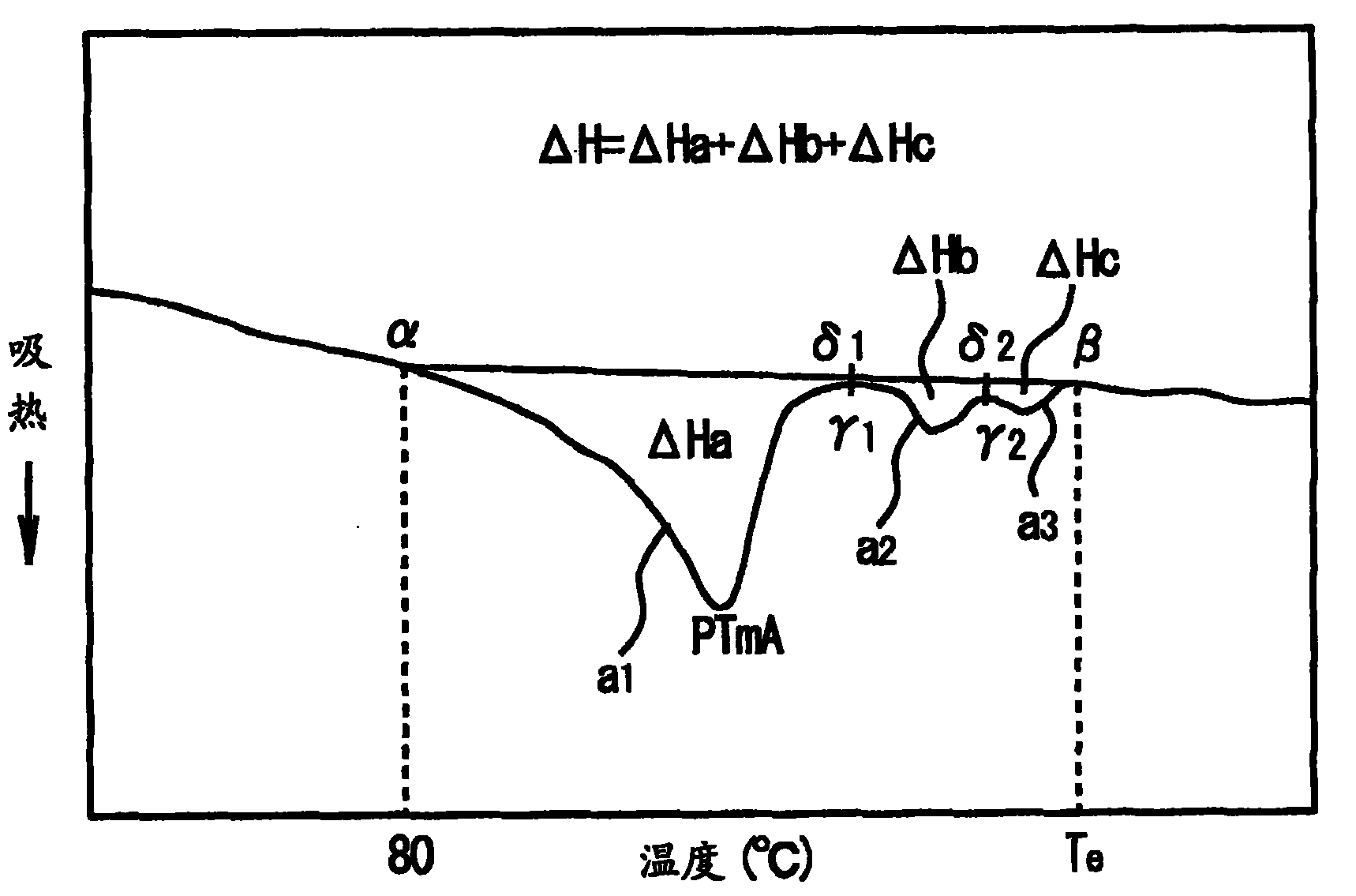

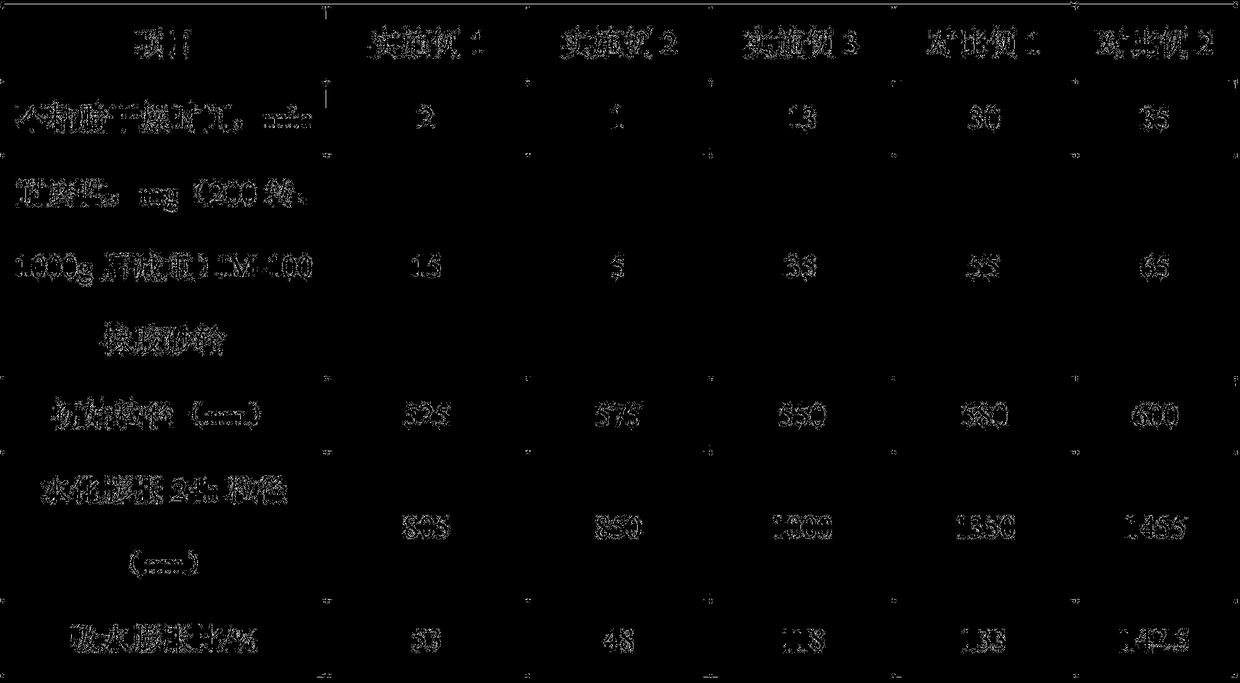

Molded product of a polypropylene-based resin expanded particle and method for producing the same

ActiveCN101875739ALow expansion ratioHigh compressive strengthApparent densityVolumetric Mass Density

The invention relates to a molded product of a polypropylene-based resin expanded particle and a method for producing the same. The object of the invention is to provide a molded product of a polypropylene-based resin expanded particle with a low expansion ratio having excellent fusibility between expanded particles mutually, small density difference between a surface part and an inner part of the molded product, better mechanical properties, such as compressive strength, compared with a conventional one, and also excellent appearance. In an in-mold molding method with the polypropylene-based resin expanded particle, the expanded particle has apparent density of 60-450 g / L, the welding rate of the polypropylene-based resin expanded particle is above 50%, the ratio between the apparent density of the expanded particle molded body to the inner density of the molded body is 1-2 and the molded product of the polypropylene-based resin expanded particle is preferably molded when satisfying the special conditions.

Owner:JSP CORP

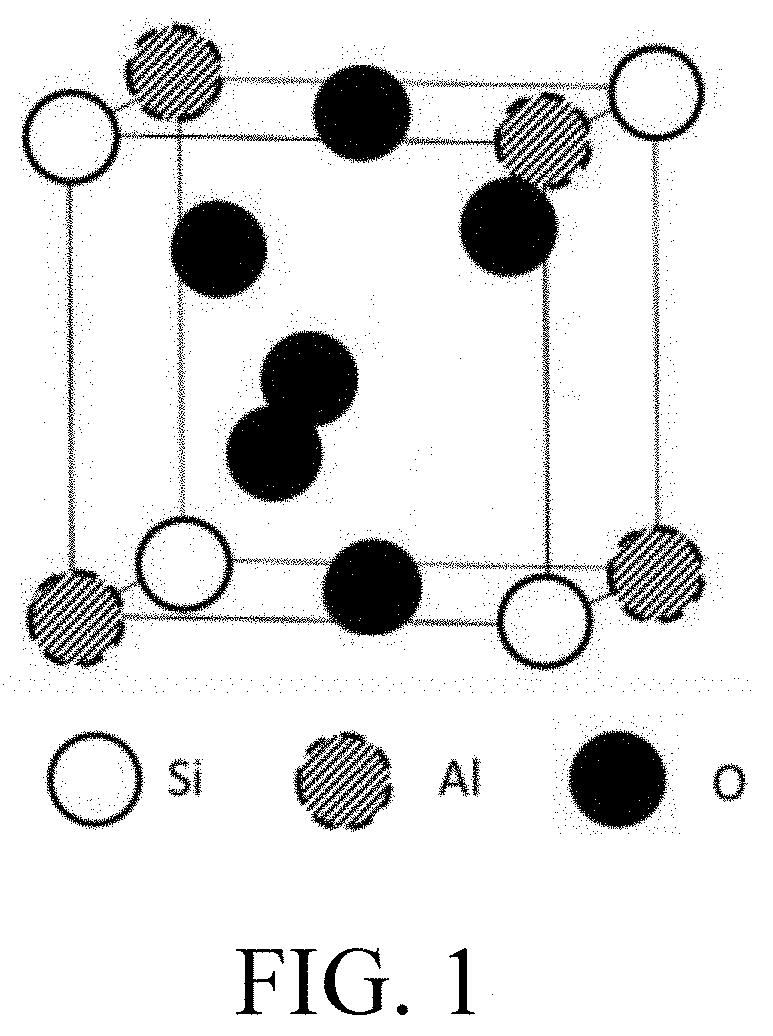

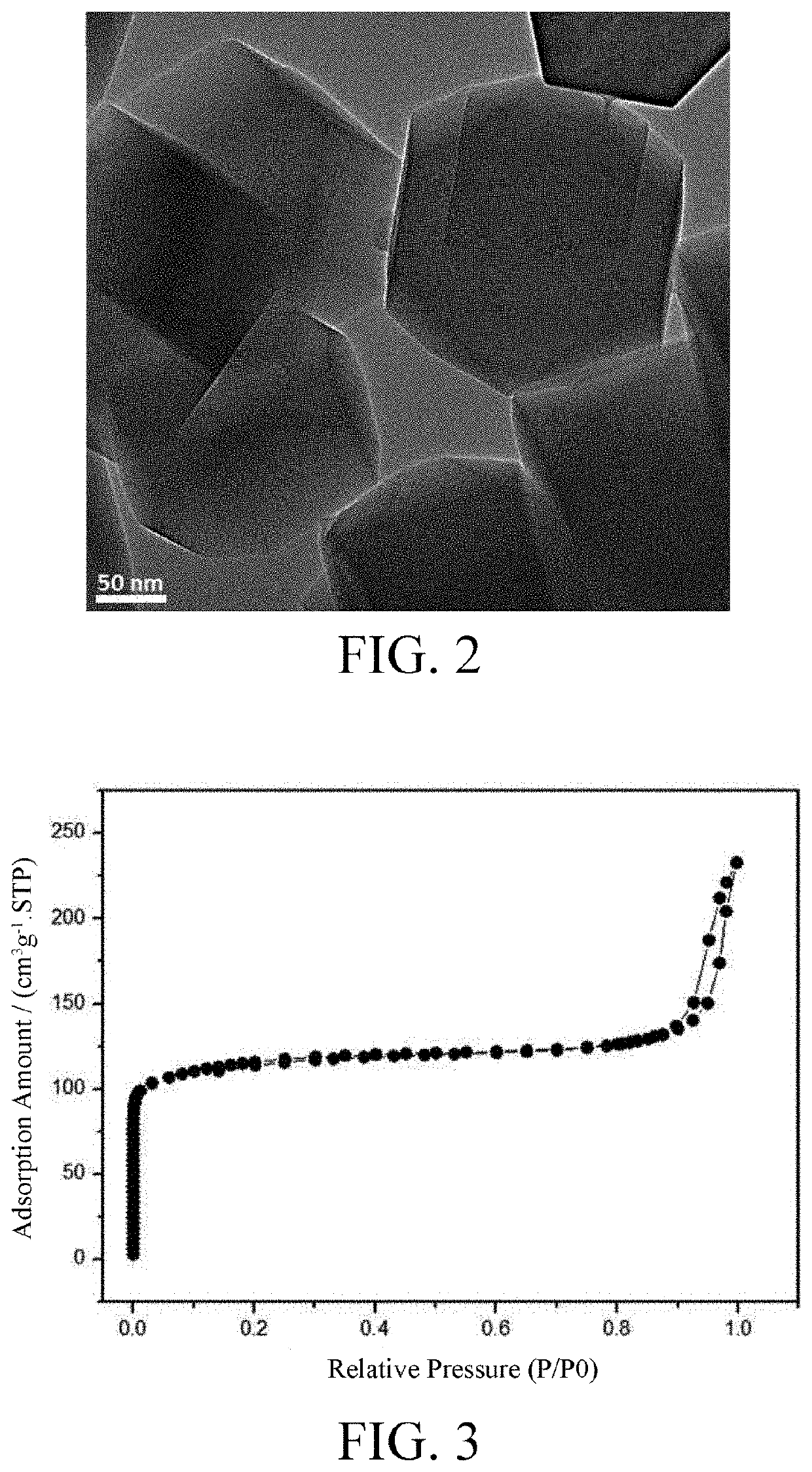

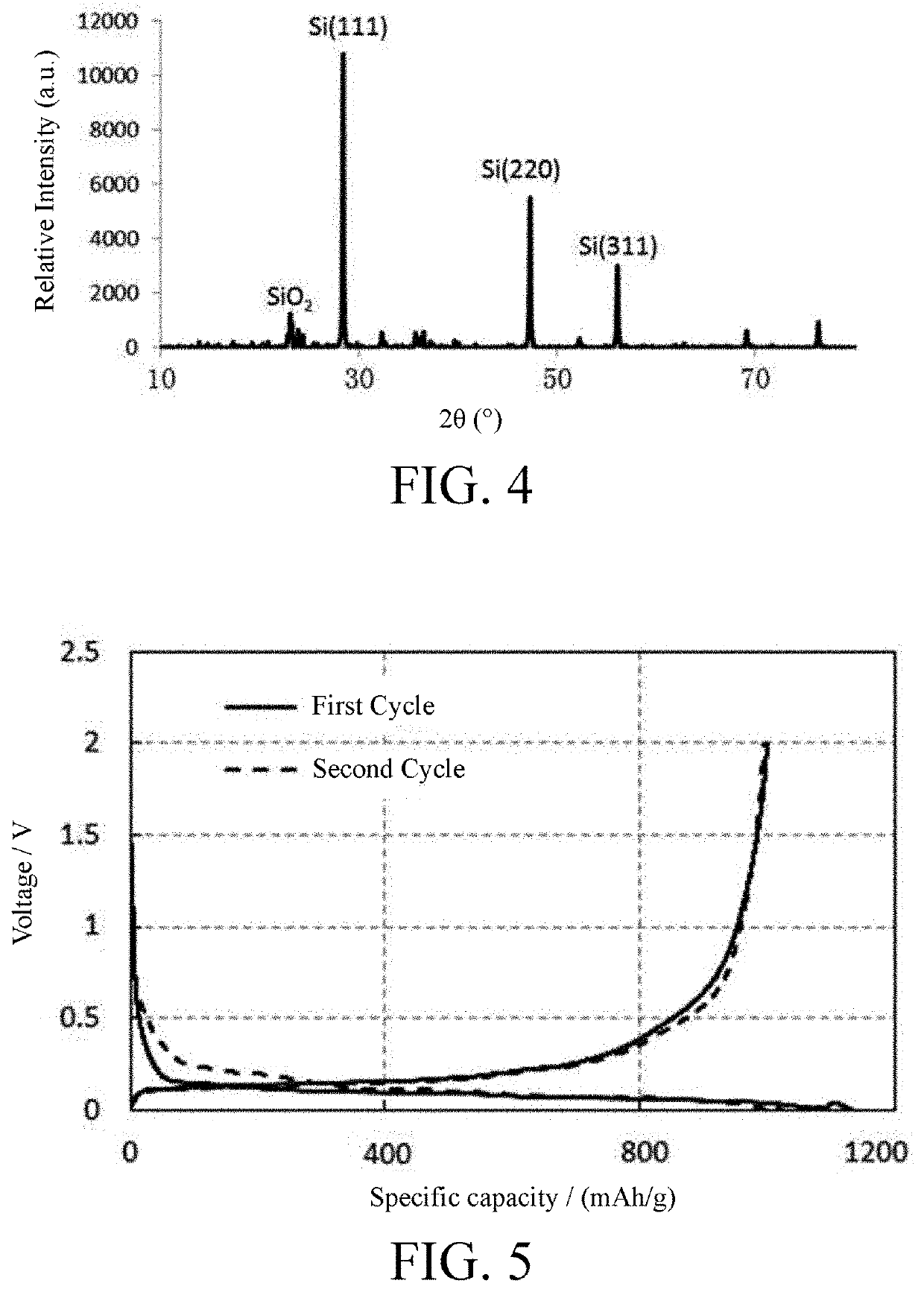

Porous material and preparation methods thereof, and anodes and devices including the same

ActiveUS20200399133A1Improve the first Coulombic efficiencyExcellent rate performanceMagnesium silicatesAluminium silicatesPhysical chemistryElectrochemistry

The present application relates to a porous material and preparation methods thereof, and anodes and devices including the same. The porous material provided by the present application includes a material of the formula SiaMbOx, wherein the ratio of x to a is about 0.6 to about 1.5, and the ratio of a to b is about 8 to about 10,000, wherein M includes at least one selected from the group consisting of Al, Si, P, Mg, Ti and Zr. The anode and an electrochemical device including the porous material exhibit higher rate performance, higher first coulombic efficiency, higher cycle stability and lower cycle expansion ratio.

Owner:NINGDE AMPEREX TECH

Rotary drilling hole forming method by using multi-stage alloy pilot roller bit in complex stratum cast-in-place pile construction

ActiveCN102409978AEasy to processEasy landing and drillingDirectional drillingLow speedSoil mechanics

The invention discloses a strong karst area cast-in-place pile construction method based on a rotary drilling hole forming manner. The cast-in-place pile construction method is characterized by comprising the steps of: (1) drilling into the surfaces of a karst layer and a gravel soil layer by adopting a conventional bit; (2) in combination with the basic theory of rock-soil mechanics, finding out a mathematic relation between an optimized value of inclination of a multi-stage alloy pilot roller bit and a coefficient of sliding friction between a rock-soil material and the interface of the bit; (3) after adopting the conventional bit to dill into the surfaces of the karst layer and the gravel soil layer, changing the conventional bit into the multi-stage alloy pilot roller bit, firstly drilling at high pressure and low speed, and then, after the bit is dilled into the rock for more than 50 cm, drilling at low pressure and high speed until the drilling depth or hole depth satisfies design requirements; (4) optimizing the design of mud specific weight in stages for preventing pile holes from collapsing and improving the bearing capacity of pile foundations; and (5) handling sudden accidents, such as fracture of drilling rods, bit falling, bit burying, fracture of cone palms in holes, accidental falling of cone palms and other small operation tools and the like, in the drilling process by adopting a drill tool overshot and a falling object salvage skip.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Low-cost and high-resilience biodegradable shock-absorbing packaging material and preparation method thereof

ActiveCN110204794AReduce rebound rateLow expansion ratioFlexible coversWrappersFiberPolyvinyl alcohol

The invention provides a low-cost and high-resilience biodegradable shock-absorbing packaging material and a preparation method thereof. The preparation method comprises the following steps: gelatinizing starch, stirring the gelatinized starch and unbunched straw fibers at a high speed to form a flocculent material, mixing starch, polyvinyl alcohol, a nucleating agent, silicone oil and water, performing screw extrusion on the obtained mixture, crushing the extruded mixture to form particles, uniformly mixing the flocculent material with the particles, and performing extrusion foaming by a single screw machine to prepare the shock-absorbing foamed packaging material. The shock-absorbing packaging material provided by the invention has the advantages of full degradation, low cost, excellentresilience, uniform surface gloss, good water and moisture resistance, moderate hardness, proper elasticity, soft surface and broad application prospect.

Owner:赣州臻丰科技有限公司

Water sucking resin microspheres for water-based coating and preparation method thereof

InactiveCN109370294ALow expansion ratioFast dryingCoatingsMicroballoon preparationWater basedResin microsphere

The invention relates to water sucking resin microspheres for a water-based coating and a preparation method thereof. The water sucking resin microspheres are prepared by treating cyclohexane as a solvent; treating nano porous silica, a comonomer, a dispersing agent, a crosslinking agent and an initiating agent as main reaction materials; performing reversed phase suspension and polymerizing, wherein the comonomer comprises crylic acid, acrylamide and vinyl pyrrolidone. The microspheres can be greatly combined with coating filming resin and can adsorb water at the inner layer of the coating; in addition, the microspheres are low in expansion rate and can be prepared into micron level and even less level. With the adoption of the water sucking resin microspheres, the coating drying rate isincreased; in addition, a special preparation process is carried out; the water sucking resin microspheres are polymerized in situ in the presence of porous silica, so that the corrosion resistance ofthe water-based coating is further improved.

Owner:浙江欧路德交通科技有限公司

Bra pad prepared from PU (polyurethane) flexible adhesive

The invention discloses a bra pad prepared from a PU (polyurethane) flexible adhesive. The bra pad is prepared from 93.5-99.2% of polyether-type polyurethane resin (main body material). The main body material comprises 15.8-21.5% of diphenylmethane diisocyanate (MDI) (black material), 75.5-79.8% of polyether glycol (white material), 1.85-2.8% of butanediol (white material), 0.05-0.3% of catalyst (white material) and 0.2-0.45% of cyclopentane physical foaming agent (white material). The polyether-type polyurethane resin, black materials and white materials are proportionally mixed thoroughly to obtain the required PU flexible adhesive. The prepared PU flexible adhesive is injected into a mold with the temperature of 50-55 DEG C and subjected to primary foam forming. The PU flexible adhesive has the skin-like sensation, and the bra pad is subjected to integral forming through the mold, thereby saving abundant human and material resources and enhancing the efficiency.

Owner:柯永展 +2

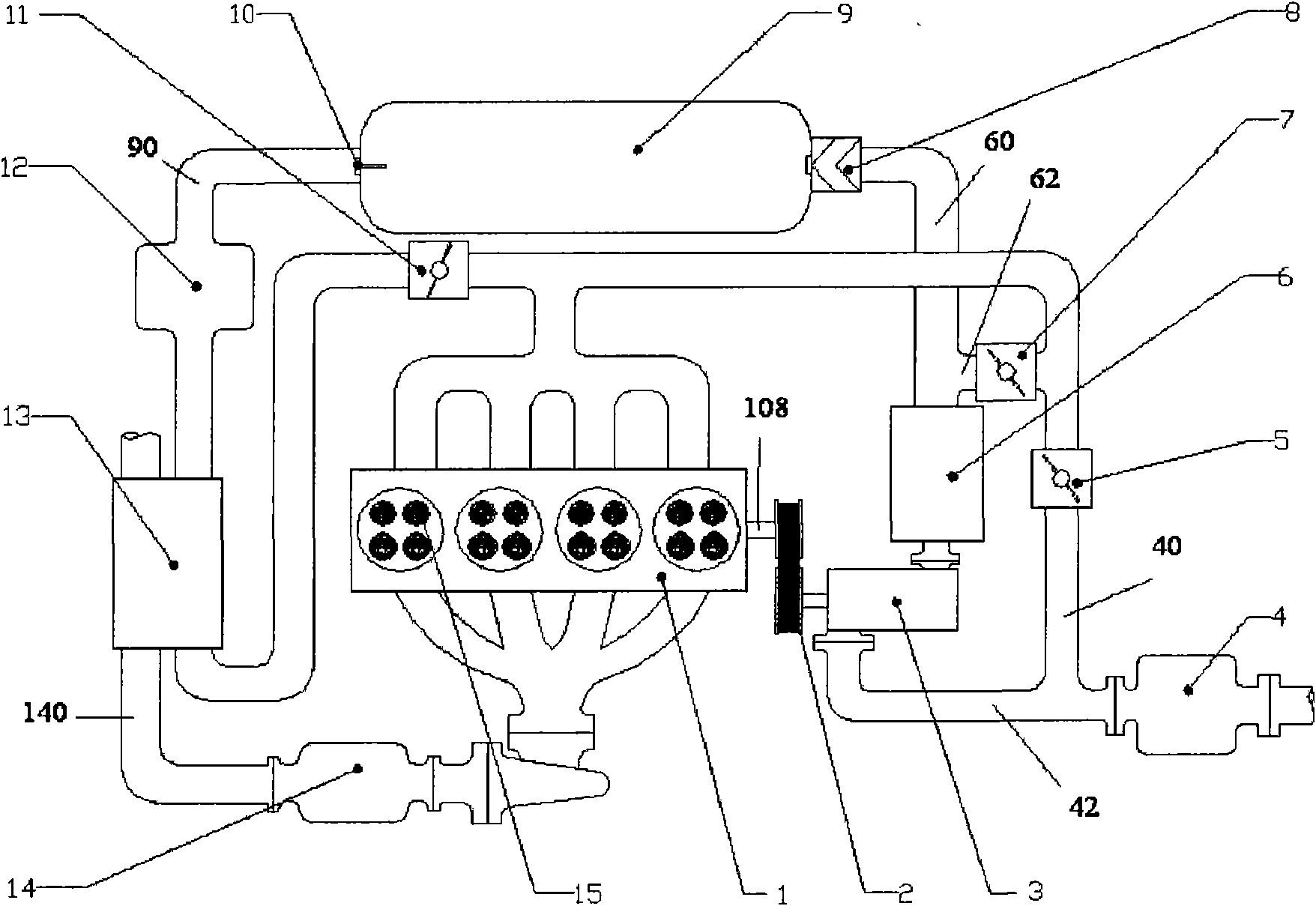

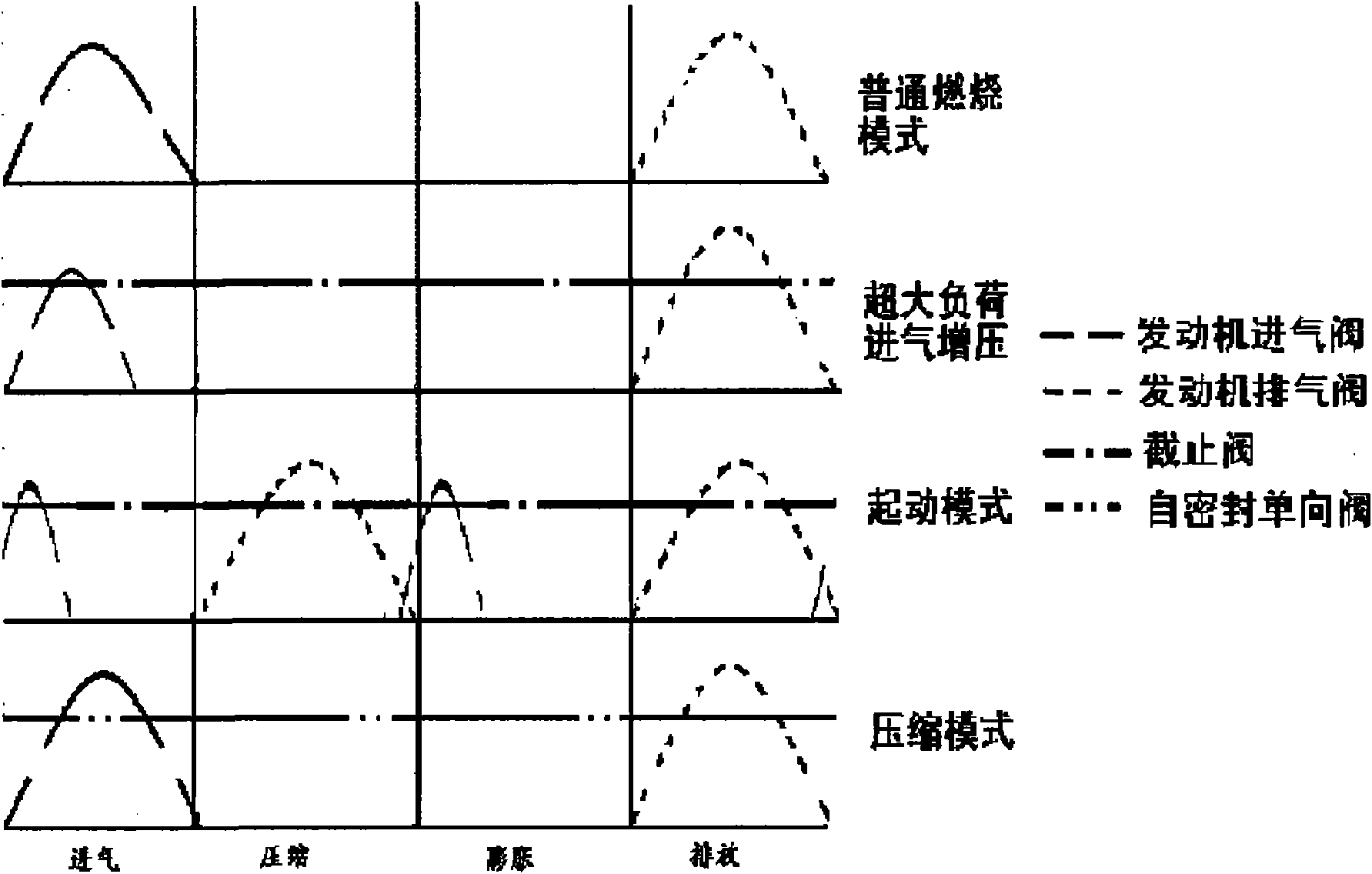

Hybrid power system

ActiveCN102261279BIncrease starting speedPrevent "ice blockage" phenomenonInternal combustion piston enginesThermal treatment of fuelAir filterIntercooler

The invention provides a hybrid power system. The system comprises an engine, first and second intake pipelines, first and second compressed air pipelines, a high pressure air pipeline and a heat exchanger, wherein the first and second intake pipelines are connected with each other in parallel and are connected with a main air intake in series via an air filter; the first air intake pipeline is connected with the engine in series; the first and second compressed air pipelines are connected with each other in parallel and are connected with a compressor in series via an intercooler; the secondcompressed air pipeline is connected with the first air intake pipeline in series; the high pressure air pipeline is connected with the first compressed air pipeline in series via a gas storage tank and is connected with the engine in series; the heat exchanger is arranged on the high pressure air pipeline; and the high pressure air pipeline is arranged adjacent to an engine exhaust pipeline in the heat exchanger so as to heat the high pressure gas from the gas storage tank, thus reducing the occurrence of ice barrier on an exhaust pipe caused by too low intake temperature and energy loss brought about by expansion of air in a cylinder under the starting condition.

Owner:SAIC MOTOR

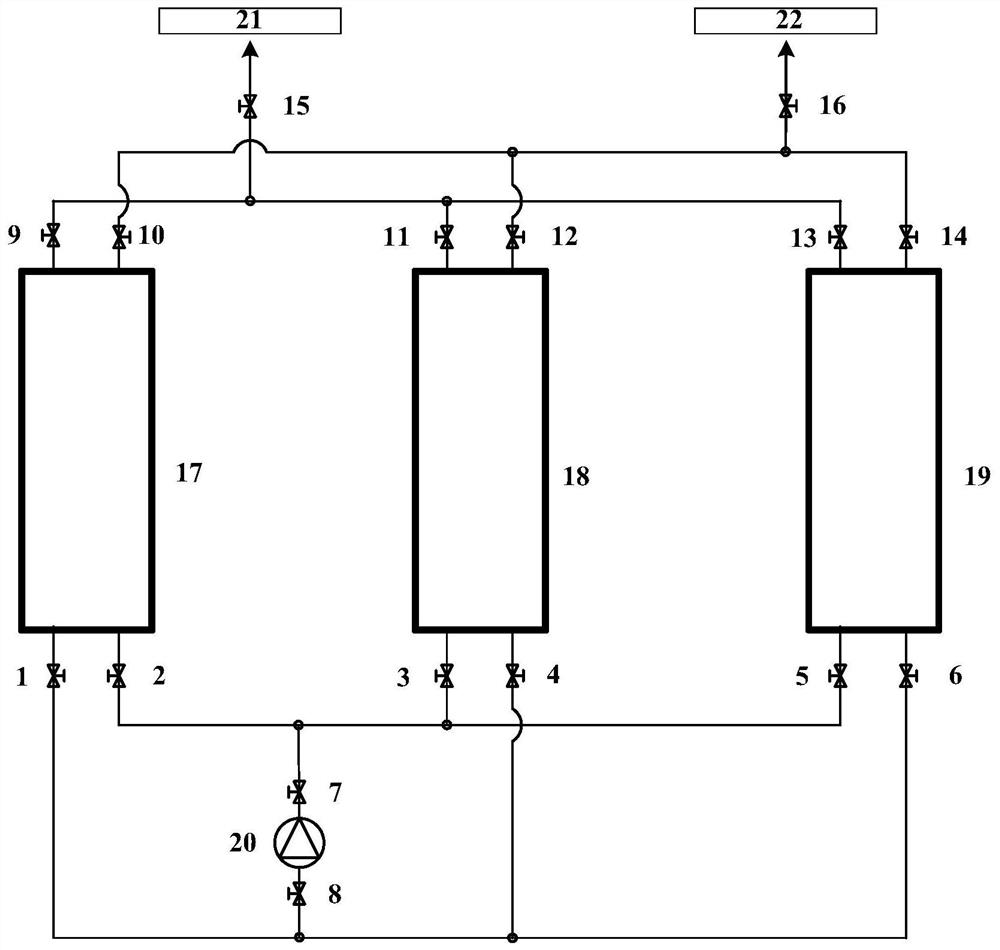

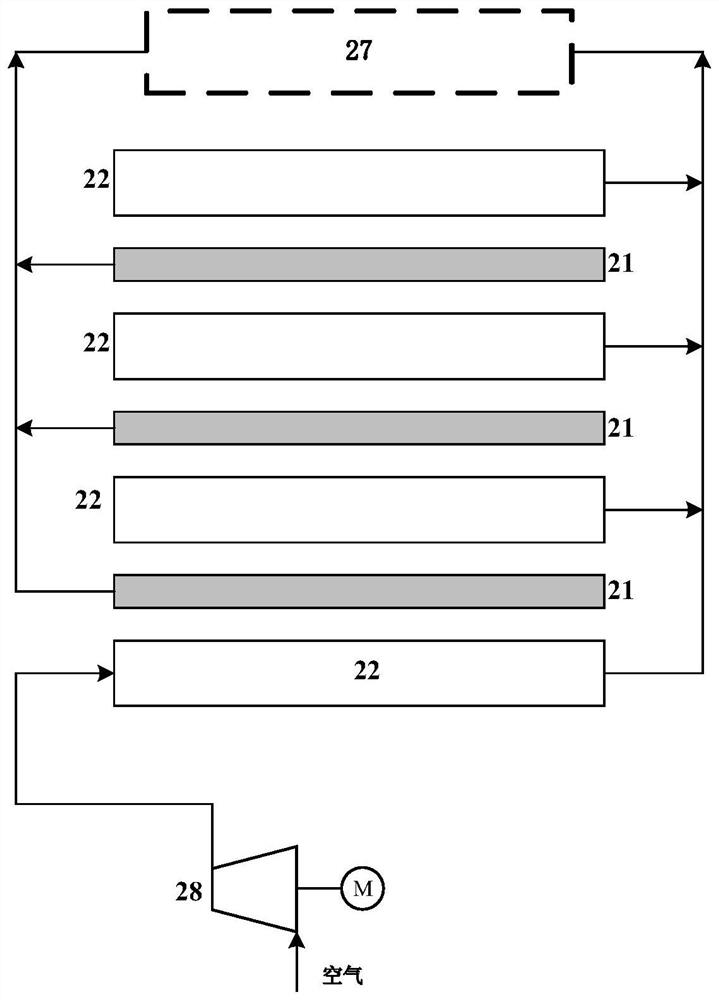

Near-isothermal compressed-air energy storage system and operating method thereof

ActiveCN112901431AOvercome the disadvantage of huge water consumptionAchieve large-scale applicationFrom solar energyPiston pumpsCollection systemEngineering

The invention provides a near-isothermal compressed-air energy storage system and an operating method thereof. The near-isothermal compressed-air energy storage system comprises a high-pressure air storage space, a low-pressure air storage space, a heat collection system, a multi-tank water-pumping compressed-air energy storage device, an energy release part and a compressor, wherein the energy release part comprises a reheater and an expansion turbine; an outlet of the low-pressure air storage space, the multi-tank water-pumping compressed-air energy storage device and an inlet of the high-pressure air storage space communicate with one another sequentially; the outlet of the high-pressure air storage space, the reheater and the expansion turbine communicate with one another sequentially; an outlet of the expansion turbine communicates with the low-pressure air storage space; an inlet and an outlet of the heat collection system communicate with an outlet and an inlet of a heat-conducting medium of the reheater separately; near-isothermal compression is realized in the compression process, so that remarkable compression heat is avoided; closed circulation is adopted, so that the overall air operating pressure is increased, and the energy density of the system is increased; and a multi-tank compression structure is adopted, so that the defect of huge water consumption of a single tank is overcome; and large-scale application of the energy storage system is realized.

Owner:XI AN JIAOTONG UNIV

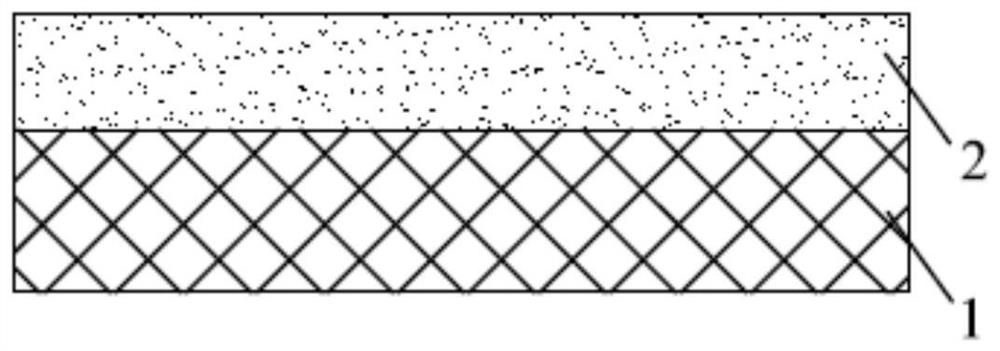

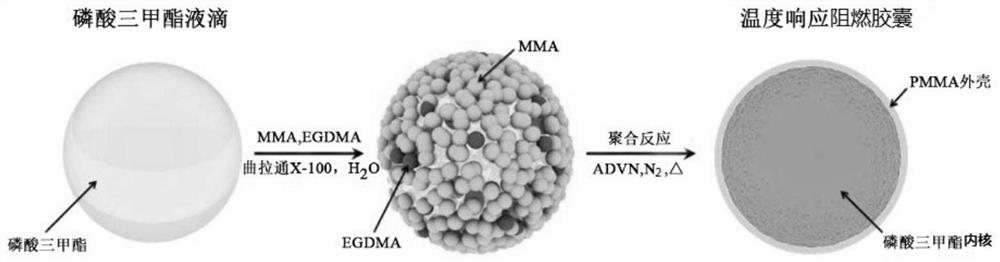

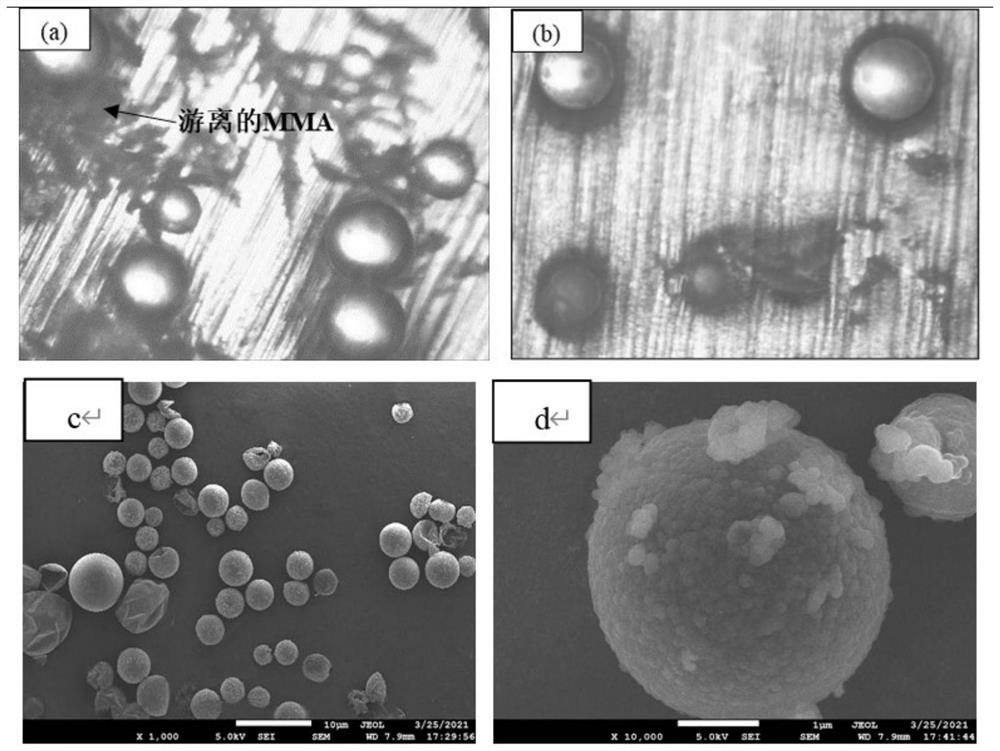

Diaphragm for secondary battery, preparation method of diaphragm and secondary battery

PendingCN114497891APrevent Thermal Runaway and ExplosionsSmall degree of swellingCell seperators/membranes/diaphragms/spacersSecondary cellsPolyvinylidene fluorideThermal runaway

The invention provides a diaphragm for a secondary battery, a preparation method of the diaphragm and the secondary battery. The diaphragm comprises a base film and a flame-retardant layer coated on at least one surface of the base film, the flame-retardant layer is composed of a polyvinylidene fluoride-hexafluoropropylene binder and a flame-retardant capsule, and the flame-retardant capsule is of a core-shell structure with a flame retardant as an inner core and polymethyl methacrylate as an outer shell. Compared with the prior art, according to the diaphragm provided by the invention, when the battery is subjected to thermal runaway, the PMMA shell is broken and can release the flame retardant, the flame retardant can capture combustion free radicals and can effectively prevent thermal runaway and explosion of the battery, and the PMMA shell is adopted, so that better bonding force can be provided for the diaphragm and a pole piece; the problem that the cycle life of the battery is difficult to guarantee while the thermal runaway of the secondary battery is blocked at present is solved.

Owner:惠州锂威电子科技有限公司

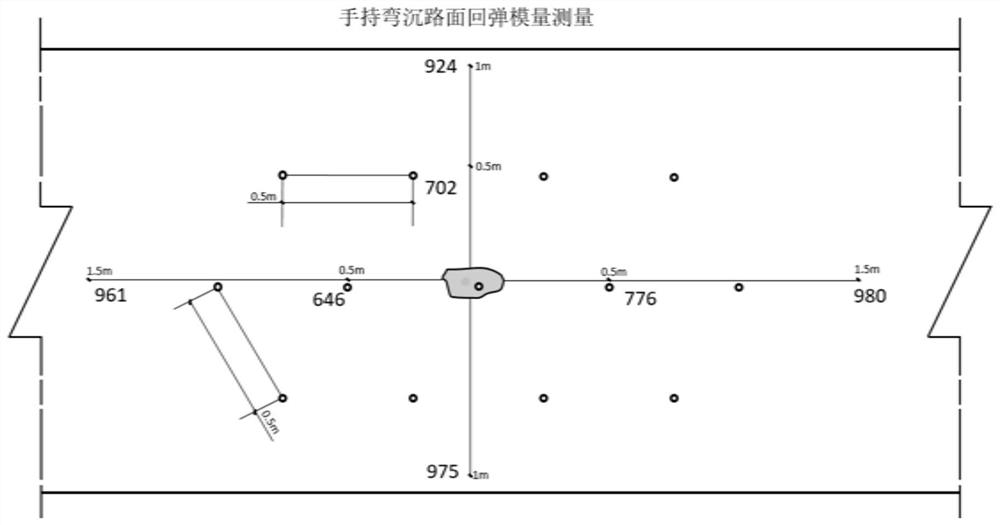

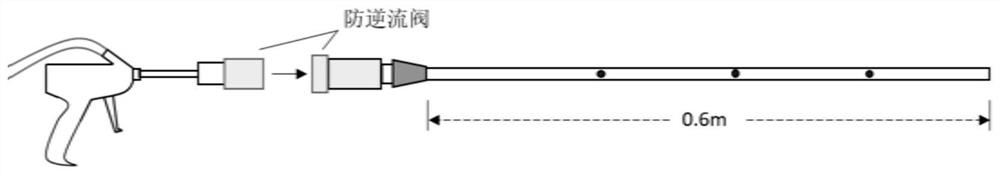

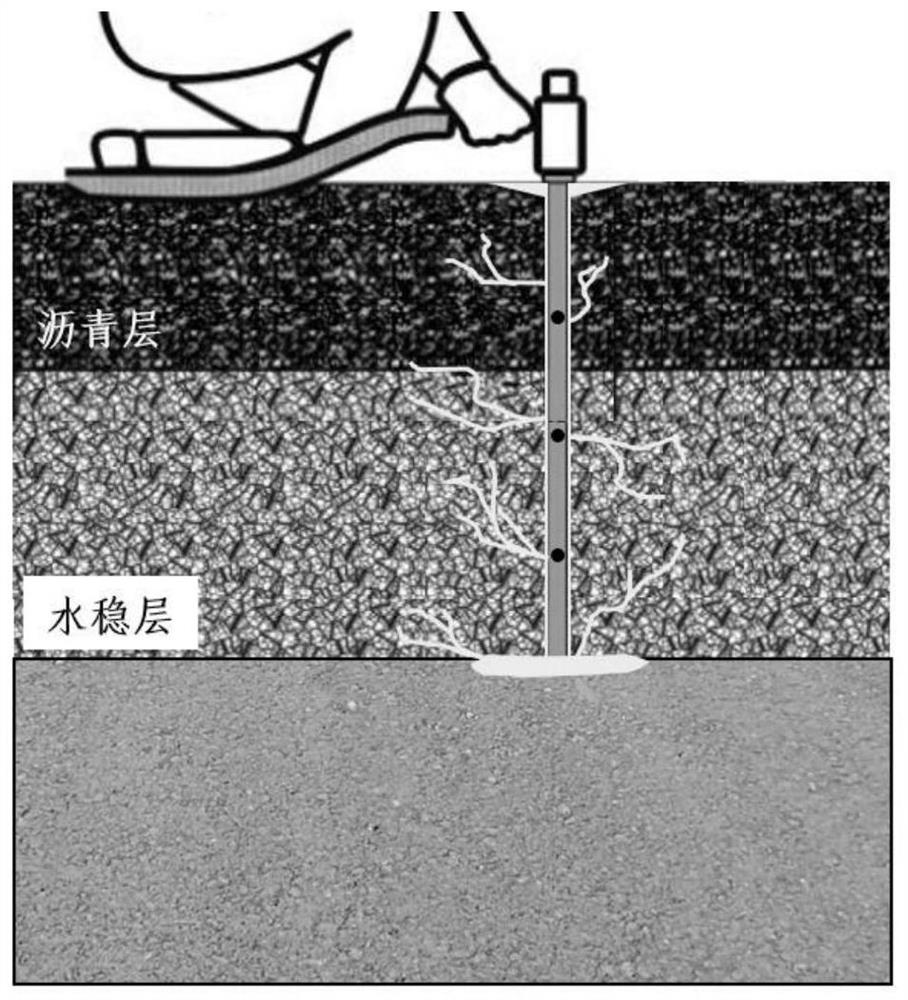

Polyether type polyurethane grouting material and treatment method for asphalt pavement pumping damage

ActiveCN112159511ALow expansion ratioCuring time controllableClimate change adaptationRoads maintainencePtru catalystPavement maintenance

The invention discloses a polyether type polyurethane grouting material and a treatment method for asphalt pavement pumping damage, belongs to the field of pavement maintenance and grouting materials,and aims to solve the technical problem of how to perform rapid minimally invasive repair on the pavement pumping damage to ensure rapid recovery of pavement bearing capacity and use functions. According to the technical scheme, the grouting material comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 0.9: 1 to 1: 1; the component A comprises polyisocyanate; the component B is mainly prepared by mixing the following raw materials in parts by weight: 80-120 parts of polyether polyol, 0.1-1.0 part of a catalyst, 10-30 parts of a chain extender, 4-8 parts of a foam stabilizer, 20-50 parts of a plasticizer, 10-25 parts of tackifying resin, 4-10 parts of a silane coupling agent and 1-5 parts of a water removal agent. The method specifically comprises the following steps: S1, disease marking: detecting and marking the pumping disease condition of a pavement; S2, grouting and hole distribution; S3, structural drainage; S4, grouting reinforcement; S5, surface loosening treatment; and S6, sealing water on surface.

Owner:SHANDONG TRANSPORTATION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com