Resin composition for foam molding, foam, and process for producing foam

A technology of resin composition and manufacturing method, which is applied in the field of resin composition for foam molding, can solve the problem that the foaming agent cannot be dispersed, dissolved, dissolved in the base, has excellent recyclability or in-mold molding processability, and cannot effectively promote Foaming and other problems, to achieve the effect of microcoagulation structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

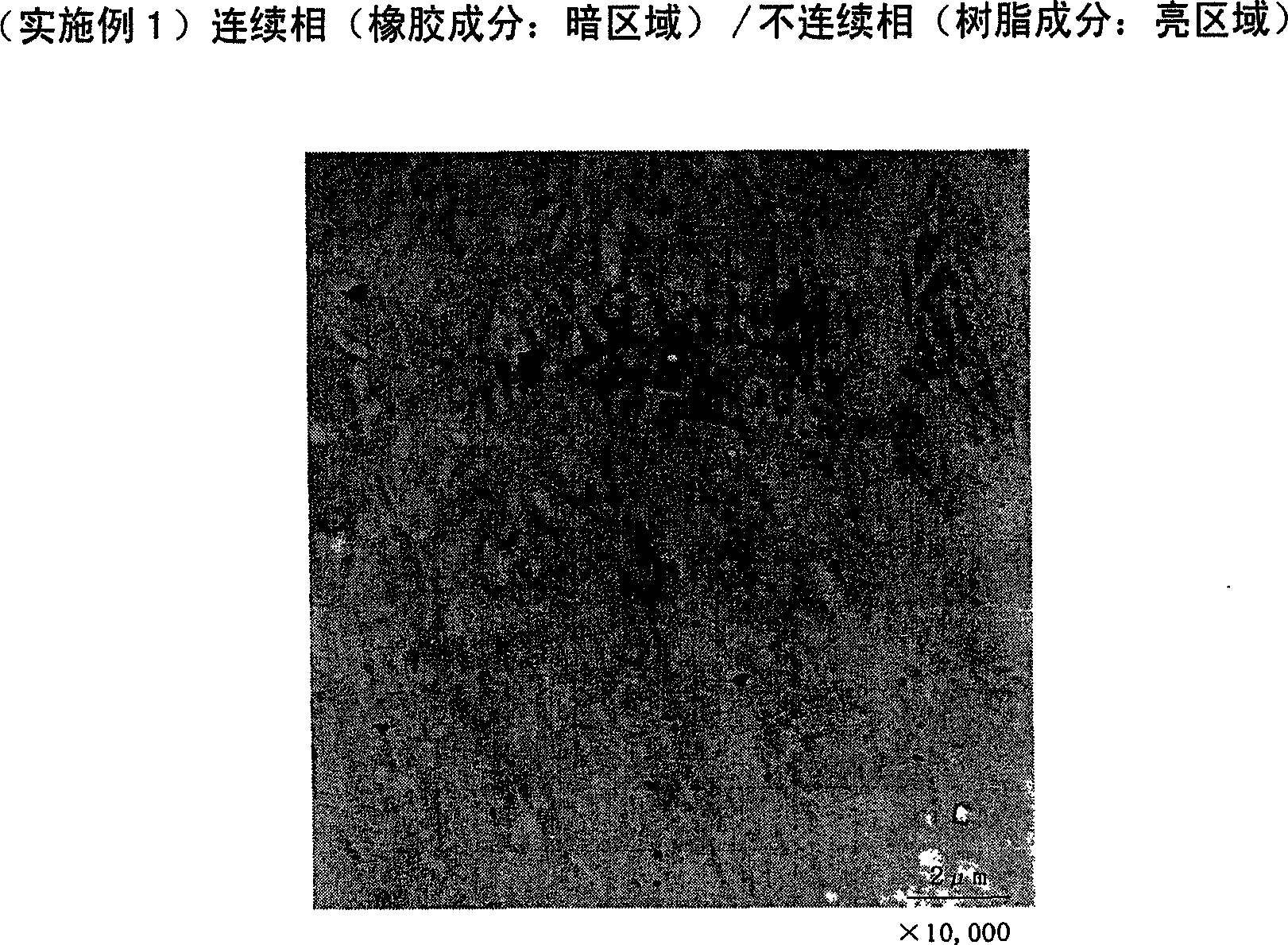

Embodiment 1

[0096]0.15 parts by weight of 2,5-dimethyl-2,5-di(tert-dibutylperoxy)hexyne-3 [peroxide] and 0.2 parts by weight of trimethylolpropane trimethacrylate [auxiliary] In the presence of parts by weight, for ethylene-propylene-non-conjugated diene copolymer rubber [EPT; ethylene content 38 mol%, iodine value 12, MFR (ASTM 1238, 190°C, 2.16 kg load) 1.1 g / 10 min] 65 Parts by weight, polypropylene [PP; propylene content 100%, MFR (ASTM 1238, 190° C., 2.16 kg load) 5.0 g / 10 minutes] 35 parts by weight were kneaded to obtain a foamable olefin-based thermoplastic elastomer (( i) The continuous phase in the microcoagulate structure is the rubber phase and the discontinuous phase is the crystalline phase, (ii) gel fraction: 3.2 wt%). 4 parts by weight of a mixture of sodium bicarbonate and citric acid were kneaded with respect to 100 parts by weight of the obtained foamable olefin-based thermoplastic elastomer to prepare a masterbatch (foamable olefin-based thermoplastic elastomer). Afte...

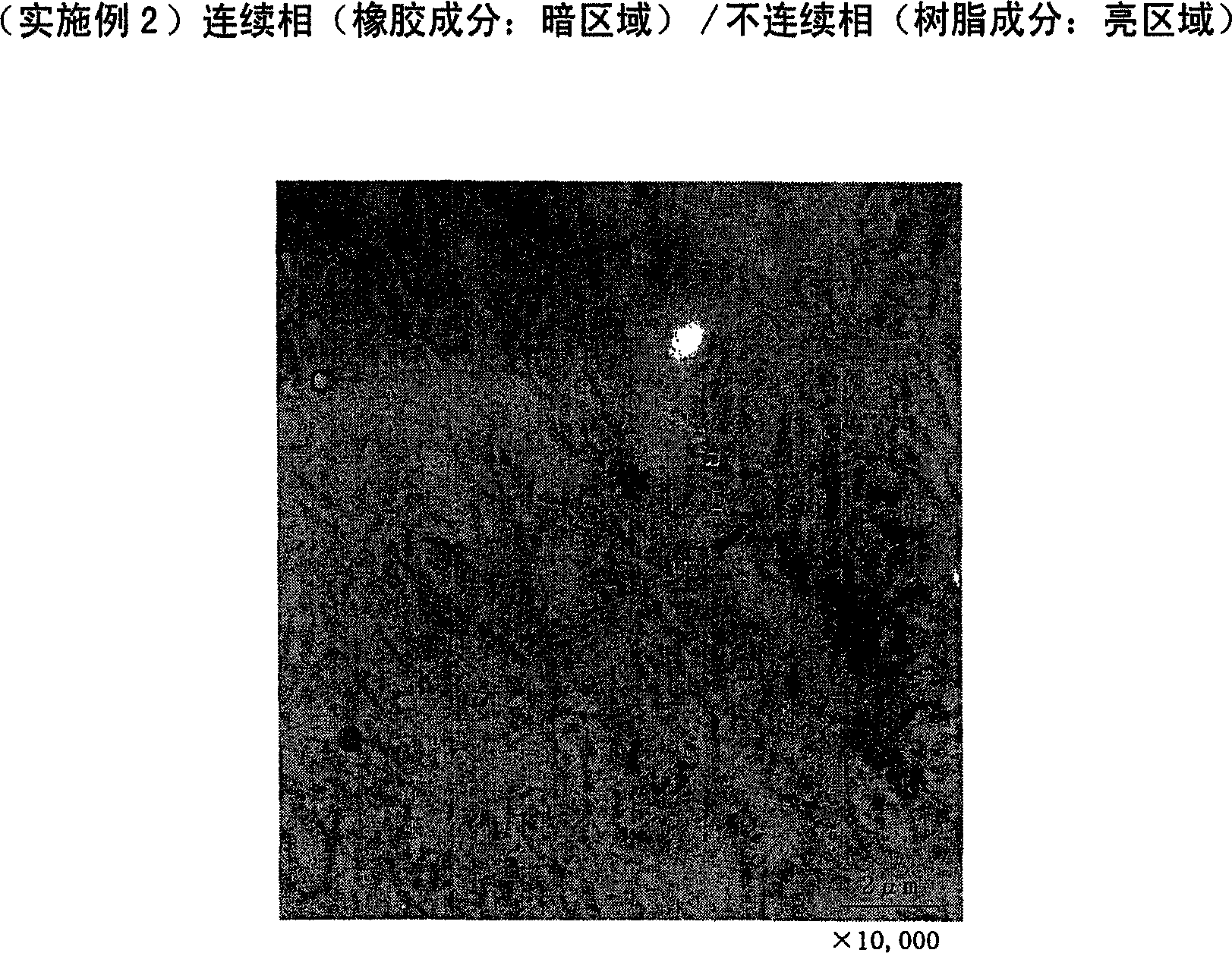

Embodiment 2

[0099] 0.15 parts by weight of 2,5-dimethyl-2,5-di(tert-dibutylperoxy)hexyne-3 [peroxide] and 0.2 parts by weight of trimethylolpropane trimethacrylate [auxiliary] In the presence of parts by weight, for ethylene-propylene-non-conjugated diene copolymer rubber [EPT; ethylene content 38 mol%, iodine value 12, MFR (ASTM 1238, 190°C, 2.16 kg load) 1.1 g / 10 min] 75 Parts by weight, polypropylene [PP; propylene content 100%, MFR (ASTM 1238, 190° C., 2.16 kg load) 5.0 g / 10 minutes] 25 parts by weight were kneaded to obtain a foamable olefin-based thermoplastic elastomer ((i ) The continuous phase in the microcoagulated structure is the rubber phase and the discontinuous phase is the crystalline phase, (ii) gel fraction: 4.2 wt%). 4 parts by weight of a mixture of sodium bicarbonate and citric acid were kneaded with respect to 100 parts by weight of the obtained foamable olefin-based thermoplastic elastomer to prepare a masterbatch (foamable olefin-based thermoplastic elastomer). Af...

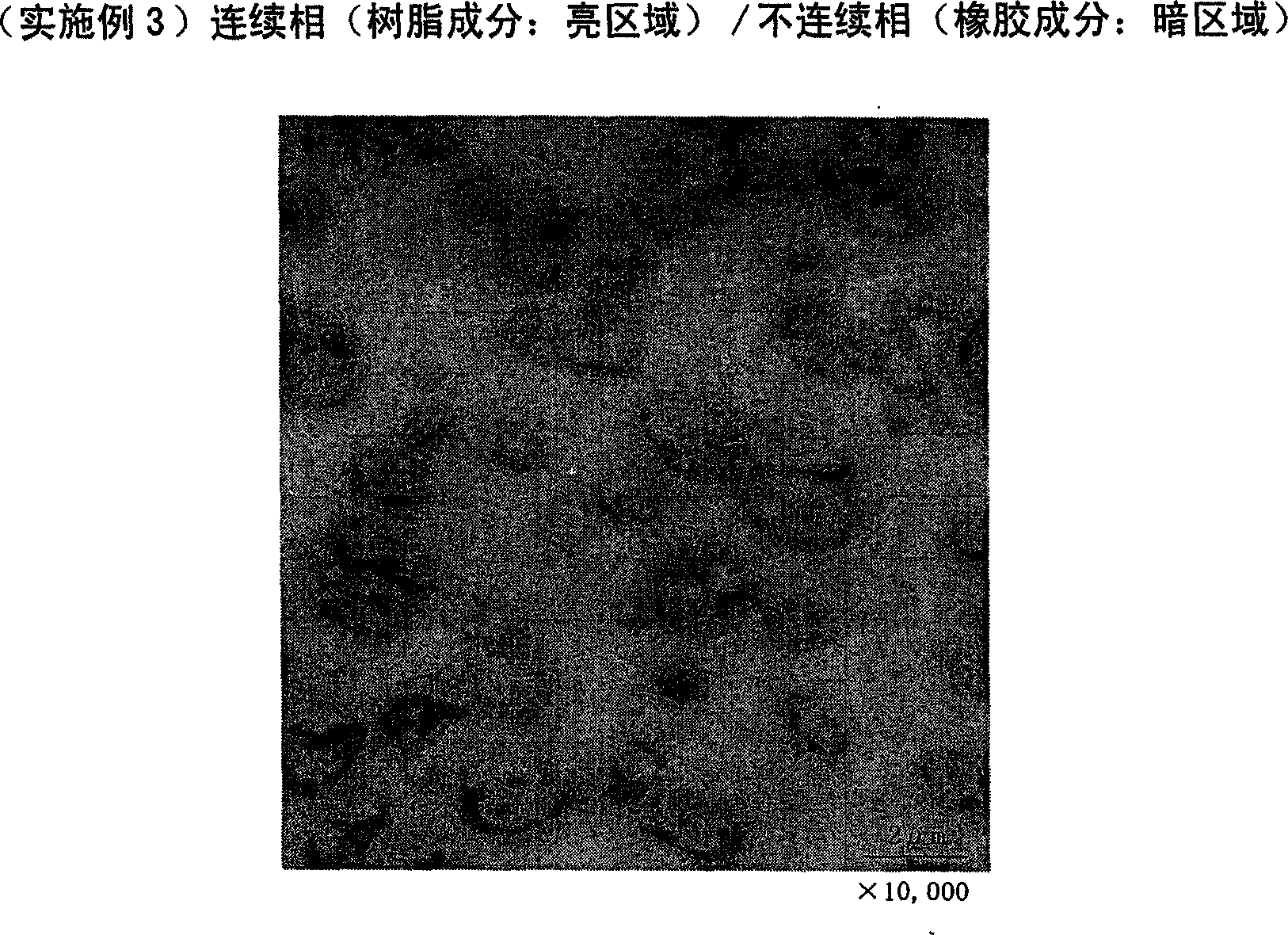

Embodiment 3

[0102] 0.10 parts by weight of 2,5-dimethyl-2,5-di(t-butylperoxy)hexyne-3 [peroxide] and 0.15 parts by weight of trimethylolpropane trimethacrylate [auxiliary] In the presence of parts by weight, for ethylene-propylene-non-conjugated diene copolymer rubber [EPT; ethylene content 38 mol%, iodine value 12, MFR (ASTM 1238, 190°C, 2.16 kg load) 1.1 g / 10 min] 75 Parts by weight, polypropylene [PP; propylene content 100%, MFR (ASTM 1238, 190° C., 2.16 kg load) 5.0 g / 10 minutes] 25 parts by weight were kneaded to obtain a foamable olefin-based thermoplastic elastomer ((i ) The continuous phase in the microcoagulated structure is the rubber phase and the discontinuous phase is the crystalline phase, (ii) gel fraction: 1.3 wt%). With respect to 100 parts by weight of the obtained foamable olefin-based thermoplastic elastomer, after melting and dispersing 0.3w% of nitrogen in a cylinder at 230°C, the foamable olefin was injected into the clamped metal mold formed by the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com