Foaming agent composition, polyurethane foam and manufacturing method thereof

A polyurethane foam and composition technology, applied in the field of polyurethane foam, can solve the problems of increased polyurethane foam manufacturing cost, complex use process, high cost, etc., and achieve the effect of excellent overall performance, good dimensional stability, and good thermal insulation performance of the foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The specific components and mass content of polyurethane foam are:

[0057] Dry white material: 100 parts by mass, organic polyisocyanate: 148.58 parts by mass, blowing agent composition: 43.1 parts by mass, wherein the blowing agent composition includes: a mixture of cyclopentane and isopentane: 15.5 parts by mass, pentafluoro Propane (HFC-245fa): 26 parts by mass, water: 1.6 parts, and the mass ratio of cyclopentane to isopentane is 7:3.

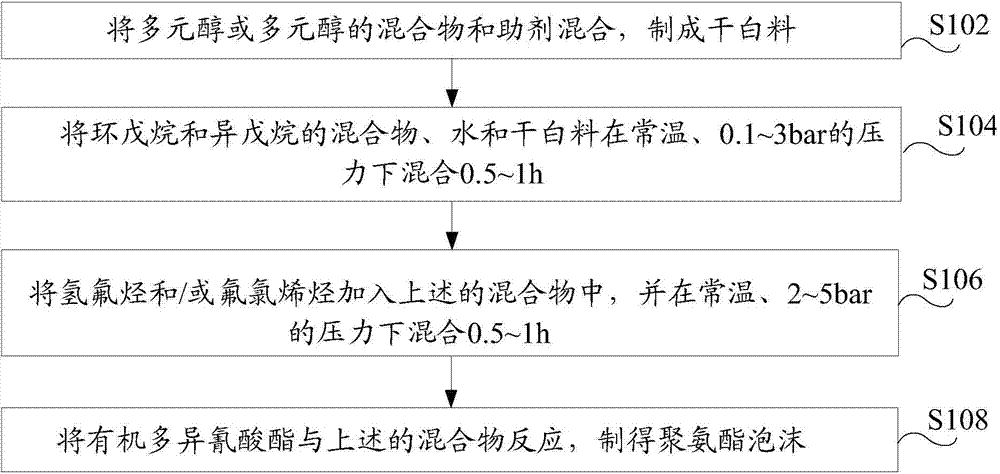

[0058] The preparation process of polyurethane foam is as follows:

[0059] I) Mixing polyols or mixtures of polyols and additives to prepare dry white materials.

[0060] II) Treat the mixture of cyclopentane and isopentane, water and dry white material: mix the mixture of cyclopentane and isopentane, water and dry white material at room temperature (15~25℃), 0.1~3bar Mix for 0.5~1h under the same pressure.

[0061] III) Add the pentafluoropropane stored in the pressure tank to the mixture prepared in step II, and mix for 0.5-1h at room te...

Embodiment 2

[0066] The specific components contained in the polyurethane foam and their mass content are: dry white material: 100 parts by mass, organic polyisocyanate: 144.33 parts, blowing agent composition: 41.5 parts, wherein the specific components contained in the blowing agent composition and Its mass content is: cyclopentane mixture: 20 parts by mass, pentafluoropropane (HFC-245fa): 20.5 parts by mass, water: 1.0 parts by mass, and the mass ratio of cyclopentane to isopentane: 6: 4.

[0067] The method for preparing polyurethane foam in this example is the same as that in Example 1, and the molding density of the prepared polyurethane foam is 26.9kg / m 3 , The thermal conductivity is 18.45mW / m·k, compared with the existing polyurethane foam, its molded density is lower, the quality of the same volume of the polyurethane foam is smaller, and the material used is less, which can reduce the manufacture of the polyurethane foam Cost; the thermal conductivity of polyurethane foam is also s...

Embodiment 3

[0069] The specific components contained in the polyurethane foam and their mass content are: dry white material: 100 parts by mass, organic polyisocyanate: 148.05 parts by mass, blowing agent composition: 42.5 parts by mass, wherein the composition of the blowing agent composition is: / Isopentane mixture: 18 parts by mass, HFC-245fa: 23 parts by mass, water: 1.5 parts by mass, and the mass ratio of cyclopentane to isopentane: 8:2.

[0070] In this example, the method of preparing polyurethane foam is the same as that of Example 1, and the molded density of the obtained foam is 27.2kg / m 3 , The thermal conductivity is 18.3mW / m·k, compared with the existing polyurethane foam, its molding density is lower, the quality of the same volume of the polyurethane foam is smaller, and the material used is less, which can reduce the manufacture of the polyurethane foam Cost; the thermal conductivity of polyurethane foam is also smaller, and the thermal insulation performance is excellent, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com