Rotary drilling hole forming method by using multi-stage alloy pilot roller bit in complex stratum cast-in-place pile construction

A technology of roller cone bits and cast-in-situ piles, which is applied in directional drilling and other directions, can solve problems such as contract performance and control of engineering costs, problems such as failure to ensure rock sockets normally, and meeting design requirements, so as to avoid repeated crushing, not easy to swing, guide Positive Performance Guaranteed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

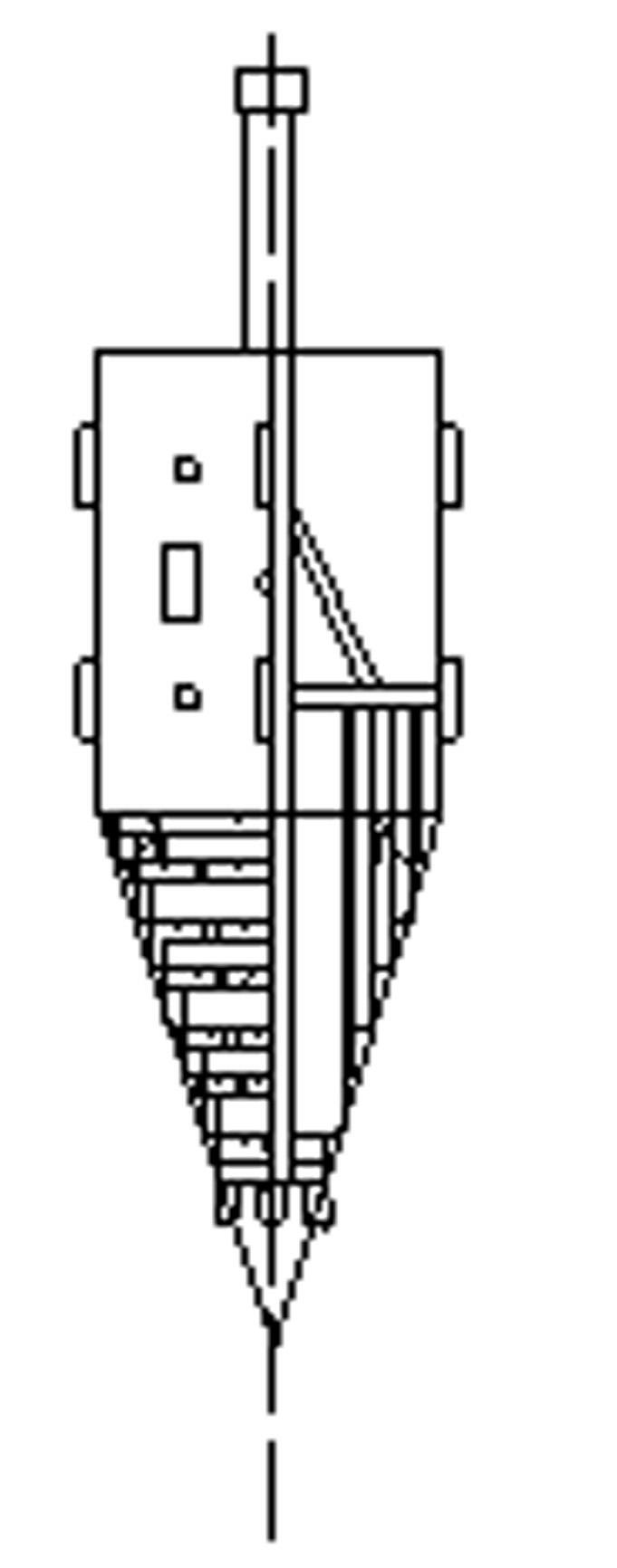

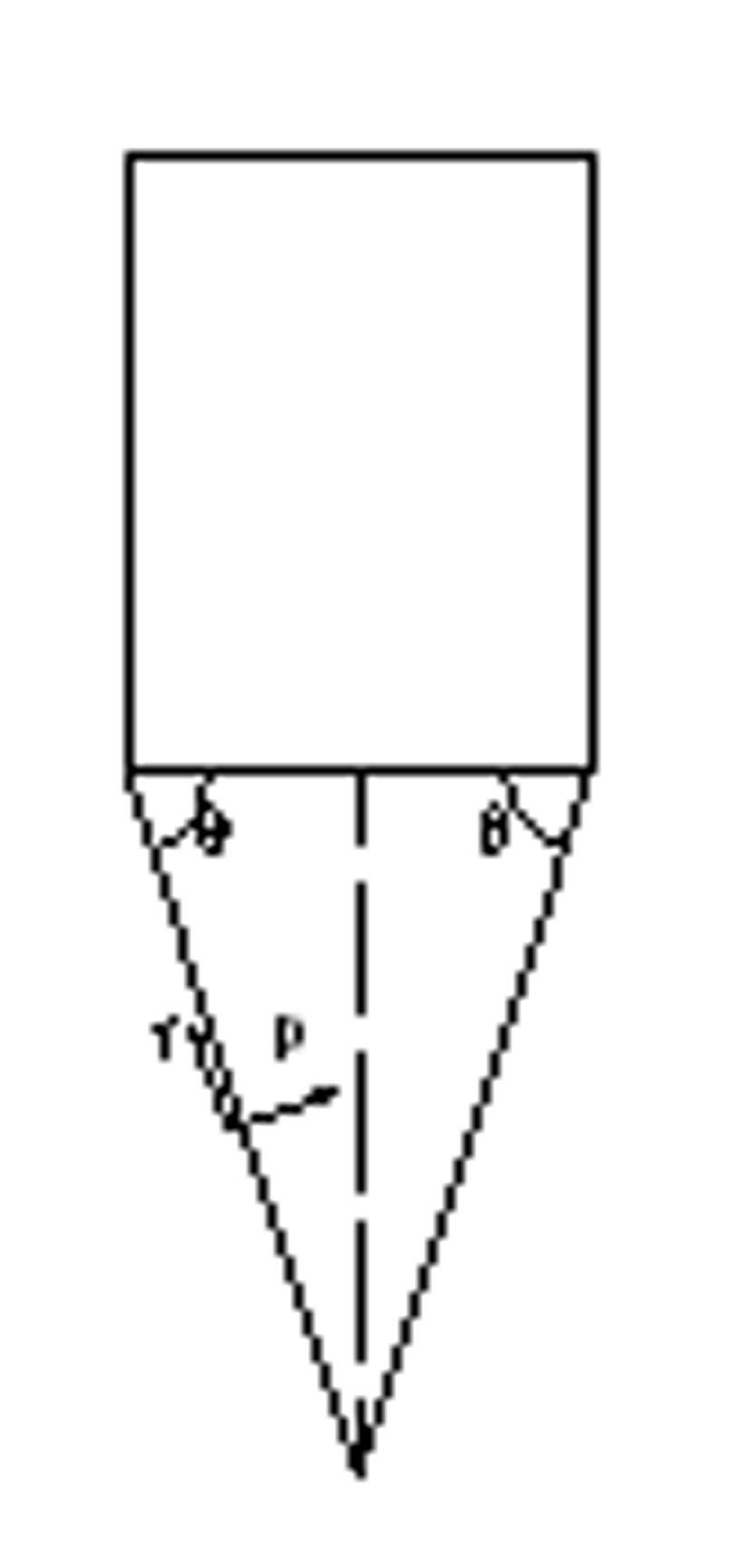

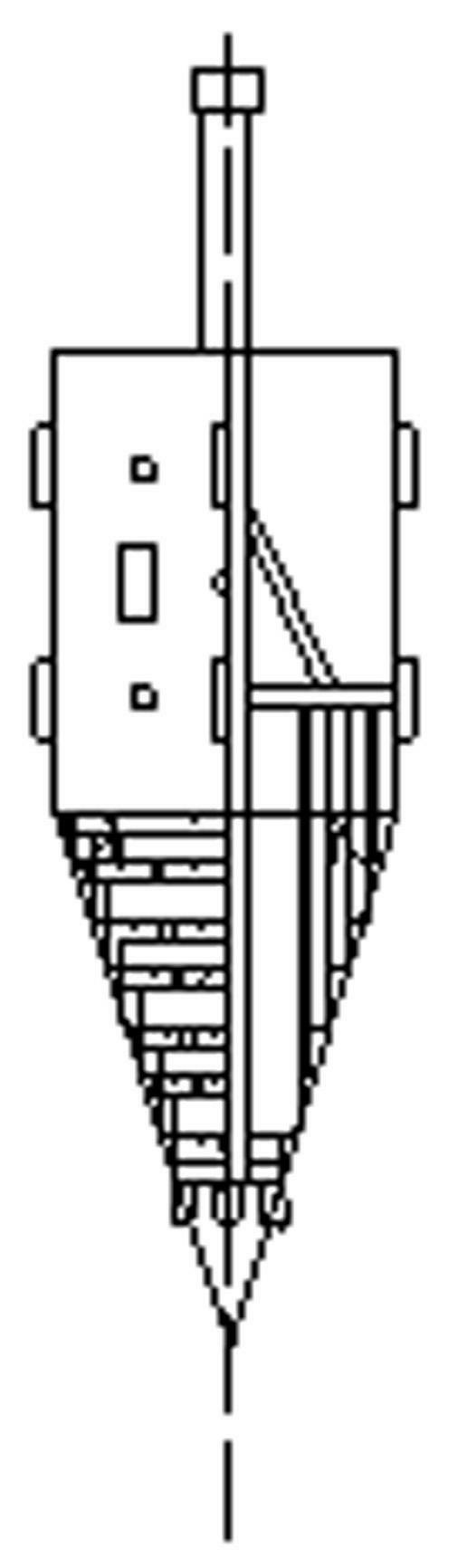

[0028] The construction of cast-in-place piles in complex strata of the present invention adopts the multi-stage alloy advanced cone bit rotary drilling method to form holes. The basic construction process operation process of this construction method is strictly in accordance with the "Technical Specifications for Building Pile Foundations (JGJ 94-2008)" about drilling and pouring The requirements for pile construction are implemented. Here, we only take the construction method of penetrating beaded karst caves in karst areas as an example, and explain its differences from traditional construction methods in detail. Others will not be explained one by one:

[0029] The conventional drill bit is used to drill to the surface of the bedrock layer, and the judgment basis is: the karst construction investigation report and the drilling speed and status (the drilling speed is obviously slowed down, the drill pipe jumps violently, and the drilling stops, which means that it has reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com