Patents

Literature

84results about How to "Guaranteed verticality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

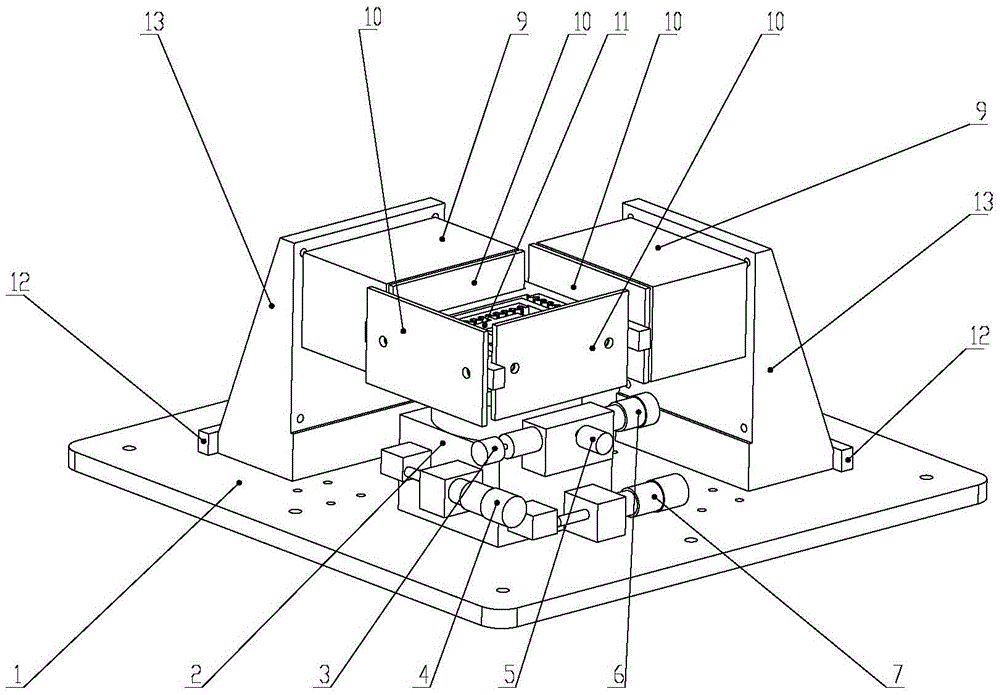

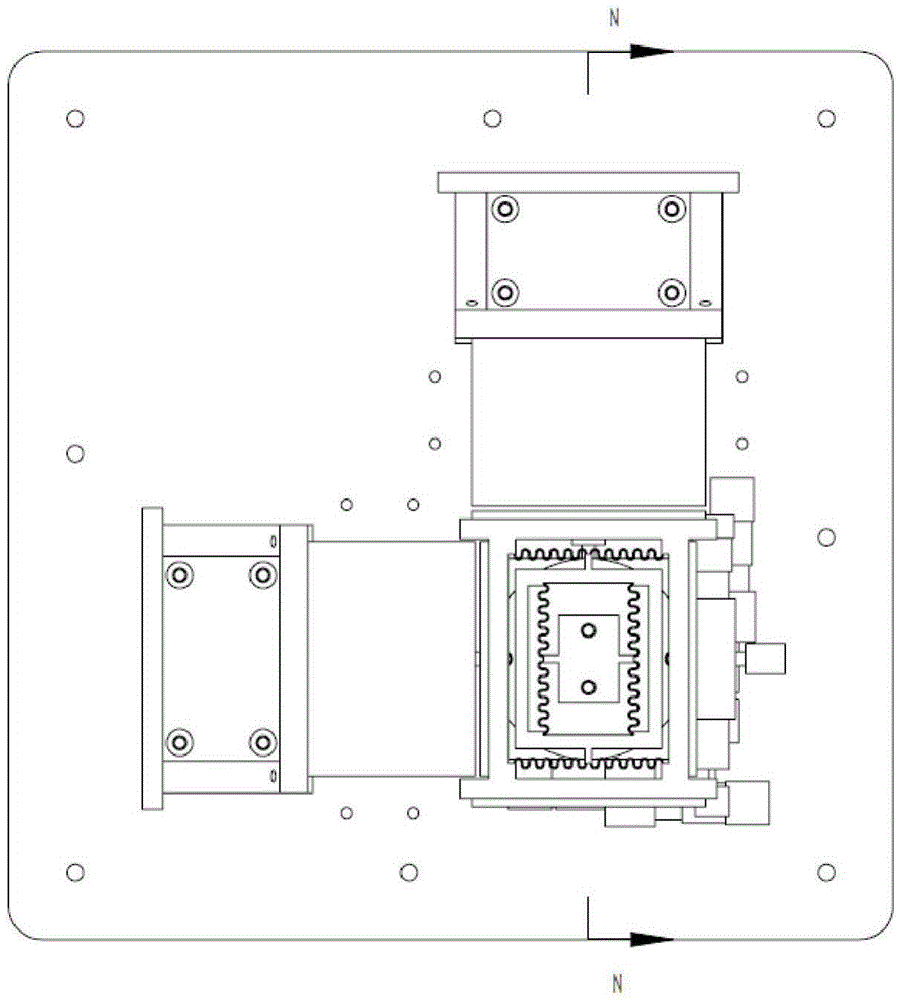

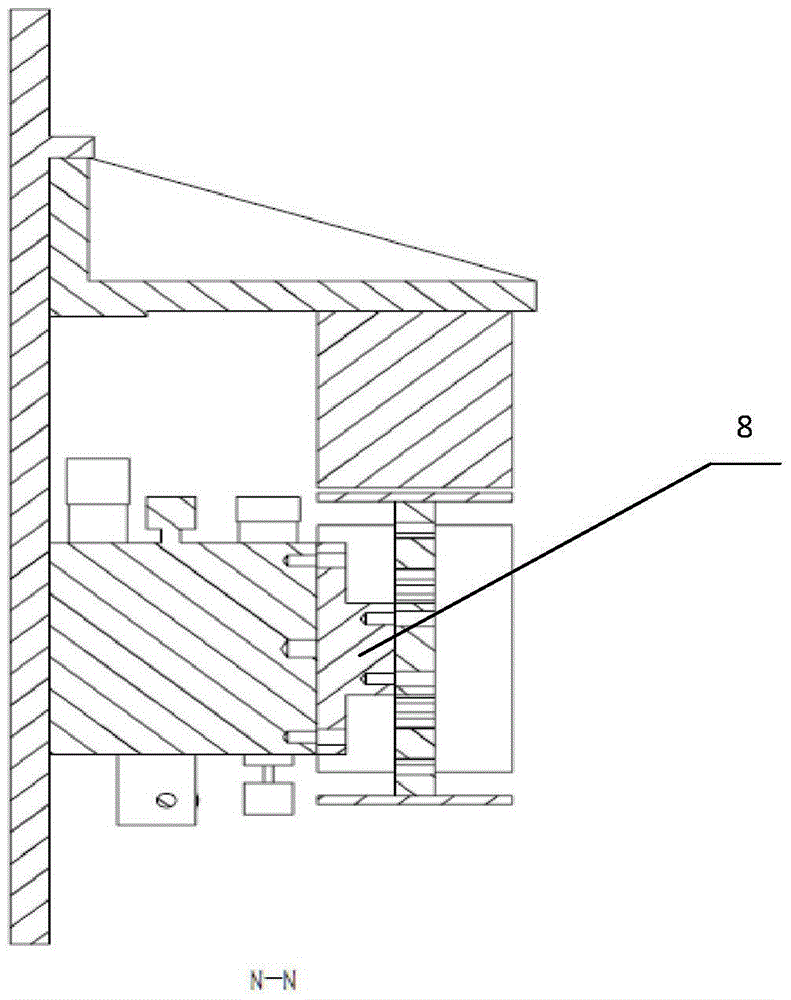

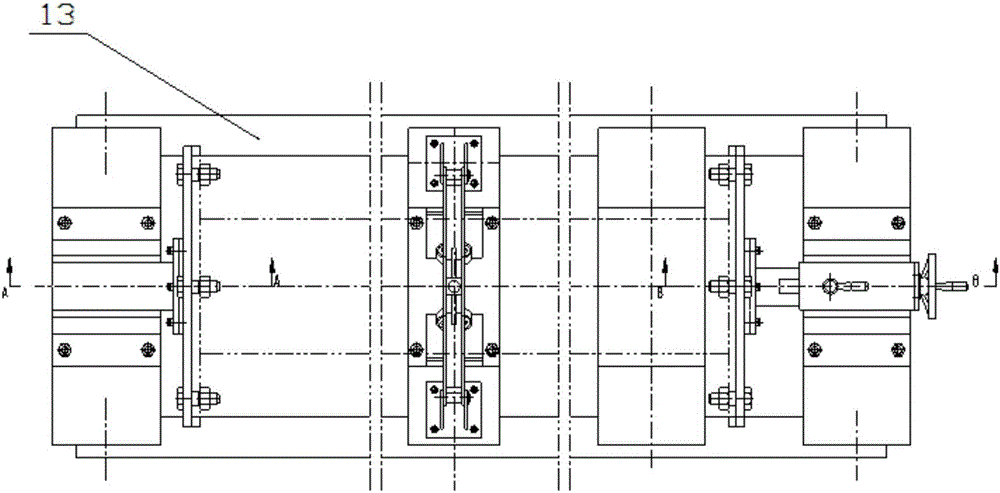

Displacement-adjustable precision locating platform

The invention discloses a displacement-adjustable precision locating platform. The displacement-adjustable precision locating platform comprises a base, a manual adjustable frame sliding table platform, a platform cushion block, a compliant hinge precision locating platform body, four electromagnetic armatures, two Z-axis right-angle junction plates and electromagnetic drivers. The manual adjustable frame sliding table platform can achieve three-freedom-degree precision locating adjustment through a cross rotating guide rail. The platform cushion block is arranged on a sliding table through four evenly-distributed threaded holes. The middle of the compliant hinge precision locating platform body is fixed to the platform cushion block through two threaded holes, and therefore the platform can achieve displacement in the X-axis direction and Y-axis direction along with the manual adjustable frame sliding table platform. The four electromagnetic armatures are fixed in the four directions of the compliant hinge precision locating platform body in a threaded connection manner. The two Z-axis right-angle junction plates are in threaded connection with the base of the platform. The electromagnetic drivers serve as drive equipment of the platform and are in threaded connection with the Z-axis right-angle junction plates to be connected with the base of the platform. The displacement-adjustable precision locating platform is simple in structure, small in overall size, low in cost and convenient to operate, and the high-precision locating requirement can be met.

Owner:SOUTH CHINA UNIV OF TECH +1

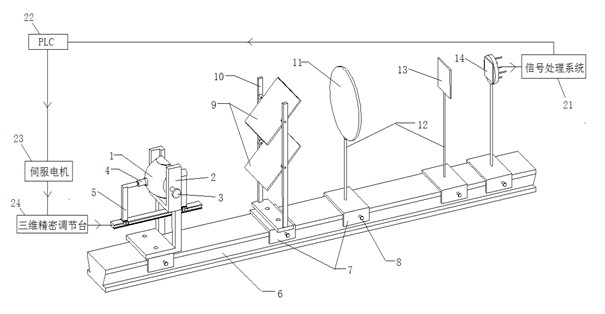

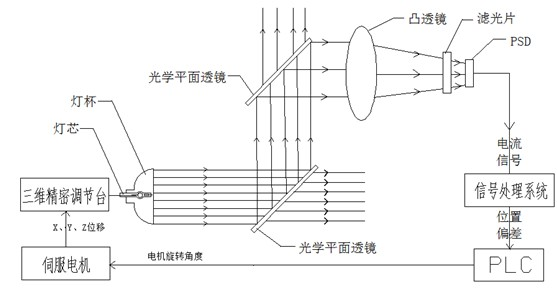

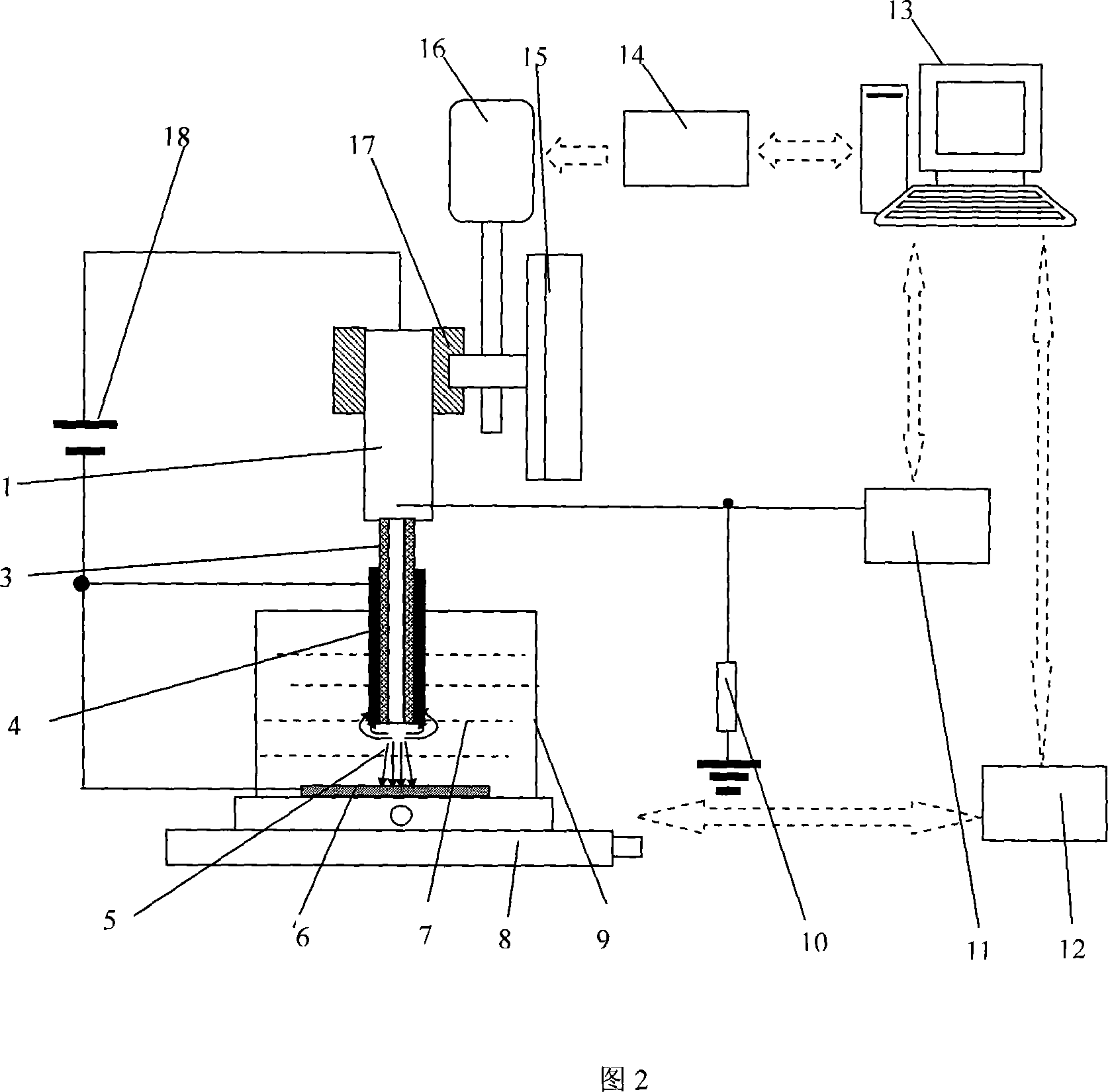

Automatic focusing device for projective bulb based on light spot detection and use method thereof

InactiveCN102305988AEasy to operateImprove efficiencyElectric circuit arrangementsProjectorsProgrammable logic controllerLight spot

The invention discloses an automatic focusing device for a projective bulb based on light spot detection and a use method thereof. The automatic focusing device comprises a lamp cup, a lamp cup clamping table, a screw I, a lampwick, a lampwick clamping frame, a large guide rail, a large slider, a screw II, an optical planar lens, a clamping holder, a convex lens, a supporting column, an optical filter, a two-dimensional photoelectric position sensor (PSD), a signal processing system, a PLC (programmable logic controller), a servo motor and a three-dimensional precise adjusting table, wherein light emitted from the lampwick can be reflected by the inner surface of the lamp cup to form parallel light beams, the parallel light beams can be transmitted and reflected twice by the optical planar lens, small parts of the light can be reflected to the convex lens, and then the light irradiates on the PSD by the optical filter after being gathered; a signal output by the PSD can be subjected to a series of conversion by the signal processing system, the PLC, the servo motor and the three-dimensional precise adjusting table; and finally the signal is used to control the position of the lampwick in the lamp cup. The device provided by the invention has the advantages of simple use method, low cost, high efficiency, high focusing precision and the like.

Owner:江苏森莱浦光电科技有限公司

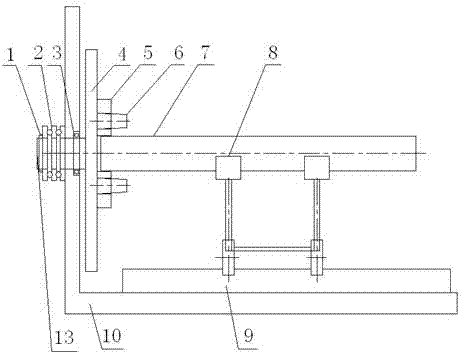

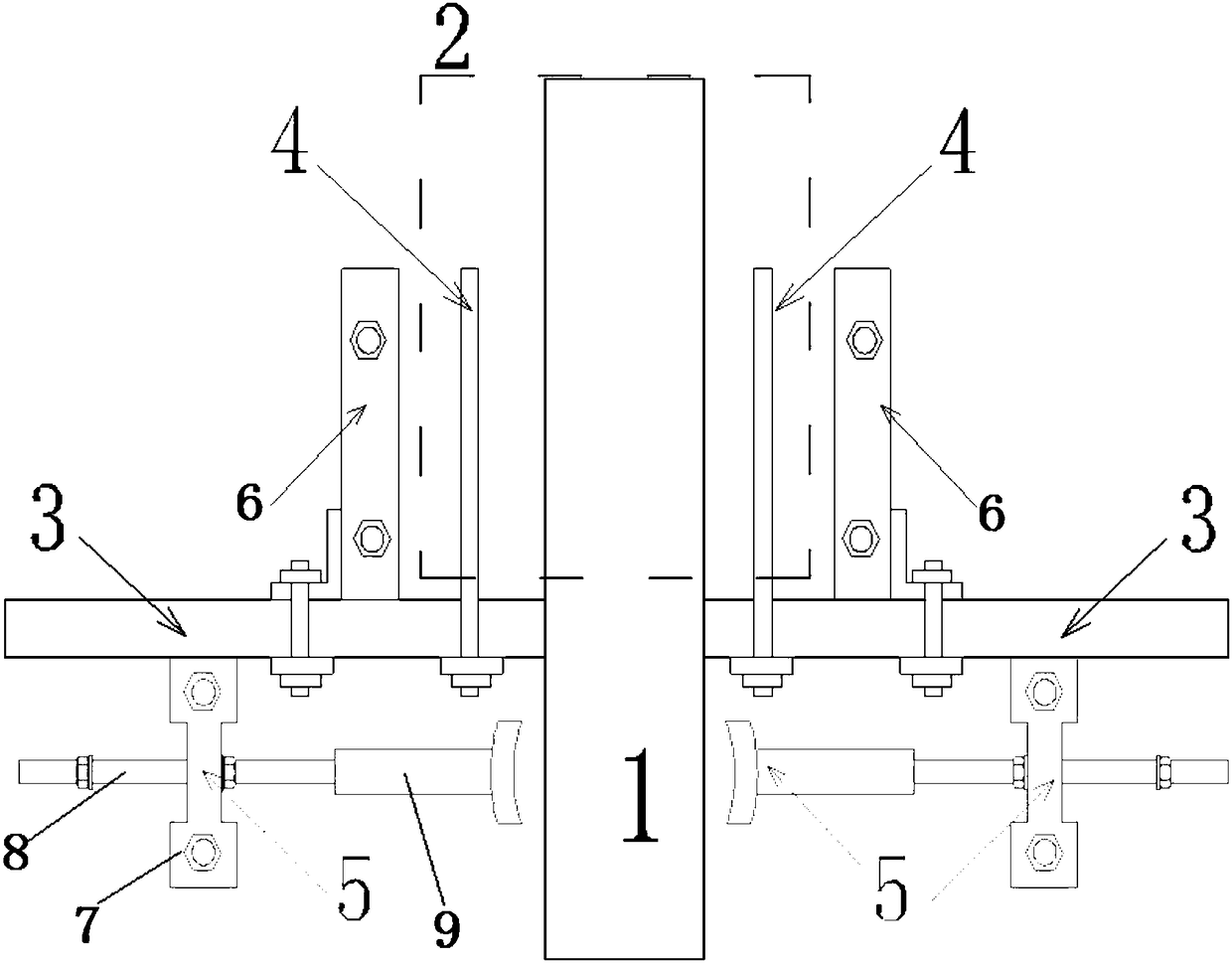

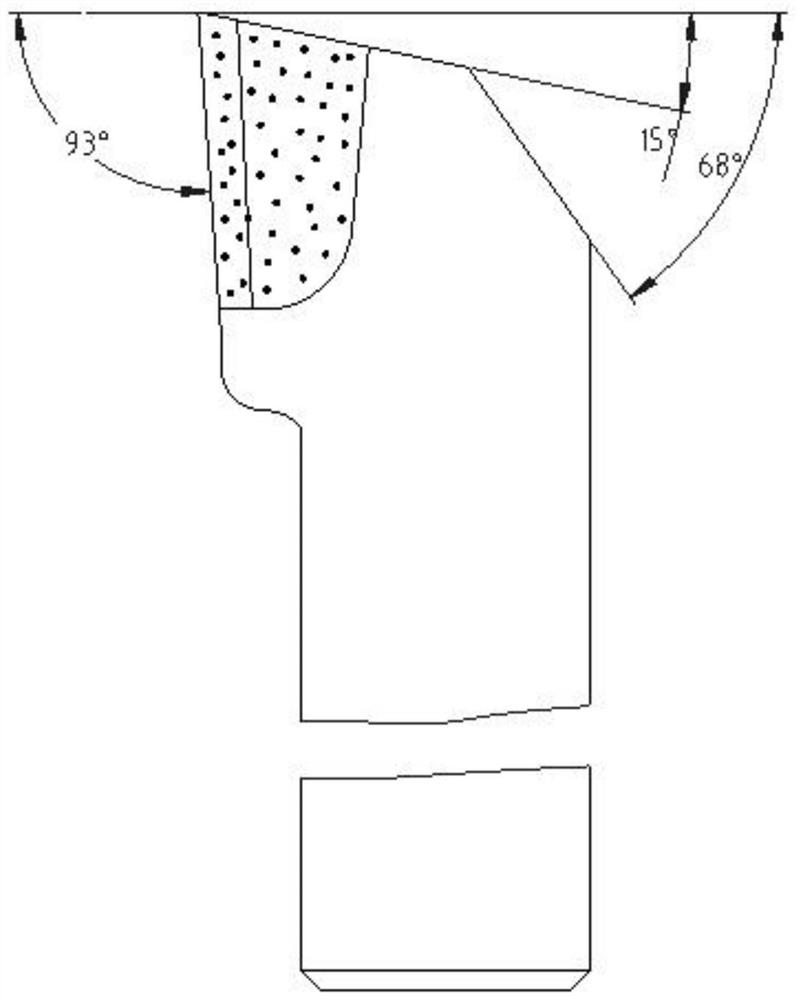

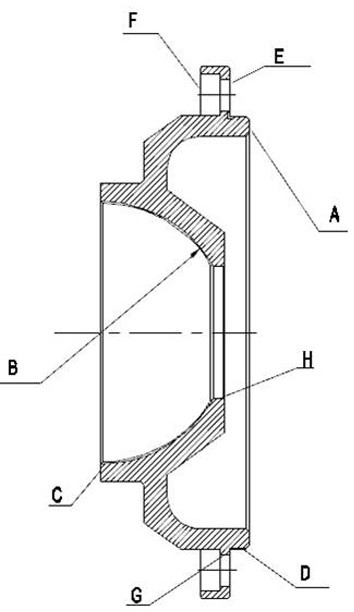

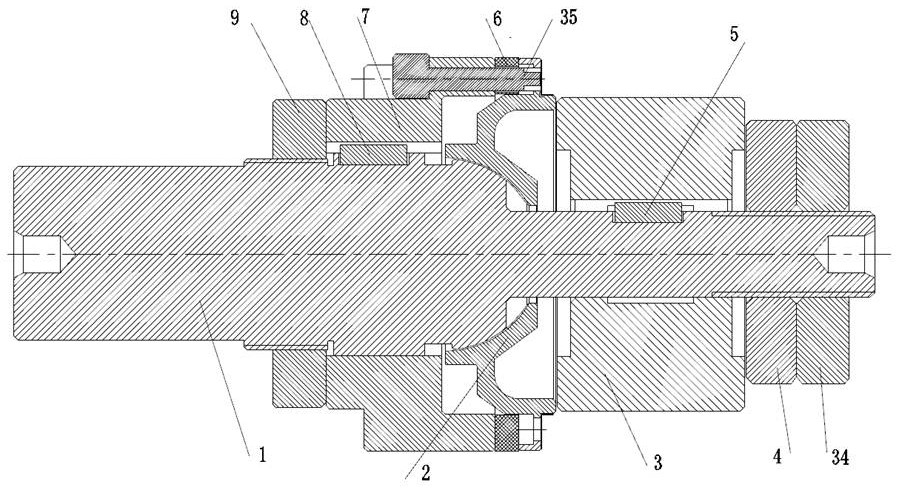

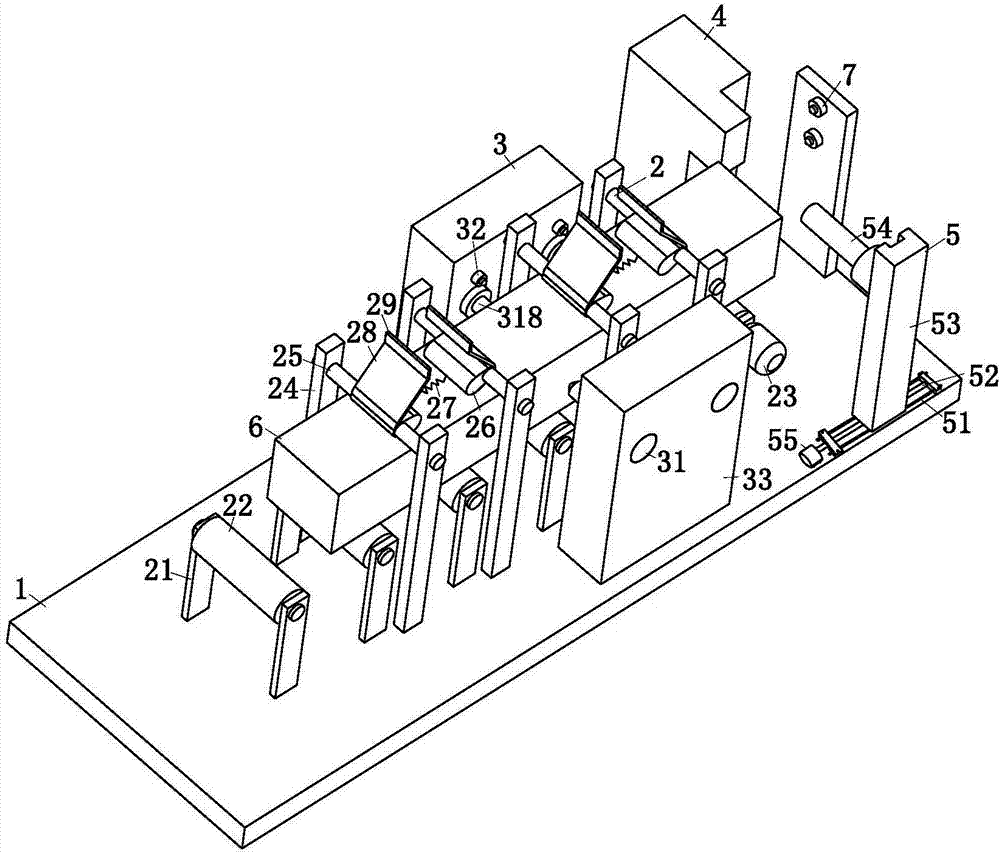

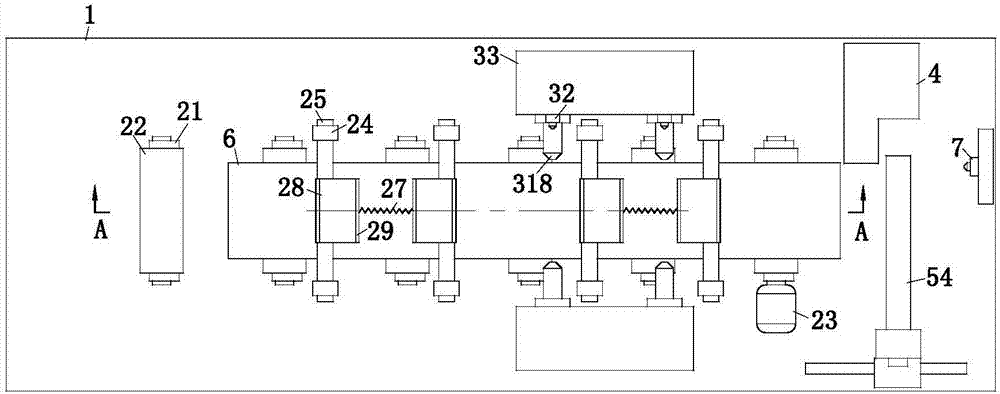

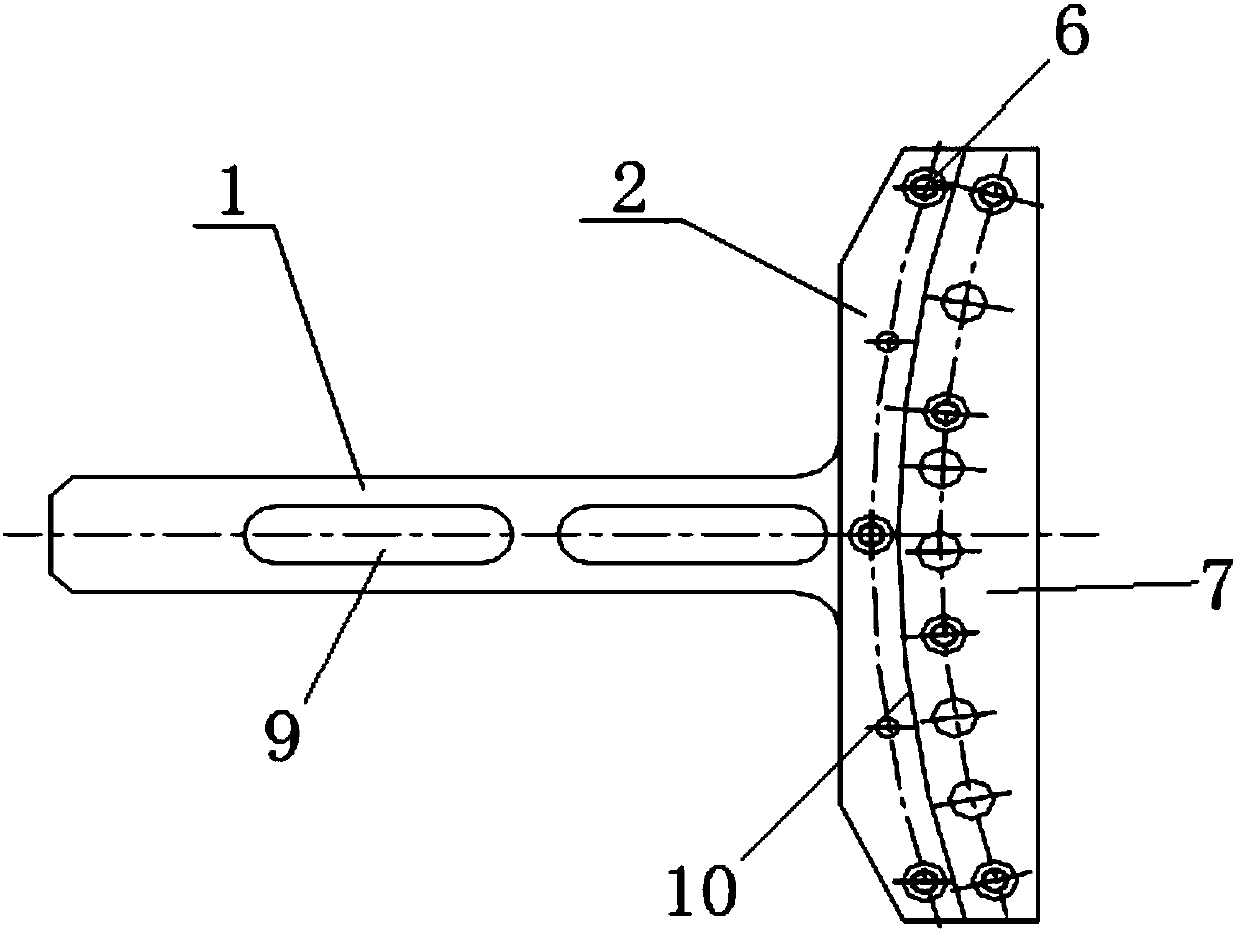

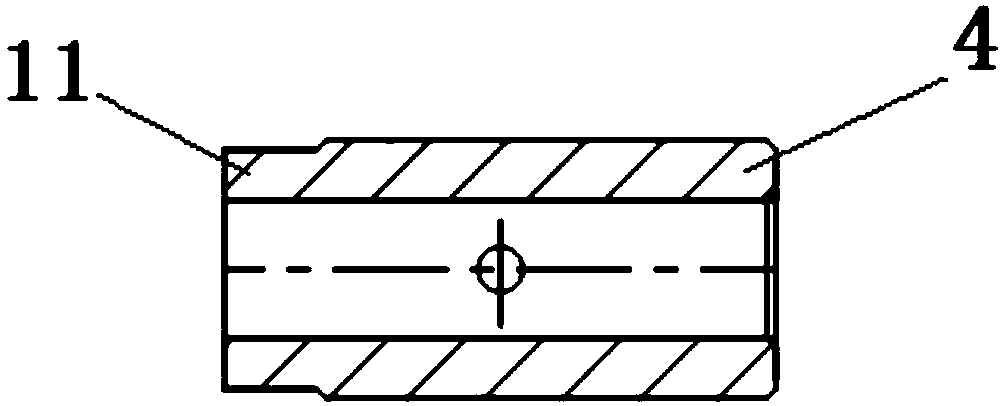

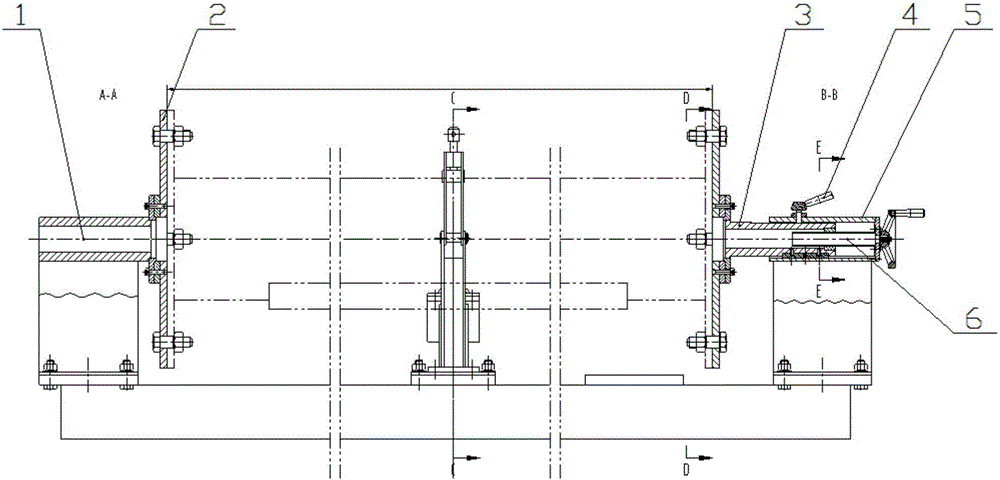

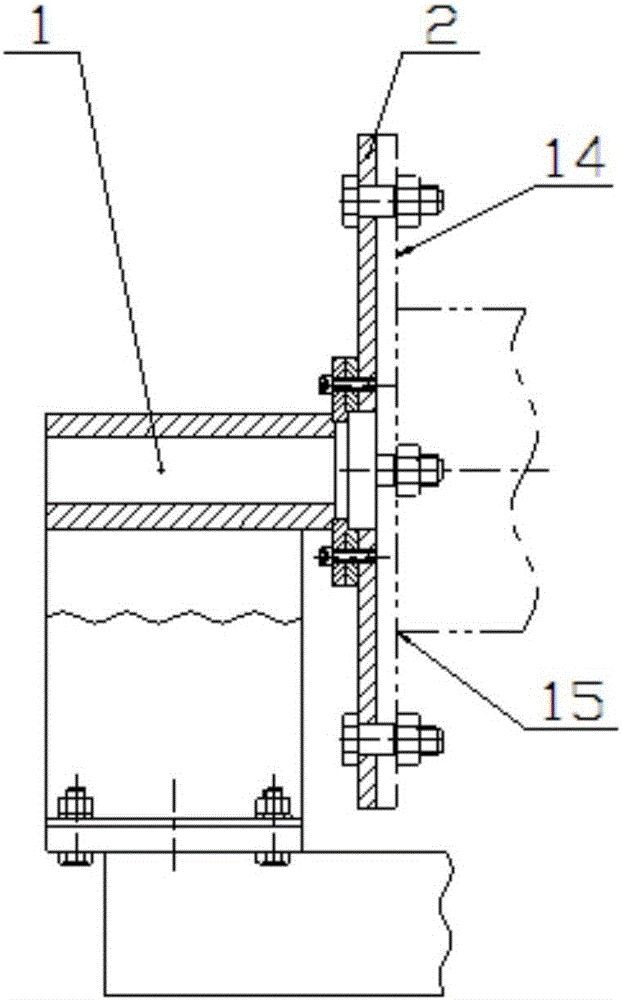

Connecting pipe and flange assembling device

ActiveCN103921043AGuaranteed verticality requirementsGuaranteed parallelismWelding/cutting auxillary devicesAuxillary welding devicesBall bearingButt joint

The invention discloses a connecting pipe and flange assembling device, belongs to the technical field of oil and gas field connecting pipe assembling, and aims to solve the problems that manual connecting pipe flange assembling efficiency is low through a skid mounted unit and assembling quality is difficult to guarantee. The assembling device comprises an L-shaped operating platform, a fixing support member, a rail, a flange fixing member, a flange, a rotary shaft, a locking nut, a planar pushing ball bearing, a deep groove ball bearing and the like. According to the device, by controlling the coaxiality during connecting pipe and flange assembling, high accuracy of connecting pipe and flange assembling is guaranteed, and consistence requirements of assembling gaps and unfitness of butt joint in the same batch can be improved; in addition, by adjusting the device once, rapid assembly of connecting pipes and flanges in batches can be implemented, labor force is saved, and assembling efficiency is improved.

Owner:XIAN CHANGQING TECH ENG

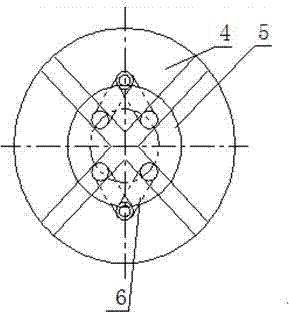

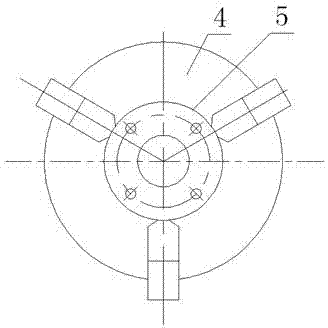

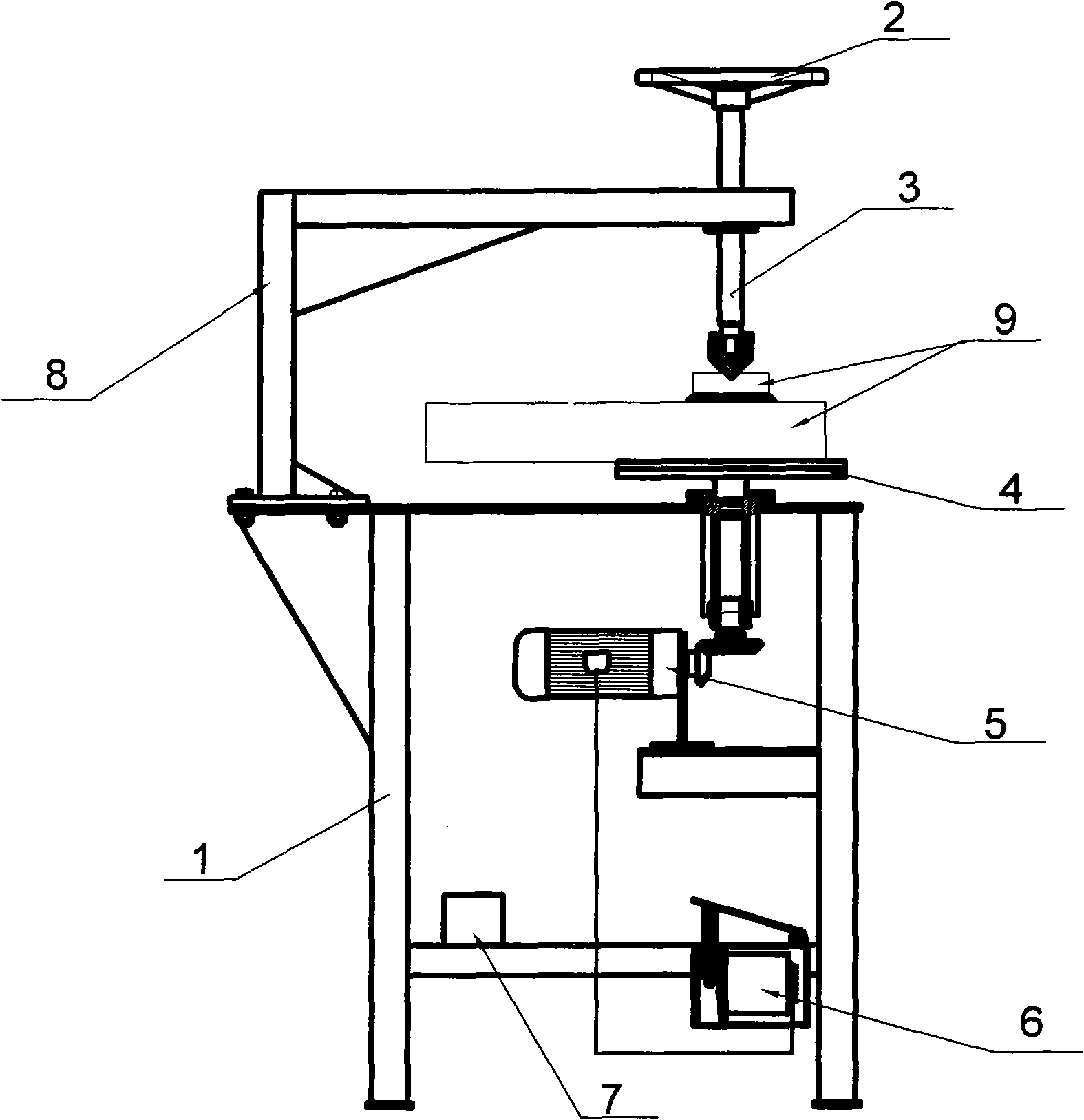

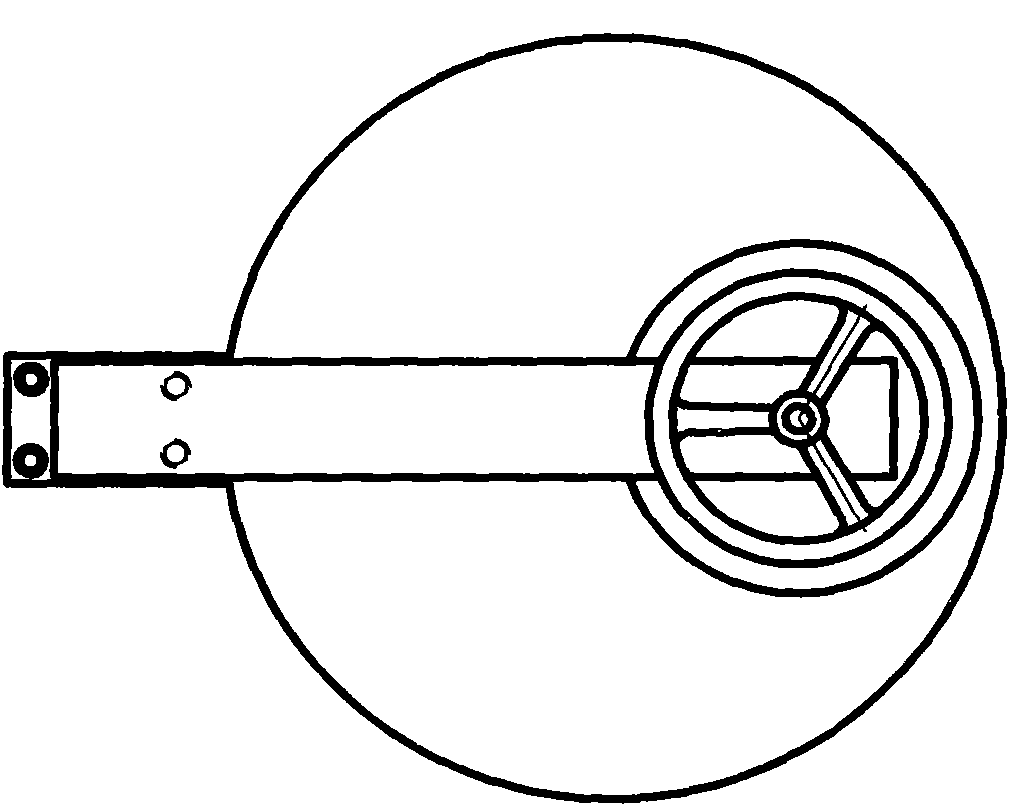

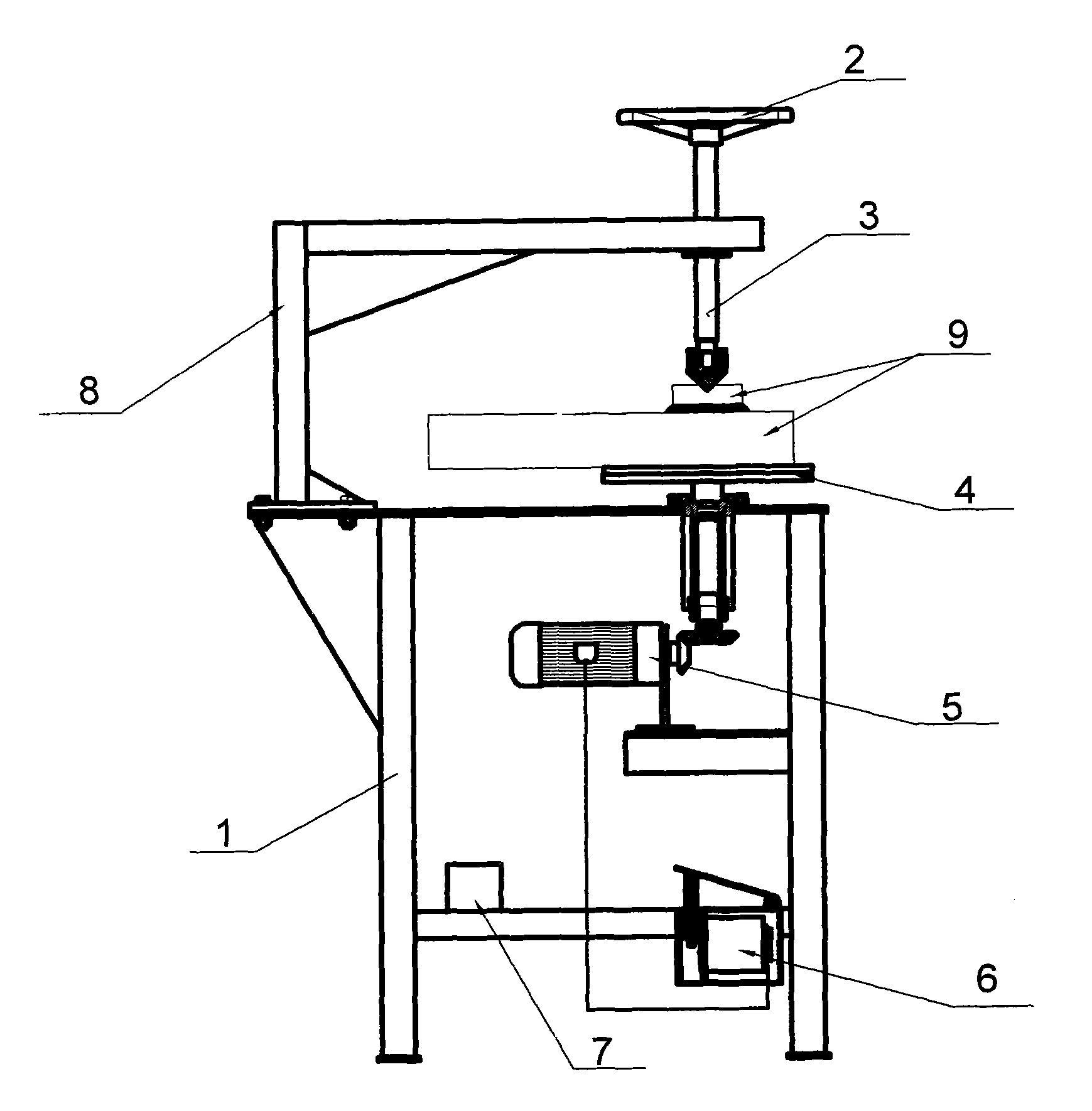

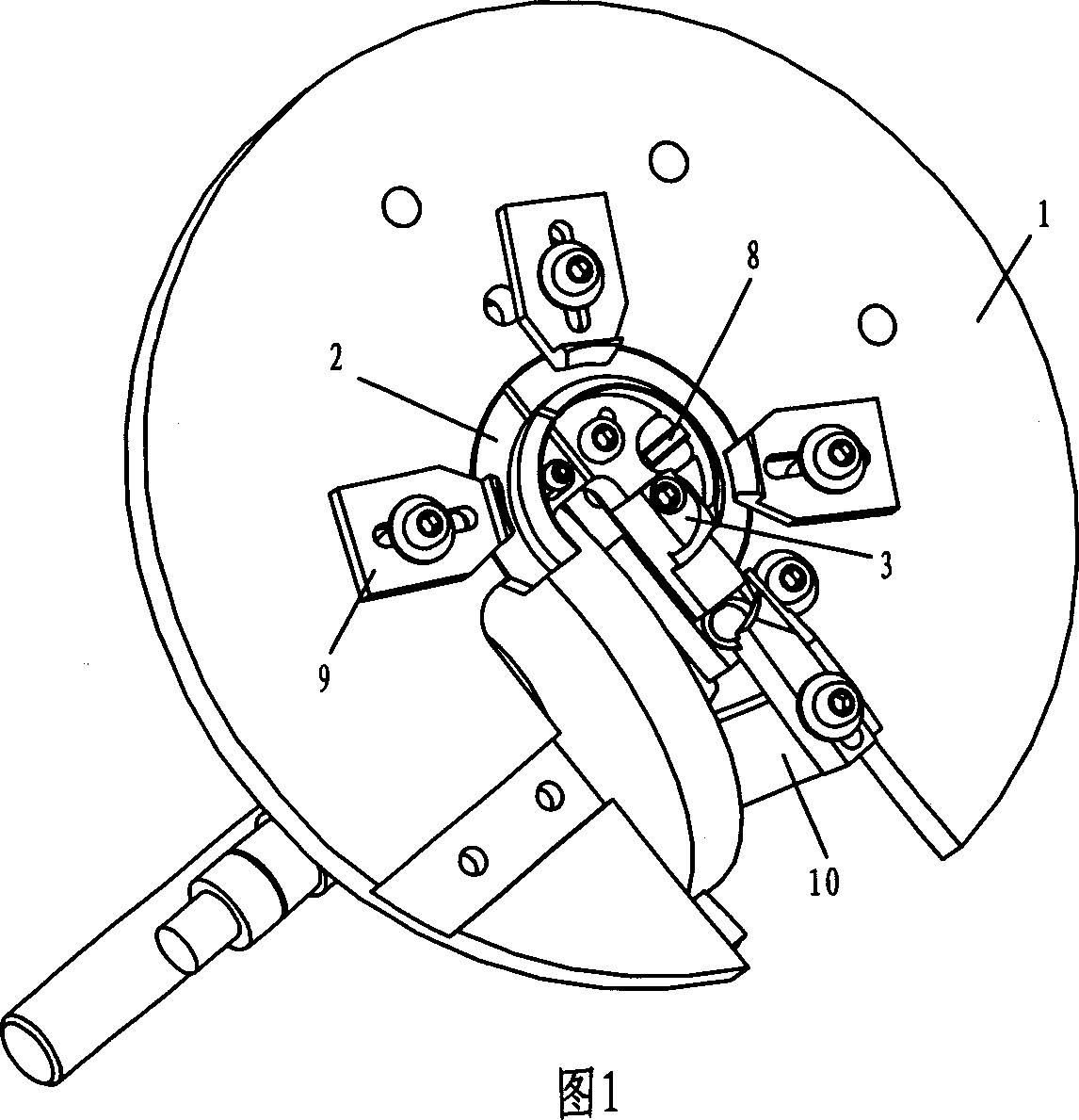

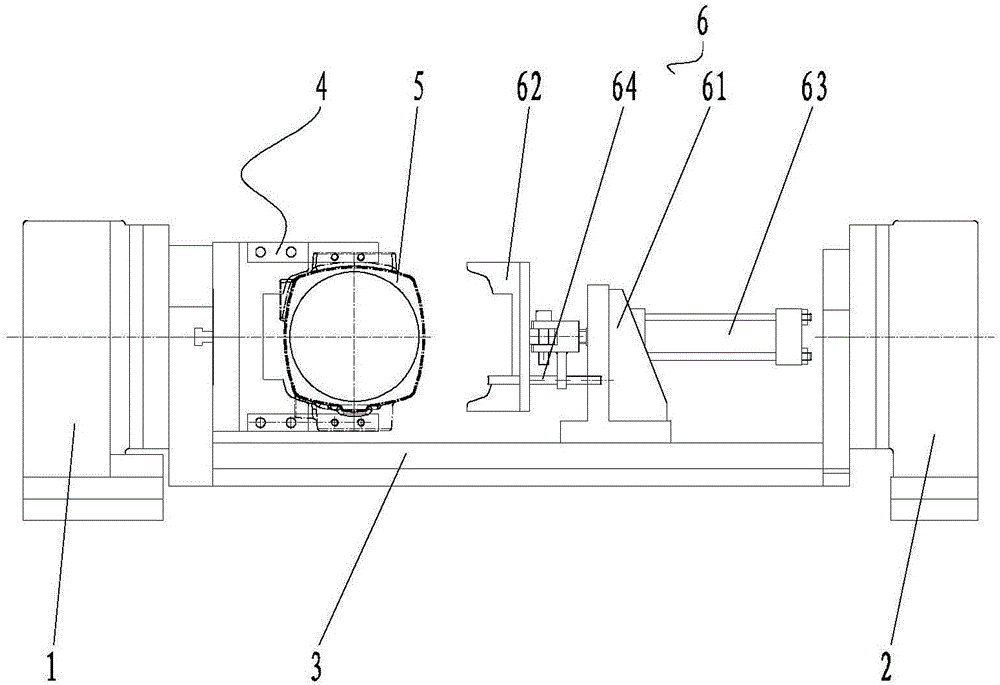

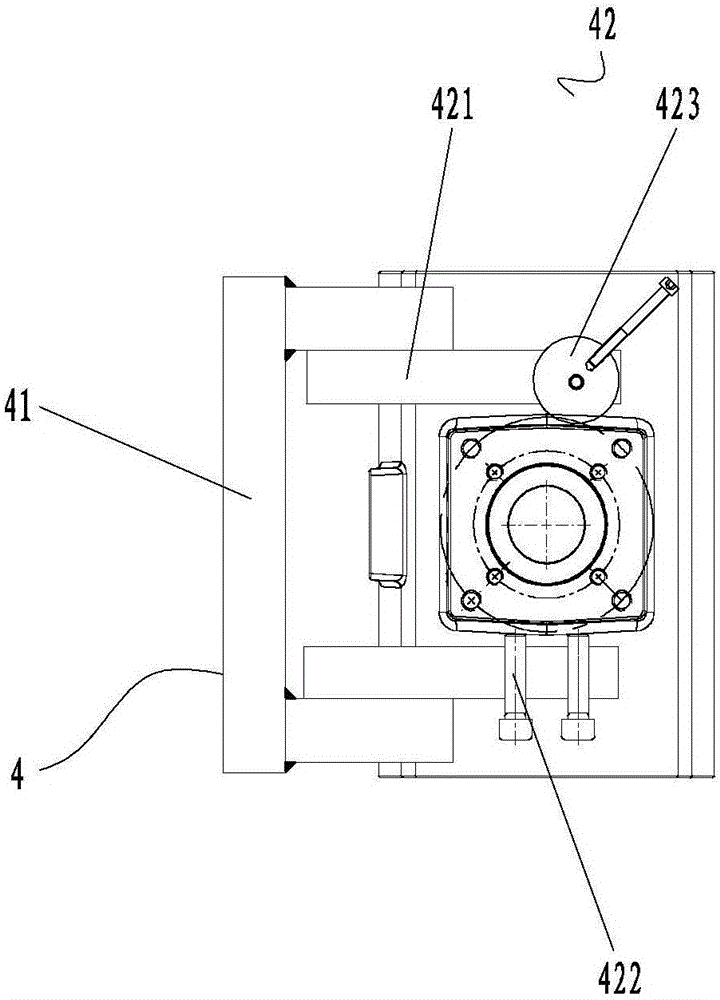

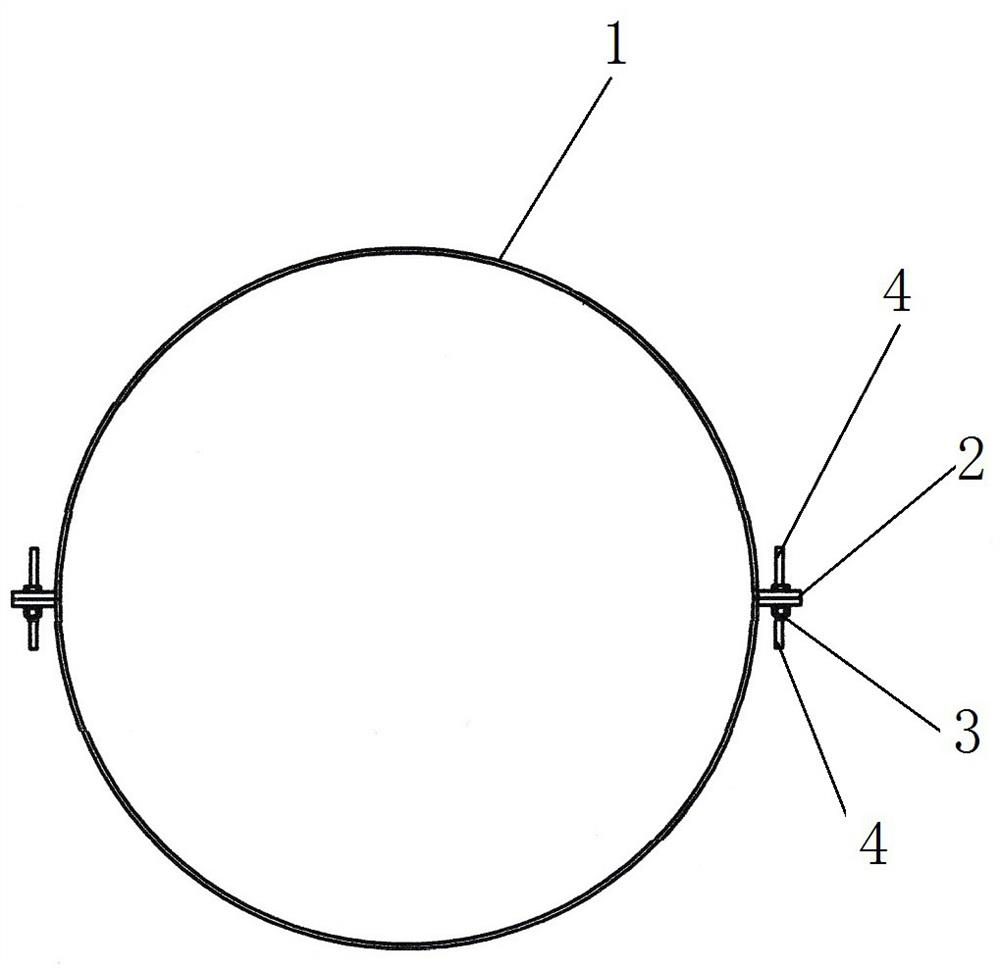

Disc semi-automatic joint welding machine and operation method thereof

InactiveCN102049596AGuaranteed verticality requirementsGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesSemi automaticEngineering

The invention discloses a disc semi-automatic joint welding machine and an operation method thereof. The disc semi-automatic joint welding machine comprises a desk-top frame, a positioning and fastening component, a disc rotary table, a reducing motor, a pedal continuously variable transmission (CVT) electric control device, an anti-interference component and a supporting argon-arc welding machine. An inversed L-shaped bracket is mounted on one end of the upper part of the desk-top frame. The workpiece center is fastened by a top clamp of the positioning and fastening component when the machine operates. The arc striking is slow when welding begins. The pedal CVT electric control device is stepped down to enter a welding stage with constant speed after the workpiece is welded for 1 to 2 centimeters. The disc semi-automatic joint welding machine provided by the invention only needs one person to operate during welding, thus reducing manual work and lowering production cost. The welding machine can also perform welding in place in one shot and the weld joints are artistic. The welding accuracy is improved to 99% from 10% originally, thus solving the difficulty in unqualified welding of joints of a heat exchanger and making up a blank in the manufacturing technique of the heat exchanger.

Owner:无锡万盛换热器制造有限公司 +1

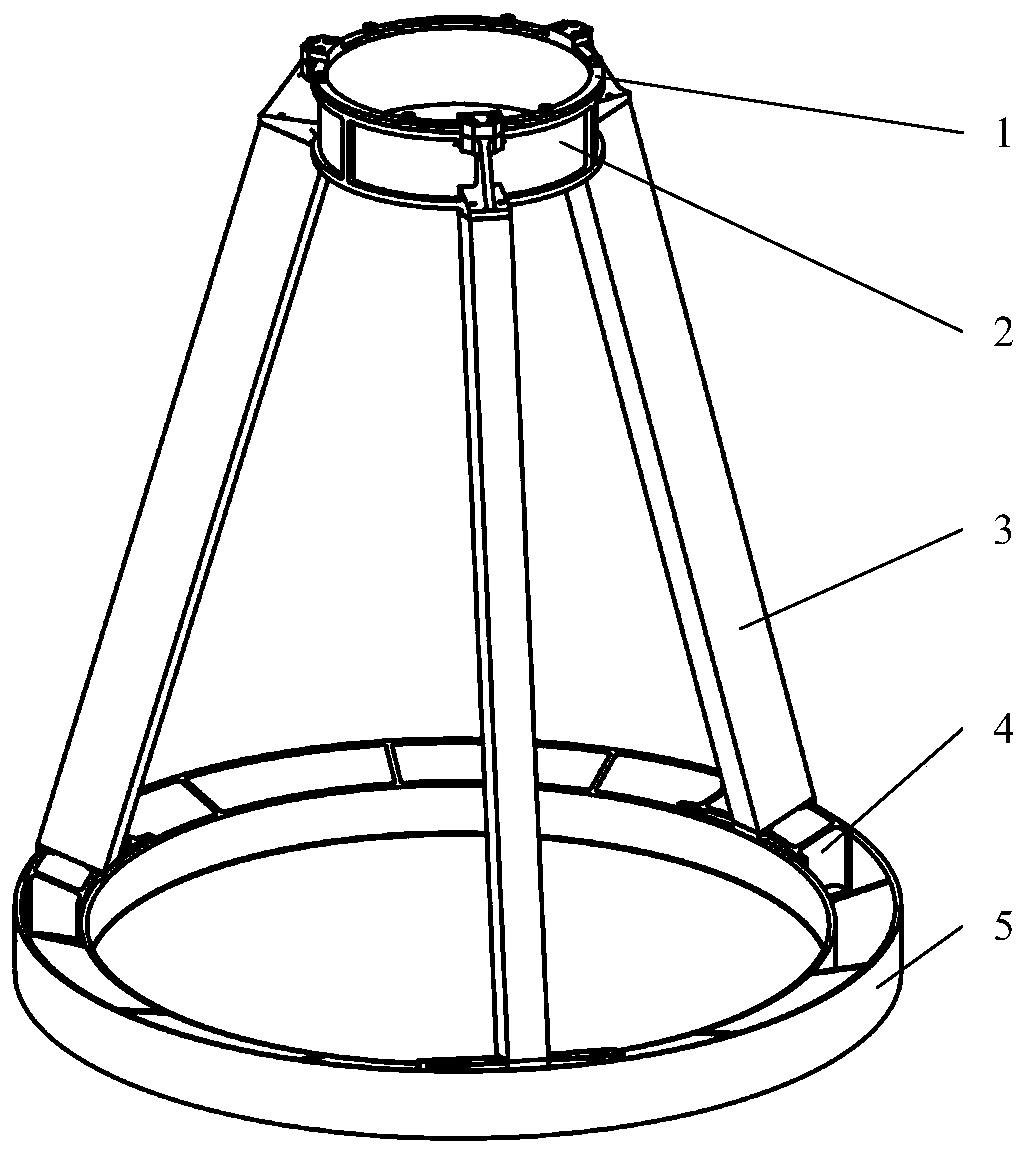

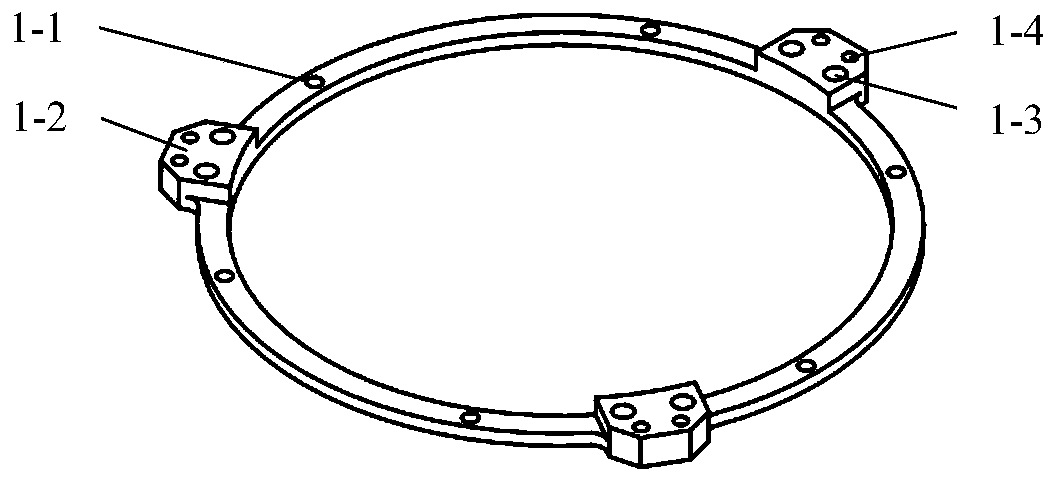

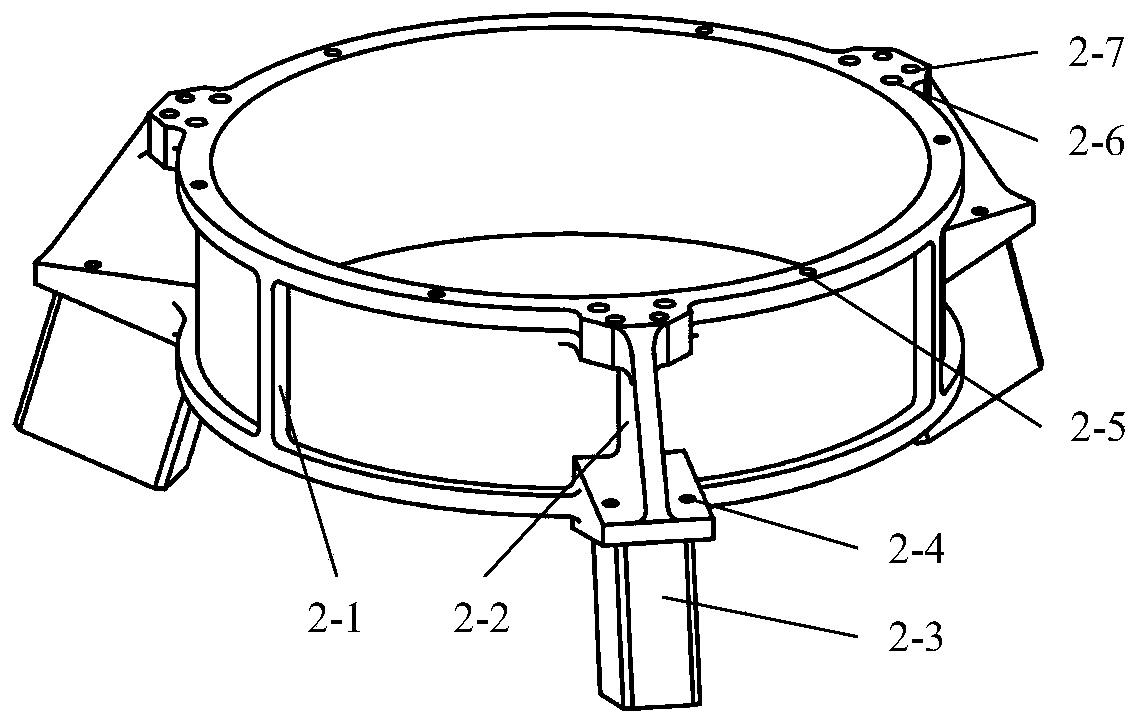

Push-condensing integrated high-resolution space optical load ultra-light carbon fiber truss support structure

ActiveCN110231689AGuaranteed verticality requirementsGuaranteed parallelismMountingsFiberEngineering

The invention relates to a push-condensing integrated high-resolution space optical load ultra-light carbon fiber truss support structure. The structure comprises an adjusting gasket, a secondary lenschamber, a truss rod, a metal embedded part and a support ring. A boss at the upper end of the adjusting gasket is an installation plane of a secondary mirror component, and a boss at the lower end of the metal embedded part is an installation plane of a truss and a primary mirror component. The adjusting gasket, the secondary lens chamber and the metal embedded part are made of titanium alloy materials, and the truss rod and the support ring are made of carbon fiber composite materials. The cross section of the truss rod is concentric-square-shaped, and the cross section of the support ringis concave-shaped. The truss support structure is less than 2.2 kg in total mass and is 1 / 3-1 / 2 times of the mass of a traditional metal truss. The truss support structure is simple, light in weight,good in strength, rigidity, structural stability and other index characteristics, can resist the influence of a complex mechanical environment on a space optical load in the transmitting process, ensures the position relation among optical elements, and meets the requirement of the push-condensing integrated high-resolution space optical load on the support structure.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

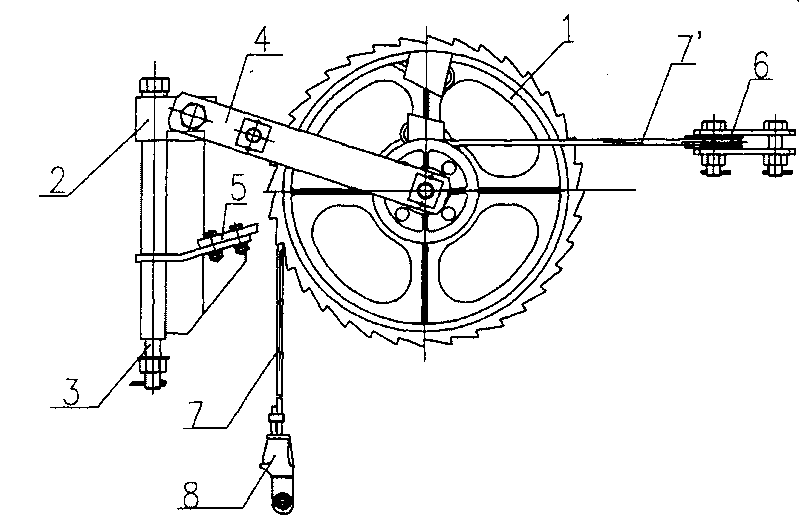

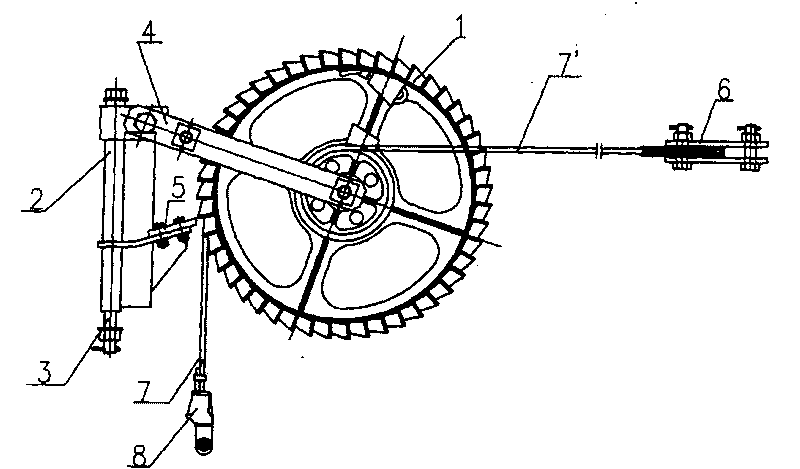

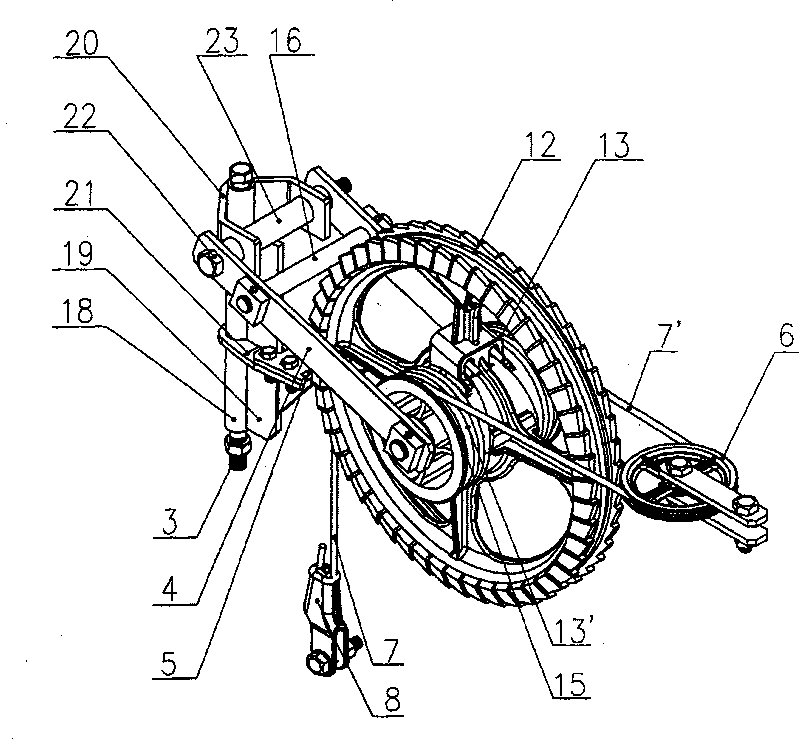

Novel ratchet compensating device

ActiveCN101722867AAvoid stuck and inflexible rotationImprove transmission efficiencyTrolley linesEngineeringRailway electrification system

The invention provides a novel ratchet compensating device. The novel ratchet compensating device comprises a ratchet body (1), a ratchet brake bracket (2), a long bolt pin (3), a ratchet frame connecting plate (4), a brake pallet (5), a balancing wheel (6), a wire cable I (7), a wire cable II (7') and a wire clamp (8), wherein the ratchet body (1) is arranged on a ratchet shaft (11) through a pair of self-lubricating sliding bearings (10); the two ends of the ratchet shaft (11) are fixed to the front end of the ratchet frame connecting plate (4), and are provided with end face self-lubricating bearings (14); and the end face self-lubricating bearings (14) are arranged between the ratchet frame connecting plate (4) and the self-lubricating sliding bearings (10). By optimizing the structural design, the manufacturing technique is simplified, the safe use performance is improved, the use working tension reaches 32kN, and a compensation distance reaches 950m. The novel ratchet compensating device not only can meet the requirements of high tension and compensation distance in a contact net of a high-speed electric railway, but also brings convenience to installation and maintenance.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

Drilling and tapping all-in-one machine for machining

ActiveCN105643022AGuaranteed verticality requirementsThread cutting toolsThread cutting machinesEngineeringMachining

The invention discloses a drilling and tapping all-in-one machine for machining. The drilling and tapping all-in-one machine for machining comprises a workbench; a workpiece holder is fixed to the right end of the workbench through screws; a chassis is fixed to the left end of the workbench through screws; the chassis is provided with a rotary supporting arm through a rolling bearing; a parallelogram supporting arm is hinged to the right end of the rotary supporting arm through a pin shaft; a self-lifting mechanism is arranged between the parallelogram supporting arm and the rotary supporting arm; a power mechanism is installed at the right end of the parallelogram supporting arm through a triangular connector and connected with a variable-frequency governor through a power signal line; and a drill is installed below the power mechanism through a clamping-connecting head. The drilling and tapping all-in-one machine for machining integrates the drilling and tapping procedures of traditional machining; by the adoption of the parallelogram supporting arm structure, the drill or a screw tap is absolutely perpendicular to the workbench, the requirement for machining perpendicularity is ensured, the power mechanism is controlled by the variable-frequency governor to achieve continuous variable transmission, and the application range is wide.

Owner:太仓市宝明化纤有限公司 +1

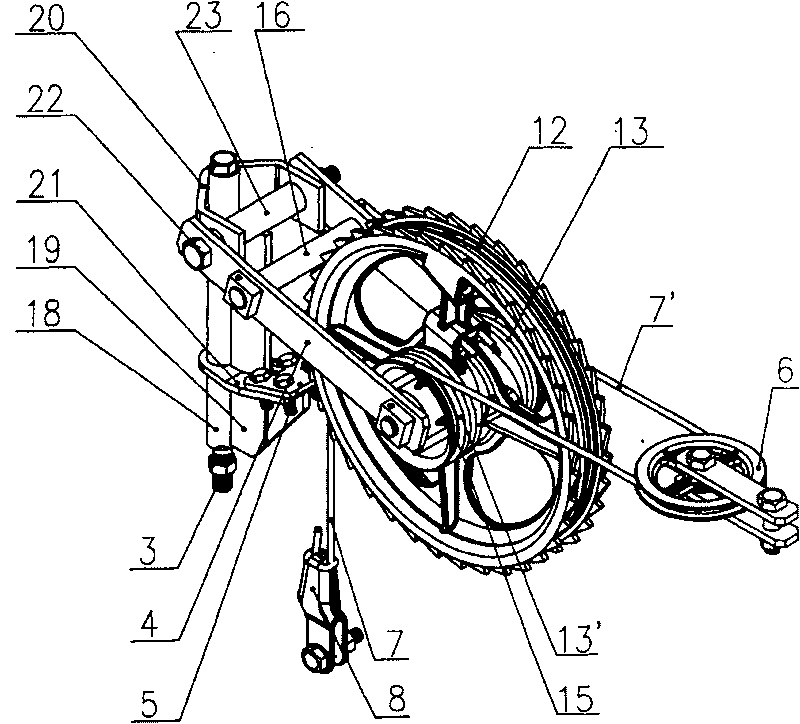

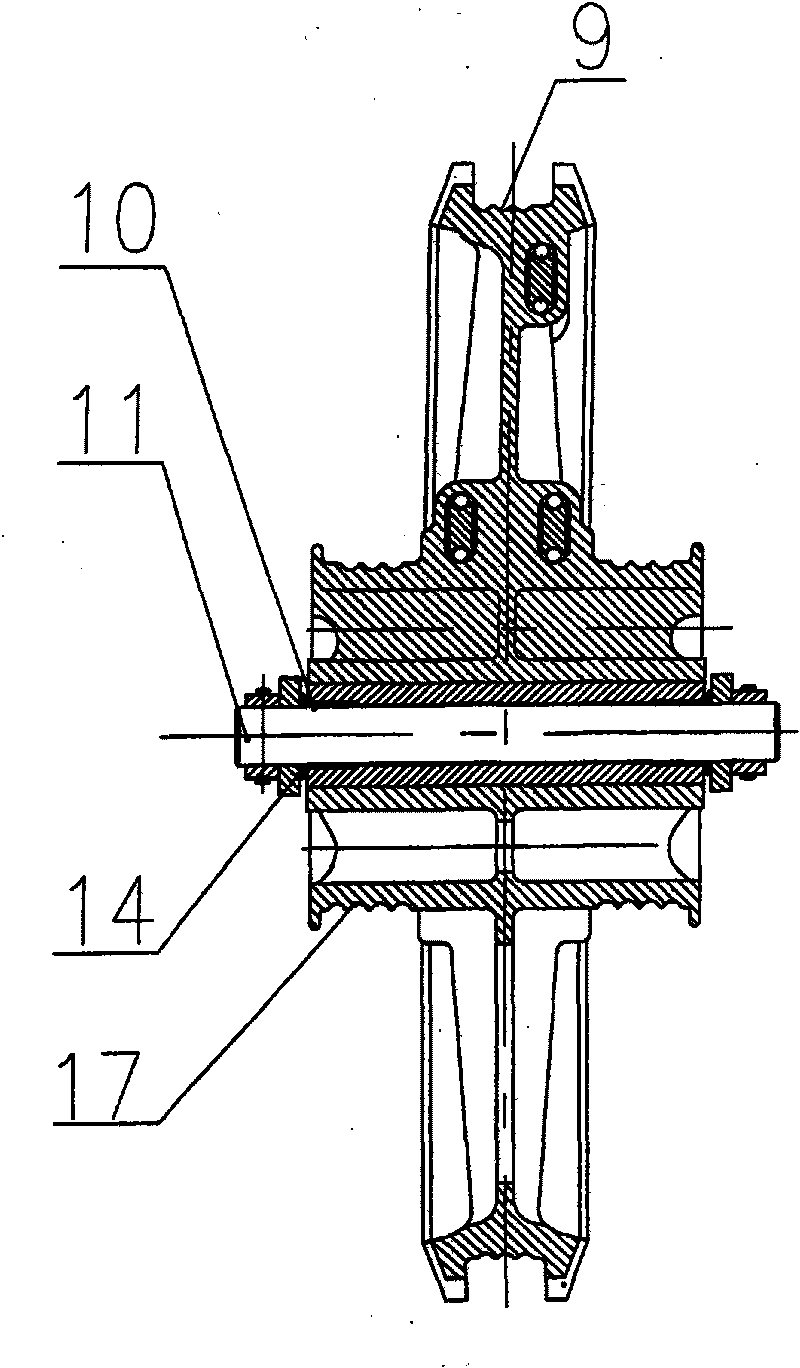

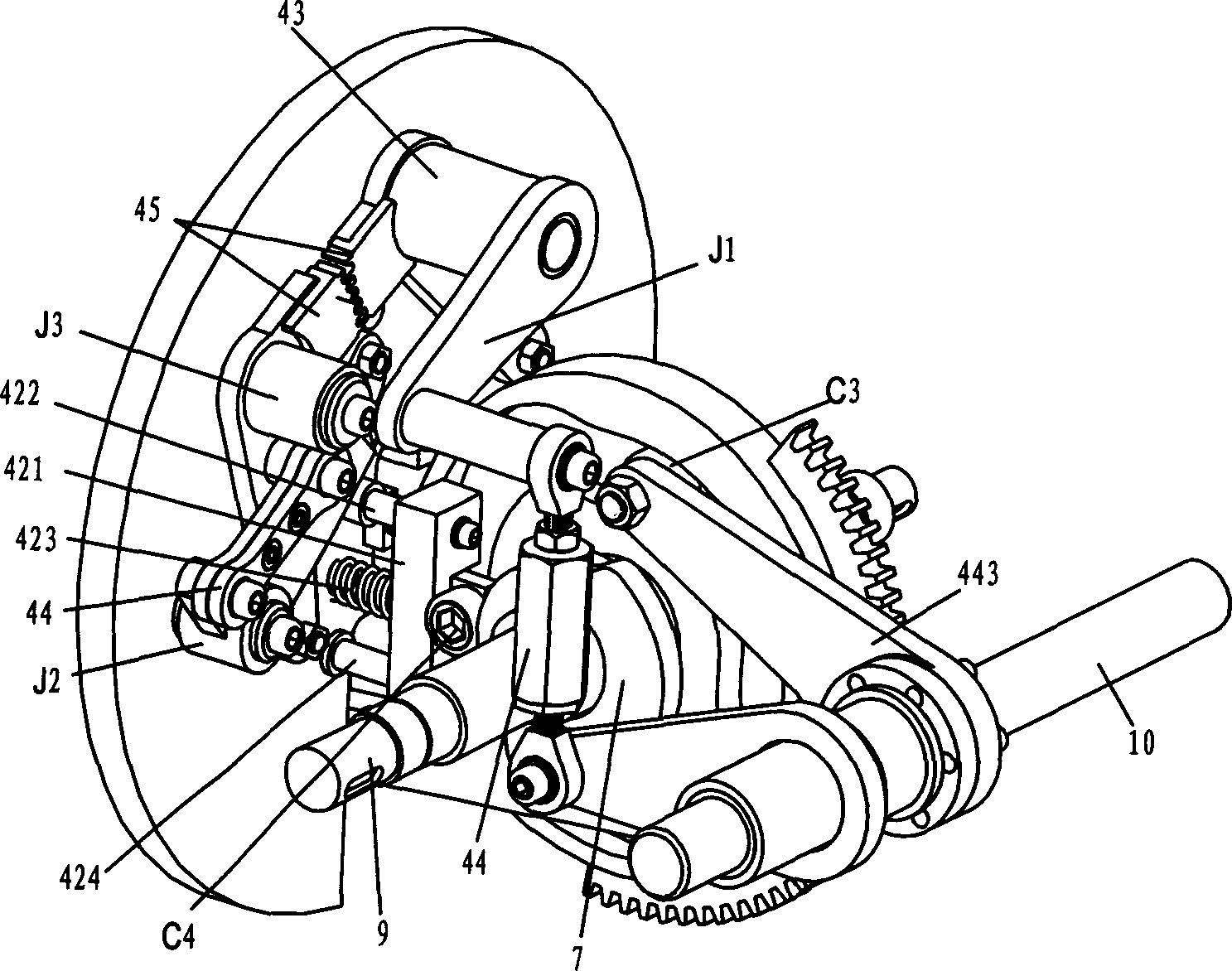

Bevel ratchet wheel compensating device

ActiveCN101716893AStrong impactComprehensive braking performance reliable insuranceTrolley linesManufacturing technologyEngineering

The invention provides a bevel ratchet wheel compensating device, comprising a ratchet wheel body (1), a ratchet wheel brake frame (2), a long bolt pin (3), a ratchet wheel framework connecting plate (4), a brake pallet (5), a balance wheel (6), a steel wire rope I (7), a steel wire rope II (7') and a cable clamp (8), wherein two rows of symmetrical bevel gears are arranged on the excircle of a bull wheel (12) of the ratchet wheel body (1), the bevel gear is composed of straight teeth (24) and side teeth (25), the straight teeth (24) are arranged at two sides of the circumference surface of the bull wheel (12), and side teeth (25) are arranged at the side wall of the bull wheel (12); and the front end of the brake pallet (5) is provided with a U-shaped brake port (26) of which the width is consistent with the spacing of the bottom parts of the two side teeth (25). In the invention, the ratchet adopts a bevel structure formed by the straight teeth and the side teeth; by optimizing the structure design, the manufacture technology is simplified, the safe use performance is improved so as to lead the working tension to reach 38.85kN and compensation distance to reach 800m, thus not only satisfying the requirements on high tension and large compensation distance for a high-speed electrified railway contact line, but also having convenient installation and maintenance.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

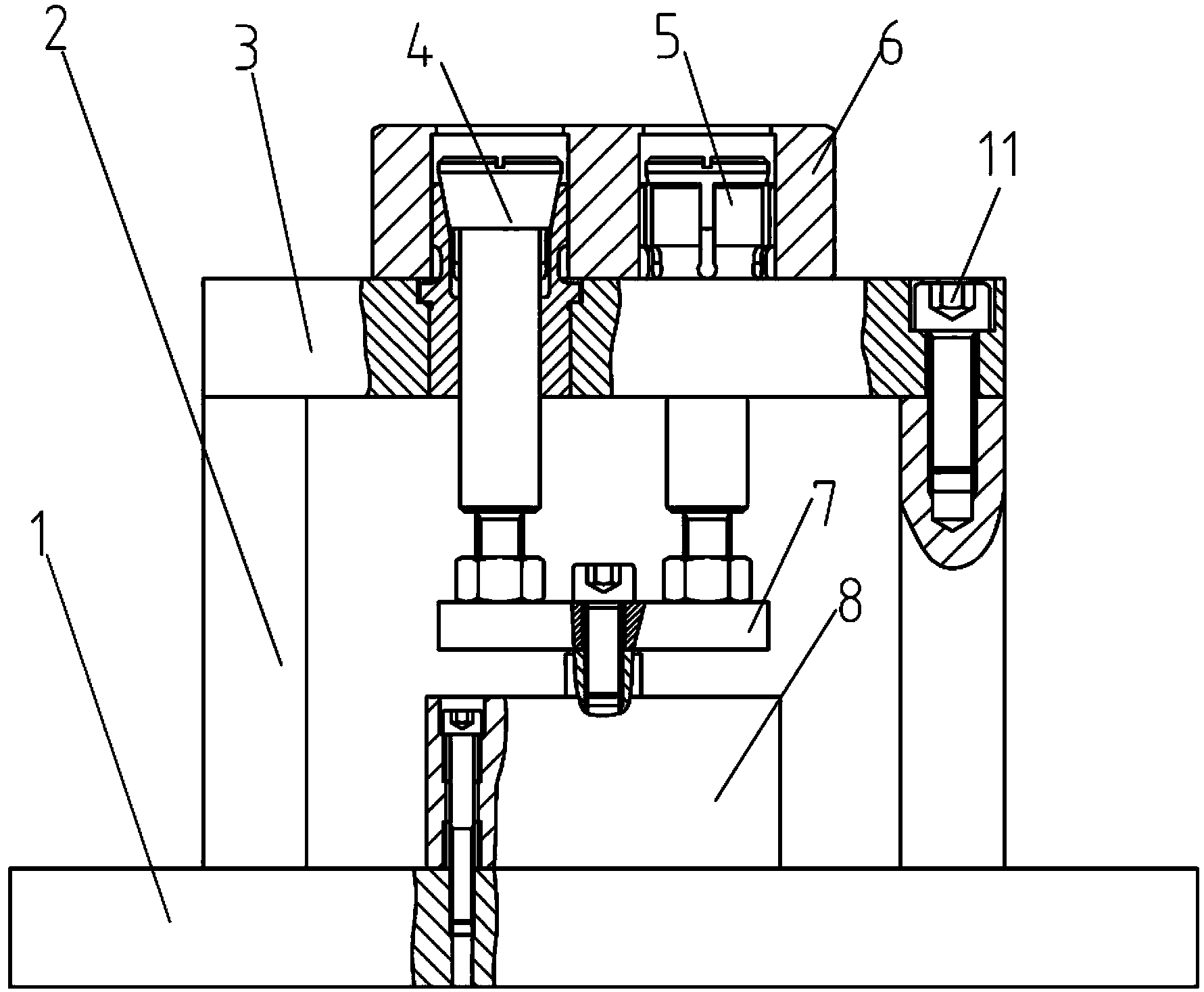

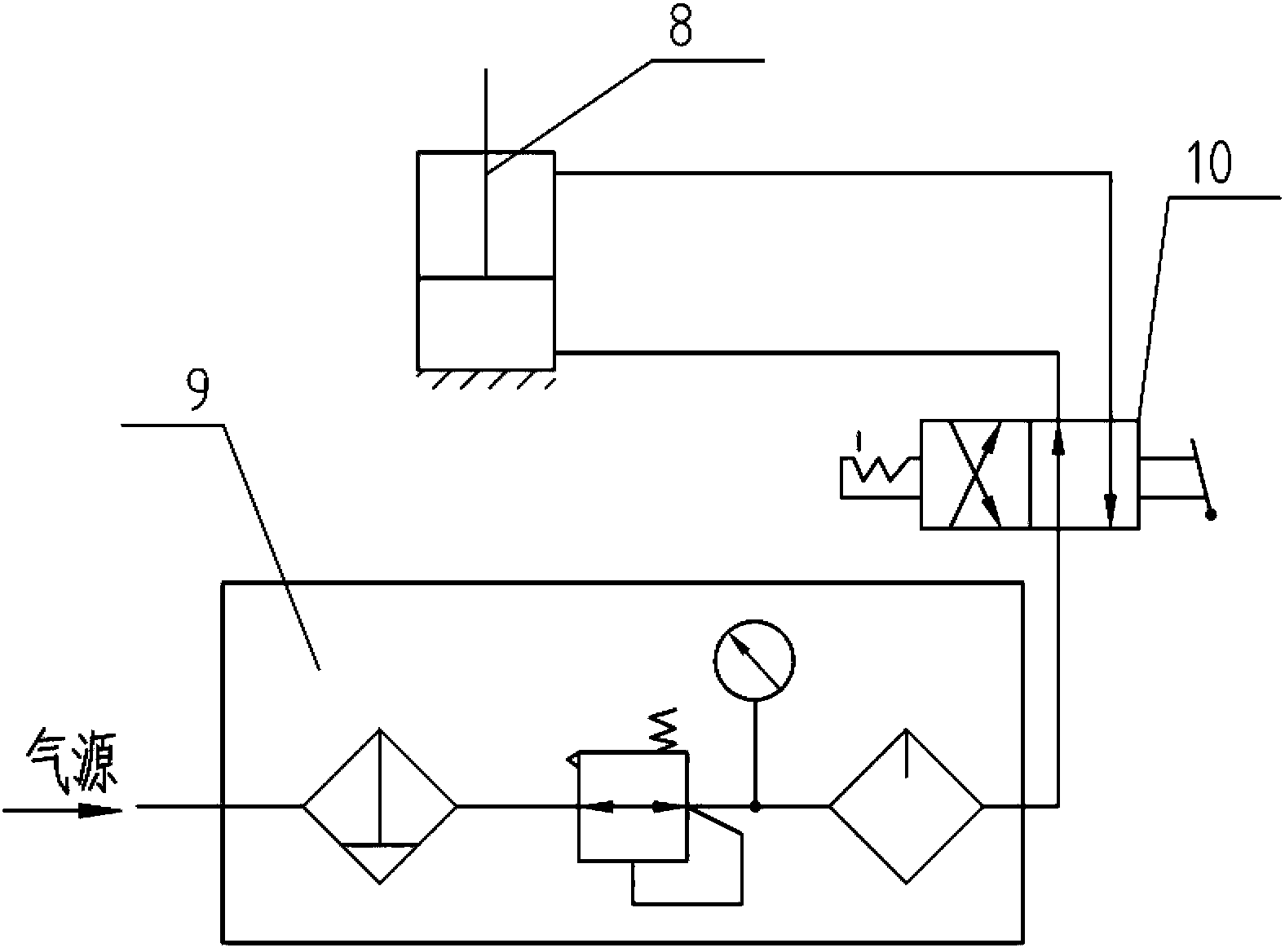

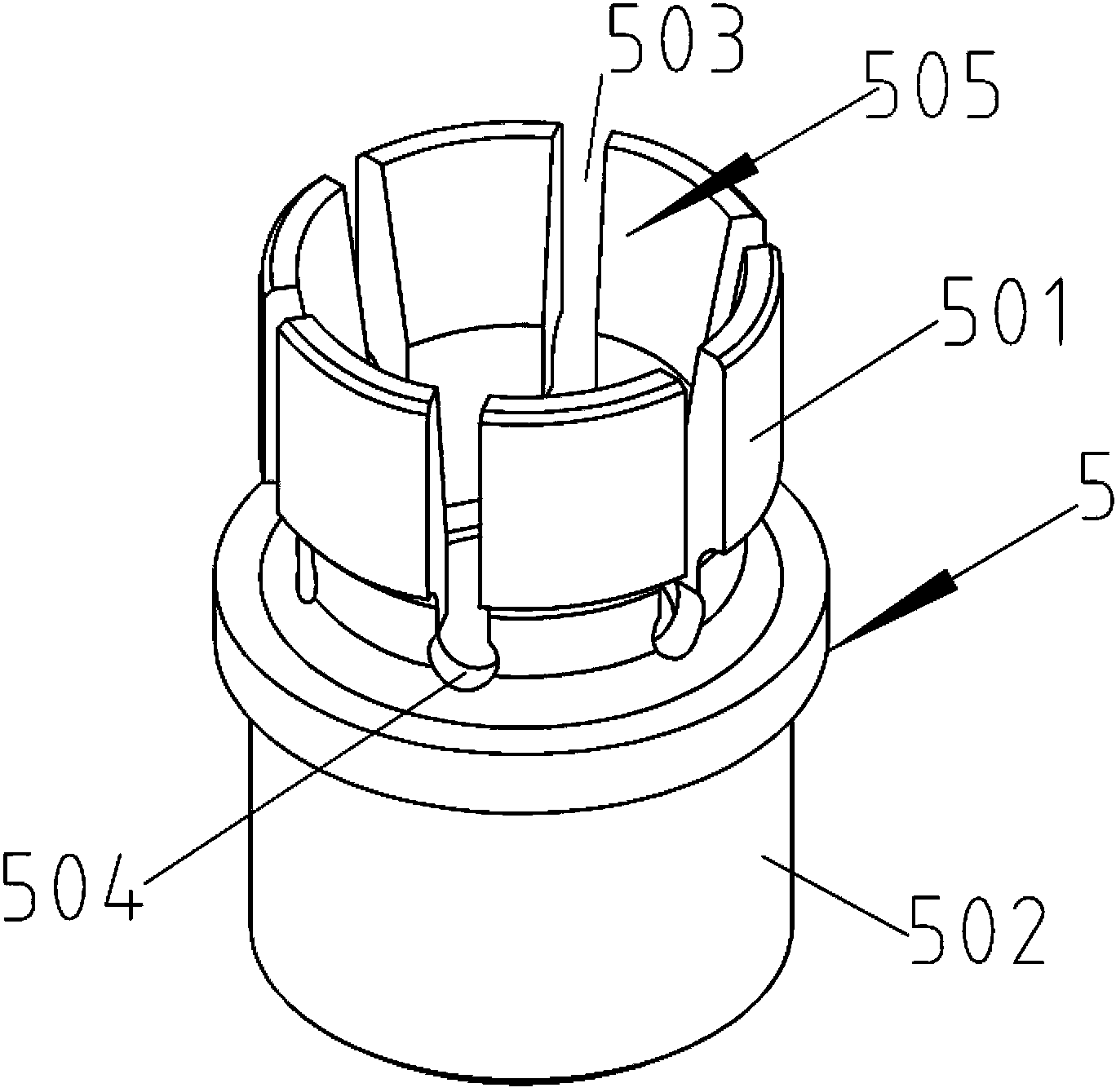

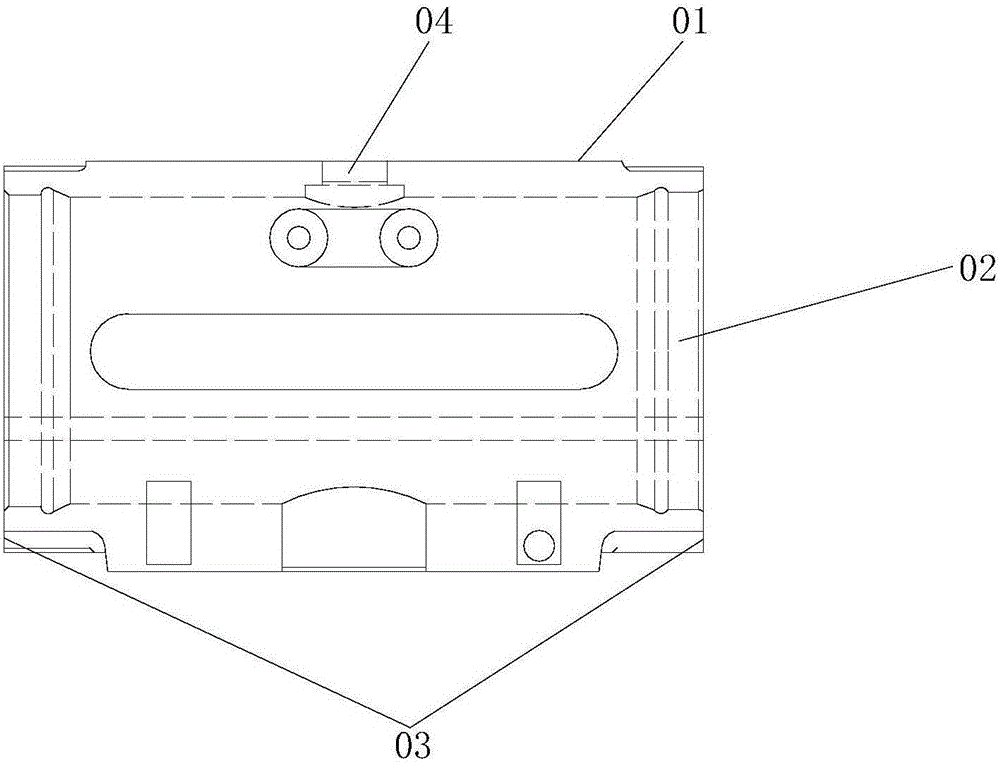

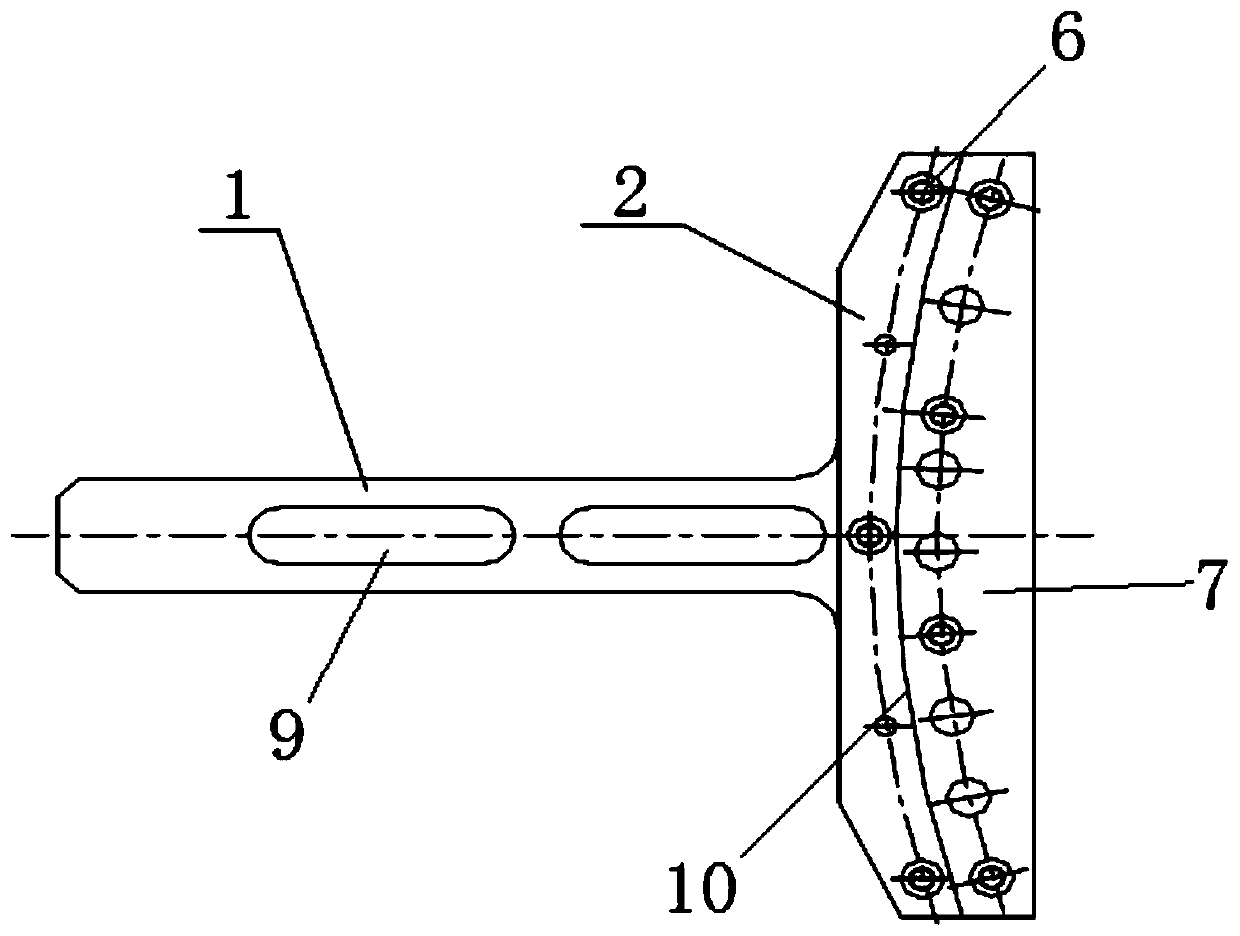

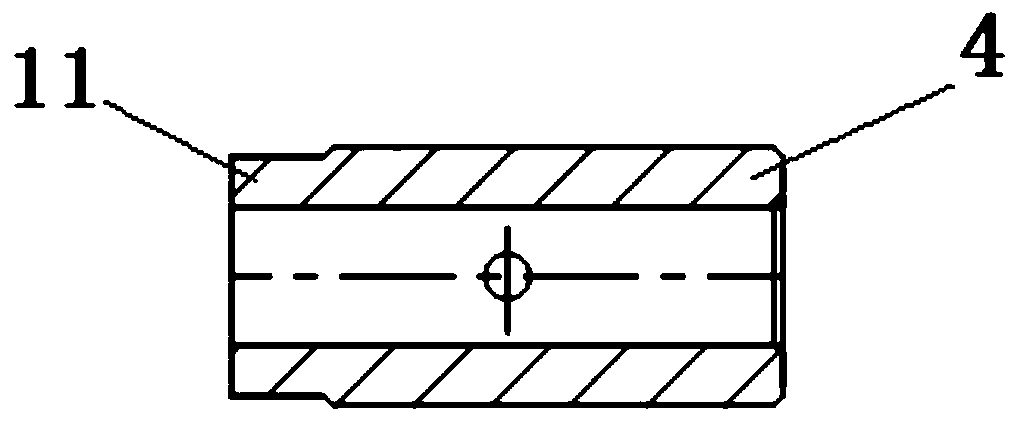

Pneumatic expansion type clamp

InactiveCN103394935AGuaranteed parallelismGuaranteed verticality requirementsPositioning apparatusMetal-working holdersPistonEngineering

The invention discloses a pneumatic expansion type clamp. The pneumatic expansion type clamp comprises a base plate, two supporting plates, a positioning plate, a pulling rod, an expansion sleeve, a cross rod and an air cylinder, wherein the two supporting plates are respectively erected at two sides of the top surface of the base plate, the positioning plate is located at the top ends of the two supporting plates and is fixedly connected with the two supporting plates, a pulling rod and an expansion sleeve which penetrate through a top plate are arranged on the top plate, the lower end of the pulling rod and the lower end of the expansion sleeve are both fixedly connected with the cross rod, and the cross rod is fixedly connected with a piston of the air cylinder. The pneumatic expansion type clamp is particularly suitable for fine machining of outlines and end surfaces of integrated shaft sleeve parts, and has the advantages of being convenient and rapid to clamp, being capable of improving machining accuracy of the integrated shaft sleeves, improving production efficiency and the like.

Owner:HEFEI CHANGYUAN HYDRAULICS

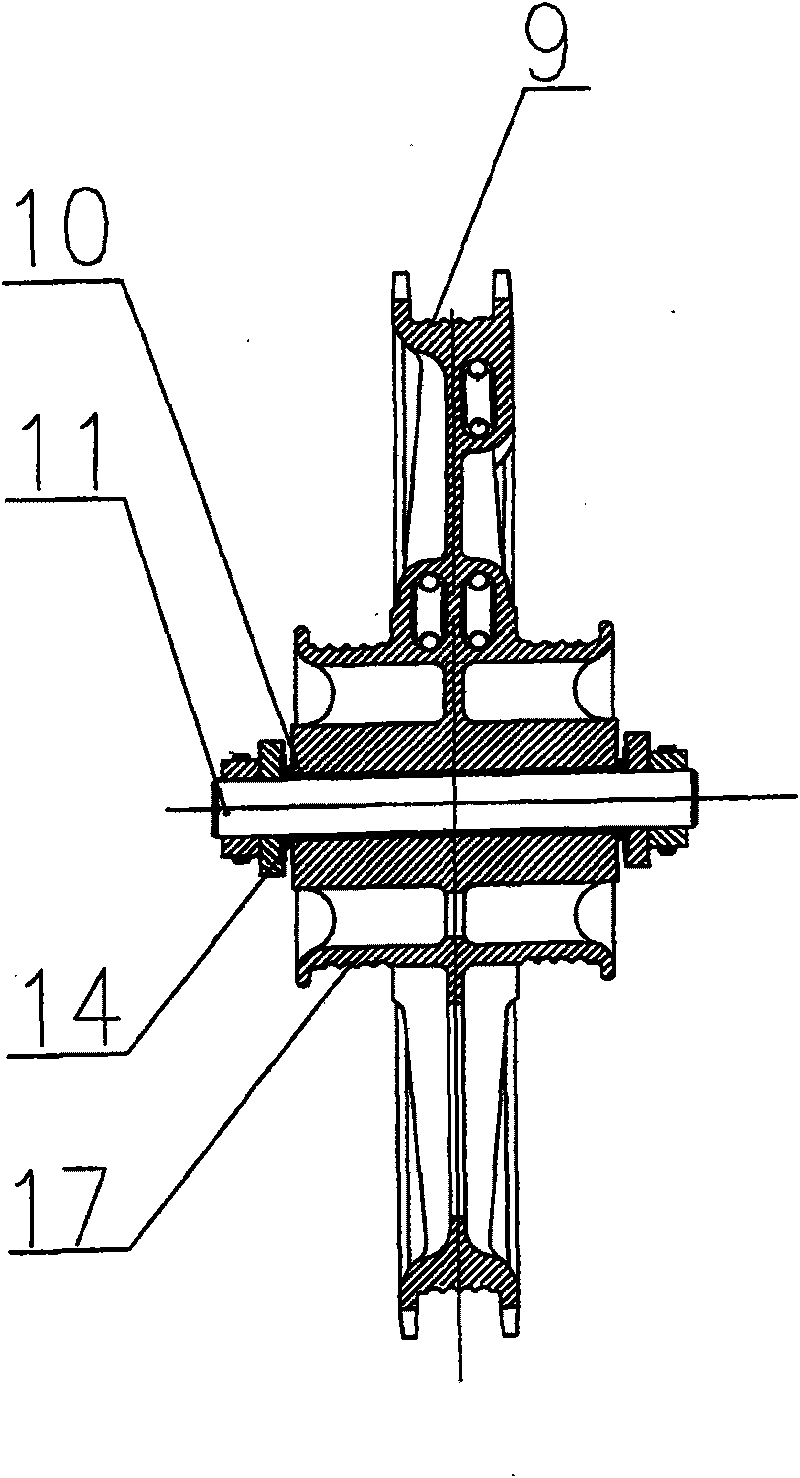

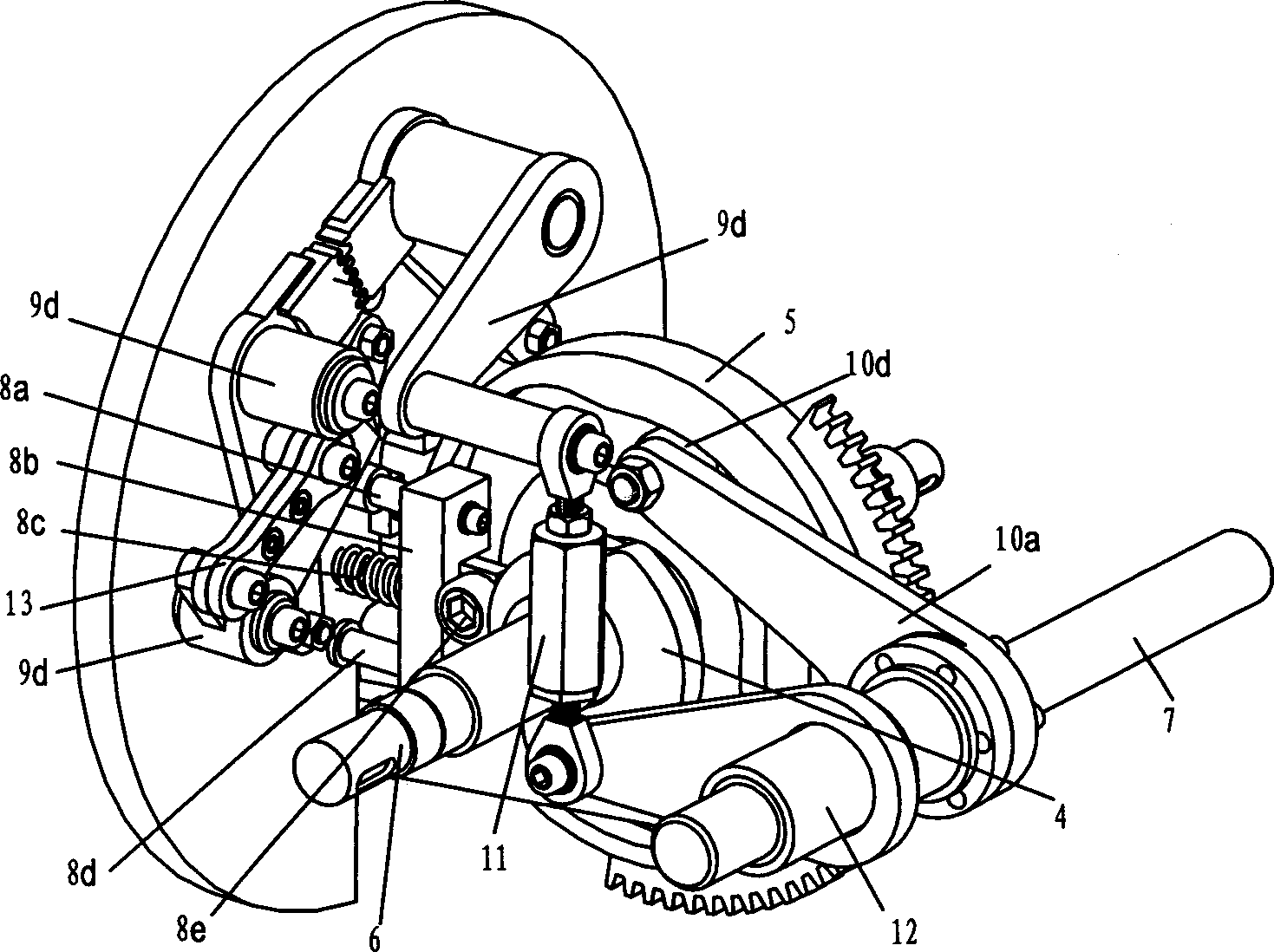

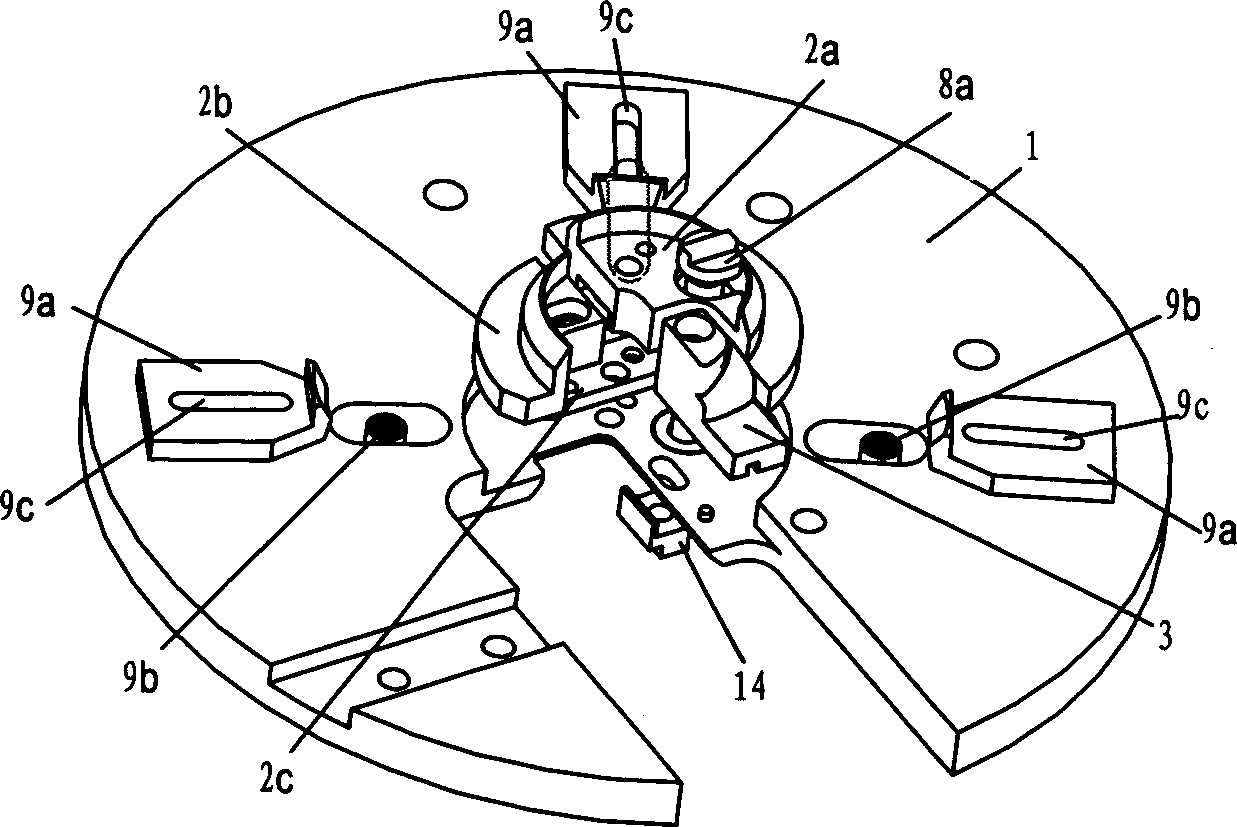

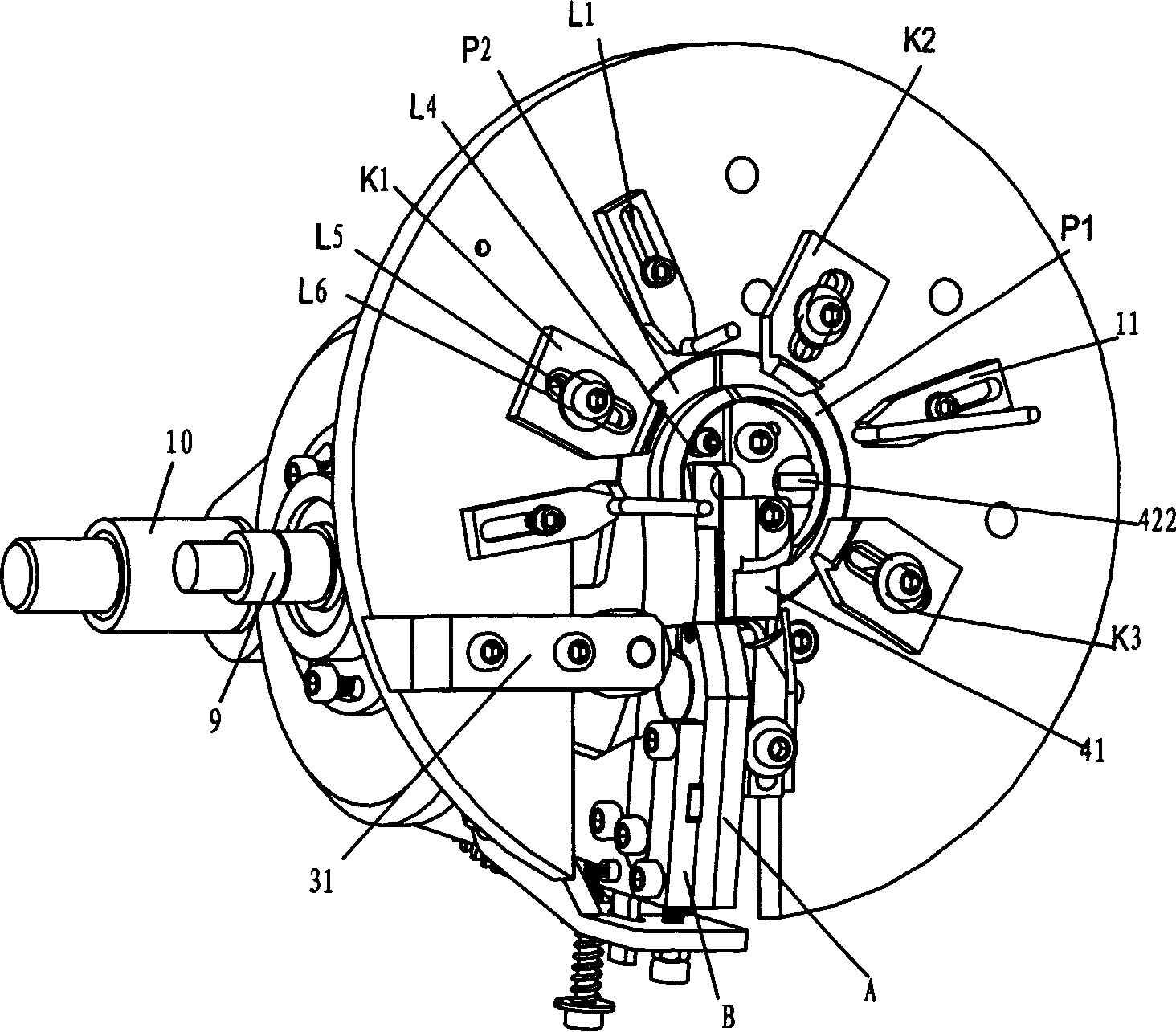

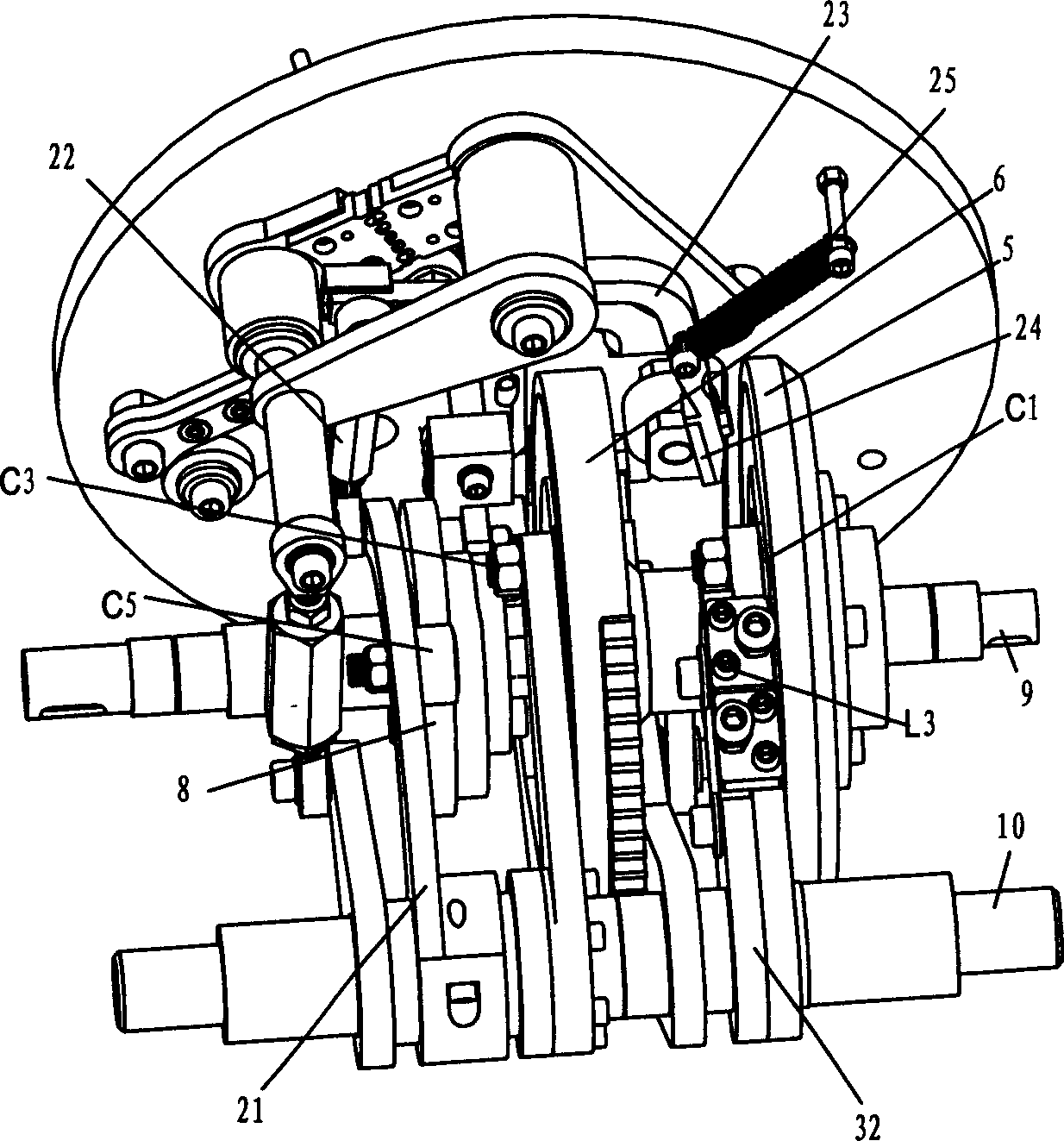

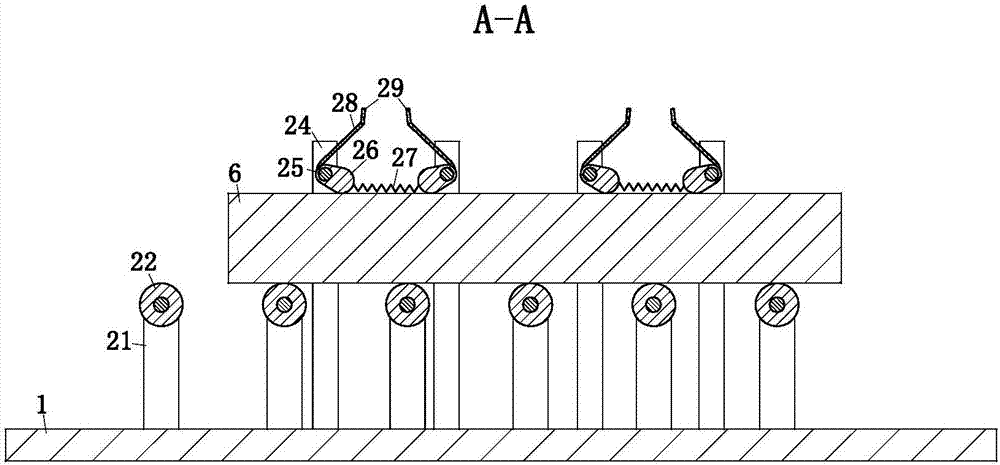

Knotting spring clamping mechanism of full-automatic spring-coiling machine

InactiveCN1788879AGuaranteed verticality requirementsEasy to adjustWork holdersWire springsWinding machineDrive shaft

The knotted spring fastening mechanism for automatic spring winding machine includes an mounting board, a diameter disc comprising two connected half discs, a steel wire rack fixed inside the long hole in the mounting board, a mandrel cam and a large toothed disc cam mounted on the same driving shaft, a driving shaft, a fixed shaft, a mandrel sliding set, a block linking set, and a block holding set. The block holding set comprises swinging rod, spring pressing block, pressing board and first cam driven part; the block linking set includes three blocks with regulating long hole; and the mandrel sliding set consists of mandrel, block, compression spring, guide shaft and second cam driven part. The knotted spring fastening mechanism has simple and reliable fastening, and raised spring knotting quality.

Owner:李德锵

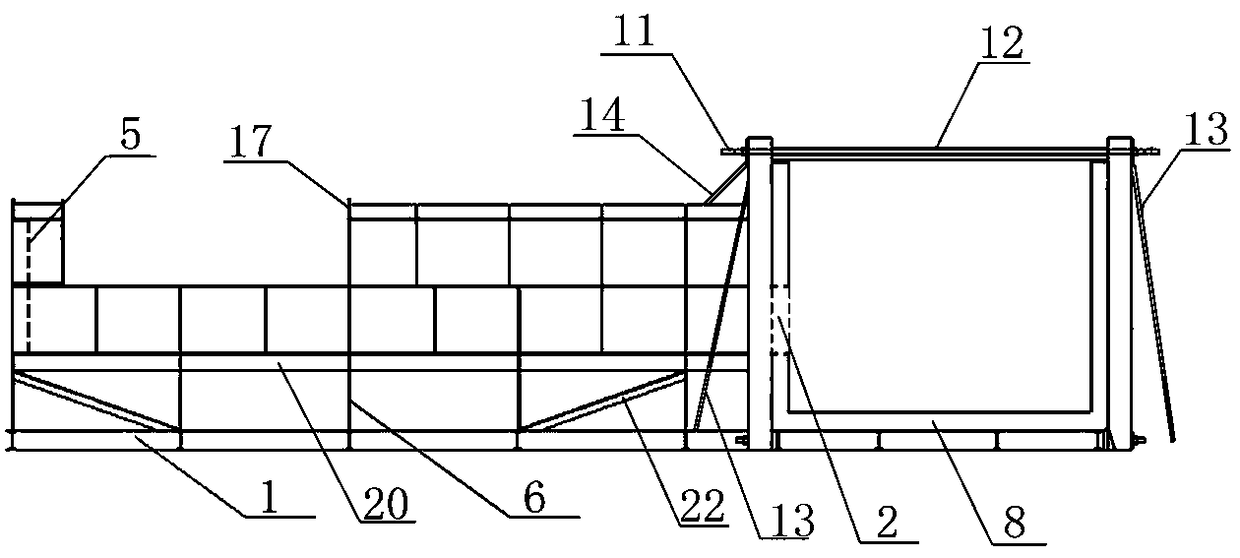

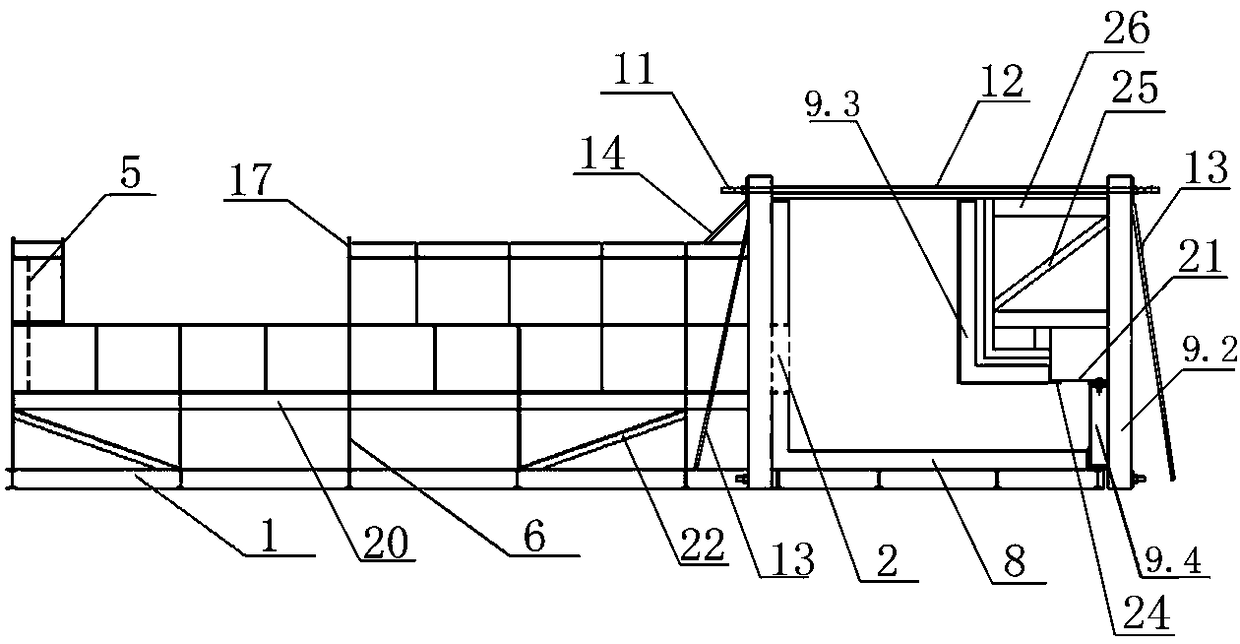

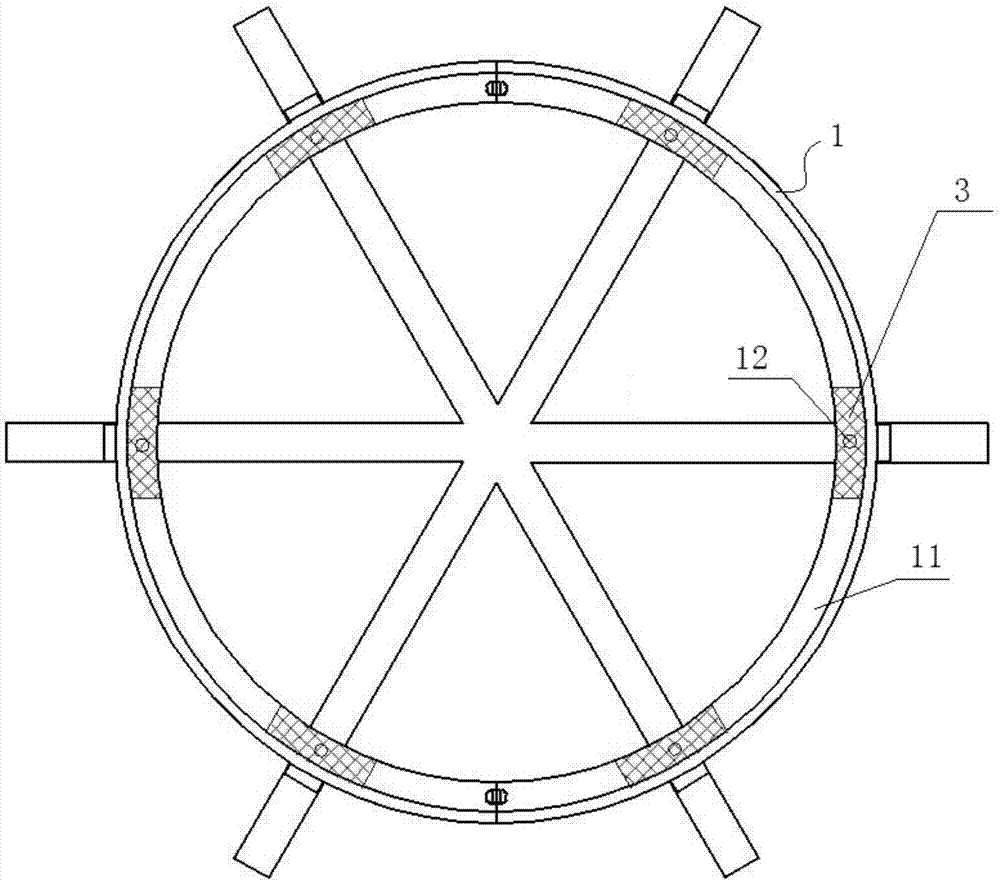

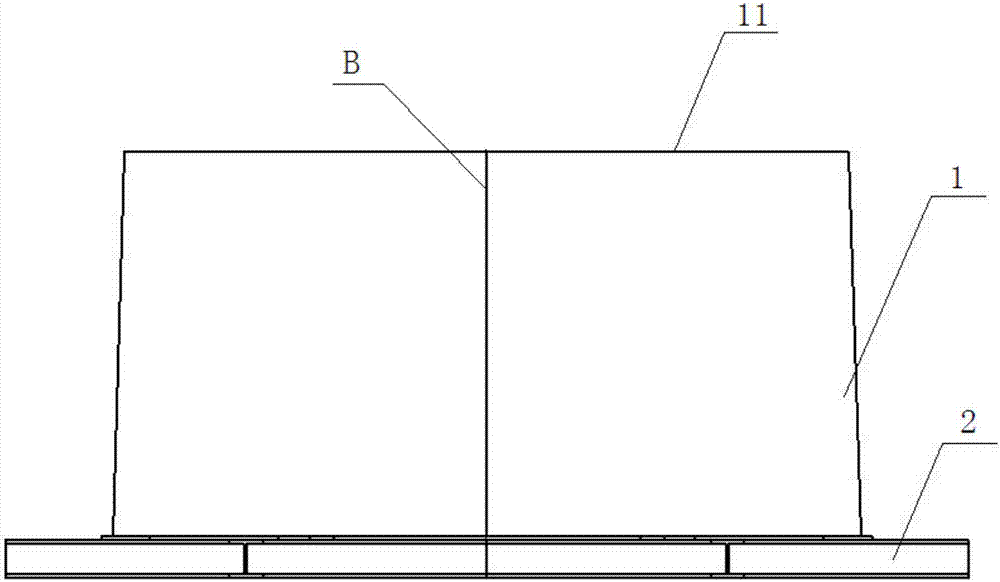

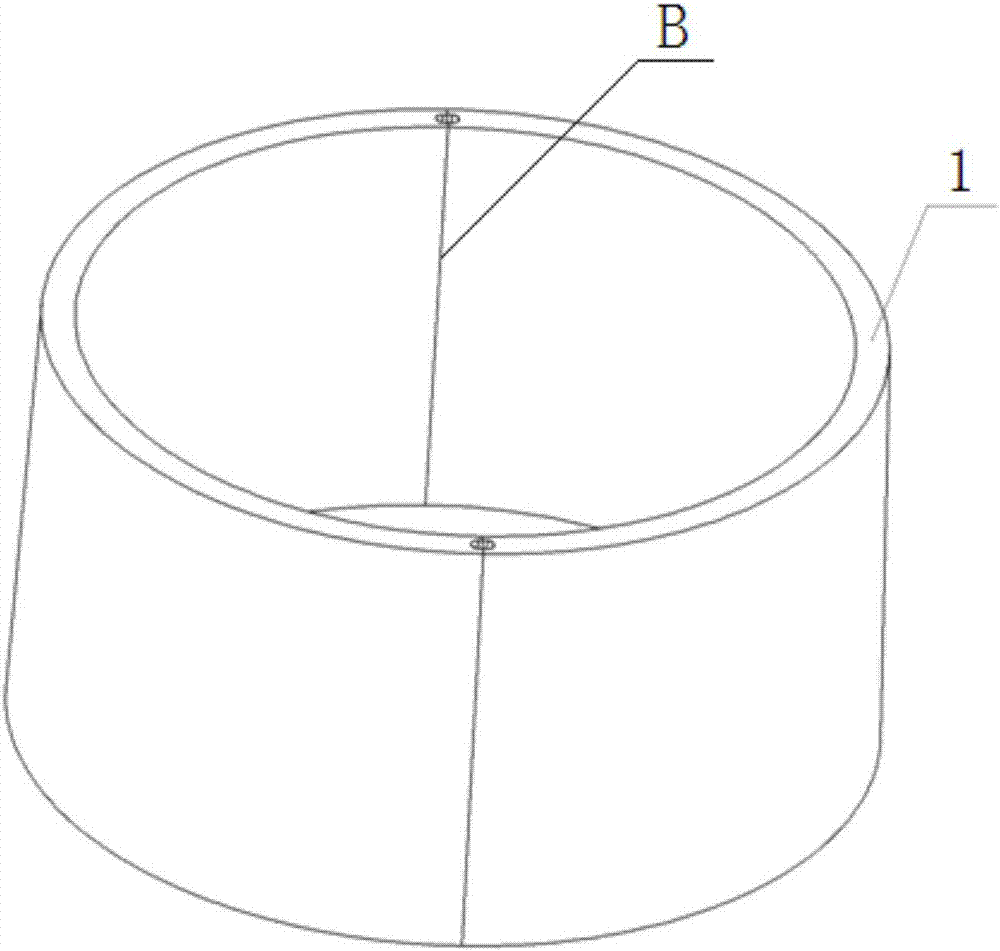

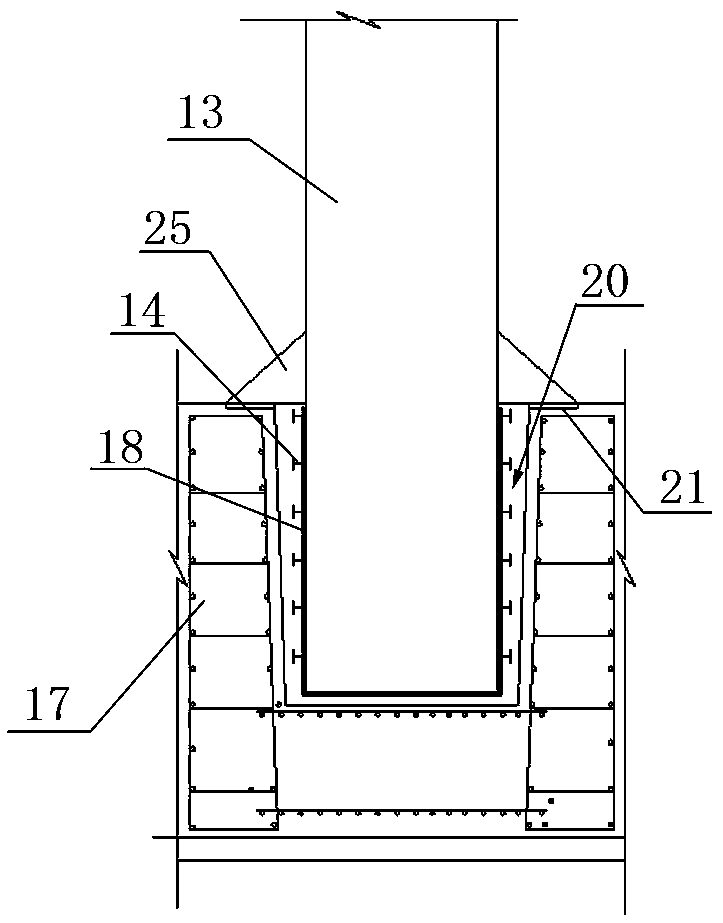

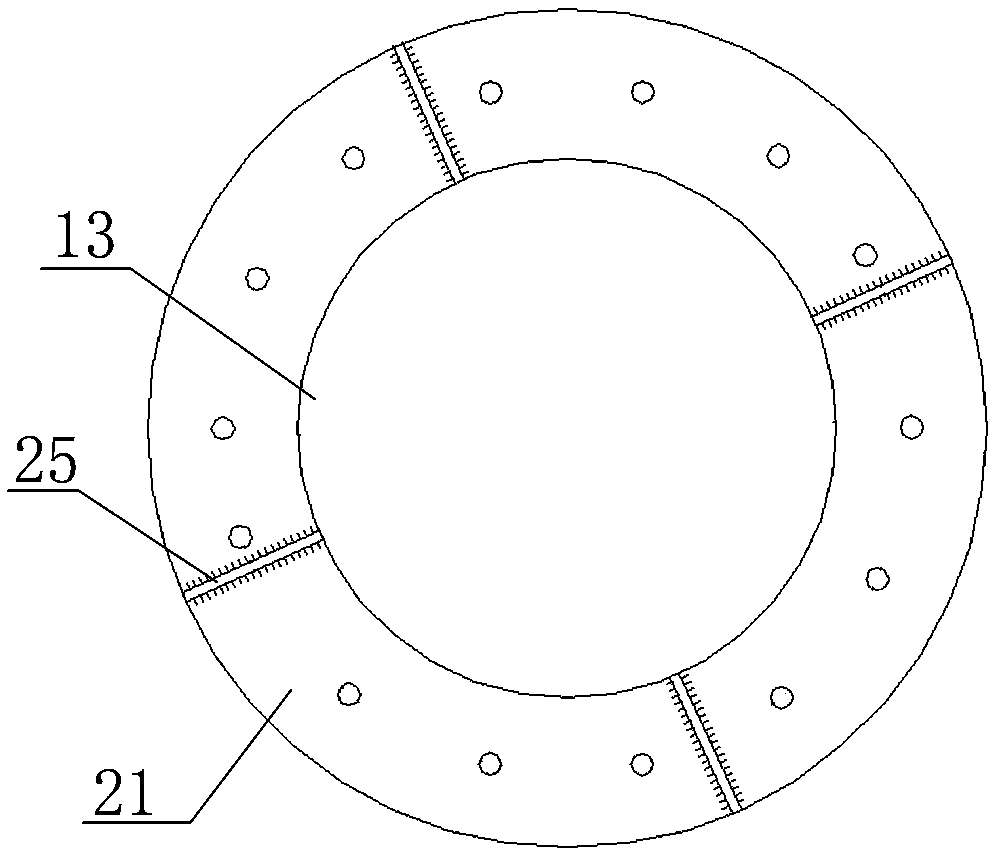

Horizontal mold for integrated prefabrication of pier column and cover beam and construction method thereof

PendingCN109176843AAccurate structure sizeGuaranteed verticality requirementsMouldsSlurryPrefabrication

The invention discloses a horizontal mold for integrated prefabrication of a pier column and a cover beam and a construction method thereof. The prefabrication mold comprises a pier column formwork structure, a cover beam formwork structure and a mold bottom frame, the mold bottom frame is T-shaped and comprises a transverse edge and a longitudinal edge; the cover beam formwork structure is arranged along the transverse edge of the mold bottom frame, the pier column formwork structure is arranged along the longitudinal edge of the mold bottom frame, the pier column formwork structure communicates with the cover beam formwork structure, the horizontal section of the cover beam formwork structure is rectangular or trapezoid, and a slurry passing opening is formed at the position, connected with the pier column formwork structure, of a side mold of the cover beam formwork structure; and the pier column formwork structure is cylindrical, and comprises a pier column bottom mold, a pier column top mold and a plugging plate, the cross section of the pier column bottom mold is in a semi-arc shape, the pier column top mold is connected to the top of the pier column bottom mold, and first pouring holes are formed in the tops of pier column top mold units. According to the mold and the construction method, the technical problems that for a traditional mode of casting the pier column and the cover beam in situ correspondingly, the construction period is long, the safety is poor, the construction quality is not easy to guarantee, and the environmental protection pressure is large are solved.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP +2

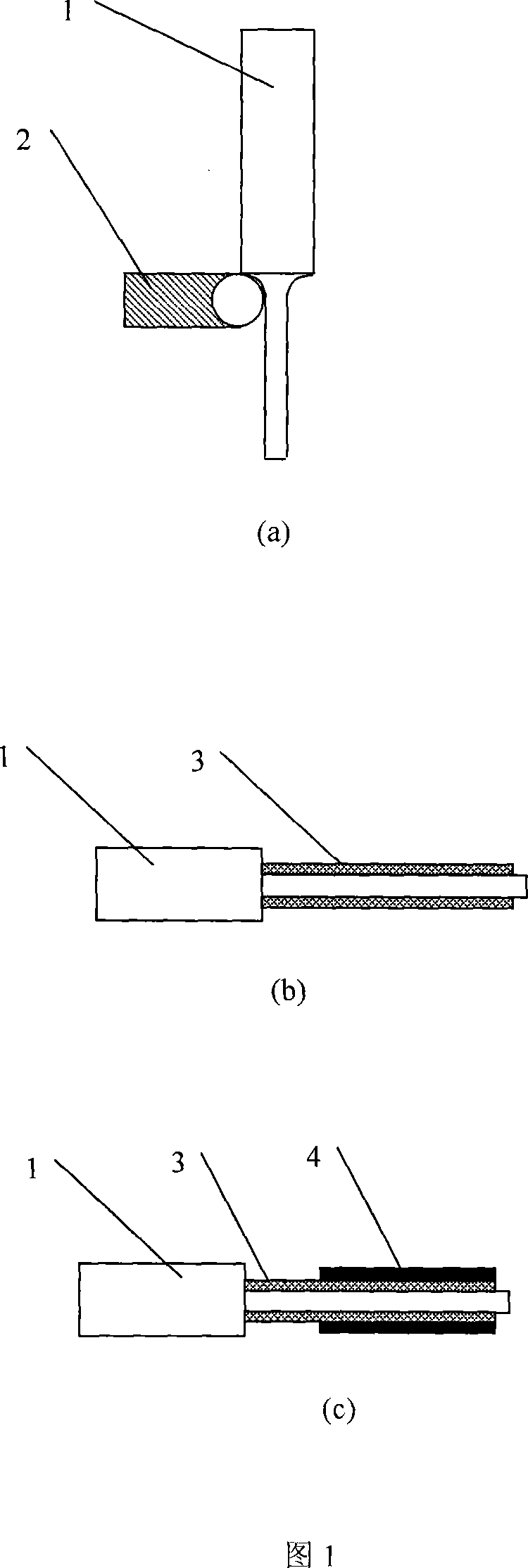

Electrochemical depositer with inductive anode

InactiveCN101074482AImprove localizationImprove machining accuracyElectroforming processesPlatinumElectricity

An electrochemical depositor by inducing anode consists of centering platinum wire(1), insulating layer(3) and conducting layer(4) of external layer. Platinum wire(1) is connected with anode of power supply, conducting layer and cathode are connected with negative polar. Conducting layer and cathode same potential absorb electric-field emitted from edge of platinum wire end, decrease covering zone on cathode surface of electric field and improve depositing locality and precision by inducing anode local electrochemical deposition.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Channel feeding section platinum body installation positioning device and installation method thereof

ActiveCN108383356ANot susceptible to deformatioLess susceptible to damageForehearthsPlatinumRefractory

The invention discloses a channel feeding section platinum body installation positioning device and an installation method thereof. In the early stage of building a kiln channel, a platinum body is hoisted into the channel, the center position of the platinum body meets requirements of installation technology, the outer layer of the platinum body is coated with a refractory material layer, the platinum body and the refractory material layer can be supported effectively through steel-structural panels, the refractory material in hanging can be fastened fixedly through supporting U-steel and braces which are used for connecting the panels, and thus, dropping and collapsing are avoided effectively, falling of the refractory material is avoided so that the platinum body is protected and is noteasy to be deformed or damaged; with application of a lower tightening mechanism, position of the platinum body on the horizontal plane can be adjusted freely through clamp and bolt tightening mechanisms without any other general tools, so that relative positions of the platinum body and the refractory material layer as well as the platinum body and the steel structure can be adjusted.

Owner:IRICO

Jig for machining cylinder hole and bearing hole of valve body

InactiveCN106002355AGuaranteed verticalityGuaranteed to be impartialPrecision positioning equipmentWork clamping meansNumerical controlLocking mechanism

The invention discloses a jig for processing the cylinder hole and bearing hole of a valve body, which includes an indexing plate, a rotating tailstock and a transverse carrier plate; one end of the transverse carrier plate is provided with a positioning device, and the positioning device includes a positioning frame , the positioning frame is respectively provided with a locking mechanism at the upper boss and the lower boss on the side wall of the valve body, and the upper boss and the lower boss on the side wall of the valve body are respectively locked on the corresponding locking mechanism; The other end of the transverse carrier plate is provided with a profiling clamping device, the profiling clamping device includes a support seat, a profiling plate and a driver, the driver is fixed on the support seat, the profiling plate is connected with the pushing end of the driver, and is formed by The actuator drives the clamp on the side wall of the valve body. The jig of the present invention can realize the process of processing the cylinder hole and the bearing hole simultaneously on the NC milling machine in one clamping, avoid the error of multiple clamping, ensure the verticality requirements of the cylinder hole and the bearing hole, and improve the product quality and production efficiency. Significantly increased.

Owner:福建华威钜全精工科技有限公司

Clamping knotter for spring of fully automatic spring coiling machine

InactiveCN1792495AWarranty requirementsGuaranteed verticality requirementsWire springsDrive shaftEngineering

A spring clamping and knot-making mechanism for full-automatic spring coiling machine is composed of spring pilot unit, knot length controller, knot making unit, spring clamping unit, knot making cam, big toothed disc, cam for push rod, fixed axle, drive shaft, installing plate, etc.

Owner:李德锵

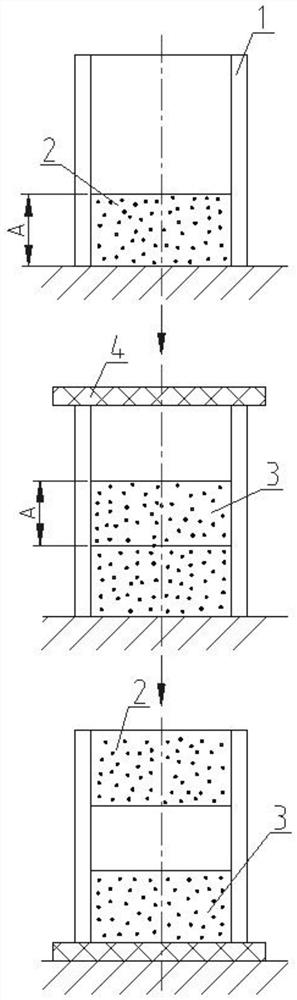

Method for turning thin-wall steel jacket

InactiveCN112404462AIncrease stiffnessGuaranteed Cylindricity RequirementsWork clamping meansPositioning apparatusCrystallographyPotassium nitrate

The invention provides a method for turning a thin-wall steel jacket, and belongs to the technical field of machining. The problems that existing thin-wall steel jacket workpieces are difficult to produce in batches, and progress cannot be guaranteed are solved. The method comprises the following steps that a mixture of 96% carbamide and 4% potassium nitrate is heated to 140 DEG C or above to prepare a self-coagulator, an inner hole of a workpiece is filled with the first batch of self-coagulator at a filling height of A, the inner hole of the workpiece is filled with a second batch of self-coagulator at a filling height of A after the first batch of self-coagulator is solidified, an upper end opening of the workpiece is covered with a rubber pad, the workpiece is turned by 180 degrees, the second batch of non-solidified self-coagulator is enabled to flow downwards, turning on an outer circle and the end face of the workpiece is performed after the second batch of self-coagulator are solidified, the workpiece is clamped by using a special clamp, and rough turning and finish turning on the inner hole of the workpiece are sequentially performed after clamping. The method is mainly used for batch machining on the thin-wall steel jacket.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Planing method for cubic part vertical faces

ActiveCN106238797AGuarantee processing qualitySimple and efficient operationPlaning/slotting machinesRound barMachine tool

The invention belongs to machining technology and relates to improvement to planing methods for cubic part vertical faces. A planing method for cubic part vertical faces comprises the steps that a gripper is detected and rectified; rough planing is conducted on four vertical faces; a horizontal face is planed; one vertical face is planed; the other vertical face is planed; and the other horizontal face is planed. According to the planing method, the perpendicularity of the vertical face of the gripper and horizontal cutter feeding of a machine tool is used, one vertical face of the gripper is used as the datum, all the vertical faces are machined, the principle of datum unification is achieved, and thus the perpendicularity requirements of the four machined cubic part faces are met. Through filling of a round bar, clamping force is focused on the middle of a jaw so that a datum plane can be attached to the fixed jaw tightly and reliably, and thus the machining quality is ensured. The planing method is simple and convenient to operate, the precision of a machined part can be improved, and deformation of machining is reduced effectively.

Owner:HARBIN

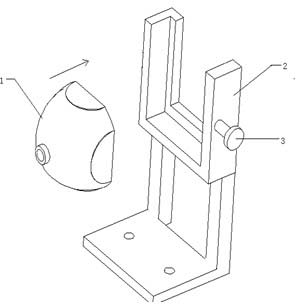

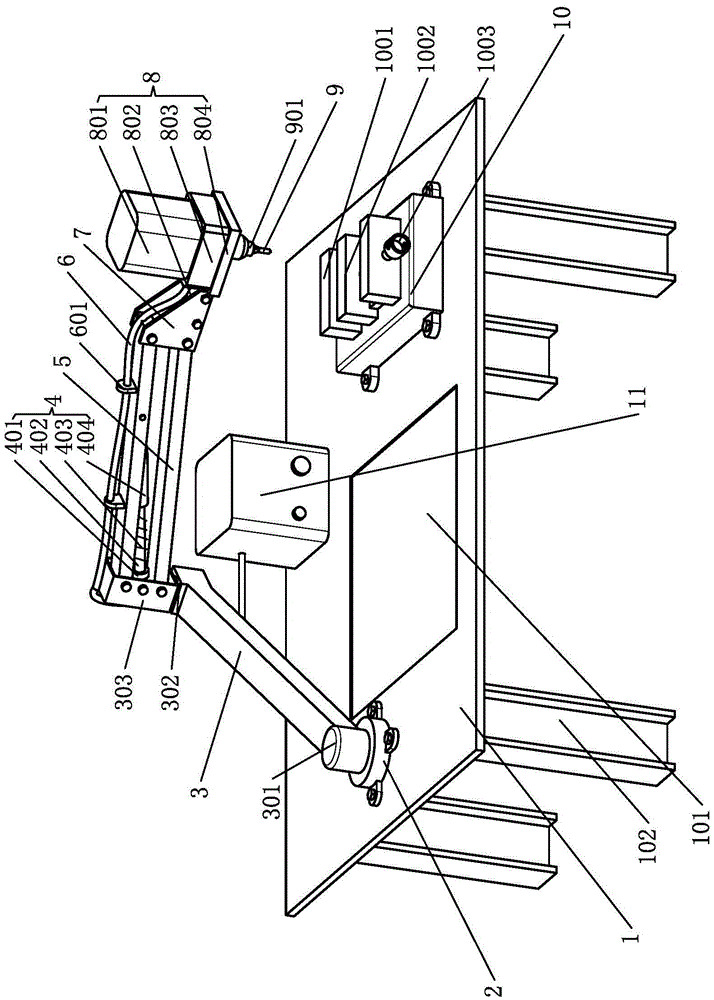

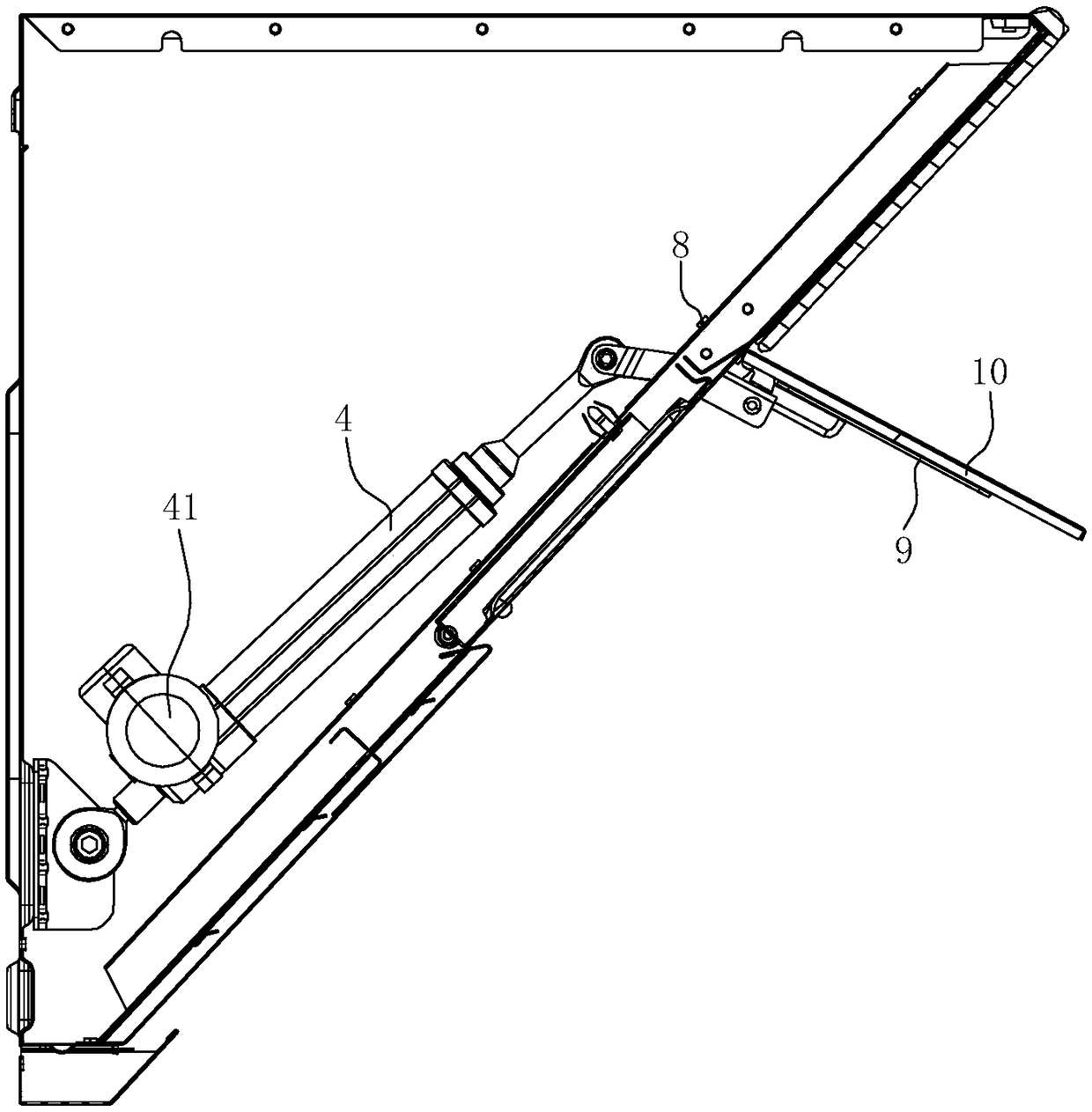

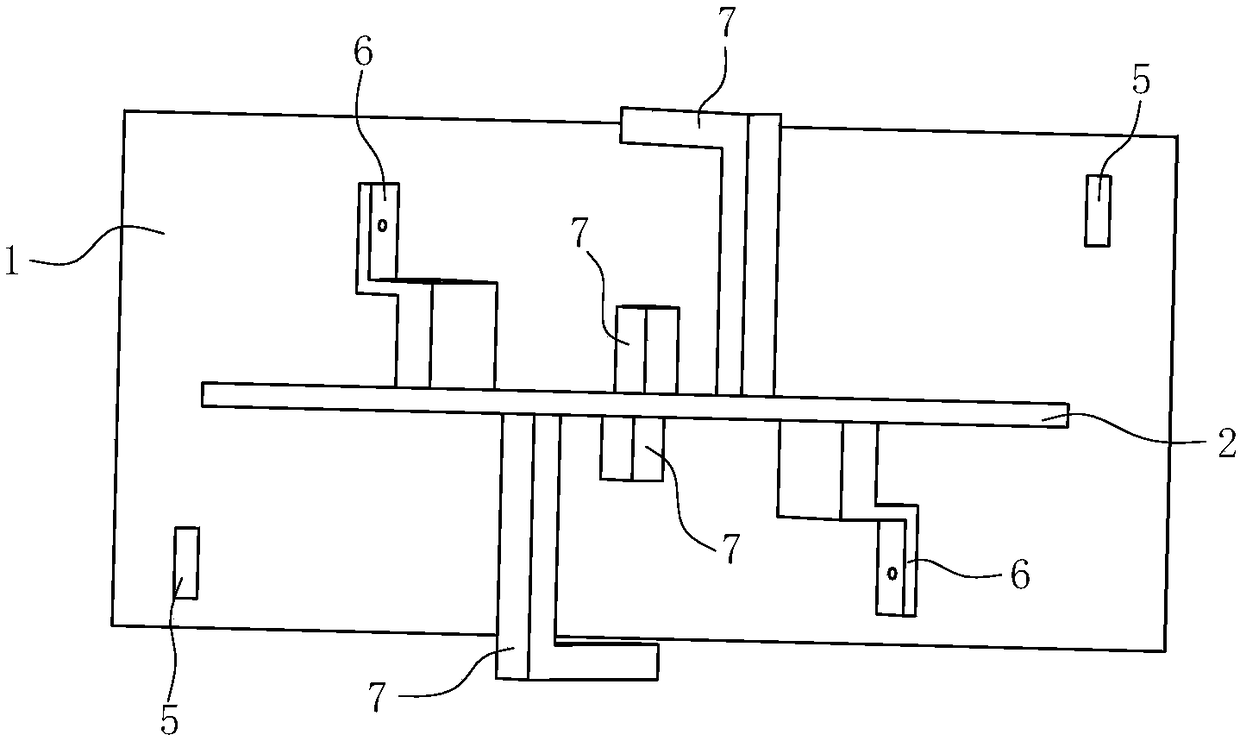

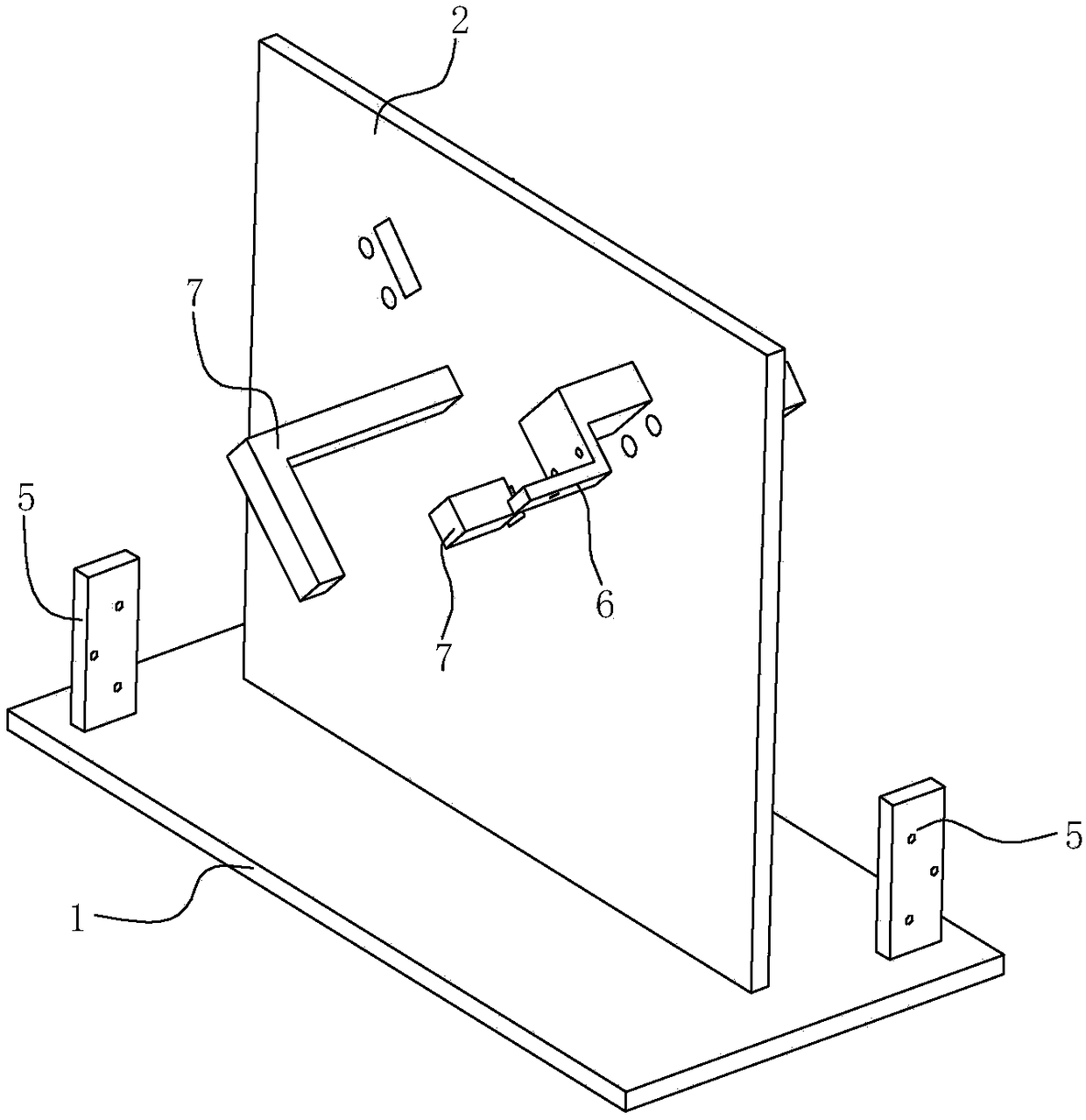

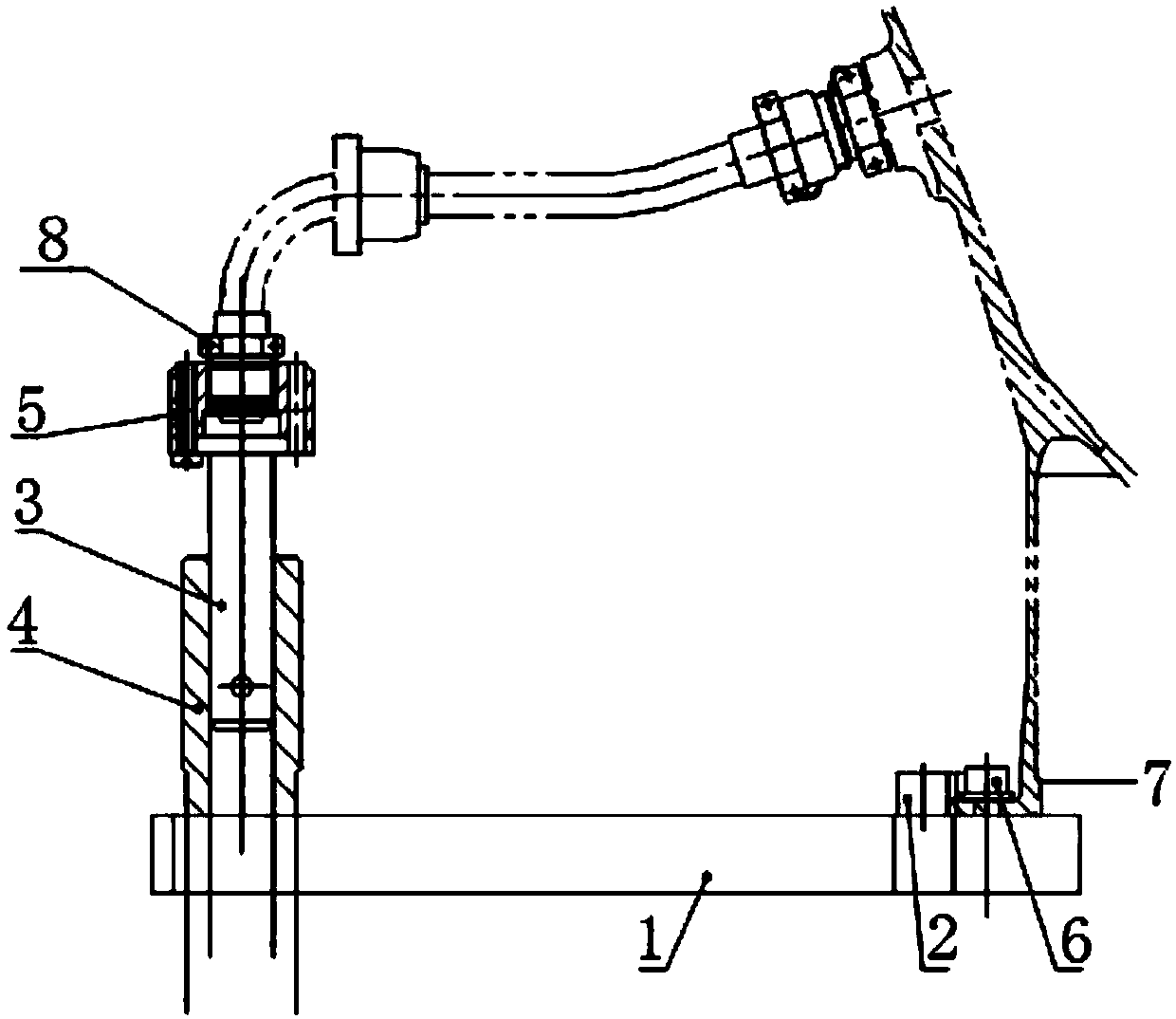

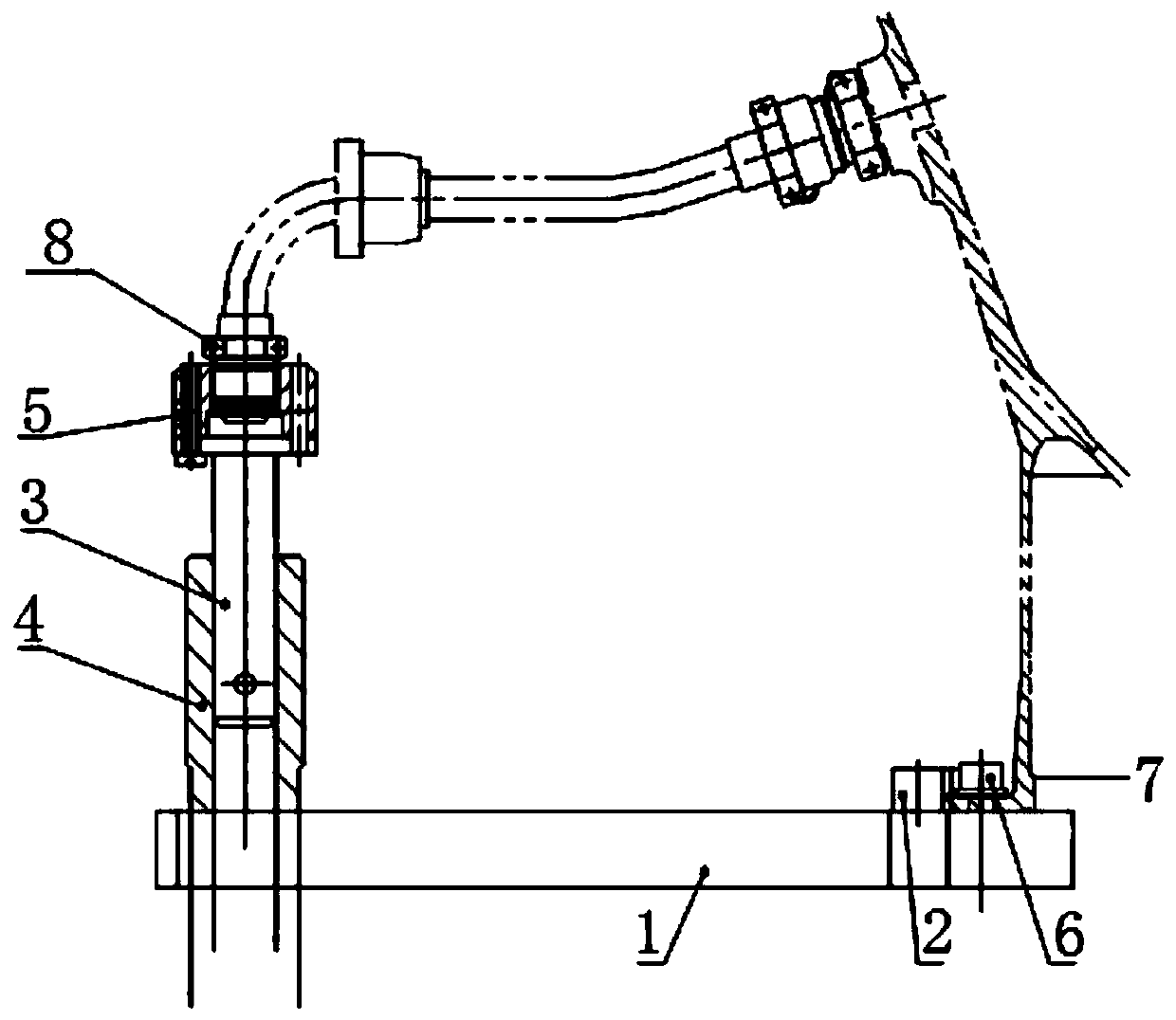

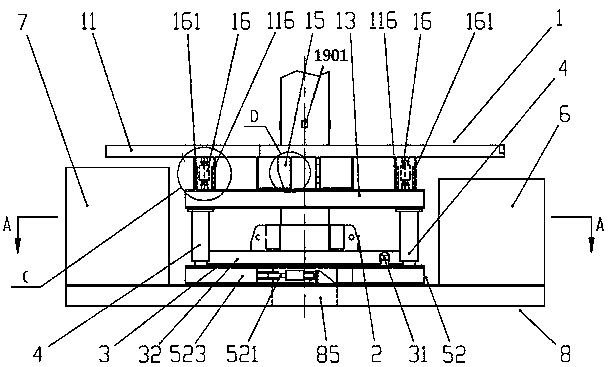

Electric push rod life test device

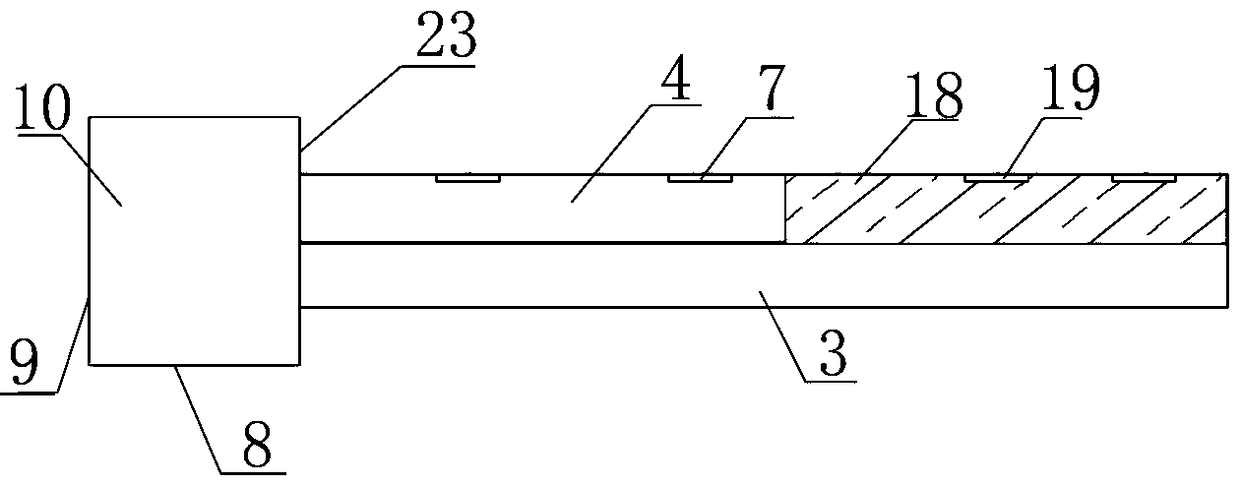

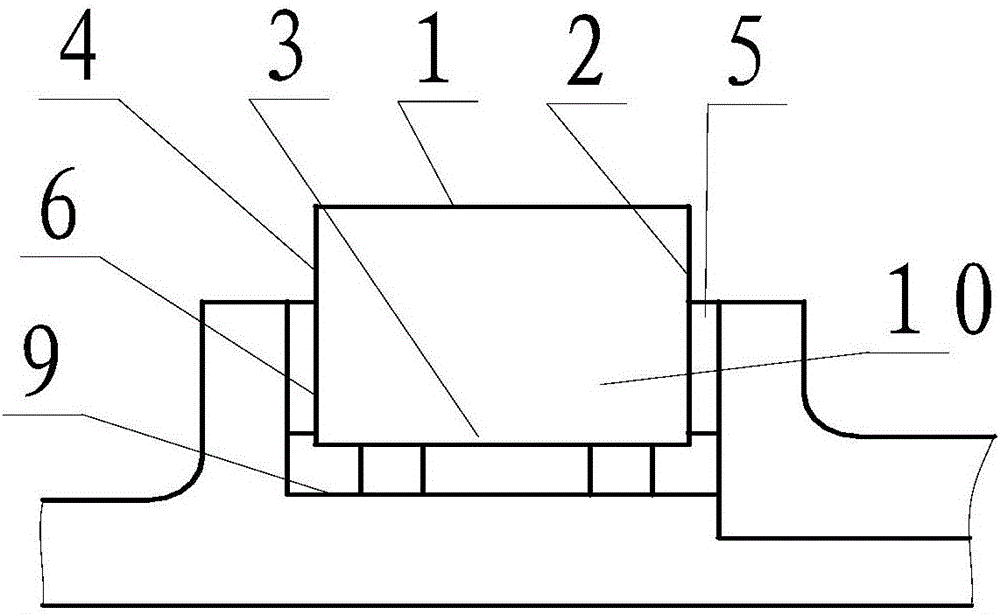

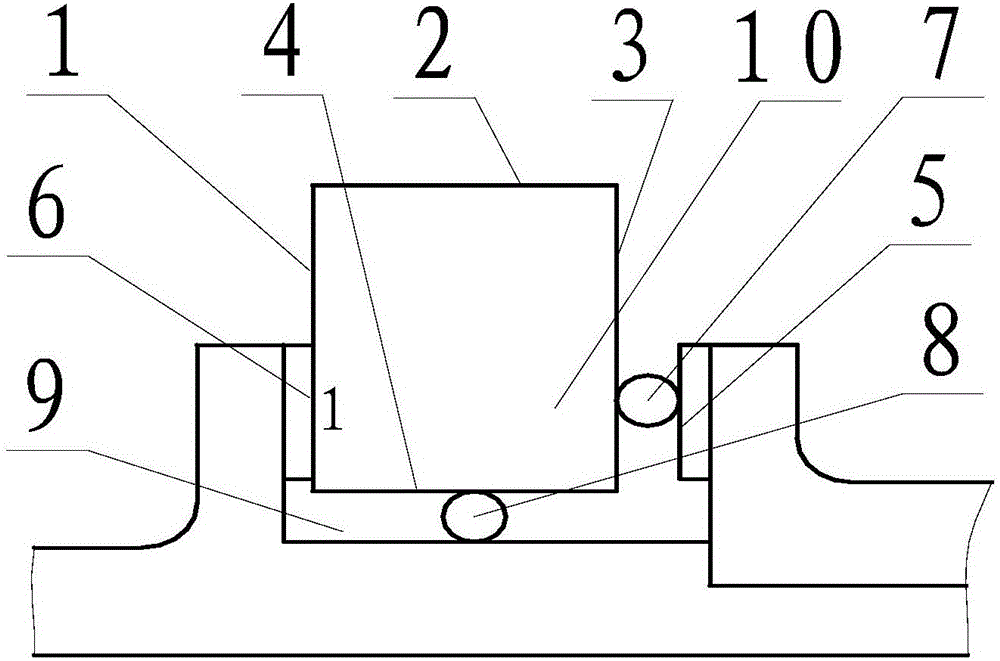

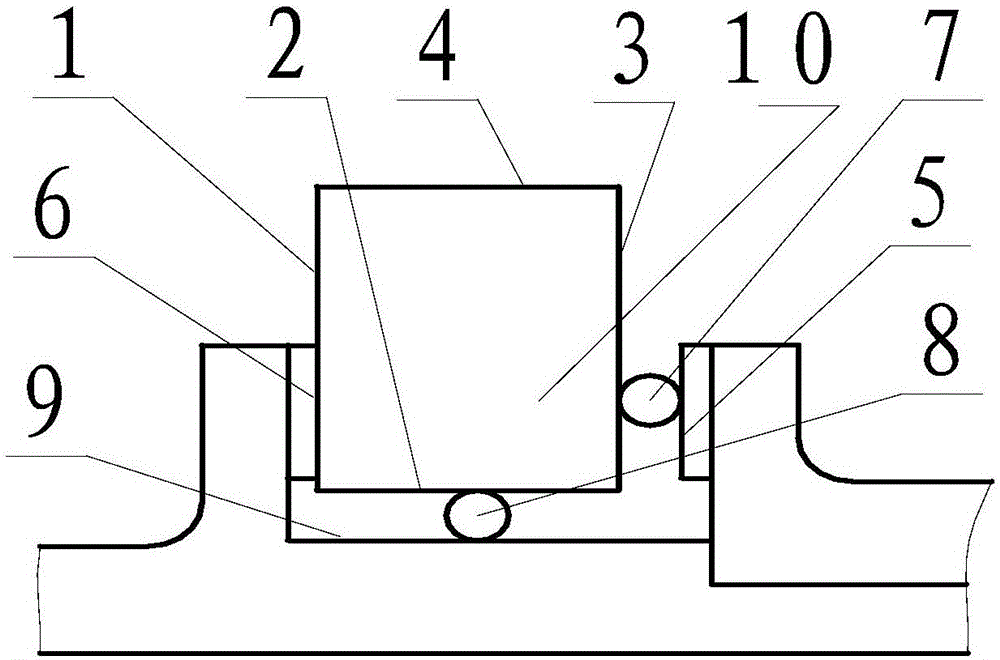

PendingCN108061641AImprove test efficiencyReduce testing costsMachine part testingEngineeringLife testing

The invention relates to an electric push rod life test device. The electric push rod life test device is characterized in that the electric push rod life test device comprises a horizontal plate (1),a vertical plate (2) and load blocks (3); the vertical plate (2) is fixed on the horizontal plate (1) and is perpendicular to the horizontal plate (1); fixing seats (5) for mounting electric push rods (4) are fixed onto the horizontal plate (1); positioning blocks (6) and limiting blocks (7) are fixed on the vertical plate (2); the positioning blocks (6) are used for fixing upper hinges (8); theload blocks (3) are fixed onto lower hinges (9); the lower hinges (9) are connected with the push rods of electric push rods to be tested (4), so that the lower hinges (9) can be driven to swing relative to the upper hinges (8); and the limiting blocks (7) are used for limiting the downward swing of the load blocks (3). The electric push rod life test device of the invention is low in cost and iscustomizable. With the electric push rod life test device adopted, the actual working status of an electric push rod can be simulated, so that prospective design reference can be provided for the design of push rods.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

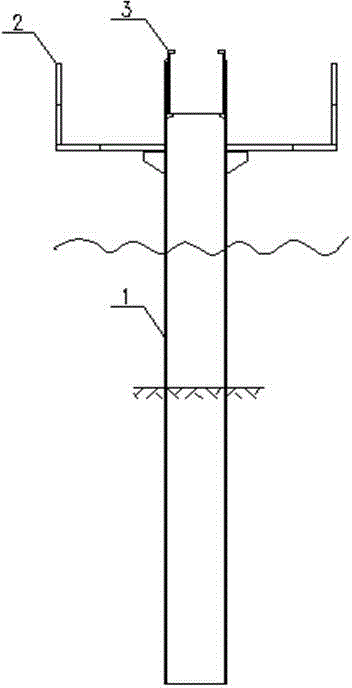

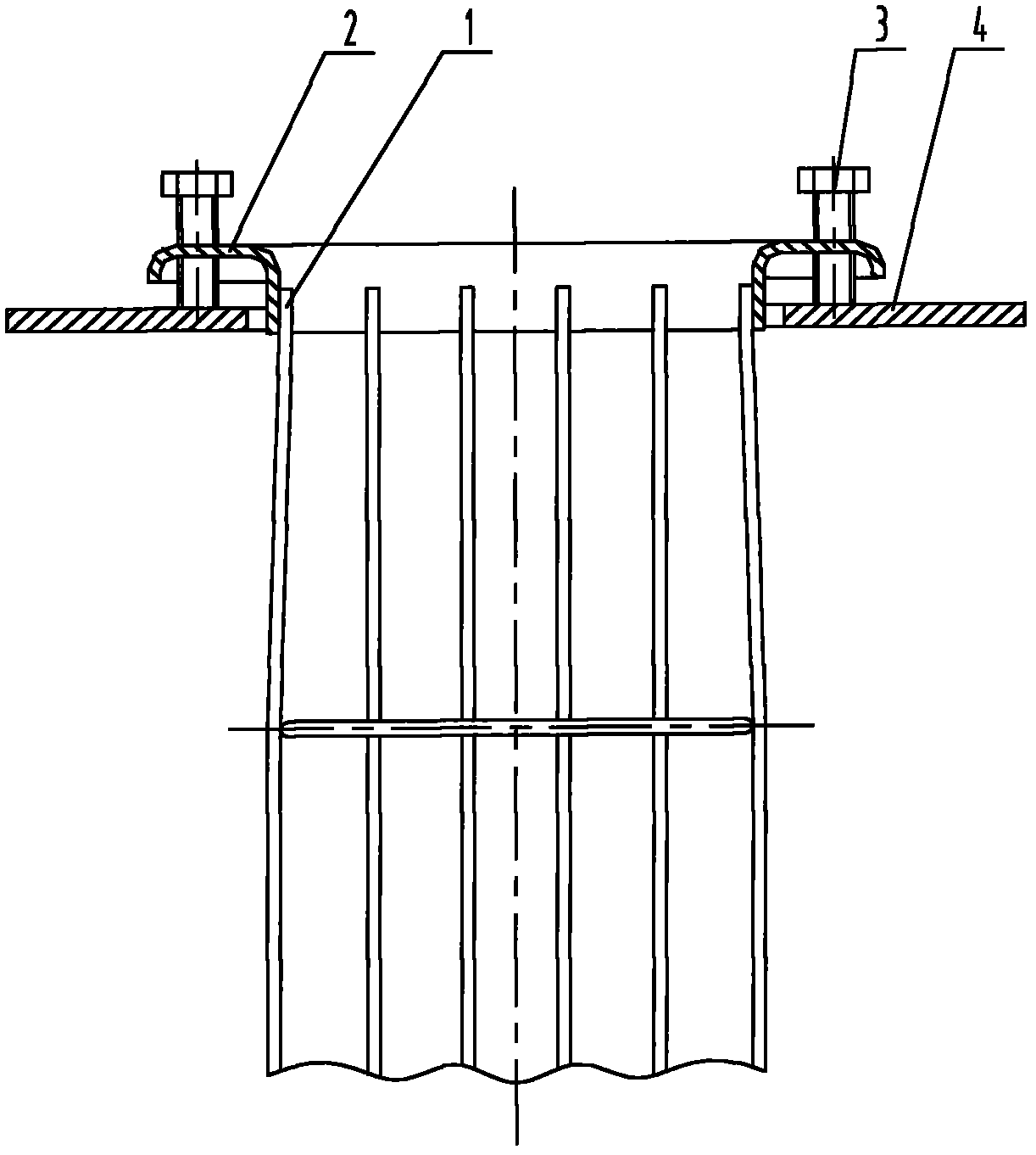

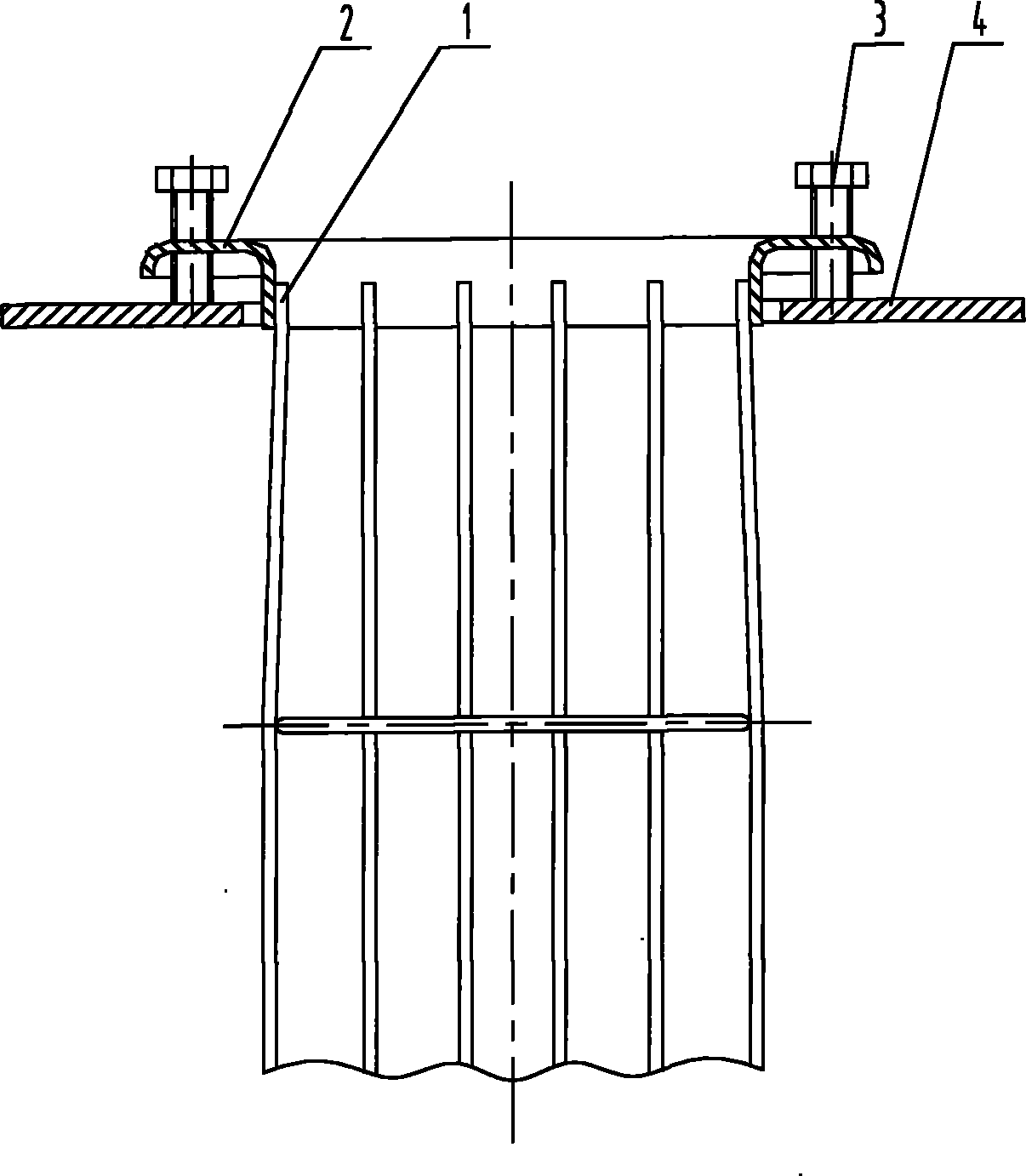

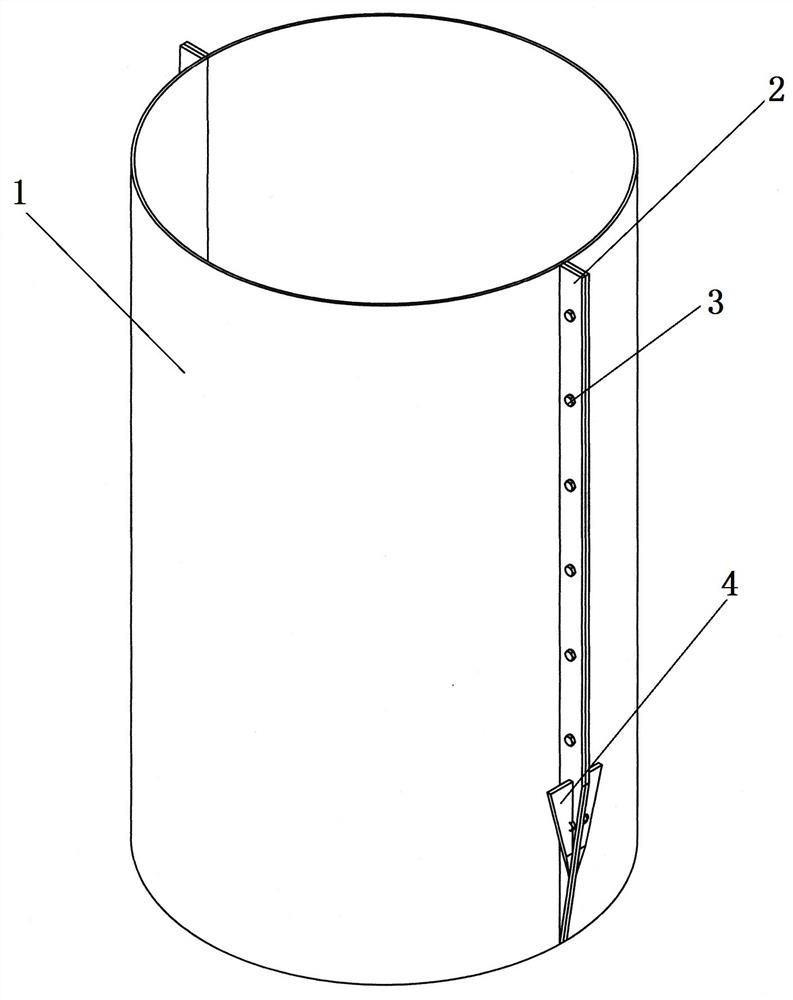

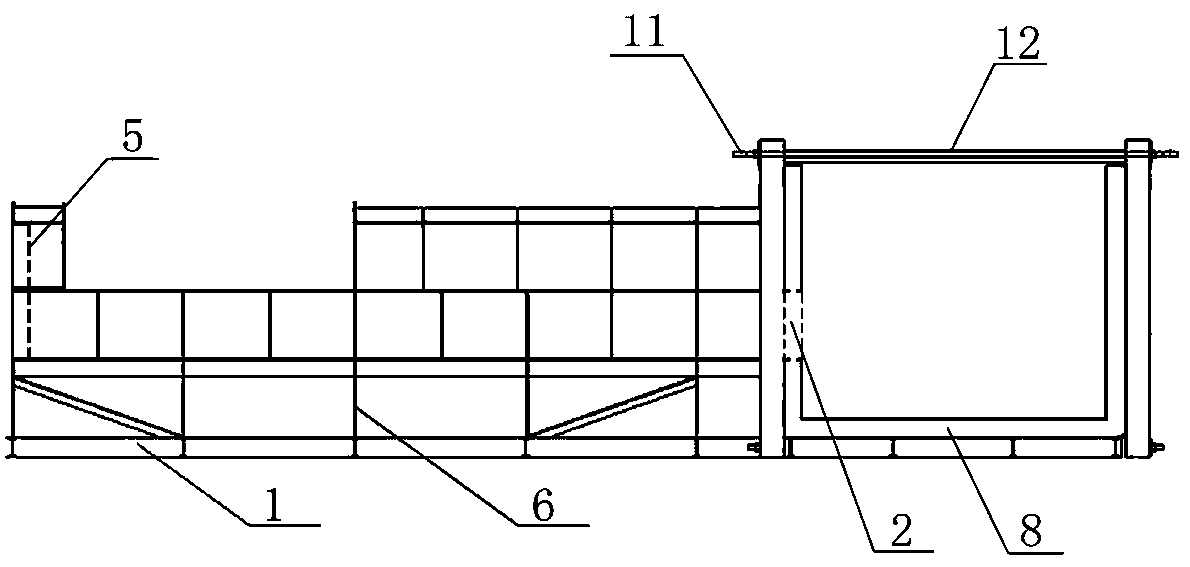

Draught fan foundation structure with single pile of transition sections and construction method

InactiveCN105317054AImprove reliabilityGuaranteed verticality requirementsFoundation engineeringWind motor componentsElectricityTower

The invention discloses a draught fan foundation structure with a single pile of transition sections. The draught fan foundation structure with the single pile of the transition sections comprises a single pile body and the transition sections. The transition sections are internally arranged on the inner side of the single pile body and are connected with the single pile body to form a whole through welding. The upper ends of the transition sections are connected with an upper tower barrel through flange rings. Operation platforms are arranged at the upper end of the single pile body and are located on the outsides of the lower ends of the transition sections. The operation platforms are clamped and buckled in preformed clamping grooves in the outside of the upper end of the single pile body. A construction method comprises five steps. The draught fan foundation structure with the single pile of the transition sections is different from a structure scheme with transition sections on the outsides, offshore grouting is not needed, the offshore operation time is saved and the cost is reduced; in addition, the transmission force of the structure is mainly conducted through a welding structure, so that the reliability of the structure is increased. Compared with a single pile foundation without a transition section structure, the requirements for construction equipment and construction technology are lowered; under the background that offshore wind power will be developed on a large scale, the construction progress is speeded up, and the verticality requirement of a single pile foundation and the safety of a flange ring structure can be ensured.

Owner:LONGYUAN (BEIJING) WIND POWER ENG & CONSULTING CO LTD

Rotary drilling hole forming method by using multi-stage alloy pilot roller bit in complex stratum cast-in-place pile construction

ActiveCN102409978AEasy to processEasy landing and drillingDirectional drillingLow speedSoil mechanics

The invention discloses a strong karst area cast-in-place pile construction method based on a rotary drilling hole forming manner. The cast-in-place pile construction method is characterized by comprising the steps of: (1) drilling into the surfaces of a karst layer and a gravel soil layer by adopting a conventional bit; (2) in combination with the basic theory of rock-soil mechanics, finding out a mathematic relation between an optimized value of inclination of a multi-stage alloy pilot roller bit and a coefficient of sliding friction between a rock-soil material and the interface of the bit; (3) after adopting the conventional bit to dill into the surfaces of the karst layer and the gravel soil layer, changing the conventional bit into the multi-stage alloy pilot roller bit, firstly drilling at high pressure and low speed, and then, after the bit is dilled into the rock for more than 50 cm, drilling at low pressure and high speed until the drilling depth or hole depth satisfies design requirements; (4) optimizing the design of mud specific weight in stages for preventing pile holes from collapsing and improving the bearing capacity of pile foundations; and (5) handling sudden accidents, such as fracture of drilling rods, bit falling, bit burying, fracture of cone palms in holes, accidental falling of cone palms and other small operation tools and the like, in the drilling process by adopting a drill tool overshot and a falling object salvage skip.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

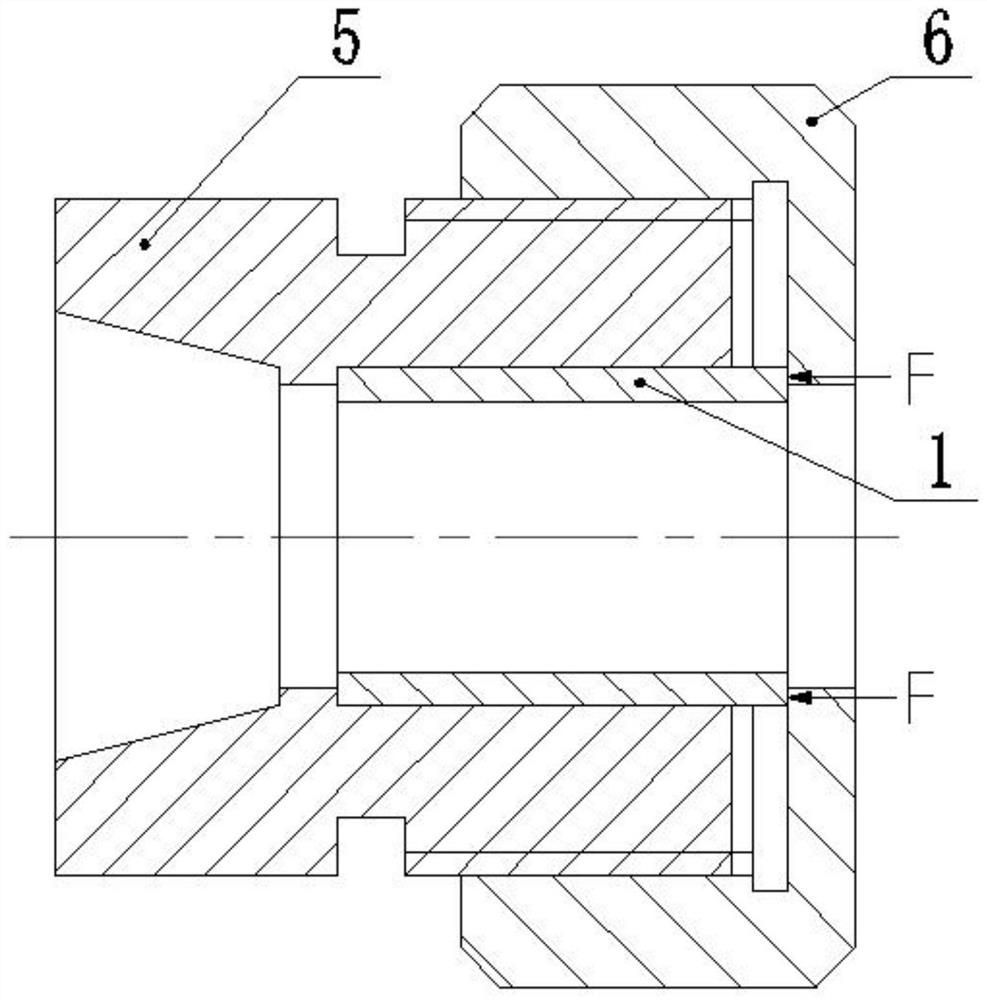

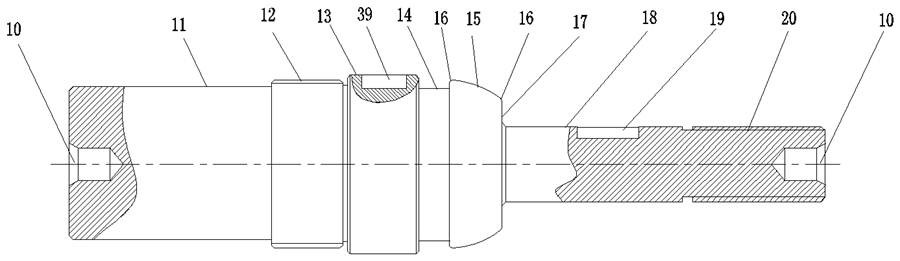

Positioning clamp and machining method for rotor cover of dynamic pressure air bearing of gyro motor

ActiveCN114589520APrecise positioningRestricted freedom of movementWork clamping meansPositioning apparatusAir bearingGyroscope

The invention relates to a thin-wall part precision turning machining method and a positioning clamp, in particular to a positioning clamp and a machining method of a gyroscope motor dynamic pressure air bearing rotor cover. The positioning clamp comprises a spherical surface positioning mandrel, a positioning lantern ring, an anti-vibration pad and a back supporting seat. The spherical positioning mandrel is a step shaft with center holes formed in the two end faces, and comprises a clamping section, a large thread section, a second guide cylindrical section, a spherical positioning section, a spherical table end face, a first guide cylindrical section and a small thread section from left to right in sequence. The machining method comprises the steps of first-step machining of the rotor cover, machining of a series of spherical positioning mandrels, machining of a positioning lantern ring and a back supporting seat, selection of a proper spherical positioning mandrel, turning of the rotor cover and the like. The problems that an existing machining method is poor in positioning precision and low in machining efficiency, and the concave spherical surface is crushed are solved, damage to the concave spherical surface is avoided by limiting six degrees of freedom, and the machining precision of the rotor cover is guaranteed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

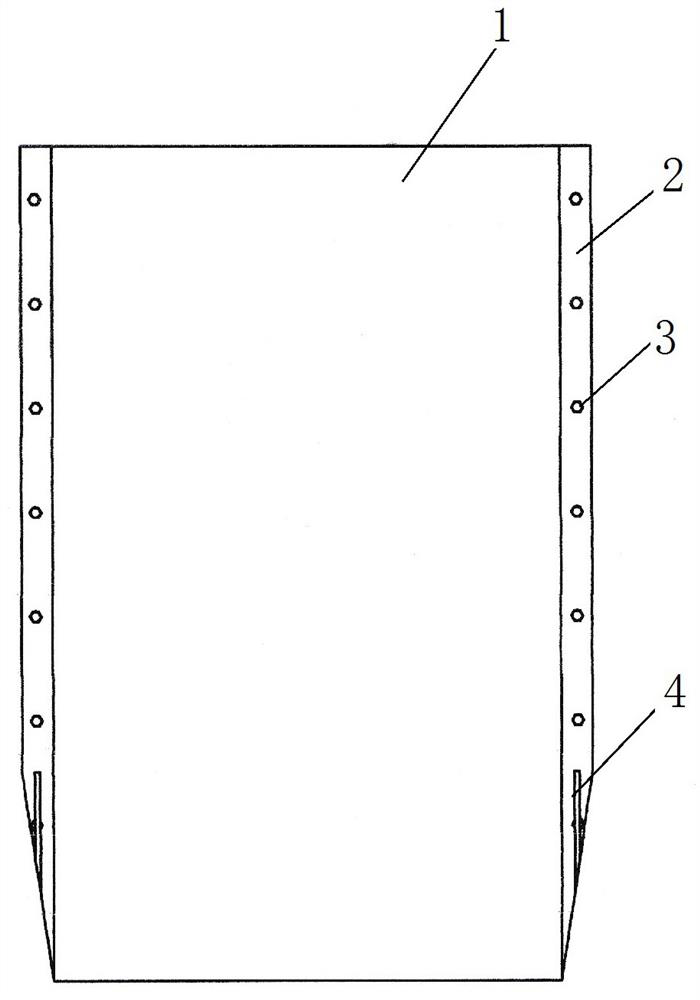

Self-aligning cage structure for bag type dust collector

InactiveCN102000464AGuaranteed verticalityGuaranteed verticality requirementsDispersed particle filtrationSpiteArchitectural engineering

The invention discloses a self-aligning cage structure for a bag type dust collector. The self-aligning cage structure comprises a top cap and a plurality of vertical ribs, wherein the tops of the vertical ribs are connected to the top cap; and the top cap is arranged on a parquet panel through an adjusting bolt. When the cage is mounted, the cage mounting verticality can be guaranteed by adjusting the height of the adjusting bolt, and in spite of the flatness of the parquet panel, the requirement of the cage mounting verticality can be met so as to prevent the bottom of the cage from being collided and a filter bag from being damaged due to the abrasion of the bottom of the bag.

Owner:浙江菲达环保科技股份有限公司

Concrete tower mounting levelling method

ActiveCN107201848AGuaranteed installation accuracyGuaranteed accuracy requirementsTowersTowerLevelling

The invention discloses a concrete tower mounting levelling method. The method comprises the steps that step 1, concrete rings are subjected to levelling in advance, wherein step 1.1, the upper surfaces of the concrete rings are divided into N equal portions, and marks are made at wall thickness midpoints of the concrete rings; step 1.2, the wall thickness midpoints of the concrete rings are subjected to measurement of levelness error; step 1.3, according to the value of the levelness error, glass fabric laminated layers of different thickness are selected, and the glass fabric is glued and connected to designated portions by epoxy resin; step 1.4, the steps 1.1-1.3 are repeated until the upper surfaces of the concrete rings reach horizontal accuracy, and the leveled concrete rings are obtained; step 2, the leveled concrete rings are mounted on a foundation layer according to the sequence of the diameter from large to small. The method is economic, simple and feasible, no grouting or large-scale manufacturing device is needed, the operation is easy, and rapid installation can be achieved; meanwhile, accuracy and perpendicularity requirements of tower mounting are guaranteed, the mounting time is shortened, and the tower use and mounting cost is reduced.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Pouring construction process for bridge pier through concrete conduit method

InactiveCN111677285AReduce excavationShorten the construction periodBridge erection/assemblyBuilding material handlingTremieArchitectural engineering

The invention discloses a pouring construction process for a bridge pier through a concrete conduit method and relates to pouring construction processes for underground bridge piers through the concrete conduit method. The process mainly aims to solve the problems of low efficiency and the like as a result of two times of construction of a pile body and a pier currently. According to the process,firstly, cut-pile elevation of a bridge pile foundation is raised to the bottom of a bent cap or an abutment, and then a construction platform is filled, wherein the elevation of the construction platform is consistent with the new cut-pile elevation; after platform filling is completed, a steel casing is inserted and driven into a pile position, and next a construction pile foundation is poured according to the conduit method, wherein steel bars in pier height are arranged according to pier steel bars; the steel casing is pulled out after concrete is poured to the top face of the steel casing, and two theodolites are used for recording a plane position when the casing is pulled out; the pier casing is inserted again according to the recorded position, and concrete is supplemented again tothe bottom of the bent cap or the abutment; and after the concrete meets the strength requirement, a soil body within the height range of the pier is excavated, the pier casing is dismantled, and thepier concrete is maintained. The process has the advantages that the construction period is short, and construction cost is low.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG +1

Linear cutting and polishing integrated machine

Owner:常熟中材钨业科技有限公司

Aeroengine single cantilever pipeline pipe nipple portion verticality measuring device

ActiveCN107726964ANovel structureLightweightMechanical measuring arrangementsCombustion chamberCantilever

The invention discloses an aeroengine single cantilever pipeline pipe nipple portion verticality measuring device comprising a positioning plate; the positioning plate is provided with a positioning block fixedly connected with the aeroengine combustion chamber sheath; the positioning plate is also provided with a shaft sleeve; the shaft sleeve is arranged right below the pipe nipple part; a positioning shaft is arranged in the shaft sleeve so as to form sliding matching, and the fitting gap between the shaft sleeve and the positioning shaft is not greater than 0.01mm; the positioning shaft upper portion is provided with a thread ring gauge sleeved with the pipe nipple part; the device also comprises a measuring mechanism used for measuring the gap between the shaft sleeve and the positioning plate contact end face. The device can directly measure the single cantilever pipeline pipe nipple part verticality on a combustion chamber unit assembly, is simple in structure, easy to use, andfast in measuring speed.

Owner:AECC AVIATION POWER CO LTD

Construction method for quickly assembling the transverse block of a bridge substructure

ActiveCN109162204AGuaranteed verticality requirementsGuaranteed accuracy requirementsBridge erection/assemblyUltimate tensile strengthSubstructure

The invention relates to a construction method for quickly assembling the transverse block of a bridge substructure, which comprises the following steps: 1, integrated construction of a precast pier column cover beam; Wherein the lower part of the pier column of the precast pier column cover beam is provided with a steel plate hoop, and shear nails are welded on the outer surface of the steel plate hoop; 2, excavate that foundation pit and temporarily supporting the foundation pit; 3, constructing a concrete cushion layer at the bottom of the foundation pit; 4, constructing pier column foundation: the pier column foundation adopts cast-in-place enlarged foundation, and a cup mouth is arranged at the top of the enlarged foundation, and a ring of anchor plates are embedded around the top ofthe cup mouth; 5, performing hoisting and positioning of the cover beam of the precast pier column; 6, backfilling the foundation pit; 7, hoisting the main girder is in place. The invention solves thetechnical problems that the lifting elevation and the axis deviation of the traditional prefabricated bridge substructure are difficult to control, the positioning accuracy is low, the strength of the filler between the expanded foundation and the expansion foundation is slow, and the construction period is long.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP +1

Stand column welding tool

InactiveCN106736178AImprove interchangeabilityGuaranteed installation accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a stand column welding tool which comprises a rack, a fixed seat, a movable seat and a supporting seat. The fixed seat is installed at one end of the rack, and the movable seat is arranged at the other end of the rack. The fixed seat comprises a fixed sleeve and a seat body which are arranged in an up-and-down manner, wherein the installation face of the fixed sleeve is perpendicularly provided with a positioning disc. The movable seat comprises a guide seat, a seat body, a movable sleeve, a screw rod and a hand wheel, wherein the guide seat and the seat body are installed in an up-and-down manner, the hand wheel rotates to drive the screw rod to rotate, and the screw rod rotates to drive the movable sleeve to move front and back. The supporting seat is installed at the position, between the fixed seat and the movable seat, of the rack. According to the V-shaped structure formed by the supporting seat, stand column guide rails can automatically centered and do not need to be straightened; flange plates are positioned through reamed holes, and the requirement for the form and location tolerance between the flange plates and stand columns can be met; the requirement for the length size is met through moving of the movable sleeve; deformation generated during welding can be controlled through a pressing mechanism, and therefore the requirement for the parallelism, perpendicularity and the location degree between the stand column guide rails and the flange plates and between the flange plates are met.

Owner:湖南中佳华悦环保科技有限公司

A verticality measuring device for the mouth of a single-cantilever pipeline of an aero-engine

ActiveCN107726964BHigh measurement accuracyImprove detection efficiencyMechanical measuring arrangementsCombustion chamberCantilever

The invention discloses an aeroengine single cantilever pipeline pipe nipple portion verticality measuring device comprising a positioning plate; the positioning plate is provided with a positioning block fixedly connected with the aeroengine combustion chamber sheath; the positioning plate is also provided with a shaft sleeve; the shaft sleeve is arranged right below the pipe nipple part; a positioning shaft is arranged in the shaft sleeve so as to form sliding matching, and the fitting gap between the shaft sleeve and the positioning shaft is not greater than 0.01mm; the positioning shaft upper portion is provided with a thread ring gauge sleeved with the pipe nipple part; the device also comprises a measuring mechanism used for measuring the gap between the shaft sleeve and the positioning plate contact end face. The device can directly measure the single cantilever pipeline pipe nipple part verticality on a combustion chamber unit assembly, is simple in structure, easy to use, andfast in measuring speed.

Owner:AECC AVIATION POWER CO LTD

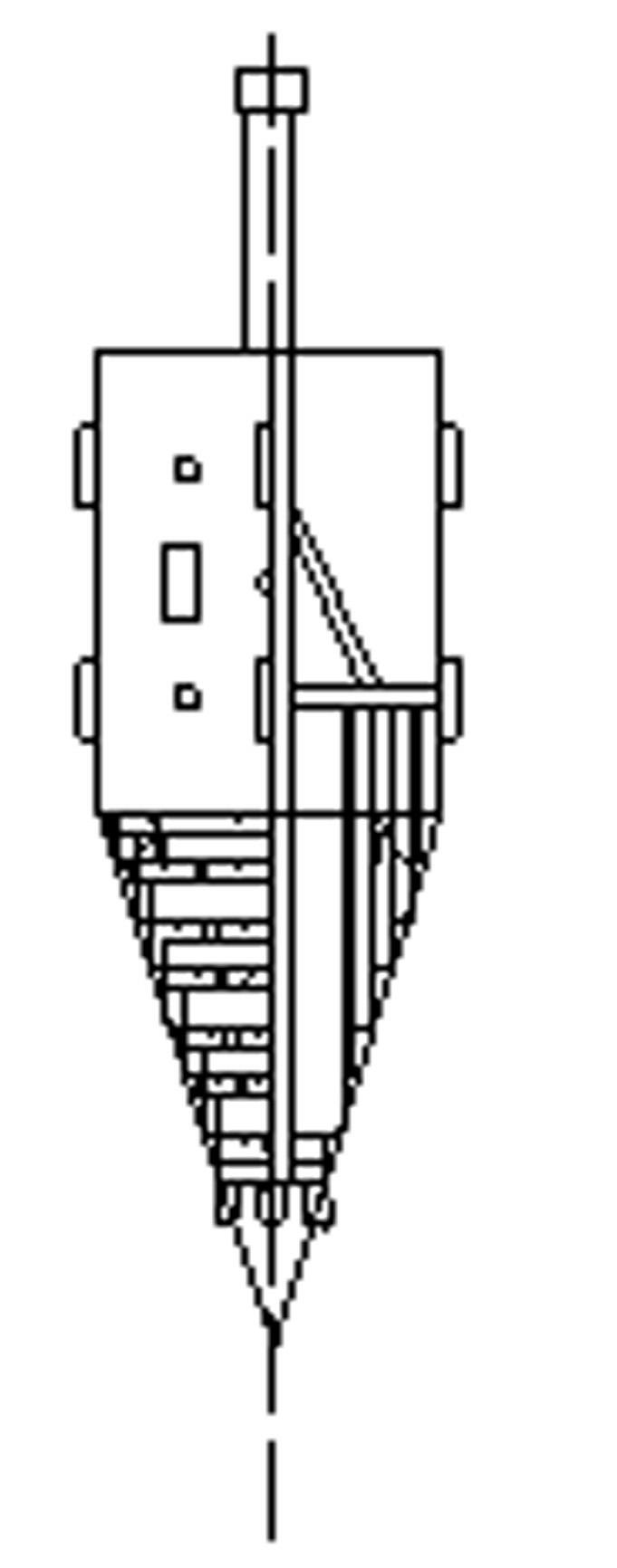

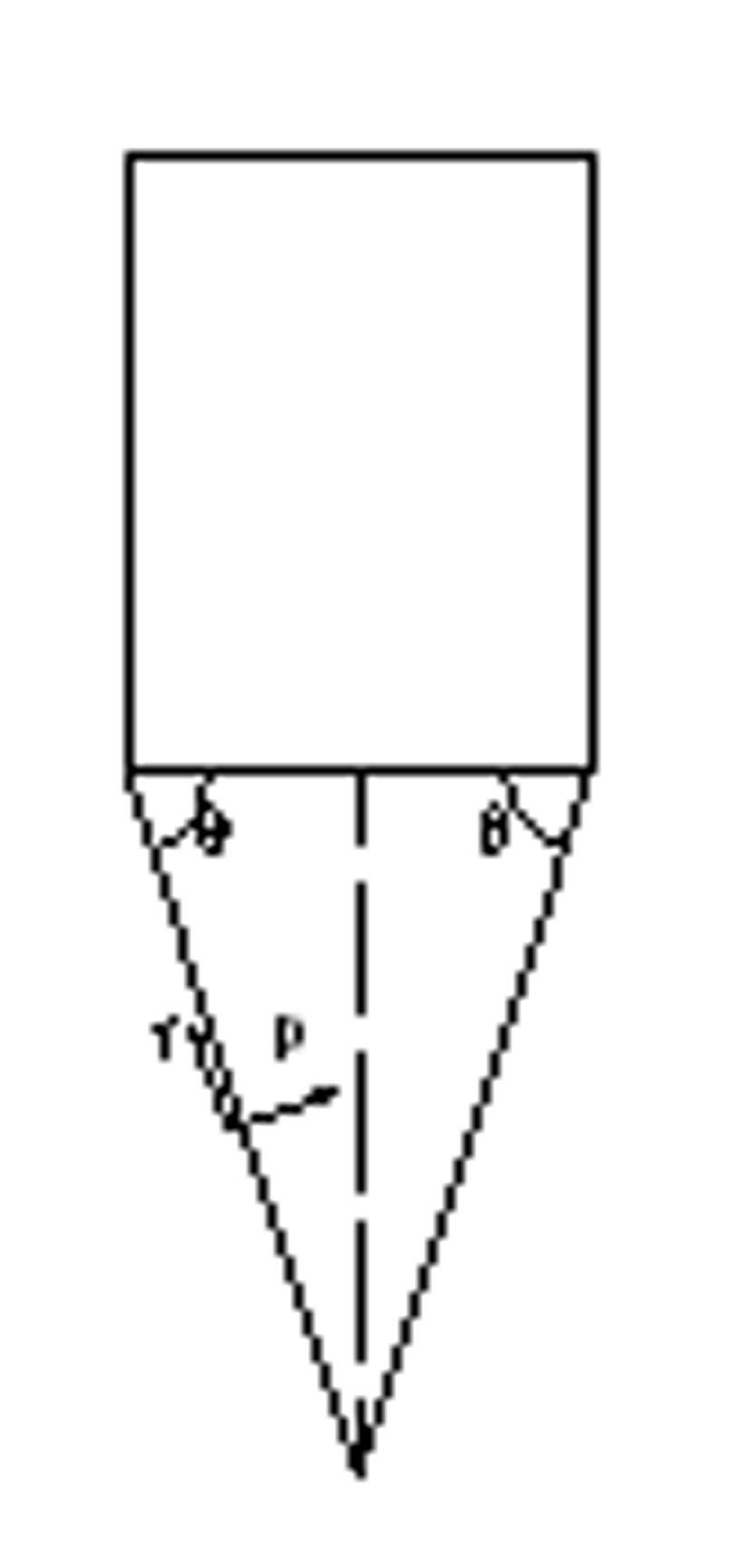

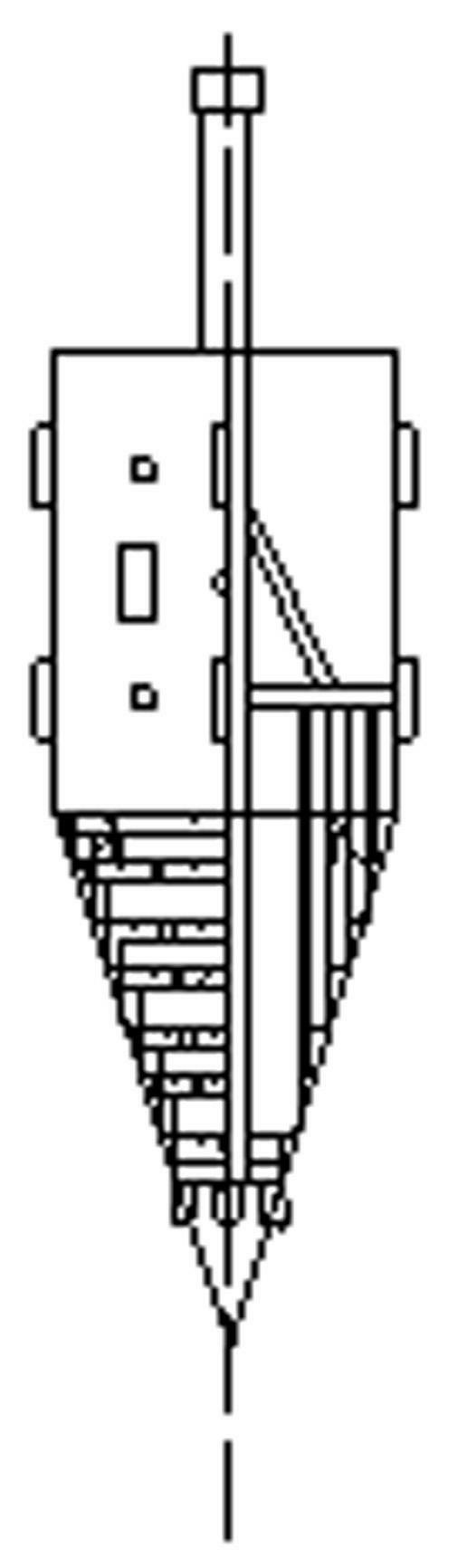

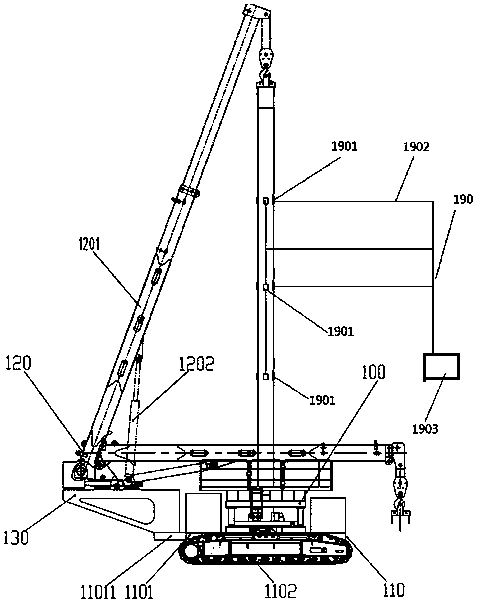

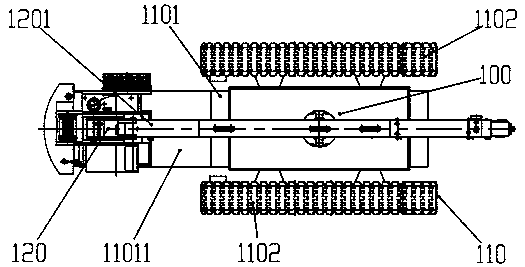

Pile planting machine with monitoring function

ActiveCN107869139APress evenlyRealize the purpose of pressurized pile plantingBulkheads/pilesButt jointMonitoring system

A pile planting machine with a monitoring function comprises a walking mechanism, a hoisting mechanism, a support frame, a clamping mechanism and a pile body monitoring system; the clamping mechanismis fixedly installed on the walking mechanism; the clamping mechanism comprises an upper rack comprising a working platform, a plurality of clamping wedge blocks, a clamping ring, an upper underframeand four groups of upper clamping cylinders, a lower clamping mechanism comprising a lower clamping cylinder, an arc ring and two lower clamping arm supports arranged symmetrically, a slewing mechanism, a fine-tuning mechanism comprising horizontal and vertical fine-tuning cylinders, and four groups of vertical jacking cylinders; and the pile monitoring system comprises a plurality of strain gauges, wire harnesses and monitoring meters, and can be used for monitoring the whole process that planted pile bodies are driven into prefabricated holes. According to the pile planting machine providedby the invention, the pile planting accuracy of precast piles is improved effectively, the pile planting machine facilitates butt joint of the precast pile bodies up and down; and the construction cost is reduced, and the operation safety of operators is improved.

Owner:SHANGHAI GUANGDA FOUND ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com