Clamping knotter for spring of fully automatic spring coiling machine

A spring clamping and coiling machine technology, applied in the field of spring processing, can solve the problems of inconvenient adjustment, difficult to guarantee spring quality, complexity, etc., and achieve the requirements of ensuring the verticality of the spring, accurate and easy clamping, and fast and easy knotting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

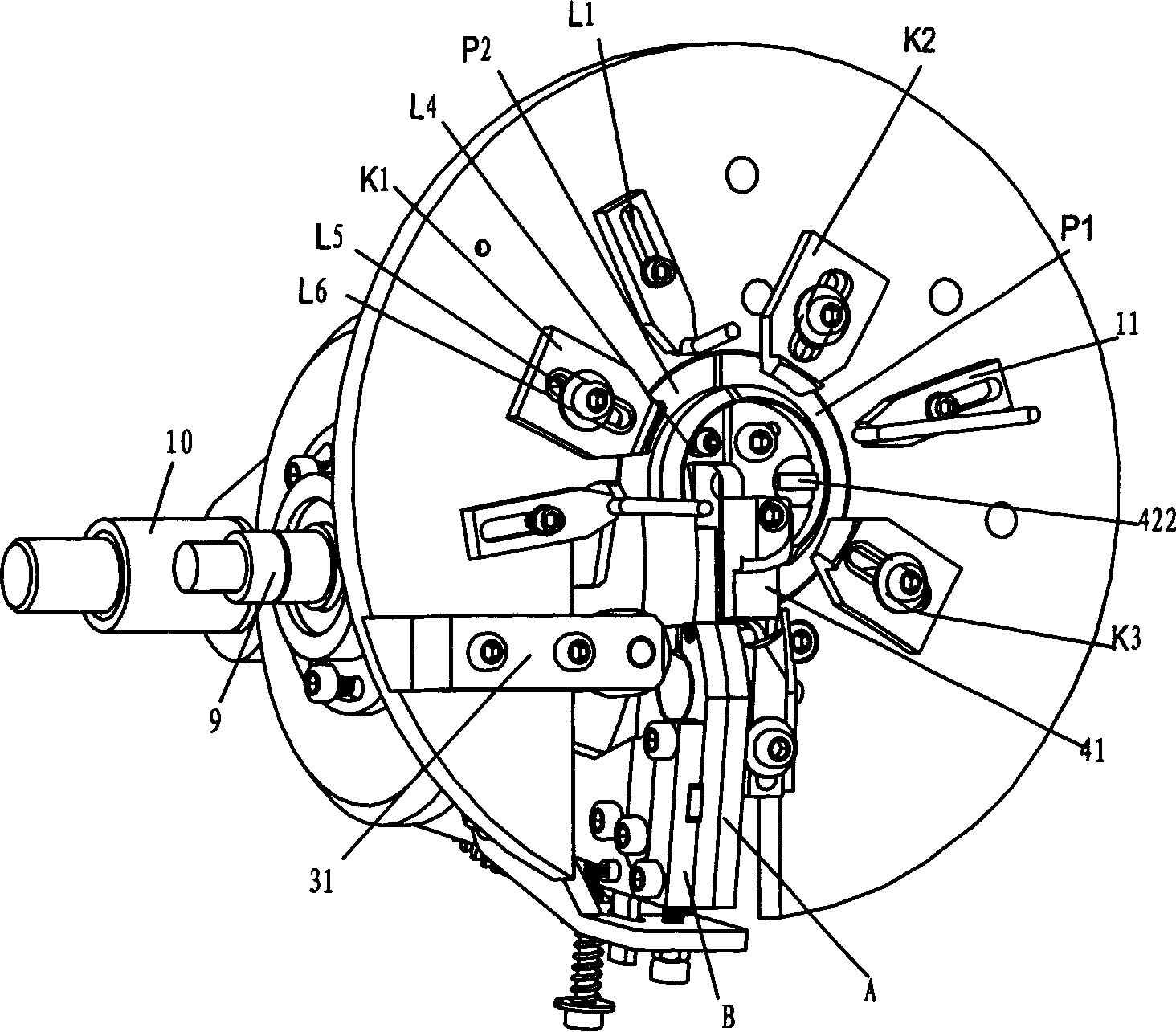

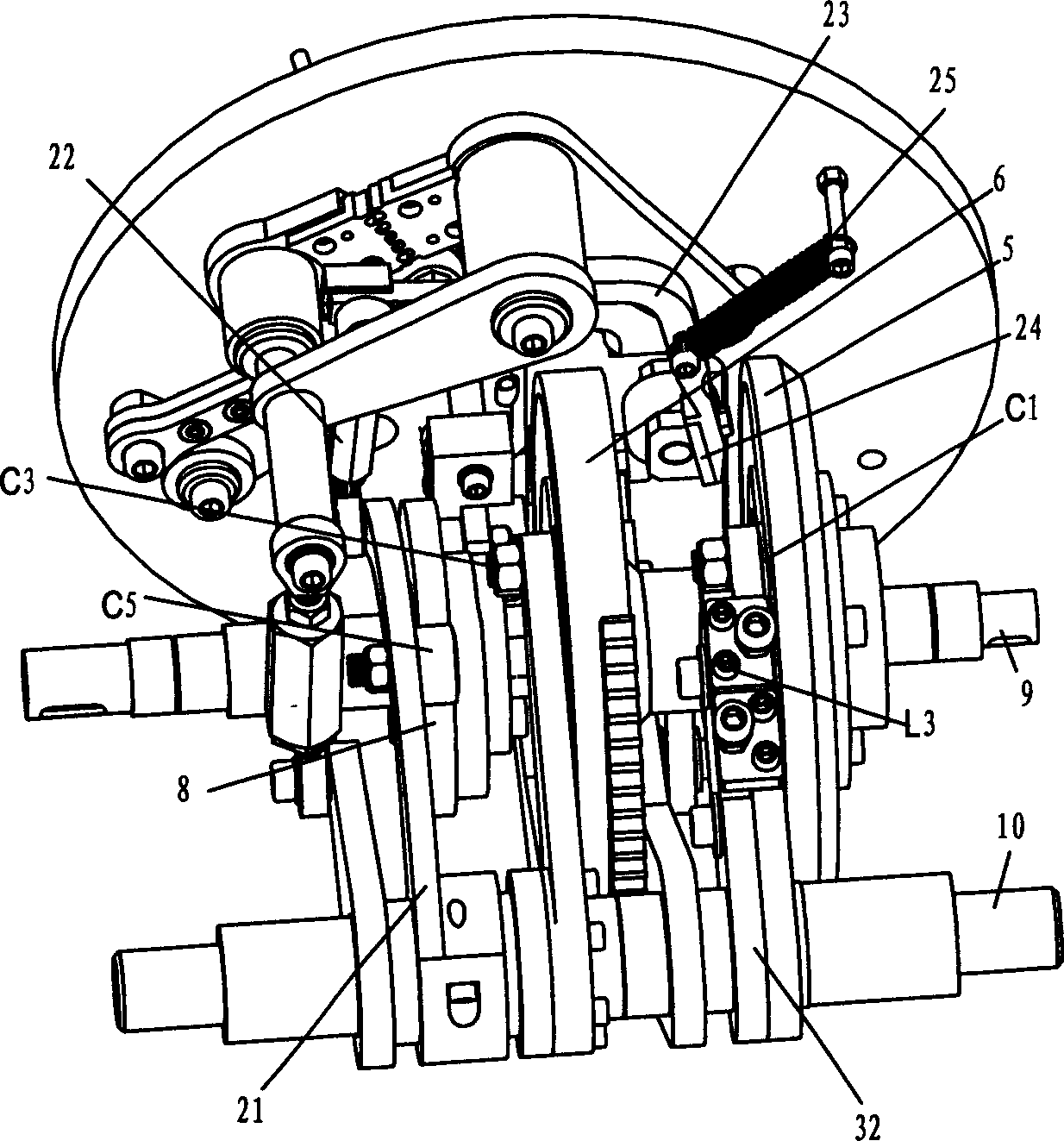

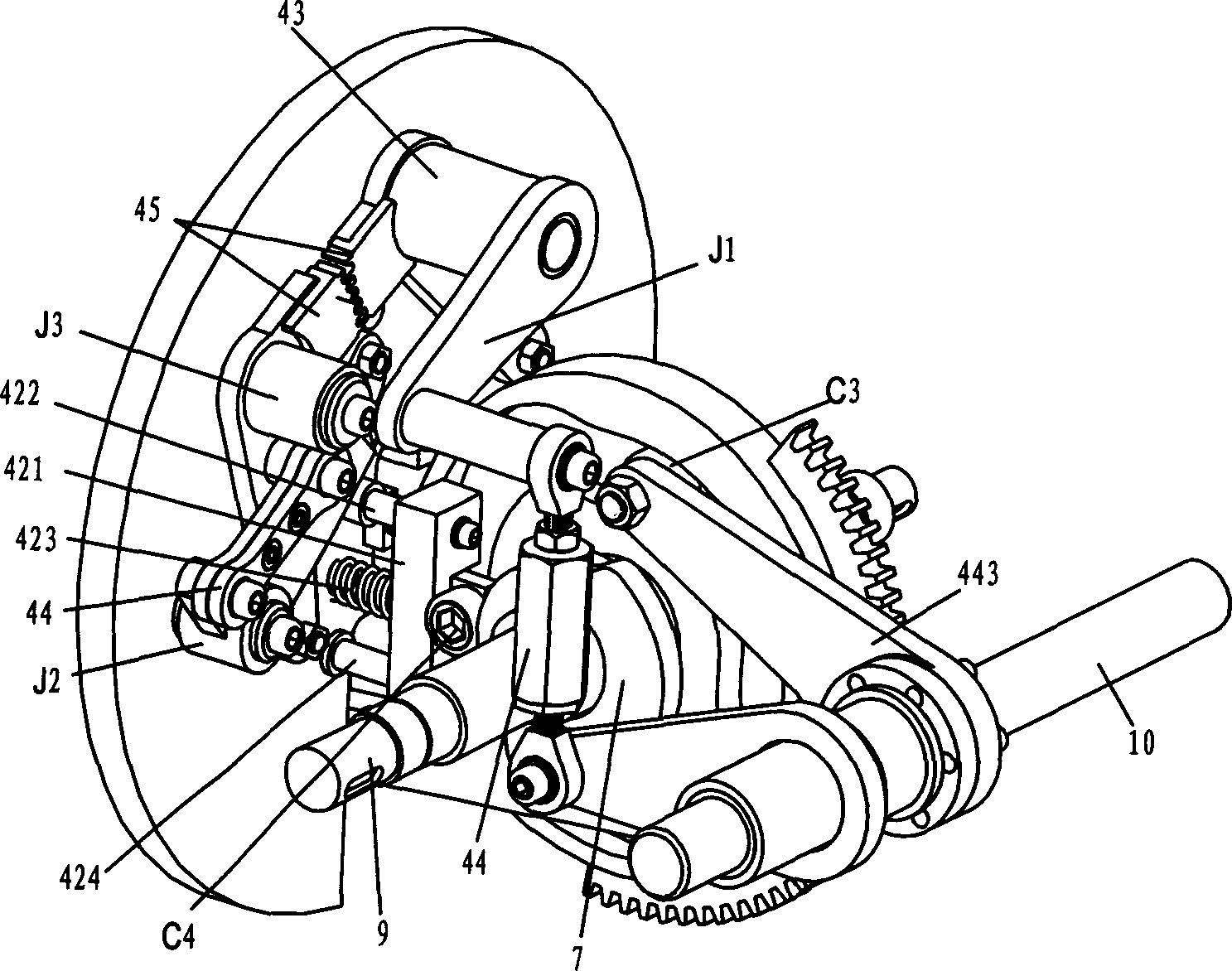

[0012] Such as figure 1 , 2 As shown, a spring clamping and knotting mechanism of a fully automatic spring coiling machine includes a guide spring device, a knot length control mechanism, a spring knotting mechanism, a spring clamping mechanism, a knotting cam 5, a knotting large toothed plate 6, Push rod cam 7, knot length control cam 8, driving shaft 9, fixed shaft 10, mounting plate, are provided with long groove L6 in the mounting plate.

[0013] Such as figure 2 , 6 As shown, the knotting cam 5 and the knotting tooth large plate are installed on the driving shaft 9 through the knotting cam 5 connection plate and the expansion sleeve respectively, and the ejector rod cam 7 and the knot length control cam 8 are installed on the driving shaft 9 through the cam seat.

[0014] Such as figure 1 As shown, the spring guide device includes three spring guide frames 11, and the spring guide frame 11 is provided with a long slot L1. Three guide spring holders 11 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com