Self-aligning cage structure for bag type dust collector

A bag filter and self-adjusting technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of cage bone collision, affecting the service life of filter bags, affecting the reliability of dust removal equipment, etc. The effect of preventing collision and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

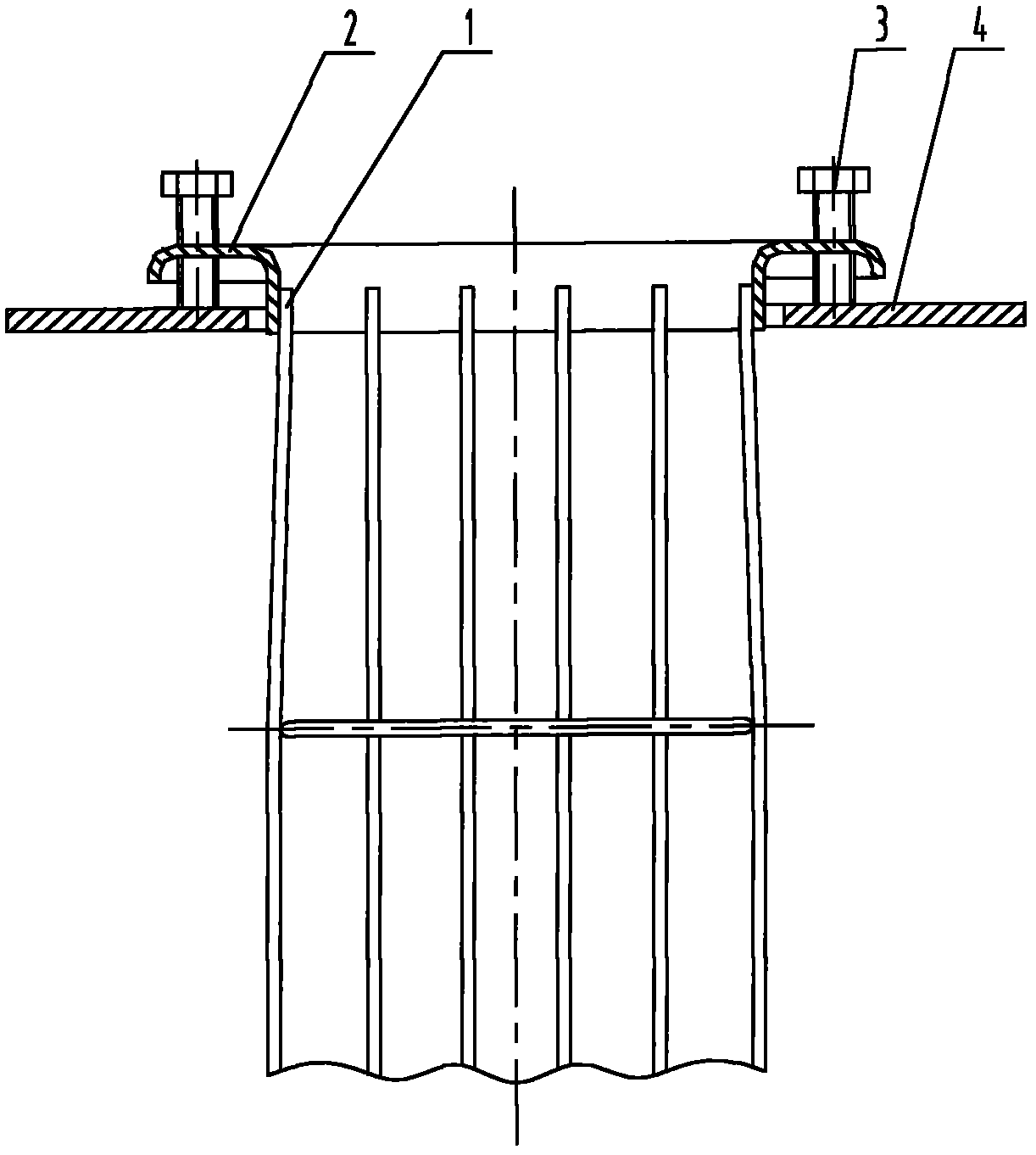

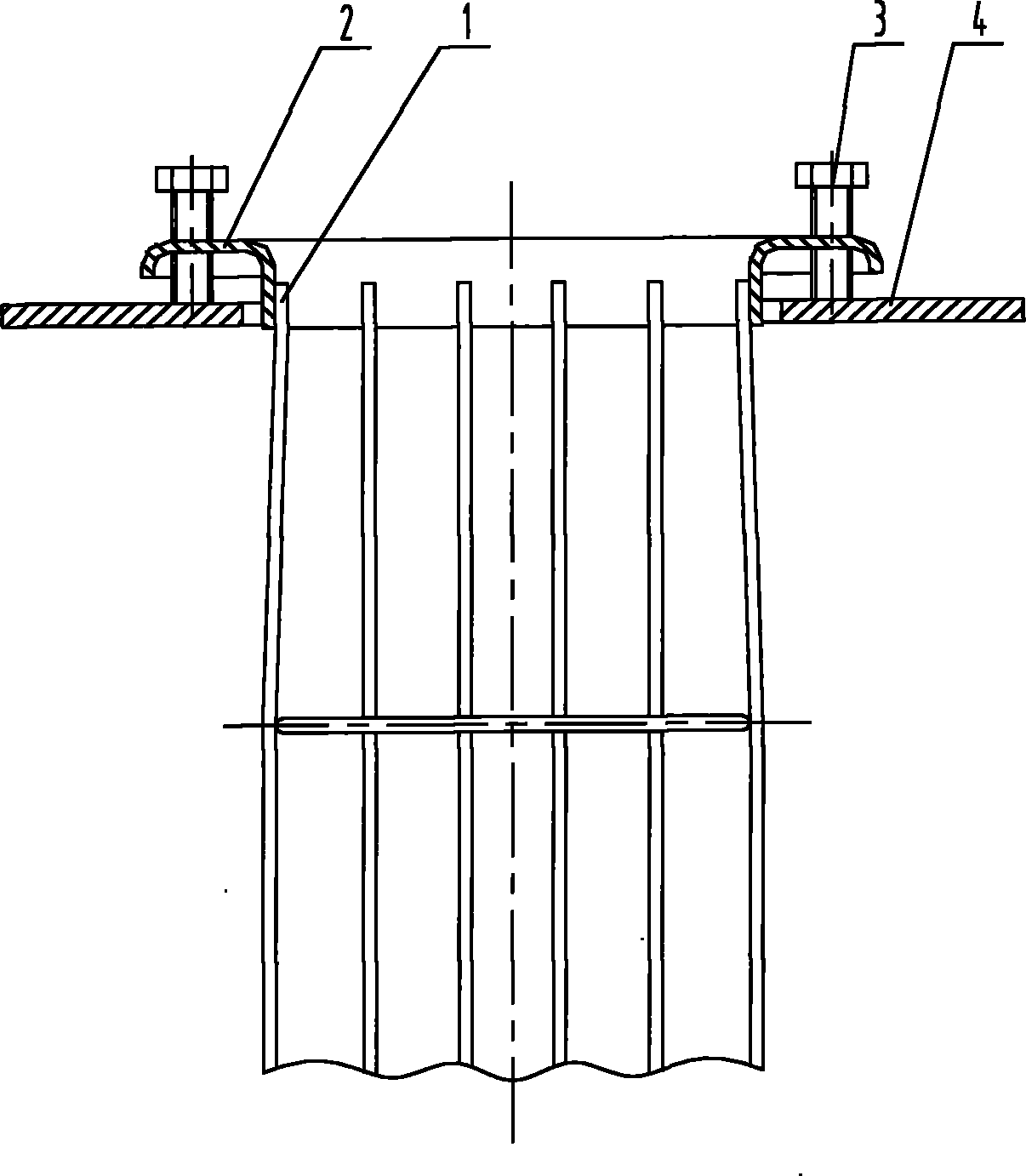

[0012] Such as figure 1 As shown, a self-aligning cage frame structure for a bag filter includes a top cap 2 and several vertical ribs 1. On the flower board 4 , the top of the vertical rib 1 is welded to the top cap 2 . The vertical rib 1 is evenly welded on the top cap 2, and rests on the flower plate 4 through the adjusting bolt 3. During installation, the height of the adjusting bolt 3 can be adjusted to ensure the verticality of the cage structure, thereby preventing the bottom of the cage from colliding.

[0013] The top of the vertical rib is welded to the top cap, which has simple structure, convenient processing and low cost. The number of the adjusting bolts is 3-4, the structure is simple, the connection is firm, and the cost is low. The adjusting bolts are M10-M16 bolts with lower cost and better performance. The diameter of the circle formed by all the vertical ribs is φ120mm-φ180mm, the structure is reasonable and the cost is low. The thickness of the top cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com