Horizontal mold for integrated prefabrication of pier column and cover beam and construction method thereof

A technology of pier column and cover beam, which is applied to the horizontal pier column cover beam integrated prefabricated mold and its construction field, can solve the problems of difficult to guarantee construction quality, long construction period, high environmental protection pressure, etc., so as to improve the appearance effect and improve the construction Quality, guarantee the effect of pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

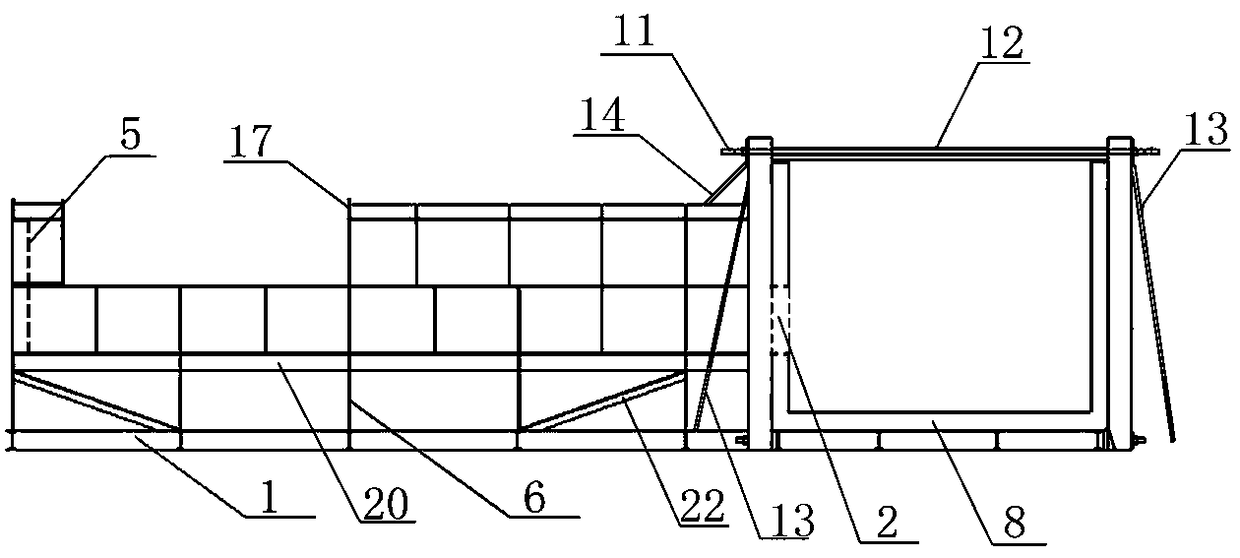

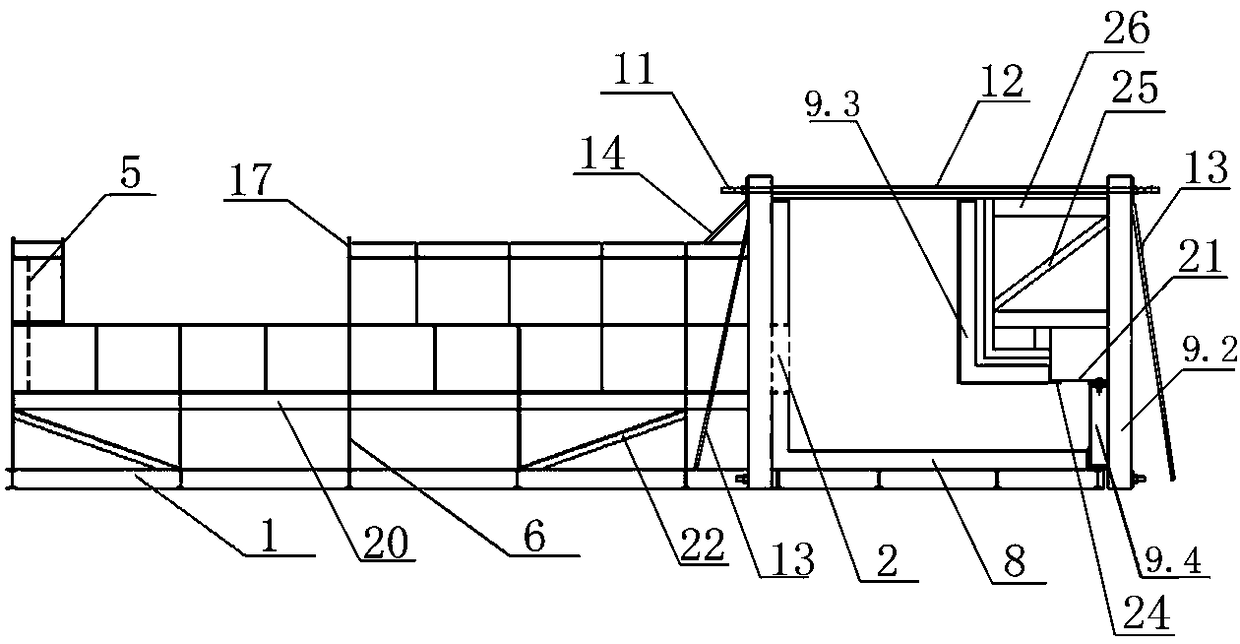

[0049] Such as Figure 1-5 As shown, this horizontal pier-column-cover-beam integrated prefabrication mold includes a pier-column formwork structure, a cover-beam formwork structure and a mold chassis 1 supported at the bottom of the pier-column formwork structure and the cover-beam formwork structure; 1 T-shaped, including horizontal and vertical sides;

[0050] The cover beam formwork structure is arranged along the transverse side of the mold chassis 1, the pier column formwork structure is arranged along the longitudinal side of the mold chassis 1, and the pier column formwork structure is connected with the cover beam formwork structure;

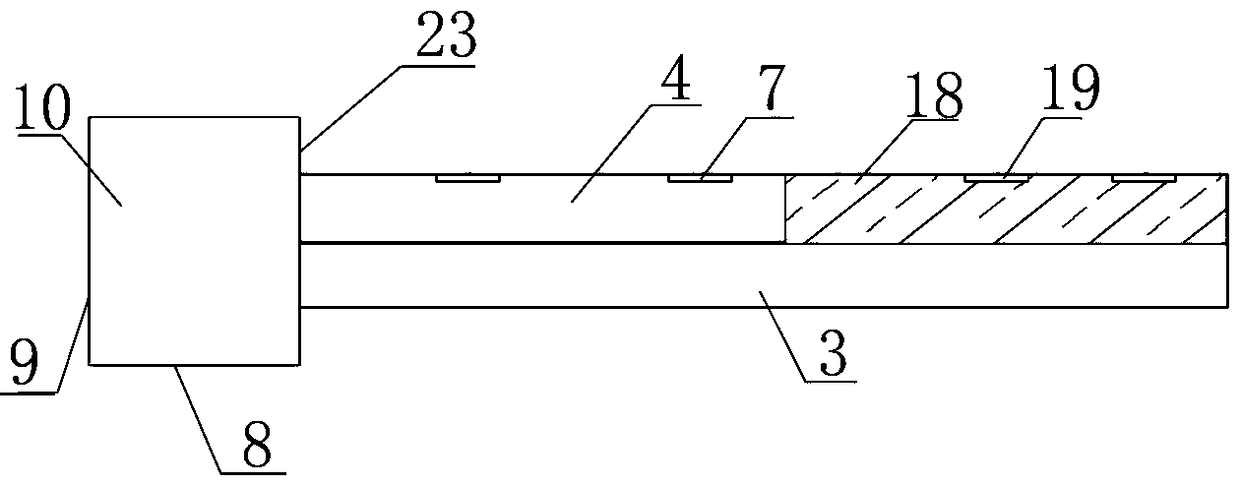

[0051] The horizontal section of the cover beam formwork structure is rectangular or trapezoidal, including a cover beam base form 8, a front lateral side form 23 arranged along the front lateral side of the cover beam base form 8, and a rear side form along the cover beam base form 8. The rear transverse side form 9 arranged on the tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com