Metal frame assembled composite formwork structure

A technology of combined formwork and metal frame, which is applied in the direction of formwork/formwork components, building structure, and on-site preparation of building components, which can solve the problems of lax joints of formwork, laborious installation, complex structure, etc., and achieve convenient Production and installation, reduce construction costs, and produce high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

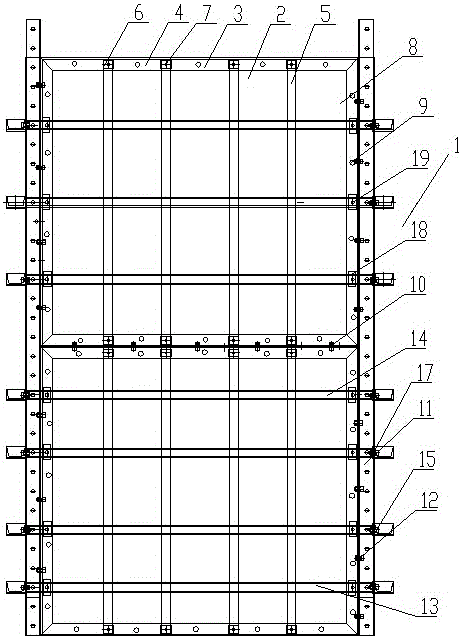

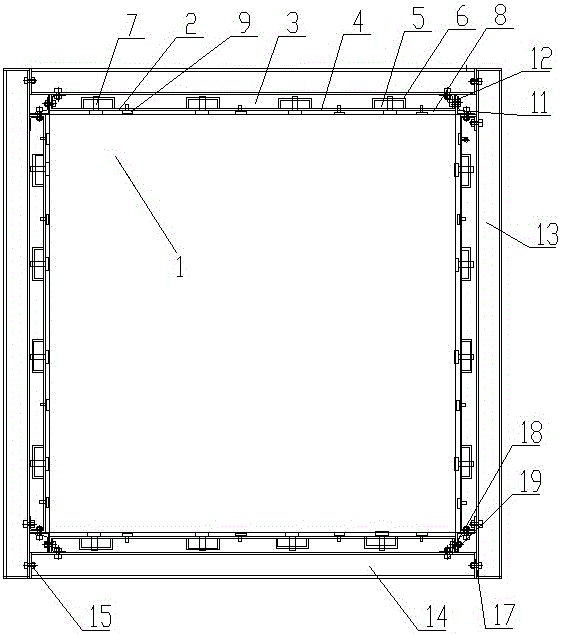

[0014] Such as figure 1 , 2 As shown, the present invention includes up to two layers of frames 1 with a rectangular transverse section, each frame 1 is surrounded by four template bodies 2, and the template body 2 includes a rectangular metal frame 3, and the metal frame 3 is welded with the first angle steel 4 Formed, the angle steel of the metal frame 3 is the end face of the side of the knuckle, and the square wood 5 arranged longitudinally is evenly distributed as a reinforcing bar. The screw 9 is fixed on the other side end face of the metal frame 3, and the building formwork 8 adopts a glass fiber reinforced plastic formwork.

[0015] The first angle steels 4 of the two-layer frames 1 superimposed on each other are fixed by the second bolts 10, and the 90° included angle positions of the four formwork bodies 2 of the two-layer frames 1 are all provided with vertically arranged second angle steels. 11. Both the second angle steel 11 and the first angle steel 4 adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com