Construction method of steel formwork firewall

A construction method and firewall technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as increased construction costs, and achieve the effects of improving work efficiency, easy demoulding, and reducing seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

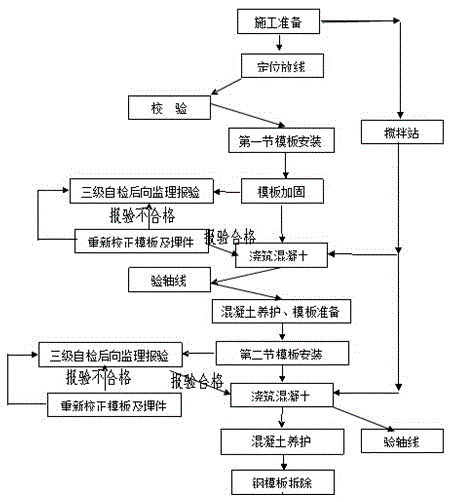

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention are given below to further describe the composition of the present invention in detail.

[0023] The construction method of the steel formwork firewall comprises the following steps:

[0024] (1) Firewall foundation pouring

[0025] Process the steel bars of the firewall. The steel bars are anchored into the foundation of the firewall. After passing the inspection by the supervisor, the foundation concrete of the firewall is poured. When the concrete is leveled, a photoelectric leveling instrument is used to strictly control the surface flatness of the foundation concrete. The error is less than 2mm, which meets the requirements of steel formwork installation. Levelness and verticality requirements;

[0026] (2) Steel formwork support

[0027] ?After the steel formwork is polished with an electric grinder, brush the formwork wax twice to prevent the concrete from sticking to the steel formwork, which will affect the appear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com