Electrode welding mechanism and mesh welding machine

A welding electrode and electrode technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of complex assembly adjustment, unusable whole machine, poor equipment stability, etc., and achieve low production cost, few connection structures, The effect of shape standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0026] Preferred embodiment:

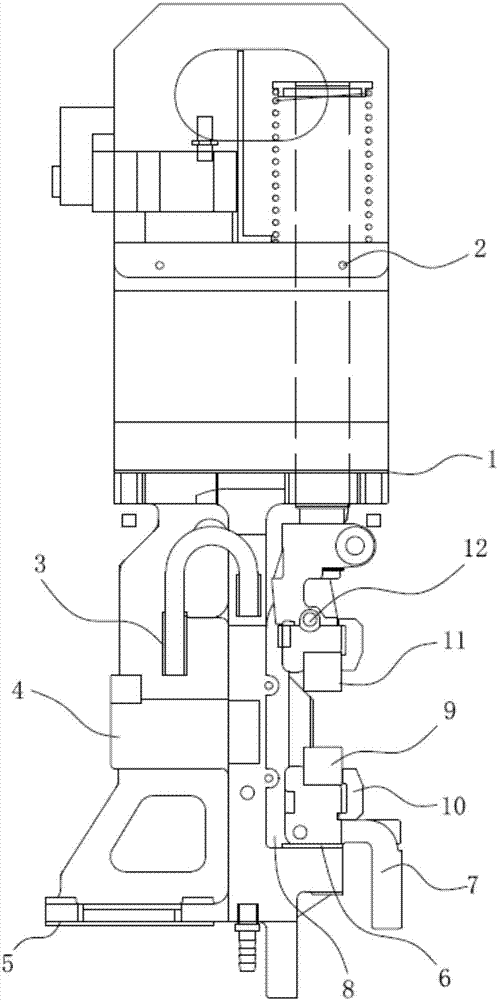

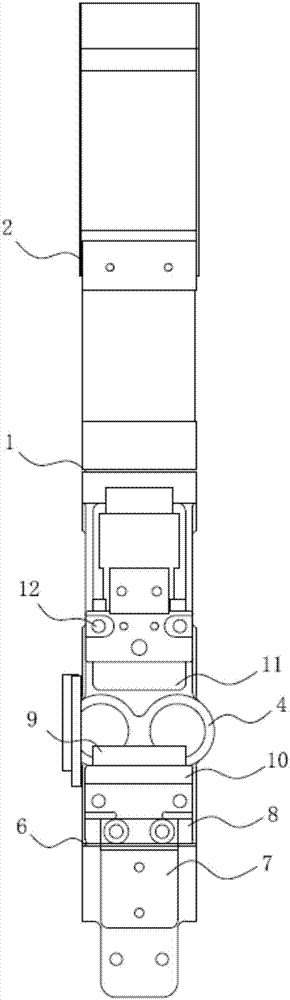

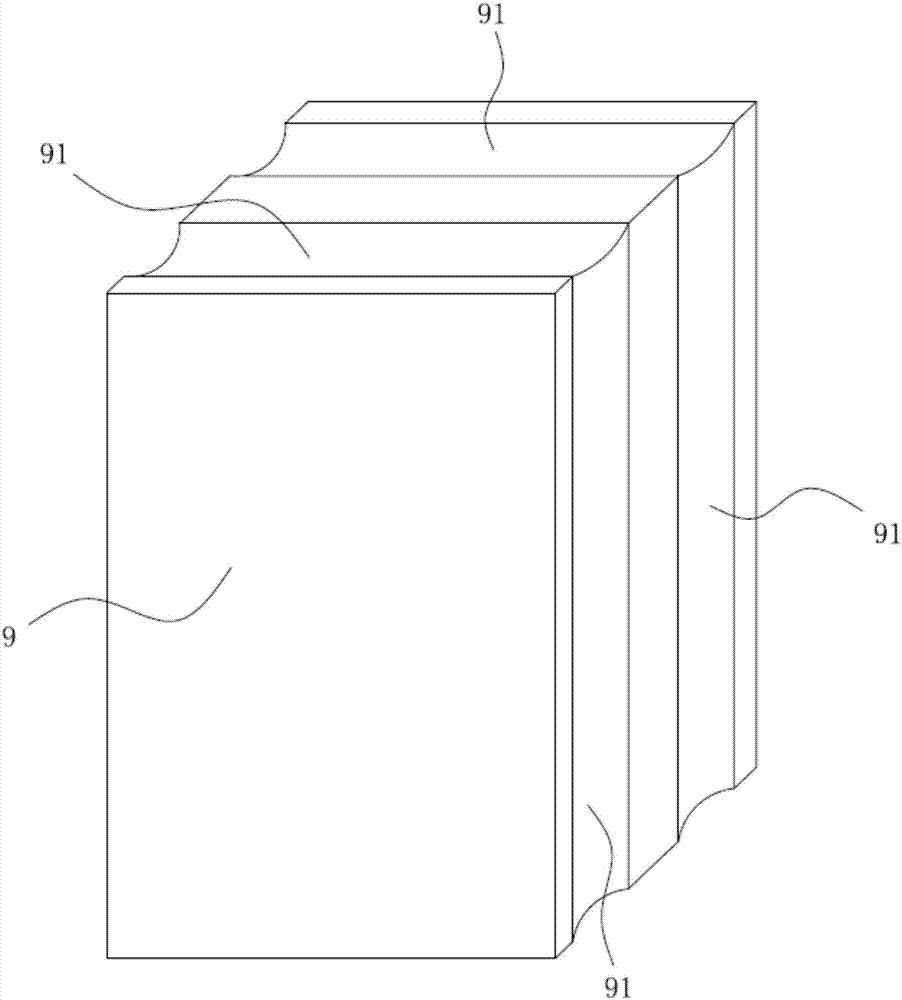

[0027] The preferred embodiment discloses a welding electrode mechanism. Such as figure 1 and figure 2 As shown, the welding electrode mechanism includes an electrode seat 4, a lower pole seat 7, an upper pole seat 12, an upper electrode 11 and a lower electrode 9; the lower pole seat 7 is installed at one end of the electrode seat 4, and the upper pole seat 12 It is installed at the end of the other side of the electrode holder 4 and can reciprocate along the electrode holder 4. The upper pole holder 12 is close to or away from the lower pole holder 7 during the reciprocating movement; the upper electrode 11 is installed on the upper pole holder 12, The lower electrode 9 is installed on the lower pole seat 7, and the welding work is completed after the upper elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com