A heat storage tank water distribution tray connection structure

A connection structure and water distribution tray technology, which is applied in the field of heat storage tank water distribution tray connection structure, can solve the influence of the space used inside the heat storage tank, the undisclosed upper water distribution tray installation structure, the undisclosed water distributor installation structure, etc. problems, to achieve the effect of improving spatial integrity and stability, meeting structural force requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0028] Example.

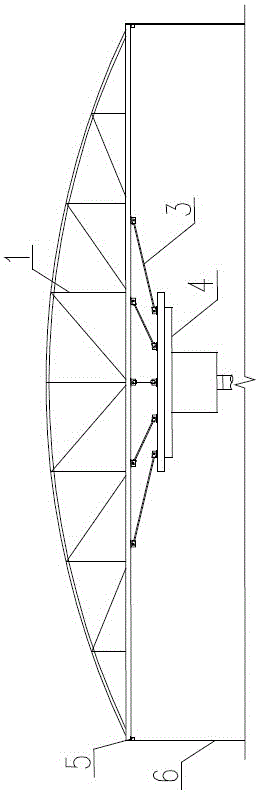

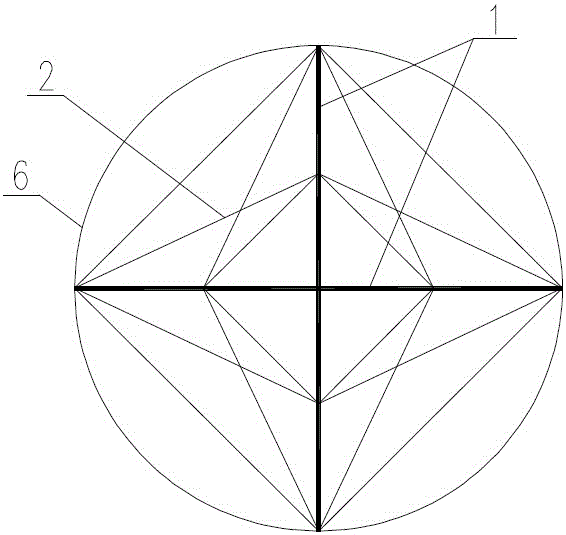

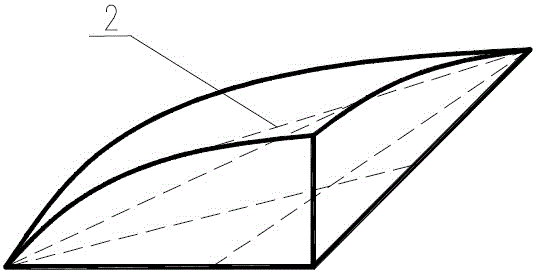

[0029] see Figure 1 to Figure 6 , the heat storage tank water distribution pan connection structure in this embodiment includes a heat storage tank water distribution pan 4, two truss structures 1 for sharing the weight of the heat storage tank water distribution pan 4, and two truss structures 1 for enhancing the stability of the truss structure 1 Truss reinforcement members 2, at least three water distribution pan suspension structures 3 for transferring the weight of the heat storage tank water distribution pan 4, and four for fixing the truss structure 1 to the upper inner wall 6 of the heat storage tank and supporting the truss structure 1 The supporting truss supports the connecting structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com