Z-axis driving connection mechanism of nozzle rod of SMT system

A technology of suction and drive connection of a placement machine, which is applied to electrical components, electrical components, etc., can solve the problems affecting the accuracy of the nozzle rod assembly, restricting the miniaturization of the placement head, and the hardness of the nozzle rod, etc., to achieve miniaturization. , Fast installation, and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

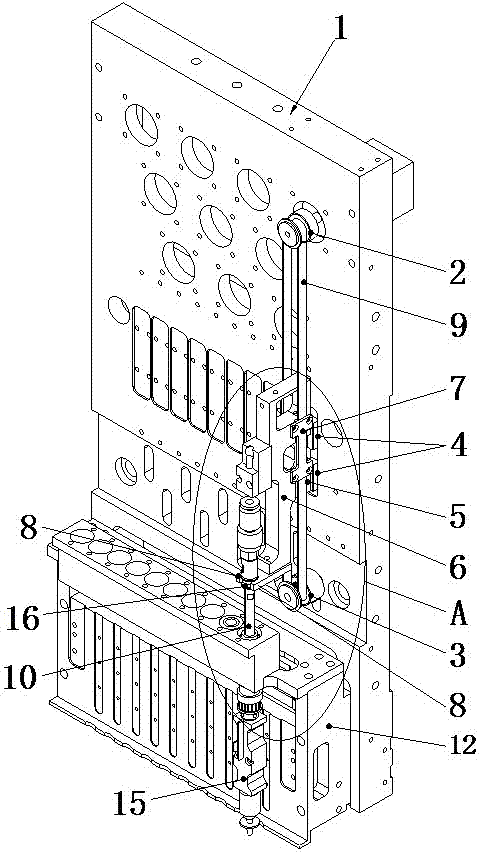

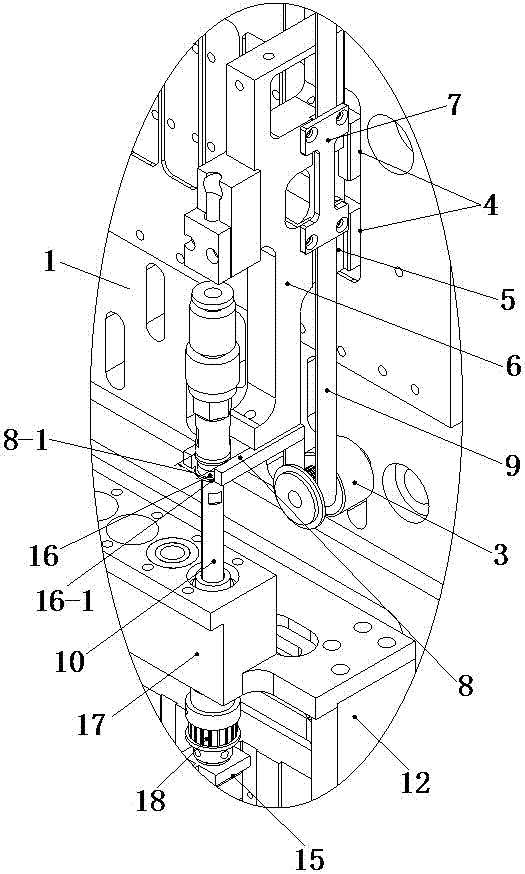

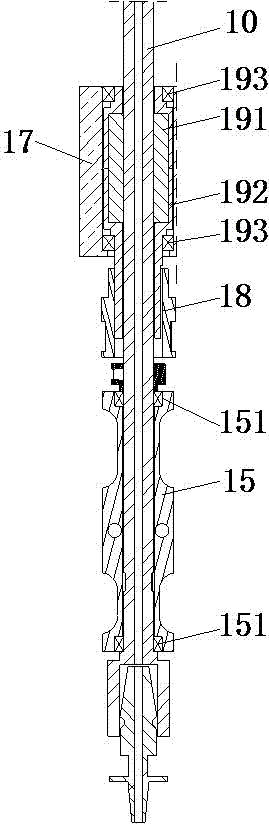

[0035] Such as Figure 1 to Figure 3 As shown, the suction nozzle rod of a chip mounter according to the present invention drives the connection mechanism in the Z-axis direction, including a Z-axis pressing motor (not shown in the figure), a motor pulley 2, a driven pulley 3, a Z The shaft belt 9 and the suction nozzle rod 10, the surface of the mounting head fixed substrate 1 is provided with a motor installation through hole matching the Z-axis pressing motor, and one end of the rotating shaft of the Z-axis pressing motor passes through the motor installation through hole A motor pulley 2 is fixedly connected, and a driven pulley 3 matching the motor pulley 2 is also provided on the surface of the mounting head fixed substrate 1; the motor pulley 2 is connected with the driven pulley 3 through a Z-axis belt 9. The spline rod section of the suction nozzle rod 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com