Excavation of Loess Tunnel with Large Section and Rapid Closing and Ring Forming Method of Primary Support

A primary support and loess tunnel technology, which is applied in tunnels, earthwork drilling, tunnel lining, etc., can solve problems such as inability to effectively protect construction safety, improve the construction environment for workers, ensure normal traffic, and quickly close primary support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] The Wanrong Tunnel constructed by our group is designed as a single-hole and double-track, with a total length of 7,683 meters, of which Ⅴ and Ⅵ-level surrounding rocks account for 97.66%, and the maximum buried depth is 90.25 meters. A total of 33 tunnels pass through roads and villages, and the surface roads are crisscross, the villages are dense, and the yellow irrigation system is staggered. In particular, the tunnel body passes through new loess and silty sand layers, and there are extremely high landslides and sand surges. Security Risk.

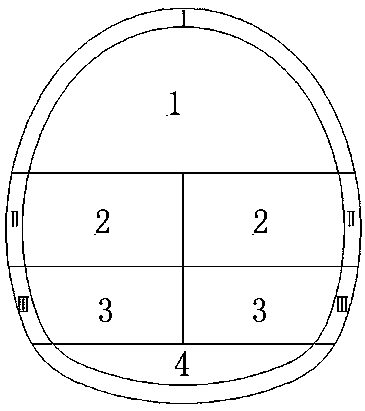

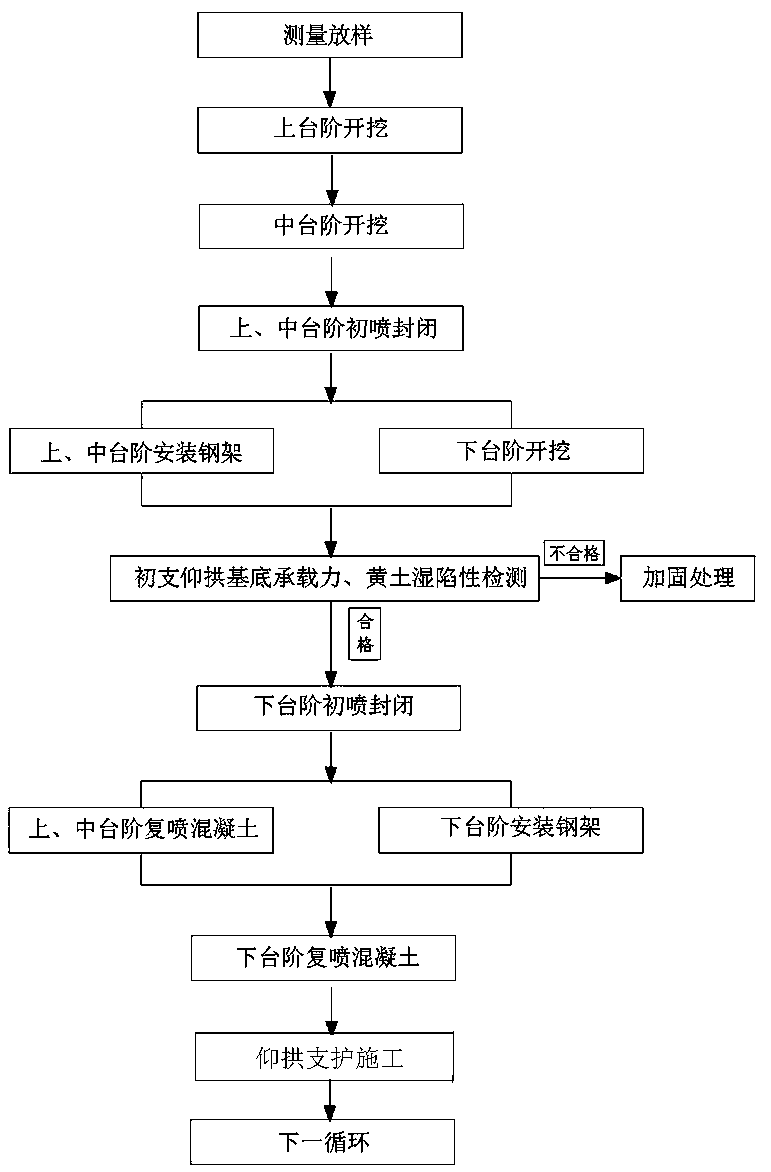

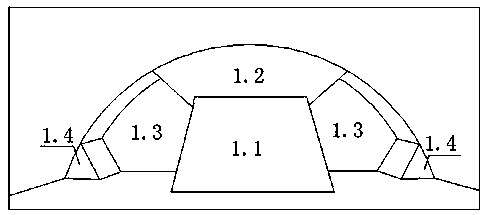

[0059] In order to effectively prevent landslides and sand gushing during construction and solve a series of construction problems such as "quick excavation, fast branching, fast sealing, and fast strengthening" in new loess and silty sand strata, our department combined the Wanrong Tunnel Engineering and geological characteristics According to the quality, safety, and construction period risk control requirements, the height an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com