Disc semi-automatic joint welding machine and operation method thereof

A disc type, semi-automatic technology, used in welding equipment, welding equipment, welding accessories, etc., can solve the problems of products that do not meet the size requirements, unsightly, irregular welding seams, etc., and meet the requirements of ensuring verticality and parallelism. The effect of reducing production costs and ensuring uniform operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

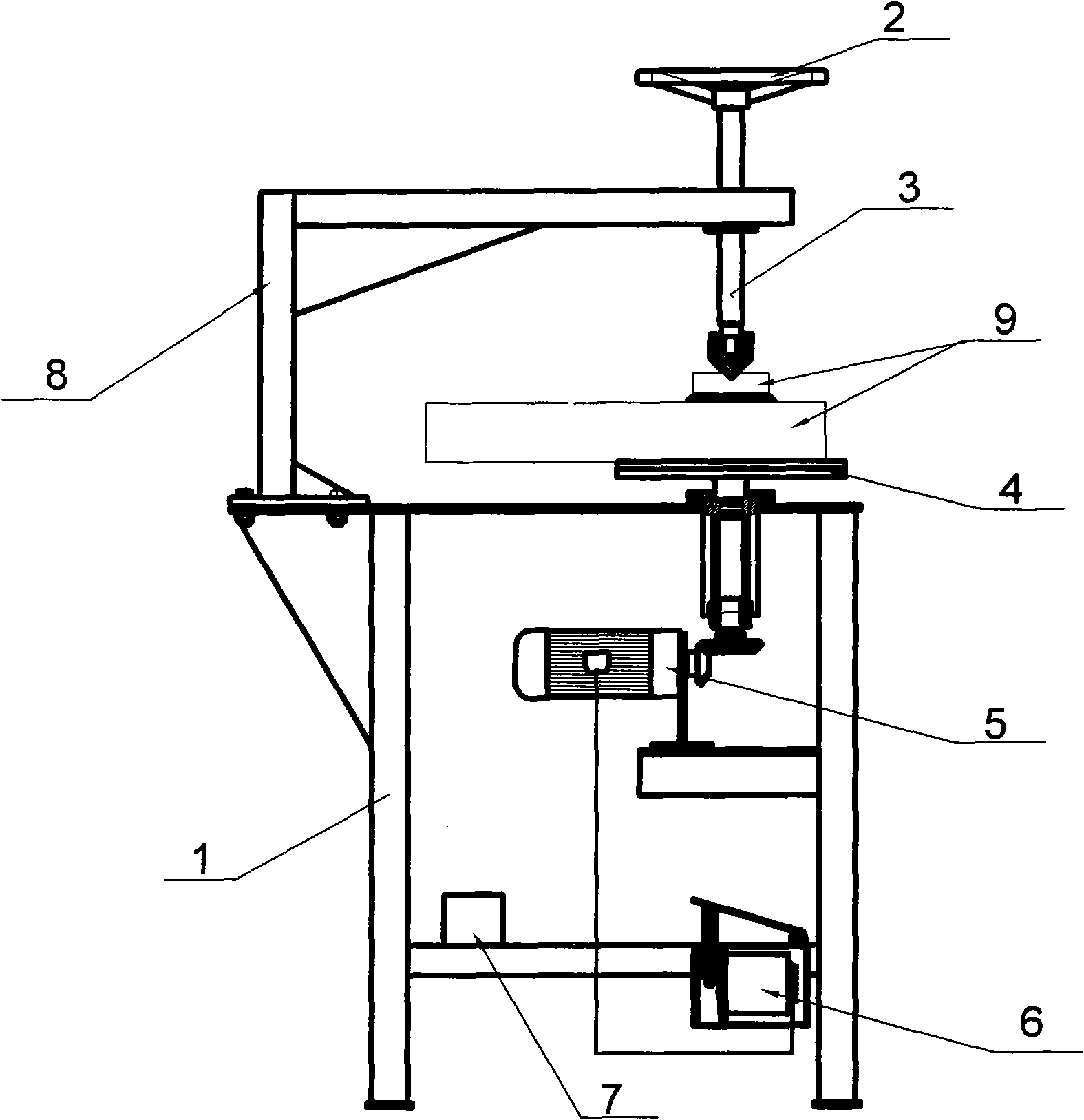

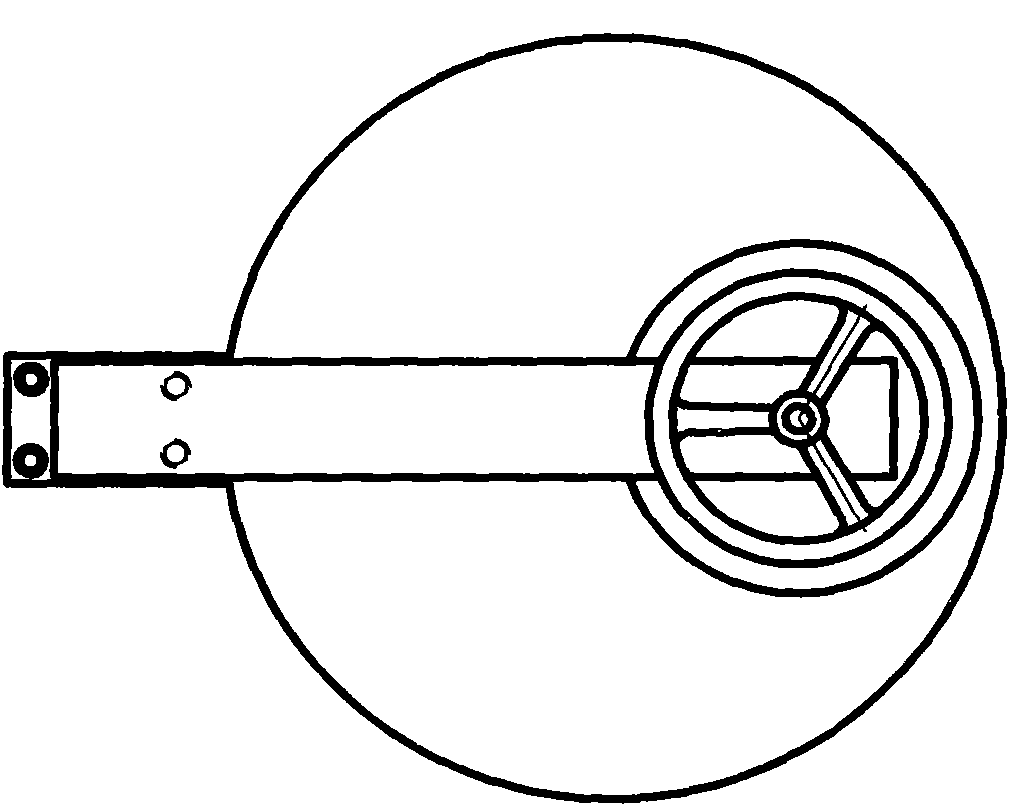

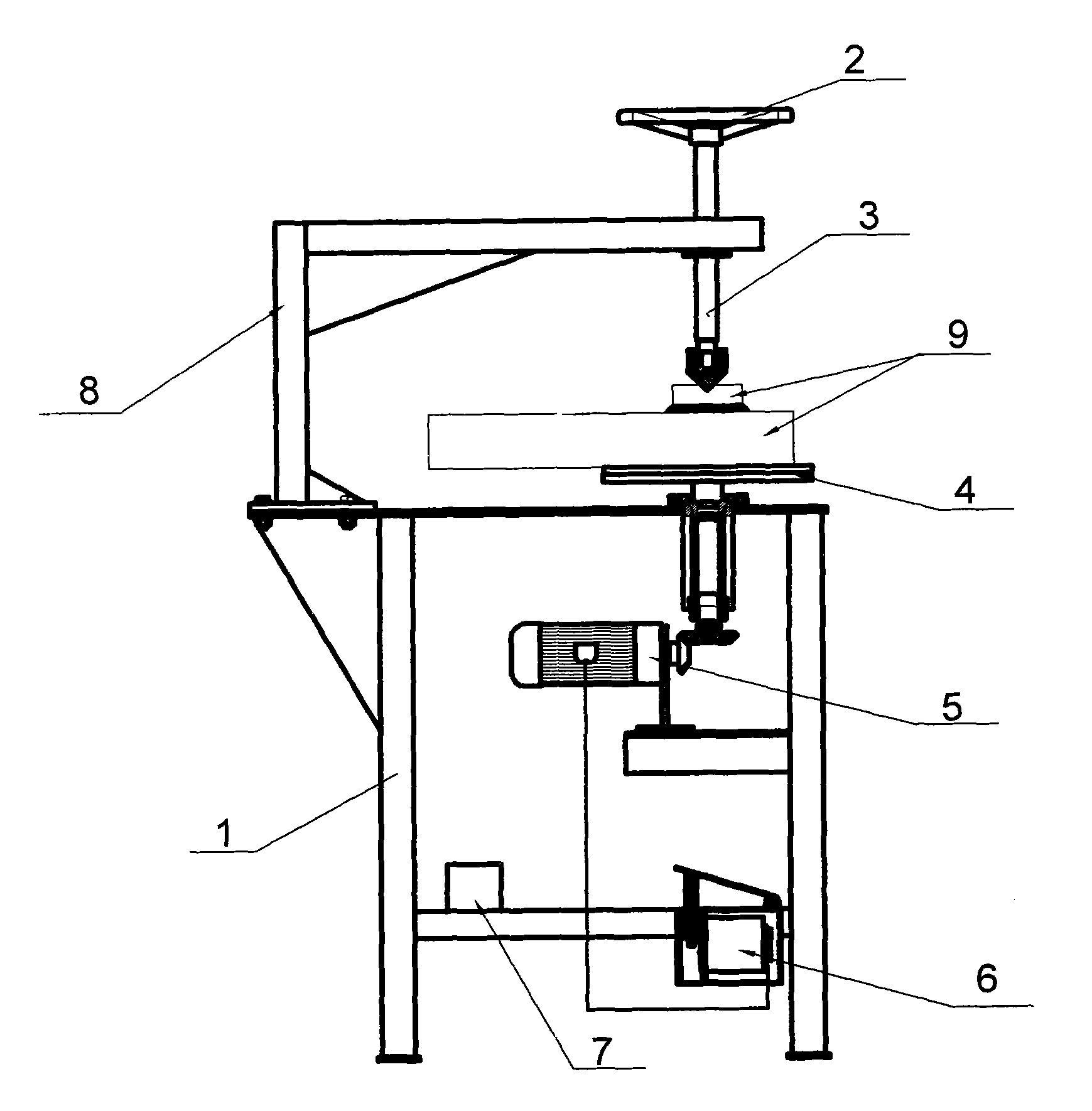

[0027] A kind of disc joint welding machine of the present invention, as figure 1 , 2 As shown, it includes desktop frame 1, positioning and locking components (hand wheel 2 and double-headed trapezoidal screw 3), disc-type rotary table 4, gear motor 5, stepless pedal electronic control device 6, and anti-interference components 7. One end on the top of the desktop frame 1 is also provided with an inverted L-shaped support 8; the double-ended trapezoidal screw rod 3 is vertically installed on the long arm of the inverted L-shaped support 8, and the double-ended trapezoidal screw rod 3 is connected to the circle on the top of the desktop frame 1. The center of the disk-type rotary table 4 is in a line; the disk-type rotary table 4 is connected with and driven by a geared motor 5, and the geared motor 5 is installed on the desktop frame 1, and the geared motor 5 is also connected with a pedal The electronic control device 6 for stepless speed change, and the electric control d...

Embodiment 2

[0030] Such as figure 1 , figure 2 As shown, it is a kind of disc-type semi-automatic joint welding machine of the present utility model. When operating specifically, the workpiece 9 (joint, head) is placed on the disc-type rotary table 3 table tops, so that the double-headed trapezoidal screw 3 The head is aligned with the center of the joint of the workpiece 9; the rotating hand wheel 2 is quickly positioned and pinned to the workpiece 9 through the double-headed trapezoidal screw 3 connected to it, and the welding starts after the workpiece is clamped. Since the workpiece itself is at normal temperature, when starting welding, The arc start should be slower. When the workpiece is welded to about 1.5 cm (1-2 cm), the workpiece starts to heat up. At this time, step on the stepless stepless speed change electronic control device to enter the normal uniform speed welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com