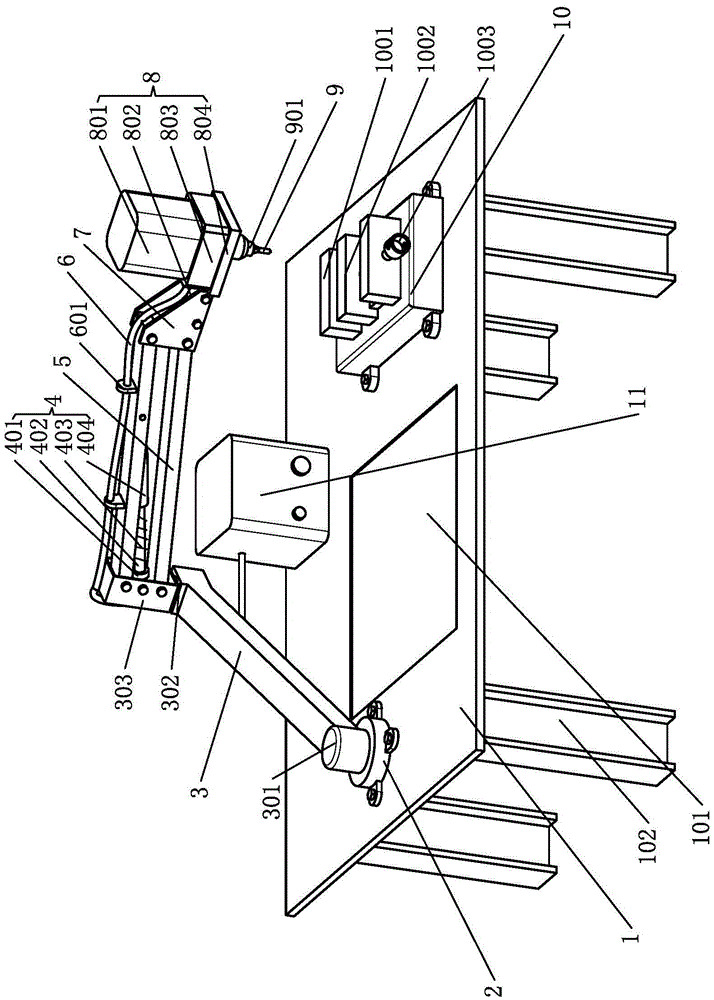

Drilling and tapping all-in-one machine for machining

A tapping and mechanical processing technology, applied in the direction of metal processing equipment, cutting machine, manufacturing tools, etc., can solve the problems of easy tapping deviation, waste of energy, time-consuming and laborious, etc., to avoid drilling deviation, facilitate promotion and popularization, and adapt to wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

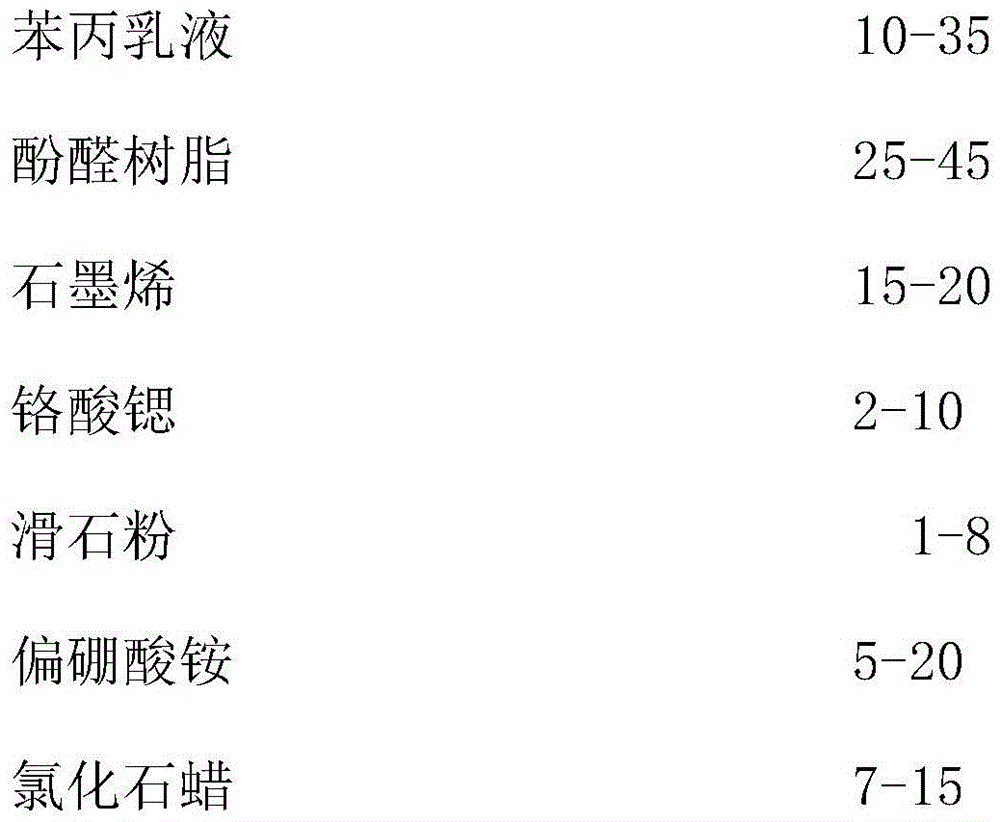

[0019] Antirust layer described in the present invention is made up of following components by weight:

[0020]

[0021]

[0022] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and talcum powder evenly, and grind them in a conical grinder until the fineness is <50 μm, then add styrene-acrylic emulsion, dibutyl phthalate, and propylene glycol Dimethyl ether and other components can be obtained by ultrasonically dispersing evenly.

Embodiment 2

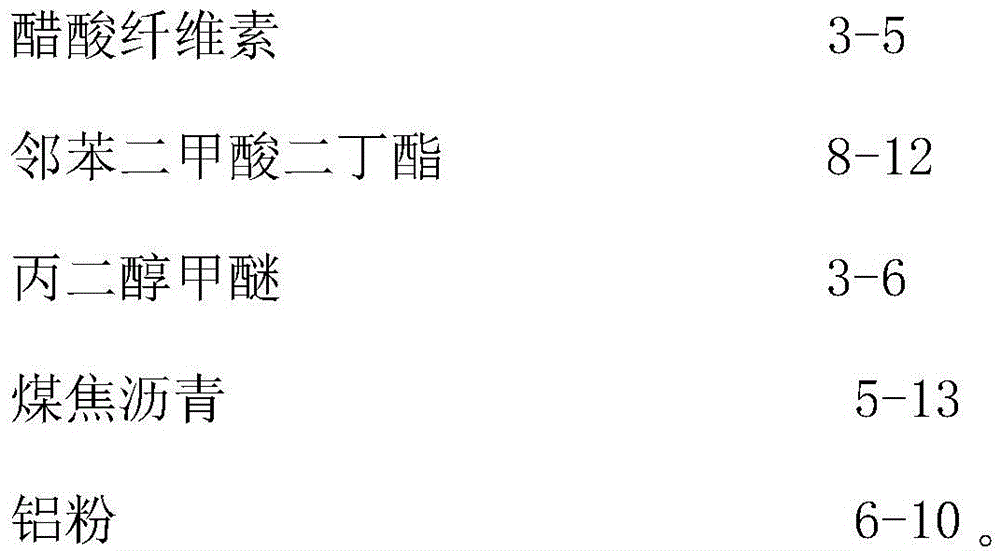

[0024] Antirust layer described in the present invention is made up of following components by weight:

[0025]

[0026] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and talcum powder evenly, and grind them in a conical grinder until the fineness is <50 μm, then add styrene-acrylic emulsion, dibutyl phthalate, and propylene glycol Dimethyl ether and other components can be obtained by ultrasonically dispersing evenly.

Embodiment 3

[0028] Antirust layer described in the present invention is made up of following components by weight:

[0029]

[0030] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and talcum powder evenly, and grind them in a conical grinder until the fineness is <50 μm, then add styrene-acrylic emulsion, dibutyl phthalate, and propylene glycol Dimethyl ether and other components can be obtained by ultrasonically dispersing evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com