Automatic focusing device for projective bulb based on light spot detection and use method thereof

An automatic focus and spot detection technology, which is applied in the field of projectors, can solve the problems of needing improvement in accuracy, low focus precision, and low efficiency, and achieve the effects of reducing detection costs, high focus precision, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

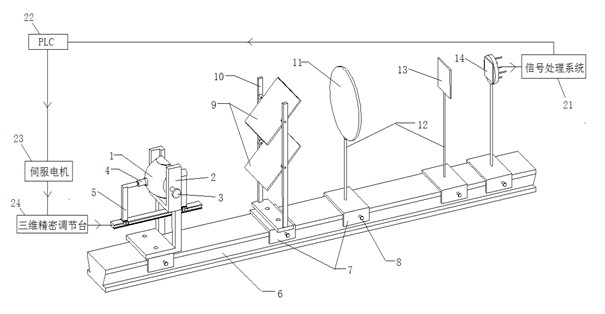

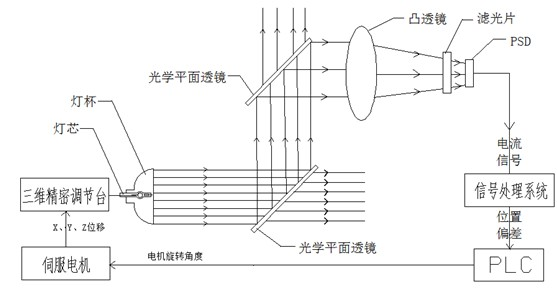

Method used

Image

Examples

Embodiment

[0051] Embodiment: A method for using an automatic focusing device for projection bulbs based on spot detection, comprising the following steps:

[0052] 1) Choose W203 two-dimensional photoelectric position sensor PSD14, its effective photosensitive surface is 21mm*21mm; adjust lamp cup clamping table 2, optical flat lens 9, convex lens 11, filter 13, two-dimensional photoelectric position sensor PSD14 position, use tools such as autocollimator to calibrate the optical path;

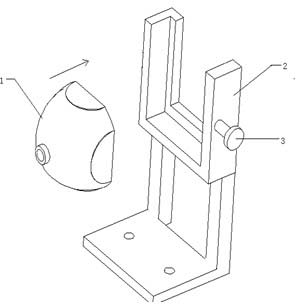

[0053] 2) Put the lamp cup 1 on the lamp cup clamping table 2, and fix it with screw I3;

[0054] 3) Put one end of the wick 4 in the sleeve 16, and hold the other end of the wick 4 with the thimble 15, so that the wick 4 is fixed on the wick clamping frame 5;

[0055] 4) Apply electricity to both ends of the wick 4. The light emitted by the wick 4 is reflected by the inner surface of the lamp cup 1 to form a parallel beam of light. The beam of light is transmitted and reflected twice by the optical fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com