Channel feeding section platinum body installation positioning device and installation method thereof

A technology for installation, positioning and feeding section, which is applied in the direction of the feeding trough, etc., can solve the problems of insufficient adjustment, tools not reaching the adjustment amount, falling and collapsing, etc., and achieve the effect of accurate adjustment, high precision, simple and convenient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

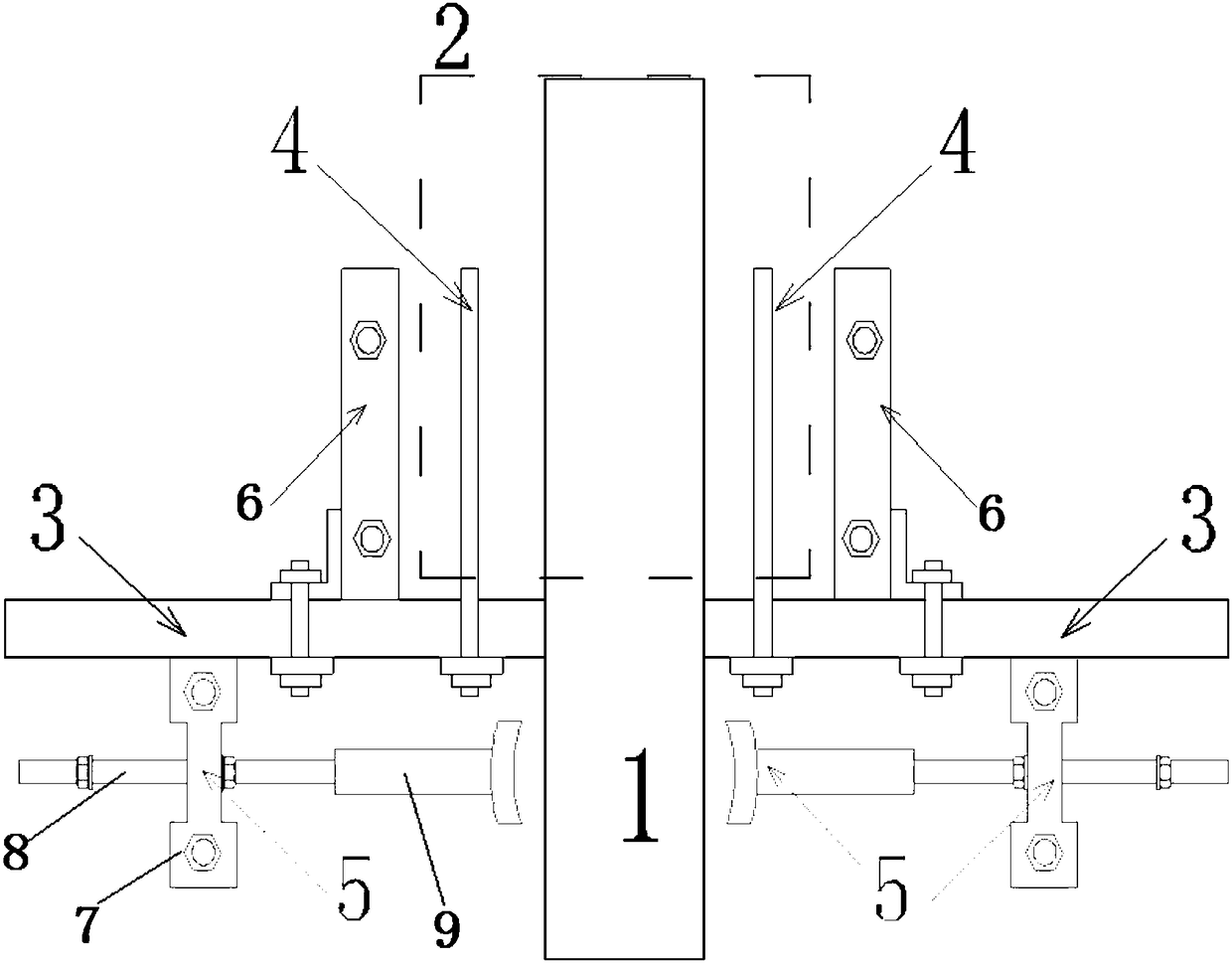

[0025] like figure 1 As shown, a platinum body installation and positioning device in the feeding section of the channel includes an upper steel structure plate 3, a support rod 4 and a lower end tightening mechanism 5, wherein the outer side of the platinum body 1 is wrapped with a refractory material layer 2, and the upper steel structure plate 3 There is a through hole in the middle, the platinum body 1 is placed in the middle through hole of the upper steel structure plate 3, the support brace 4 is fixed on the upper end of the upper steel structure plate 3, and the refractory material layer 2 is located between the platinum body 1 and the support brace 4; The lower end clamping mechanism 5 is fixed on the lower end of the upper steel structure plate 3, the lower end clamping mechanism 5 includes a fixed support 7, a clamping chuck 8 and a telescopic rod 9, the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com