Planing method for cubic part vertical faces

A vertical surface and cube technology, applied in the field of mechanical processing, can solve problems that affect processing accuracy, cannot use grinding machines, workpiece deformation, etc., to achieve the effects of ensuring processing quality, improving precision, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

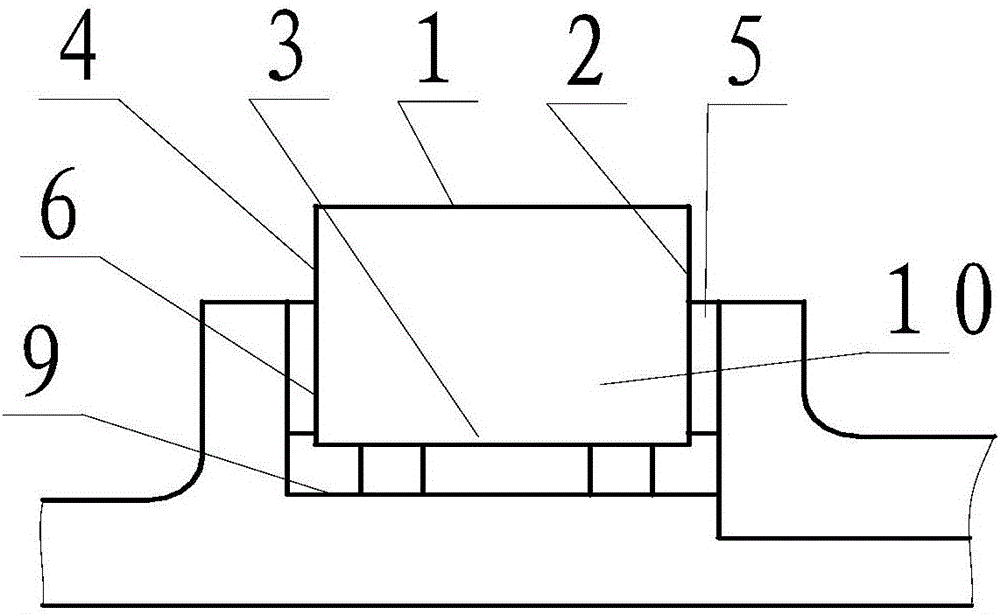

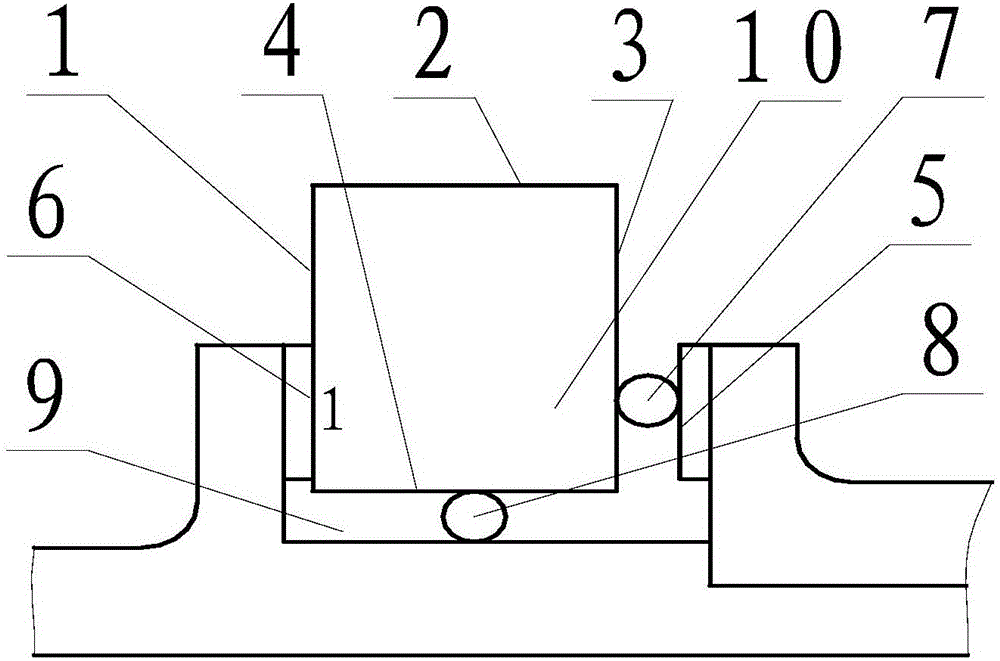

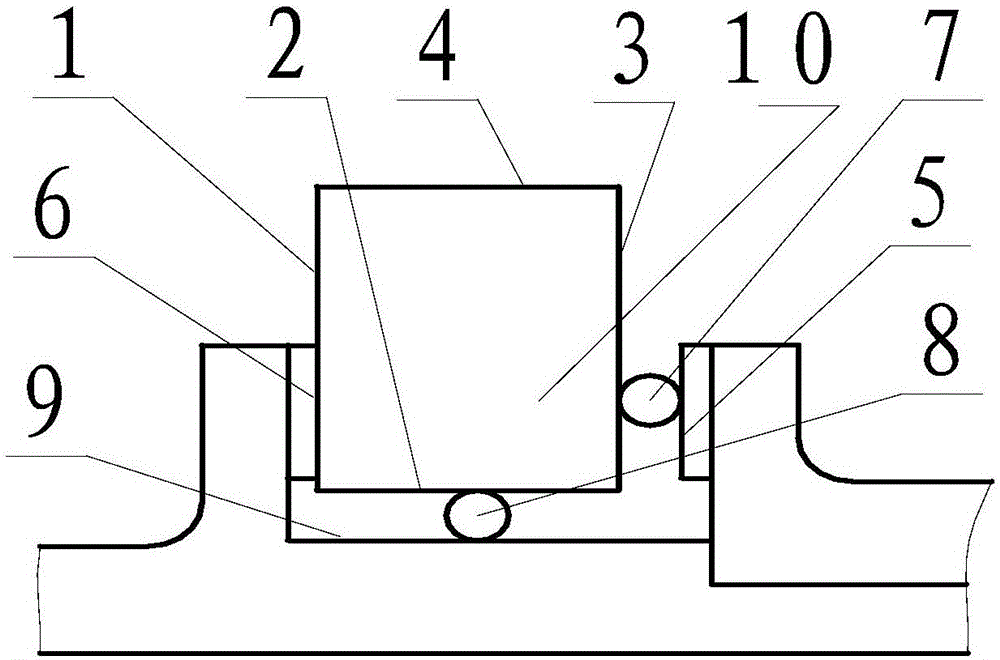

[0017] The present invention will be described in further detail below. see figure 1 , figure 2 , image 3 , Figure 4 , a planing method for a vertical surface of a cube part, comprising:

[0018] 1.1. Inspection and calibration clamps: Install the flat-nose pliers on the planer workbench, clamp the dial indicator on the planer tool holder, check the verticality of the jaws of the flat-nose pliers by moving the tool holder up and down on the machine tool, and check by moving the tool holder horizontally If there is deviation in the straightness of the jaws of the flat-nose pliers, adjust it until it is qualified, and fix the flat-nose pliers on the workbench.

[0019] 1.2. Rough planing four vertical surfaces: Clamp the workpiece 10 rough planing four sides according to the traditional method, leaving about 0.5mm fine planing allowance on each side.

[0020] 1.3. Planing a horizontal plane: select the relatively flat and large surface 1 in the length direction as the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com