Pouring construction process for bridge pier through concrete conduit method

A construction technology and concrete technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low construction efficiency, difficult construction, difficult operation, etc., to reduce construction costs, shorten construction period, and beautiful surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

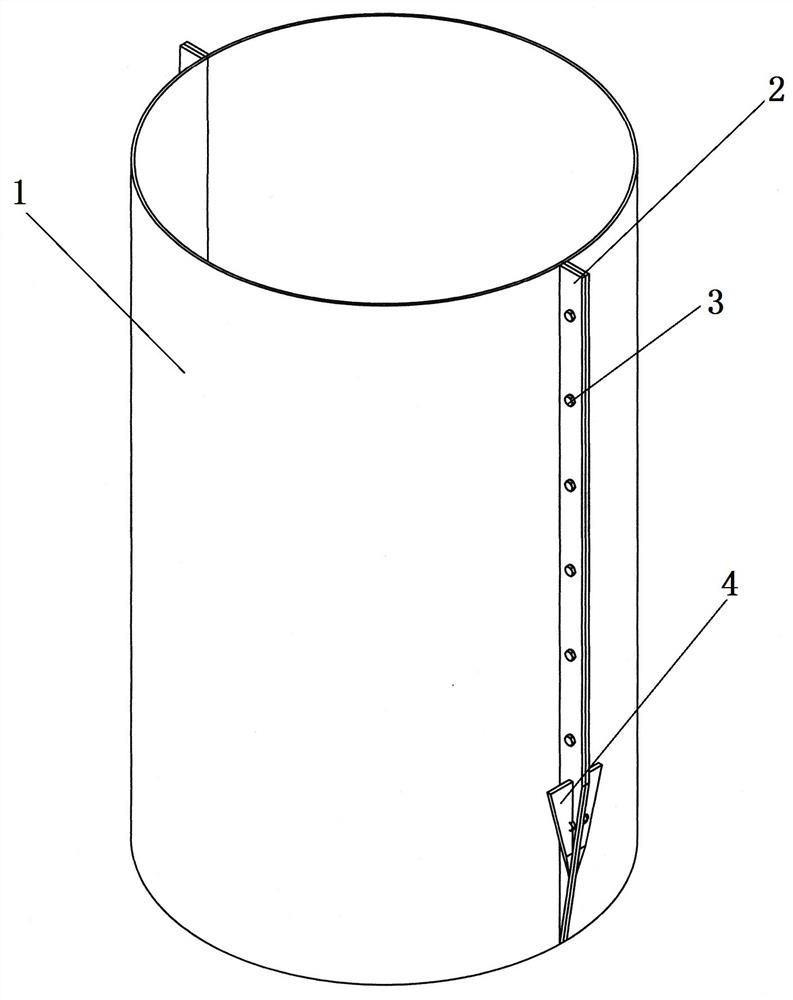

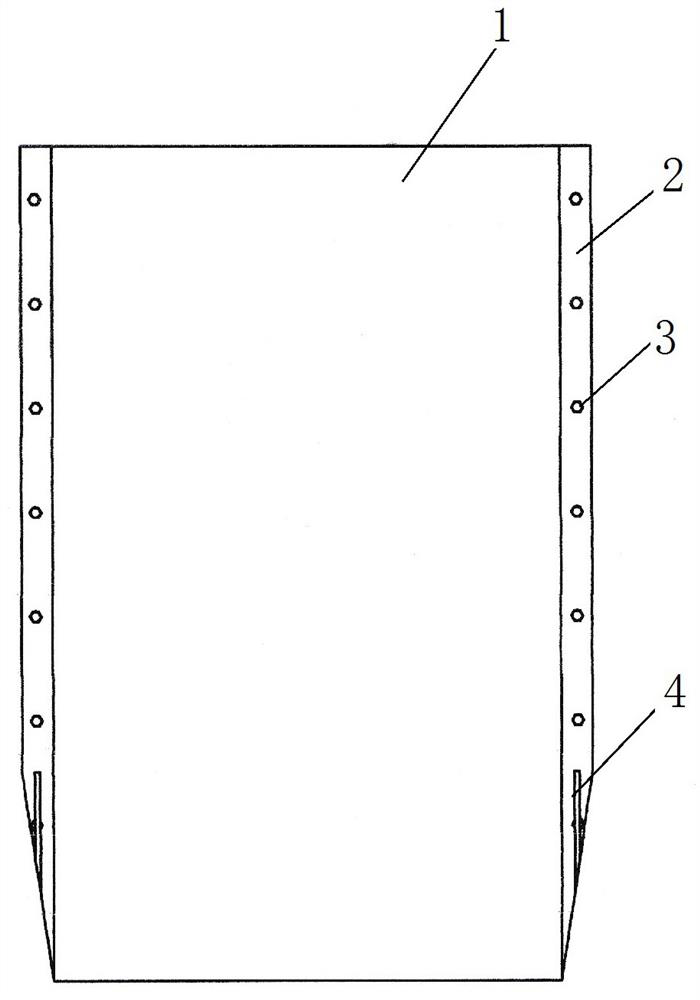

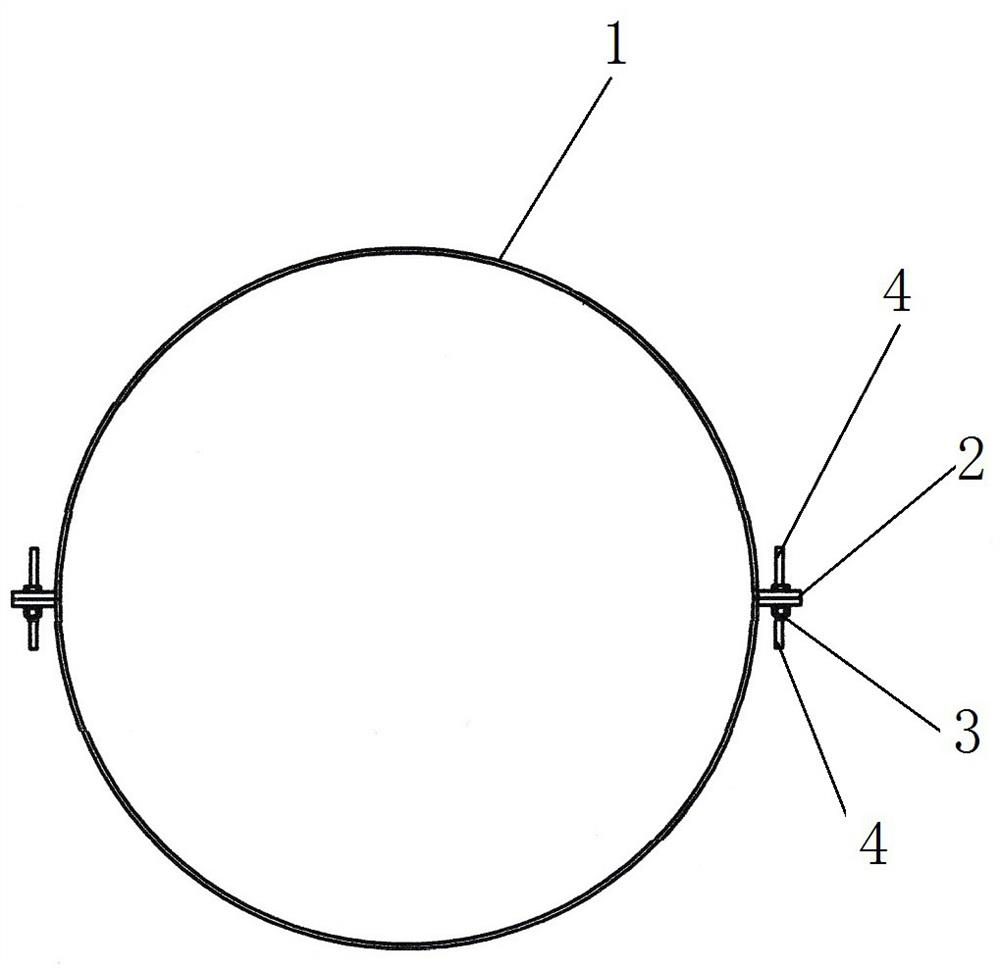

[0016] Before constructing the bridge pile foundation, first raise the cut pile elevation of the bridge pile foundation to the bottom of the cap beam or abutment, and then fill the construction platform, whose elevation is consistent with the new cut pile elevation. After the platform is filled, a steel casing is inserted at the pile site. The diameter of the steel casing is slightly larger than the diameter of the pile foundation by 10mm, and the steel casing is 500mm higher than the platform. Next, the construction pile foundation is poured according to the conventional conduit method. The steel bars inside the designed pier column height are set according to the pier column steel bars. When the concrete is poured to the top surface of the steel casing, the steel casing is pulled out. During the process of pulling out the steel casing, two theodolites are used to record the plane position of the casing when it is pulled out. Reinsert the new pier column casing according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com