Overlapped organic rankine cycle efficient heat machine

A Rankine cycle, cascade technology, applied in the direction of machine/engine, combined engine, mechanical equipment, etc., can solve the problem that heat cannot be used directly, and achieve environmental protection, reduce emissions, and reduce heat transfer loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

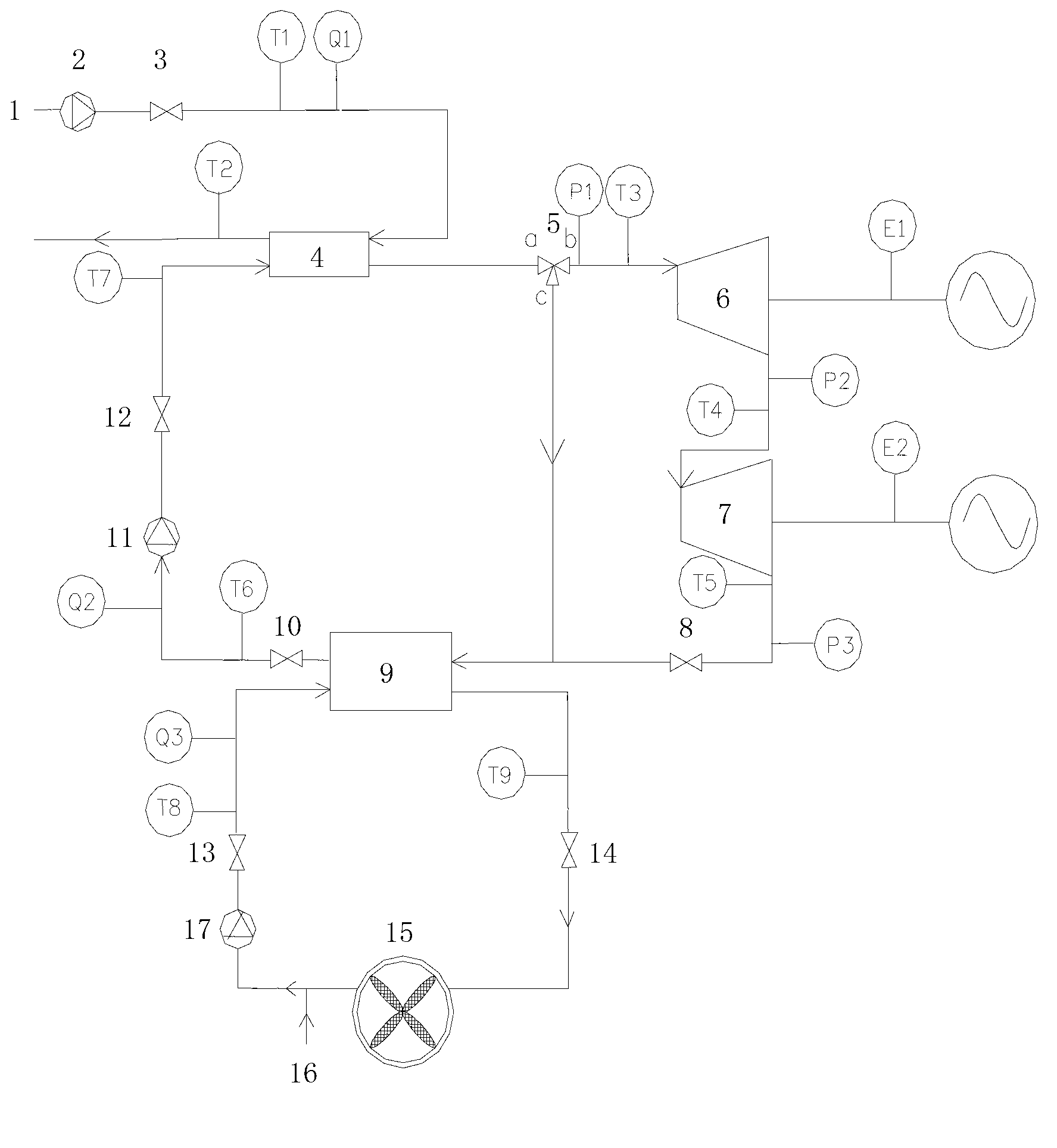

[0037] figure 1 Shown is the system flow chart of the cascaded organic Rankine cycle, showing each component equipment in the system, the operation mode and the circulating flow direction of the organic working fluid. The device includes three sub-circulation systems: organic working proton circulation system, cooling water sub-circulation system and heat-conducting oil sub-circulation system. The structures of the sub-circulation systems are:

[0038] In the organic working proton circulation system, the outlet of the evaporator 4 is connected to the inlet a of the three-way valve 5, the outlet c of the three-way valve 5 is connected to the inlet pipeline of the condenser 9, and the outlet b of the three-way valve 5 is connected to the first pressure sensor P1 Connected, the other end of the first pressure sensor P1 pipeline is connected to the third temperature sensor T3, then the pipeline is connected to the suction port of the primary expander 6, the output shaft of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com