Diaphragm for secondary battery, preparation method of diaphragm and secondary battery

A secondary battery and diaphragm technology, applied in the field of secondary battery diaphragm and its preparation, can solve the problems of inability to carry out the combustion process of the electrolyte solution, reduce the ionic conductivity of the electrolyte solution, decrease the electrochemical performance, etc. Good cycle performance, preventing thermal runaway and explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second object of the present invention is to provide a method for preparing the above-mentioned secondary battery separator, comprising the following steps:

[0039] S1. Mix methyl methacrylate, cross-linking agent, surfactant, solvent, initiator and flame retardant to form a homogeneous solution, and remove the active oxygen in it, then heat to 40-50°C and operate at 200-300rpm / Carry out the polymerization reaction at min speed for 5-6 hours; after the reaction, take out the synthesized flame-retardant capsules, wash and dry them for more than 24 hours;

[0040] S2. Dissolve the polyvinylidene fluoride-hexafluoropropylene binder in a volatile solvent, then add the flame-retardant capsule obtained in step S1 into it and stir, then immerse the base film 1 in it, take out the base film 1, and dry Finally, a secondary battery separator containing the flame-retardant layer 2 is obtained.

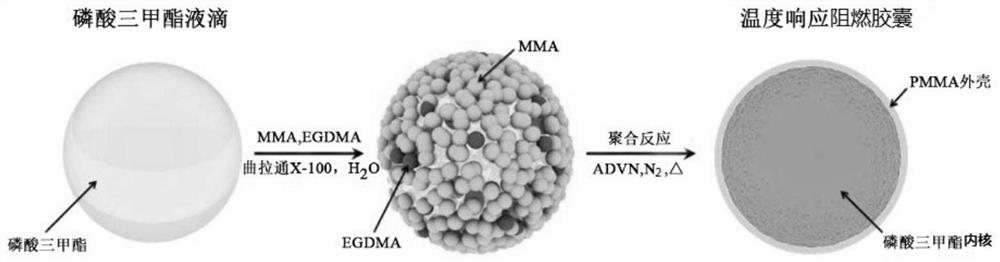

[0041]In step S1, methyl methacrylate (MMA) is mixed and dispersed with crossli...

Embodiment 1

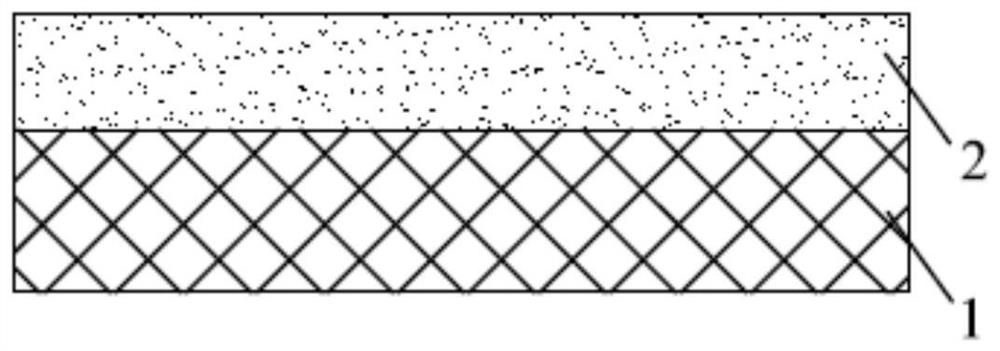

[0053] A separator for a secondary battery, such as figure 1 As shown, it includes a PE base film 1 and a flame retardant layer 2 coated on at least one surface of the PE base film 1; the flame retardant layer 2 is made of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) binder and a Composed of a flame-retardant capsule, the flame-retardant capsule is a core-shell structure with trimethyl phosphate as the core and polymethyl methacrylate (PMMA) as the shell.

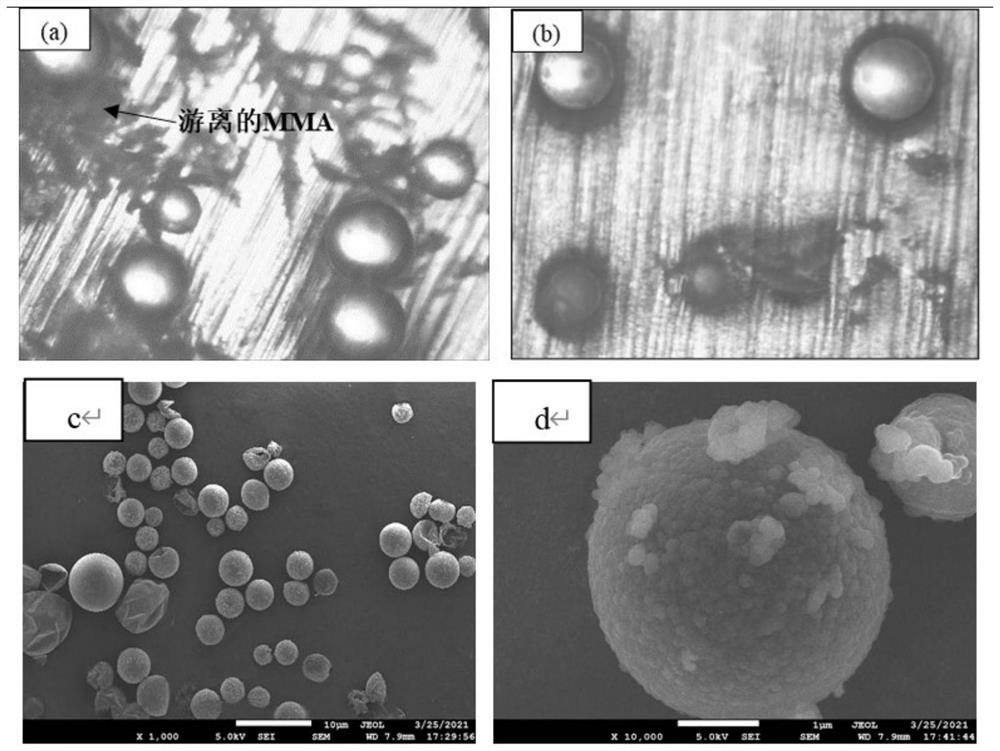

[0054] The preparation method of this membrane can be as Figure 2-4 shown, including the following steps:

[0055] S1. Preparation of flame retardant capsules: In a three-necked flask, add 30ml methyl methacrylate (MMA, monomer) and 0.3ml ethylene glycol dimethacrylate (EGDMA, crosslinking agent) to 500ml deionized water And in 2.5g triton X-100 (surfactant), pass into N 2 Remove the active oxygen in the three-necked flask, and stir at 800rpm / min for 30min to form a homogeneous mixed solution; then take 30mL t...

Embodiment 2

[0058] The difference from Example 1 is the preparation method of the flame retardant capsule.

[0059] S1. Preparation of flame retardant capsules: In a three-necked flask, add 30ml methyl methacrylate (MMA, monomer) and 0.3ml ethylene glycol dimethacrylate (EGDMA, crosslinking agent) to 500ml deionized water And in 2.5g triton X-100 (surfactant), pass into N 2 Remove the active oxygen in the three-necked flask, and stir at 800rpm / min for 30min to form a homogeneous mixed solution; then take 30mL trimethyl phosphate, 0.3g 2,2-azobis(2,4-dimethylvaleronitrile) (ADVN, initiator) was added, stirred at 1800-2000rpm / min for 20-30min to form a uniform solution; then heated to 45°C and polymerized at 1800-2000rpm / min for 5h; after the reaction was completed, add Excessive NaCl precipitated the synthesized flame-retardant capsules, filtered them, washed them with water and ethanol three times, and dried them at room temperature for 1 day to obtain flame-retardant capsules.

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com