Antibacterial fresh-keeping composite freeze-thawed edible film for chilled fresh meat and preparation method thereof

A chilled meat, freeze-thaw technology is applied in the field of chilled meat antibacterial and fresh-keeping composite freeze-thawed edible film and its preparation, so as to achieve the effects of maintaining edible quality, improving mechanical properties, and delaying the process of quality deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

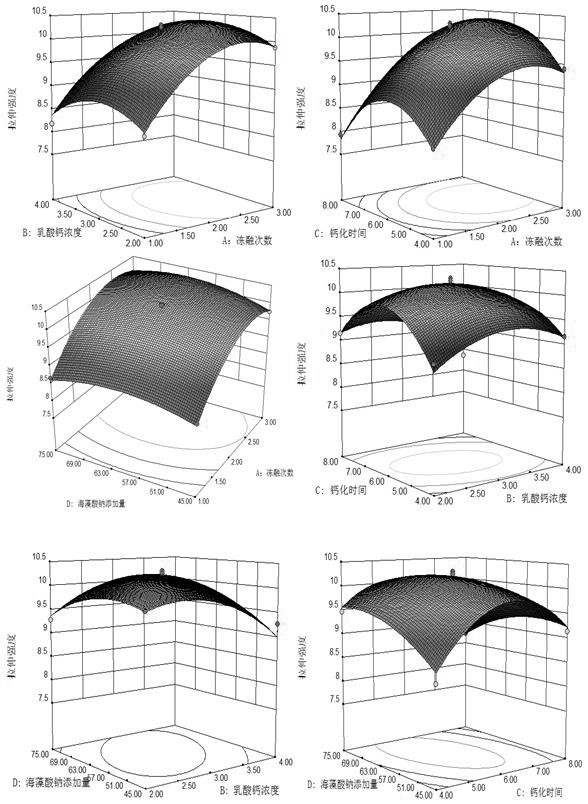

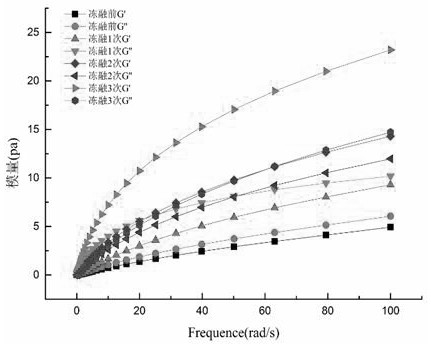

Image

Examples

Embodiment Construction

[0032] A preparation method for antibacterial and fresh-keeping composite freeze-thaw edible film of cold fresh meat, comprising the following steps

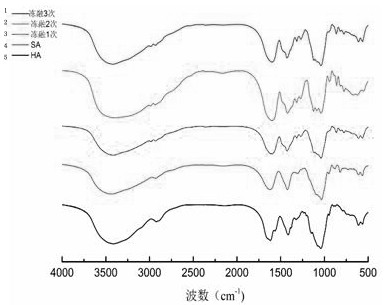

[0033] A. Preparation of hyaluronic acid solution: weigh hyaluronic acid powder and add it to distilled water, add every 1.00 g of hyaluronic acid powder to 100 mL of distilled water, heat to 60°C and use an electric stirrer to continuously stir at 300 rpm / s until It dissolves completely, let it stand for 10-15 minutes to remove air bubbles, and obtain a hyaluronic acid solution with a solid-to-liquid ratio of 1%;

[0034]B. Preparation of sodium alginate solution: Weigh sodium alginate powder and add it to distilled water, add every 1.50 g of sodium alginate powder to 100 mL of distilled water, heat to 60°C and use an electric stirrer to continuously stir at 300 rpm / s until It dissolves completely, let it stand for 10-15 minutes to remove air bubbles, and obtain a sodium alginate solution with a solid-to-liquid ratio of 1.5%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com