Water sucking resin microspheres for water-based coating and preparation method thereof

A technology of resin microspheres and water absorption, which is applied in the direction of microsphere preparation, microcapsule preparation, coating, etc., can solve the problems of low durability and achieve the effects of promoting rapid drying, increasing drying speed, and small expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

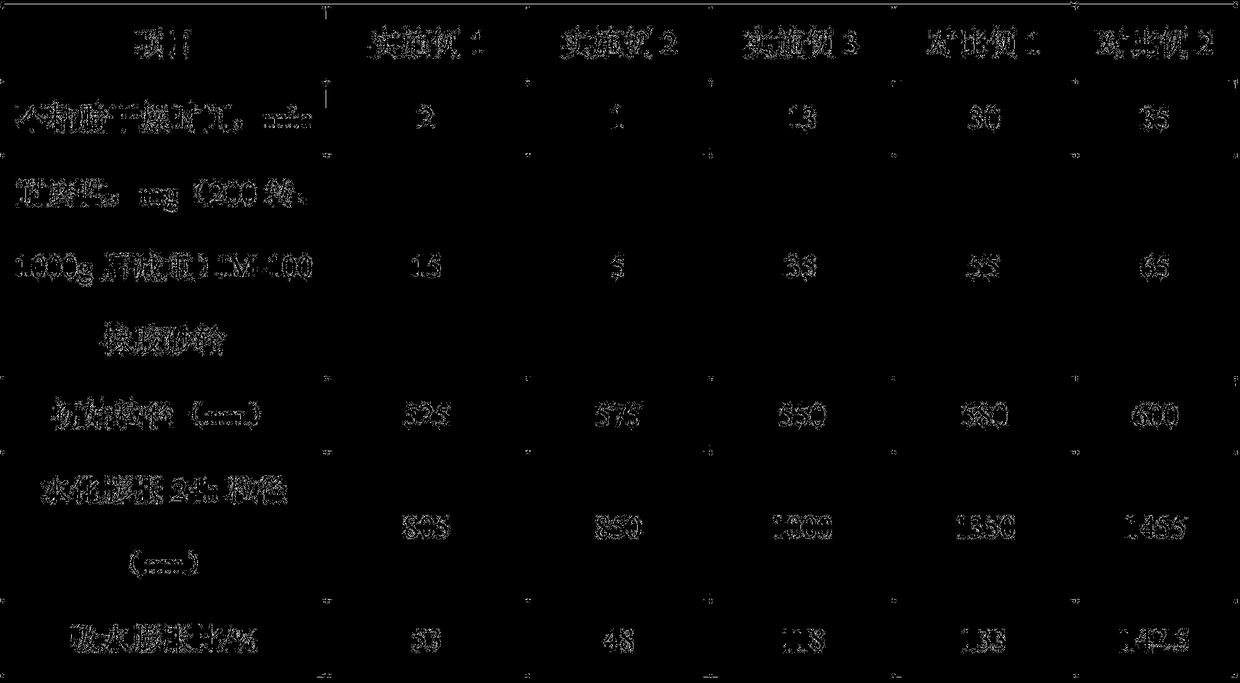

Examples

preparation example 1

[0029] (1) Dissolve the purified acrylic acid in water, place it in a conical flask under an ice-water bath, stir and slowly add NaOH solution dropwise therein to form an acrylic acid solution with a neutralization degree of 55%, cool to room temperature, and Add cross-linking agent N,N-methylenebisacrylamide, initiator ammonium persulfate, acrylamide and vinylpyrrolidone to the final acrylic acid solution, stir well to dissolve, and obtain a mixed solution;

[0030] (2) Add nanoporous silicon dioxide (the particle size of nanoporous silicon dioxide is about 100nm) and dispersant span-60 in cyclohexane, stir fully, heat up to 40°C, keep nitrogen atmosphere, and then (1 ) into the three-necked flask, heated to 75°C and reacted for 2.5 hours, filtered after the reaction, washed with methanol, dried in an oven, slightly ground and vacuum-dried to obtain a white powder superabsorbent resin microspheres.

[0031] In parts by weight, 20 are acrylic acid, 5 are acrylamide, 5 are vin...

preparation example 2

[0033] In parts by weight, it is 15 parts by weight of acrylic acid, 5 parts of acrylamide, 5 parts of vinylpyrrolidone, 1 part of nanoporous silicon dioxide, 1 part of dispersant, 0.05 part of crosslinking agent and 0.05 part of initiator. Others are the same as Preparation Example 1.

preparation example 3

[0035] No vinylpyrrolidone was added, 10 parts of acrylamide was added, and the others were the same as in Preparation Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com