Foaming PET (Polyethylene Terephthalate) sheet and preparation method thereof

A sheet material and foaming agent technology, applied in the field of polymer foaming material preparation, can solve the problems of unfavorable bubble nucleation and stability, inability to realize continuous production, high processing temperature, etc., and achieve excellent cell size distribution and mechanical properties , The production process is highly continuous and stable, and the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

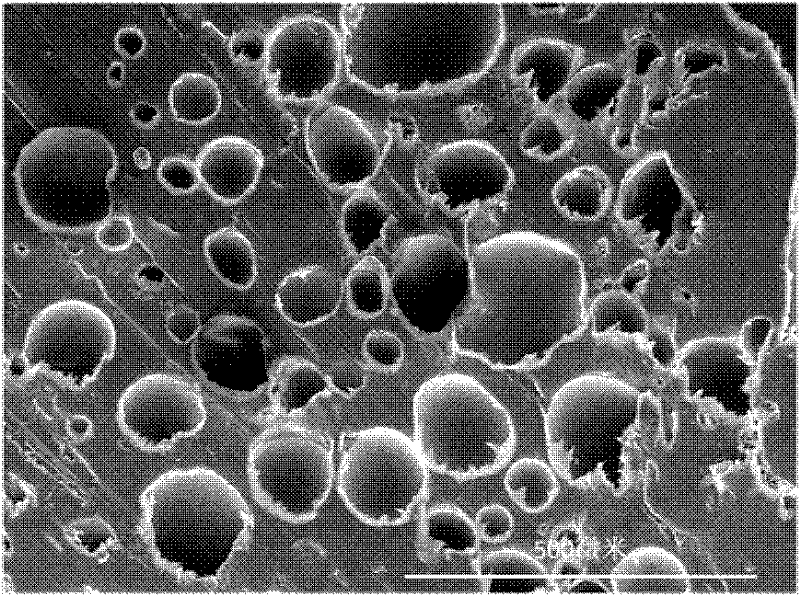

[0035] Example 1 Preparation of foamed PET sheet.

[0036] Dry the PET resin and bubble nucleating agent at 100°C for 10 hours.

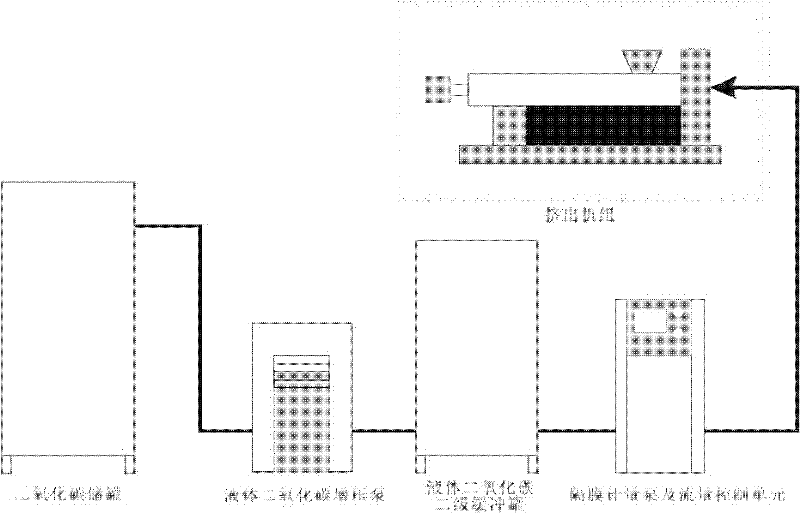

[0037] Use 100 parts by weight of PET (intrinsic viscosity 0.87), add one part by weight of modified montmorillonite bubble nucleating agent, and inject liquid carbon dioxide at 0.6kg / h. In the second-stage single-screw extruder, the extrusion temperature As follows: extruder conveying section 200, 210, 215°C; compression section 215, 220, 225, 225, 215, 215, 210, 210°C; homogenization section 205, 205, 205, 205°C. The temperature of the machine head is 200℃.

[0038] The properties of the obtained PET foam sheet are shown in Table 1.

[0039] Table 1

[0040] Density (g / cc)0.74 Tensile strength (MPa)13.20 Impact strength (KJ / cm 3 ) 11.36 Foaming ratio 2.14

Embodiment 2

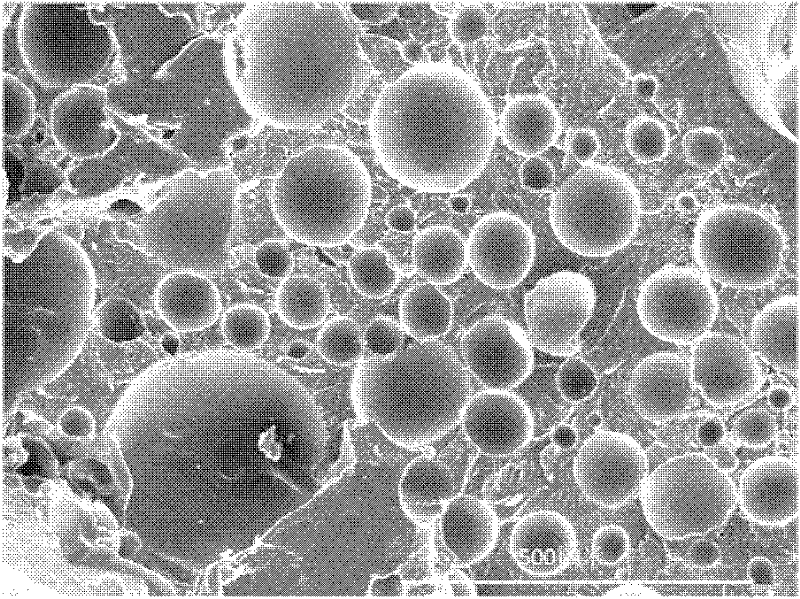

[0041] Example 2 Preparation of foamed PET sheet.

[0042] Dry the PET resin and bubble nucleating agent at 100°C for 10 hours.

[0043] Use 100 parts by weight of PET (intrinsic viscosity of 1.15), add one part by weight of modified montmorillonite bubble nucleating agent, and inject liquid carbon dioxide at 0.6kg / h. In the second-stage single-screw extruder, the extrusion temperature As follows: extruder conveying section 200, 210, 215°C; compression section 215, 220, 225, 225, 215, 215, 210, 210°C; homogenization section 205, 205, 205, 205°C. The temperature of the machine head is 200℃.

[0044] The properties of the obtained PET foam sheet are shown in Table 2.

[0045] Table 2

[0046] Density (g / cc)0.53 Tensile strength (MPa)16.40 Impact strength (KJ / cm 3 ) 14.27 Foaming ratio 3.42

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com