Thermal circulation process of gas turbine based on pure oxygen or oxygen-enriched combustion

A gas turbine and oxygen-enriched combustion technology, which is used in gas turbine devices, fuel control of turbine/propulsion devices, and mechanical equipment, etc., can solve the problems affecting the efficiency of gas turbines, the expansion ratio cannot be improved, and the circulating intake pressure is low. The effect of increasing the power generation efficiency, improving the power generation efficiency and high cycle pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

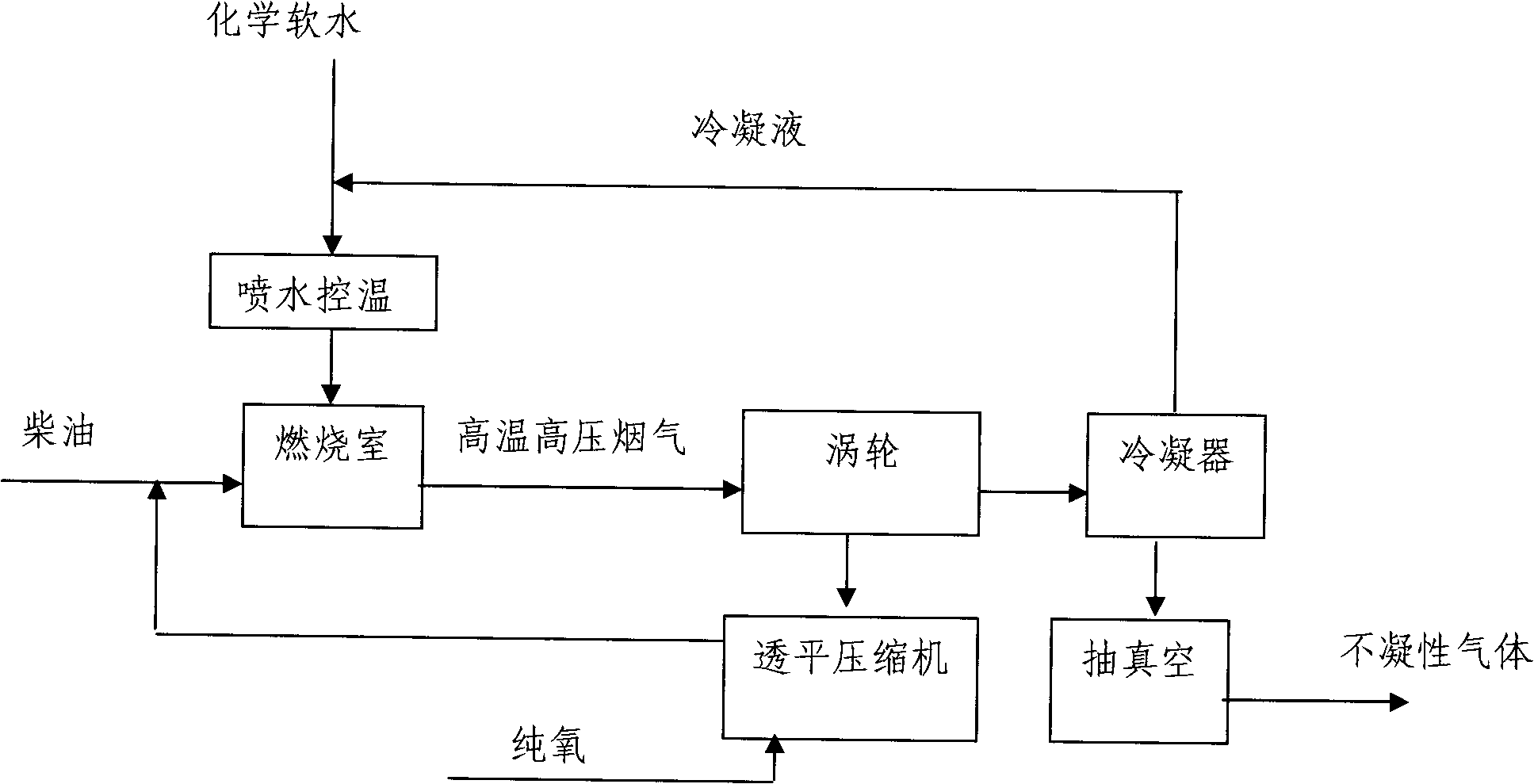

[0029] The first embodiment of the present invention, such as figure 2 As shown, the oxygen that has been produced at a pressure of 2.0Mpa is compressed to 20.0Mpa by a turbo compressor driven by a gas turbine, and the oxygen flow rate is 10000Nm 3 / h. The diesel is pressurized to 20.0Mpa by the oil pump, and the flow rate of the diesel is 4100kg / h. It is sprayed into the combustion chamber to be burned with oxygen, and chemical soft water is injected at the same time. The high-pressure and high-temperature flue gas after combustion is expanded by the gas turbine to do work. A condenser is installed after the gas turbine to cool the circulating water, most of the water vapor is condensed into liquid water and circulated back to the combustion chamber to replace the chemical soft water, a small amount of water vapor and non-condensable gas CO 2 , O 2 , use a vacuum pump to extract the vacuum pressure and control it at 0.02Mpa; on the premise that the working conditions can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com