A kind of aluminum oxide modified gradient laser cladding layer and preparation method thereof

A technology of laser cladding and cladding layer, applied in the direction of coating, metal material coating process, etc., can solve the problems of excessive physical property difference, increase in organizational inhomogeneity, galvanic corrosion of cladding layer, etc. Adverse effects, promoting uniform distribution, reducing over-oxidation and burn-out effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

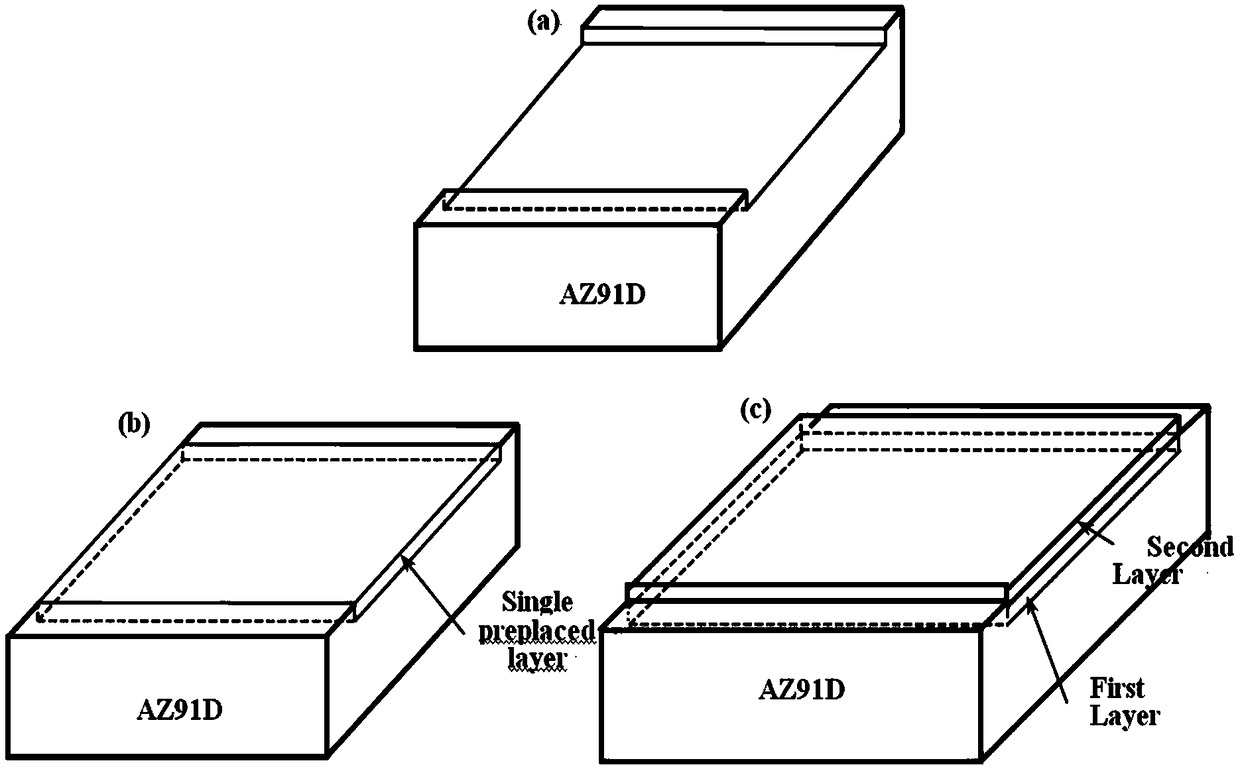

[0041] Embodiment 1 Test material and method of the present invention

[0042] 1.1.1 Base material: The base material used in this test is AZ91D cast magnesium alloy, which is most widely used in the field of magnesium alloy engineering structural materials, and was purchased from Ruihe Ribiao Metal Material Co., Ltd., Dongguan, Guangdong. Its chemical composition is shown in Table 1.

[0043] Table 1 AZ91D magnesium alloy nominal chemical composition (wt.%)

[0044]

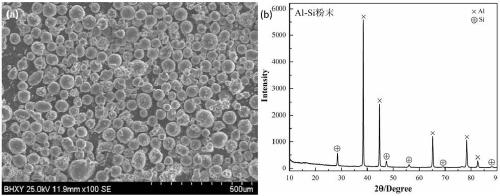

[0045] 1.1.2 Coating material: The coating material used in the test is Ni35 self-fluxing alloy powder, the powder particle size is 140-325 mesh, and its chemical composition is shown in Table 2. Ni35 is in the form of round particles, mainly including γ-Ni, M 23 C 6 , Ni 3 B, composed of CrB. In this experiment, Ni35 powder was used to laser clad the surface of AZ91D magnesium alloy to obtain a cladding layer with excellent corrosion resistance. However, the physical properties of Ni35 and the base mate...

Embodiment 2

[0067] Example 2Ni35 cladding layer microstructure analysis

[0068] 2.1 Structural characteristics of the cladding layer:

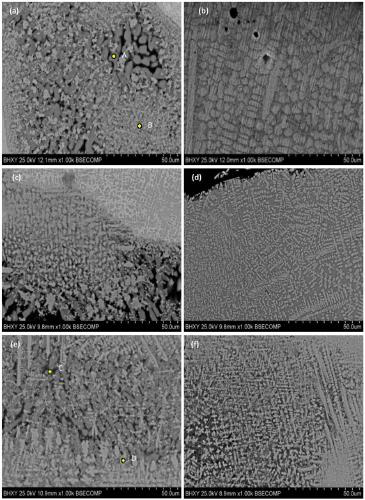

[0069] Observation of the microstructure morphology of different areas from the bottom to the upper part of the cladding layer of the A2 sample is mainly the eutectic structure between the γ-Ni dendrites precipitated first and the Ni-Cr-B-Si elements between the dendrites. Ni35 powder is easy to form eutectic structure because it contains B, Si and other elements, and it can be seen from the phase diagram that compounds between Ni and Mg, Cr, B, Si elements are easier to form eutectic structure, so there must be a large amount of eutectic structure in the cladding layer. crystal organization. In the microstructure, a long strip-shaped single structure was observed, which is the enrichment area of Mg at the bottom of the cladding layer, which is caused by the uneven distribution of heat in the molten pool, and there is a dendritic pre-precipitated phas...

Embodiment 3

[0085] Example 3 Al-Si / Ni35 cladding layer microstructure analysis

[0086] The AZ91D magnesium alloy substrate and the laser cladding Al-Si / Ni35 sample were respectively subjected to corrosion electrochemical tests, and the potentiodynamic polarization curves were measured as follows: Image 6 shown. The corrosion potential and corrosion current density of the tested samples are obtained through chi660e software fitting, as shown in Table 6. The highest corrosion potential of the cladding layer is -0.955V, which is 0.563V higher than that of the base material, and the corrosion current density is only 1 / 8 to 1 / 30 of that of the base material, indicating that the Al-Si / Ni35 cladding layer can better improve the corrosion resistance of AZ91D magnesium. Alloy surface corrosion resistance. Compared with the cladding layer only cladding Ni35, when v=200 and 300mm / min, the corrosion resistance performance is increased by 4 to 5 times. This is related to the excellent corrosion r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com