On-line control method of banded structure and hardness of gear steel and post-rolling on-line controlled cooling bed device

A banded structure and control method technology, applied in the direction of cooling bed, heat treatment process control, metal rolling, etc., can solve the problems of increasing the difficulty of cutting gear steel, reducing the service life of tools, unstable structure and performance, etc., to achieve applicability Strong, improve production efficiency, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

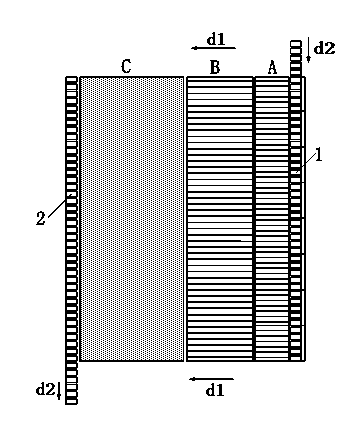

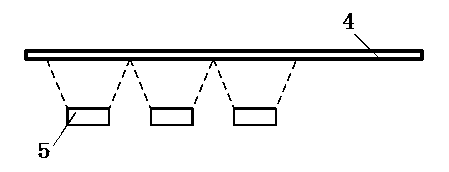

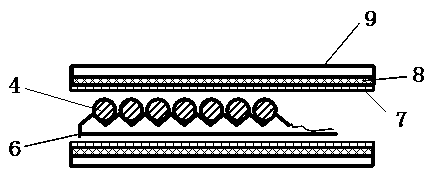

[0029] In this example, see Figure 1 ~ Figure 4, an on-line controlled cooling and cooling bed device after rolling, which is composed of an input roller table 1, a cooling bed system, an output roller table 2 and a control system, and the control system is connected to a series of temperature sensor output terminals of the cooling bed system. , the temperature sensor respectively detects the initial cooling temperature of the gear steel bar 4 entering the cooling bed system and the final cooling temperature leaving the cooling bed system, the command signal output end of the control system and the rolling material conveying mechanism of the cooling bed system, and then controls the gear steel bar The cooling speed and cooling residence time of material 4 are characterized in that: the cooling bed system is composed of pre-cooling cooling bed A, air-cooling cooling bed B and slow cooling cooling bed C three-section step-by-step cooling bed in sequence, and the pre-cooling cool...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this example, AISI 8620H (20CrNiMo) gear steel is selected, the specification of the continuous casting slab is 300mm×300mm, the diameter of the gear steel bar 4 after final rolling is φ120mm, and the surface temperature is 930~970°C. 1 Arrive at the pre-cooling cooling bed A, pre-cooling on the pre-cooling cooling bed A for 160~170s, the surface temperature of the gear steel bar 4 reaches 800~830°C, the temperature sensor on the pre-cooling cooling bed A receives the signal, and the control system passes the pre-cooling The moving gear rack stepping mechanism of cooling bed A transports the gear steel bar 4 to air-cooling cooling bed B. The axial flow fan 5 performs forced air cooling on the gear steel bar 4, and the gear steel bar 4 quickly passes through the α+γ two-phase region on the Fe-C phase diagram, effectively suppressing the pro-eutectoid ferrite along the rolling direction...

Embodiment 3

[0037] This embodiment is basically the same as the previous embodiment, and the special features are:

[0038] In this example, Cr-Mo series SCM822H (22CrMoH) gear steel is selected, the specification of the continuous casting slab is 300mm×340mm, the diameter of the gear steel bar 4 after final rolling is φ90mm, and the surface temperature is 930~980°C. The output roller table 1 reaches the pre-cooling cooling bed A, and pre-cools on the pre-cooling cooling bed A for 130~150s. The surface temperature of the gear steel bar 4 is 800~830°C. The feeding mechanism transports the rods to the air-cooled cooling bed B. The axial flow fan 5 performs forced air cooling on the gear steel bar 4, and the gear steel bar 4 quickly passes through the α+γ two-phase region on the Fe-C phase diagram, effectively suppressing the pro-eutectoid ferrite along the rolling direction Band-shaped precipitation, air cooling for about 400s. The surface temperature of the gear steel bar 4 is 660°C, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com