Hard and semi-hard tin-coated copper wire manufacturing method

A technology of tinned copper wire and manufacturing method, which is applied in cable/conductor manufacturing, hot-dip plating process, coating, etc., can solve problems such as poor mechanical hardness, and achieve the effect of easy plugging and riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Make a φ8.0mm electrical copper wire billet into a φ2.6mm bare copper wire by drawing.

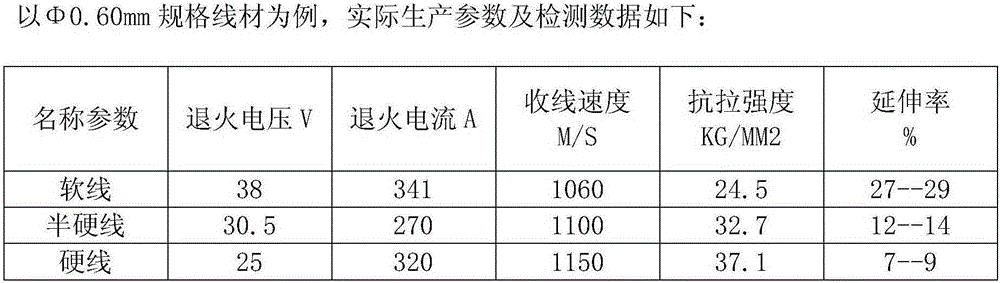

[0019] 2. Send the qualified φ2.6mm bare copper wire into the annealing frame, and stretch it through the inner eye mold of the wire drawing machine to obtain a φ0.60mm copper wire, and then pass through a certain annealing voltage of 30.5V and annealing current of 270A. Annealed and softened to make it a semi-hard copper wire with an outer diameter of φ0.60mm. The tensile strength of the prepared copper wire is 32.7KG / MM2, and the elongation is 12-14%.

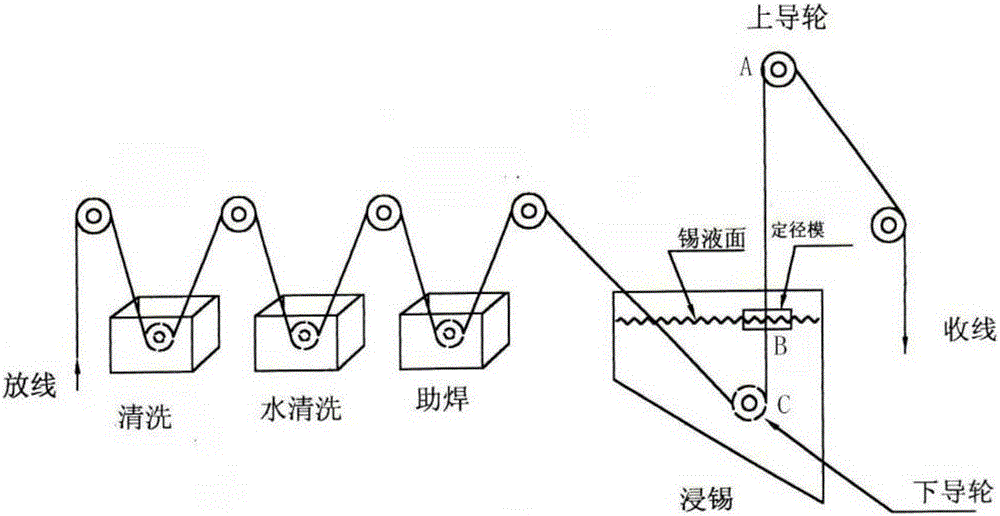

[0020] 3. The qualified semi-hard copper wire is sent to the wire rack, the surface oil, oxides and impurities are cleaned with a cleaning agent, the impurities are scraped off with rubber, and then the cleaning agent and impurities on the surface of the copper wire are cleaned with water, and finally clean water Clean the surface and use rubber to clean the surface of the copper wire to make the surface of the copper wire clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com