Patents

Literature

144results about How to "Easy riveting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

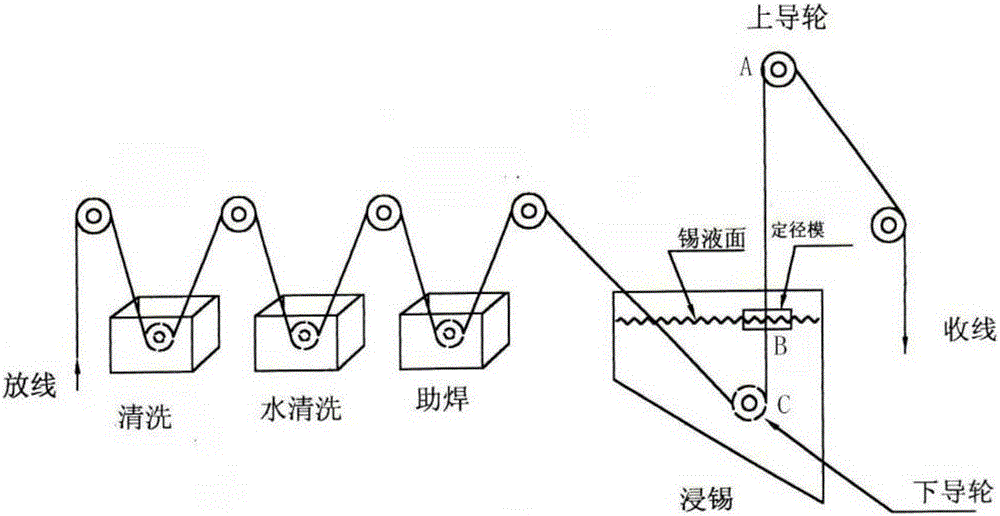

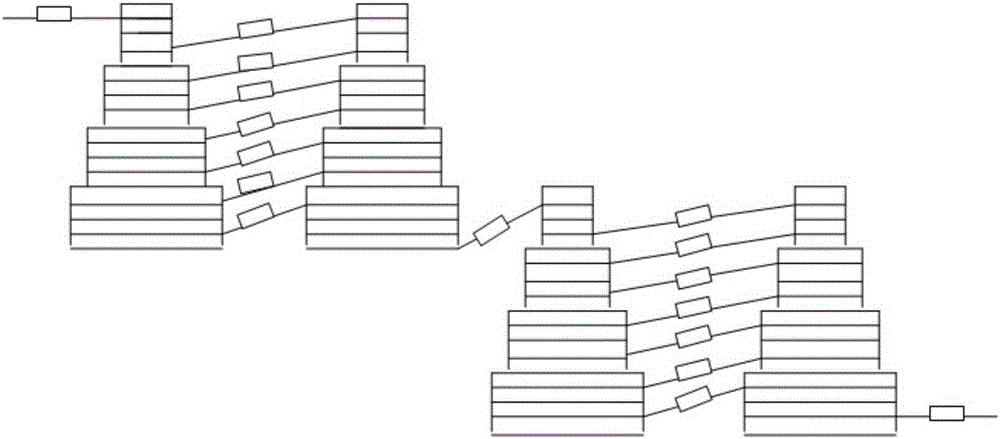

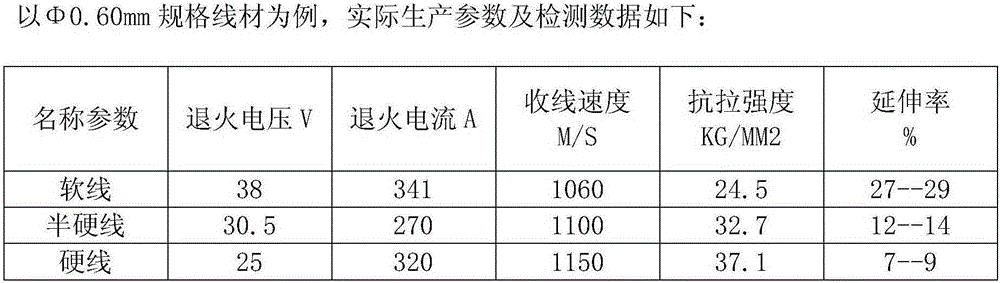

Hard and semi-hard tin-coated copper wire manufacturing method

InactiveCN105304221AEasy plugging and rivetingHas hardnessHot-dipping/immersion processesCable/conductor manufactureCopper wireVoltage

The invention provides a hard and semi-hard tin-coated copper wire manufacturing method. The method comprises the following steps: heavy-duty drawing: using a copper drawing stock for electrical purposes to make a bare copper wire; medium drawing: sending the qualified bare copper wire to a wire release support, enabling the bare copper wire to be stretched through hole mold drawing, preparing a copper wire with a required wire diameter, conducting annealing softening on the copper wire through a certain annealing voltage, and enabling the copper wire to be a circular soft copper wire with a required external diameter; and tinning: detecting the qualified copper wire and sending the copper wire to a wire feed support, cleaning oil stains, oxides and impurities on the surface of the wire by a cleaning agent, sending the cleaned copper wire to a tinning pan for tinning, scraping superfluous tin off the tinned wire through a specification hole mold, ensuring that a surface coating on the copper wire is smooth and even, cleaning the surface of the tin-coated copper wire after cooling, and making a finished product with a required specification by reeling the wire. The beneficial effects of the method are that tin-coated copper wires manufactured by the method exhibit certain hardness, meet the hardness requirement for some special industries, and are convenient to plug, unplug and rivet.

Owner:天津市宏远电子有限公司

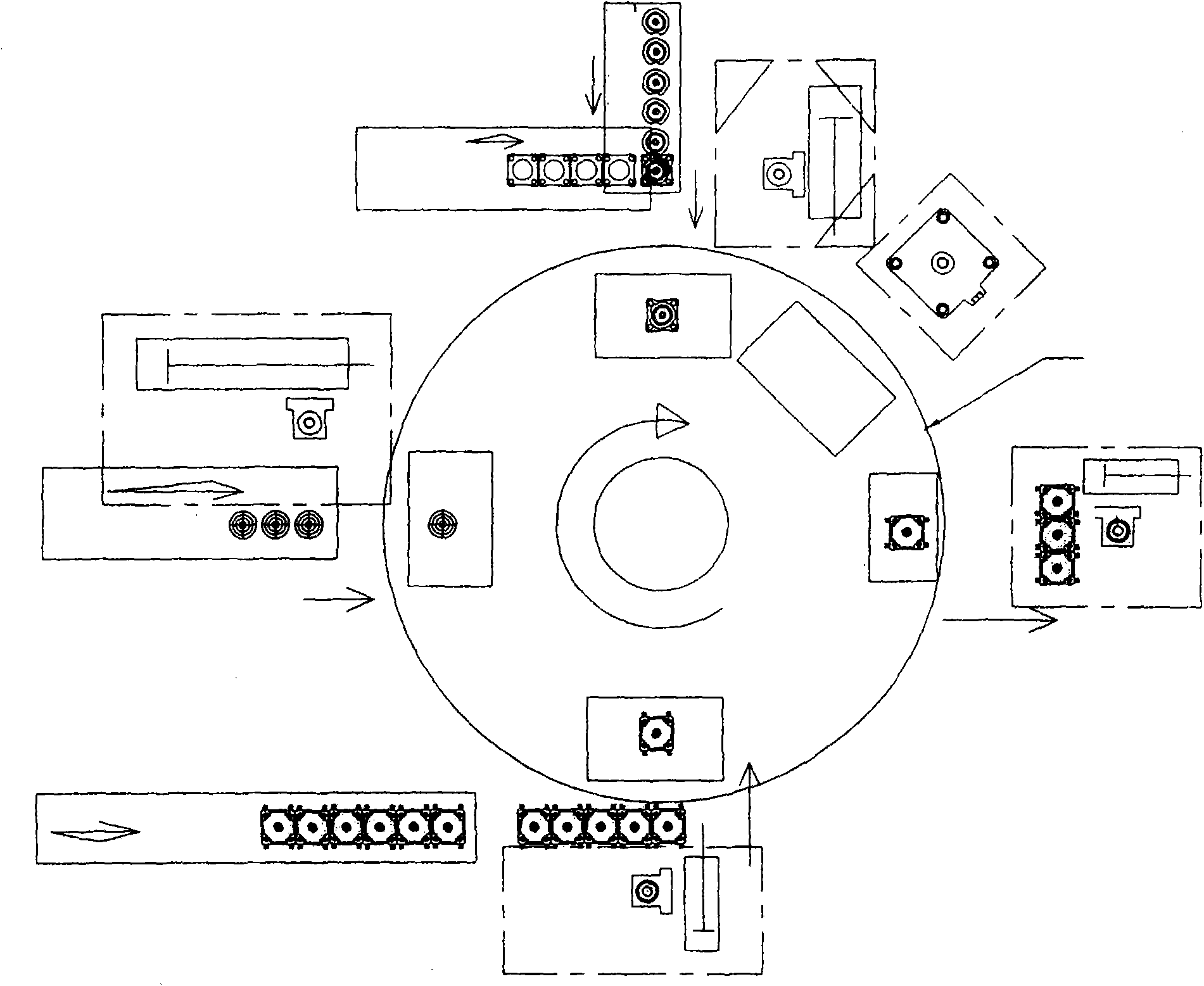

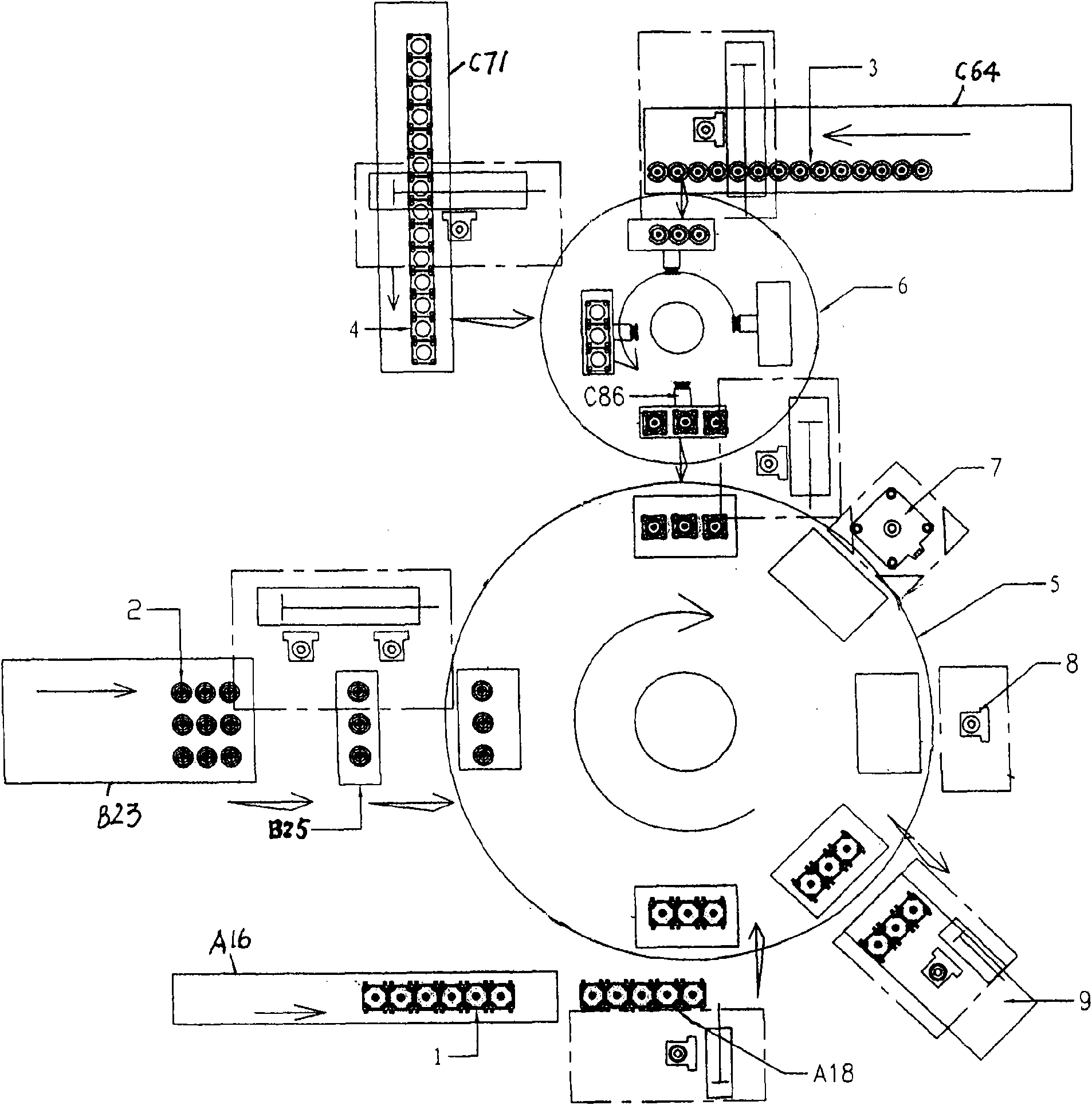

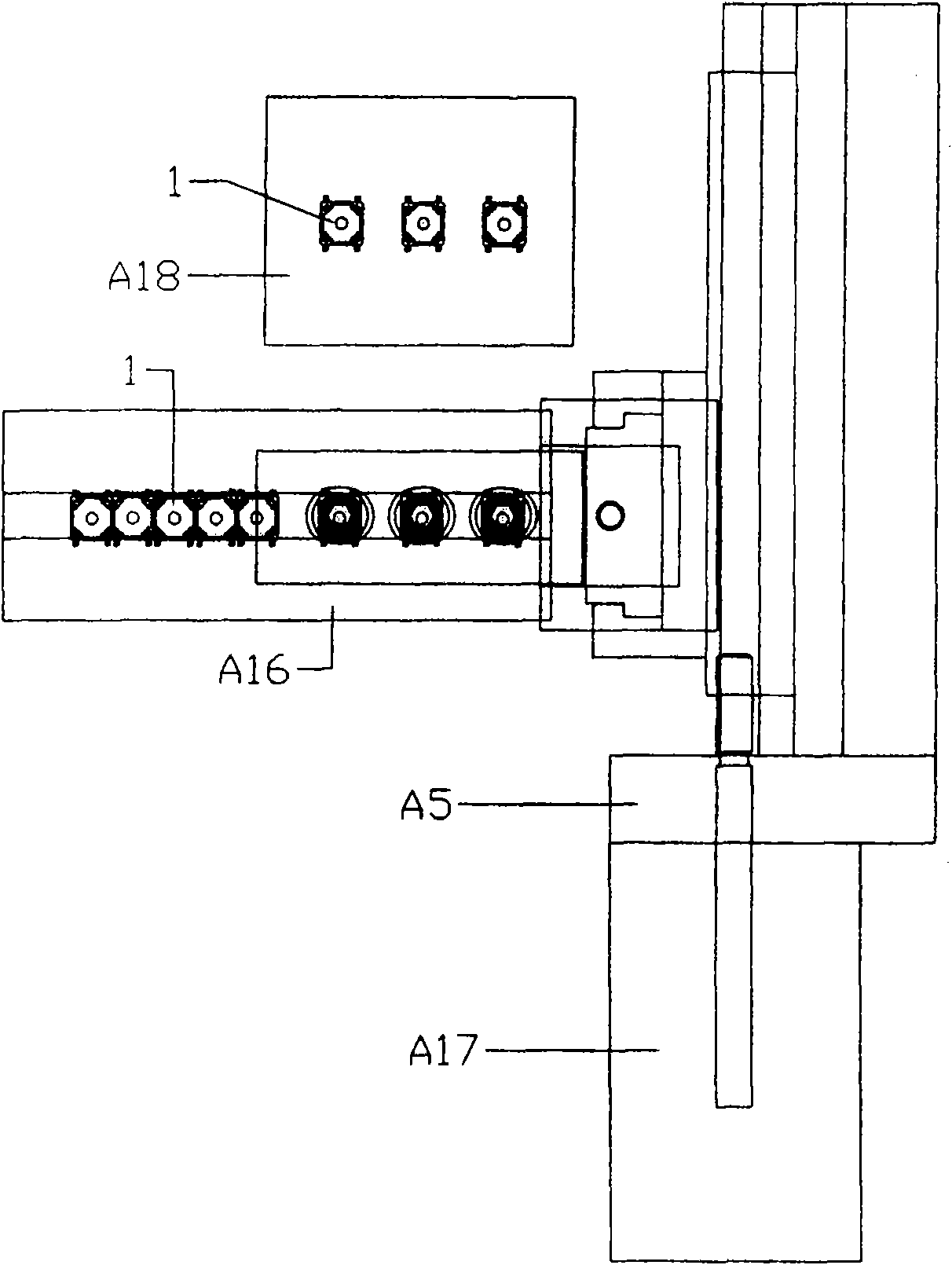

Automatic assembling machine of light touch switch

InactiveCN101673630AUnique locationService life is not affectedElectric switchesLight touchEngineering

The invention relates to an automatic assembling machine of a light touch switch, comprising an assembling jig; the assembling jig is fixed on an assembling main disc or an assembling moving belt andcorresponds to a plurality of positioning stations and a scale midstation disc when in rotating or moving; a transfer positioning station is fixed on the scale midstation disc, the transfer positioning station is connected with an air pipe joint; vacuum absorbing is generated when materials are put into the transfer positioning station, and the vacuum absorbing is stopped when materials are removed from the transfer positioning station; the side of the assembling main disc or the assembling moving belt is provided with a vacuum absorbing mechanism of a bottom seat and a vacuum absorbing mechanism of an elastic piece; and the side of the scale midstation disc is provided with a vacuum absorbing mechanism of a button upper cover. The automatic assembling machine improves the assembling speedand assembling quality of the light touch switch.

Owner:温州和泰电子有限公司 +1

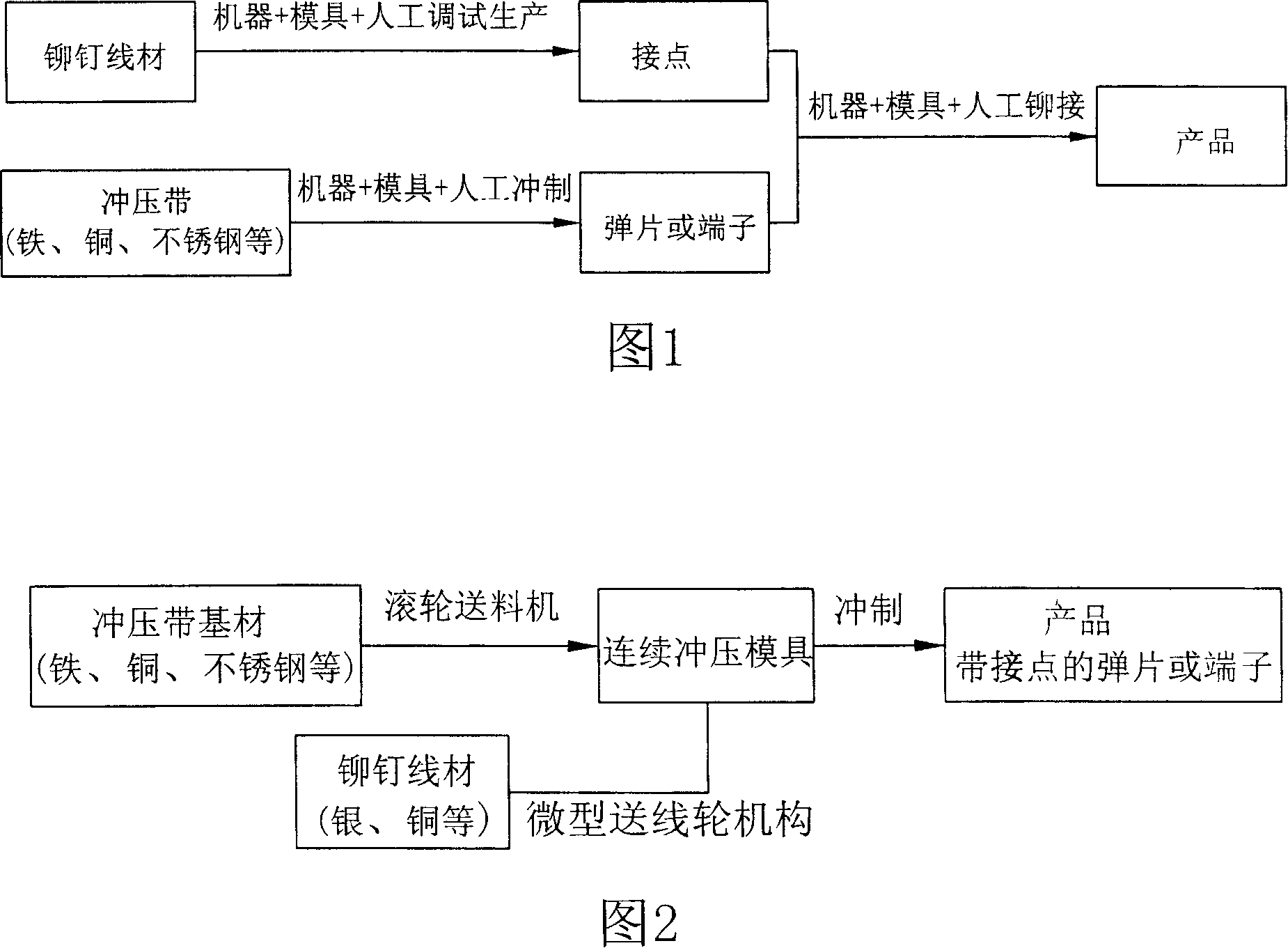

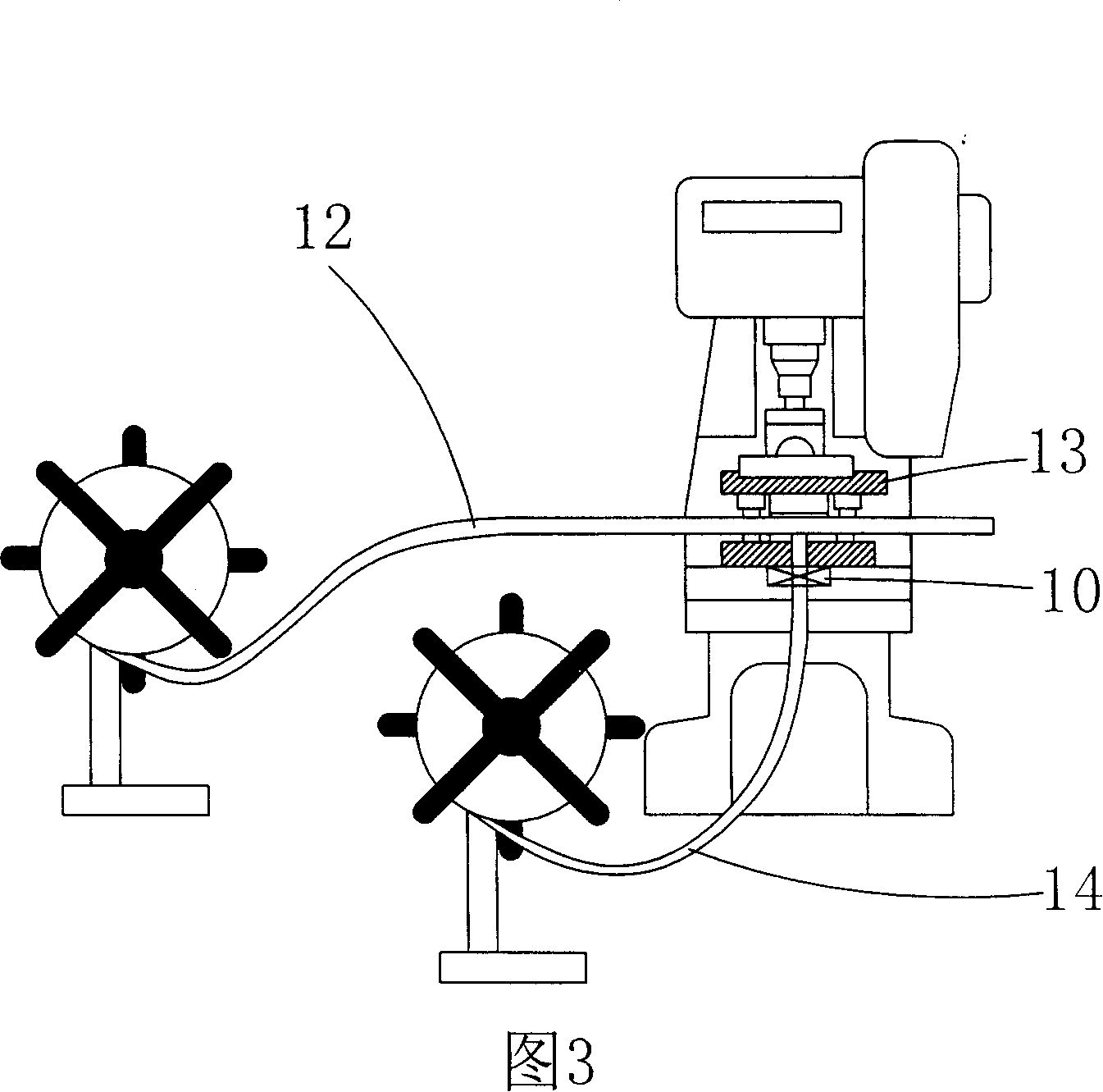

Thread feeding automatic riveting stamping technology

The present invention relates to punching technology, and is especially one automatic wire feeding, riveting and punching process. By means of using punching die with several punching die cavities for simultaneous punching formations on the base material, one miniature wire feeding wheel mechanism for automatic wire feeding and one wire cutting block mechanism for cutting off wire, the present invention completes one automatic wire feeding, riveting and punching process including terminal punching, rivet punching and riveting in one punch to produce terminal with joint. The present invention has less production steps, low cost, high production speed and high riveting quality, and is suitable for batch production.

Owner:东莞市中一合金科技有限公司

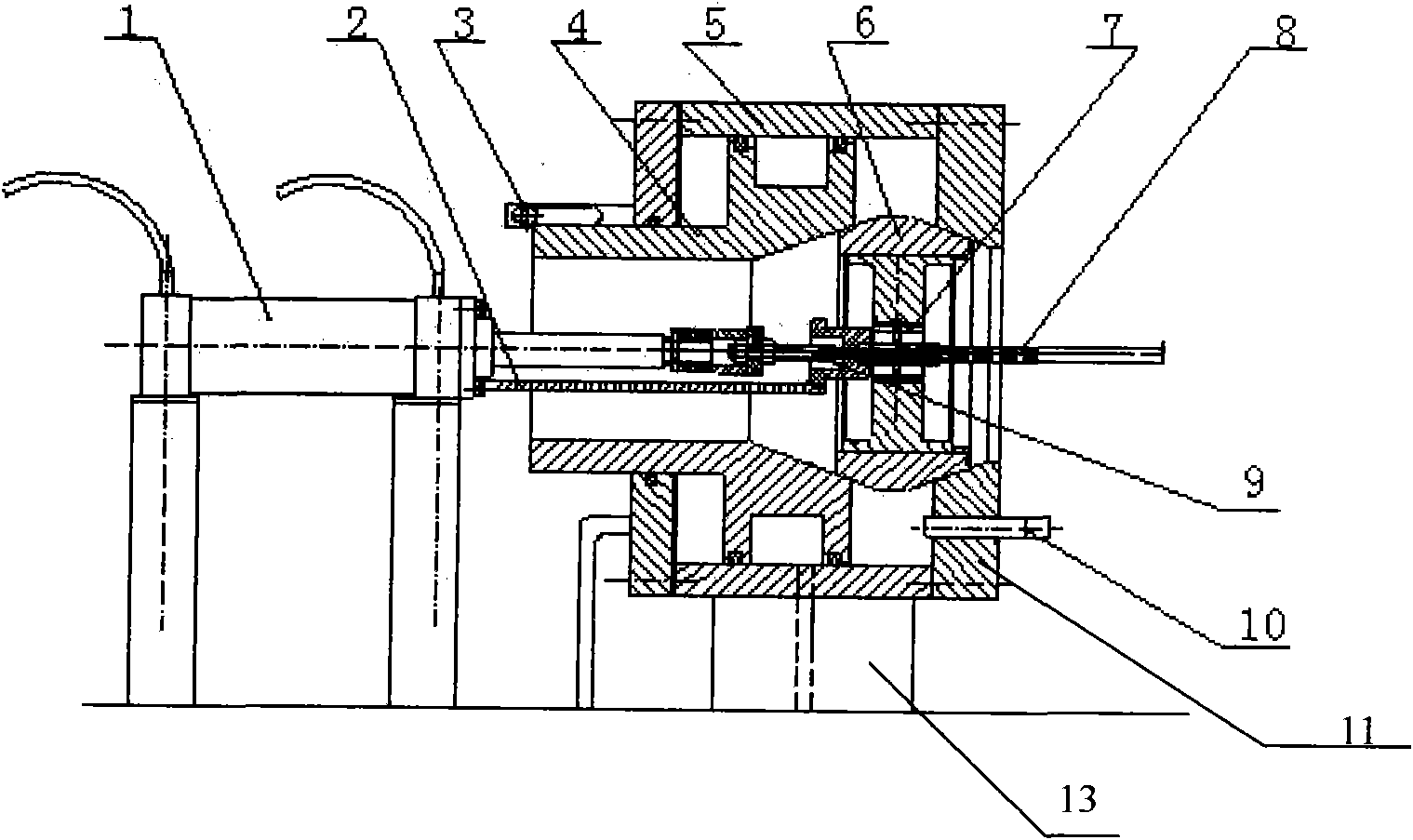

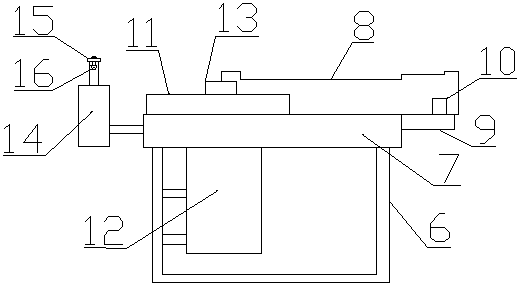

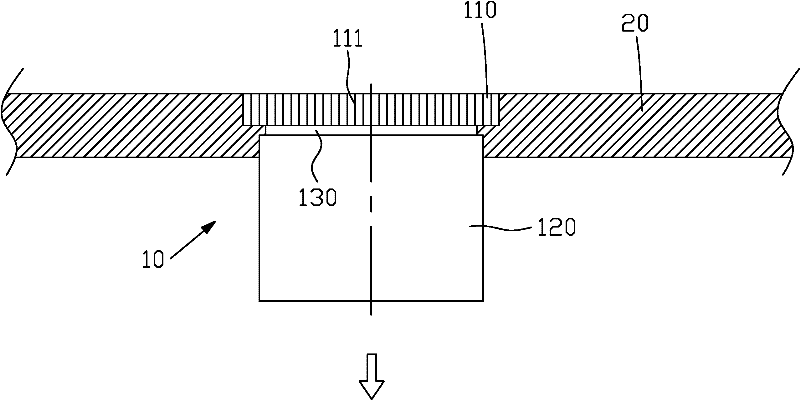

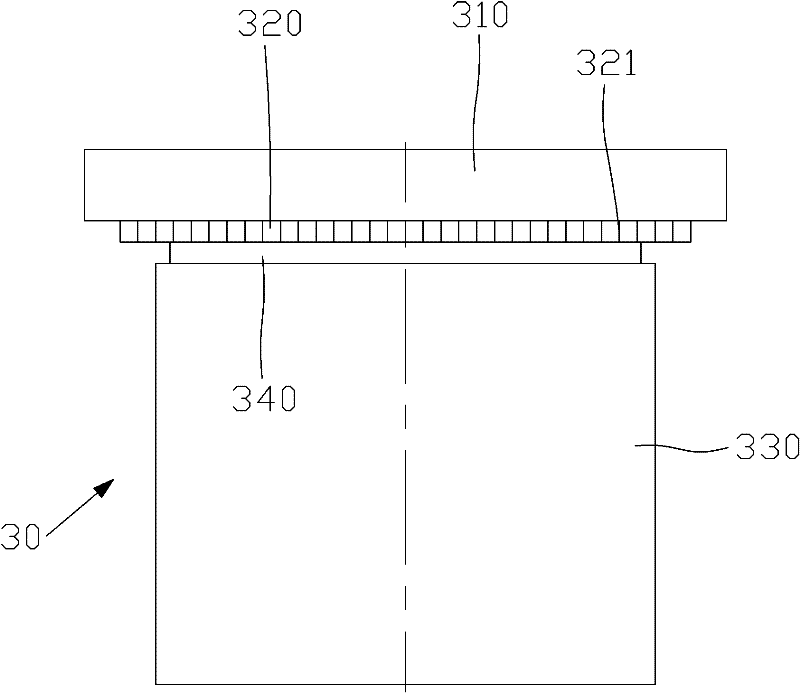

Method and equipment thereof for buckling-riveting outer sleeve of push-pull flexible shaft

The invention discloses a method and equipment thereof for buckling-riveting an outer sleeve of a push-pull flexible shaft, which are used for automobiles or engineering machinery and the like. Through the method and the equipment, an inner hole of an inner lining tube can be effectively prevented from deformation, the tensile force bearing capacity of a pipe joint is improved, and the service life of the push-pull flexible shaft is prolonged. The method comprises the following steps of: inserting the inner lining tube of a pressure hose inserted into a sleeve joint and placing the sleeve joint onto a buckling-riveting mold; starting a hydraulic system, making an external mold axially move to force an elastic mold pressing element set, so that mold pressing elements are radically retracted to rivet and press the sleeve joint; and changing a direction, making a piston rod of an oil cylinder drive the external mold to reversely move, expanding the elastic mold pressing element set and pulling a core rod out. The buckling-riveting equipment comprises the hydraulic system, the buckling-riveting mold, a stander and the like, wherein the buckling-riveting mold is provided with the external mold with an inner taper hole and the elastic mold pressing sheet set formed into an outer conical surface; springs are arranged between every two mold sleeves; the elastic mold pressing element set is in contact with a stopper; the piston rod of the oil cylinder is connected with the external mold; and a core pulling device comprising a cylinder and the core rod is arranged axially.

Owner:LIUZHOU JINYUAN MACHINERY MFG

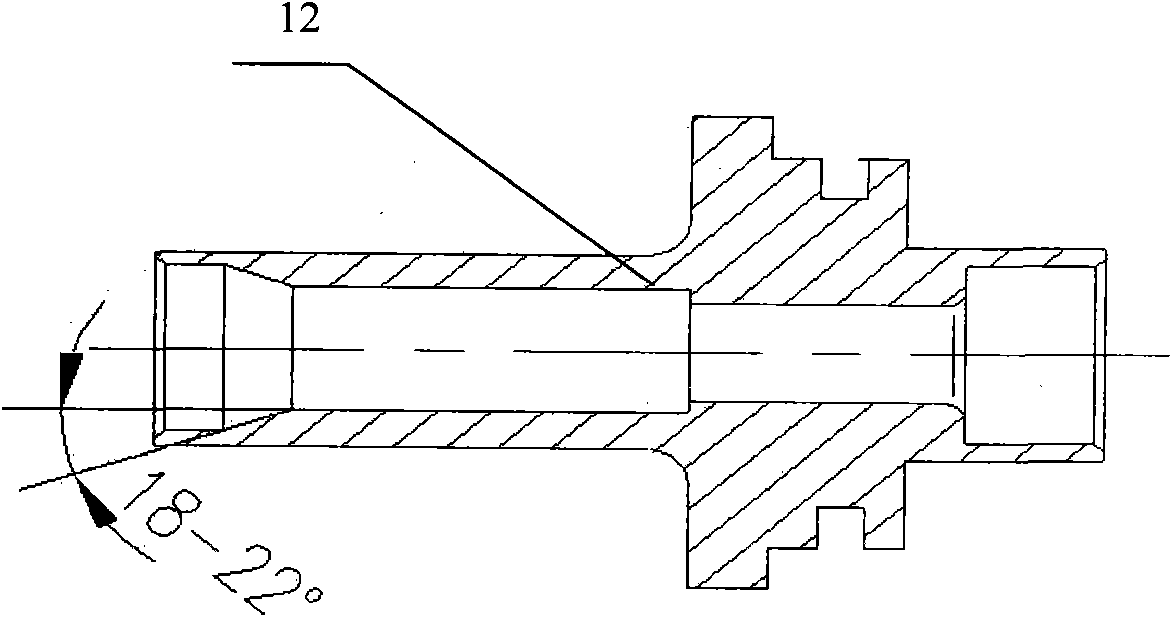

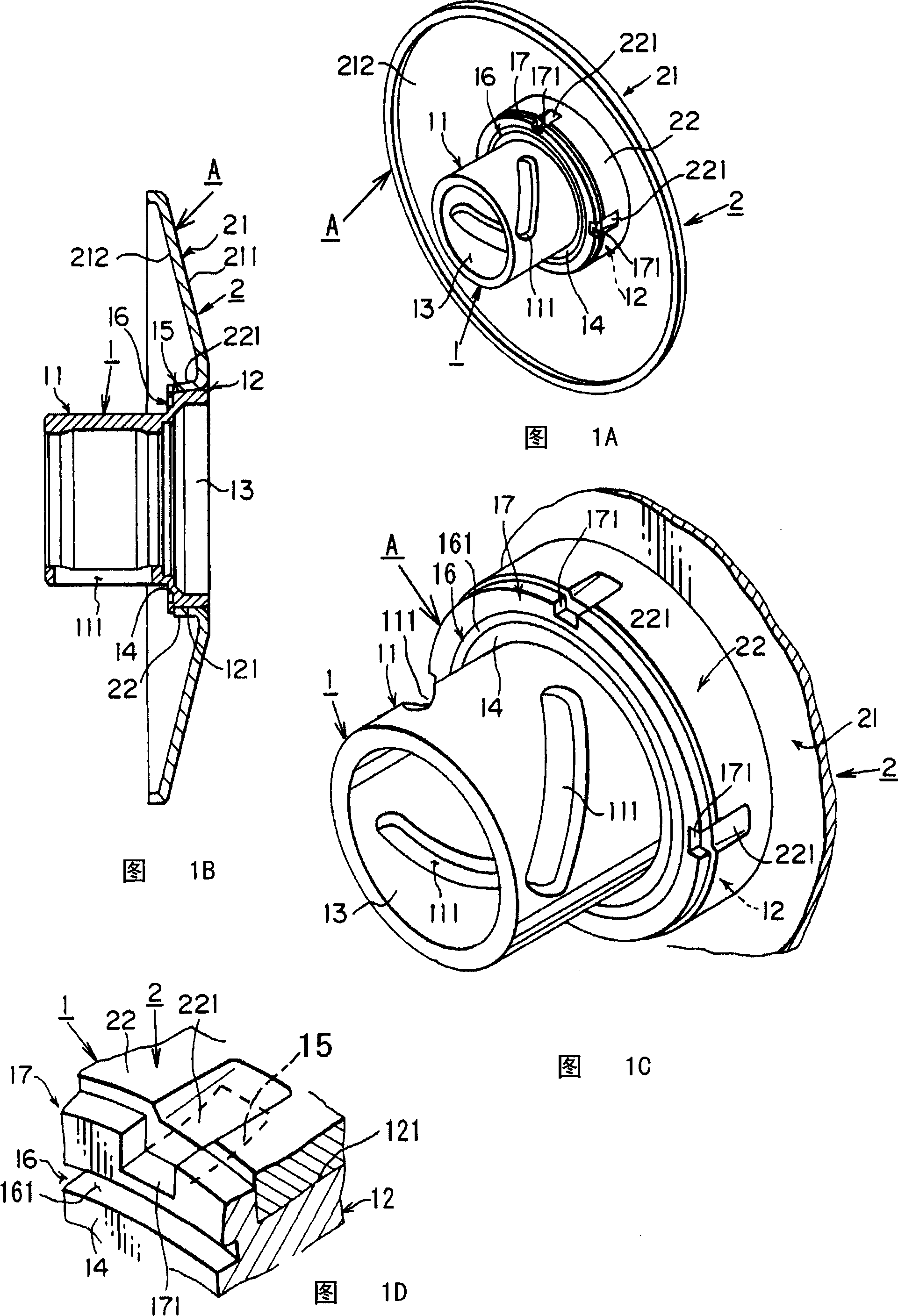

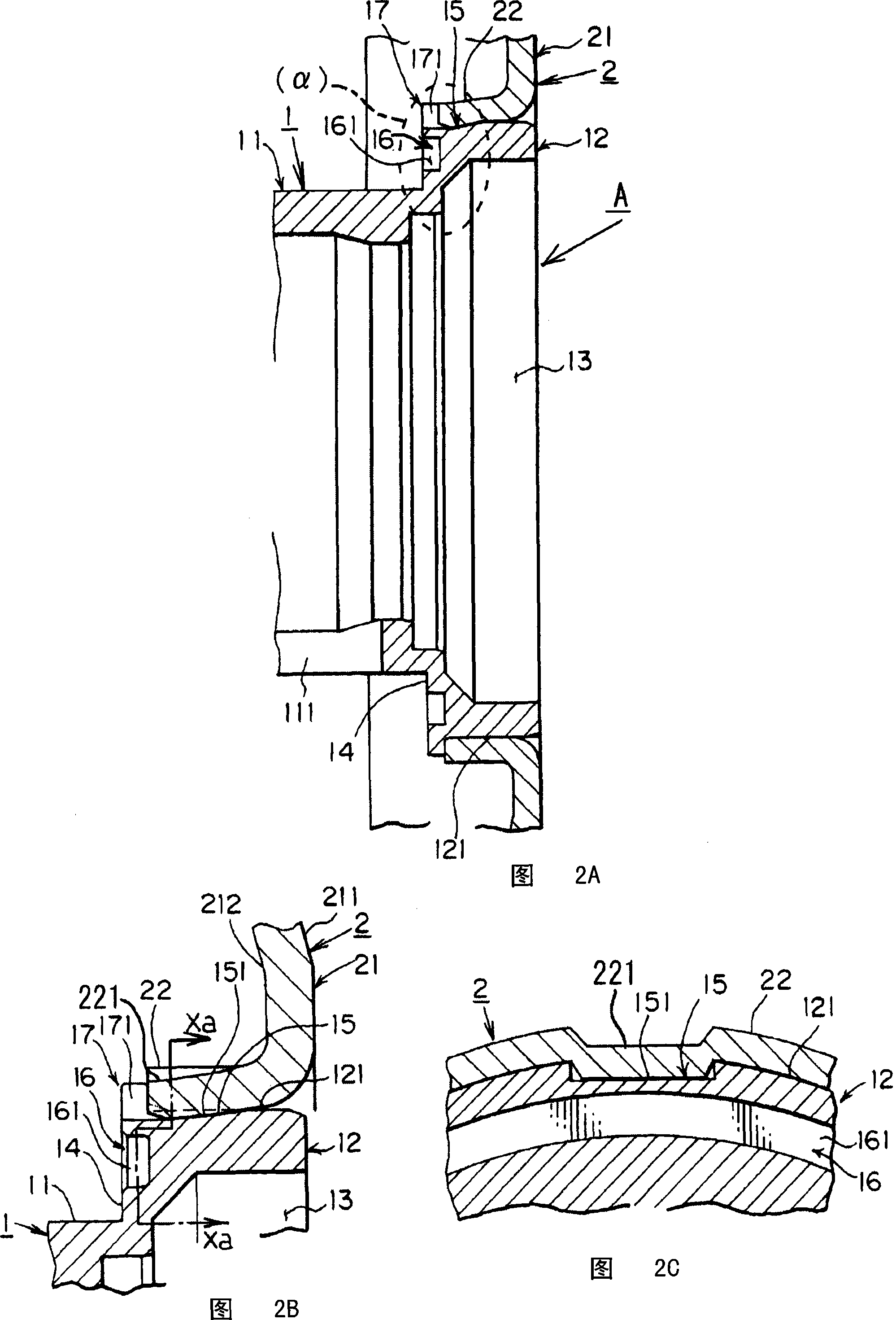

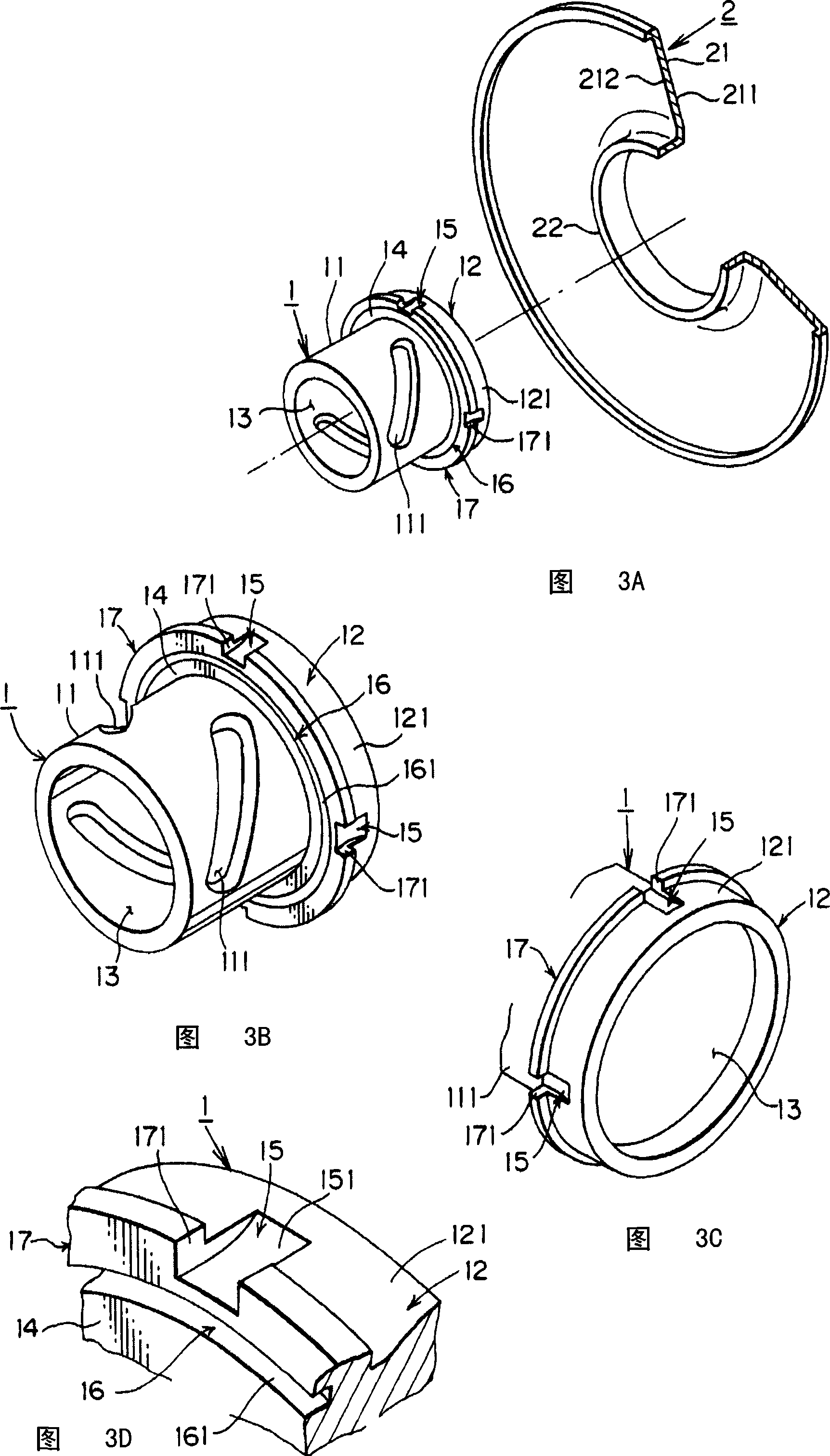

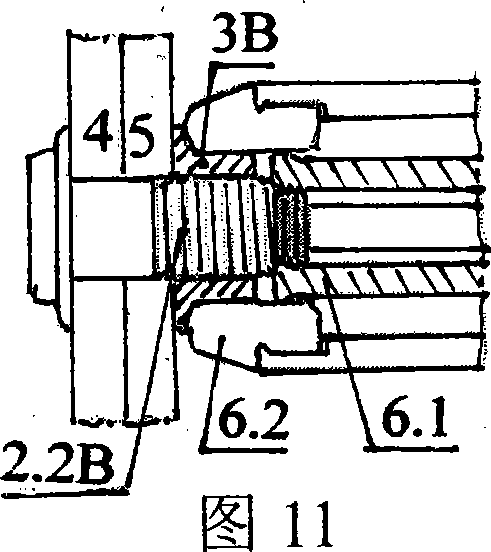

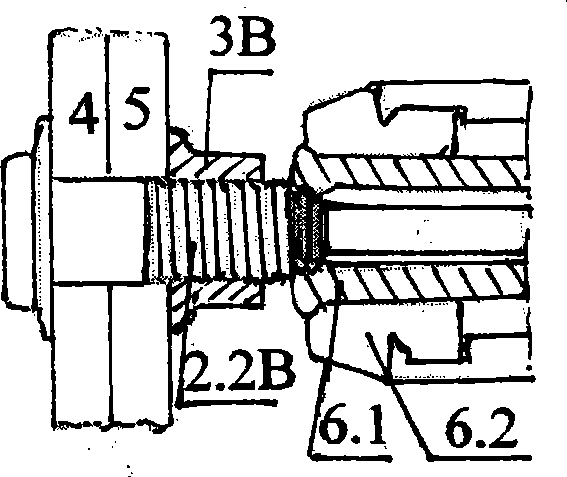

Belt wheel for V-belt type automatic variable speed gear

A V-belt automatic shift pulley is provided, pulley surface can be mounted simply and quickly with respect to a hub shaft, and the combination is firm. Parts (1) forming the hub element comprise a hub shaft (11), a large-diameter circular cylinder part (12) disposed at one side terminal in the axial direction of the hub shaft (11), a step surface (14) formed between the hub shaft (11) and the large-diameter circular cylinder part (12), a groove formed in an axial direction at the peripheral lateral surface of the large-diameter circular cylinder part (12). A movable pulley surface (2) is formed, and a circular cylinder combination portion (22) is formed at the diameter center of the pulley surface (21). The circular cylinder combination portion (22) is inserted by the large-diameter circular cylinder part (12), and the wall shape of the circular cylinder combination portion (22) along said groove portion is riveted.

Owner:YAMADA SEISAKUSHO KK

Anti-loose self-locking nut and production method thereof

The invention relates to the field of manufacturing of automobile parts, in particular to an anti-loose self-locking nut simple in structure, capable of effectively preventing the nut from falling off, convenient to mount and dismount and capable of being reused. The anti-loose self-locking nut comprises a nut body and a nut collar rotatably arranged at the lower end of the nut body, a threaded hole is penetratingly arranged in the middle of the nut body, a stepped groove is formed in the upper end of the nut body, a spring steel piece is placed in the stepped groove, a bending portion used for clamping the spring steel piece in the stepped groove is arranged on the upper portion of the stepped groove, the spring steel piece comprises an annular piece and more than two clamping pieces evenly arranged at the upper end of the annular piece and protruding along the radial direction, the annular piece is formed by a tilt surface rotating and scanning around the axis of the threaded hole, the clamping piece protrudes inwardly to extend into the threaded hole of the nut body, and the extending length of the clamping piece is located between the inner diameter and outer diameter of the threaded hole. The invention further comprises a production method of the anti-loose self-locking nut.

Owner:QUANZHOU JINQI MACHINERY PARTS

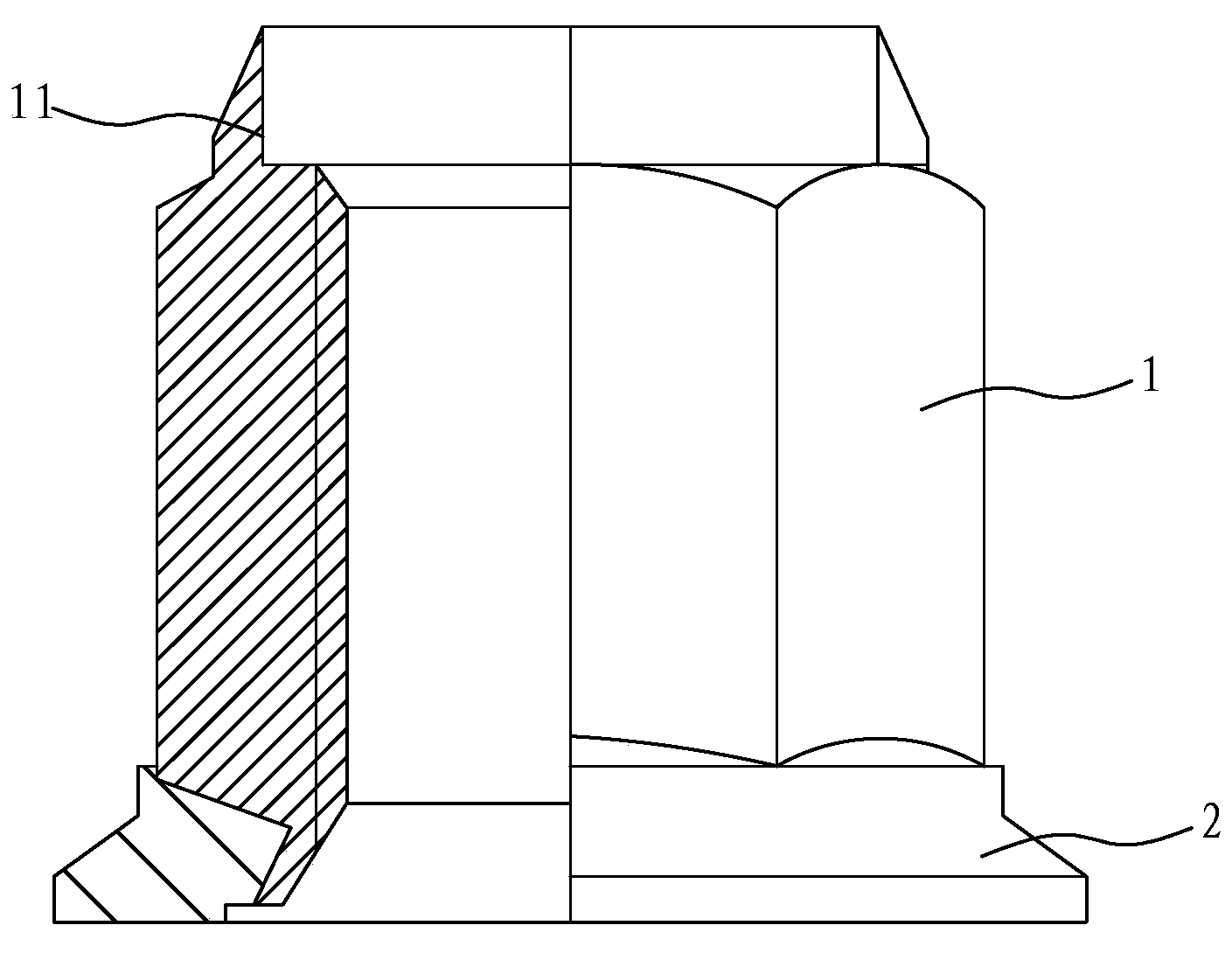

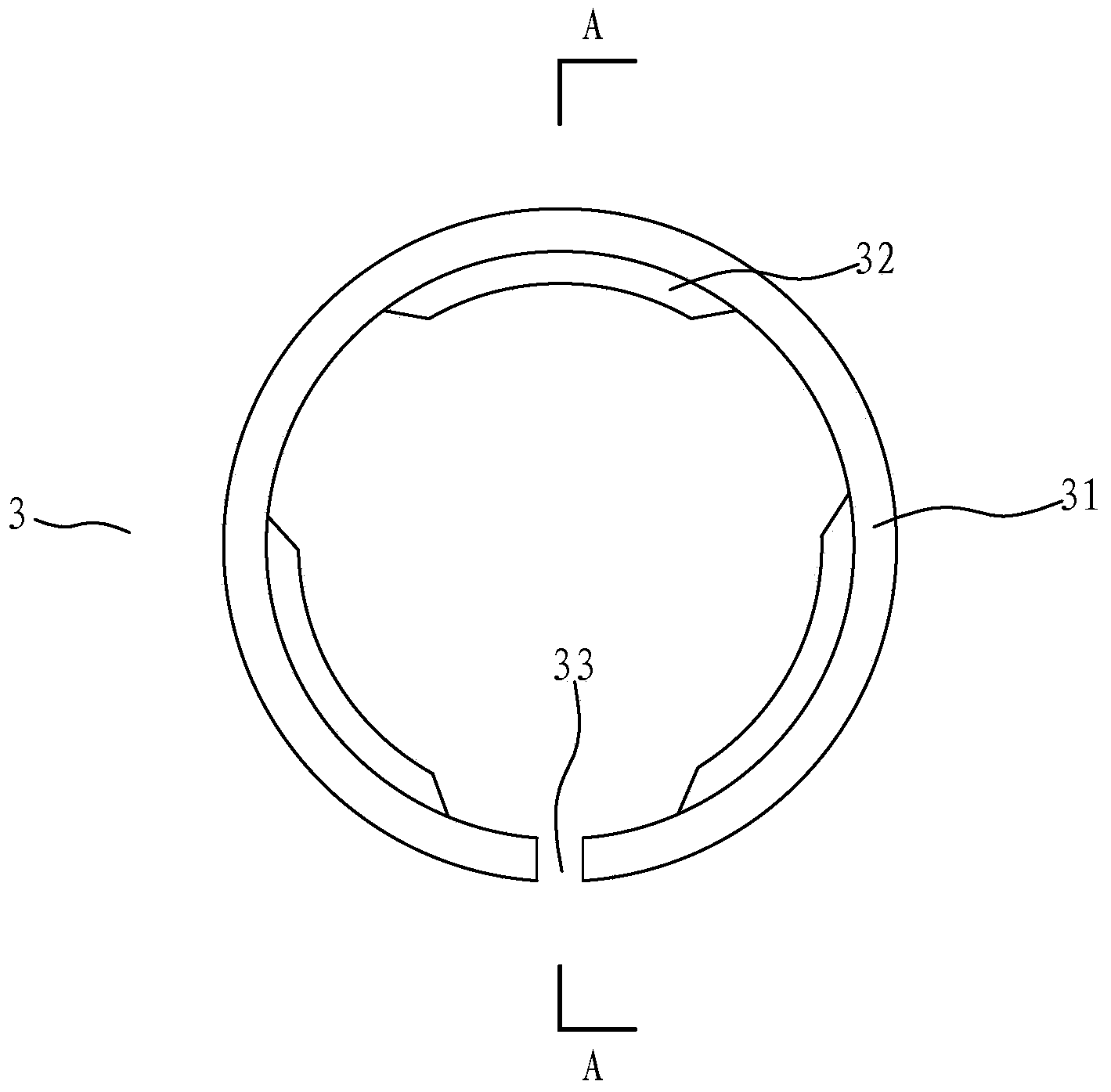

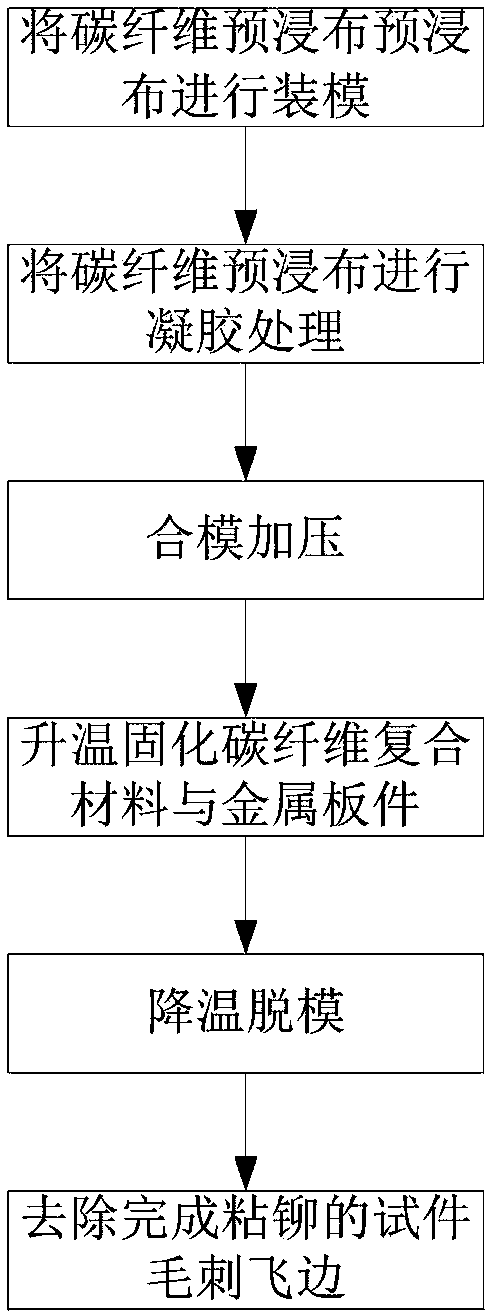

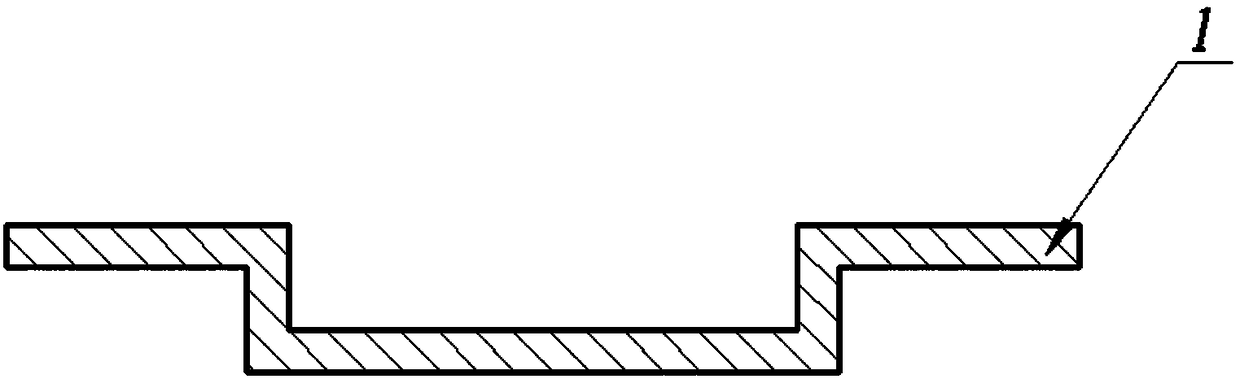

Integrated device and method for forming of carbon fiber composite material and sticky-riveting of carbon fiber composite material and metal sheet piece

PendingCN108297458ALow investment costReduced production footprintDomestic articlesWeight reductionCarbon fiber compositeBond properties

The invention relates to an integrated device and method for forming of a carbon fiber composite material and sticky-riveting of the carbon fiber composite material and a metal sheet piece, and belongs to the technical field of composite riveting. The technical problems that gaps exist in connecting of the composite material and a metal material, the composite material and an adhesive layer are damaged due to riveting, and the technology procedure is complicated exiting in the prior art are solved. The carbon fiber composite material and metal material sticky-riveting method applying the device comprises the following steps that a carbon fiber prepreg is subjected to die-filling; the carbon fiber prepreg is subjected to gelling; the gelled carbon fiber prepreg and a metal sheet are subjected to die-closing and pressurizing; the carbon fiber prepreg and the metal sheet piece are subjected to heating curing; cooling and die-releasing are conducted; and burrs and flashings at the edge parts when a carbon fiber composite material plate and a metal sheet sticky-riveting test piece are formed are removed. According to the integrated device and method for forming of the carbon fiber composite material and sticky-riveting of the carbon fiber composite material and the metal sheet piece, the effect that bonding can be completed while the carbon fiber composite material is subjected to die-pressing forming is achieved; and the bonding property is effectively improved, and the bonding strength is improved.

Owner:JILIN UNIV

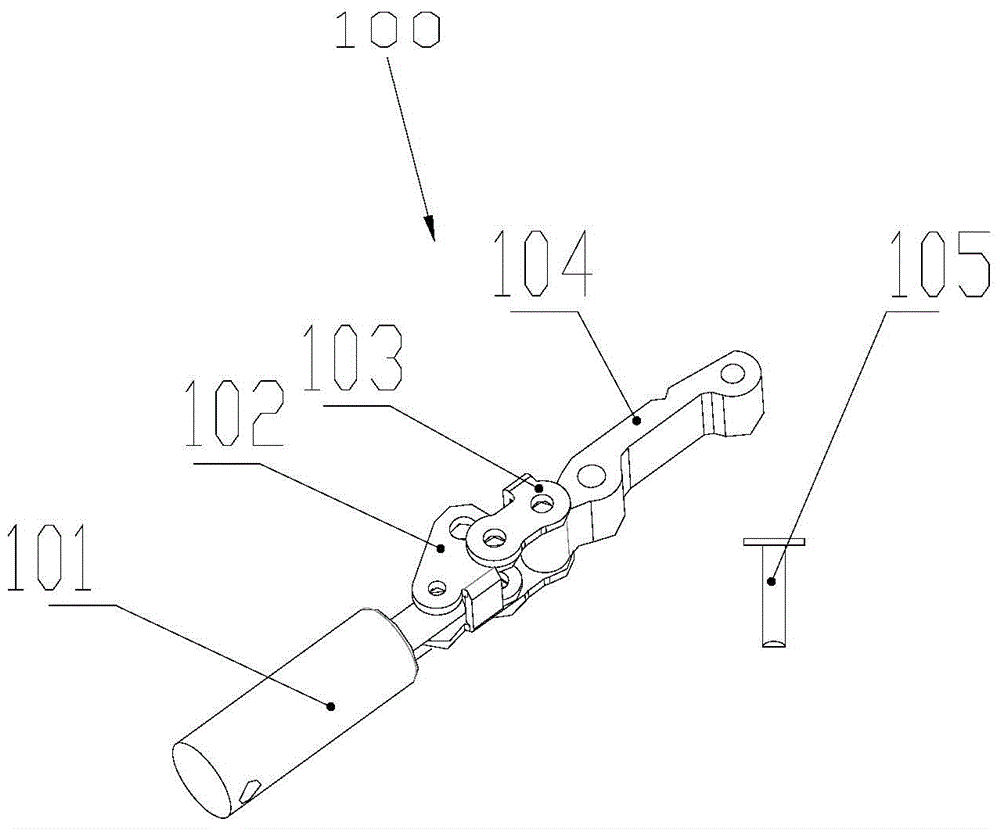

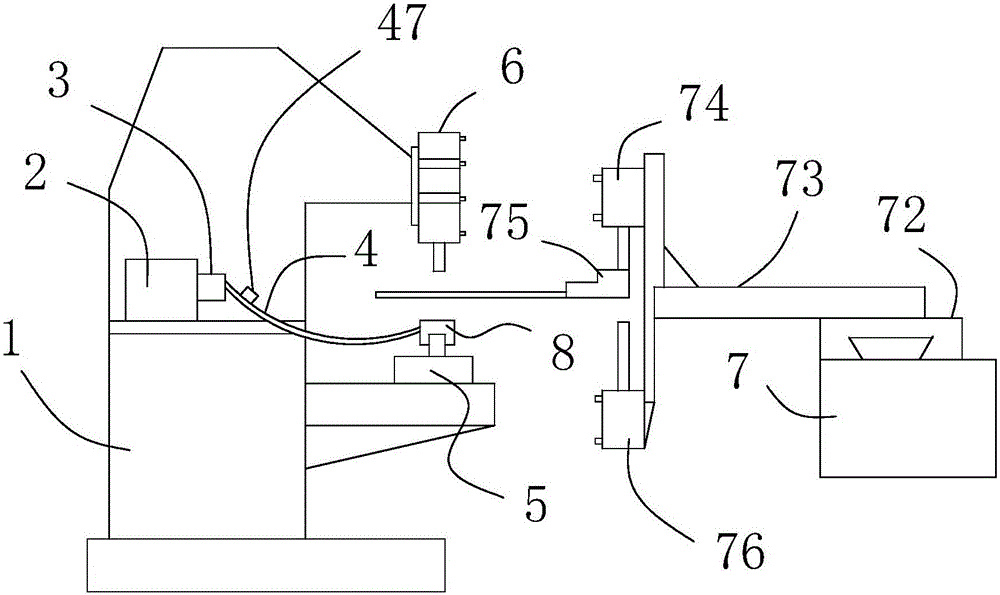

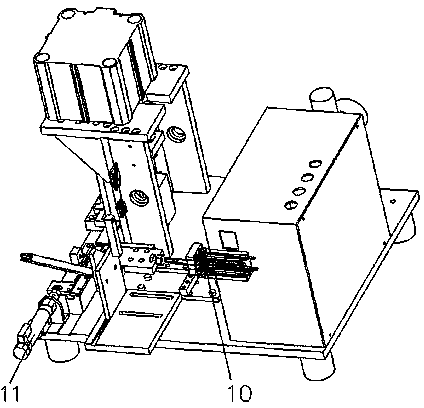

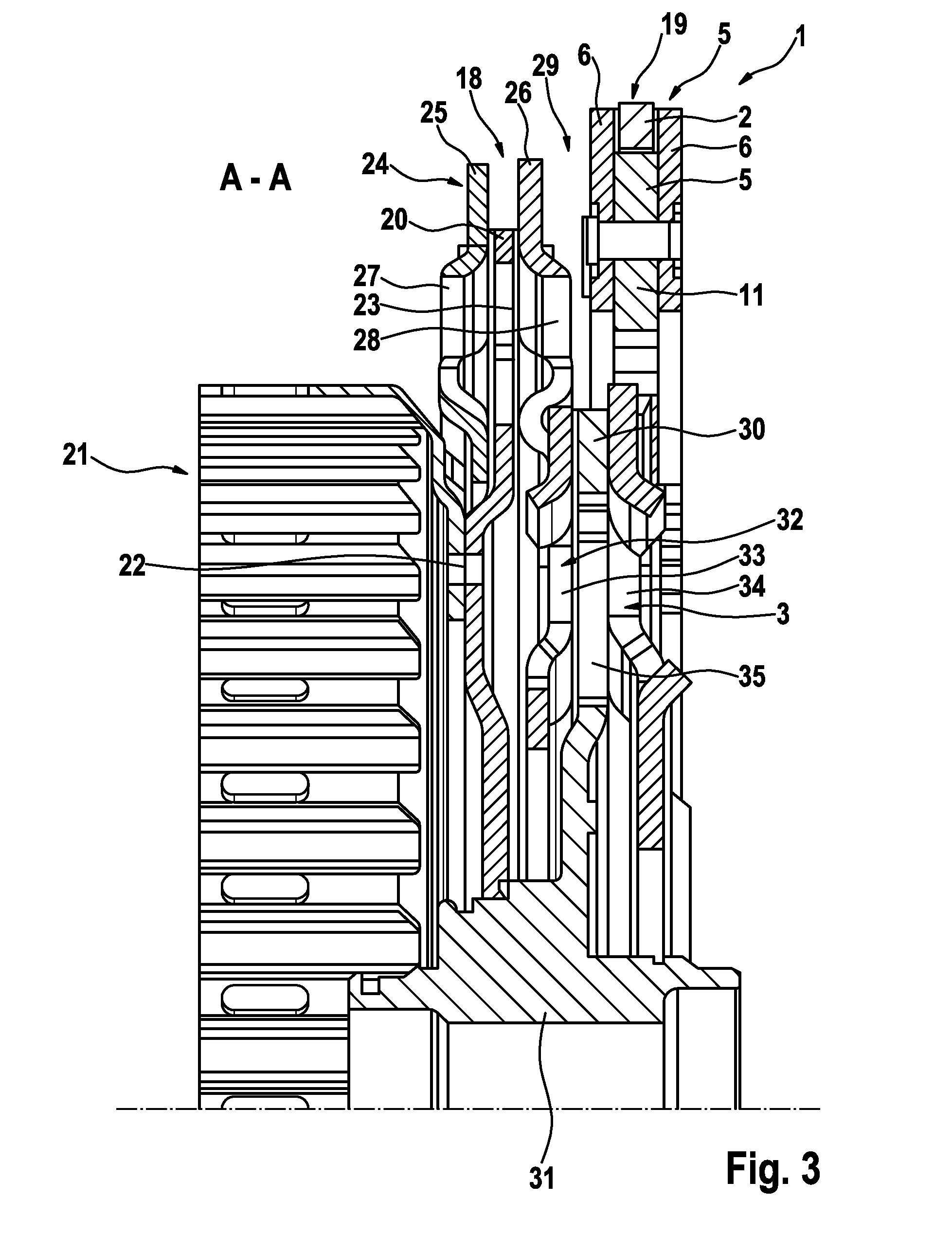

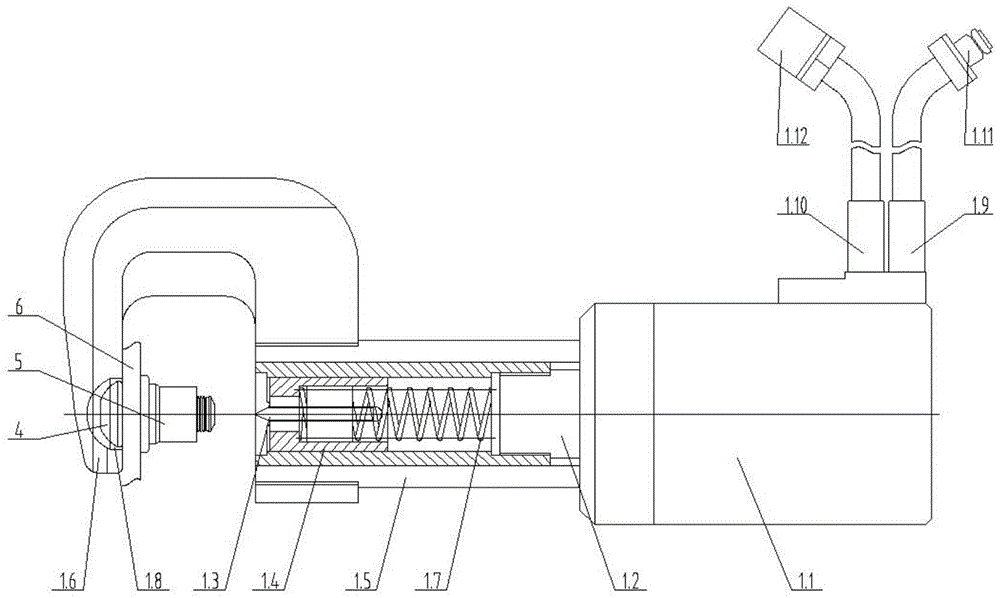

System and method for assembling telescopic rod module in hydraulic hinge

The invention is applicable to the technical field of hydraulic hinge production, and discloses a system and a method for assembling a telescopic rod module in a hydraulic hinge. The system comprises a supporting rack, wherein a feeding workstation, a riveting workstation and a fixture releasing workstation are arranged on the supporting rack; a feeding fixture module is arranged at the feeding workstation; a riveting module is arranged at the riveting workstation; a fixture releasing module is arranged at the fixture releasing workstation; a discharging module and a transferring module are further arranged on the supporting rack; the feeding fixture module is arranged on the transferring module. In the method, the system for assembling the telescopic rod module in the hydraulic hinge is used. The system and the method have the advantages of high degree of automation, high efficiency, low production cost and high product quality.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

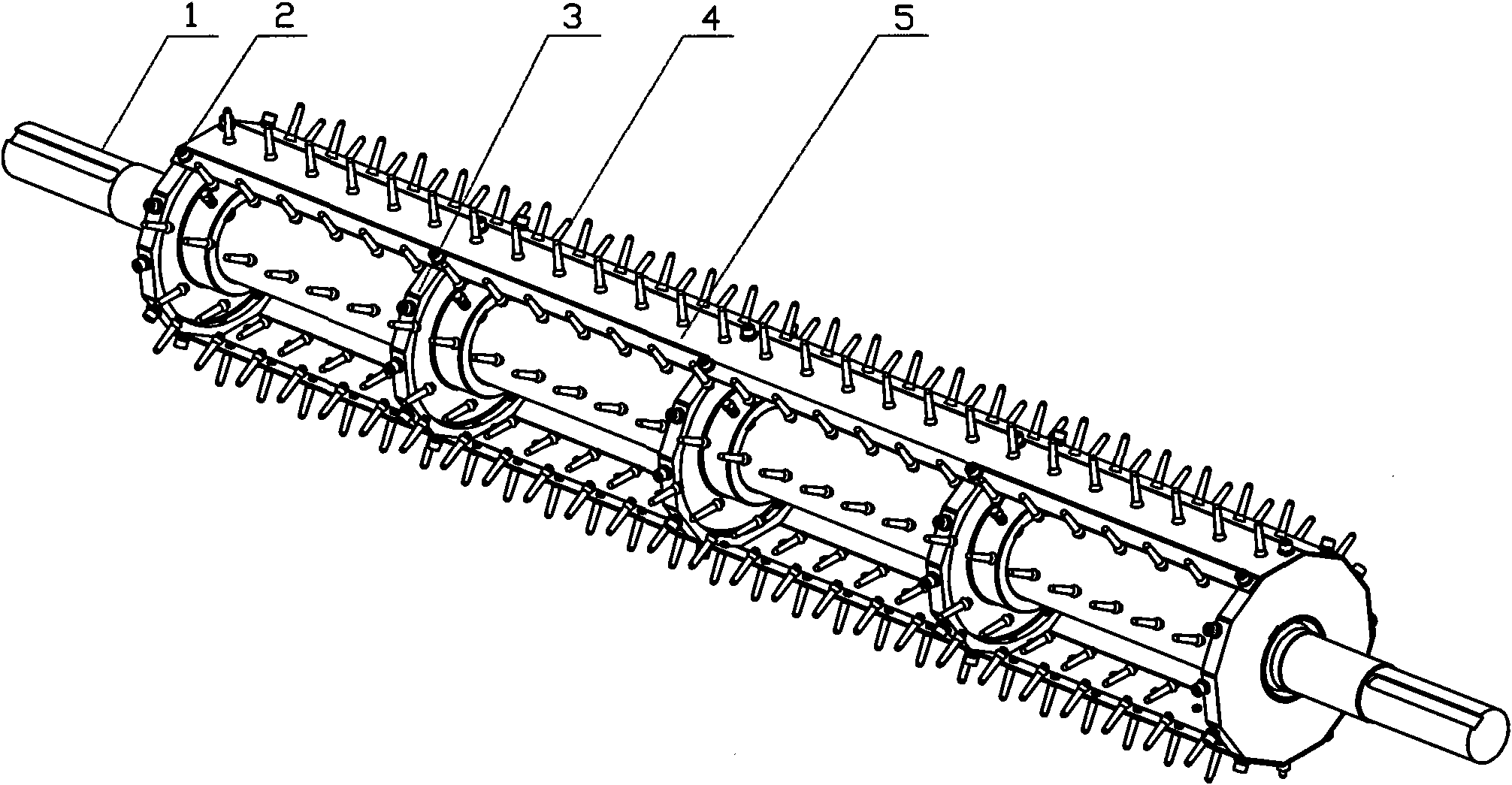

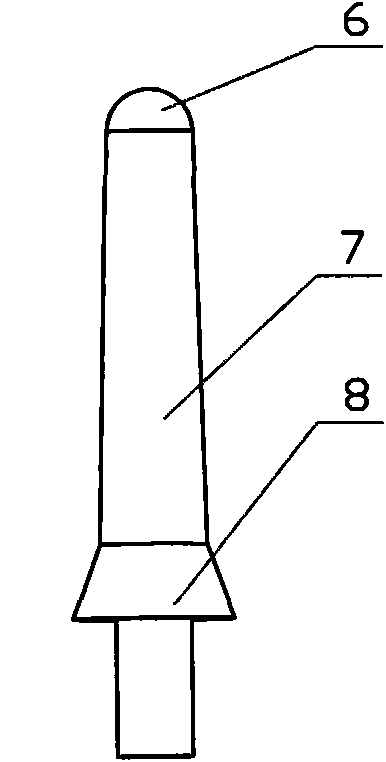

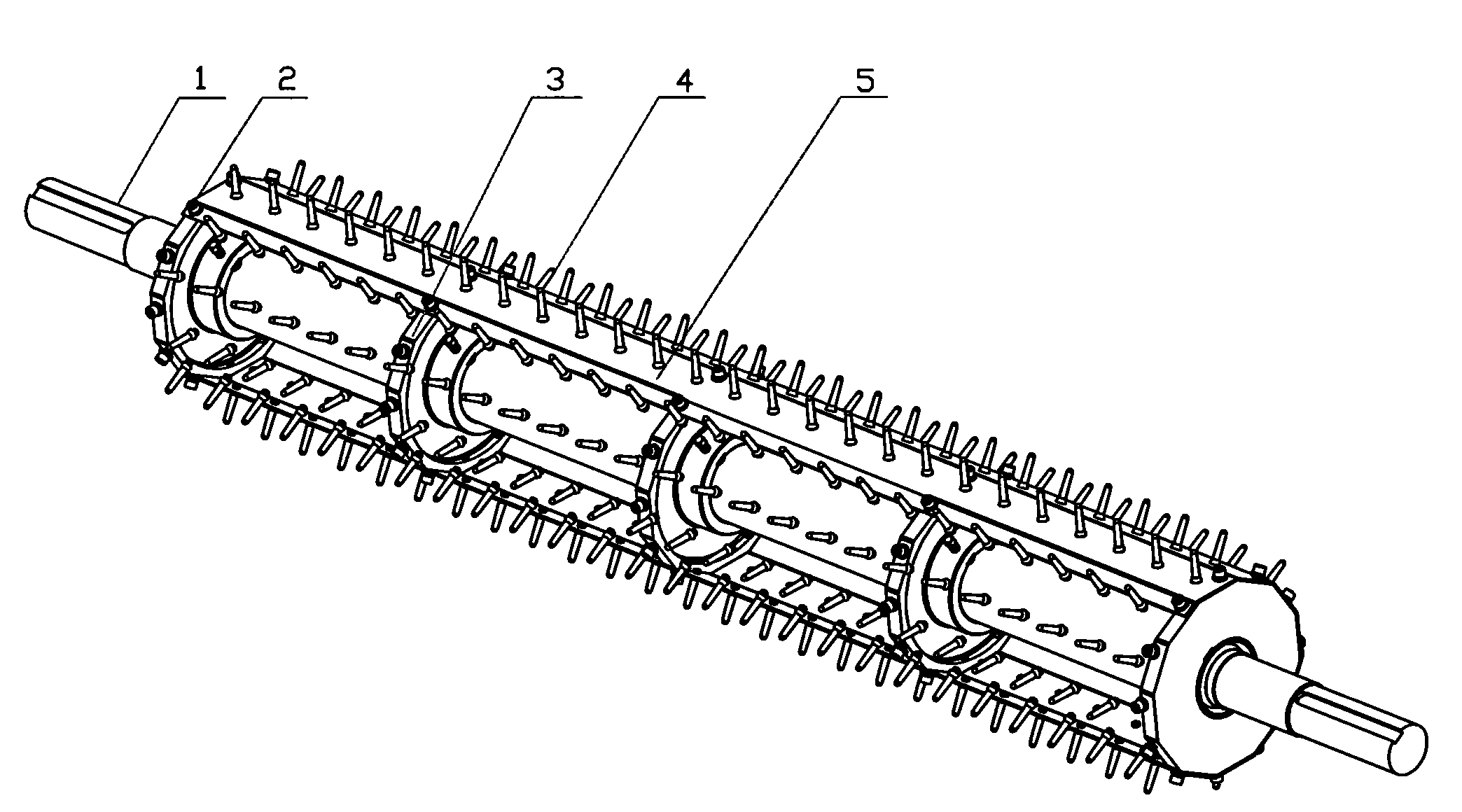

Barbed nail roller assembly

The invention discloses a barbed nail roller assembly which comprises a pipe shaft, a group of flanges and a wrapping plate, wherein the flanges are arranged along with axial direction of the pipe shaft and are coaxial with the pipe shaft; the wrapping plate is fixed on the flanges to form a cylinder; barbed nails are uniformly arranged on the wrapping plate; each flange has a regular pyramid structure; the wrapping plate comprises a plurality of split bodies which are exactly divided by the arris number of the regular pyramid; the split blocks are used for forming the side surface of the cylinder; and the barbed nails are spherical crown tapered barbed rivets. The barbed nail roller assembly has high motion precision, high reliability and long service life.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

Bobtail tension rivet and riveting method

The invention discloses a short-tail tension rivet and a riveting method thereof. The tension rivet consists of a rivet head, a rivet rod and a sleeve ring. The rivet rod is provided with a feed rod section, a ring groove section which is extruded and matched with the sleeve ring, and a short and thin ring groove section clamped by a riveting device collet from the front to the back. Compared to the prior tension rivet, a separating groove on the rear end of the tension rivet and a groove section tension rod are removed, so that the rivet rod is shortened and the material is saved by one third; when the rivet is riveted, the separating groove can not be broken; the riveting steps are reduced from the prior four steps to three steps, and the riveting is accelerated; and riveting can not cause impact, and the assembling place has no noise. If the prior same riveting device and the riveting stroke are adopted, the length of the ring groove section or a thread section can be lengthened correspondingly, so that rivets with the same specification can be applied to multiple riveting thicknesses, and the range of application is widen. The rear end of an inner hole of the sleeve ring for thread riveting is provided with a small section of screw thread; before the start of the riveting device, the sleeve ring is rotated manually and moved advance on the screw thread section, and positioned and sleeved on the screw thread section, so that when the riveting device is operated by operating staff for next step, the sleeve ring is not required to be held manually, and further the rivet is riveted relaxedly, conveniently and quickly. The screw thread and the groove riveting can be selected according to occasions.

Owner:CRRC MEISHAN

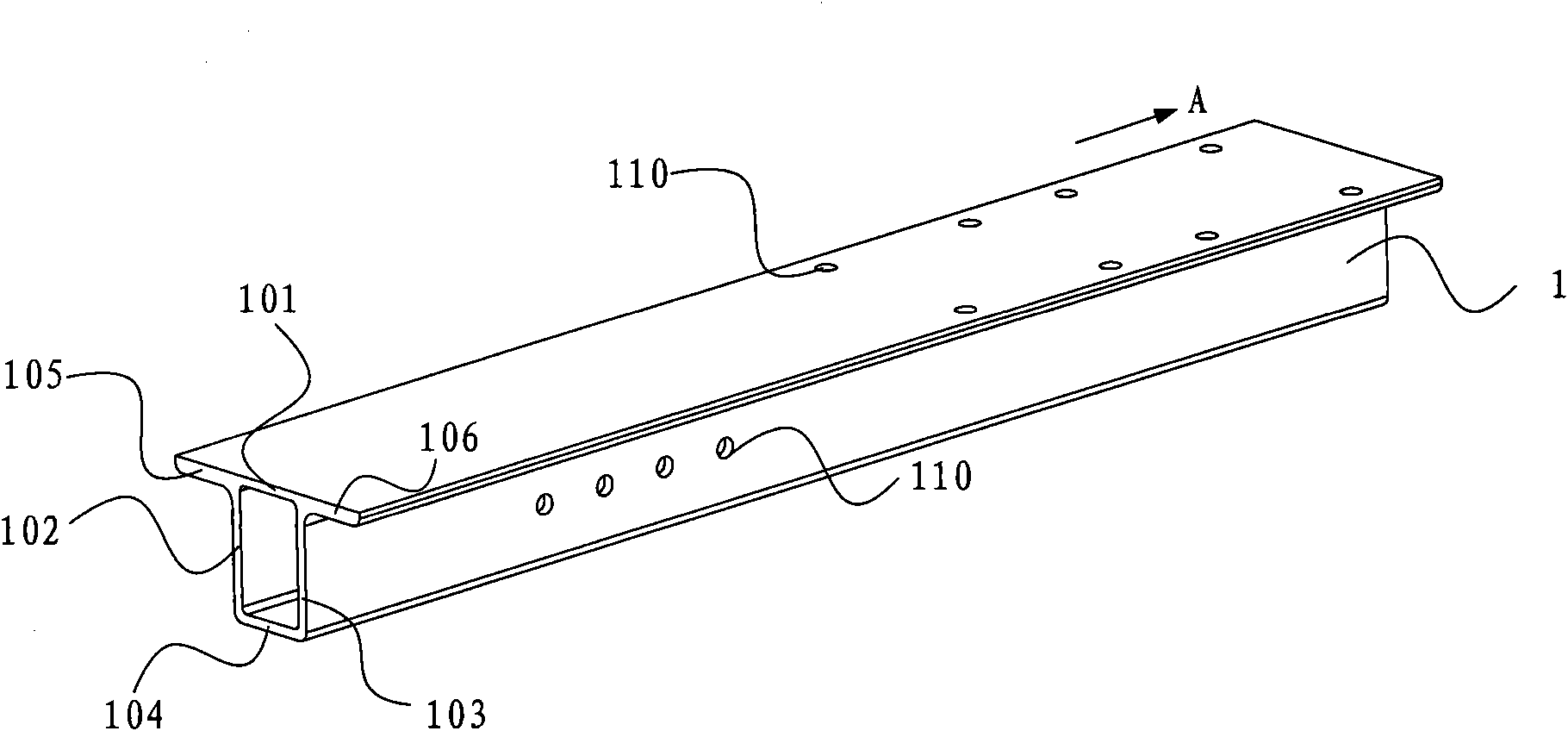

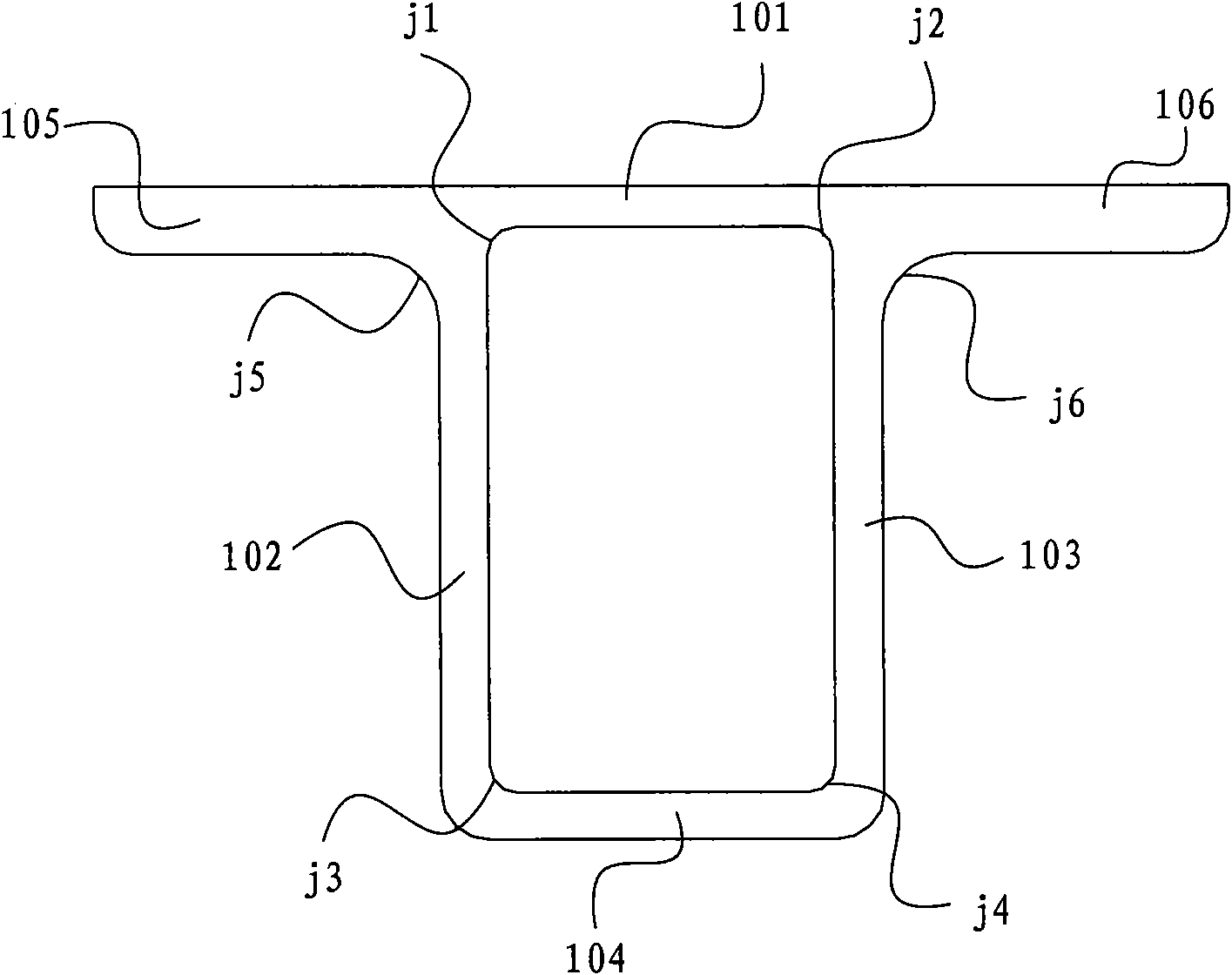

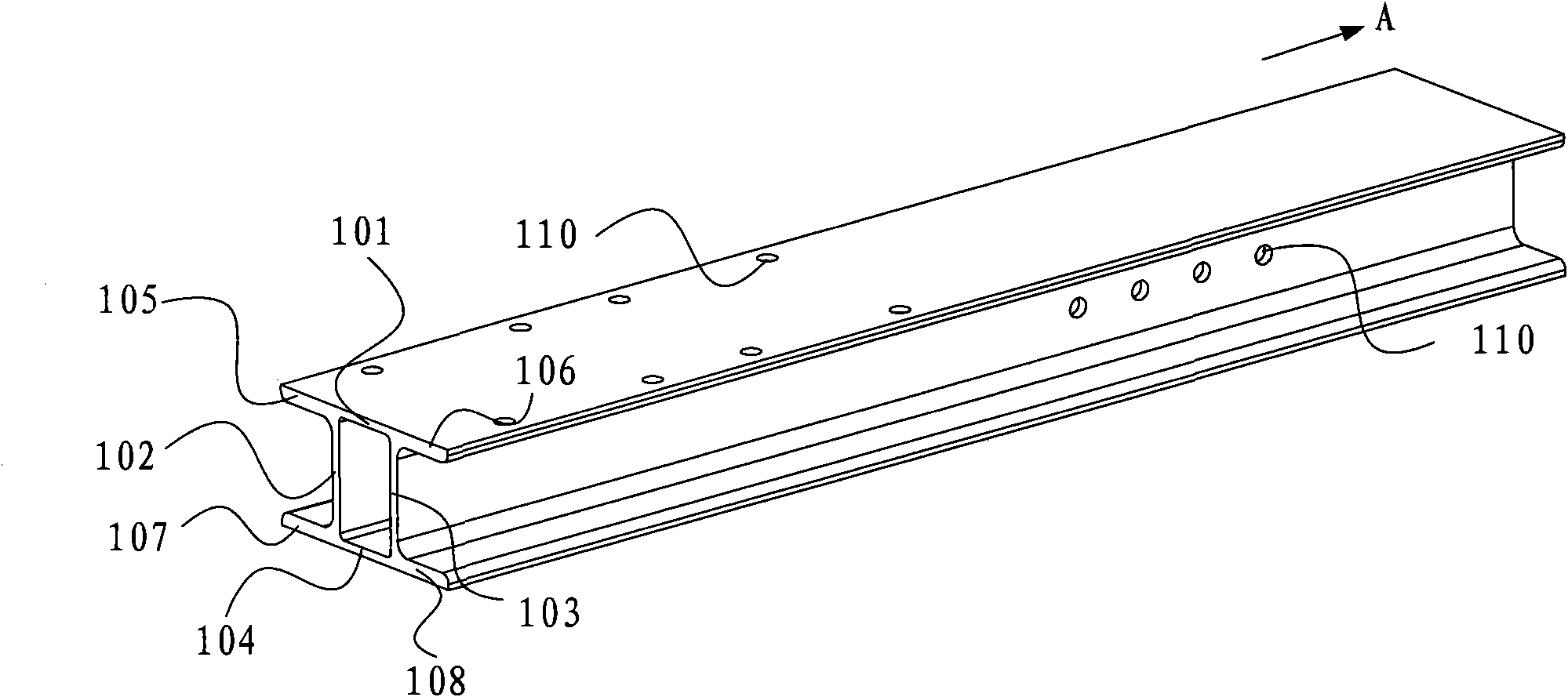

Longitudinal beam structure for commercial vehicle

The invention provides a longitudinal beam structure for a commercial vehicle. A vehicle frame longitudinal beam is in a groove-shaped structure and is divided into an inner layer and an outer layer integrally formed by wrapping, the inner layer structure of the vehicle frame longitudinal beam is made of an aluminum alloy material to form a main beam, the outer layer of the vehicle frame longitudinal beam is made of steel, the steel structure of the outer layer is divided into an upper outer beam and a lower outer beam which are vertically and correspondingly arranged with a gap therebetween,the upper outer beam and the lower outer beam bend inward, the cross sections of the upper outer beam and lower outer beam are in 'L' shapes, and the 'L'-shaped structures of the upper outer beam andlower outer beam wrap the inner layer structure made of the aluminum alloy material and are integrally riveted with the inner layer structure made of the aluminum alloy material. The longitudinal beamstructure for the commercial vehicle has the advantages that a form of the combination of steel and aluminum is adopted, on the basis of meeting the intensity of a vehicle frame, the weight of the vehicle frame is reduced, the aluminum alloy material serves as a main body material of the vehicle frame longitudinal beam, the outer side of the longitudinal beam is riveted with the steel outer beamsin order to improve the intensity of the vehicle frame, and the thickness of the main beam made of the aluminum alloy material is greater than those of the upper outer beam and lower outer beam of the outer layer steel structure; the density of the aluminum alloy is less than that of a steel material, the density of the aluminum alloy is 2.8 g / cm<3>, the density of the steel material is 7.85 g / cm<3>, and therefore, the overall weight of the longitudinal beam is reduced.

Owner:DONGFENG SHENYU VEHICLE CO LTD

Manufacturing method and product of power connector with wires

InactiveCN102394410AQuick assemblySimplify the work processContact member manufacturingContact member cases/bases manufactureManufacturing cost reductionThin metal

The invention provides a manufacturing method and a manufacturing product of a power connector with wires. The method mainly comprises the following steps: first carrying out stamp molding on a plurality of hardware terminals by means of stamping on a thin metal material belt, and connecting the stamp molded hardware terminals with one another through combination parts to form a product material belt, wherein each hardware terminal is provided with at least one fixing ring, thus facilitating use of equipment such as a terminal crimping machine and the like to rivet connecting wires and continuously operating and being in favor of realizing automation; and then directly assembling the riveted hardware terminals and the connecting wires into an insulator or manufacturing the power connector with wires by means of embedding injection molding. By adopting the manufacturing method provided by the invention, while the production process and flow of the connectors are simplified, the reliability and production efficiency of the product are also improved, and the manufacturing cost is reduced at the same time.

Owner:SHENZHEN ZHITAI ELECTRONICS

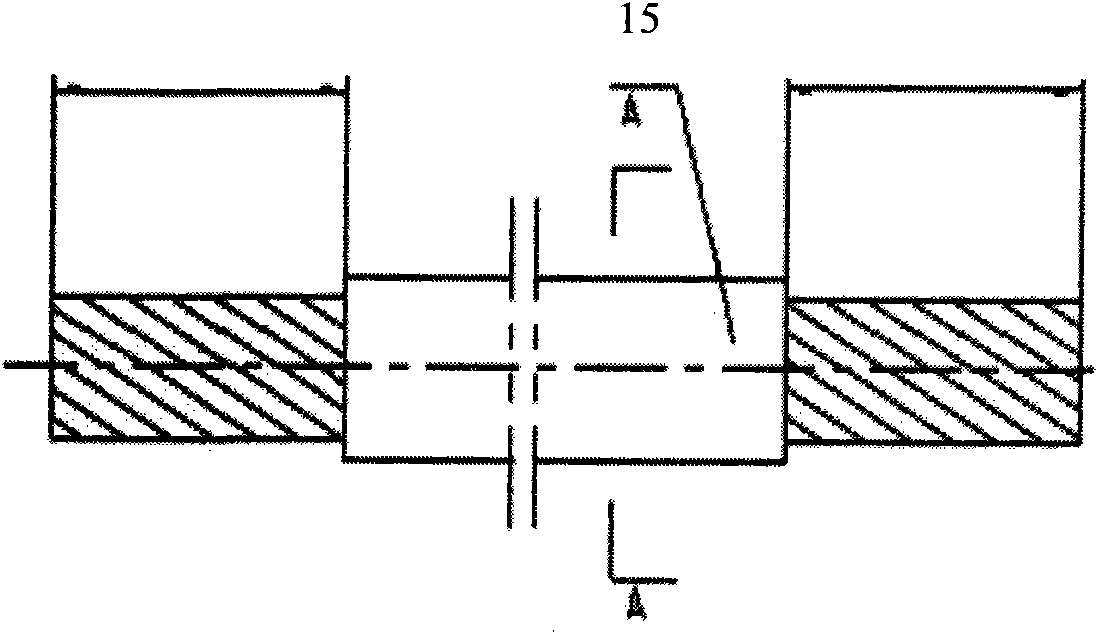

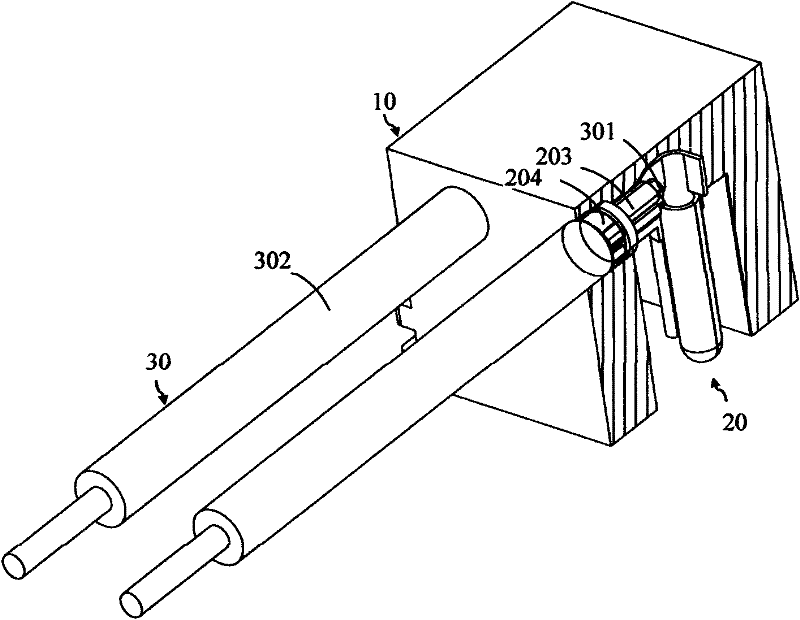

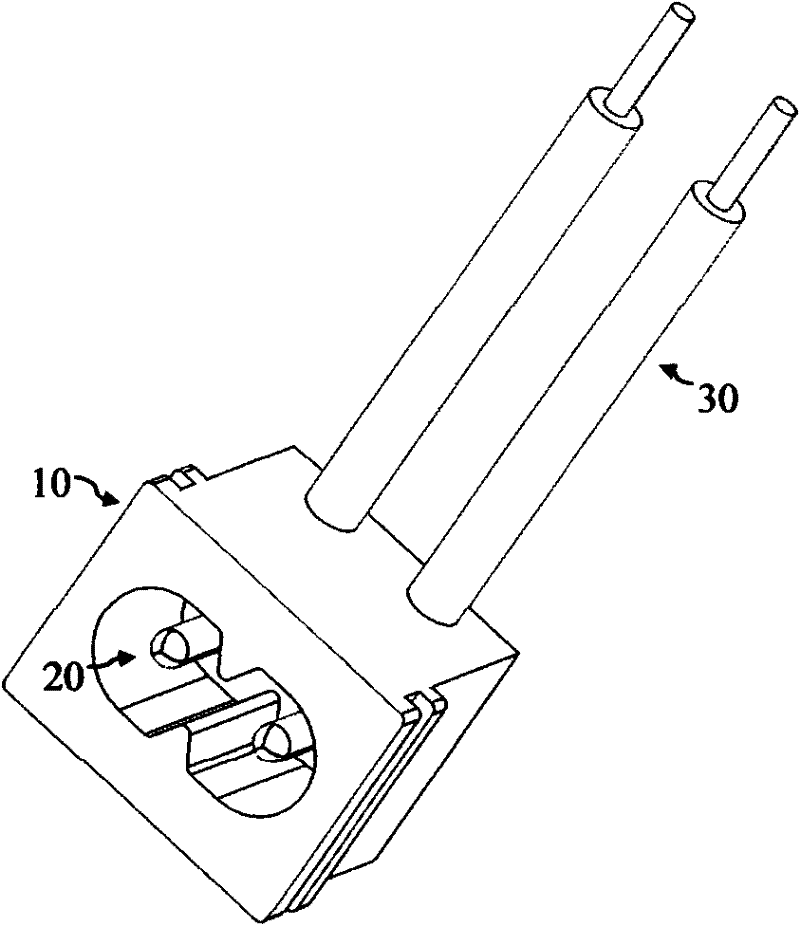

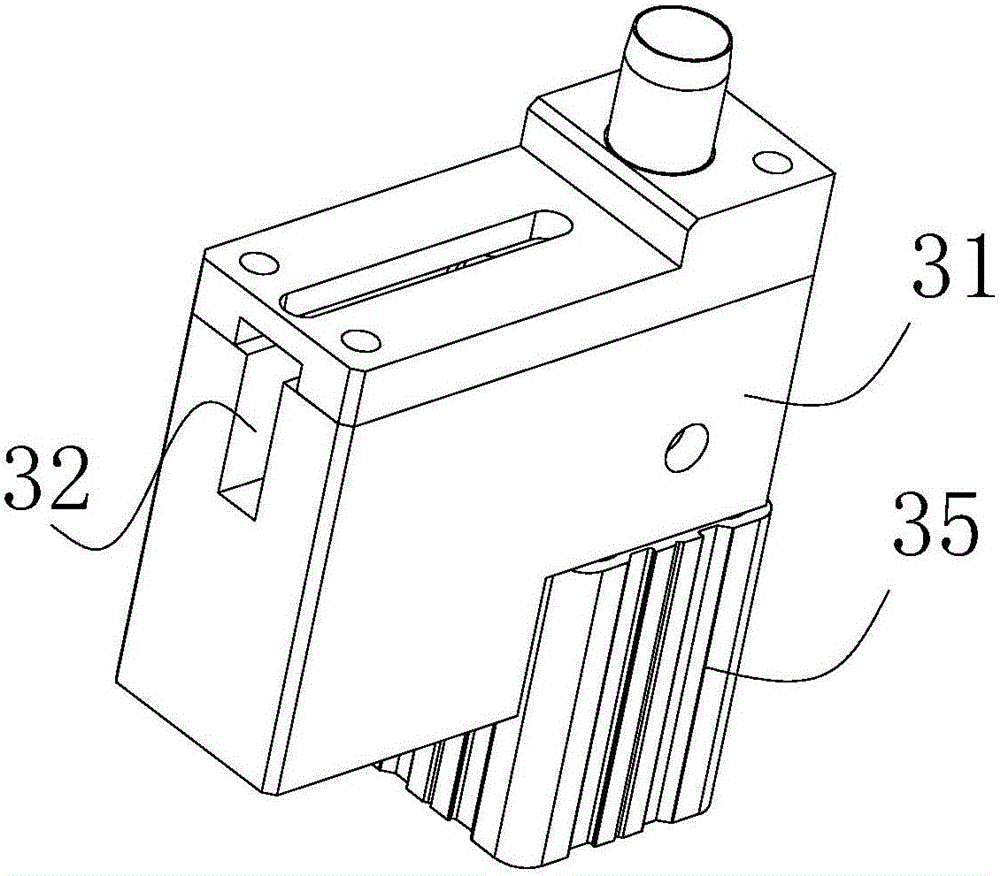

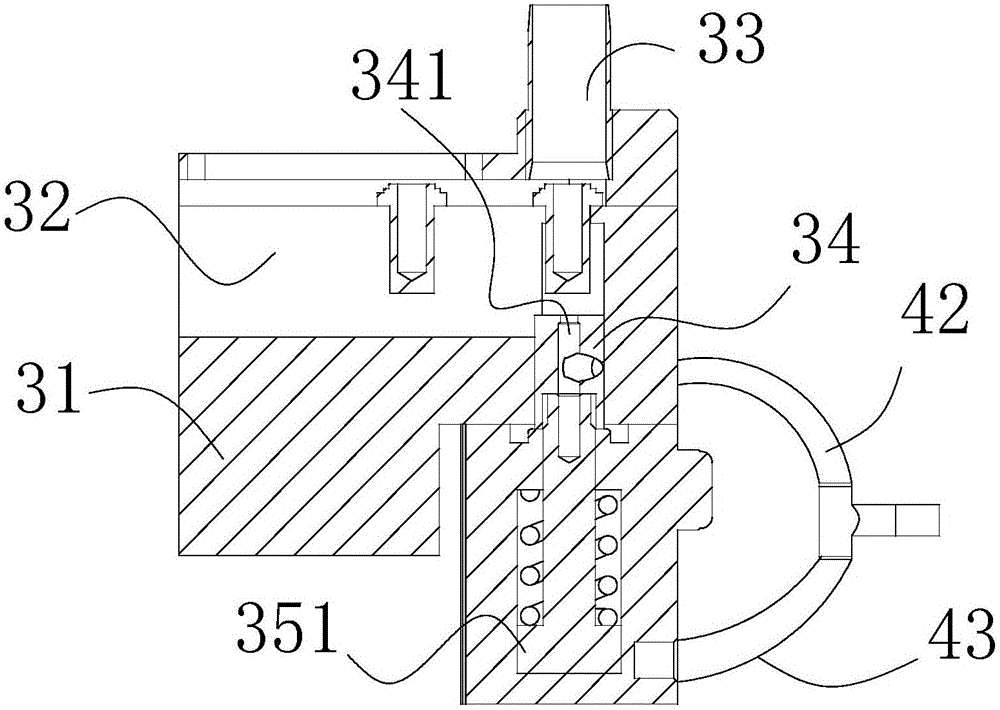

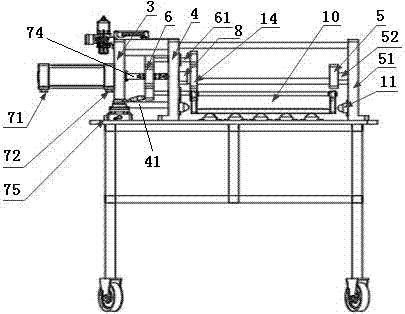

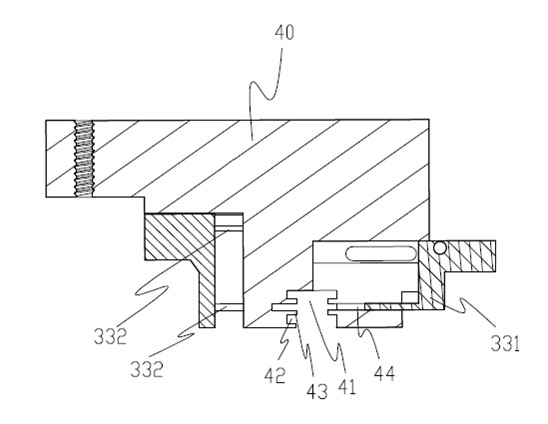

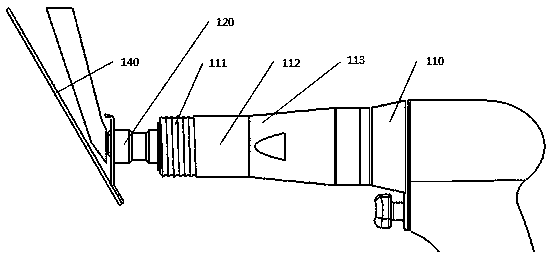

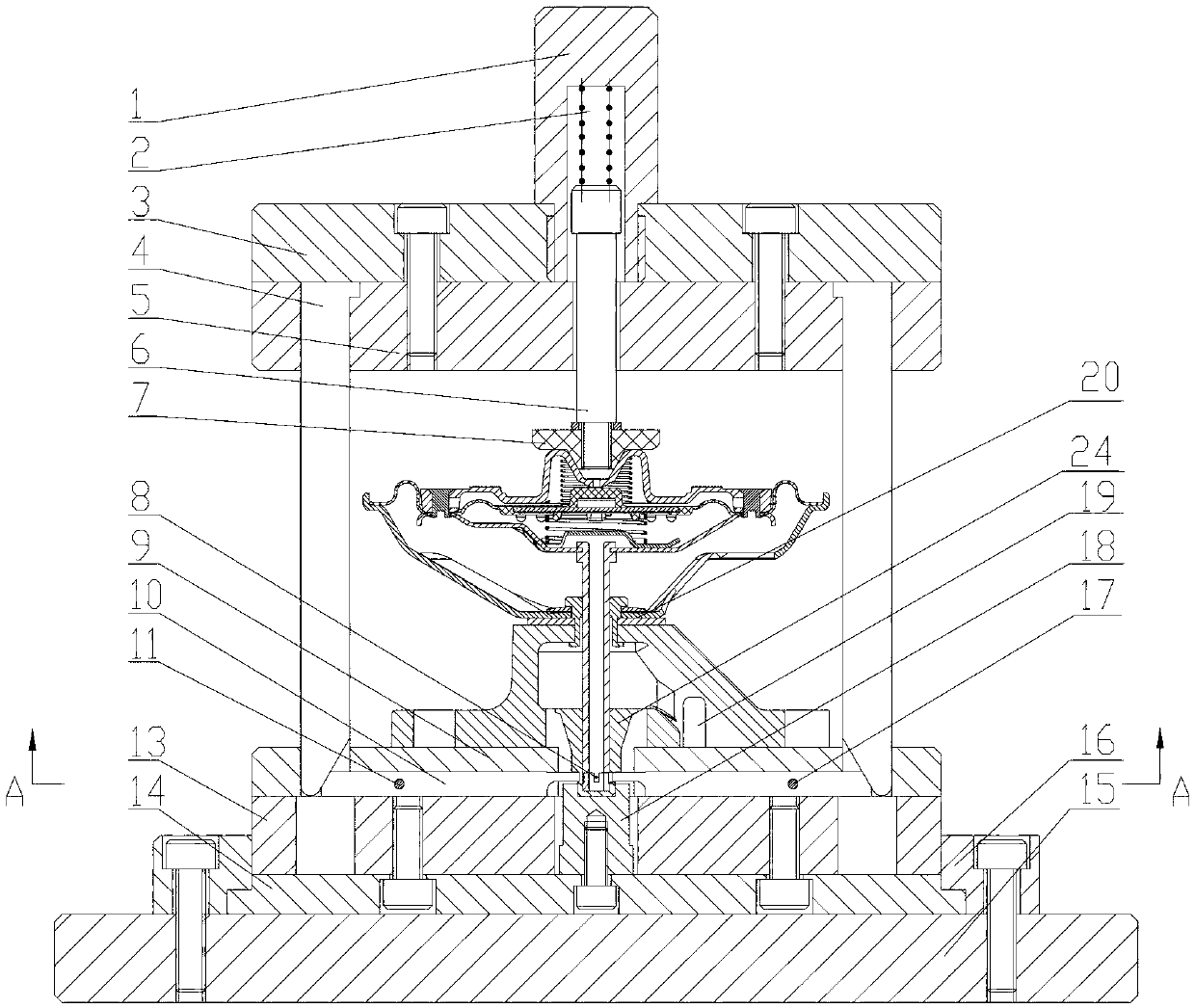

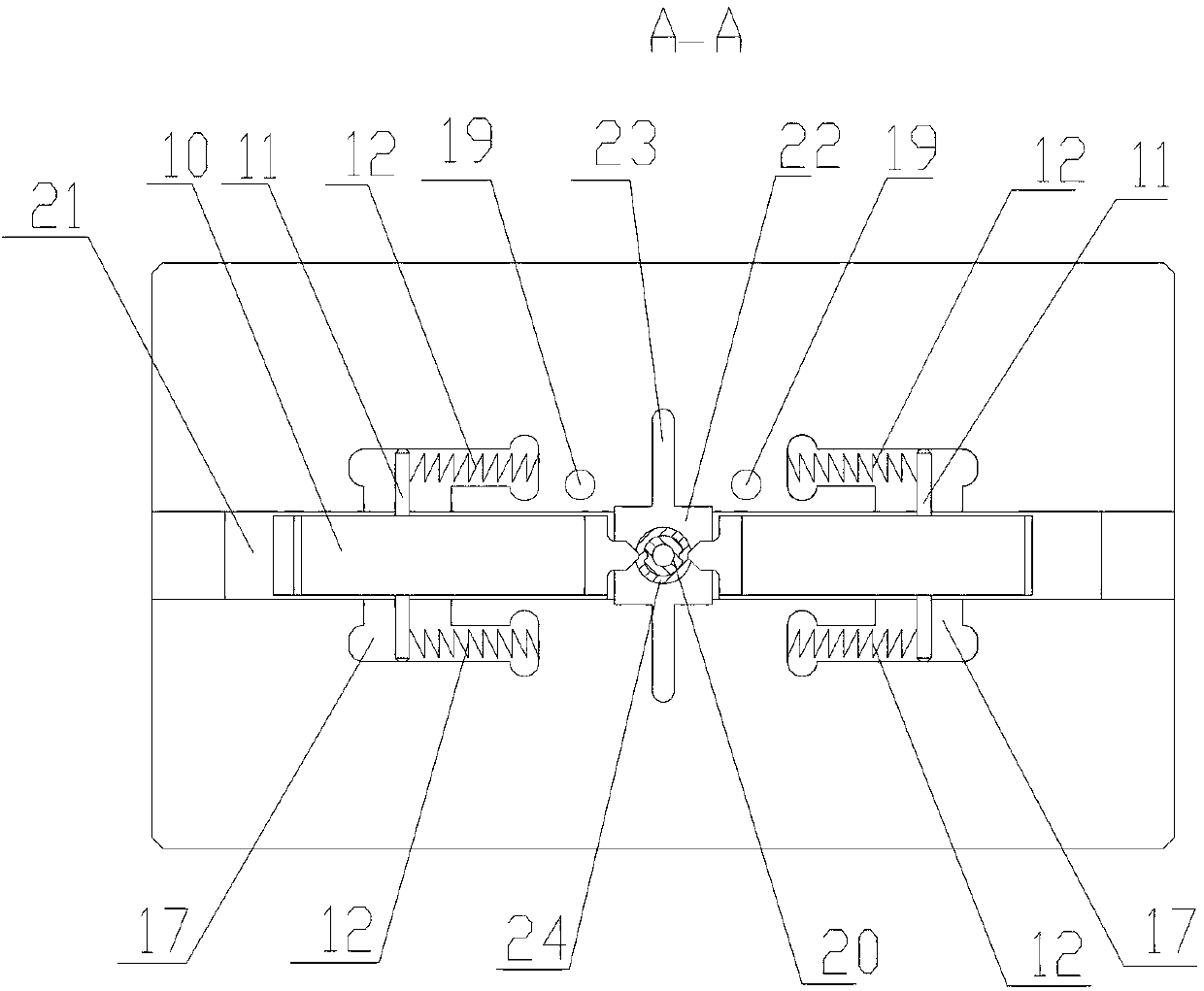

Squeeze riveter capable of automatically feeding

ActiveCN105772586AQuick rivetingEasy rivetingMetal-working feeding devicesMetal working apparatusEngineeringMechanical engineering

The invention relates to a squeeze riveter capable of automatically feeding. The squeeze riveter capable of automatically feeding comprises a stand and a mechanical arm; a riveting base module, a gas-liquid booster cylinder and a vibrating disc are arranged on the stand; the gas-liquid booster cylinder is positioned above the riveting base module; a feeding module is arranged in an outlet of the vibrating disc; the riveting base module is provided with a guide base; the feeding module includes a base; a working cavity is formed in the base; an inner end of the working cavity forms a spraying station; a spraying port is formed above the spraying station; a waterproof nut column is provided with a pushing hole on the base below the spraying station; a pushing block is arranged in the pushing hole; an air spraying hole is vertically formed in the pushing block; an outlet of the air spraying hole is positioned on the upper end surface of the pushing block; and an inlet of the air spraying hole is connected with a first air pipe. The squeeze riveter needs no manual operation to load the waterproof nut column, realizes automatic installation of the waterproof nut column, is fast, convenient and safe in the riveting process, and greatly improves the riveting efficiency and quality.

Owner:CHANGZHOU LINGXIE INTELLIGENT EQUIP CO LTD

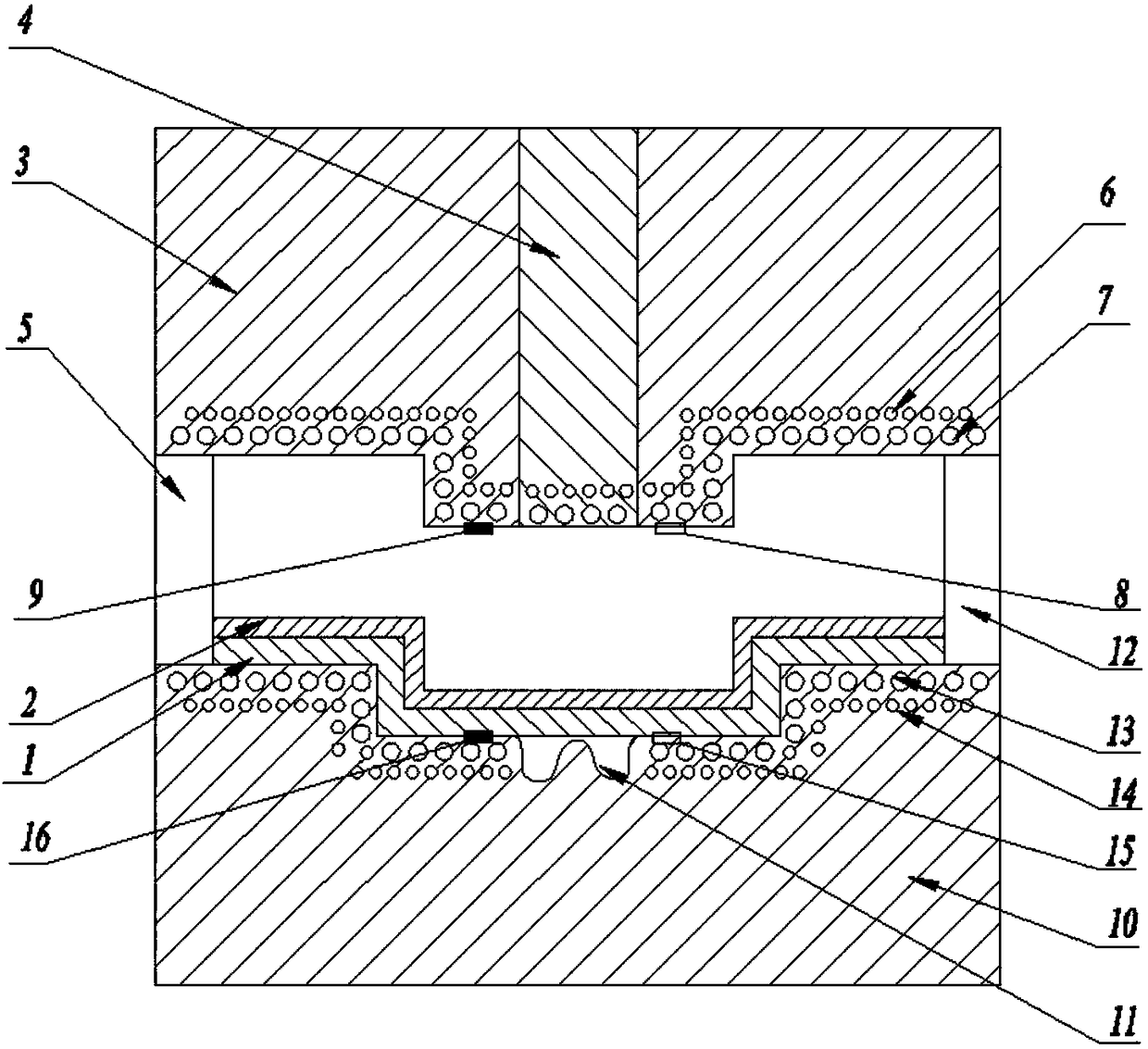

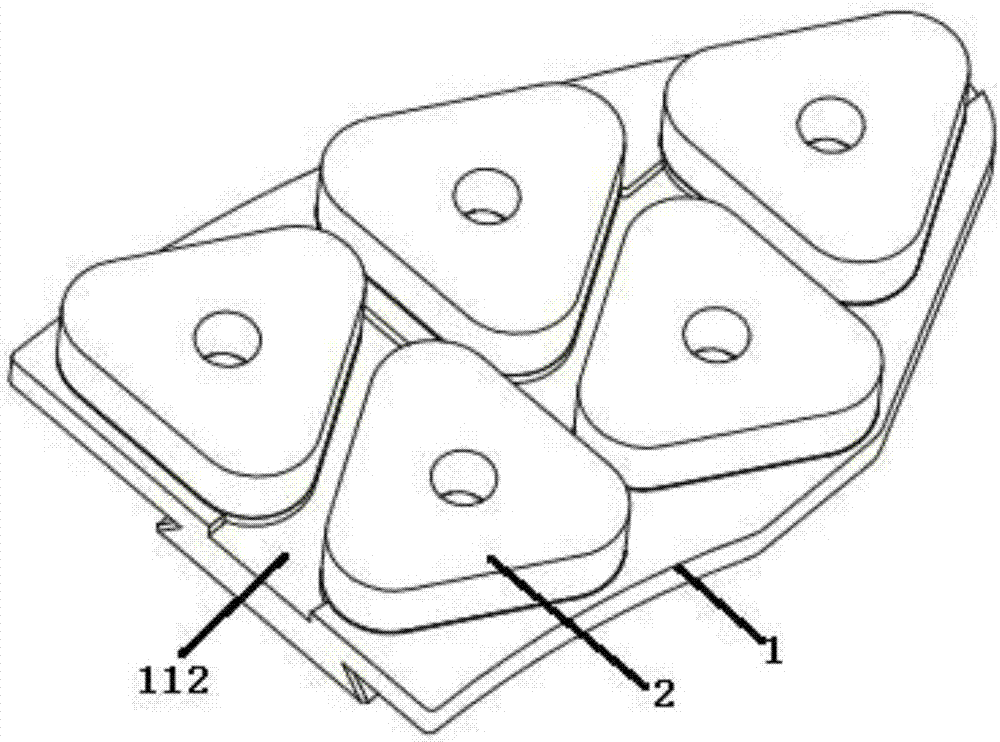

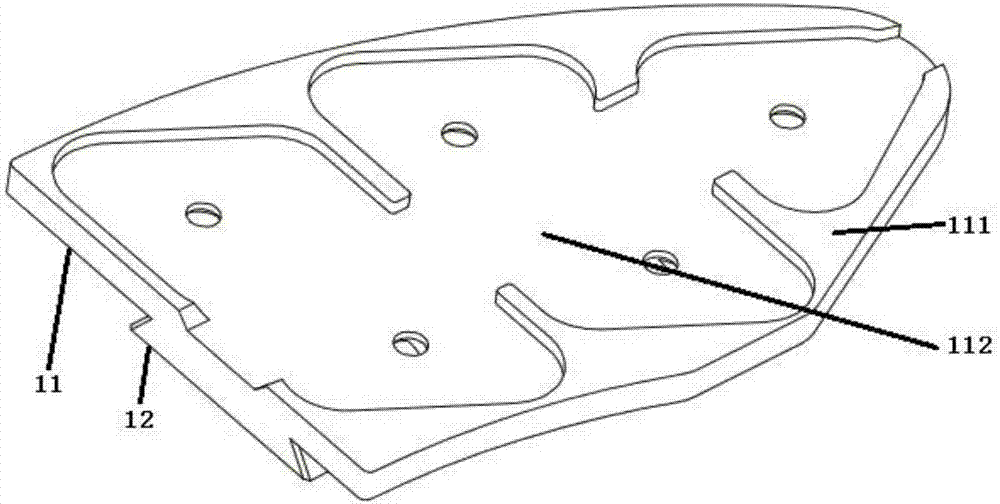

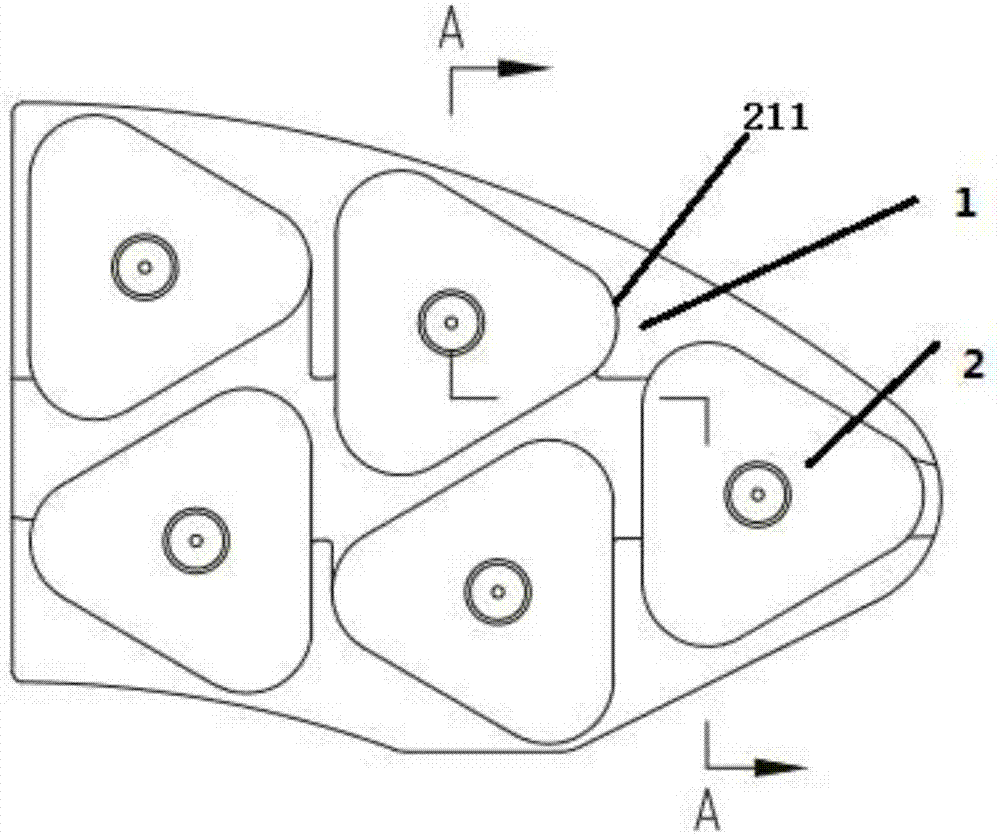

Powder metallurgy brake pad for D-series high-speed train set

PendingCN107061576AIncrease stiffnessImprove stress distributionFriction liningEngineeringMachining process

The invention discloses a powder metallurgy brake pad for a D-series high-speed train set. The powder metallurgy brake pad comprises a steel backboard, a dovetail block and a plurality of brake pad friction bodies. The steel backboard and the dovetail block are of an integrated forming structure, any brake pad friction body is fixed to the steel backboard through a big gasket and a rivet, each big gasket is located between the corresponding brake pad friction body and the steel backboard, and the positions, located on the edges of the brake pad friction bodies, of the steel backboard are provided with flanges matched with the brake pad friction bodies in shape. According to the brake pad, due to adoption of the structure of particular design, rigidity and reliability of the steel backboard are increased, the machining process and riveting process are simplified, the production cost of the brake pad is lowered, reliability of the brake pad is improved, the service life of the brake pad is prolonged, and the powder metallurgy brake pad can be widely applied to brake systems of various railway vehicles and high-speed D-series train sets.

Owner:湖南博科瑞新材料有限责任公司

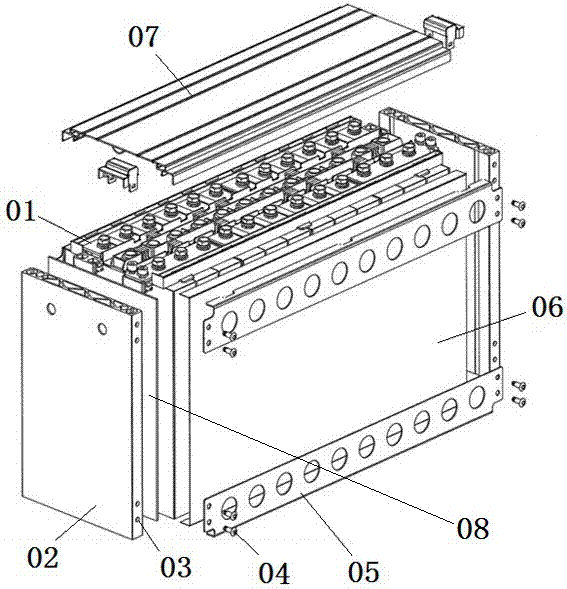

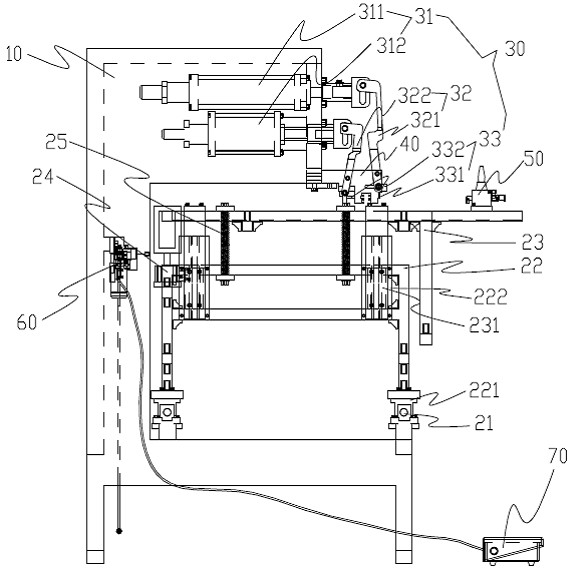

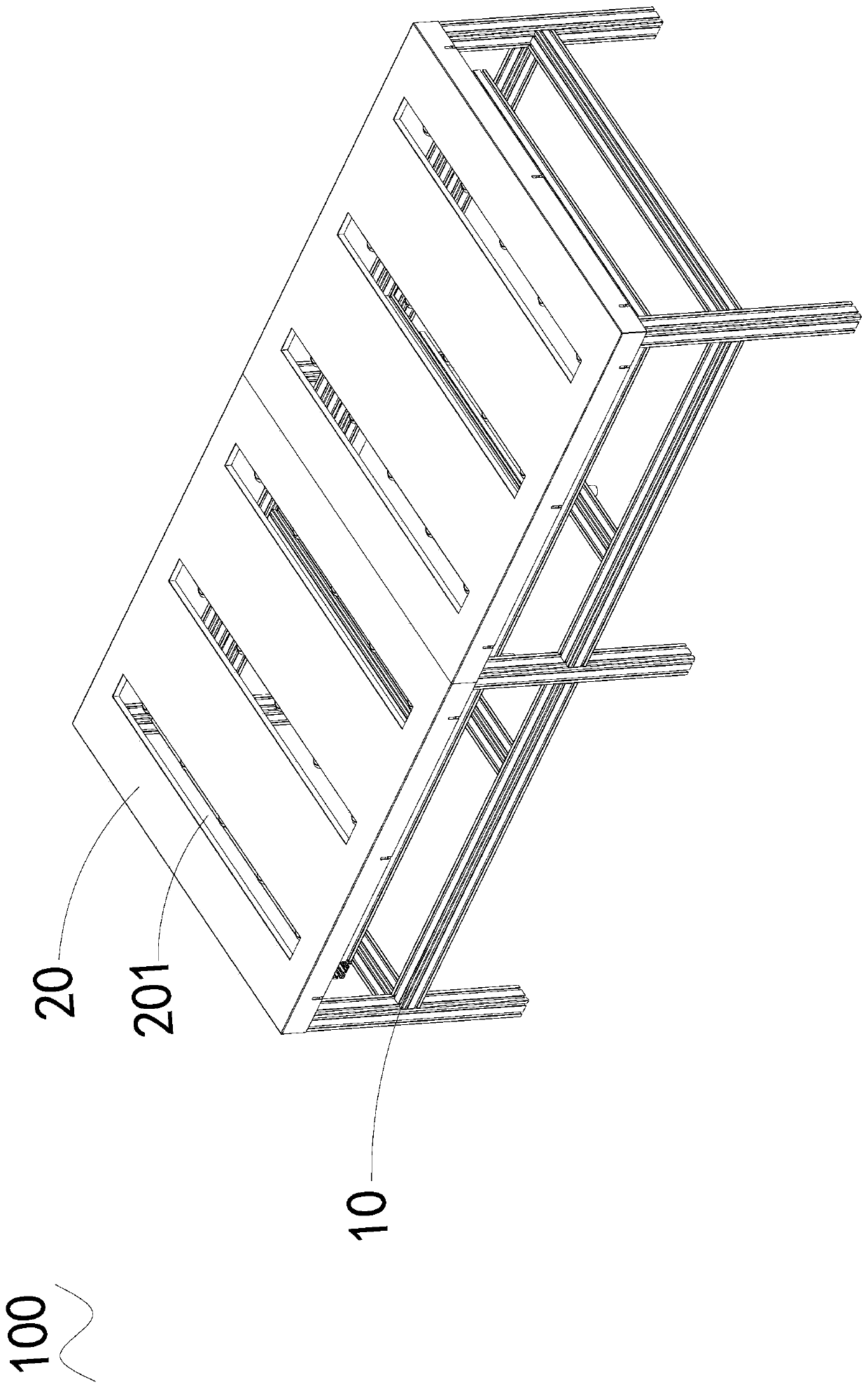

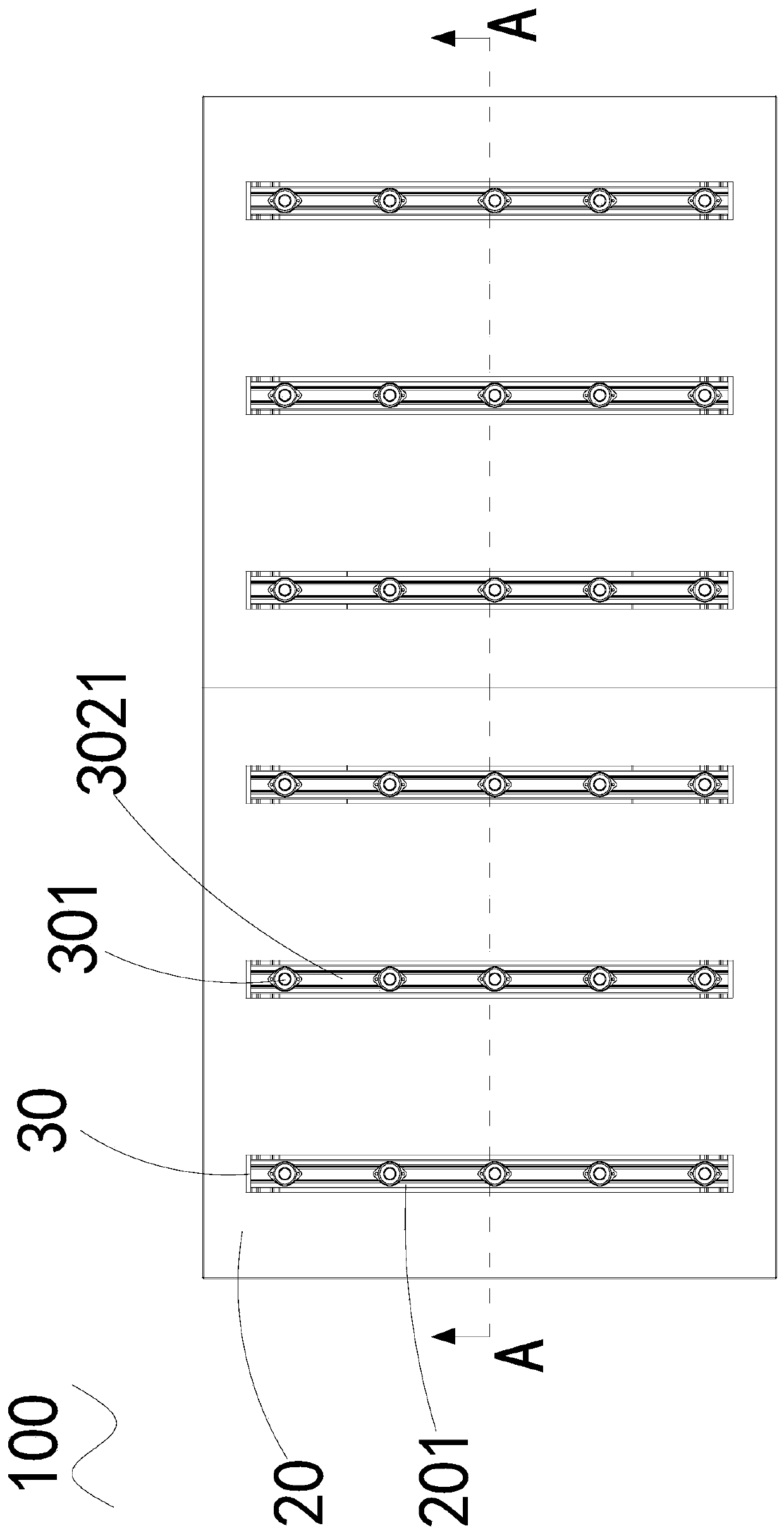

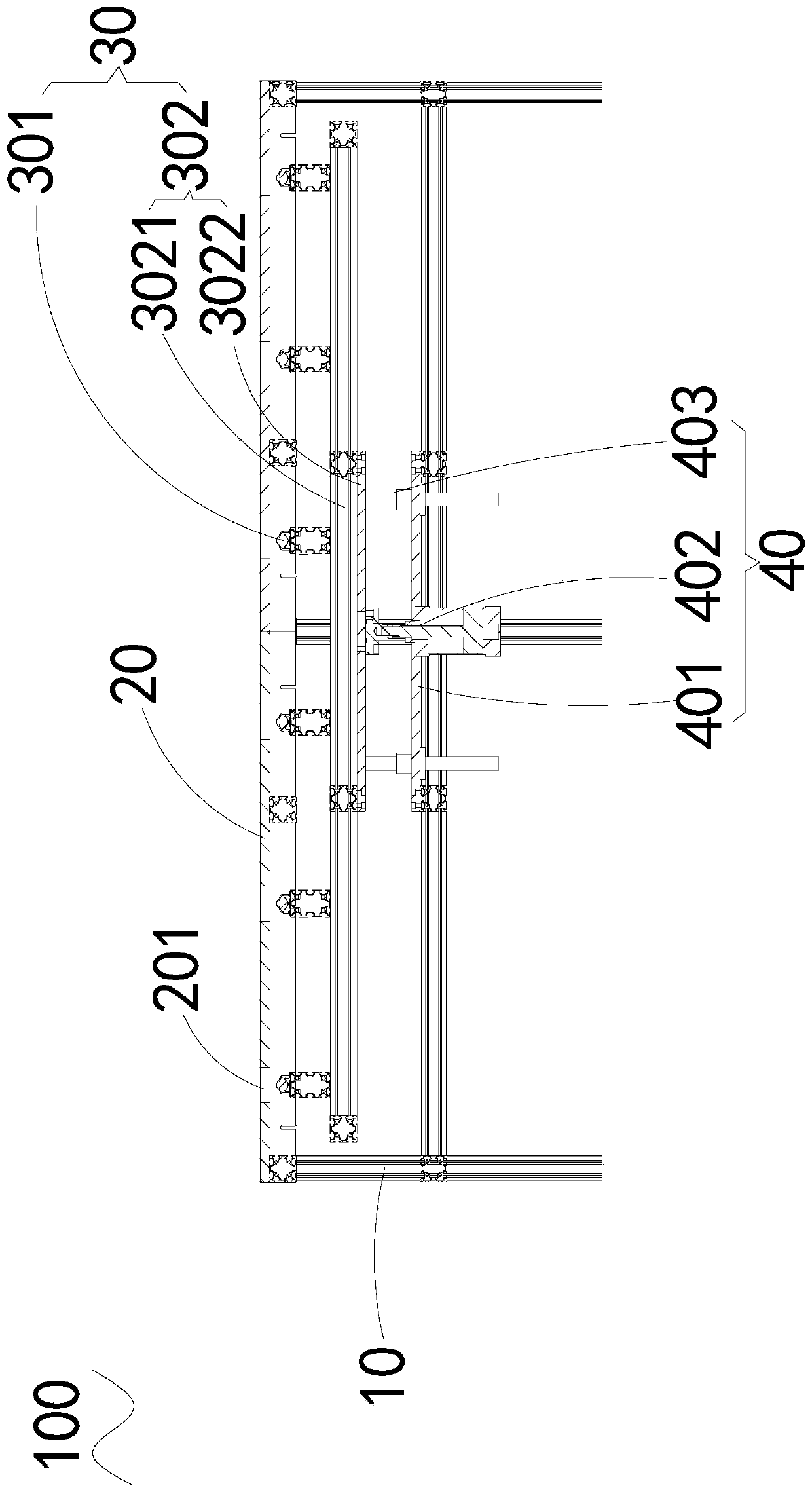

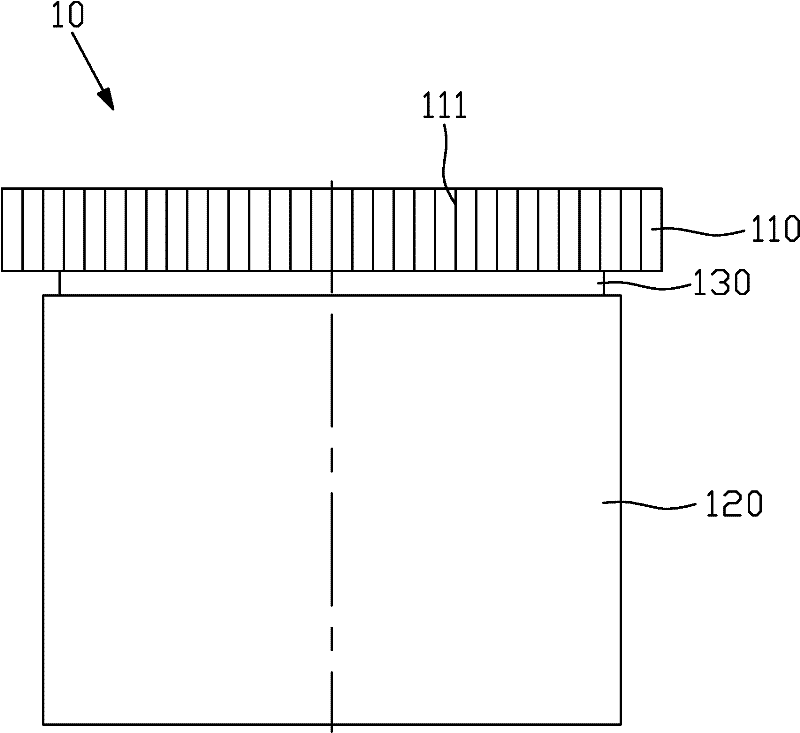

Battery module compressing equipment and rack thereof

ActiveCN107331884AEasy rivetingSimple structurePrimary cell manufactureAssembling battery machinesAdhesiveAssembly line

The invention relates to battery module compressing equipment and a rack thereof. The battery module compressing equipment comprises the rack, wherein first and second baffles are fixedly arranged on a platform of the rack at an interval, an extrusion station for accommodating a to-be-compressed battery module is arranged between the two baffles, a driving device on the first baffle drives a telescopic arm to telescope in the direction of the second baffle, an extrusion head at the end of the telescopic arm is driven to extrude the battery module in a tray, a battery in the battery module, a buffer pad as well as a structural adhesive between end plates are extruded to be scattered, loose parts are compressed, and the overall length of the battery module is reduced, so that riveting of angle iron and the battery module is facilitated. The equipment is simple in structure and convenient to operate, the tray is a movable component and can be but-jointed with an assembly line conveniently, and the compression efficiency of the battery module is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Riveting machine of wiring harness terminal

ActiveCN103545687ANo movementReduce the burden onLine/current collector detailsState of artEngineering

The invention discloses a riveting machine of a wiring harness terminal. The riveting machine comprises a base and a slant plate. The riveting machine is characterized in that a back air cylinder is arranged on the base, a conveying plate is connected to the front end of the back air cylinder, the slant plate for feeding is arranged on the lateral face of the conveying plate, a feeding plate is arranged on the base, a lateral air cylinder is arranged on one side of the feeding plate, conveying grooves capable of being butted with each other are formed in the conveying plate and the feeding plate, a carrying tool plate is arranged at the front end of the feeding plate, a pressing plate is arranged at the upper end of the carrying tool plate, the pressing plate is driven by a driving mechanism, and a linkage riveting pressing plate is arranged at the bottom of the pressing plate and located above the wiring harness riveting position of the carrying tool plate. According to the riveting machine, the problems that the riveting position has the deviation and the riveting accuracy is low due to the fact that a riveting device in the prior art is low in automation degree and low in machining speed and a wiring harness can move when the wiring harness is machined are solved. A linkage riveting pressing mechanism of the riveting machine of the wiring harness terminal is high in automation degree, high in machining speed, high in riveting accuracy and excellent in riveting quality.

Owner:昆山鑫泰利汽车电子科技有限公司

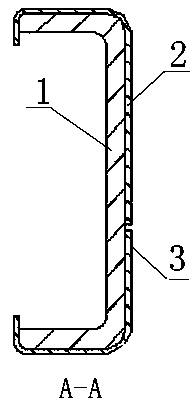

Automotive frame component

InactiveCN102009699AExtended service lifeHigh strengthSuperstructure connectionsLoading-carrying vehicle superstructuresVehicle frameBaseboard

The invention relates to the field of automotive manufacturing, in particular to an automotive frame component applied to a framework structure of a passenger car. The automotive frame component comprises a square baseboard and a groove arranged on the baseboard, and the baseboard and the groove together form a square hollow tubular structure; riveting holes are respectively arranged on the first and second flanges of the baseboard far away from the hollow tubular structure; and the automotive frame component is made of aluminum alloy or magnesium alloy material. According to the using demand, a supporting rib can be added in the hollow tubular structure, or a flange, parallel to the baseboard, can be added to the side edge of the square hollow tubular structure, which is far away from the baseboard; and the supporting rib and the base board as well as the supporting rib and the side edge far away from the baseboard can be connected by a Y-shaped structure to ensure that the automotive frame component has stronger impact resistance and bending resistance capabilities. As fillet designs are used for the connection between the baseboard and the groove, the connection between the groove and the flange arranged thereon, and other corner parts, the occurrence of cracks caused by over-concentrated local stress is prevented.

Owner:贾秉成

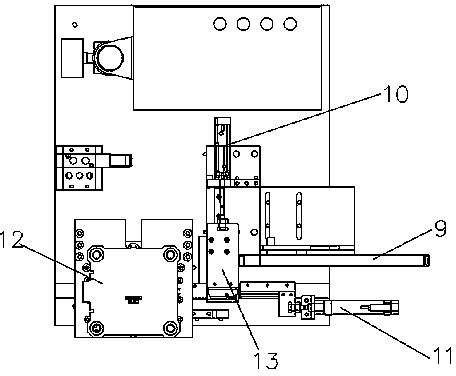

Inner frame riveting machine for bag filter

The invention discloses an inner frame riveting machine for a bag filter, which is simple in structure and reasonable in design and comprises a frame. A conveying mechanism and a riveting mechanism are arranged on the frame, the conveying mechanism comprises a guide rod, a moving frame and a transmission mechanism, the moving frame comprises a first moving frame and a second moving frame, the first moving frame bilaterally slides along the guide rod, the second moving frame vertically slides along the first moving frame, and the transmission mechanism comprises a vertical cylinder and an elastic device. The riveting mechanism comprises a riveting cylinder, a transmission rod and a punching device, the transmission rod is arranged on a fixed bock, one end of the transmission rod is connected with a cylinder rod of the riveting cylinder, the other end of the transmission rod is connected with the punching device, the punching device comprises a riveting punch and an ejector rod, and the transverse axis of the riveting punch is overlapped with that of the ejector rod. The inner frame riveting machine is reasonable in structural design, convenient and practical in operation, high in automation degree, firm and reliable in riveting, stable in product quality, time-saving and labor-saving, an inner frame of a filter bag can be rapidly riveted with the filter bag, production efficiency is improved, and cost is saved.

Owner:张福安

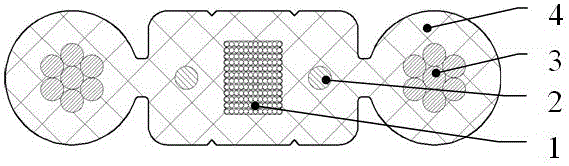

Dual self-holding optical fiber ribbon type wiring optical cable

InactiveCN105954845AImprove protectionPlay a tensile roleFibre mechanical structuresFiberEngineering

The invention discloses a dual self-holding optical fiber ribbon type wiring optical cable. The dual self-holding optical fiber ribbon type wiring optical cable comprises an optical fiber ribbon, reinforcement members, messenger wires and an oversheath. The wiring optical cable is symmetrical on the left and on the right; the optical fiber ribbon is disposed at the center of the wiring optical cable; the two messenger wires are respectively disposed at the left end and the right end of the wiring optical cable; the two reinforcement members are respectively disposed between the optical fiber ribbon and the corresponding messenger wires; and the oversheath is disposed at the peripheral side of the wiring optical cable. The wiring optical cable provided by the invention is large in cable core number, small in dimension and high in tensile strength, and can be applied to machine room wiring or fiber to the premise of indoor and outdoor buildings.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

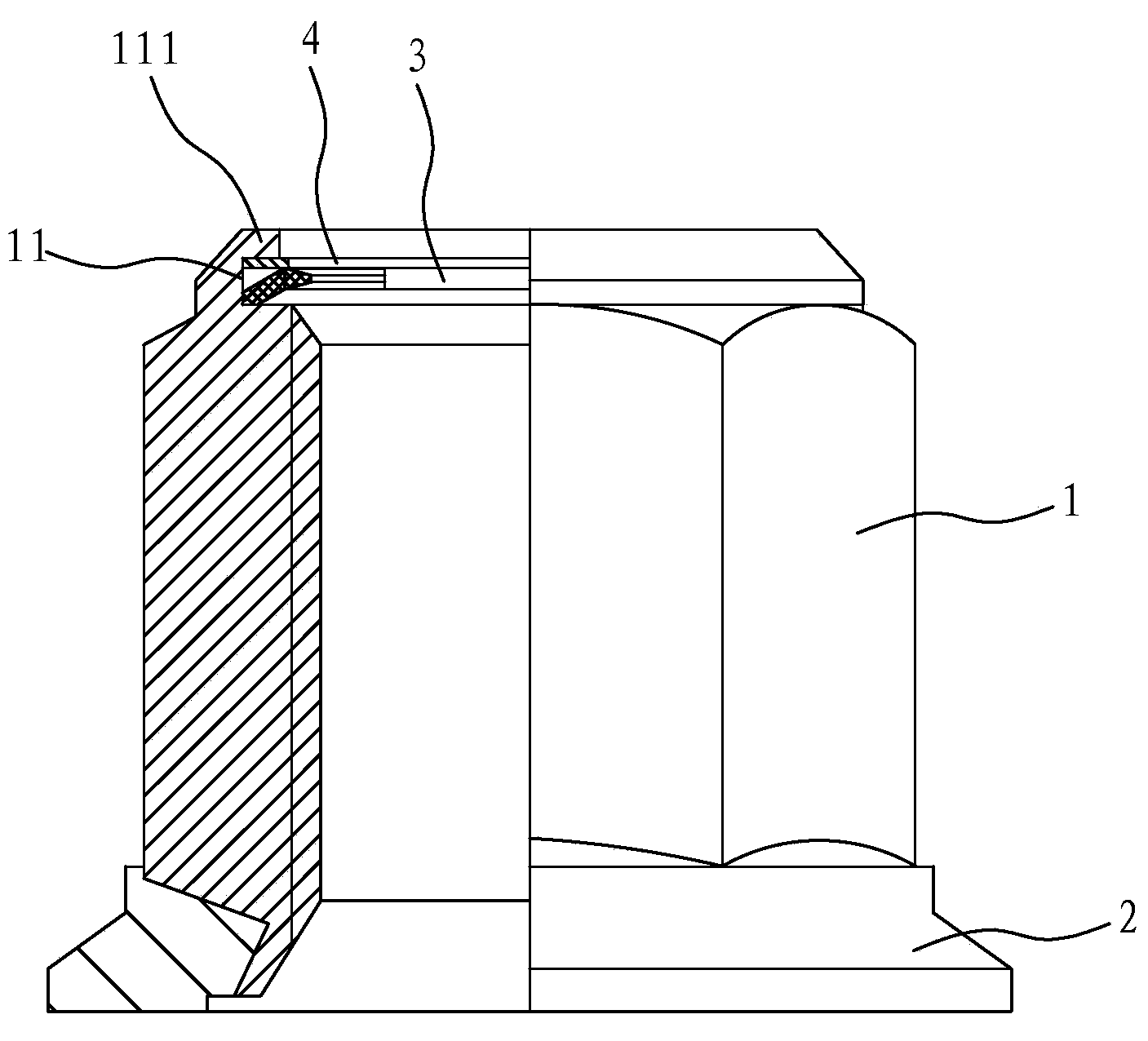

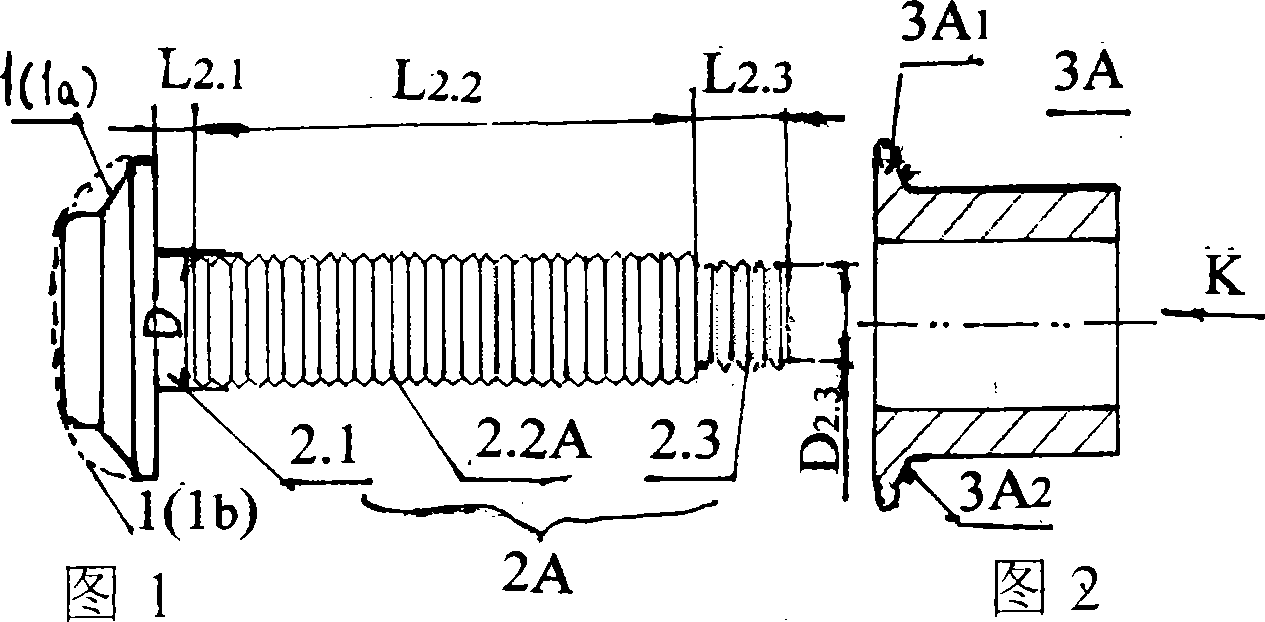

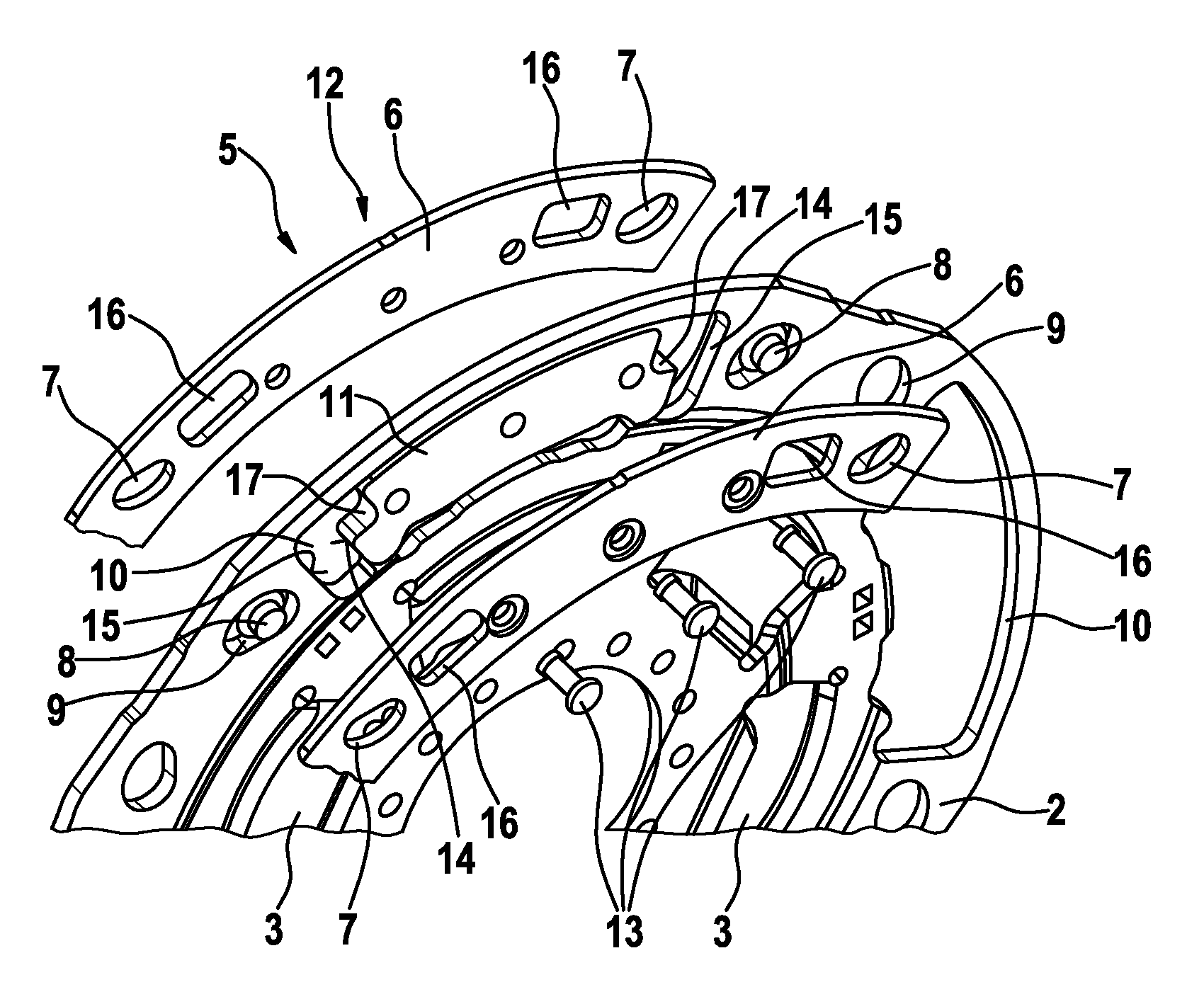

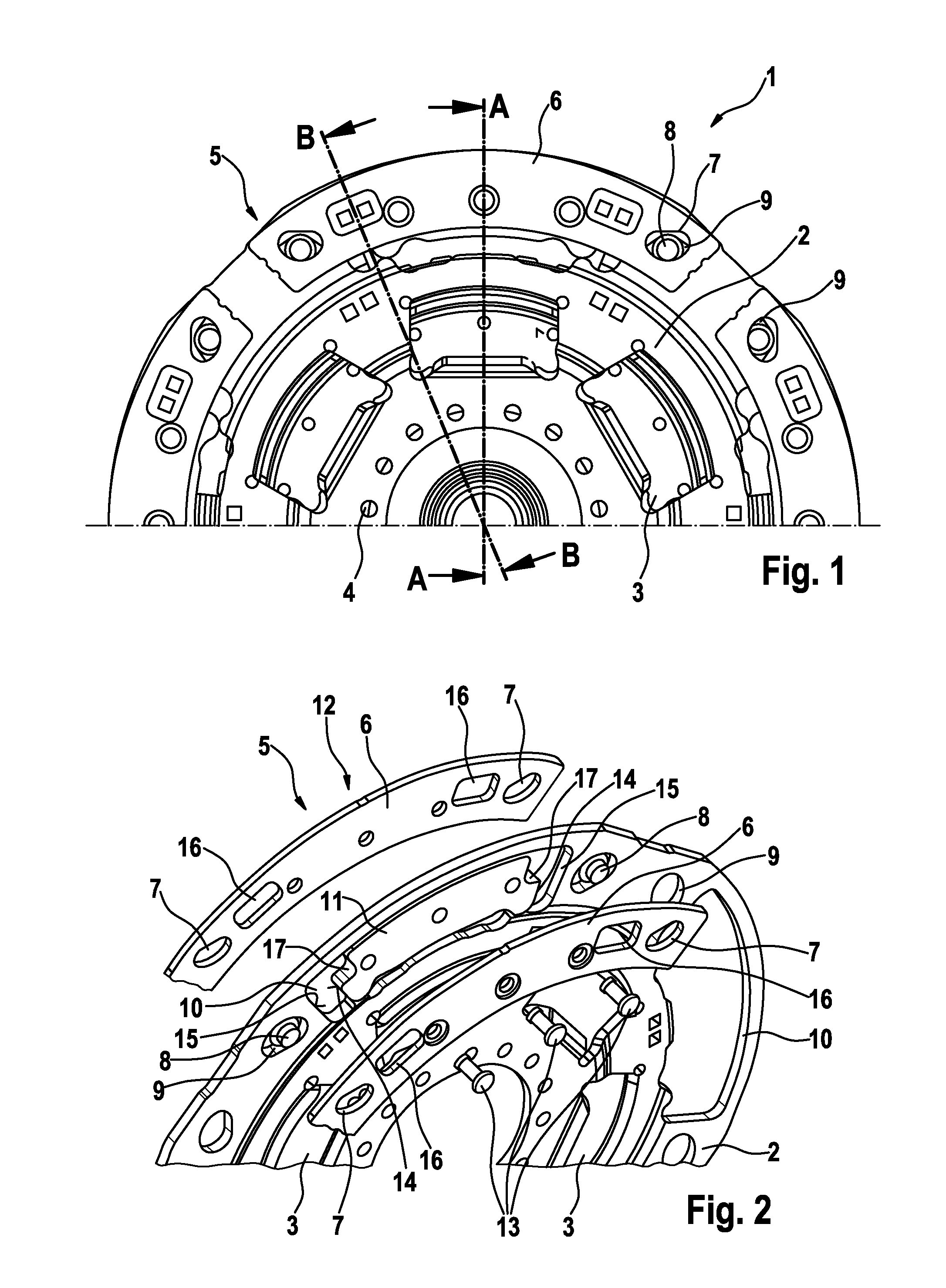

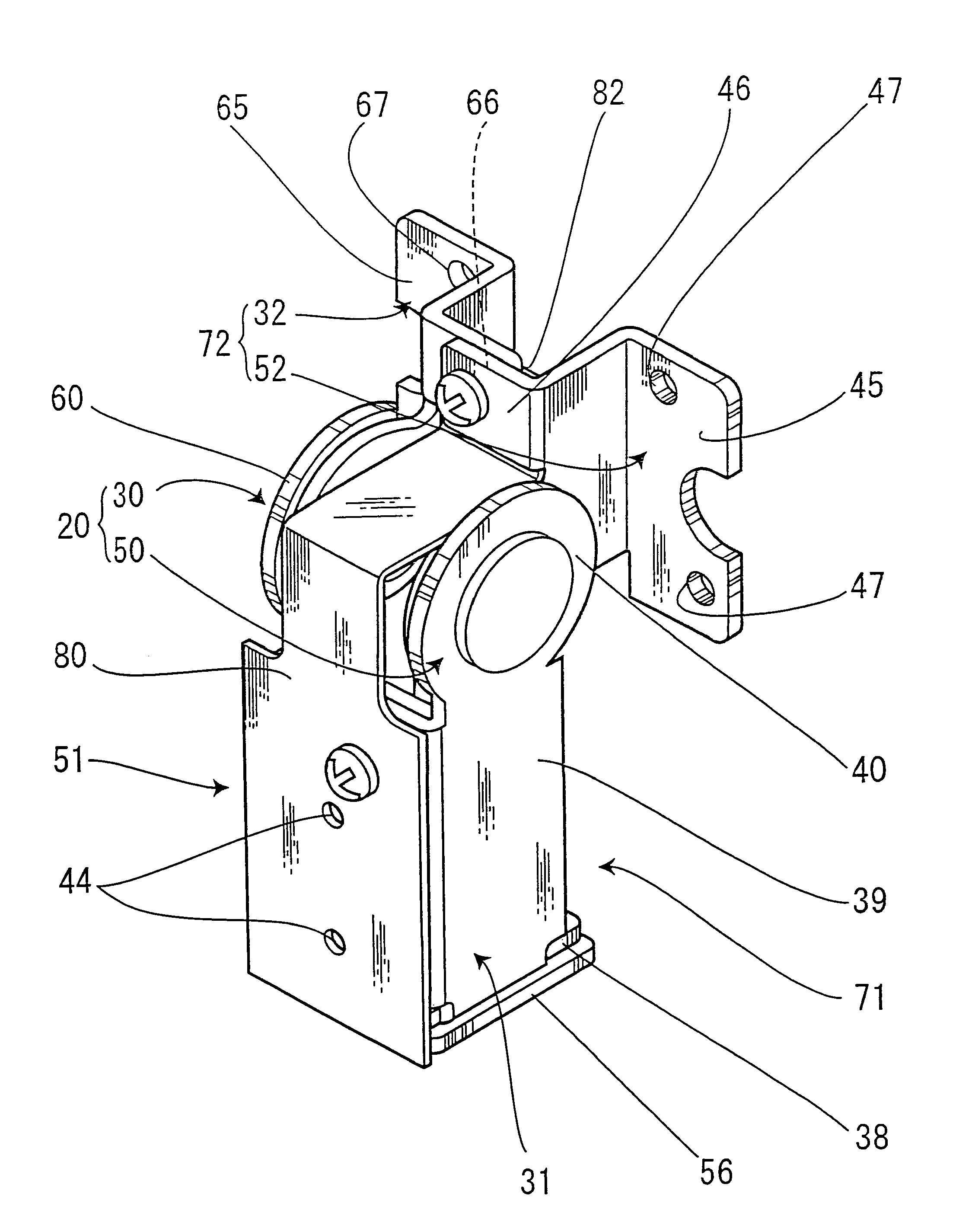

Rotary vibration damper with centrifugal force pendulum

ActiveUS8739523B2Premature wear and defect can be avoidedEasy rivetingRotating vibration suppressionMechanical actuated clutchesEngineeringCentrifugal force

A rotary vibration damper with an input part and an output part having a centrifugal force pendulum disposed on a flange part of the input part or output part, with several mass parts distributed over the circumference of the flange part, and disposed on two sides of the flange part, in raceways of the flange part, and limitedly displaceable in the circumferential direction, and in the radial direction by which two mass parts are interconnected respectively on opposite sides of the flange part.

Owner:SCHAEFFLER TECH AG & CO KG

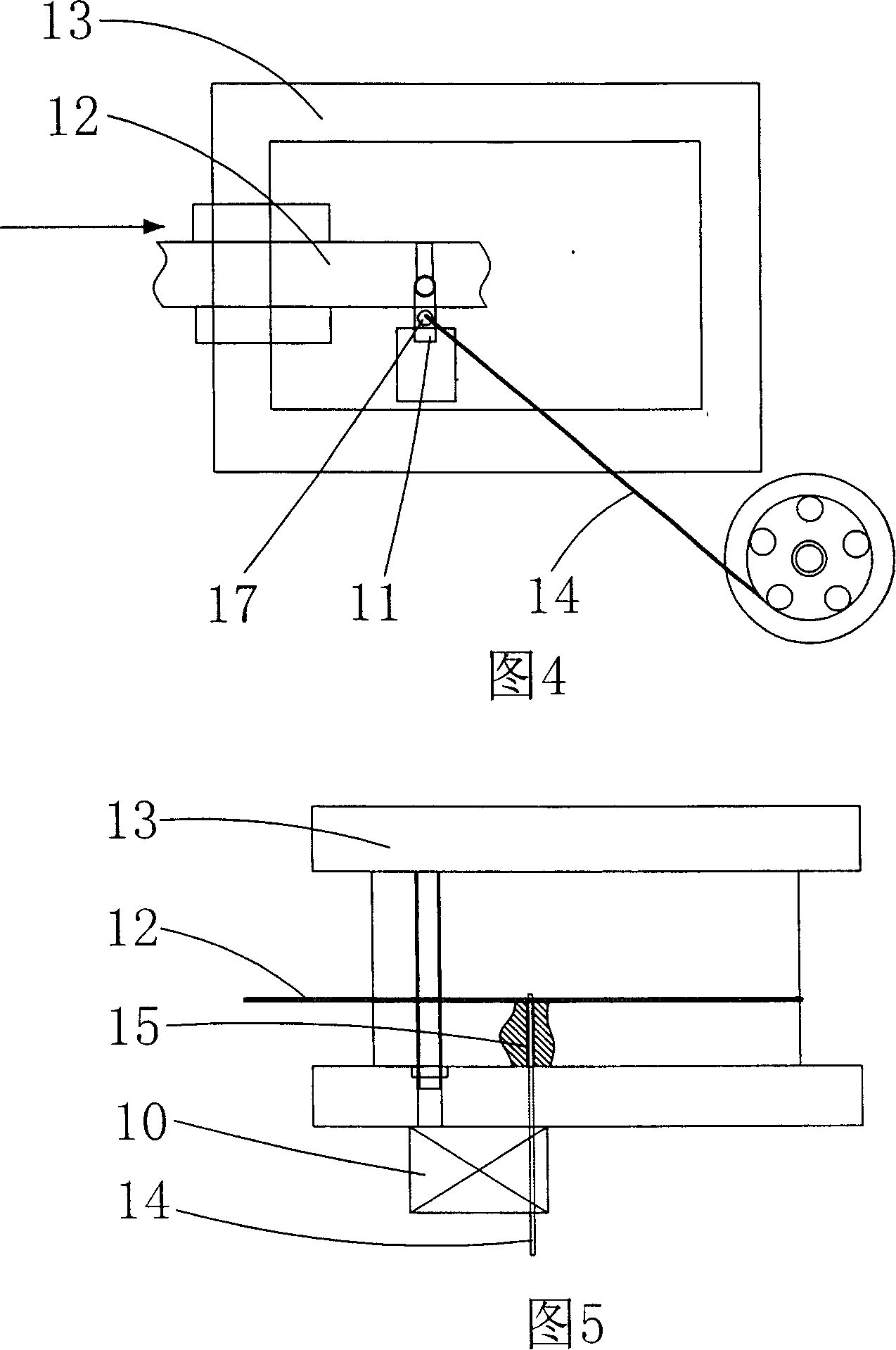

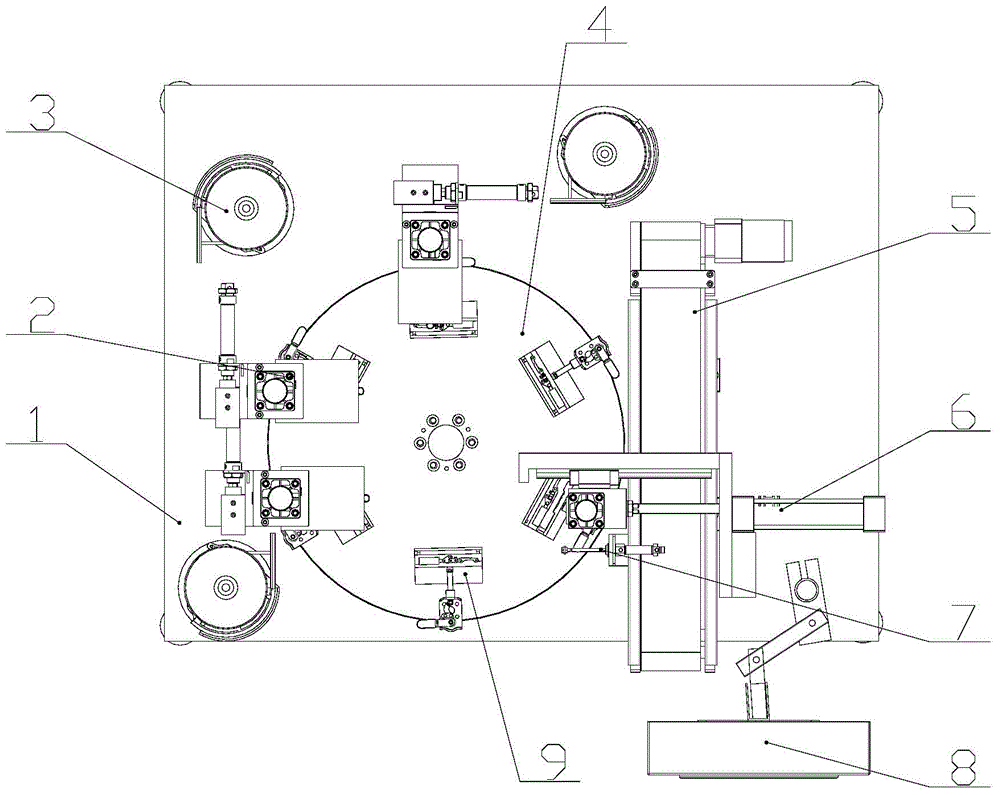

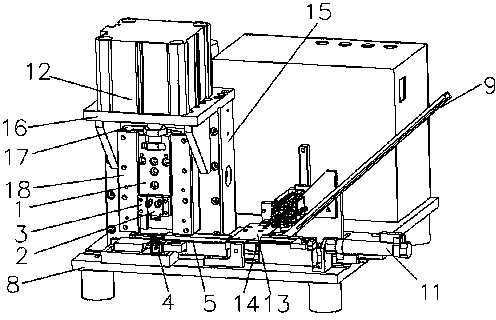

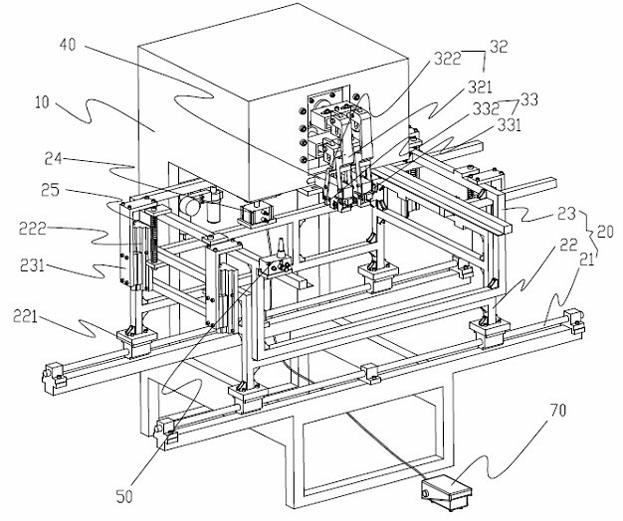

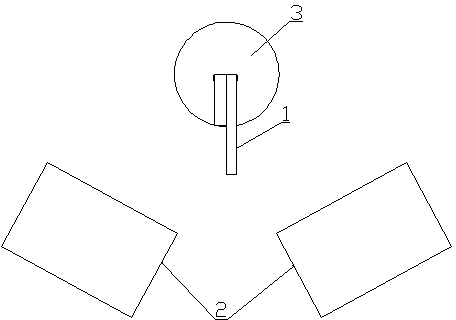

Automatic riveting device for automobile skylight glass sliding rails and bracket

ActiveCN104353743AIncrease productivityQuality assuranceMetal-working feeding devicesPositioning devicesManipulatorGlass slide

The invention discloses an automatic riveting device for automobile skylight glass sliding rails and a bracket. Riveting is carried out through arrangement of two identical clamping tables and adoption of a riveting manipulator. One clamping table is used for riveting, the other is used for feeding, operation is repeatedly carried out in the same way, the production efficiency can be greatly improved, and the quality is ensured. First clamps are arranged at the upper four corners of the clamping tables for clamping two sliding rails, middle second clamps are used for clamping a bracket between the two sliding rails, sensing positioning is carried out on workpieces through the arrangement of a positioning sensor, a clamping press-down cylinder and a clamping upwards pushing cylinder are started after well positioning to clamp all the workpieces, and then, the clamped workpieces on one side are automatically riveted by the riveting manipulator. The automatic riveting device is simple in structure and easy to operate, can efficiently and rapidly rivet the automobile skylight glass sliding rails with the bracket at high quality and is suitable for production.

Owner:WUHU MOTIONTEC AUTOMOTIVE

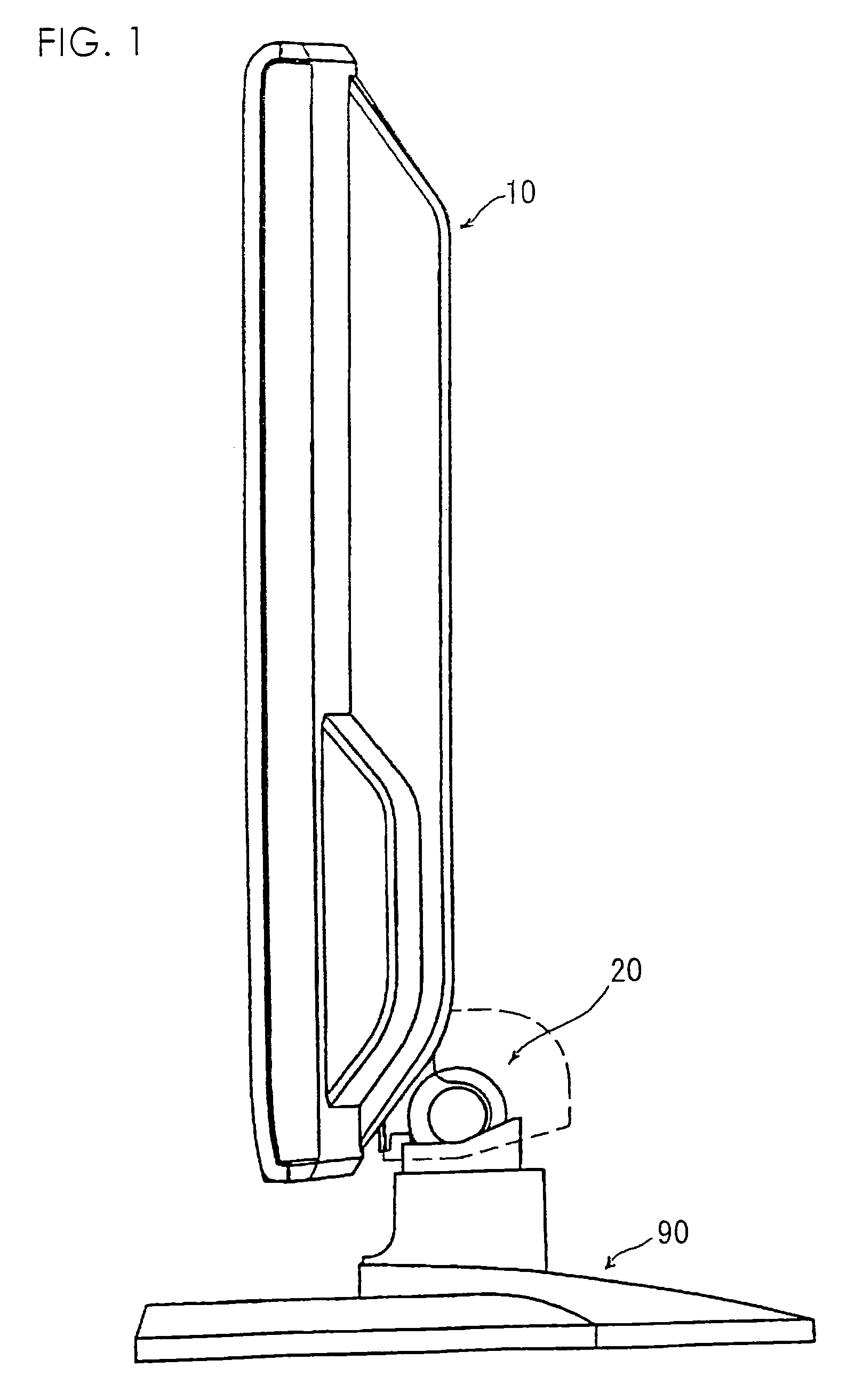

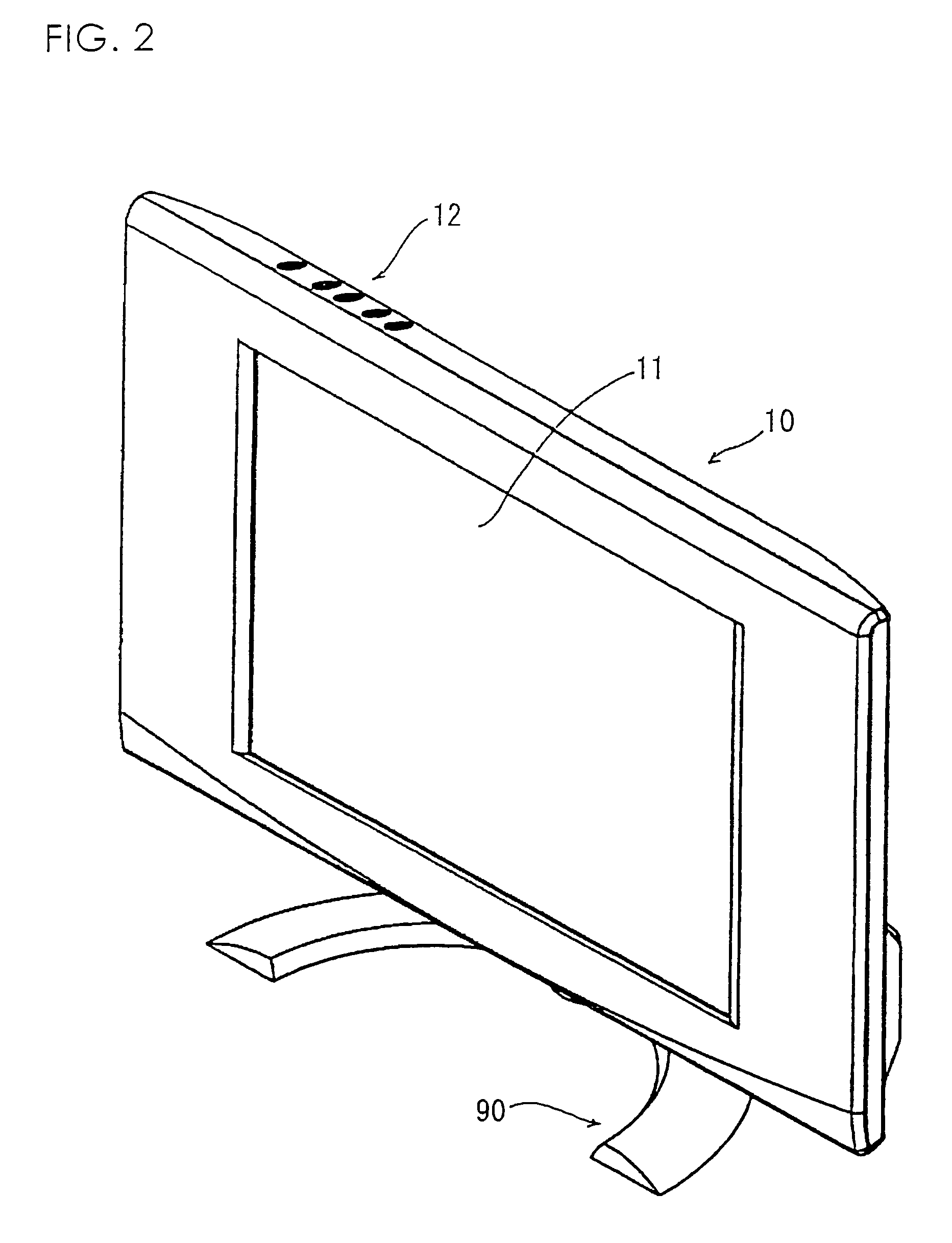

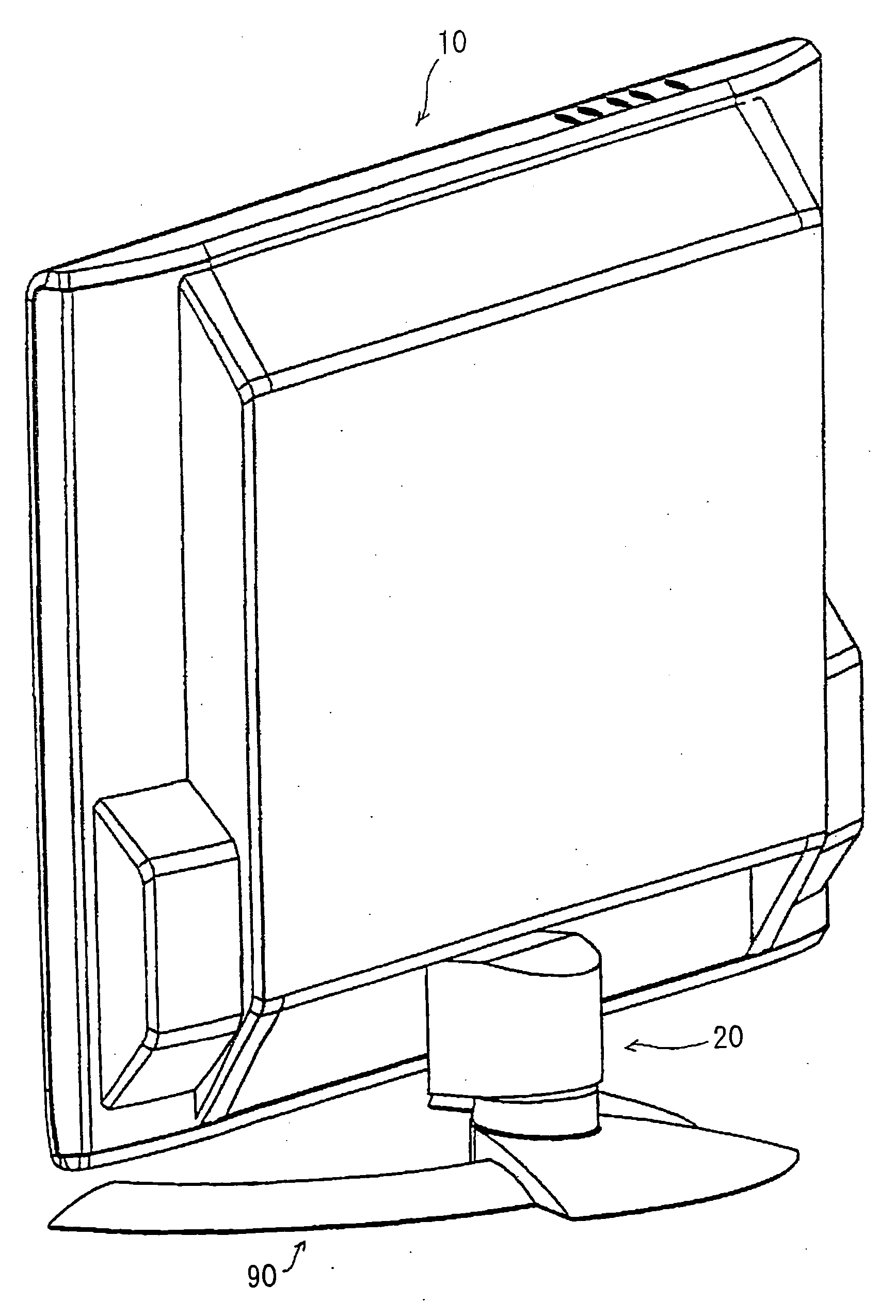

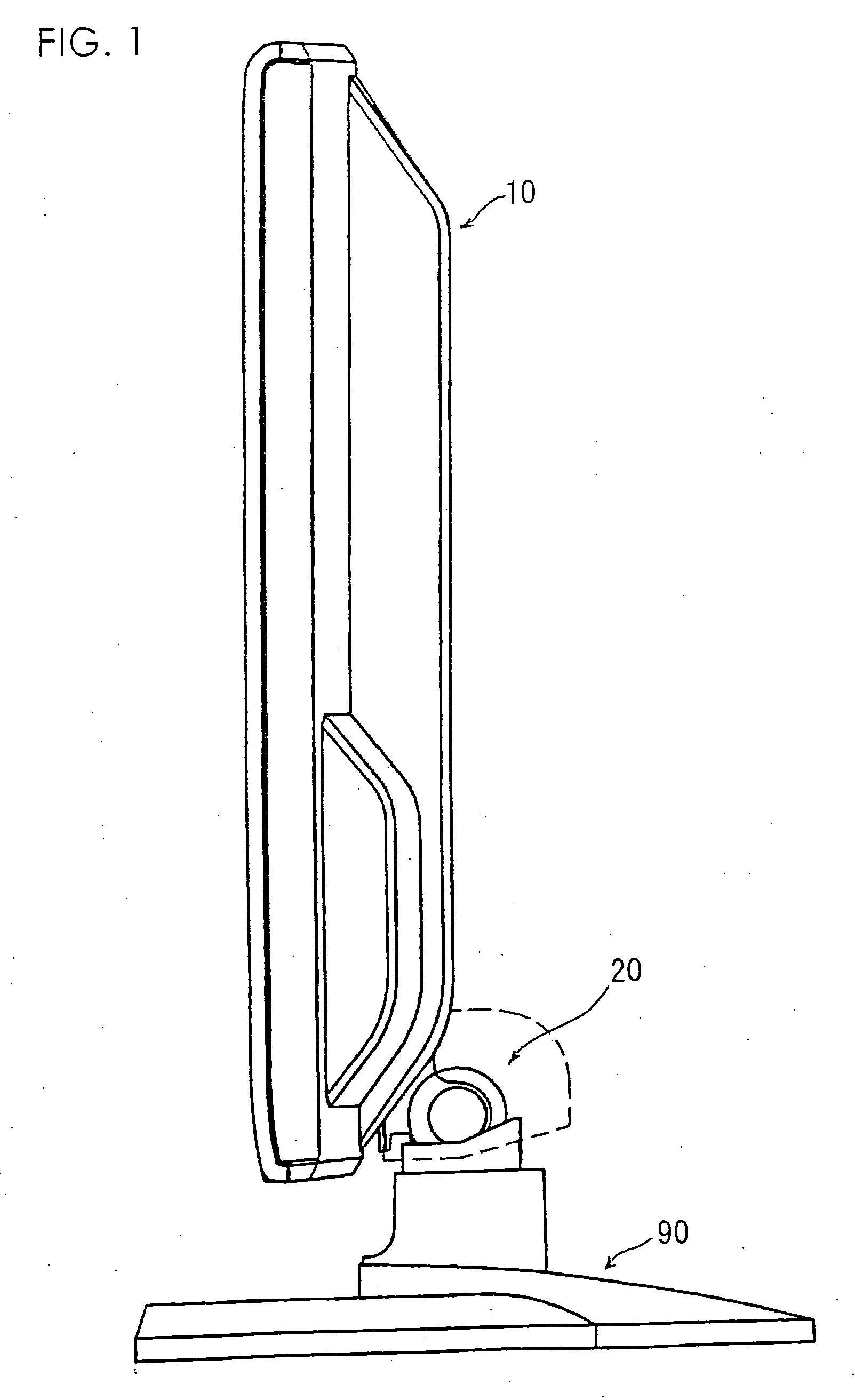

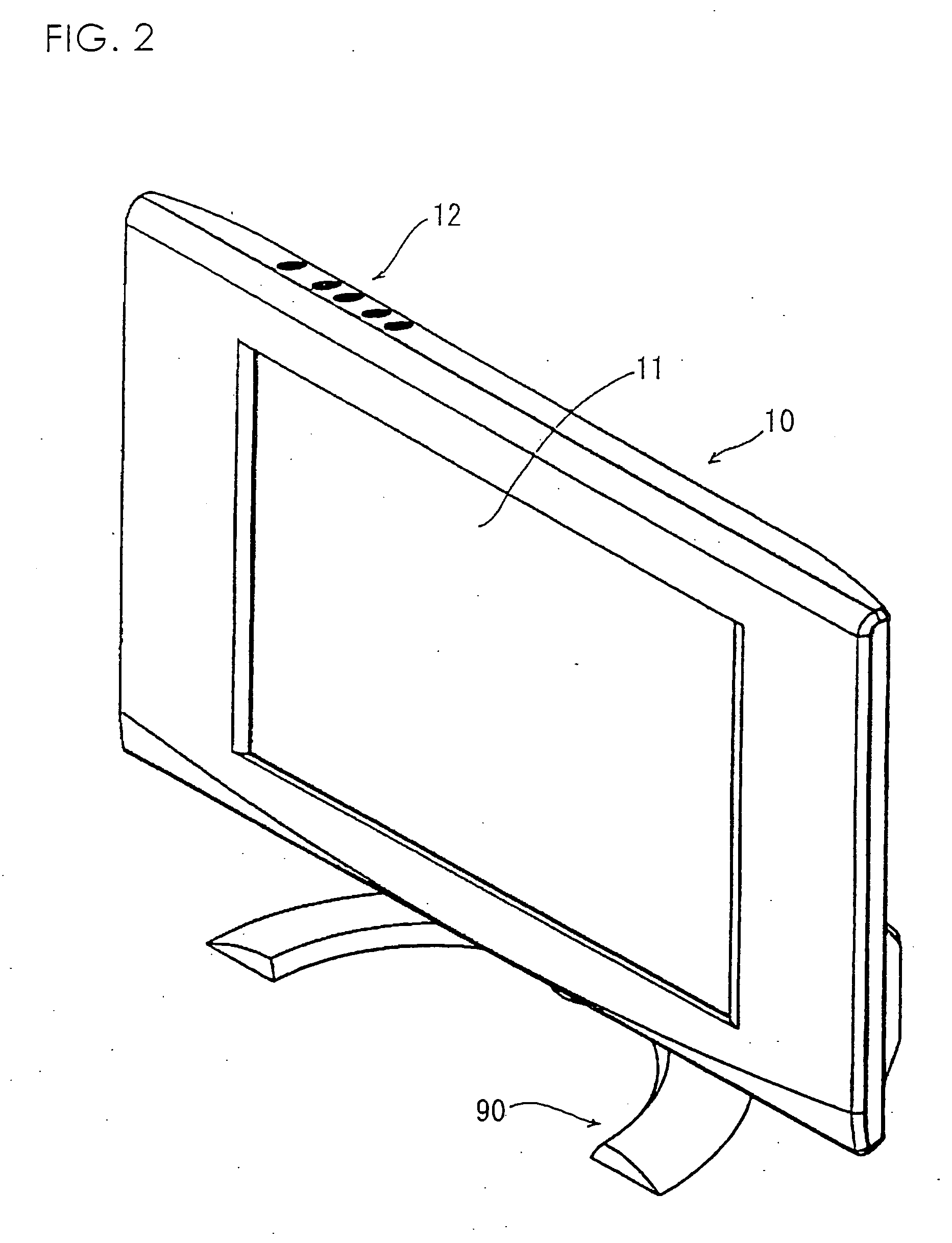

Liquid crystal television receiver

InactiveUS7382418B2Small widthStrong and stable structureTelevision system detailsTelevision system scanning detailsTelevision receiversFace sheet

The invention provides a liquid crystal television receiver, a liquid crystal display of a desktop computer and the like, which is equipped with a pivoting means capable of statically maintaining the image display portion stably with the hinge portion prevented from being loosened even after performing tilting operation repeatedly for a long period of time. The invention provides a liquid crystal television receiver comprising a television receiver body equipped with a liquid crystal panel and a control unit, which is pivotally supported on a leg portion so as to enable tilting of the television receiver body, wherein a hinge portion pivotally supporting the television receiver body in a tiltable manner is composed of a pair of left and right hinge portions, the left and right hinge portions are respectively composed of a stand portion attached to the leg portion and a swing portion attached to the television receiver body, and the left and right hinges are assembled to form an integral hinge portion.

Owner:ORION ELECTRIC CO LTD

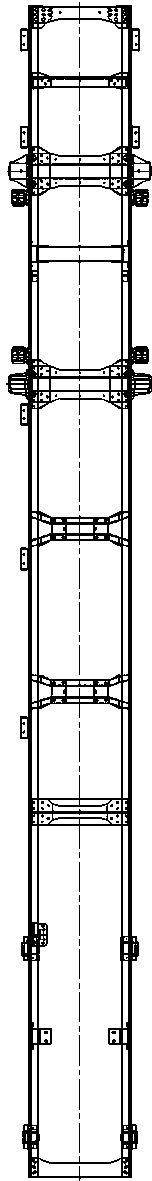

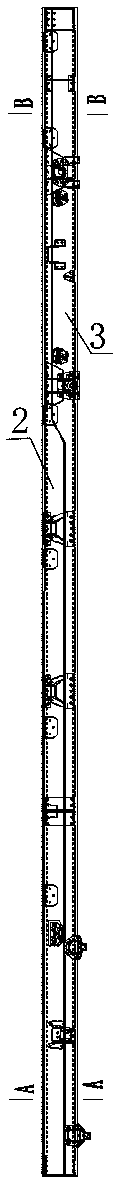

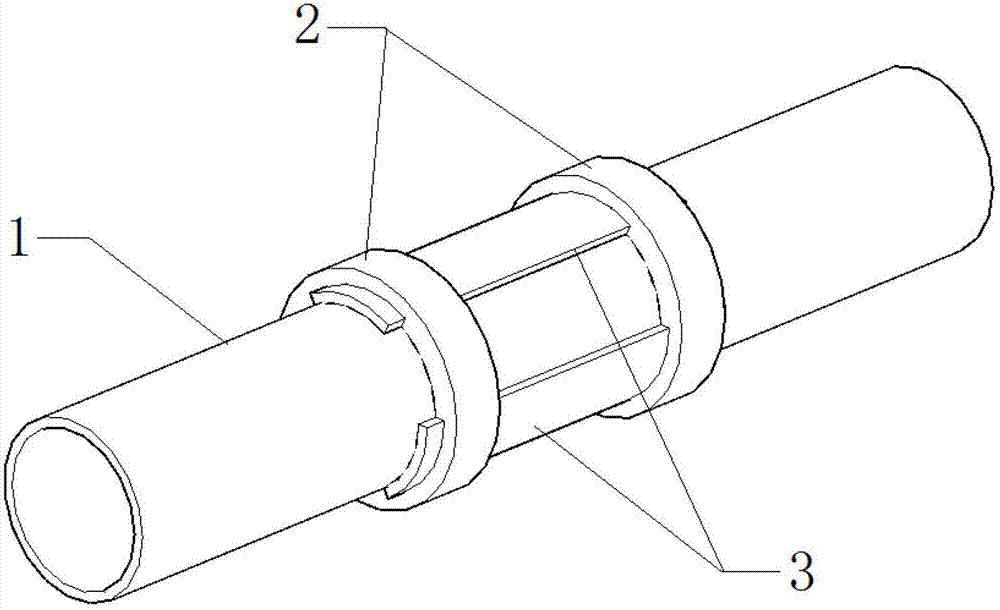

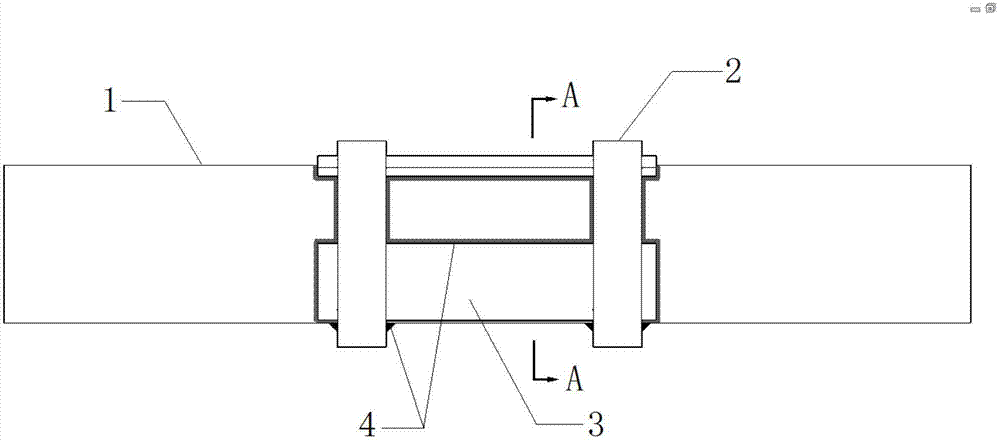

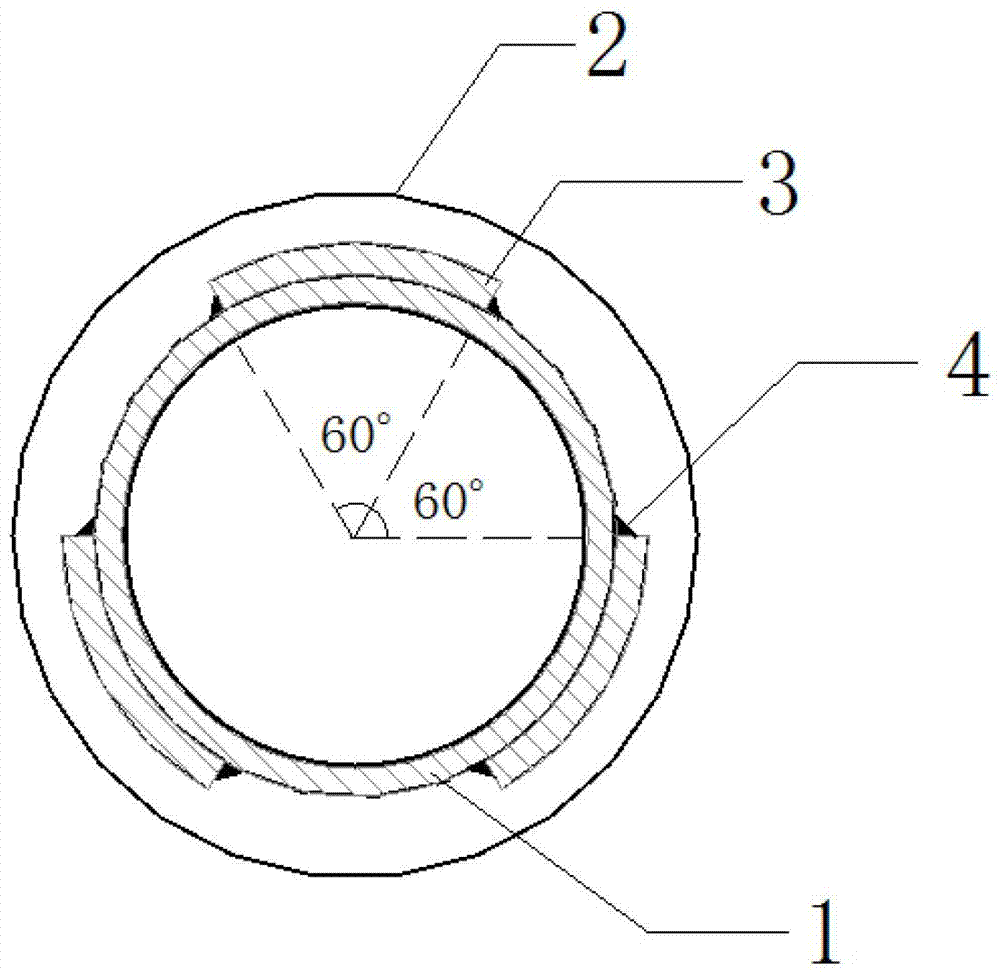

Combined strengthening type bulking-preventing device capable of preventing submarine pipeline from bulking-propagation

InactiveCN103162013AImprove the anti-bending effectPlay a blocking rolePipe laying and repairSheet steelEngineering

The invention belongs to the technical field of submarine pipeline paving and relates to a combined strengthening type bulking-preventing device capable of preventing a submarine pipeline from bulking-propagation. The combined strengthening type bulking-preventing device capable of preventing the submarine pipeline from bulking-propagation is fixed on the exterior of the submarine pipeline which is needed to be protected. The combined strengthening type bulking-preventing device capable of preventing the submarine pipeline from bulking-propagation comprises at least two arc-shaped long-striped steel plates and at least two steel rings. A cross section of every arc-shaped long-striped steel plate is a section of a circular arc. The inner radius of the circular arc is equal to the outer radius of the submarine pipeline. A plurality of arc-shaped grooves are arranged inside of the steel rings. The inner diameters of the steel rings are equal to the outer diameter of the submarine pipeline. The number of the arc-shaped grooves is not less than the number of the arc-shaped long-striped steel plates. The width of the grooves is equal to the width of the arc-shaped long-striped. Each arc-shaped long-striped steel plate is uniformly distributed on the exterior of the submarine pipeline along the axial direction of the pipeline. Each arc-shaped long-striped steel plate is fit with the submarine pipeline and is embedded in an arc-shaped groove of each steel ring. The combined strengthening type bulking-preventing device capable of preventing a submarine pipeline from bulking-propagation is light in weight, easy to install and capable of having high efficiency at the same time.

Owner:TIANJIN UNIV

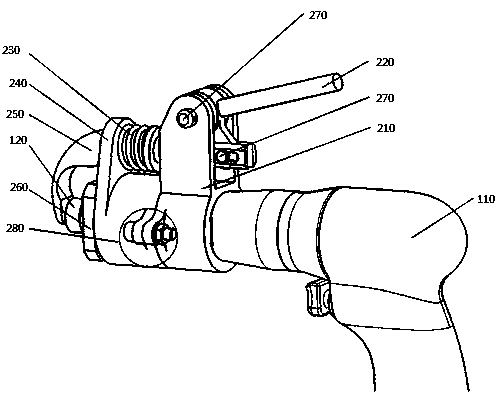

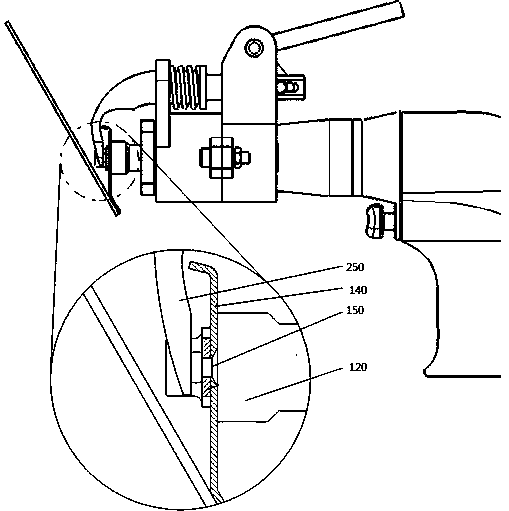

Supporting plate nut riveting assisting device

The invention discloses a supporting plate nut riveting assisting device. The supporting plate nut riveting assisting device comprises a front machine frame, a rear machine frame, a tight-and-loose handle, elbow ejector iron and a locking nut. The front machine frame comprises a main body and a large lug, the rear machine frame comprises a cylinder body and a mounting seat; the working end of a riveter sequentially penetrates through the cylinder body and the main body and is connected to the locking nut; a mounting plate is disposed in parallel with the large lug, and the large lug and the mounting plate are separately provided with a cavity and a mounting plate correspondingly; and one end of the tight-and-loose handle is installed at the top of the mounting plate in a hinged mode; the elbow ejector iron includes an assisting end and a driving end, wherein the assisting end is connected with the driving end through a bend cylinder body; and the driving end of the elbow ejector iron sequentially penetrates through a mounting hole, the mounting plate and is connected with a convex lug in a sliding mode. The supporting plate nut riveting assisting device reduces the complexity and difficulty of the riveting of a workpiece to be machined, improves the stability of the rapid forming and riveting quality of rivets, greatly reduces the difficulty and complexity of the riveting, andmeets the riveting demands of high quality and high efficiency in a space limited area.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

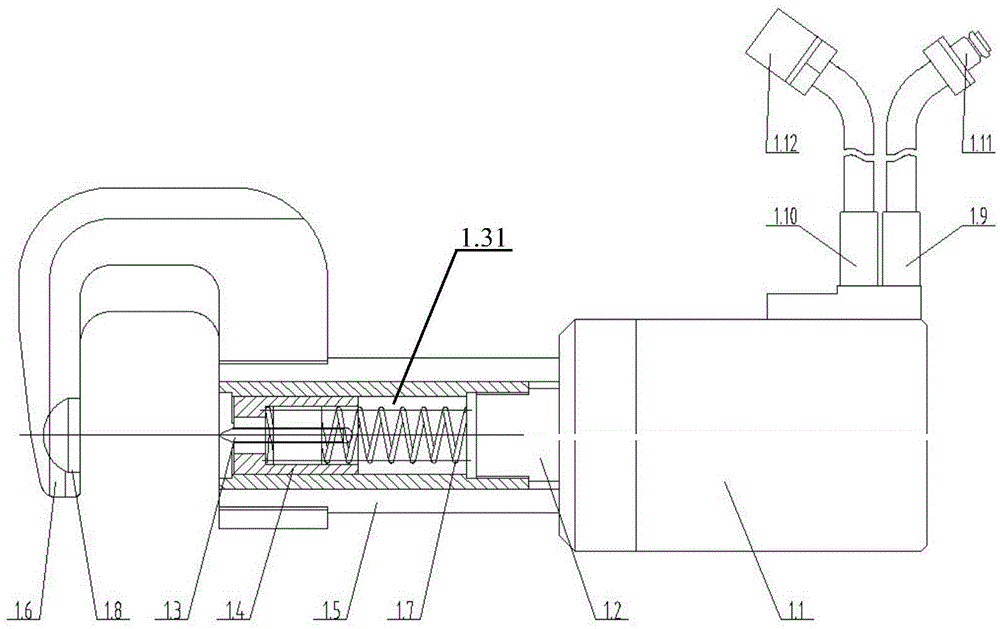

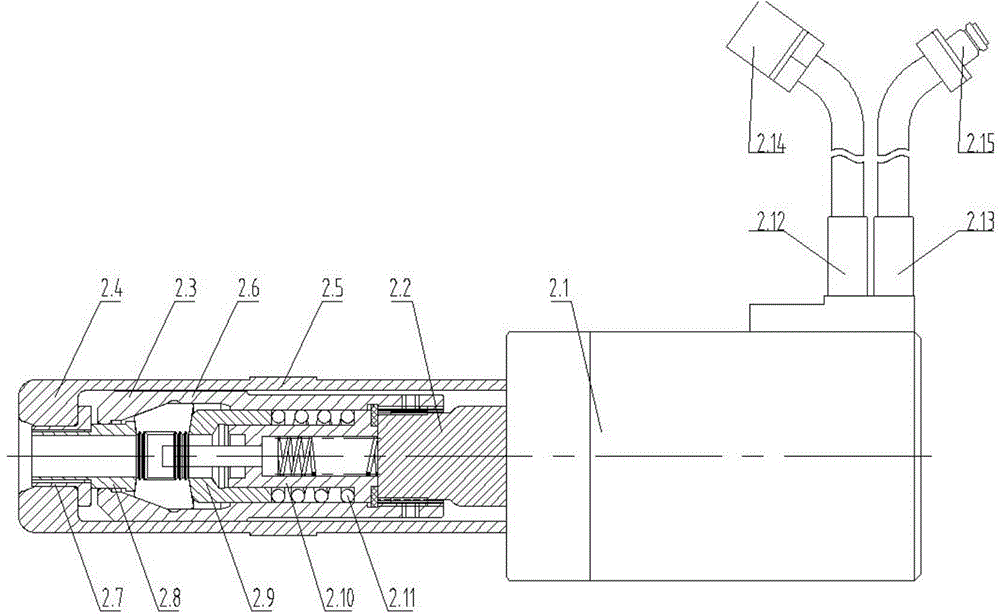

Wagon 120-valve protection hood rivet disassembling device

The invention provides a wagon 120-valve protection hood rivet disassembling device. The rivet disassembling device is composed of a riveting device, a splitter and a hand-operated hydraulic pump. The splitter comprises a splitter oil cylinder assembly, a splitter piston, a cutter head assembly, a positioning sleeve, a splitter connection jacket, a C-shaped clamp, a spring, an oil pipe and a quick-change connector. The riveting device comprises a riveting device oil cylinder assembly, a riveting device piston, an inner sleeve, an outer sleeve, a riveting device connection jacket, a clamping section, an upper limiting sleeve, a lower limiting sleeve, a buffering front sleeve, a buffering rear sleeve, a spring, an oil pipe and a quick-change connector. The hand-operated hydraulic pump is provided with a pump body, a reversing valve, the oil pipe and the quick-change connector. The reversing valve is used in a hand-operated mode. The technical scheme is used for riveting and splitting of pultrusion rivets with the diameter being 12 on the wagon 120-valve protection hood portion, the riveting forming is good, splitting is smooth, and the disassembling device is convenient to carry and operate and capable of quickly riveting or splitting rivet lantern rings under the conduction that no electricity, gas and other power sources exist and achieving disassembly of a 120-valve protection hood.

Owner:CRRC MEISHAN

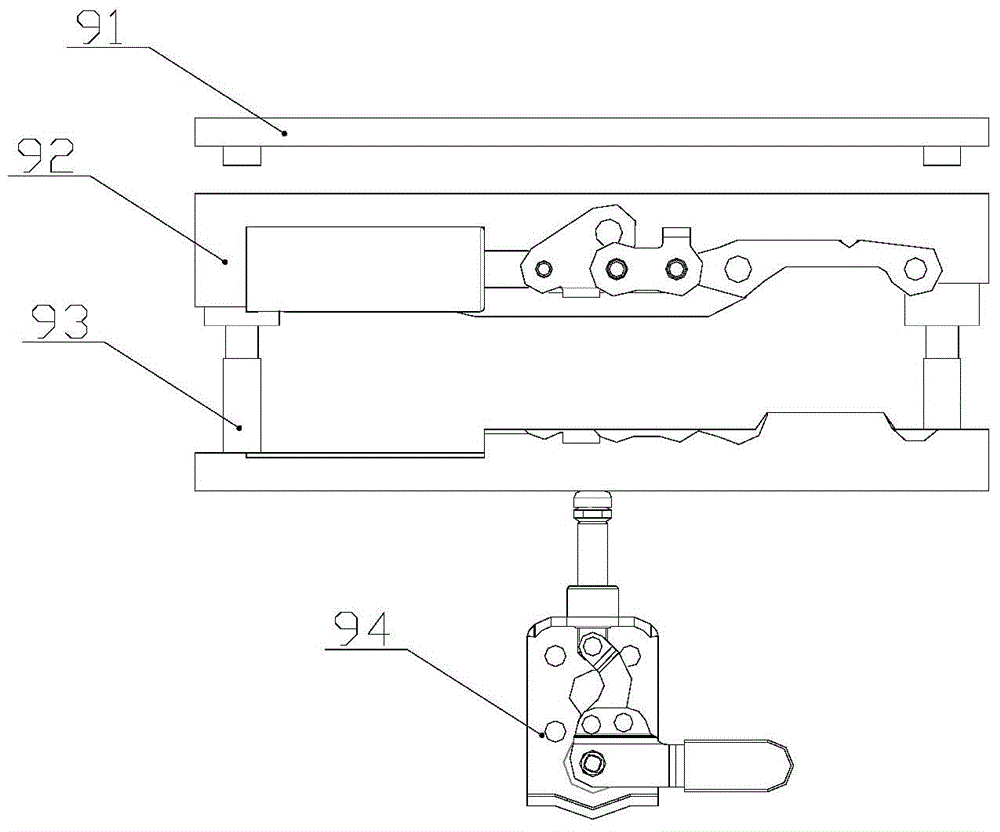

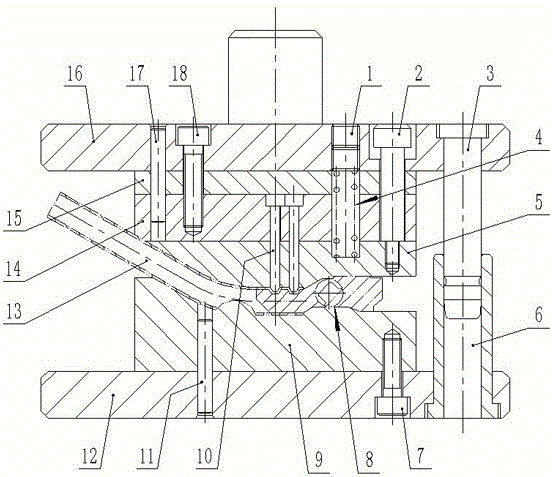

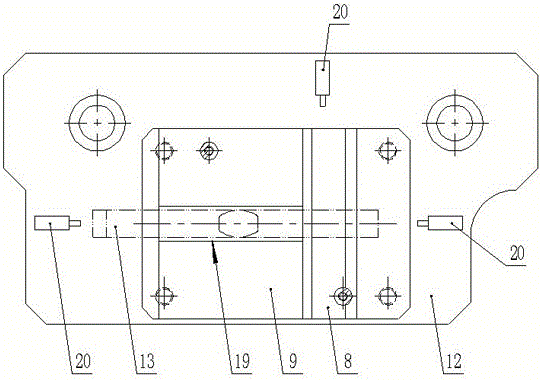

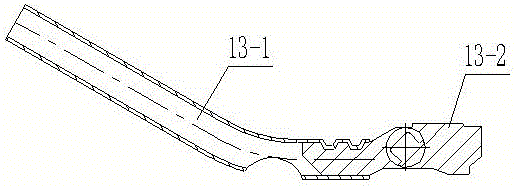

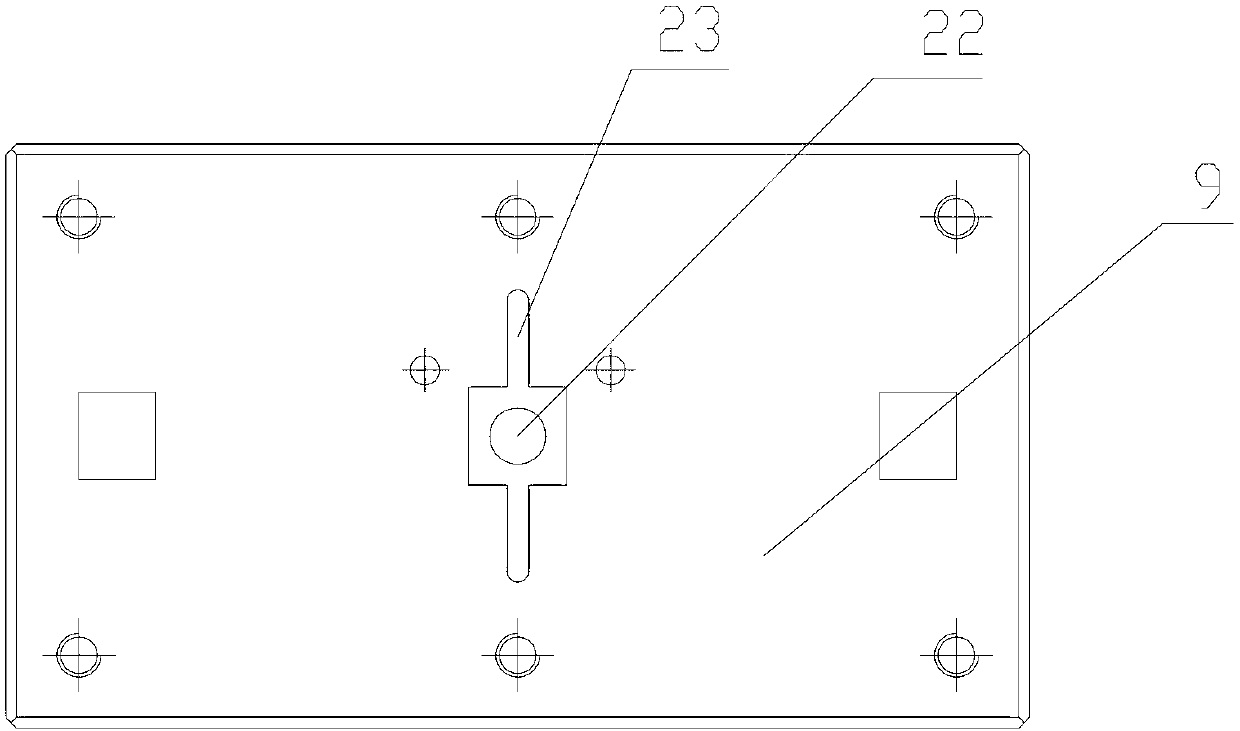

Automotive light driving lever punching point closing riveting die with CCD visual inspection systems

InactiveCN106140975AAccurate and reliable positioningImprove efficiencyShaping toolsMetal-working feeding devicesLight drivenEngineering

The invention discloses a riveting die for punching and closing the punch point of an automobile light lever with a CCD visual inspection system, belonging to a bar riveting die, and aims to provide a bar punching riveting die with low labor intensity, high efficiency and accurate positioning. It includes an upper die part, a lower die part and a guide part; the upper die part consists of two punches (10) fixed on the back of the upper die plate (16) by a fixing plate (14), and a discharger located on the back of the fixing plate (14) The plate (5) and the spring (4) arranged between the stripper plate and the upper template (16) are composed; the lower mold part is composed of a concave mold (9) fixed on the surface of the lower template (12). There is a positioning groove (19) and a positioning boss (8); the guide component is composed of a guide column (3) and a guide sleeve (6); the two ends of the positioning groove (19) and the side surface of the positioning boss (8) are fixed with a CCD Vision Inspection System (20). The invention has simple structure and convenient operation, and is a mold for riveting the light lever of automobiles.

Owner:HUAYANG ELECTRIC APPLIANCES CORP OF GUIZHOU GUIHANG AUTOMOTIVE COMPONENTS

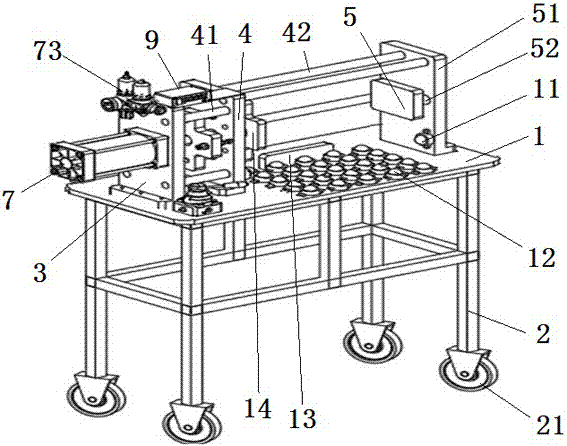

Workbench, riveting equipment and riveting method

The invention relates to a workbench. The workbench comprises a support, an operating platform supported on the support, an adjusting device and a driving device, wherein the operating platform is provided with at least one hollowed part; the adjusting device is used for adjusting machining positions of workpieces, is arranged on the side, close to the support, of the operating platform and further corresponds to the hollowed part; and the driving device is installed on the support and can further drive the adjusting device to penetrate out of the hollowed part or to reset after driving the adjusting device to penetrate out of the hollowed part. By adoption of the workbench, the workpieces can be put and conveyed on the adjusting device independently, operation by technical staff is facilitated, machining time of the workpieces is shortened and tooling cost of the workpieces is reduced. The invention further provides riveting equipment and a riveting method for riveting the workpieceswith the riveting equipment.

Owner:SUZHOU SIWANGXI ELECTROMECHANICAL CO LTD

New stud structure

A new type of stud structure, which is applied to riveting products. The new type of stud structure includes a tension ring with successively smaller diameters, a riveting spline, a column and an extrusion groove. The force ring, the riveting flower teeth, the extruding groove and the column are sequentially connected, and the riveting flower teeth are provided with a gear-shaped structure. The riveting teeth of the novel stud structure of the present invention are relatively thin and easy to be riveted, and the new stud structure adds a pressure-resistant ring on the riveting teeth, and when the new stud structure bears a large pulling force, the riveting The flower teeth will not splinter.

Owner:SUZHOU MITAC PRECISION TECH

Nut cap riveting die

The invention discloses a nut cap riveting die which comprises an upper die and a lower die, wherein the lower die comprises a positioning board arranged on a base plate; a rectangular groove is arranged in one surface, which is in contact with the base plate, of the positioning board,,and a through hole for placing a workpiece is arranged in a middle position of the rectangular groove of the positioning board; plunger chips are respectively arranged in the rectangular groove and positioned in two sides of the through hole; a plunger chip compressed spring is arranged between each plunger chip and the positioning board; inclined wedges matched with the plunger chips are arranged on the upper die, and the inclined wedges enable the plunger chips to extrude the workpiece through extruding the plunger chip via the tail ends for realizing riveting. The nut cap riveting die has a simple structure, realizes riveting of a nut cap by driving the plunger chips to horizontally move through vertical movement of the inclined wedges, is convenient for riveting, is safe and reliable, facilitates the positioning of the workpiece and the nut cap, and can be widely applied to the field of riveting of the end part of the workpiece.

Owner:昌辉汽车电器(黄山)股份公司

Liquid crystal television receiver

InactiveUS20050078229A1Simple structureHigh strengthTelevision system detailsTelevision system scanning detailsLCD televisionLiquid crystal

The invention provides a liquid crystal television receiver, a liquid crystal display of a desktop computer and the like, which is equipped with a pivoting means capable of statically maintaining the image display portion stably with the hinge portion prevented from being loosened even after performing tilting operation repeatedly for a long period of time. The invention provides a liquid crystal television receiver comprising a television receiver body equipped with a liquid crystal panel and a control unit, which is pivotally supported on a leg portion so as to enable tilting of the television receiver body, wherein a hinge portion pivotally supporting the television receiver body in a tiltable manner is composed of a pair of left and right hinge portions, the left and right hinge portions are respectively composed of a stand portion attached to the leg portion and a swing portion attached to the television receiver body, and the left and right hinges are assembled to form an integral hinge portion.

Owner:ORION ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com