Wagon 120-valve protection hood rivet disassembling device

A technology for railway freight cars and protective covers is applied in the field of rivet riveting and dismantling equipment for 120 valve protective covers of railway freight cars, which can solve the problems of incompatibility with the requirements of transportation, high cost, inconvenience, etc., and achieves convenient operation, improved service life, and improved work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be construed that the scope of the above-mentioned subject matter of the present invention is limited to the following examples.

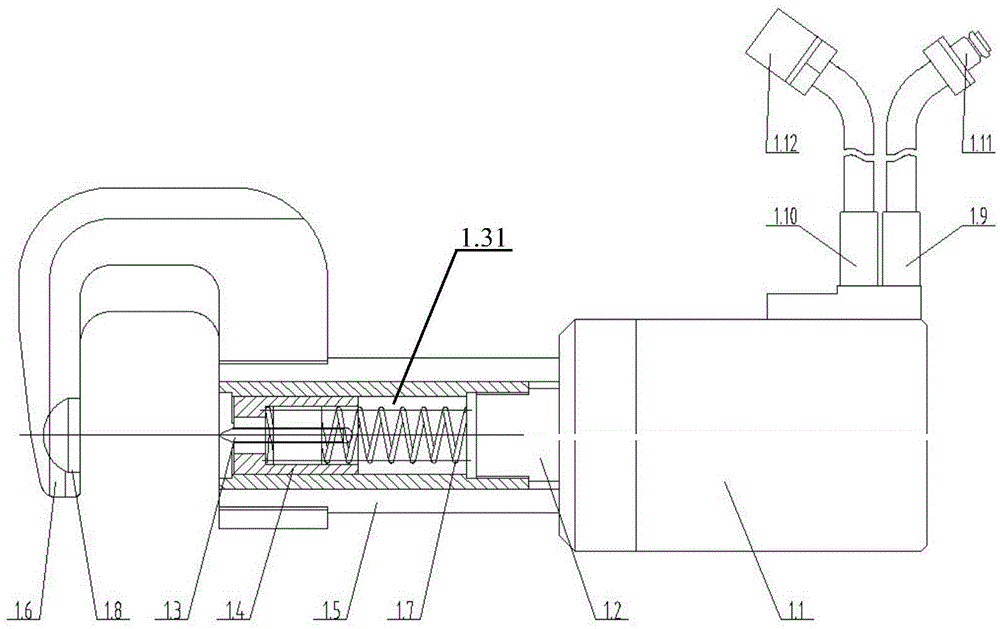

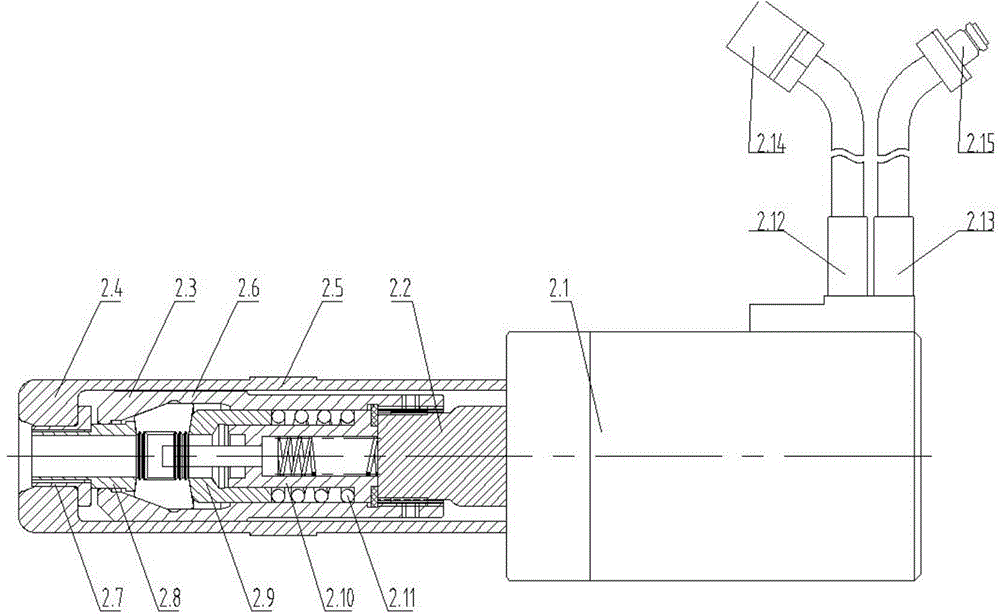

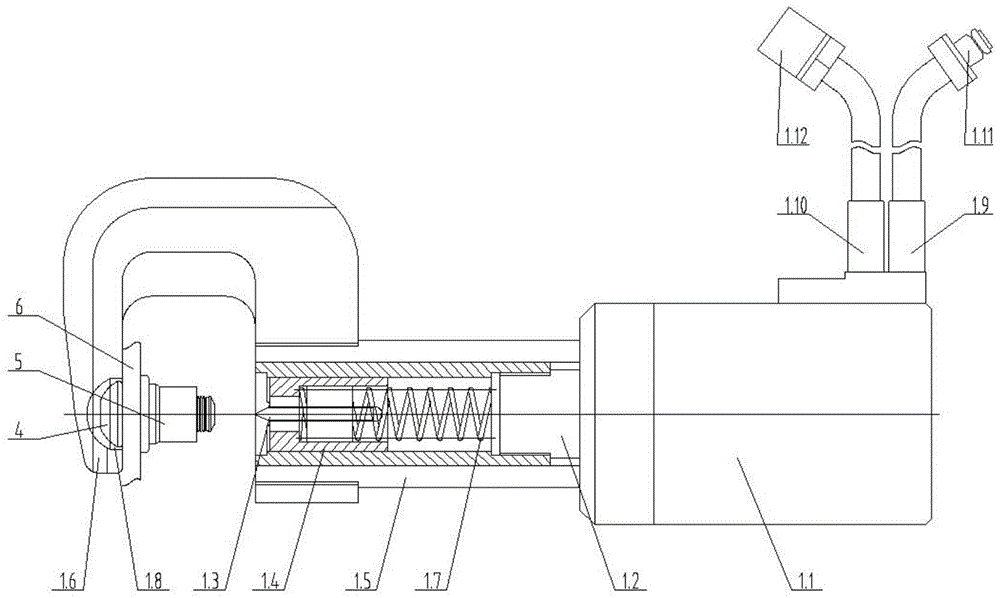

[0029] combine figure 1 — Figure 7 , the present invention provides a rivet riveting equipment for a 120 valve protective cover of a railway freight car. The rivet dismantling equipment is composed of a riveter 2, a cutter 1 and a manual hydraulic pump 3. For demolition, the riveter 2 is used for riveting the rivet 4, and the manual hydraulic pump 3 provides the power source.

[0030] The cutter 1 of the rivet riveting equipment is composed of cutter cylinder 1.1, cutter piston 1.2, cutter head assembly 1.3, positioning sleeve 1.4, cutter connection jacket 1.5, C-shaped pliers 1.6, cutter spring 1.7 , Cutter oil inlet pipe 1.9, Cutter oil return pipe 1.10, Cutter quick-change joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com