Patents

Literature

35results about How to "Quick riveting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

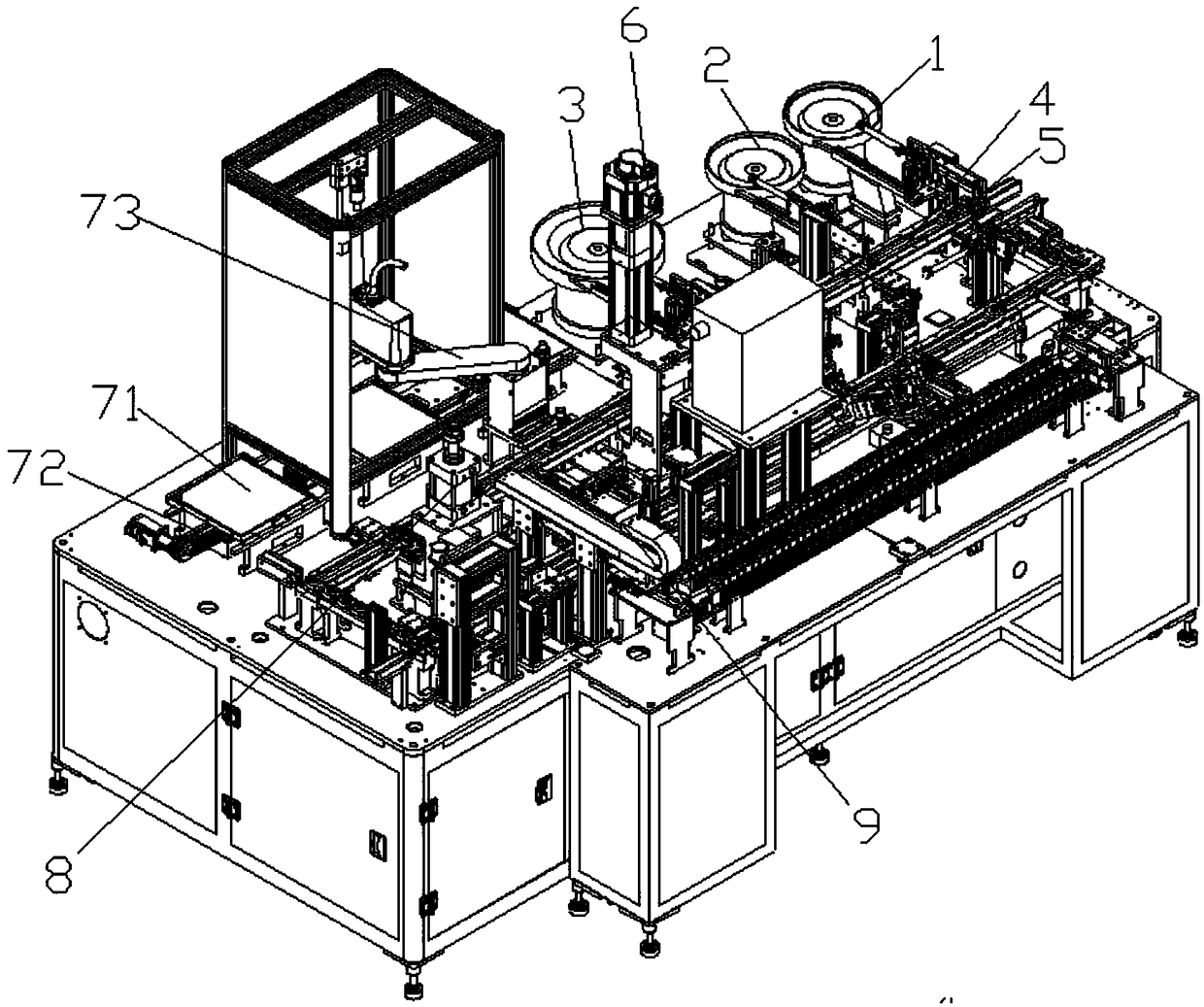

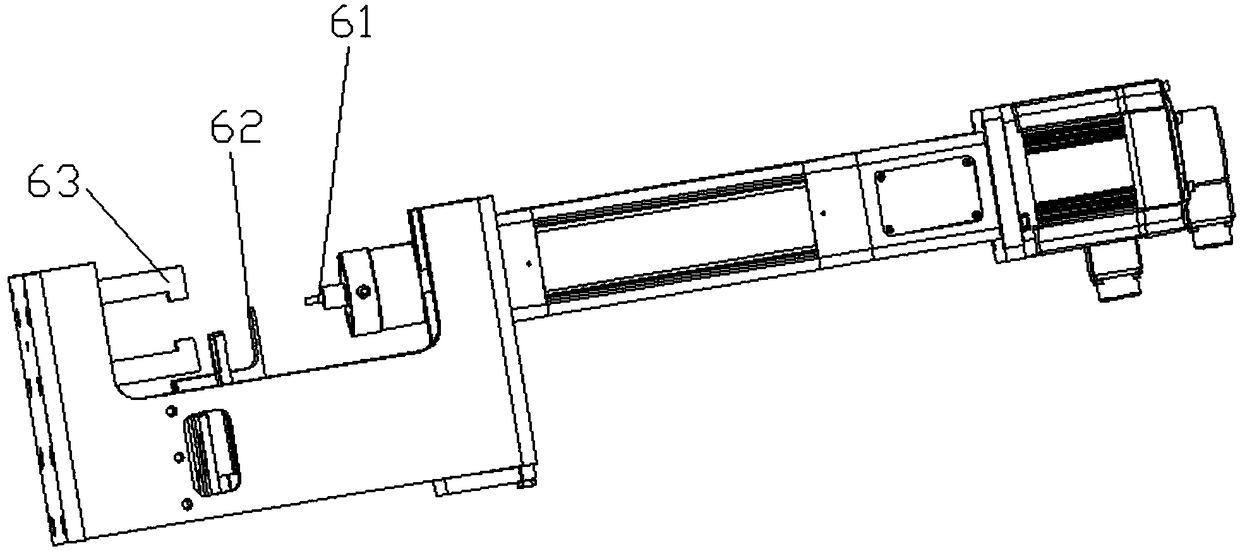

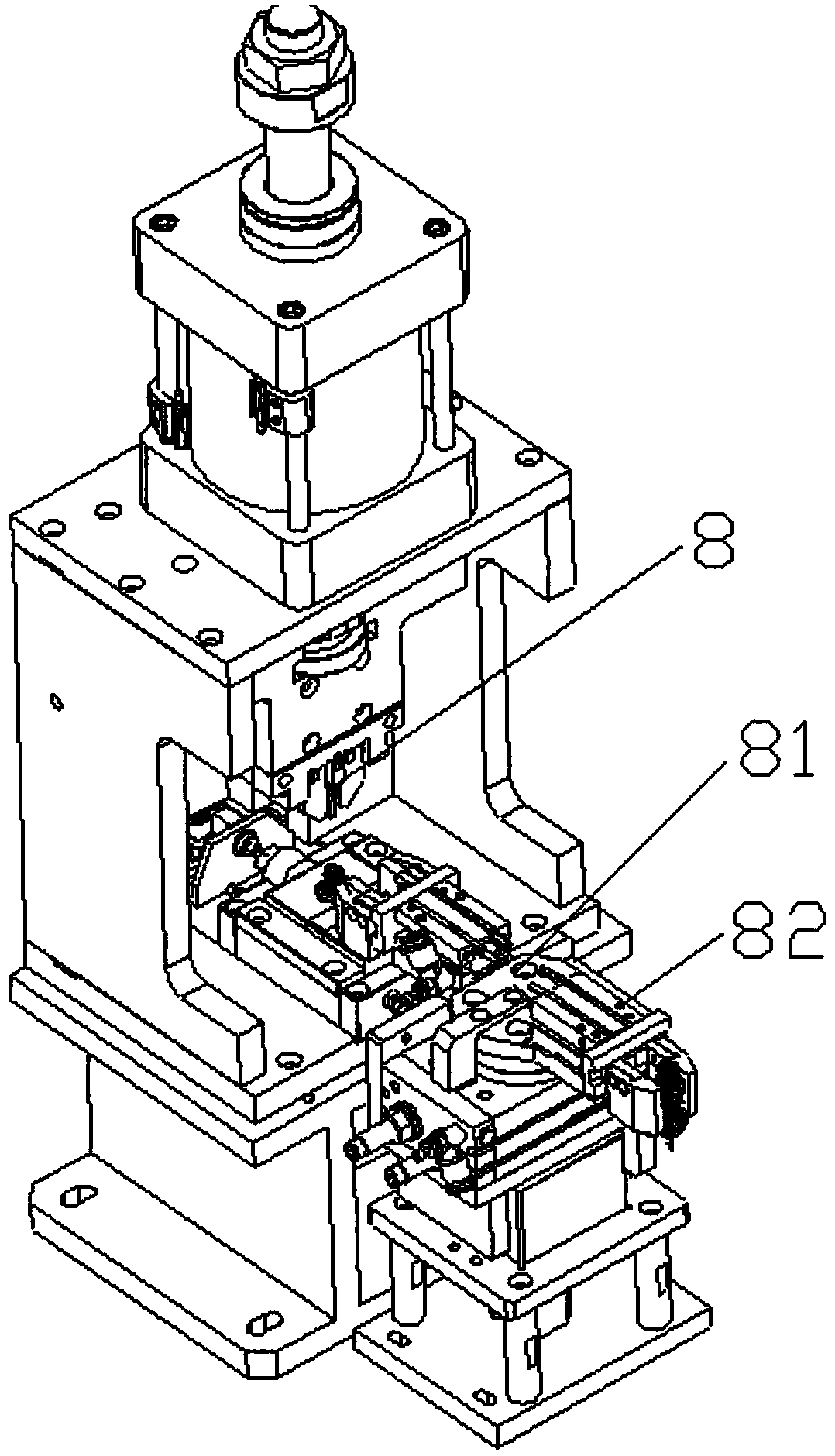

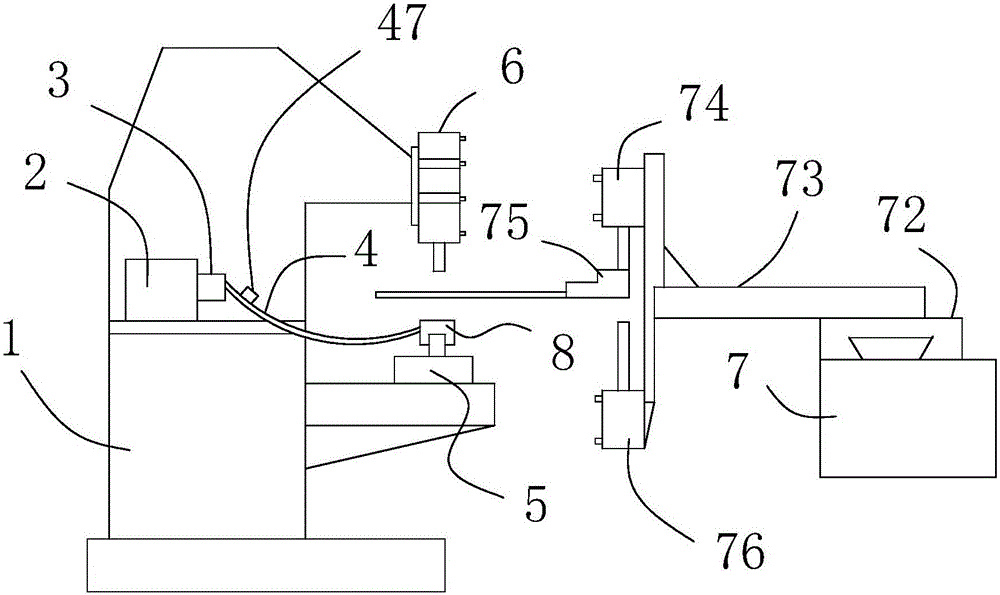

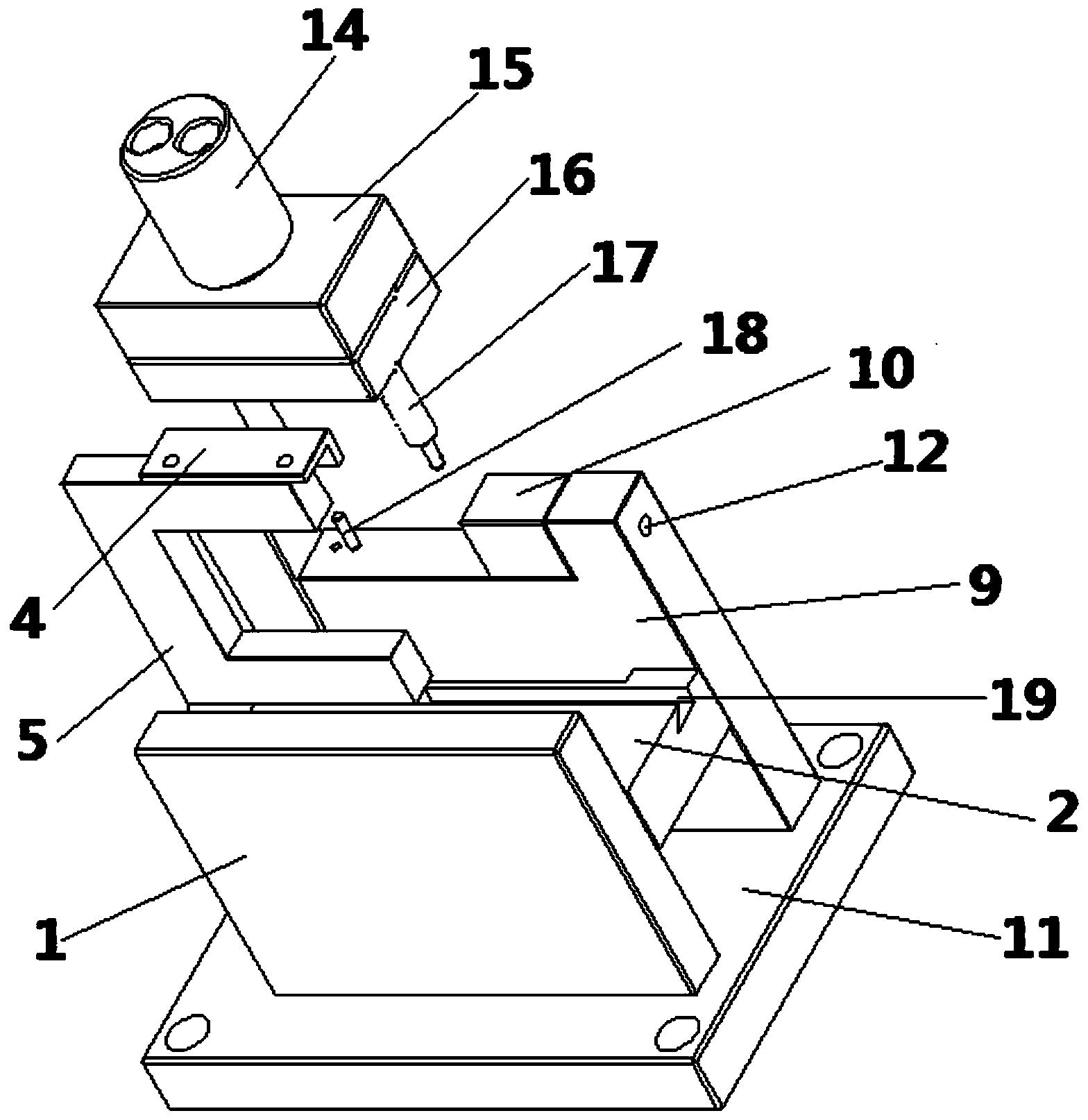

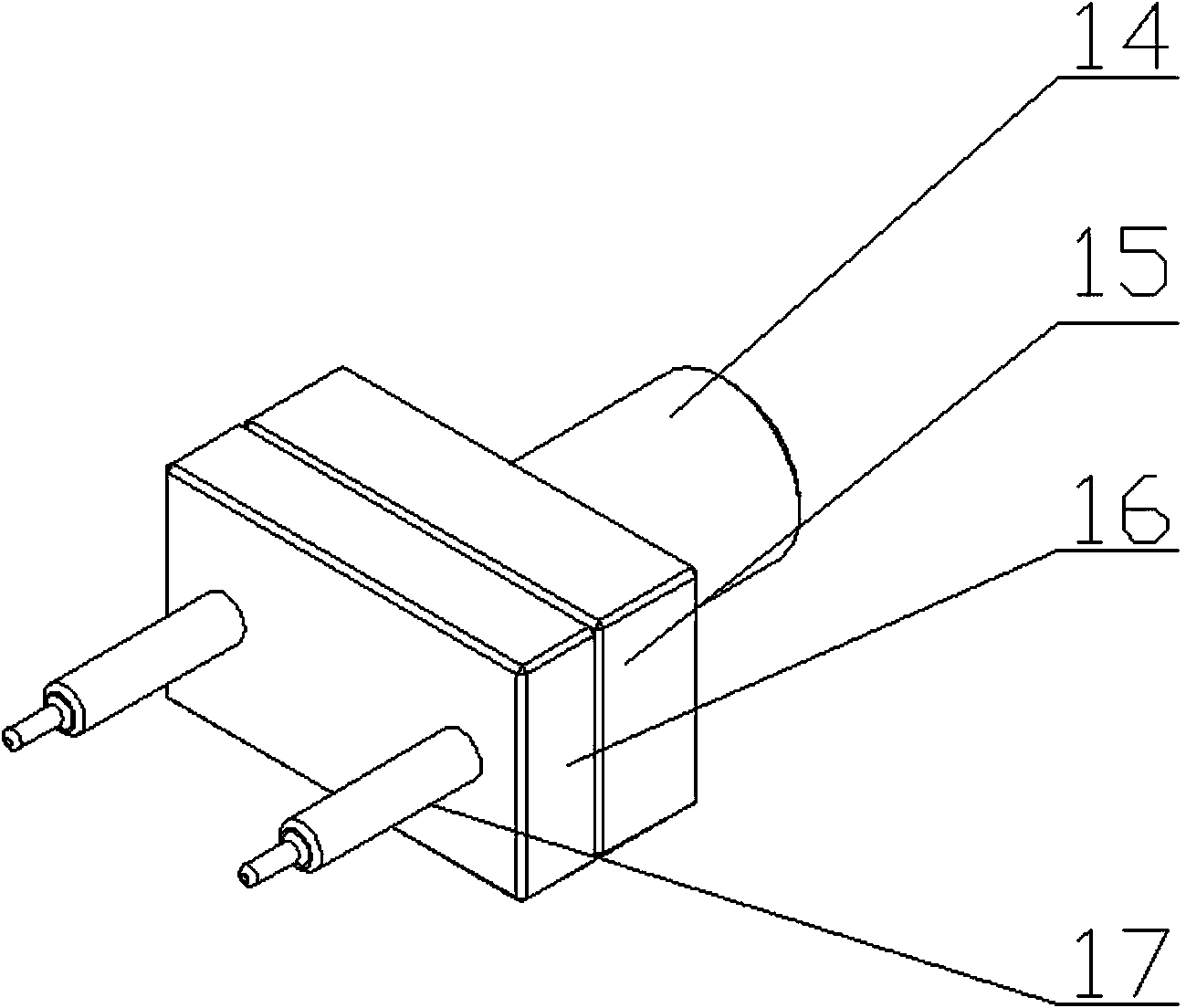

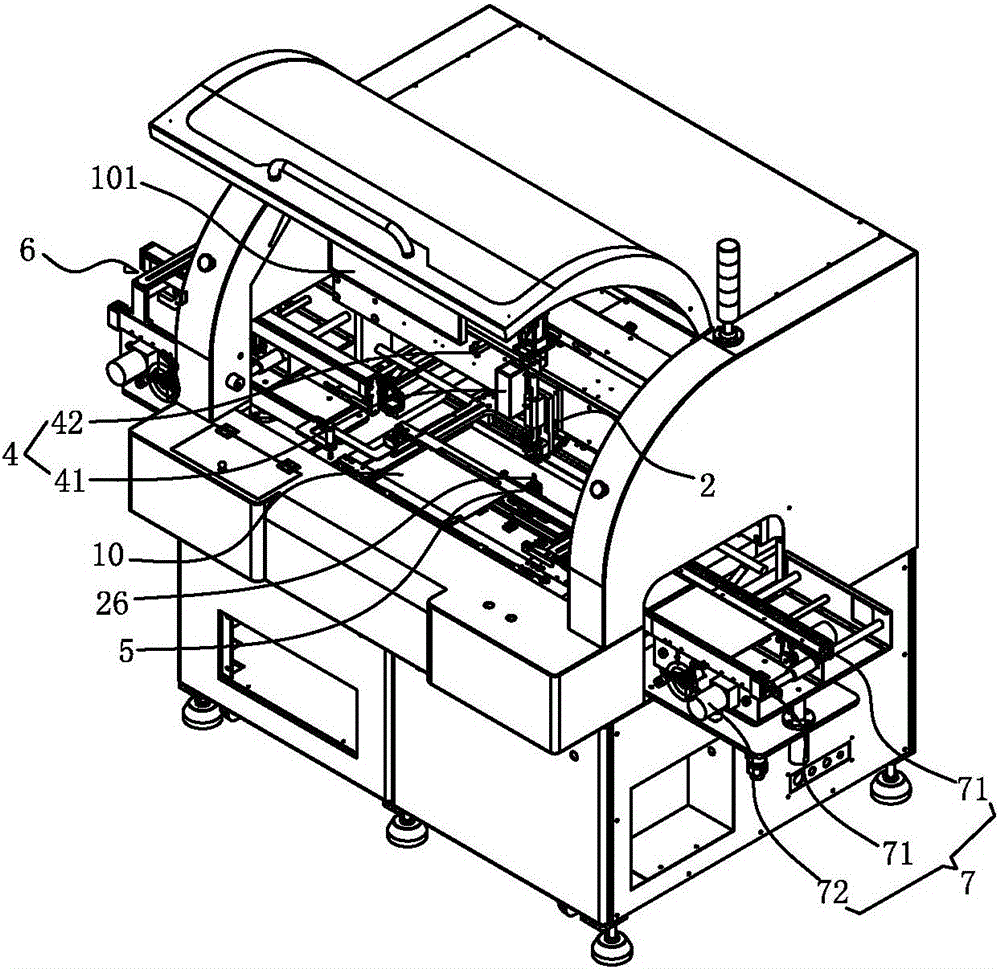

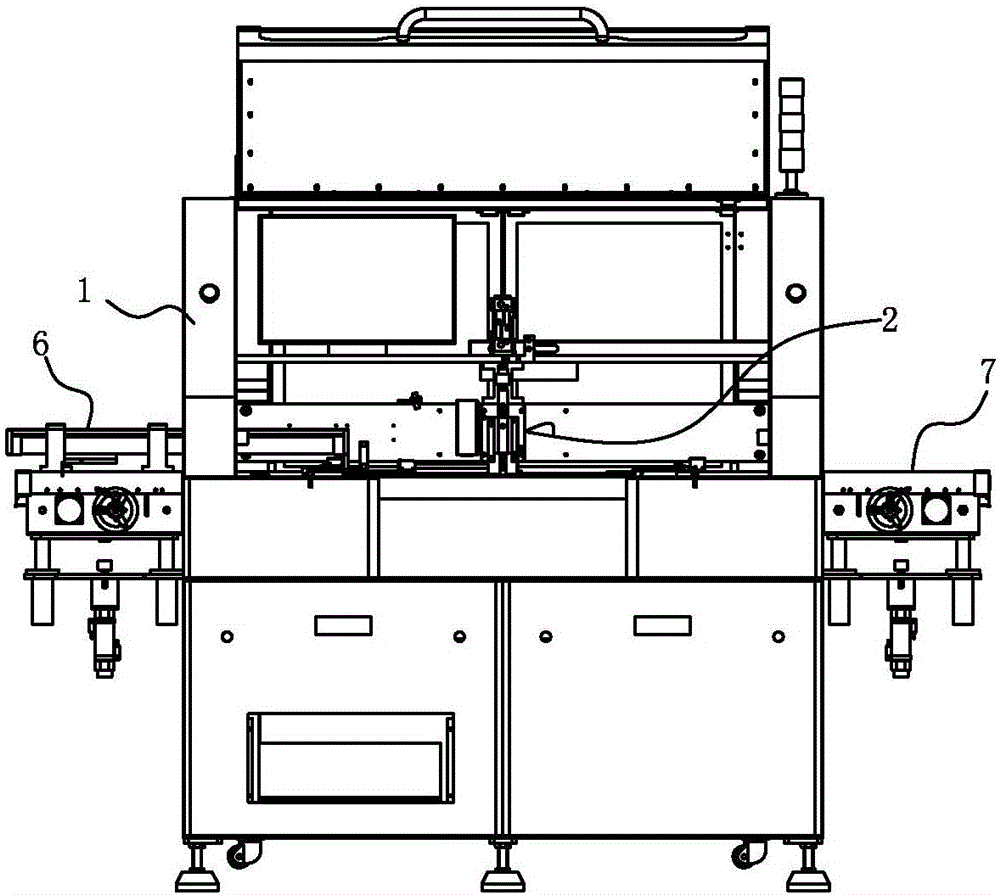

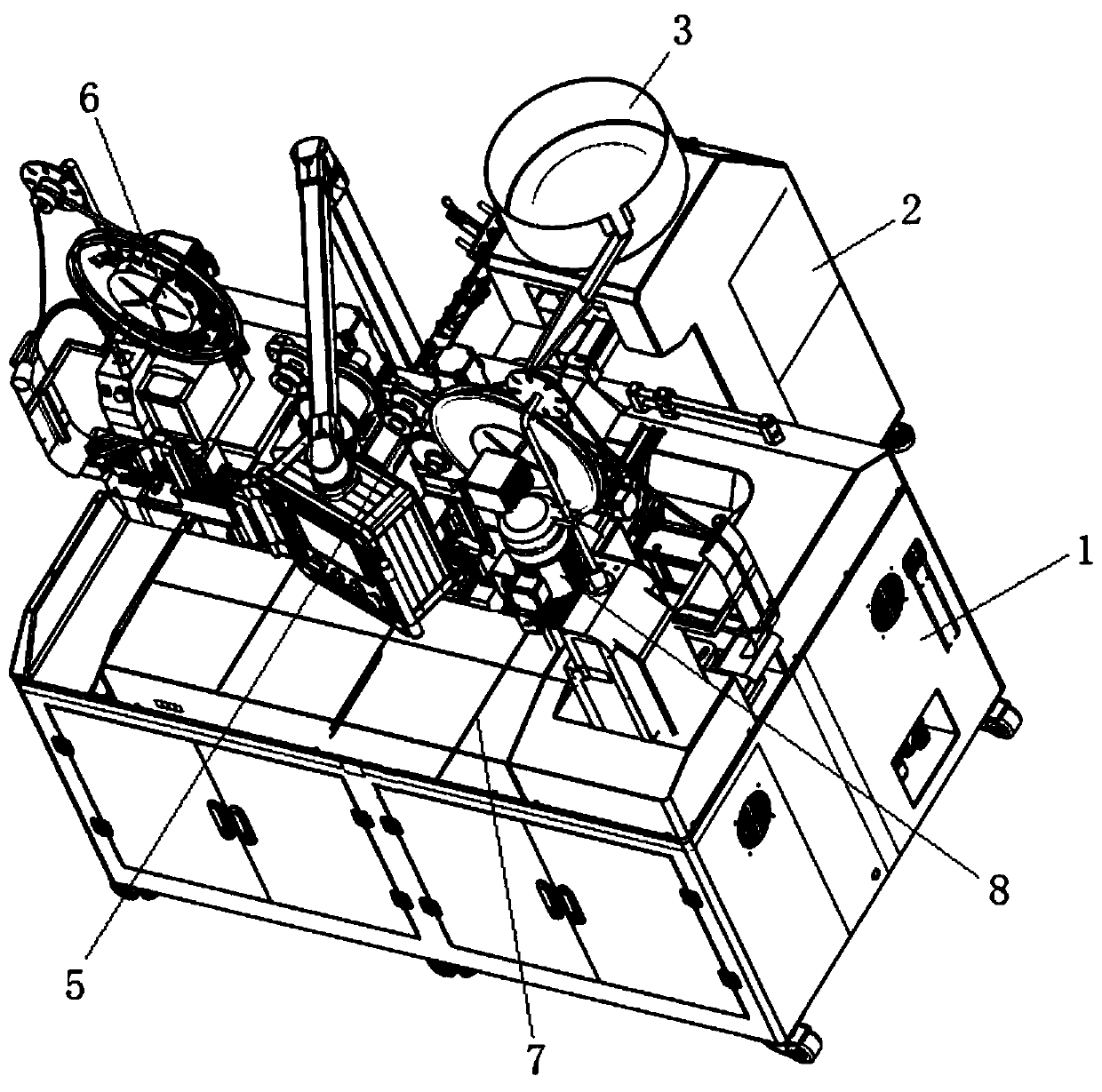

Electromagnetic valve assembling machine

PendingCN108311883AReduce loading spacePrecision weldingAssembly machinesOther manufacturing equipments/toolsEngineeringElectromagnetic valve

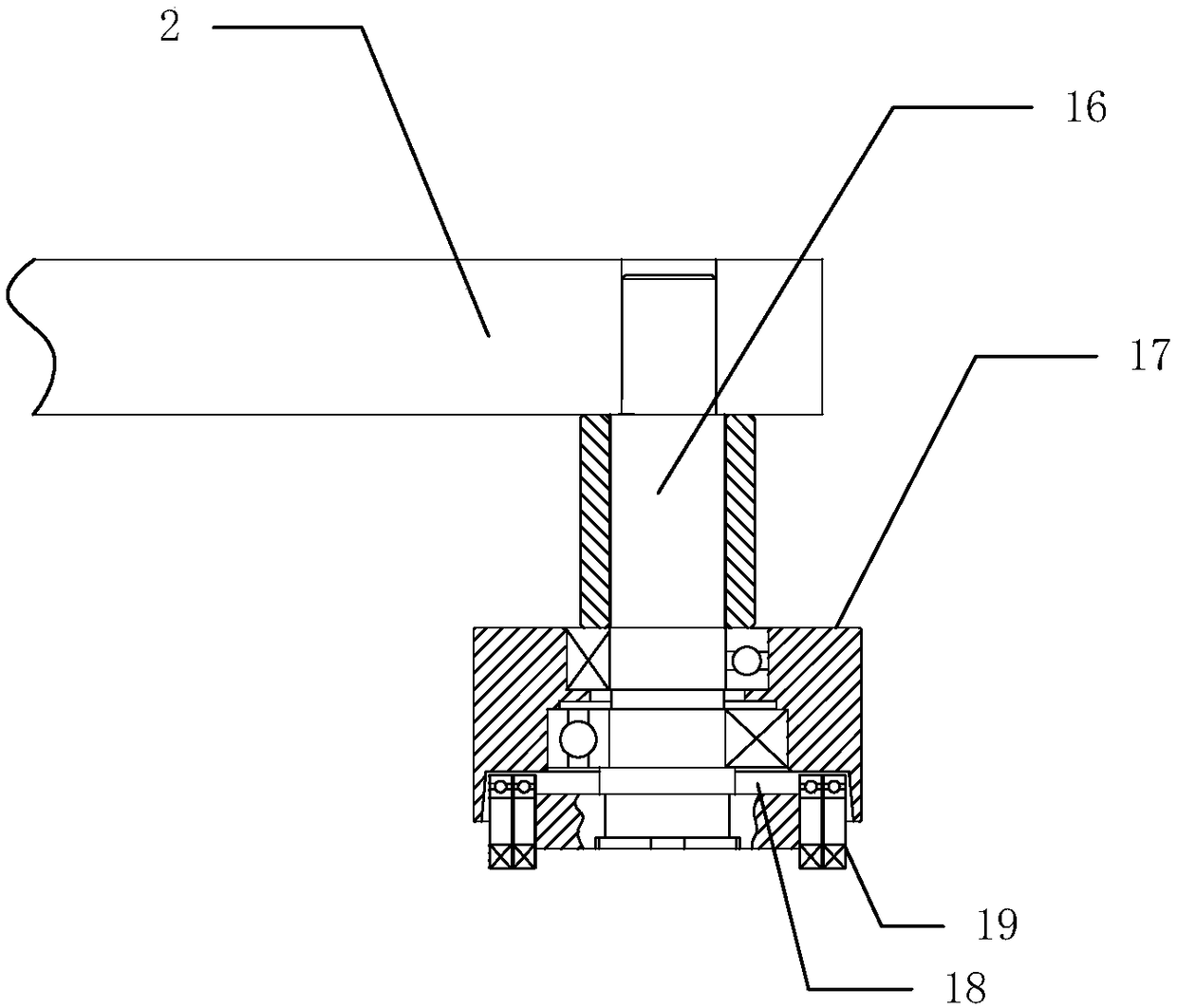

The invention discloses an electromagnetic valve assembling machine. The electromagnetic valve assembling machine comprises a needle vibrating loading mechanism, a gasket vibrating loading mechanism and a valve seat vibrating loading mechanism which are successively arranged, wherein a pin pressing mechanism, a valve element loading mechanism for putting a valve element in a valve seat, a valve seat riveting pressure mechanism for fixing the valve element and the valve seat, a coil assembling mechanism for assembling a coil to an electromagnetic valve body, a coil welding mechanism and a coiltailoring mechanism are successively arranged on two sides of an electric runner; the moving directions of a first coil electric track and a second coil electric track are opposite; a first pushing air cylinder for pushing a coil to the input end of the second coil electric track is arranged at the output end of the first coil electric track; and a second pushing air cylinder for pushing the coilout of the output end of the second coil electric track and a chuck mechanism for conveying the coil to the coil assembling mechanism are arranged at the output end of the second coil electric track.The coil loading space is reduced, and the track is lengthened, so that the coil is manually loaded conveniently.

Owner:KUNSHAN HUAYU AUTOMATION TECH

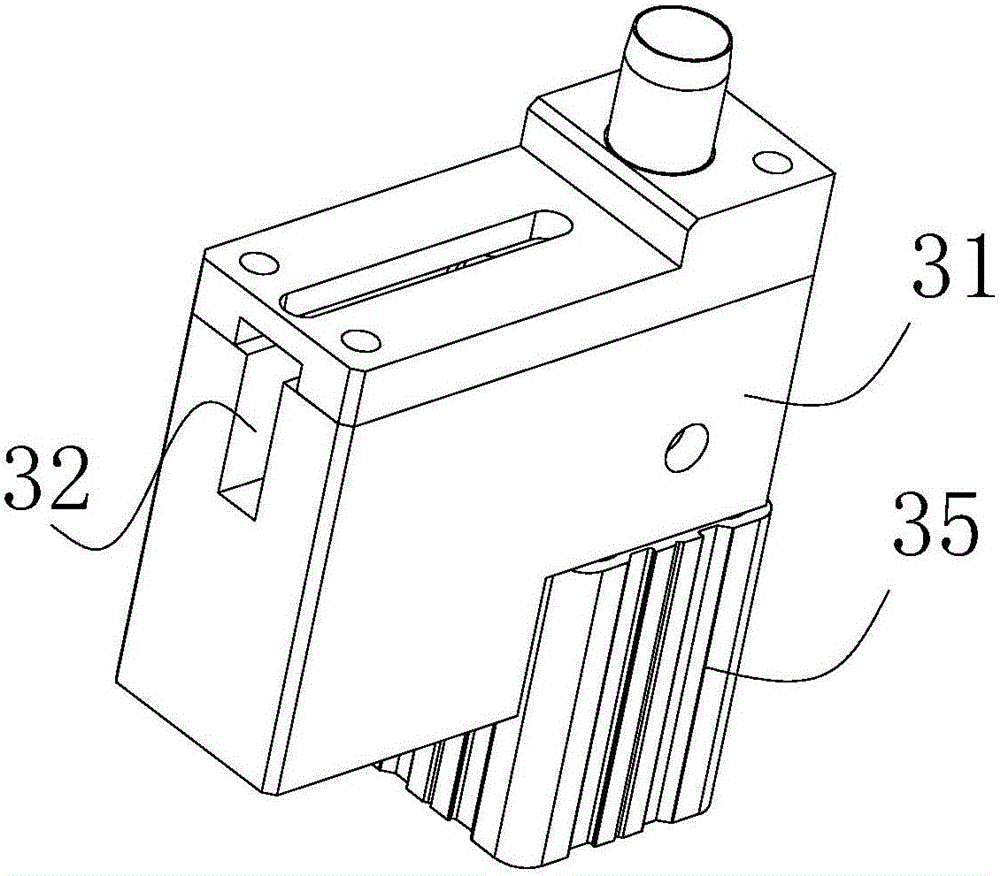

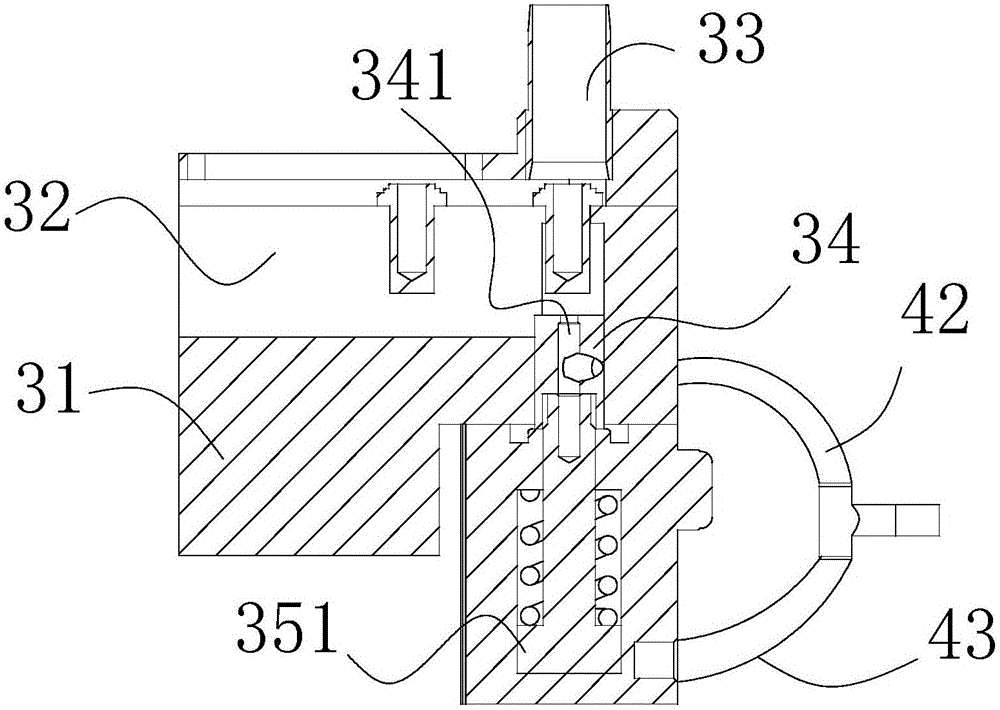

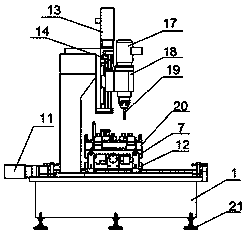

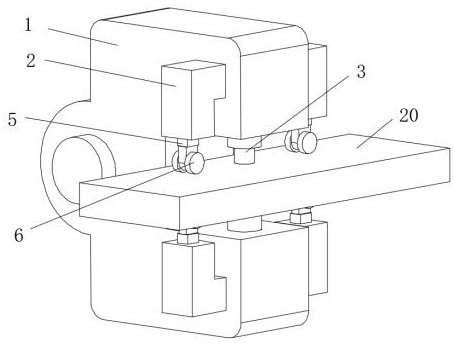

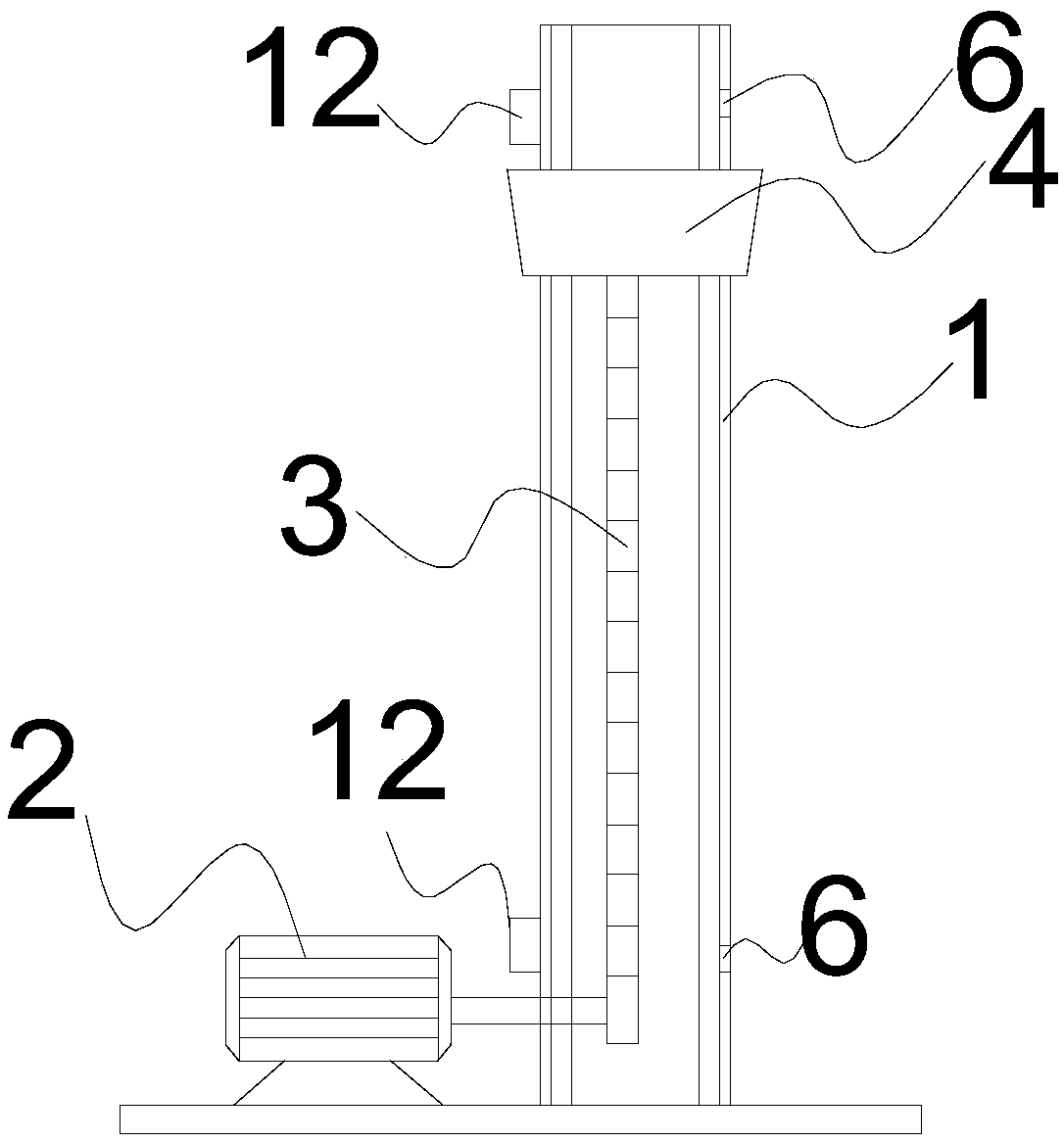

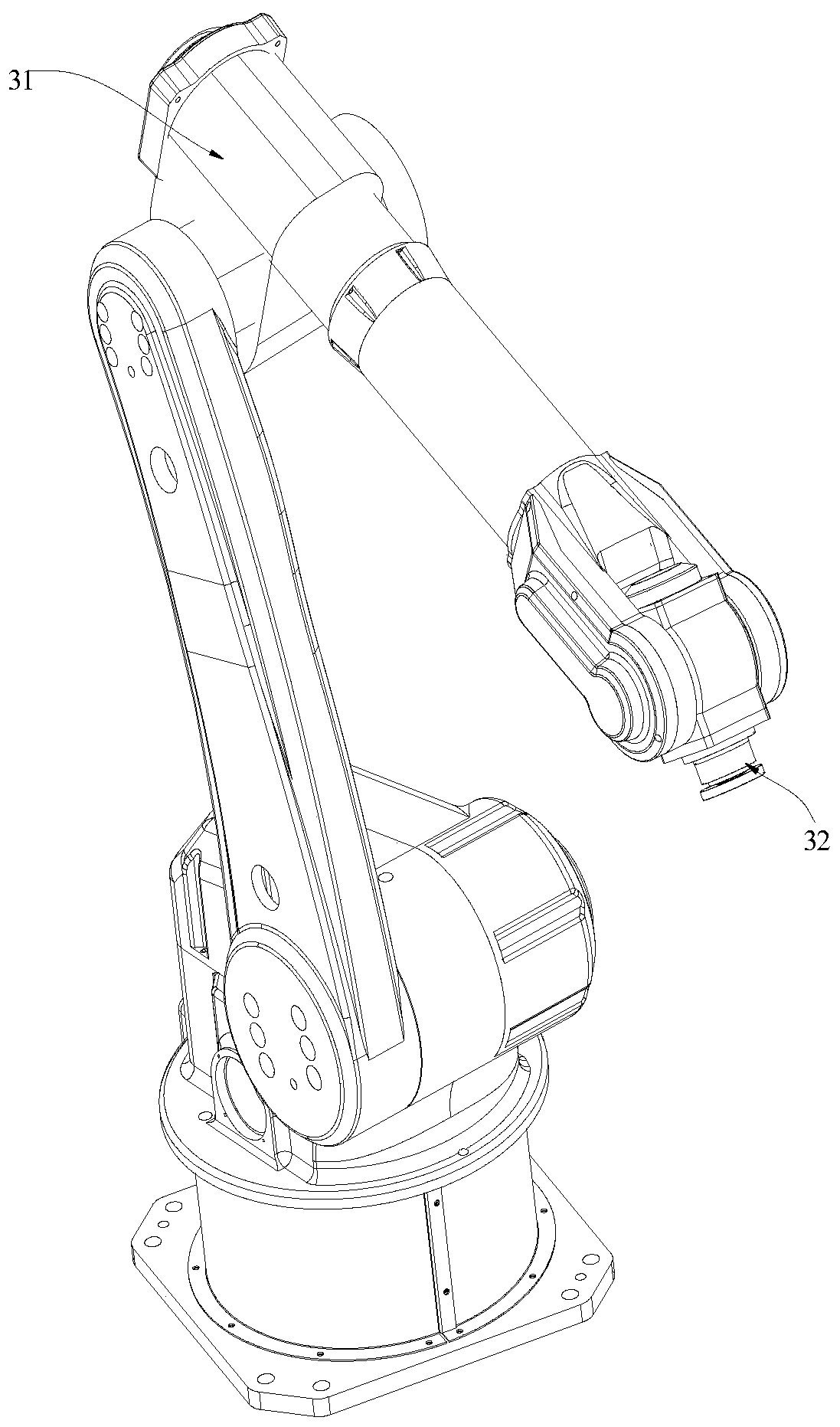

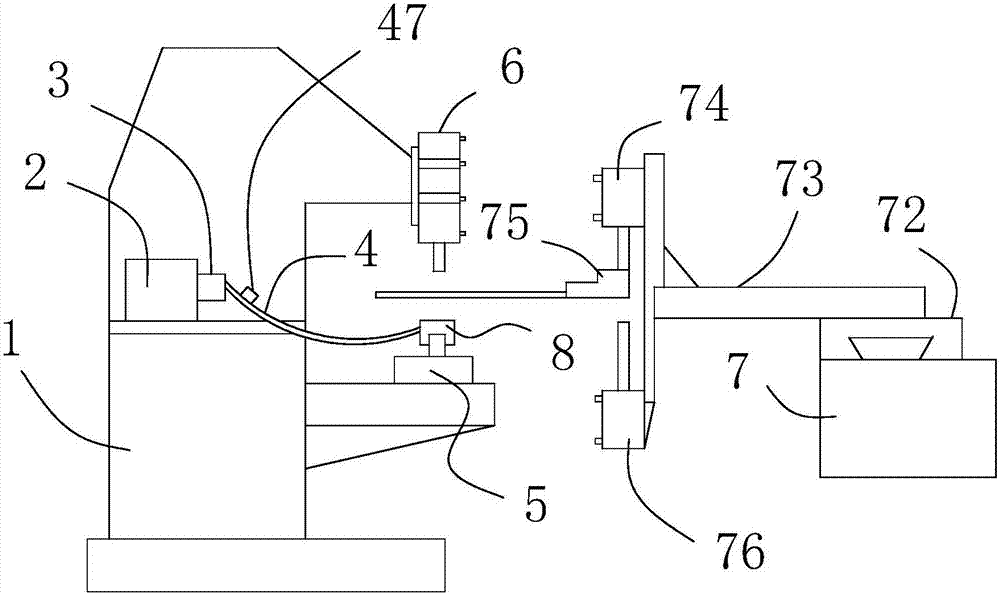

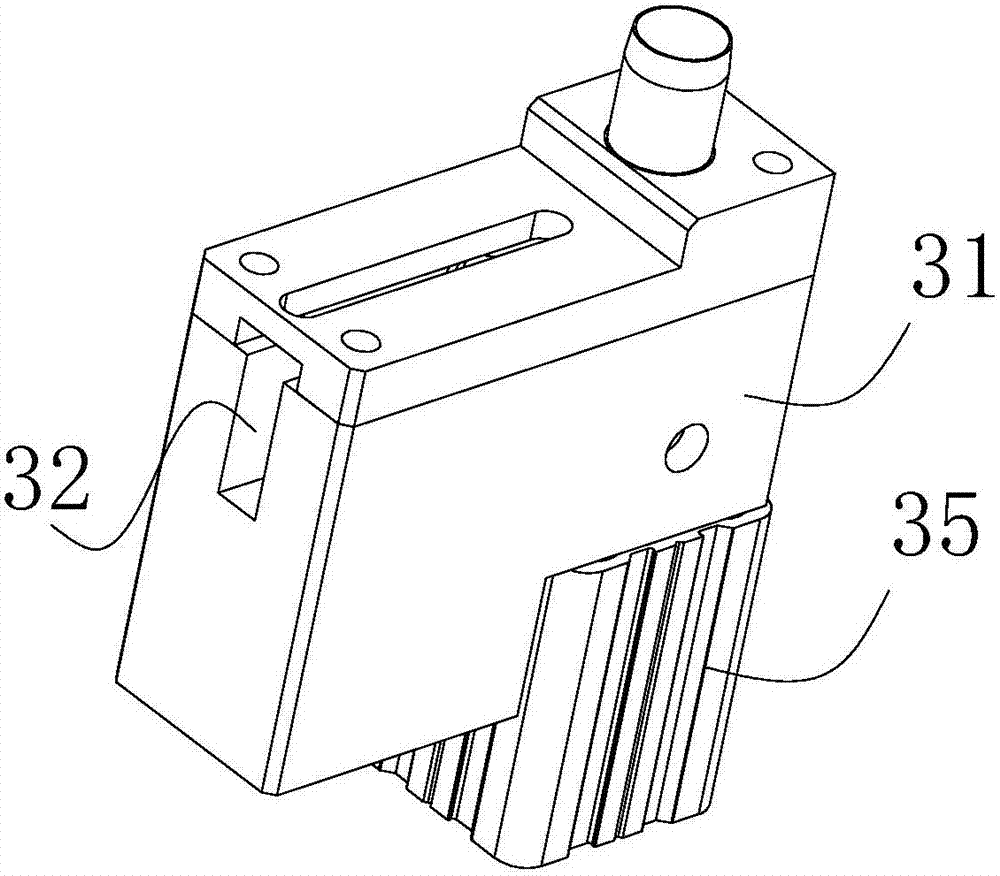

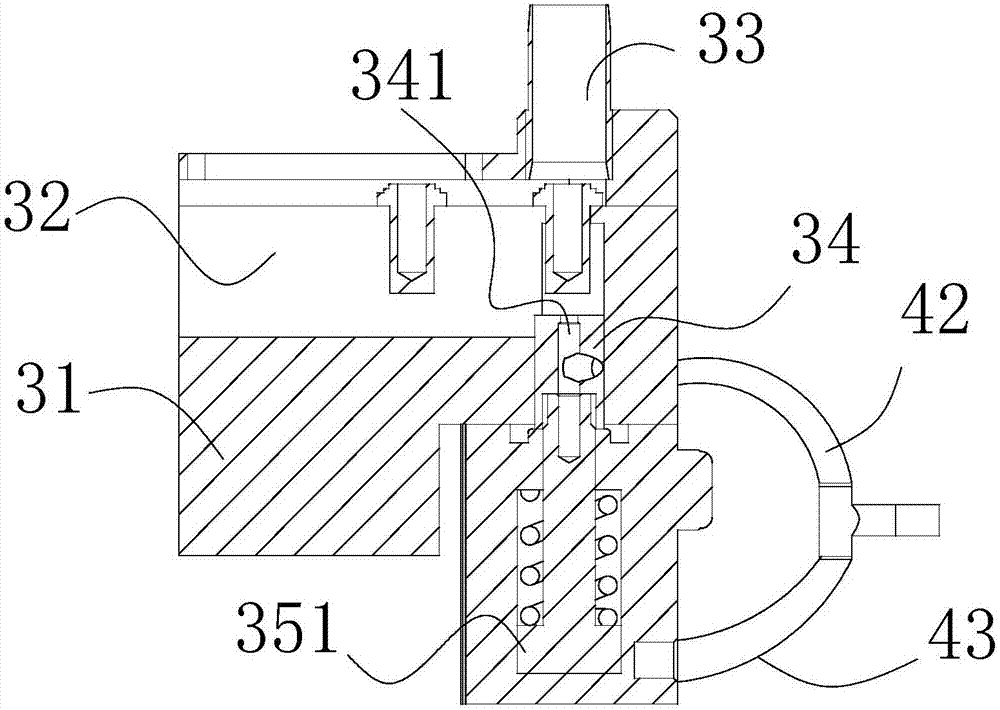

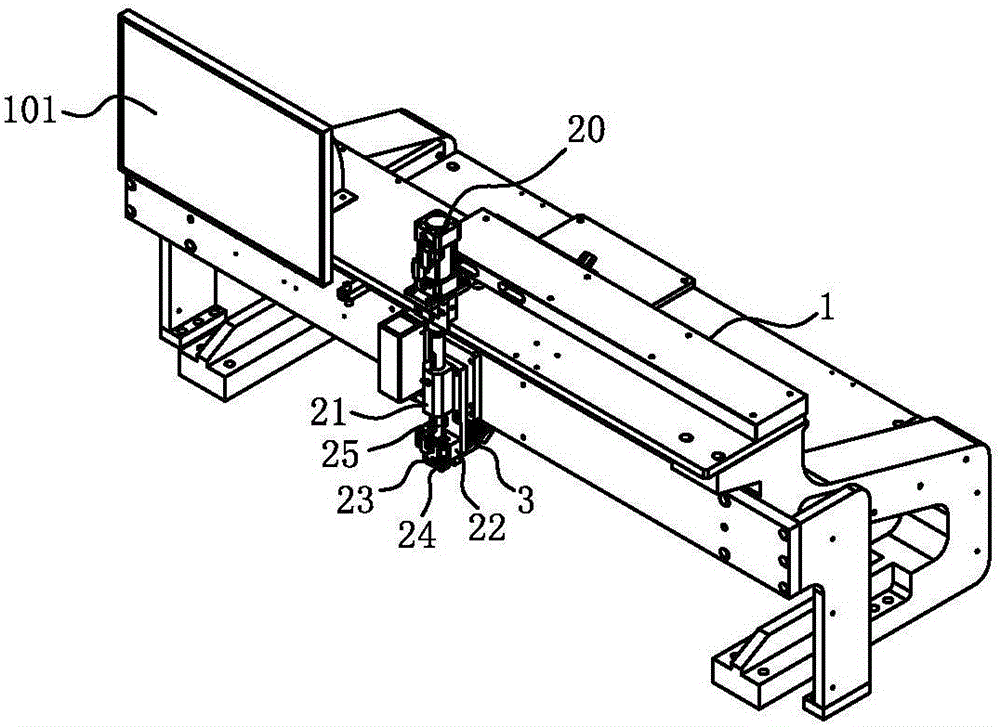

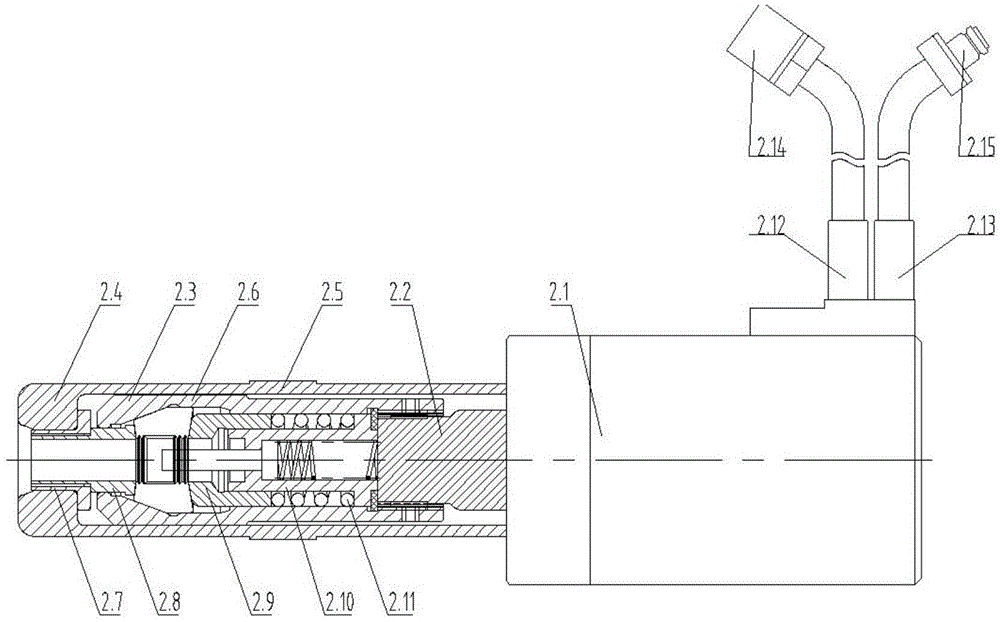

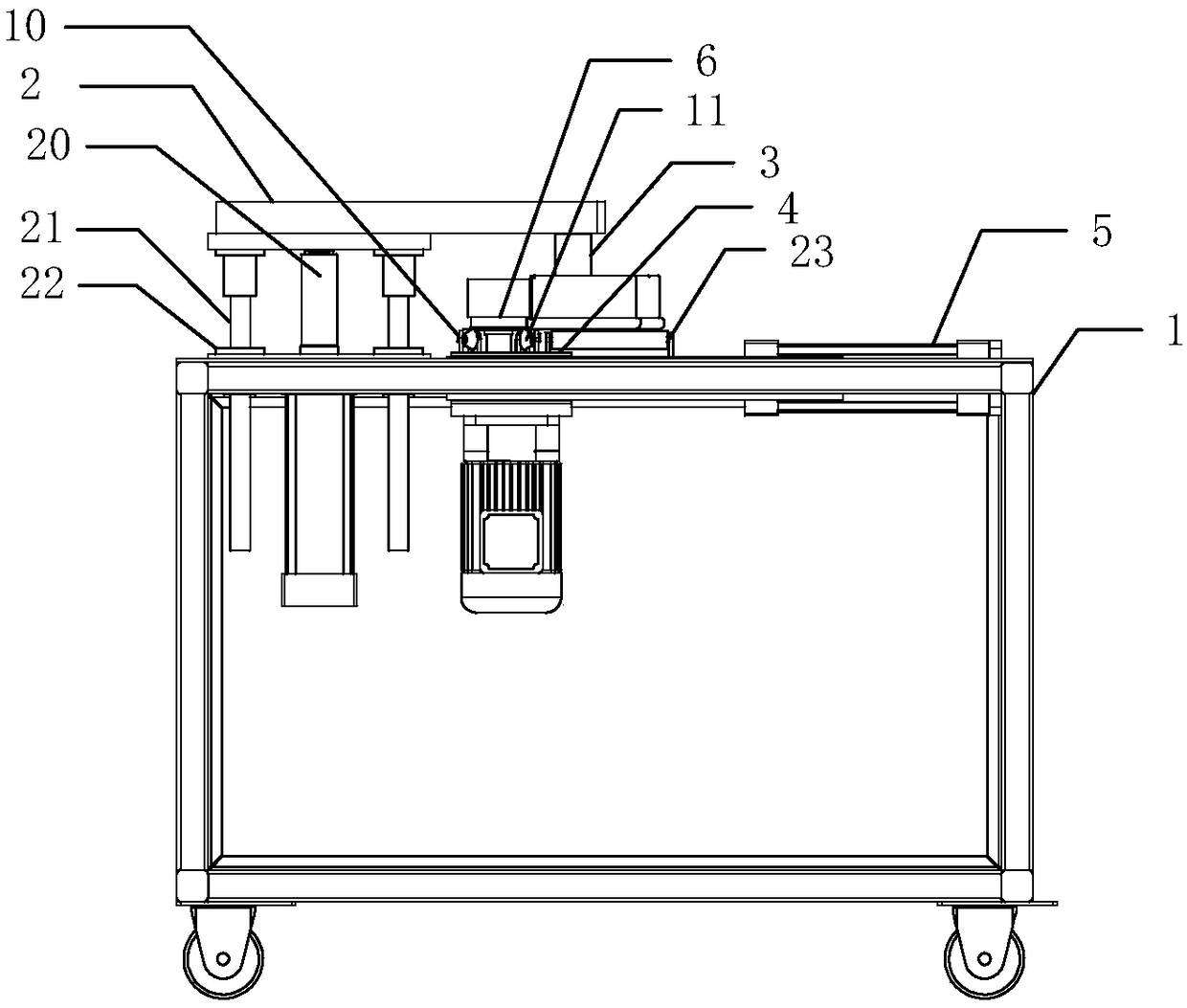

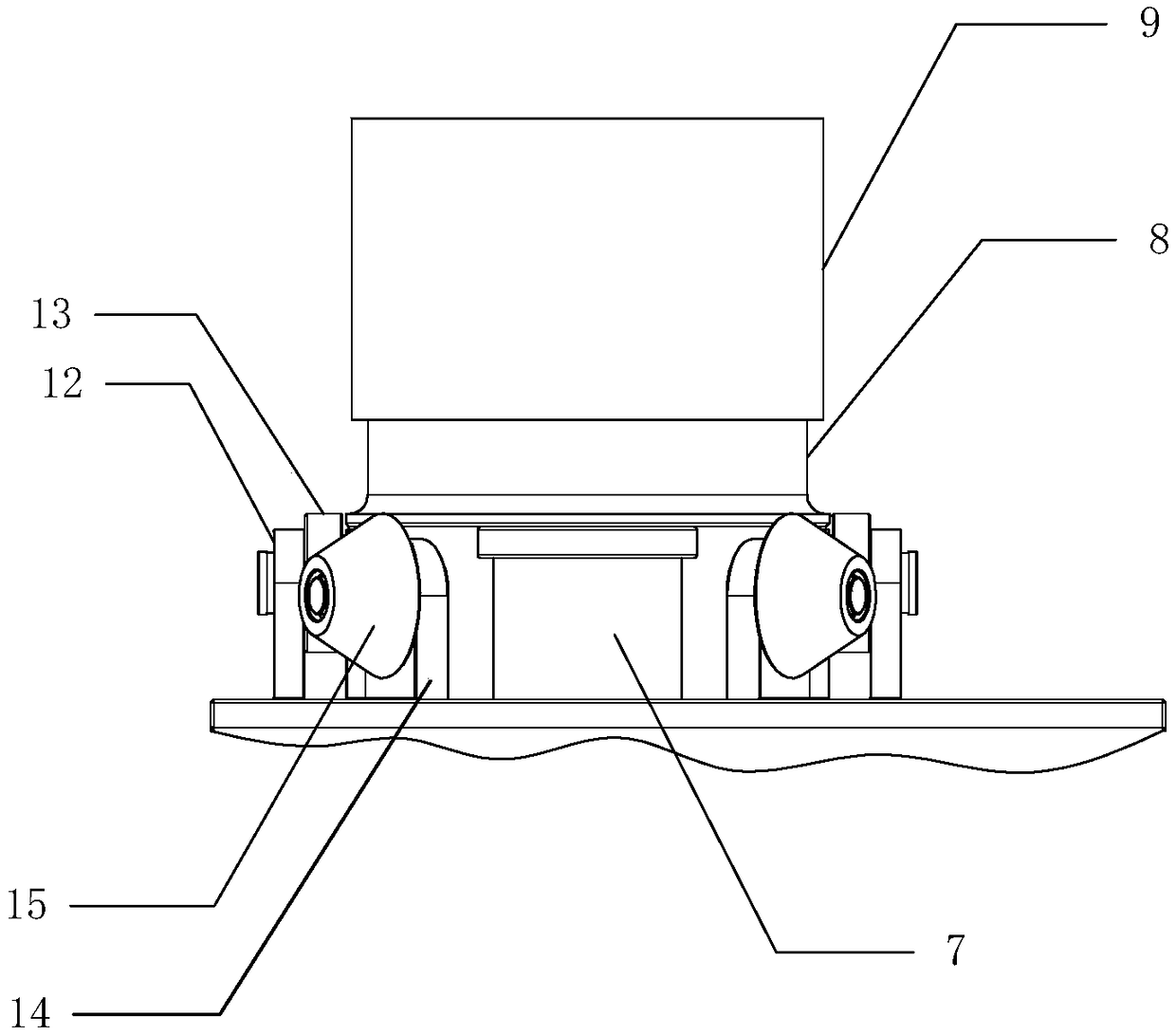

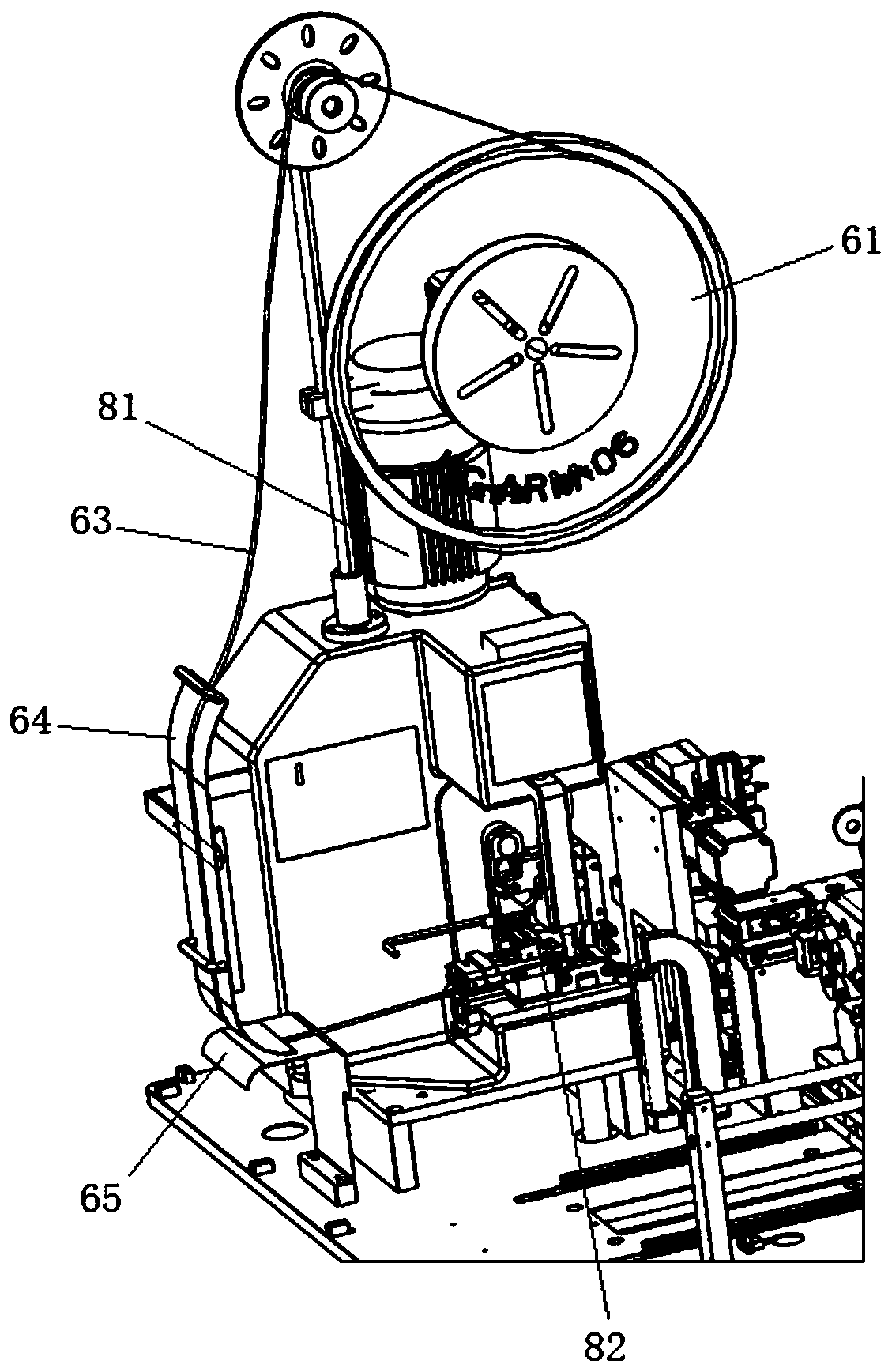

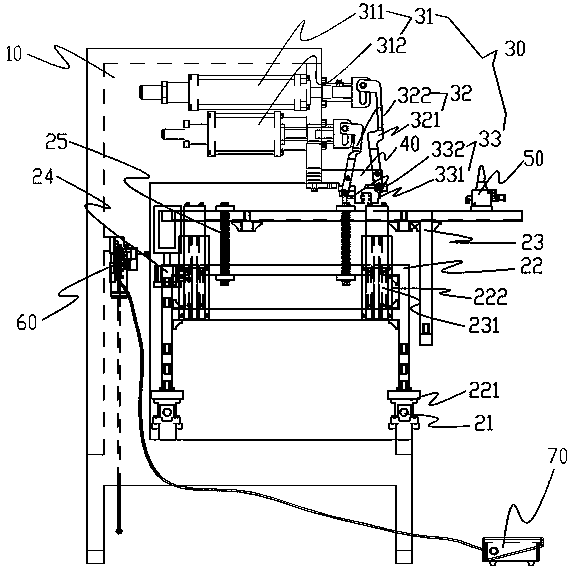

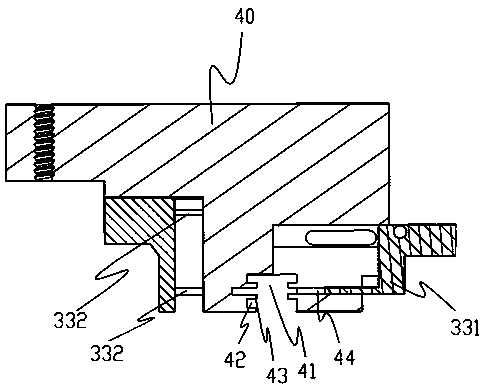

Squeeze riveter capable of automatically feeding

ActiveCN105772586AQuick rivetingEasy rivetingMetal-working feeding devicesMetal working apparatusEngineeringMechanical engineering

The invention relates to a squeeze riveter capable of automatically feeding. The squeeze riveter capable of automatically feeding comprises a stand and a mechanical arm; a riveting base module, a gas-liquid booster cylinder and a vibrating disc are arranged on the stand; the gas-liquid booster cylinder is positioned above the riveting base module; a feeding module is arranged in an outlet of the vibrating disc; the riveting base module is provided with a guide base; the feeding module includes a base; a working cavity is formed in the base; an inner end of the working cavity forms a spraying station; a spraying port is formed above the spraying station; a waterproof nut column is provided with a pushing hole on the base below the spraying station; a pushing block is arranged in the pushing hole; an air spraying hole is vertically formed in the pushing block; an outlet of the air spraying hole is positioned on the upper end surface of the pushing block; and an inlet of the air spraying hole is connected with a first air pipe. The squeeze riveter needs no manual operation to load the waterproof nut column, realizes automatic installation of the waterproof nut column, is fast, convenient and safe in the riveting process, and greatly improves the riveting efficiency and quality.

Owner:CHANGZHOU LINGXIE INTELLIGENT EQUIP CO LTD

Inner frame riveting machine for bag filter

The invention discloses an inner frame riveting machine for a bag filter, which is simple in structure and reasonable in design and comprises a frame. A conveying mechanism and a riveting mechanism are arranged on the frame, the conveying mechanism comprises a guide rod, a moving frame and a transmission mechanism, the moving frame comprises a first moving frame and a second moving frame, the first moving frame bilaterally slides along the guide rod, the second moving frame vertically slides along the first moving frame, and the transmission mechanism comprises a vertical cylinder and an elastic device. The riveting mechanism comprises a riveting cylinder, a transmission rod and a punching device, the transmission rod is arranged on a fixed bock, one end of the transmission rod is connected with a cylinder rod of the riveting cylinder, the other end of the transmission rod is connected with the punching device, the punching device comprises a riveting punch and an ejector rod, and the transverse axis of the riveting punch is overlapped with that of the ejector rod. The inner frame riveting machine is reasonable in structural design, convenient and practical in operation, high in automation degree, firm and reliable in riveting, stable in product quality, time-saving and labor-saving, an inner frame of a filter bag can be rapidly riveted with the filter bag, production efficiency is improved, and cost is saved.

Owner:张福安

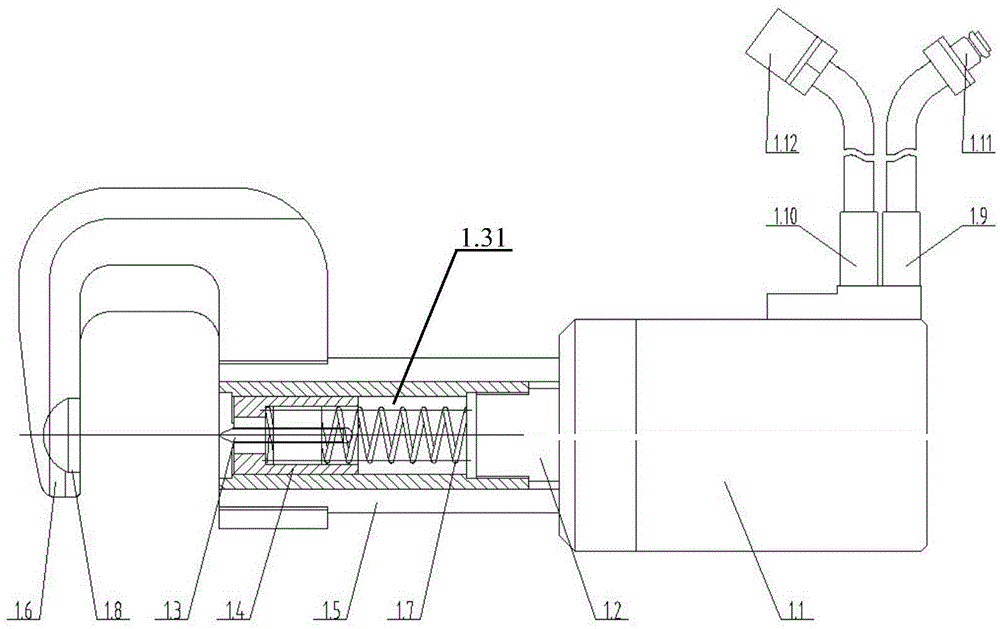

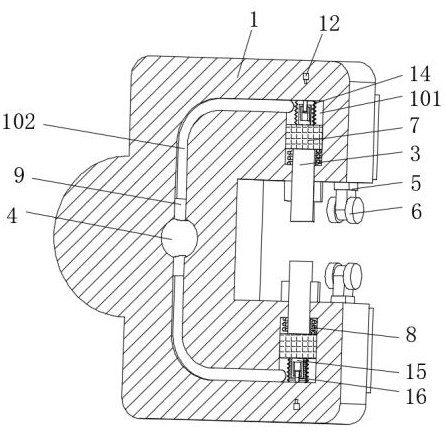

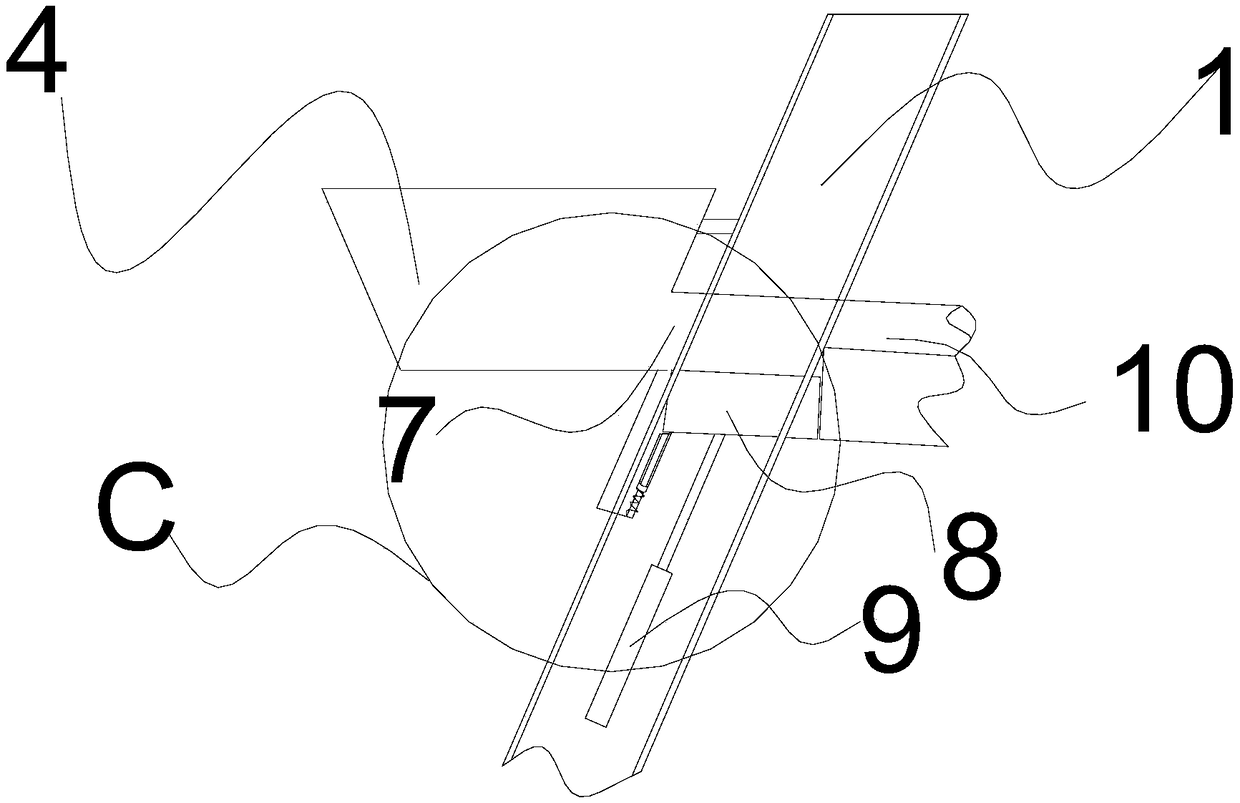

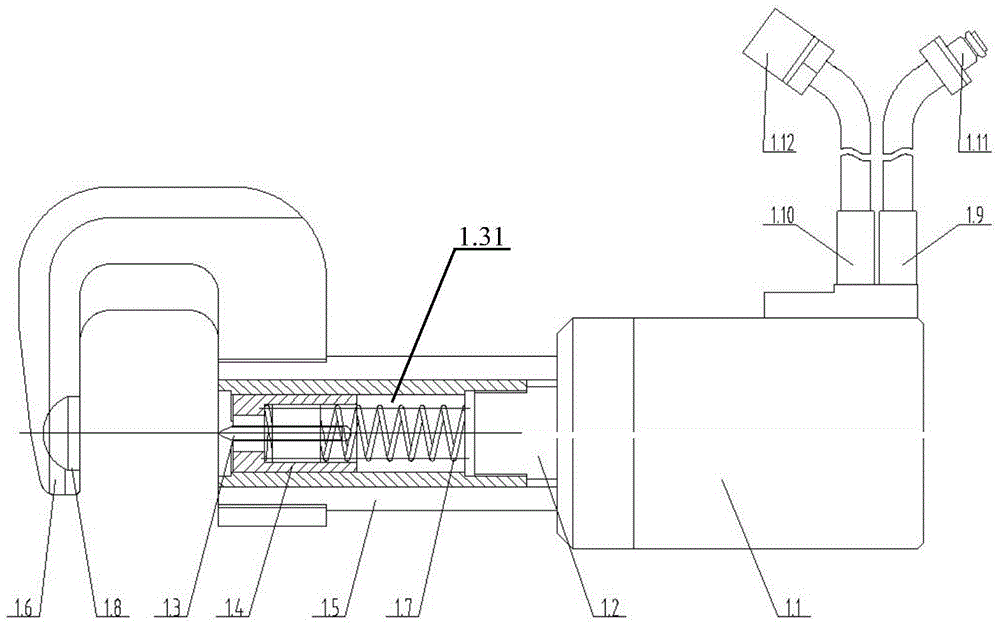

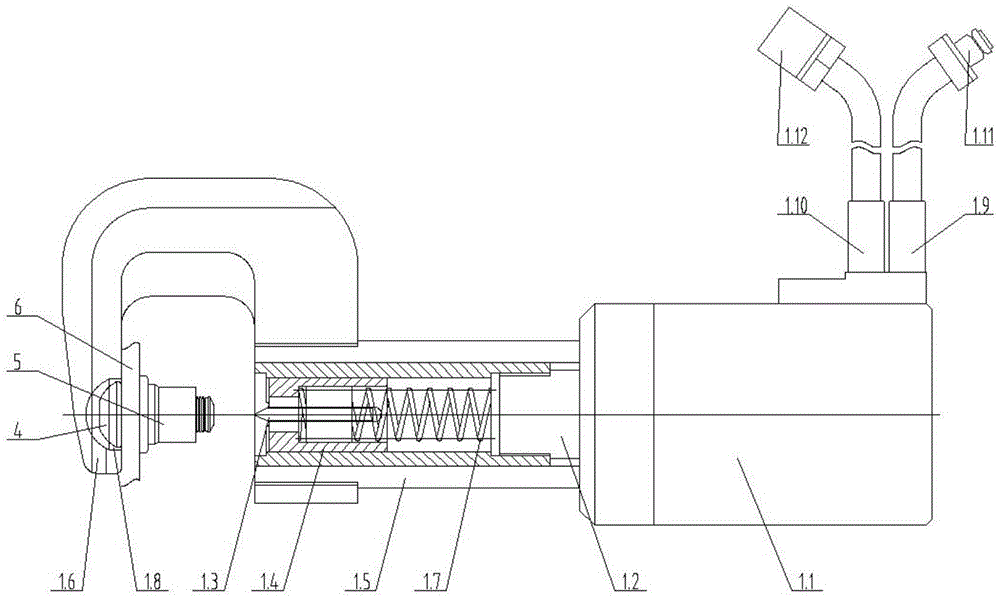

Wagon 120-valve protection hood rivet disassembling device

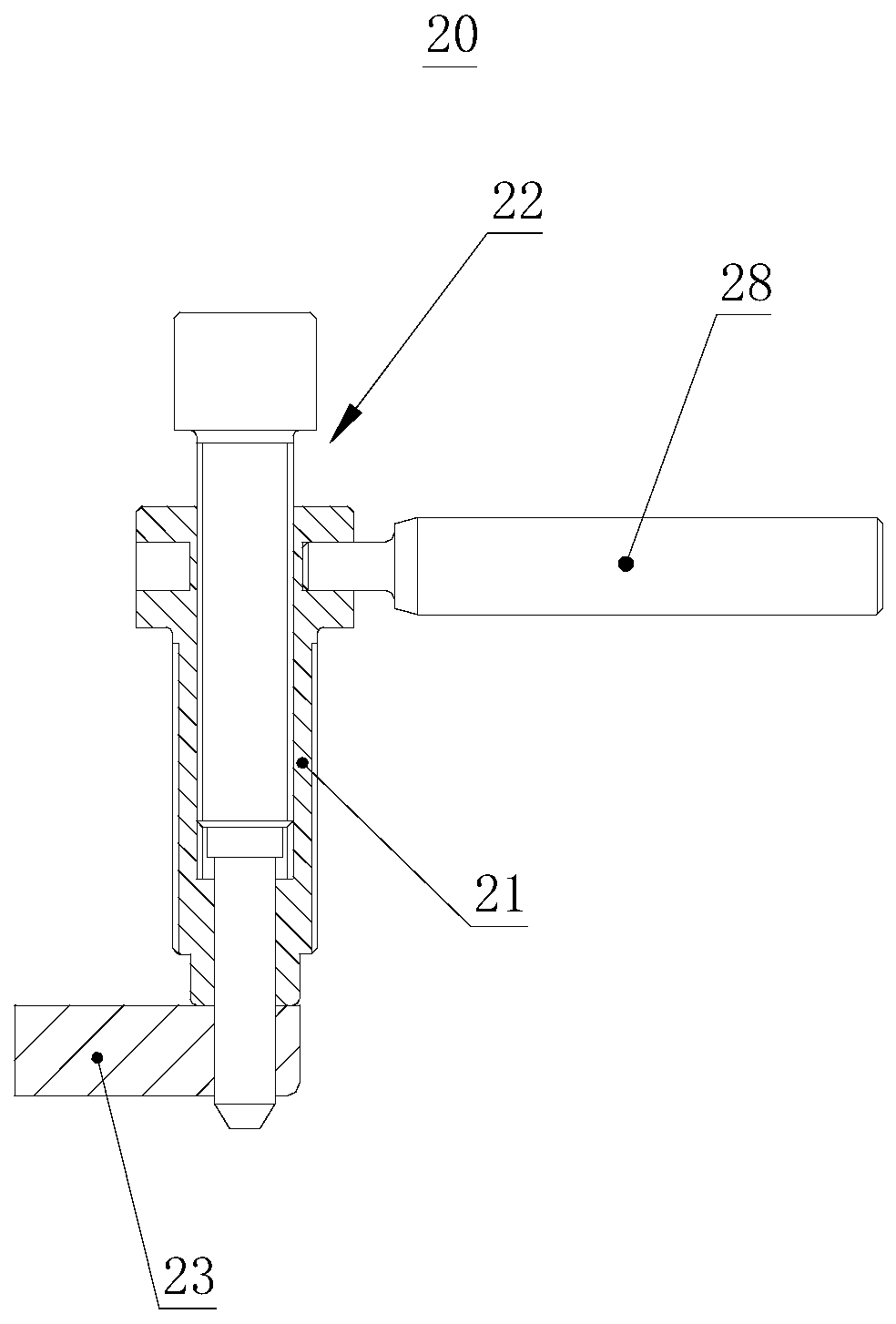

The invention provides a wagon 120-valve protection hood rivet disassembling device. The rivet disassembling device is composed of a riveting device, a splitter and a hand-operated hydraulic pump. The splitter comprises a splitter oil cylinder assembly, a splitter piston, a cutter head assembly, a positioning sleeve, a splitter connection jacket, a C-shaped clamp, a spring, an oil pipe and a quick-change connector. The riveting device comprises a riveting device oil cylinder assembly, a riveting device piston, an inner sleeve, an outer sleeve, a riveting device connection jacket, a clamping section, an upper limiting sleeve, a lower limiting sleeve, a buffering front sleeve, a buffering rear sleeve, a spring, an oil pipe and a quick-change connector. The hand-operated hydraulic pump is provided with a pump body, a reversing valve, the oil pipe and the quick-change connector. The reversing valve is used in a hand-operated mode. The technical scheme is used for riveting and splitting of pultrusion rivets with the diameter being 12 on the wagon 120-valve protection hood portion, the riveting forming is good, splitting is smooth, and the disassembling device is convenient to carry and operate and capable of quickly riveting or splitting rivet lantern rings under the conduction that no electricity, gas and other power sources exist and achieving disassembly of a 120-valve protection hood.

Owner:CRRC MEISHAN

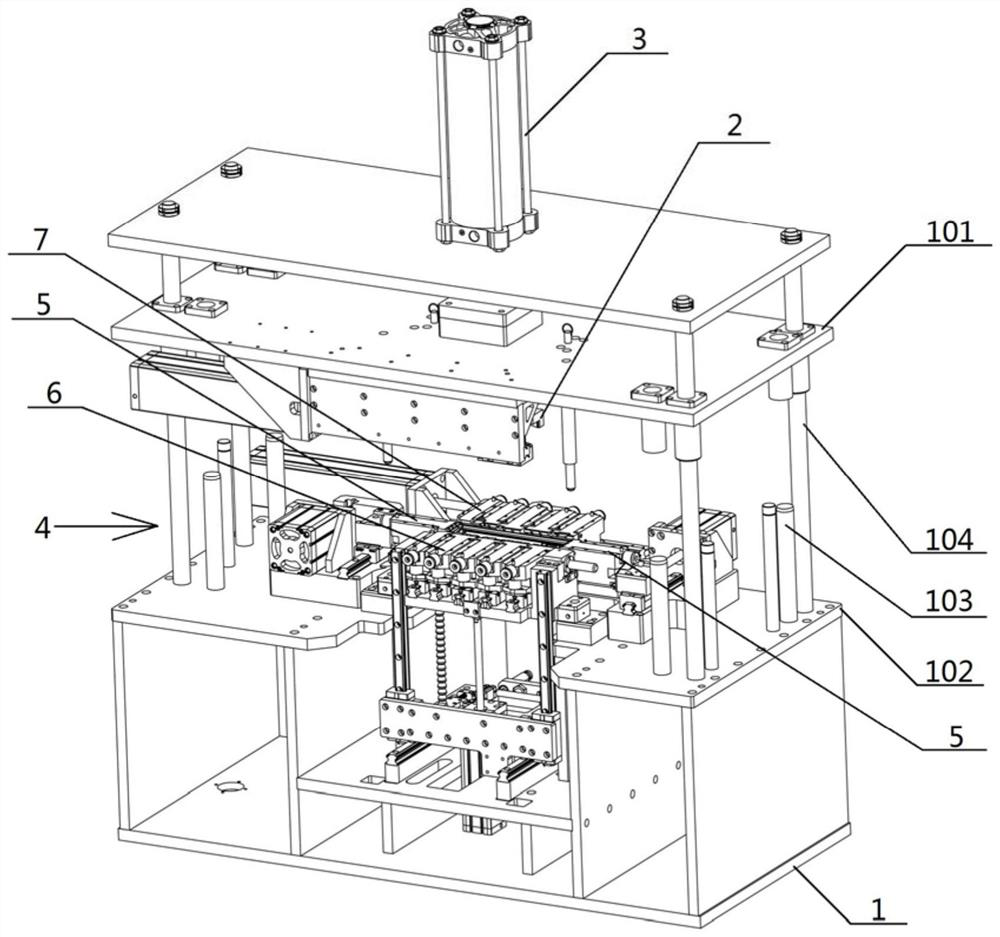

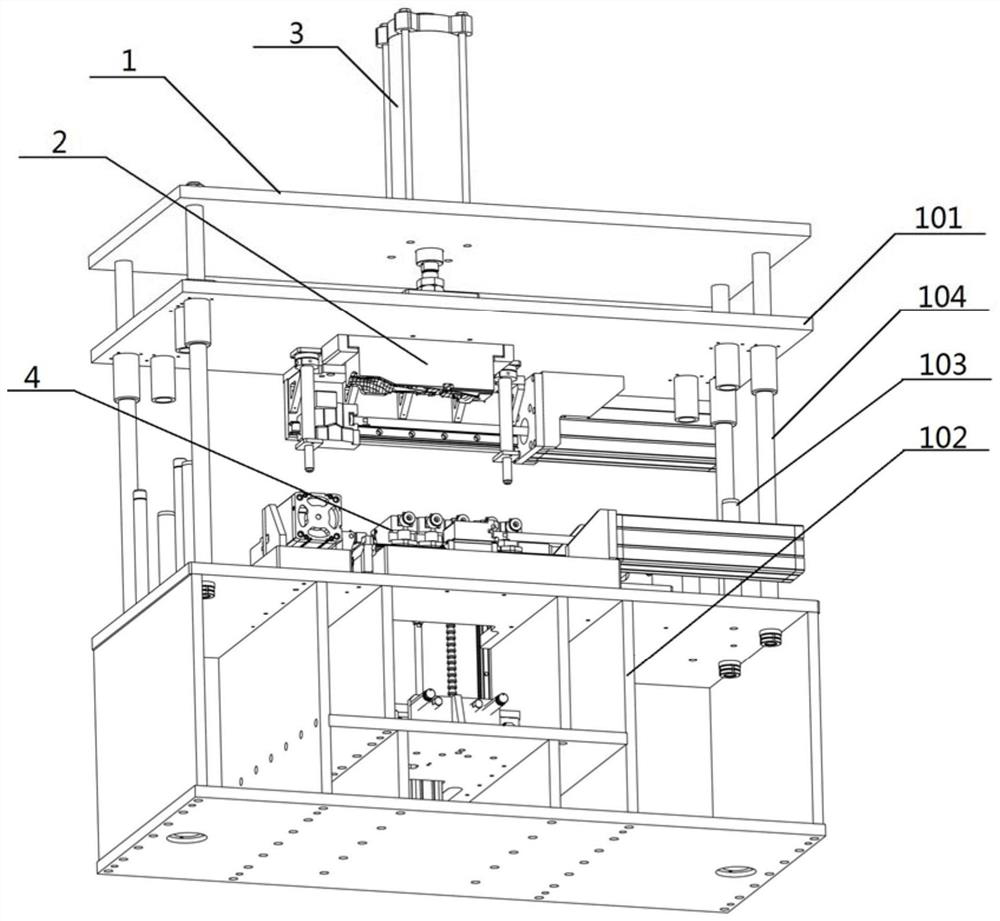

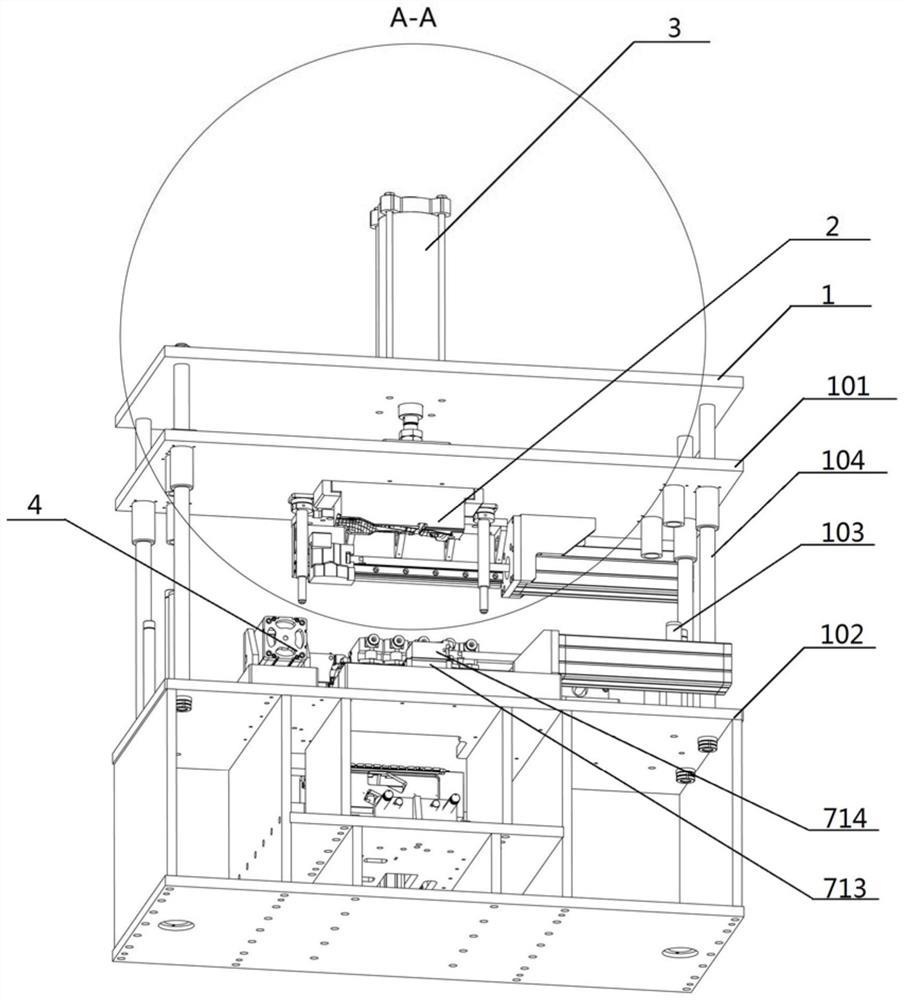

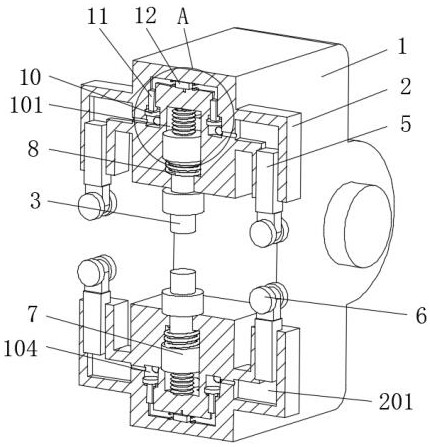

Flanging riveting equipment based on engine intake manifold

PendingCN113799405AImprove manufacturing efficiencyLow manufacturing costShaping toolsDomestic articlesAutomotive engineeringIntercooler

The invention relates to flanging riveting equipment based on an engine intake manifold. The flanging riveting equipment comprises a rack, a profiling moulding bed mounted on an upper die platform of the rack, an upper die driving air cylinder mounted on the rack and used for driving the profiling moulding bed, and a flanging riveting device mounted on a lower die platform of the rack, the flanging riveting mechanism is used for flanging riveting of a plastic shell and an intercooler, and the profiling moulding bed is used for positioning the intercooler on the flanging riveting device; and the flanging riveting device is composed of two side edge riveting mechanisms located at the two ends of the intercooler, a lifting type riveting mechanism located at the front side of the intercooler and a main riveting mechanism located at the rear side of the intercooler, and the side edge riveting mechanisms are used for flanging the side faces of the intercooler. The lifting type riveting mechanism and the main riveting mechanism are used for flanging the front side and the rear side of the intercooler; and the flanging riveting equipment has the advantages that the flanging riveting device can realize quick riveting of the intercooler and the injection molding shell, and the connecting structure is riveted, so that the manufacturing efficiency of the intake manifold is improved, and the manufacturing cost is reduced.

Owner:长春超维智能设备制造有限公司

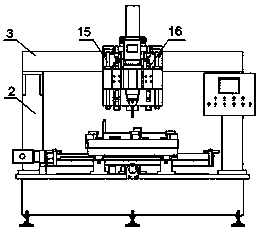

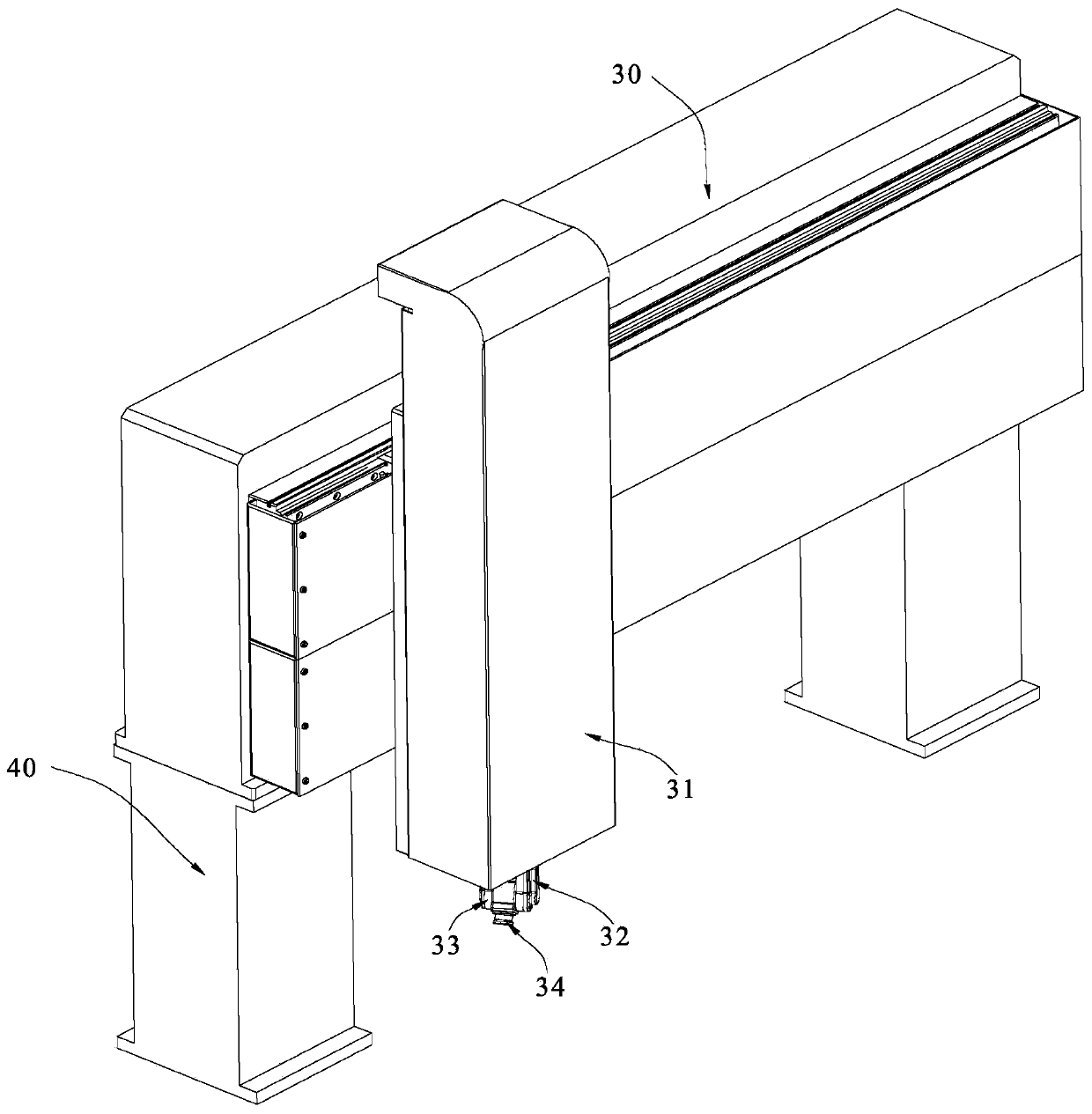

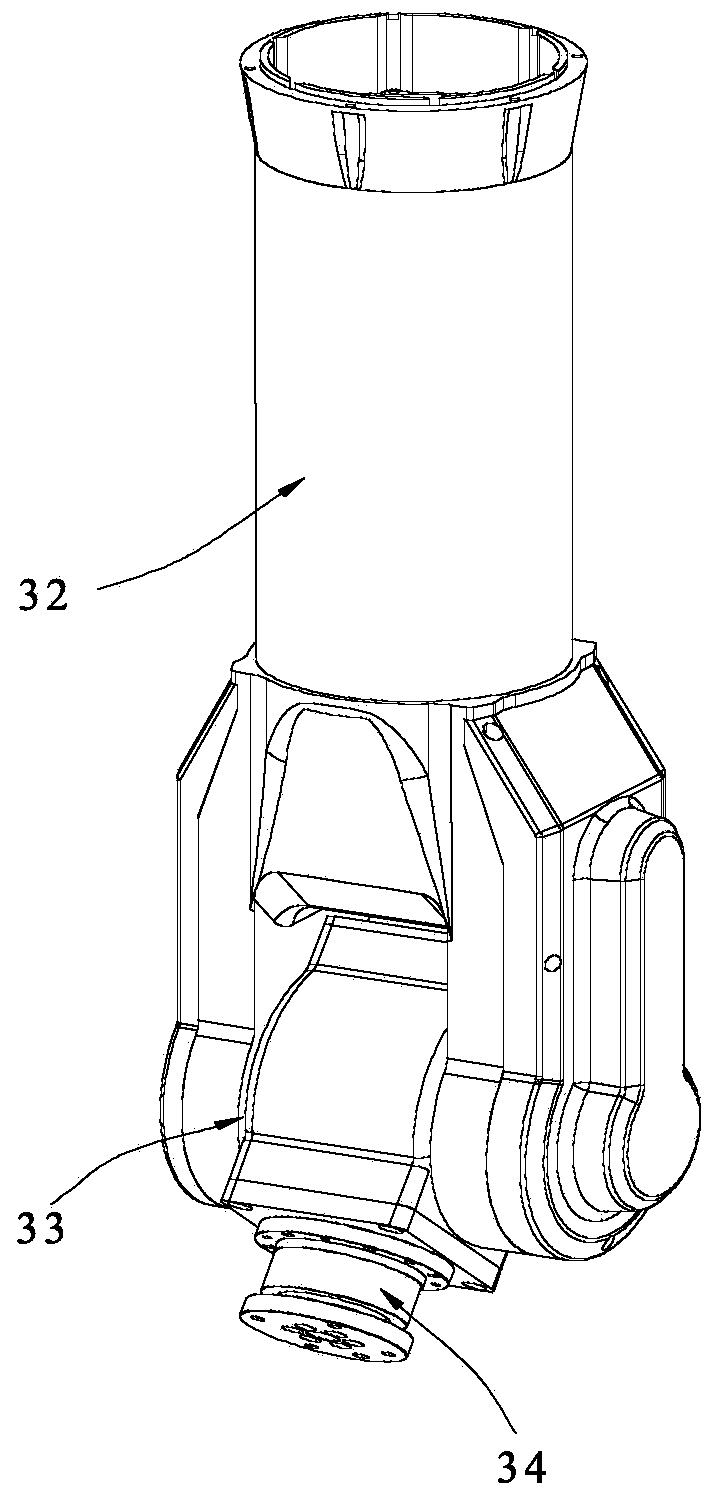

Gantry type three-shaft numerical control riveting machine

The invention discloses a gantry type three-shaft numerical control riveting machine. The machine comprises a machine base, the bottom of the machine base is supported by an adjusting cushion iron, astand column and a cross beam are fixedly arranged on the upper end face of the machine base, and the machine base, the stand column and the cross beam form a gantry type structure; a workbench is further installed on the machine base, the workbench is positioned on the lower side of the gantry type structure which is composed of the machine base, the stand column and the cross beam, an X-shaft servo motor is fixedly installed on the machine base, and a rotating shaft of the X-shaft servo motor is fixedly connected with a X-shaft screw rod; and the X-shaft screw rod is in transmission connection with an X-shaft sliding plate on a X-shaft linear line rail, a Y-shaft servo motor is fixedly installed on the X-shaft sliding plate, a Y-shaft screw rod is fixedly connected to an electric rotating shaft of the Y-shaft servo motor, and the Y-shaft screw rod is in transmission connection with a Y-shaft sliding plate located on the Y-shaft linear guide rail. According to the machine, the gantrytype three-shaft numerical control riveting machine has the advantages of being labor-saving, energy-saving, high in efficiency, high in stability and high in precision, and is worthy of popularization and application.

Owner:吕向华

Riveting tooling for automobile sunroof guide rail frame

A riveting tooling for an automobile sunroof guide rail frame is characterized by comprising a bottom plate used for weighting, wherein bottom columns are arranged below the bottom plate; a mounting plate for mounting guide rails is arranged on the bottom plate; a connecting plate is arranged between the bottom plate and the mounting plate; pushing cylinders for riveting pressing are arranged on the connecting plate. With the adoption of the riveting tooling for the automobile sunroof guide rail frame, the sunroof guide rail frame can be quickly riveted, and meanwhile, structural parts on the sunroof guide rails can be accurately mounted; the riveting tooling applies to the riveting mounting of sunroof guide rail frames with different specification and size.

Owner:ANHUI DIKUN AUTO SKYLIGHT TECH CO LTD HEFEI

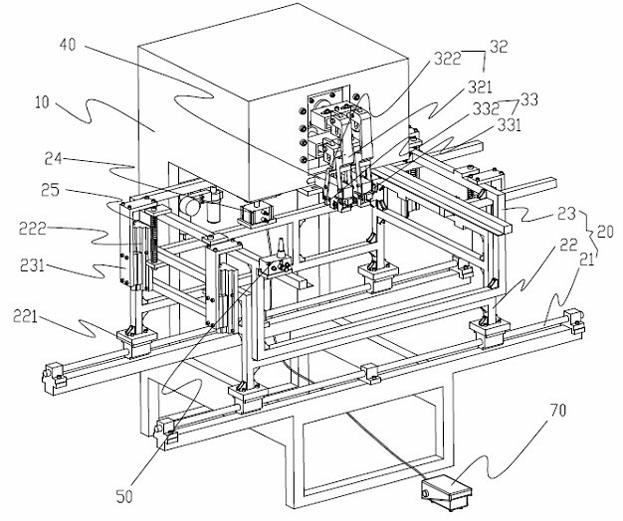

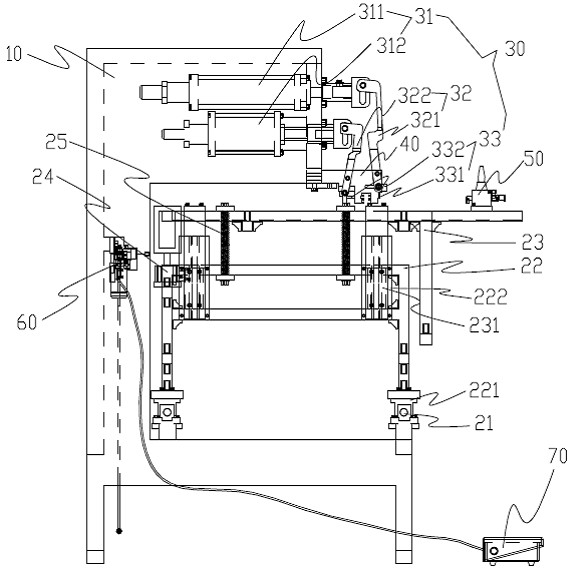

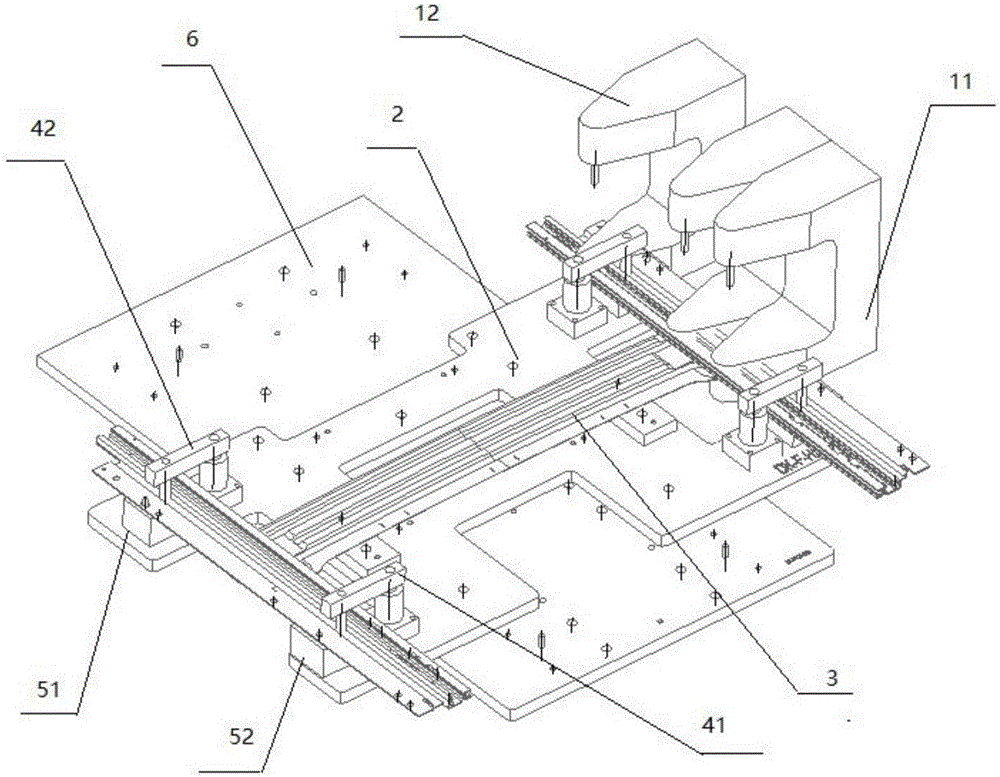

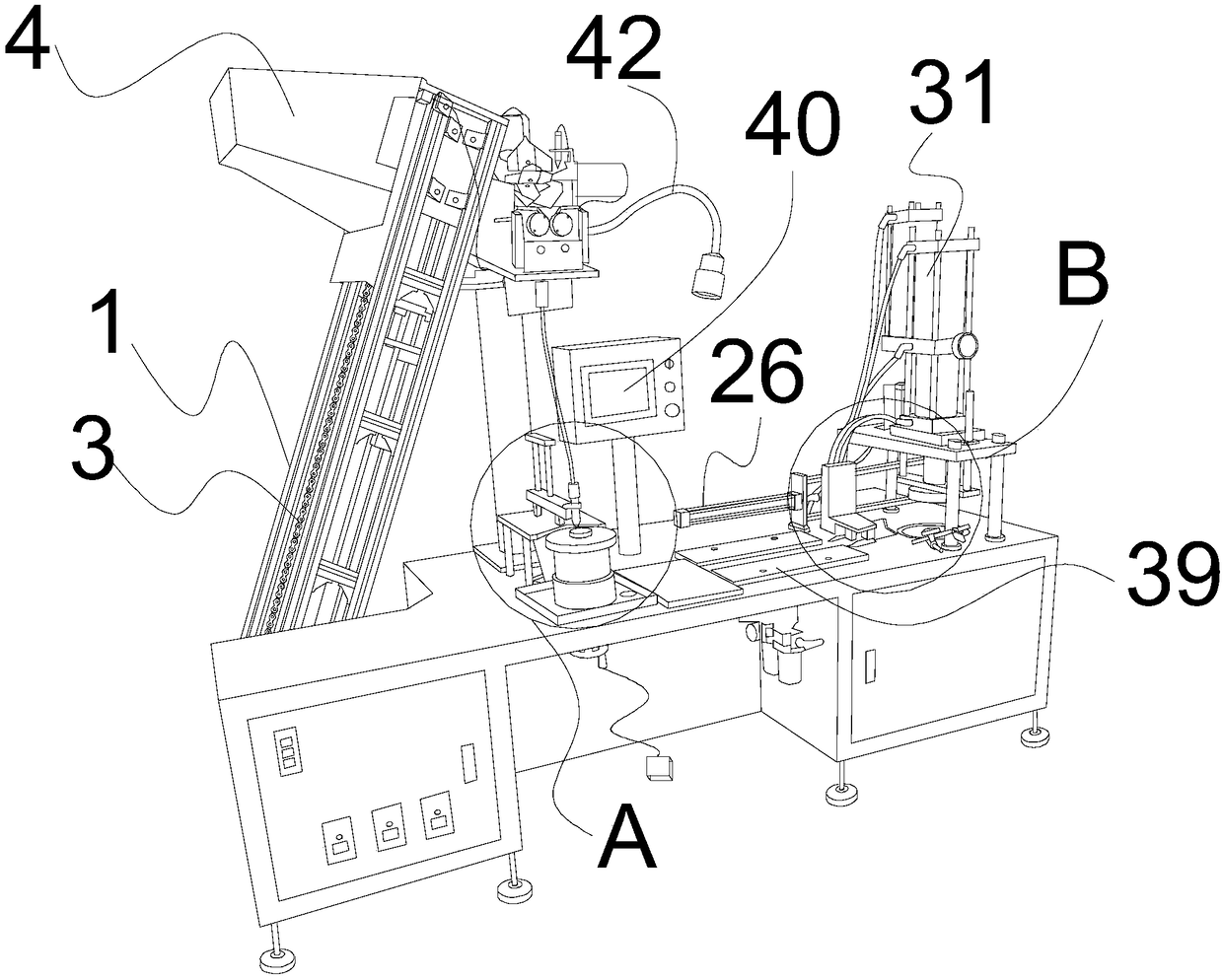

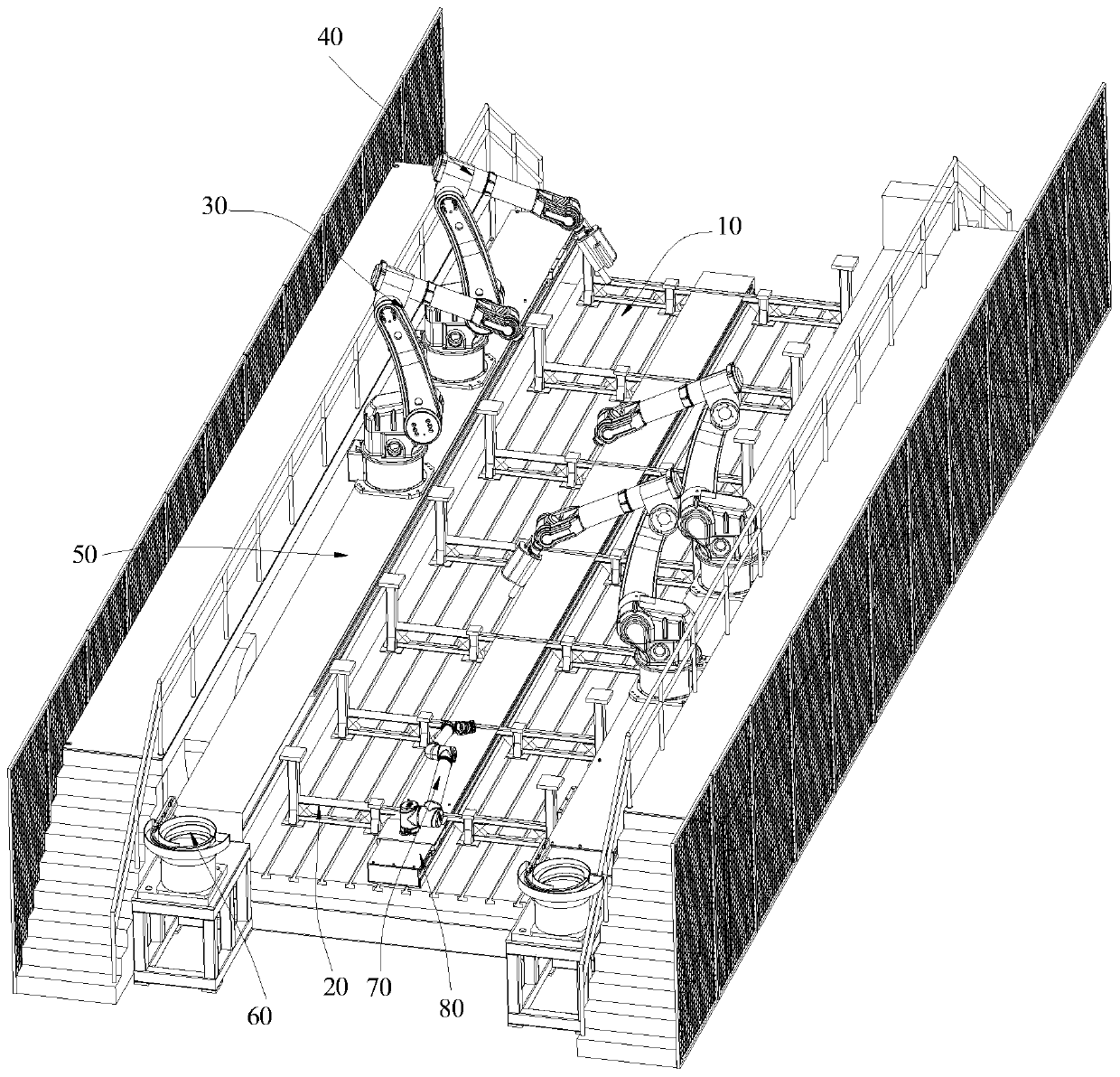

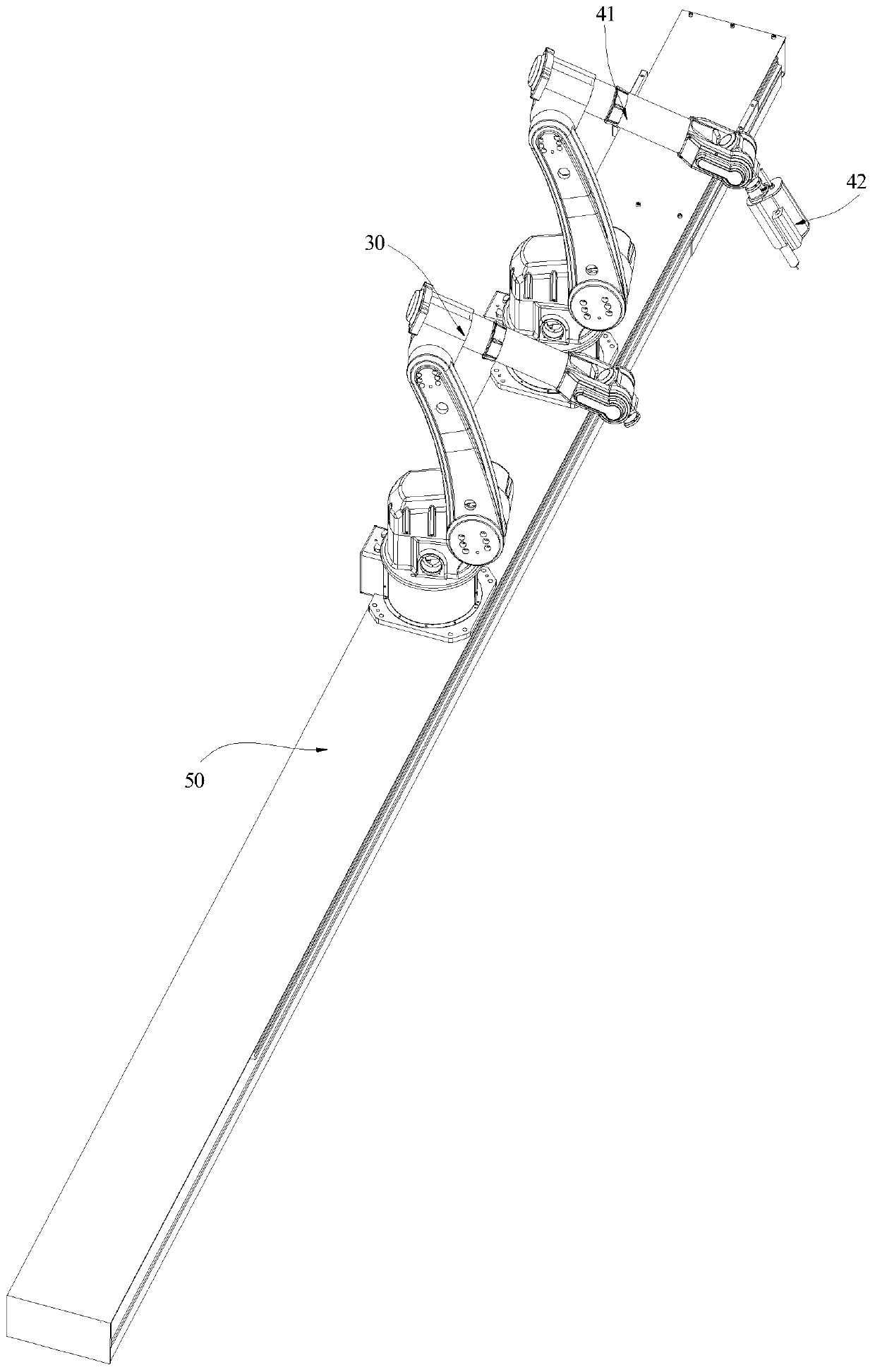

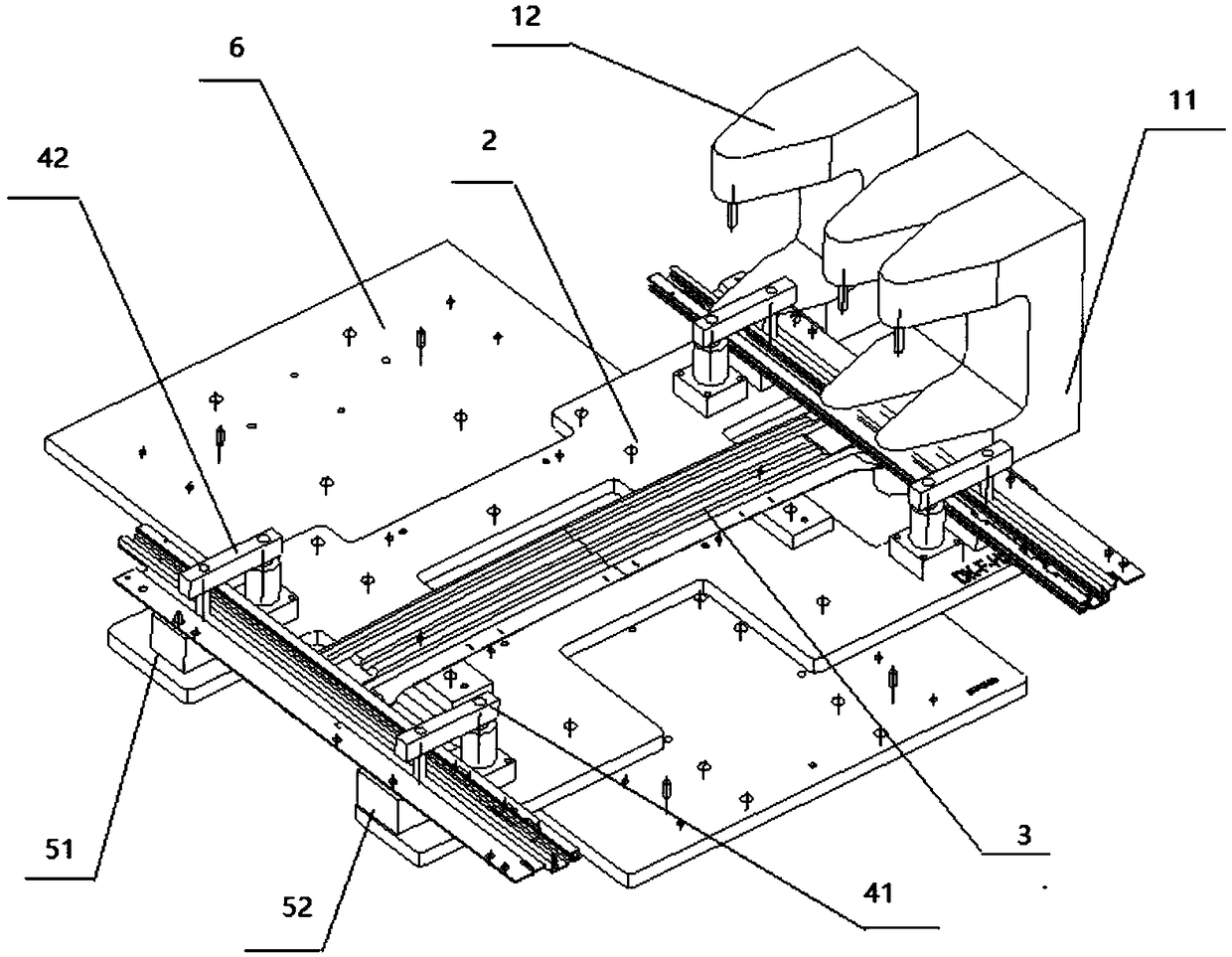

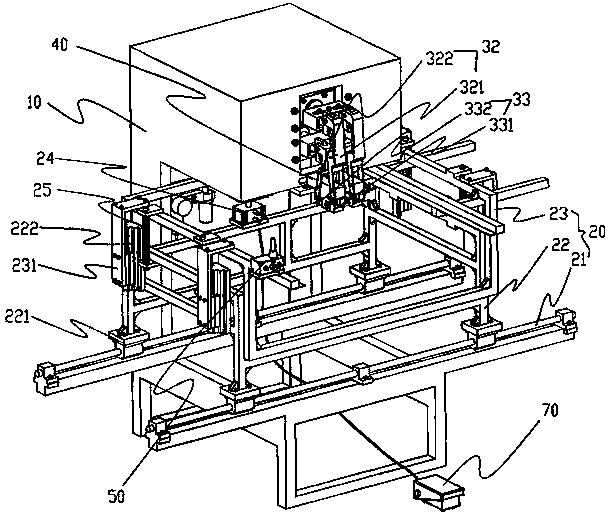

Full-automatic gantry type riveting production line

PendingCN111360189AQuick rivetingHigh degree of automationOther manufacturing equipments/toolsManufacturing lineSupport surface

The invention discloses a full-automatic gantry type riveting production line which comprises a machine body and a riveting and perforating component, wherein a support component is arranged on the machine body and comprises at least two support frames; a support surface is formed at the top end of each of the support frames; at least two support surfaces are used for supporting workpieces; the riveting and perforating component comprises a perforating component, a clamping component, a first driving mechanism, a second driving mechanism, a third driving mechanism, a first mounting beam and two second mounting beams; a mounting rack is arranged on each of the second mounting beams; the perforating component and the clamping component are mounted on the mounting racks; the first driving mechanism is used for driving the two second mounting beams to extend in the length direction of the machine body; the second driving mechanism is used for driving the mounting racks to move along the second mounting beams in the width direction of the machine body; the third driving mechanism is used for driving the mounting racks to move in the height direction of the machine body; the perforatingcomponent is used for perforating the workpiece; and the clamping component is used for clamping a rivet. The full-automatic gantry type riveting production line can automatically rivet and is high inriveting efficiency.

Owner:深圳爱多多智能装备科技有限公司

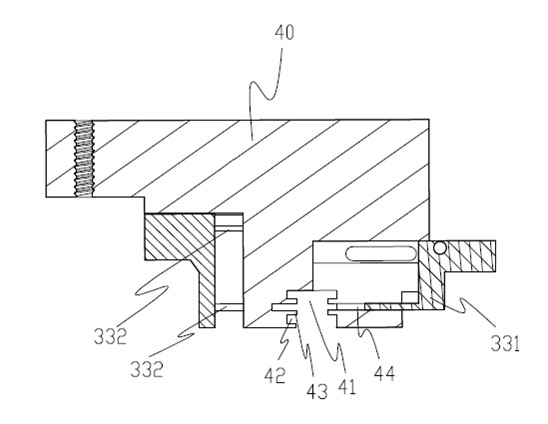

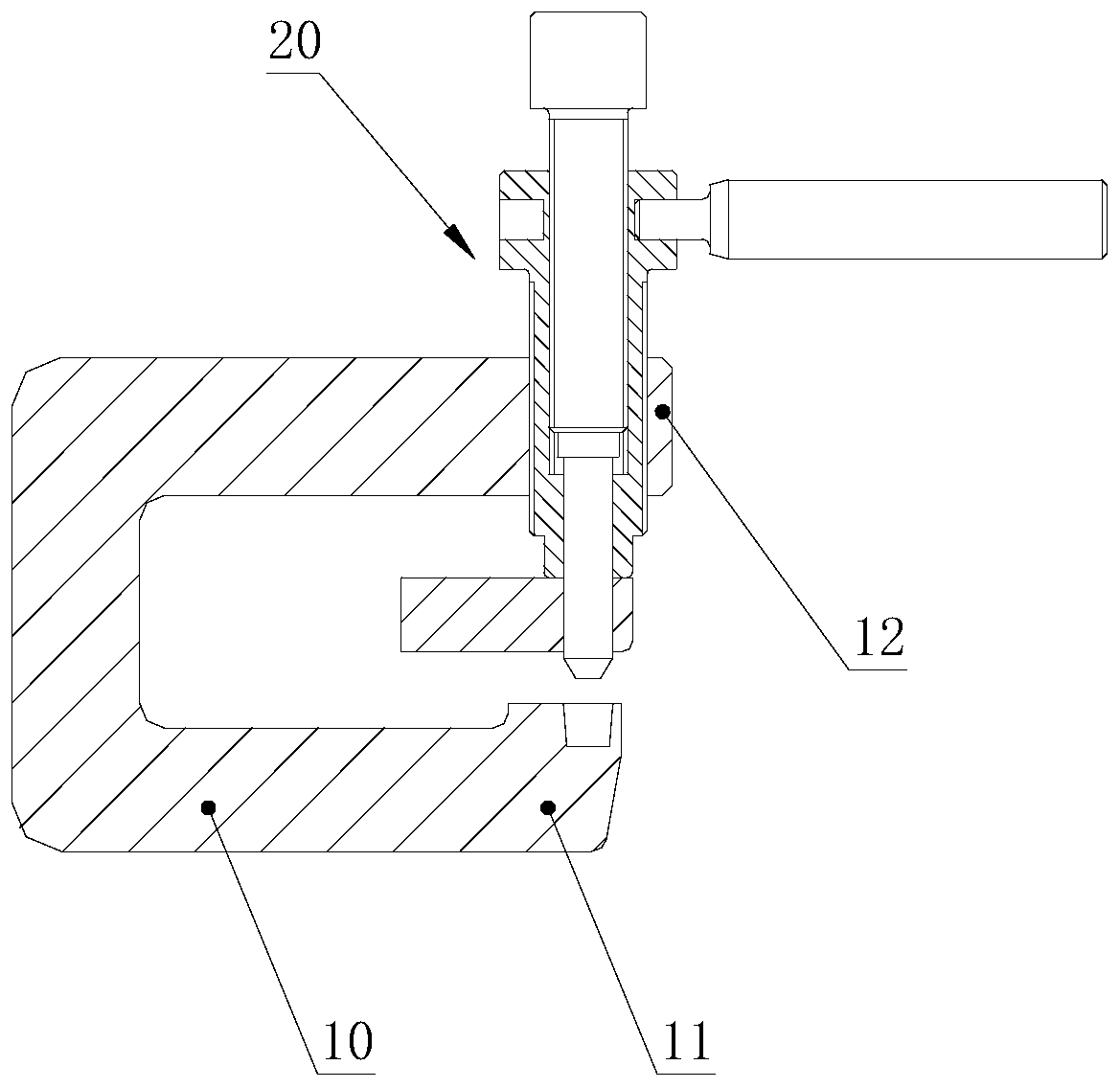

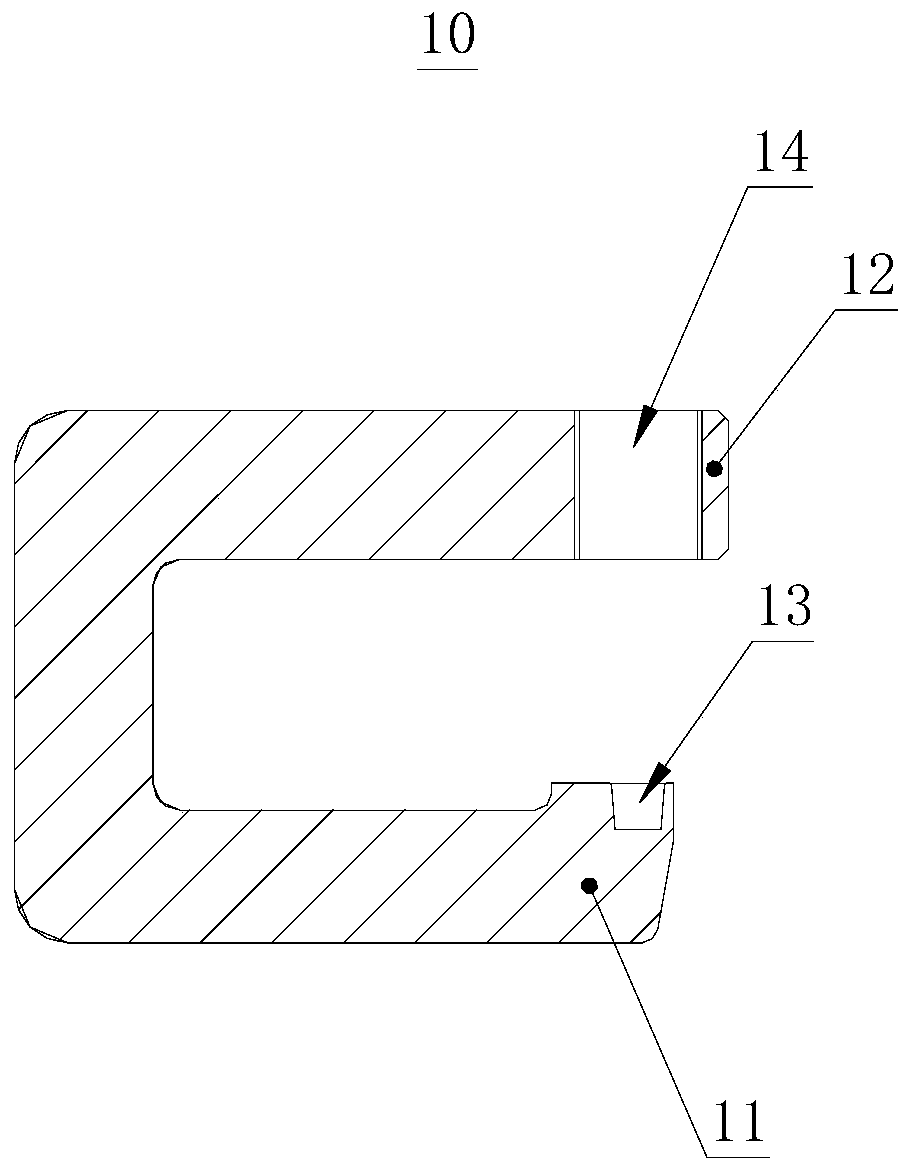

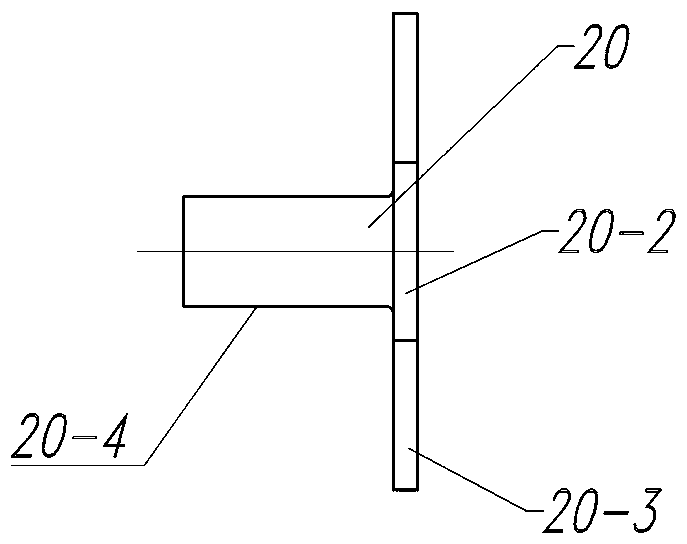

Assembly device of casing threaded pin

The invention discloses an assembly device of a casing threaded pin, and belongs to the technical field of aircraft engine assembly. The assembly device of the casing threaded pin comprises a fixing frame and an assembly component, the fixing frame comprises a first limiting block and a second limiting block which are arranged in a spaced mode, the first limiting block is provided with a positioning hole, the second limiting block is provided with a threaded hole, the assembly component comprises a connecting rod and an ejector rod, the connecting rod penetrates through the second limiting block and is in threaded connection with the second limiting block, the ejector rod penetrates through the connecting rod and faces the positioning hole, and the ejector rod is in threaded connection with the connecting rod. According to the assembly device, the threaded pin and a casing can be quickly and accurately positioned, so that the threaded pin and a bottom hole of the casing can be rivetedquickly through the ejector rod, in addition, the ejector rod carries out extrusion movement through threads, the pressure of a screw pair is strong, assembly can be carried out stably, and the assembly quality is high.

Owner:AECC AERO SCI & TECH CO LTD

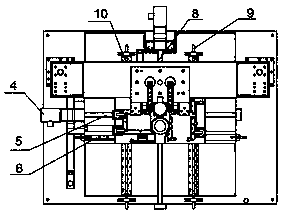

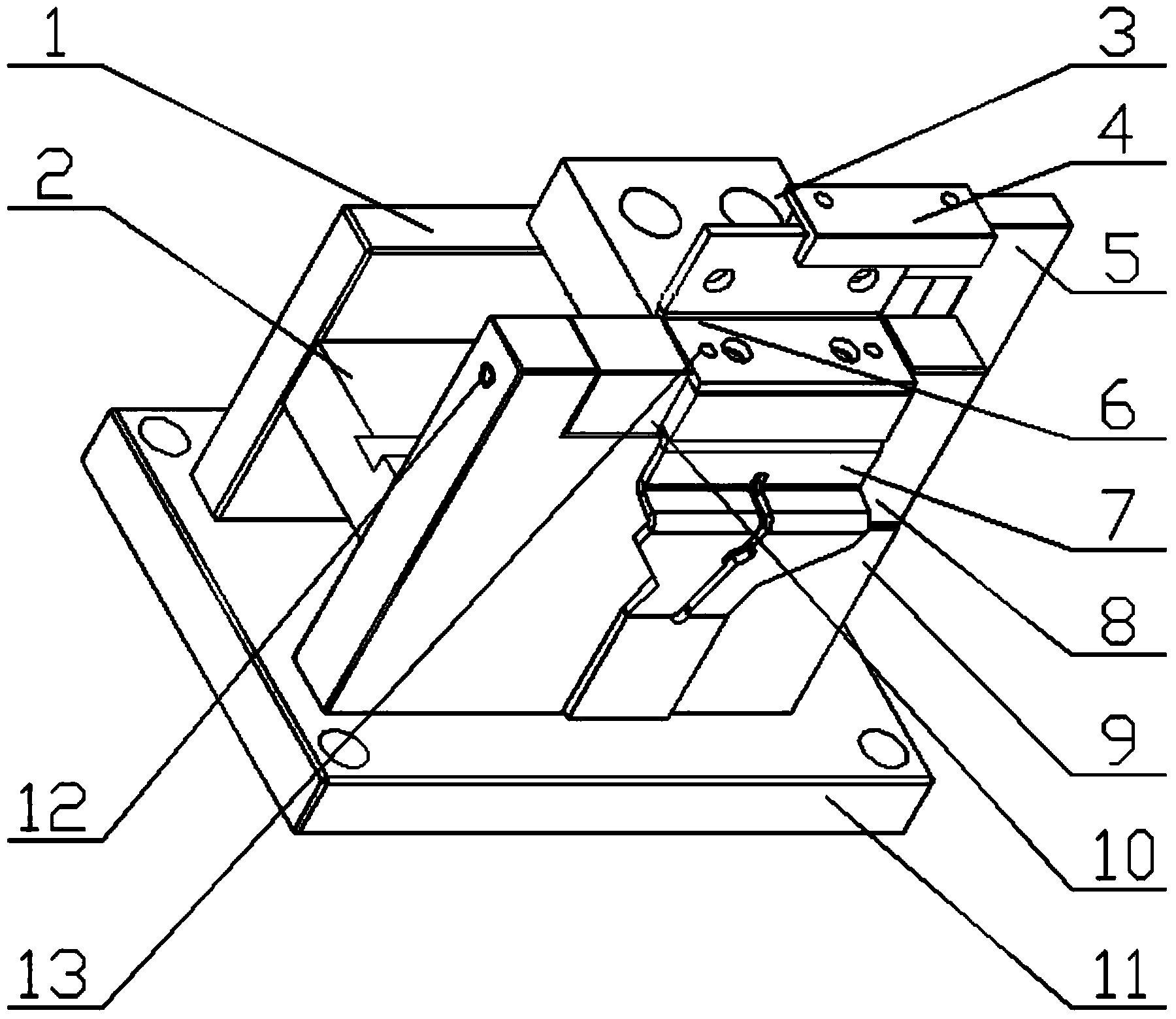

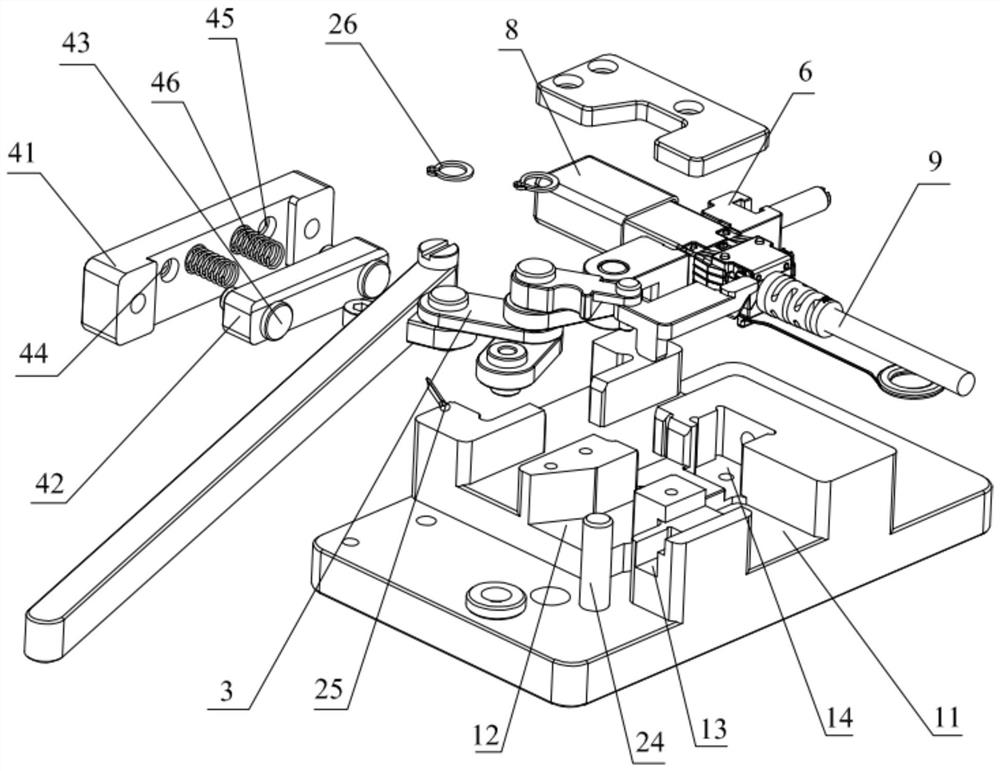

Universal breaker static contact head piece riveting clamp

ActiveCN104259373AImprove general performanceGuaranteed assembly dimensional accuracyBusbarCircuit breaker

The invention discloses a universal breaker static contact head piece riveting clamp, and the universal breaker static contact head piece riveting clamp comprises a pedestal (11) and a limit support plate (9) arranged on the pedestal (11), the limit support plate (9) is opened with the grooves for holding the riveting piece run-on plate (7), outlet busbar (3) and angle bracket (6), a locating pin (18) is formed in the groove, the side of the limit support plate (9) is provided with a clamping press block (8); the clamp further comprises a limit frame (5) being parallel to the limit support plate (9), the limit frame (5) is provided with a locating plate (4) locating the angle bracket (6). According to the technique solution, the accuracy of the riveting position of the static contact head piece is guaranteed, the production efficiency is raised and the product quality is also guaranteed.

Owner:芜湖鸠江科技企业孵化器管理有限公司

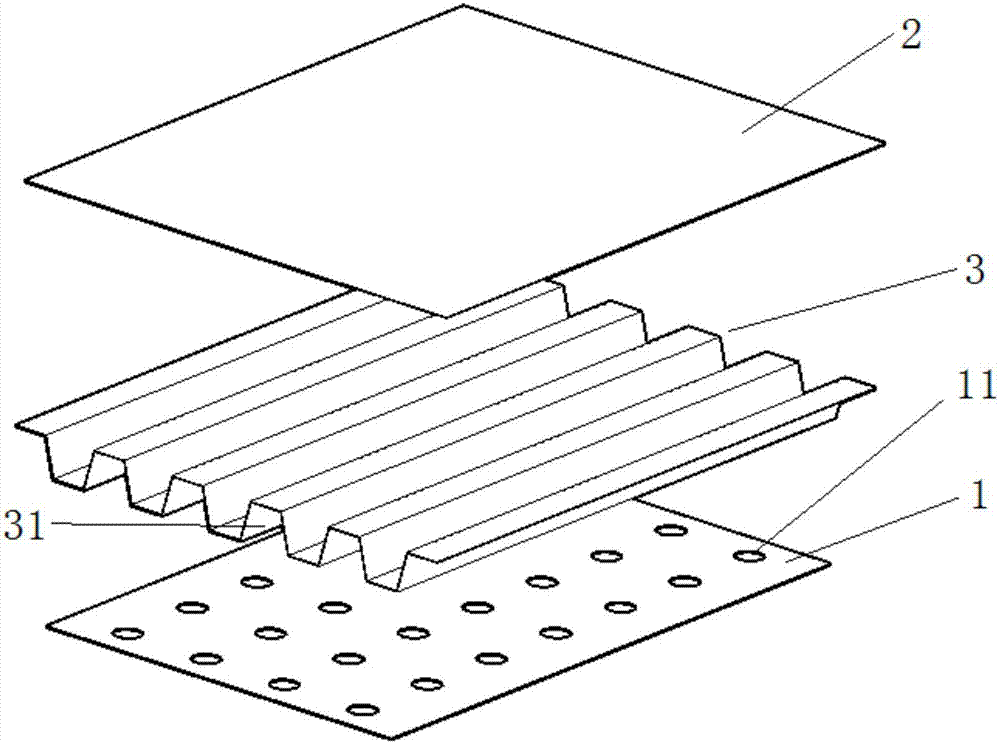

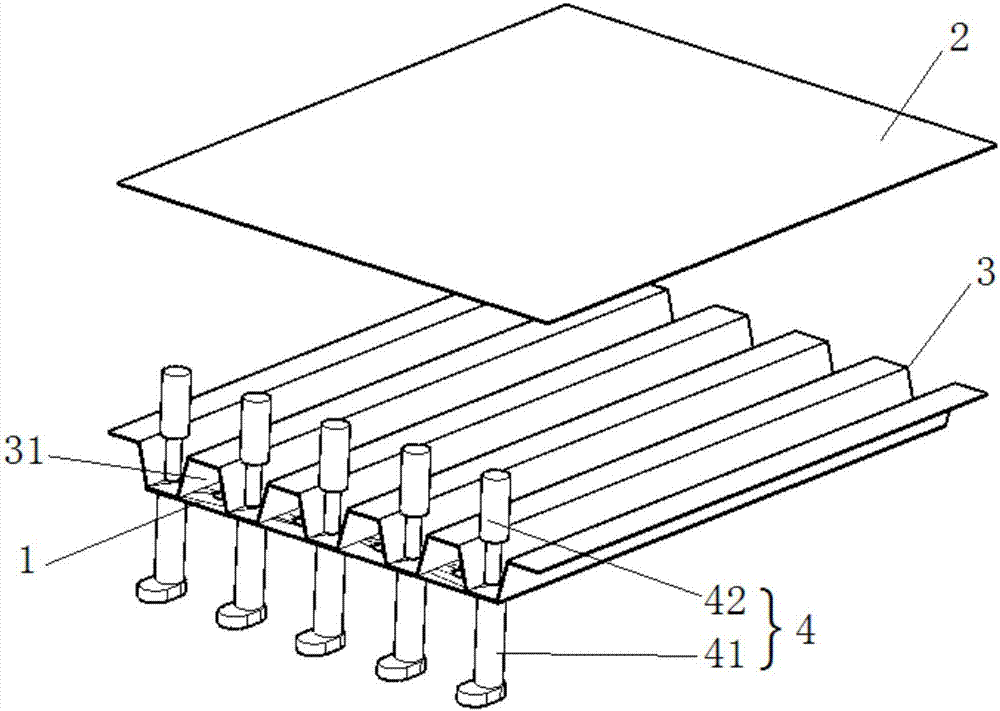

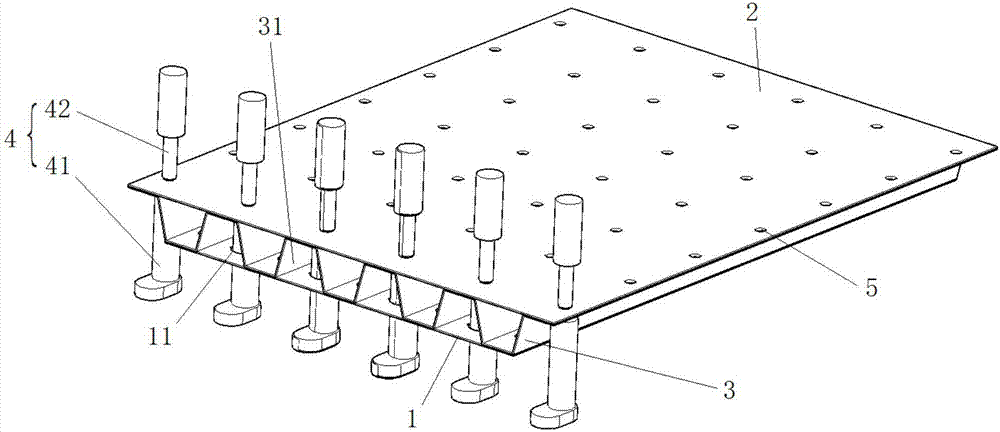

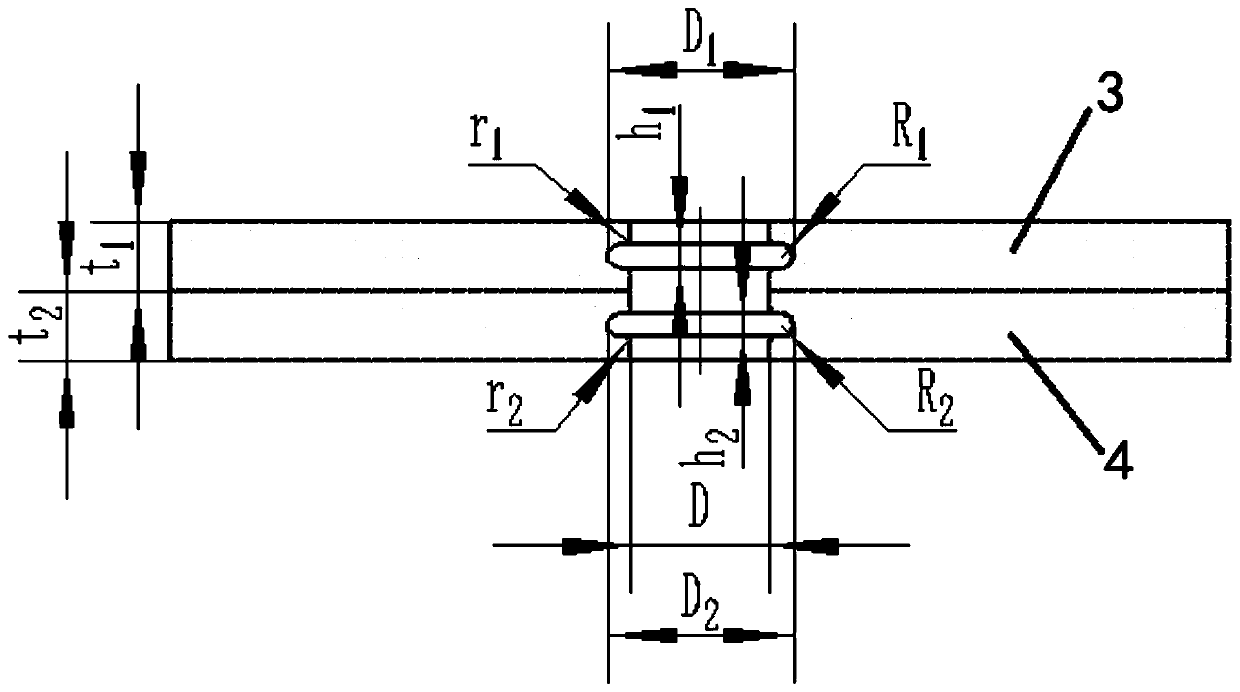

Composite metal plate and manufacturing method thereof

ActiveCN106881915AExcellent mechanical propertiesQuick rivetingMetal-working apparatusConstructions elementsEngineeringFace sheet

The invention discloses a composite metal plate and a manufacturing method of the composite metal plate. The composite metal plate comprises a first panel, a corrugated panel and a second panel, the corrugated panel is arranged between the first panel and the second panel, a plurality of fabrication holes are formed in the first panel, the first panel is fitted with a lower panel surface of the corrugated panel, the second panel is fitted with an upper panel surface of the corrugated panel, a plurality of stamping riveted structures vertical to the panel surface are formed on the combination surfaces between the first panel and the corrugated panel and between the second panel and the corrugated panel, the riveted structure is a combination part formed in a way that a female mould and a male mould of a riveting tool stamp on the first panel, the second panel and the corrugated panel, and the first panel and the second panel are respectively fixedly connected with the corrugated panel through the riveted structure. Through the plurality of fabrication holes formed in the first panel by the female mould and the male mould of the riveting tool, the first panel and the second panel are respectively rapidly riveted with the corrugated panel, and compared with the existing composite metal plate manufactured through a welding method, the manufactured composite metal plate has better mechanical properties.

Owner:CENT INT GROUP

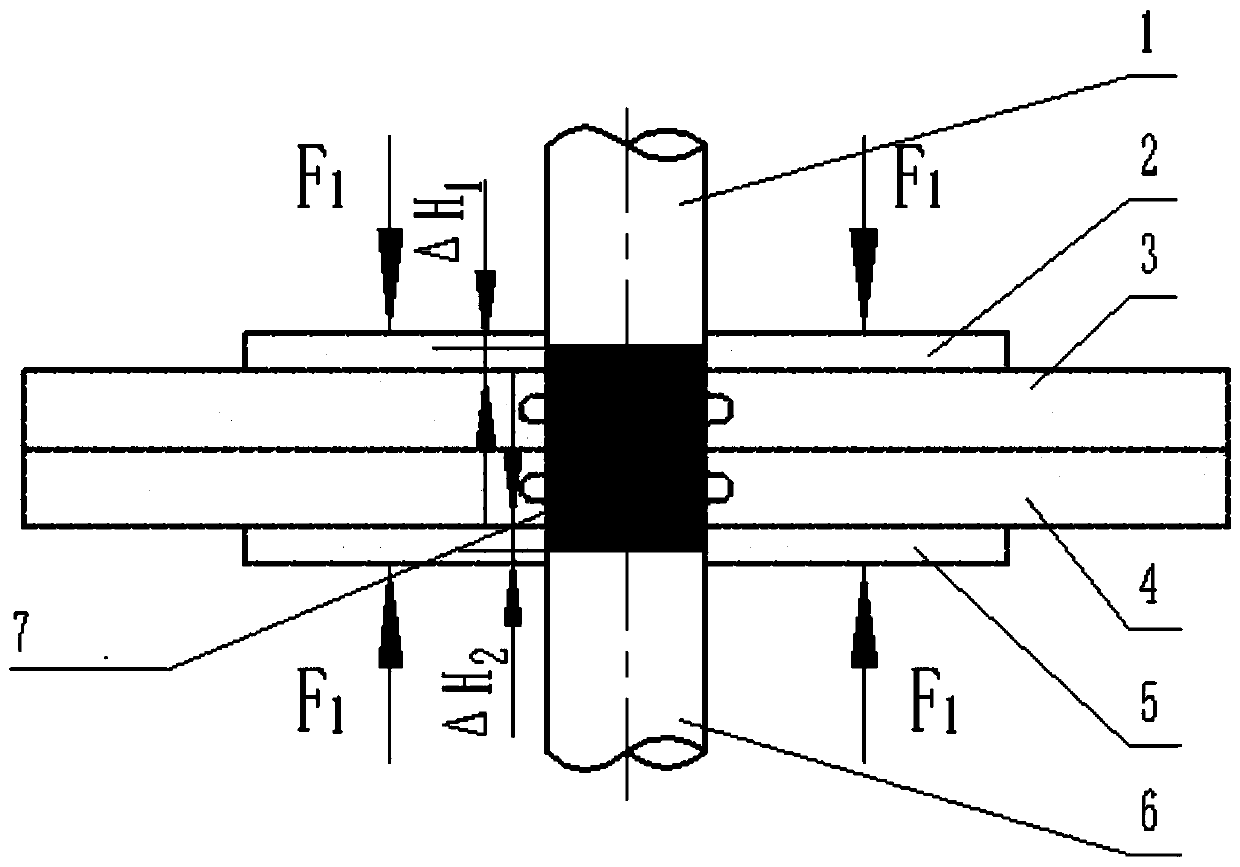

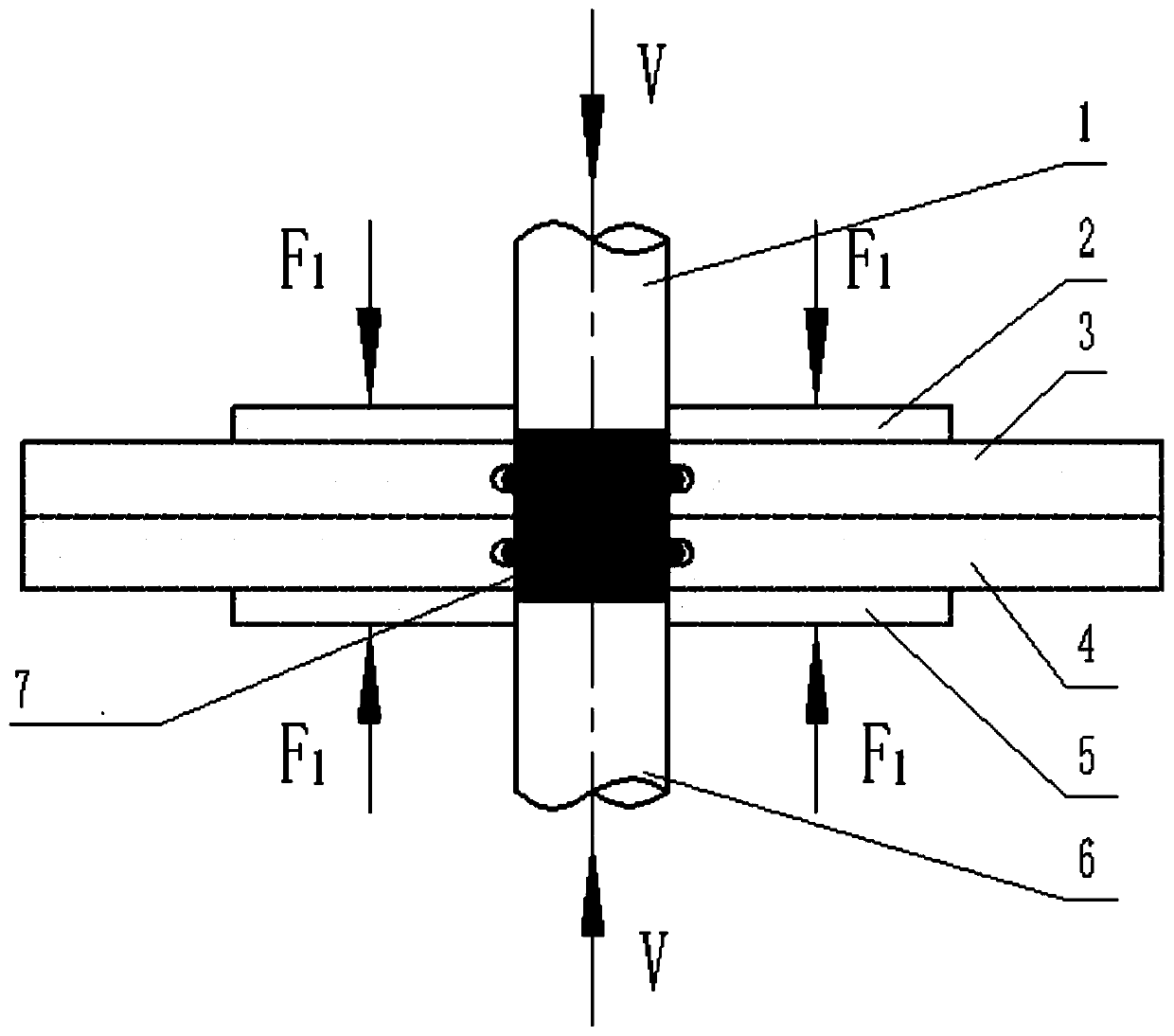

Method of riveting heavy and medium metal sheets without projections on double faces

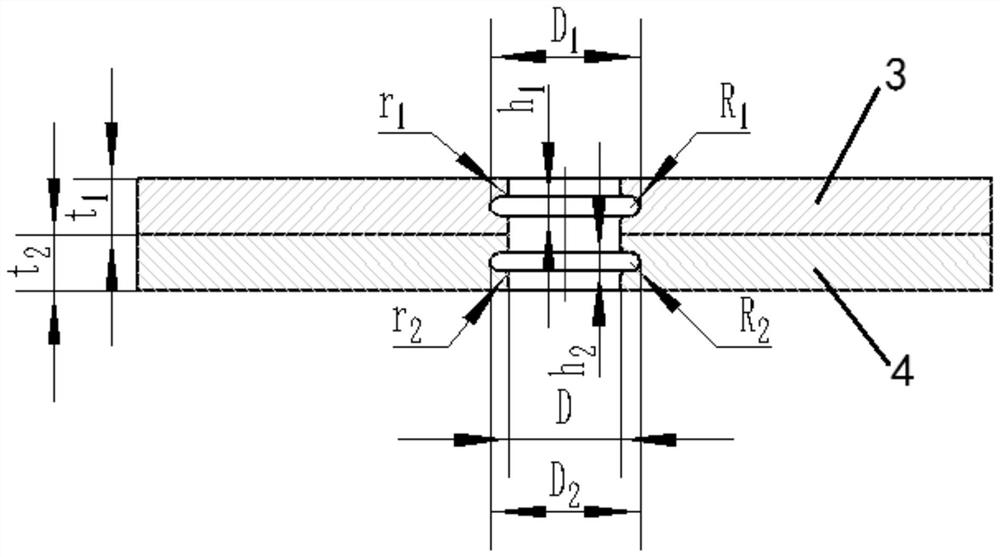

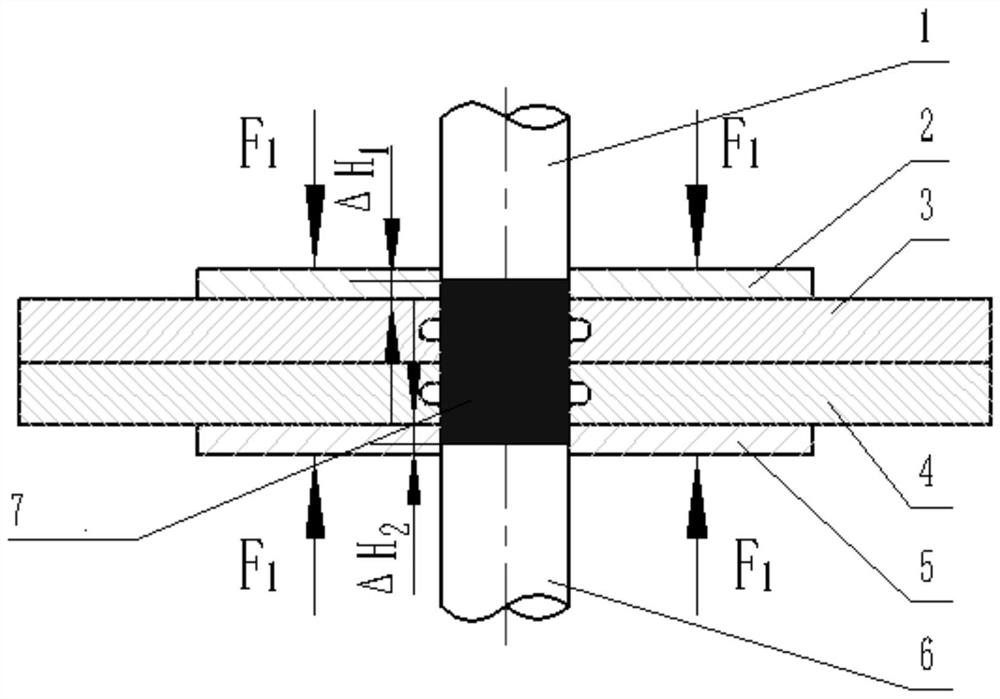

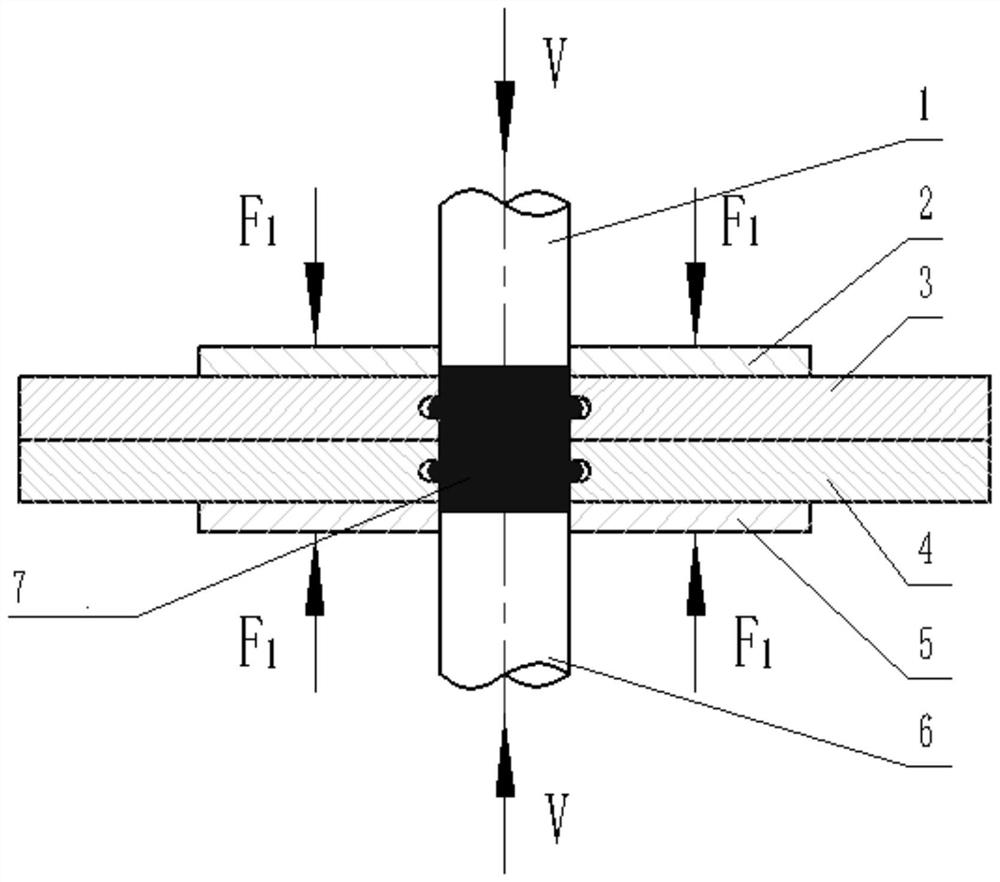

ActiveCN110640071AEfficient rivetingReduce grinding processStructural engineeringManufacturing engineering

The invention discloses a method of riveting heavy and medium metal sheets without projections on double faces and belongs to the technical field of material connection. The heavy and medium metal sheets are riveted quickly and efficiently by adopting a method of prefabricating holes with annular grooves in the two to-be-connected heavy and medium metal sheets and placing simply shaped connectingcolumns into the holes, and applying external forces to two sides of the connecting columns through upper and lower punches, wherein the connecting columns deform plastically to fill the annular grooves. According to a volume invariable law, the connecting columns which deform plastically can be filled into the annular grooves of upper and lower panel veneers without obvious protruding height points, so that the grinding step is reduced and the production efficiency is improved. The used parts of the device are simple in structure, convenient to process and good in compatibility with conventional equipment, the pre-treatment process of the to-be-welded panels is simple, the production efficiency is high and the cost is low. The surface of the connected part is smooth and is free of projections, so that the heavy and medium metal sheets are more attractive. Furthermore, after the connecting columns deform plastically, the tensile strength and the shear strength of the riveted part are improved and the connection is more stable.

Owner:SHAANXI UNIV OF SCI & TECH

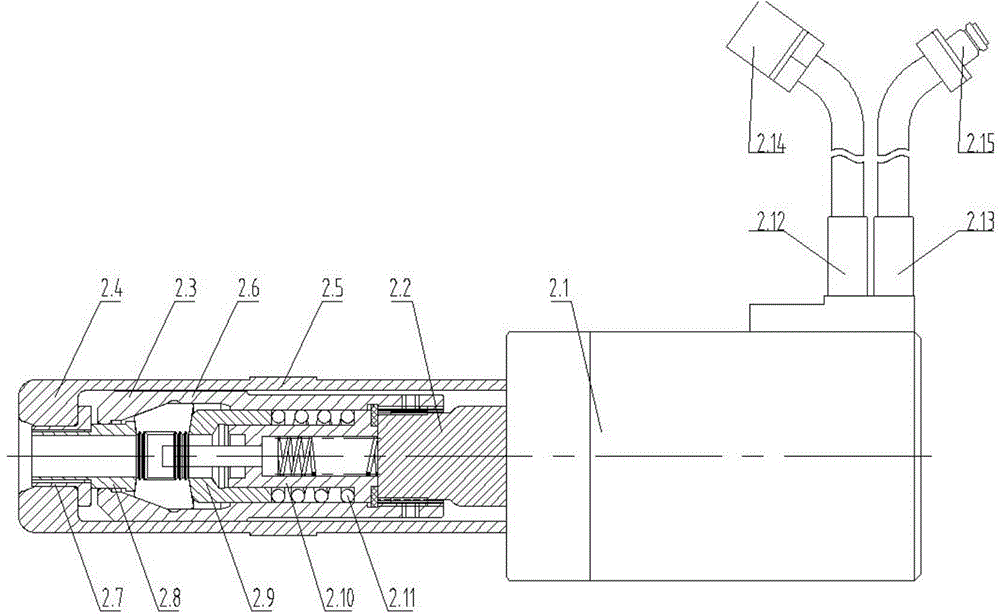

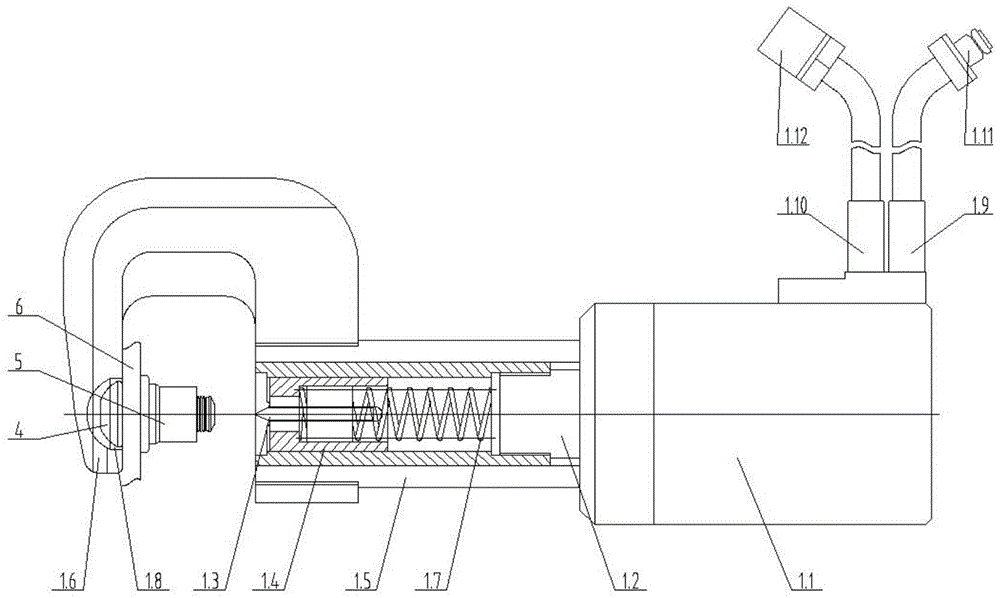

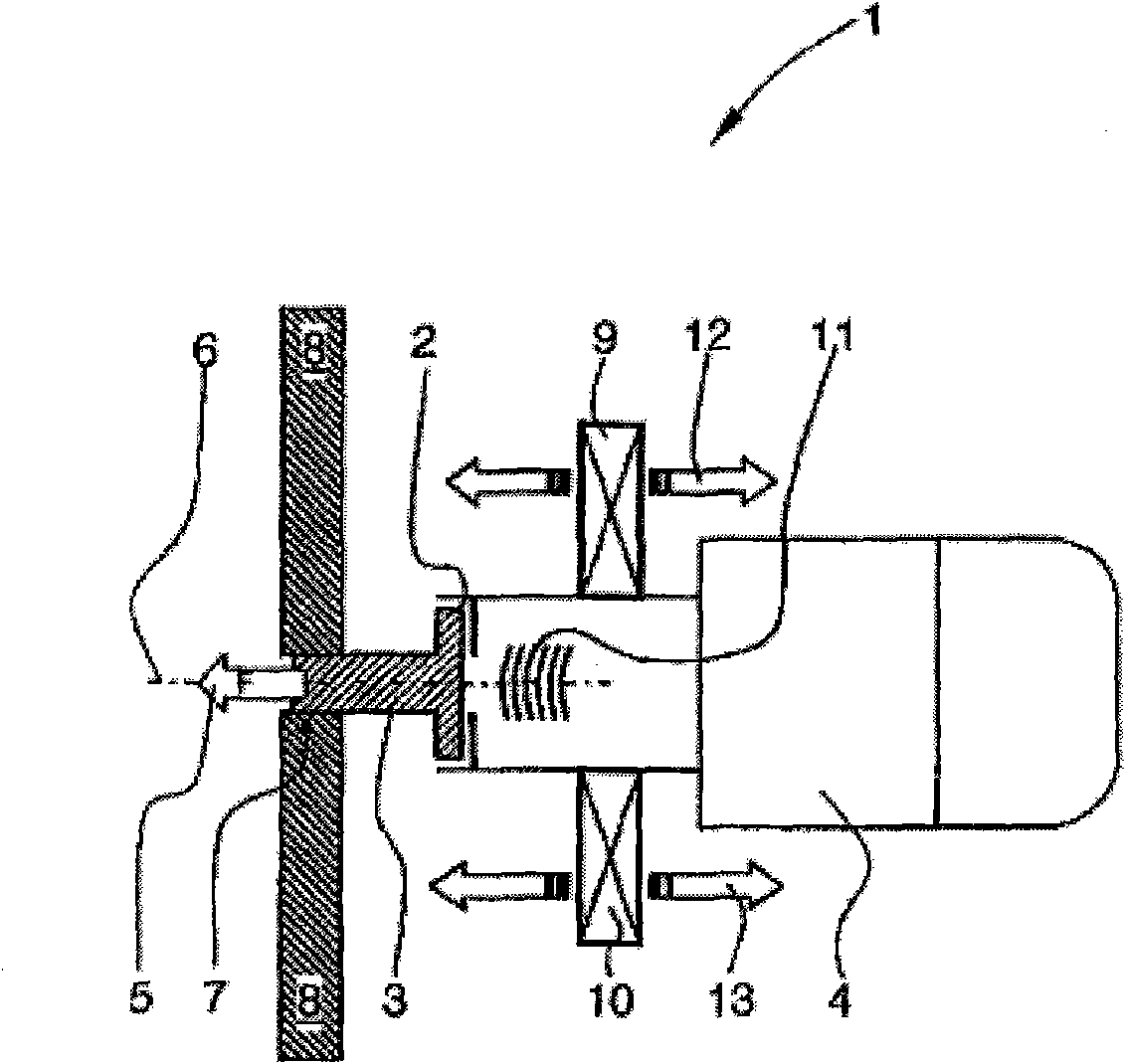

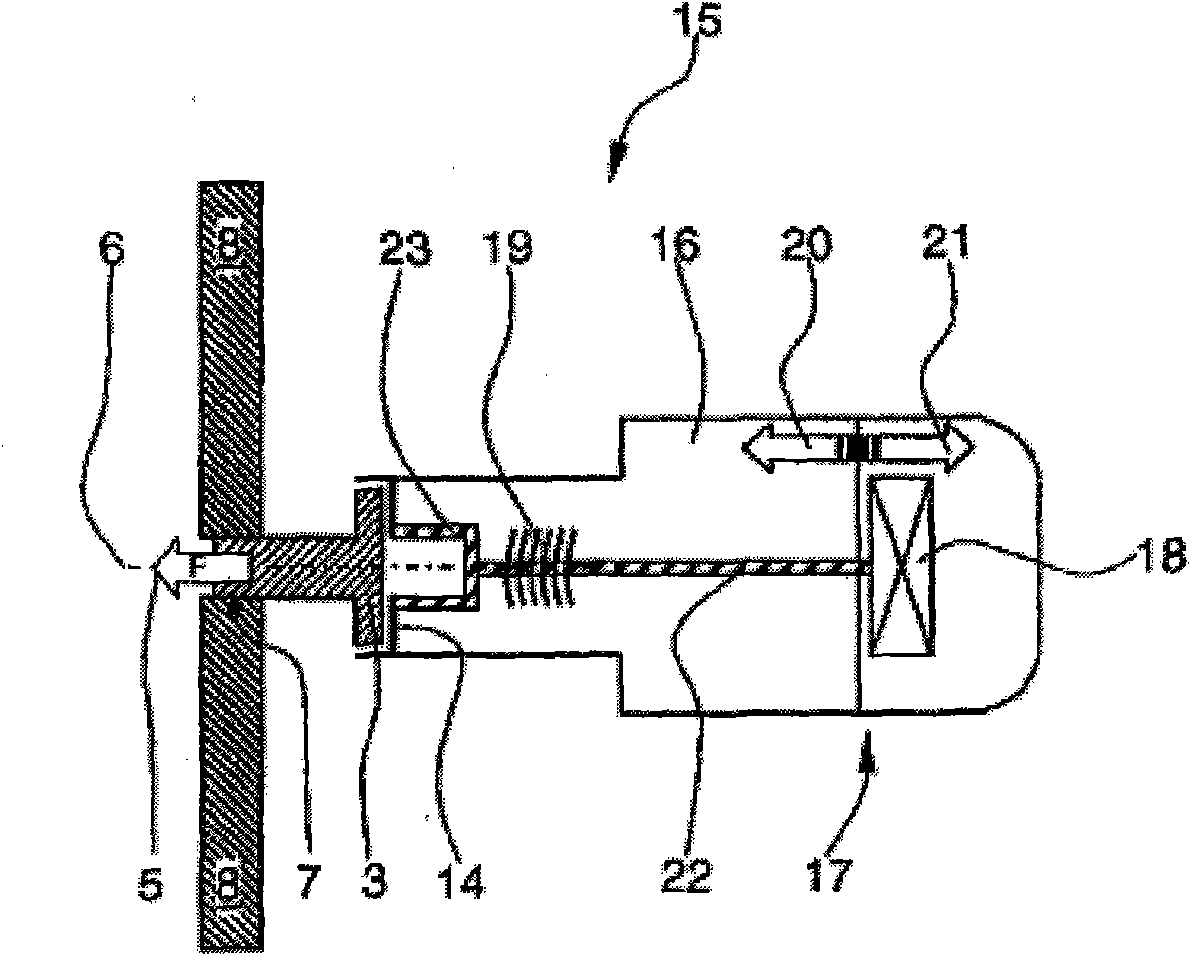

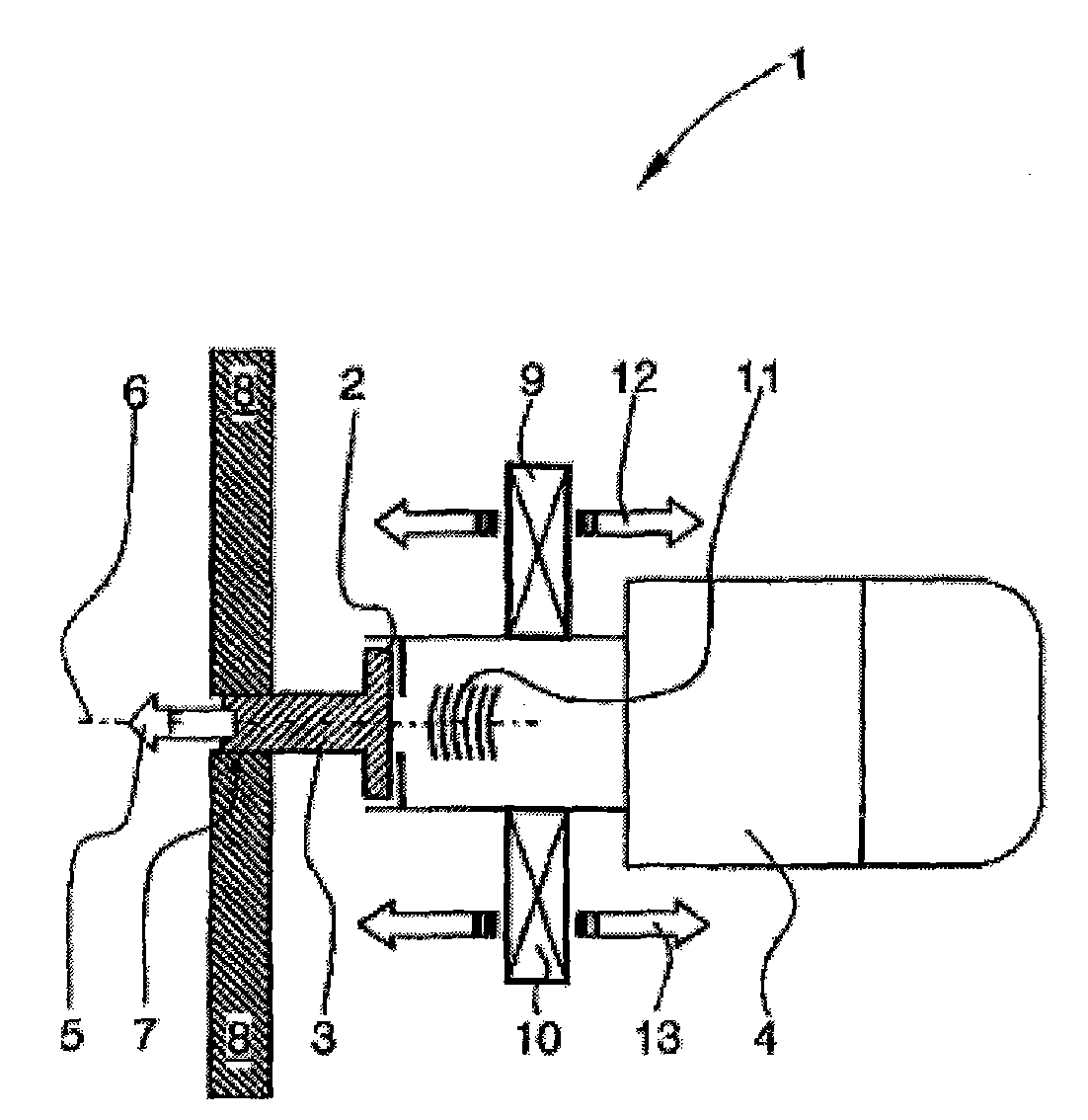

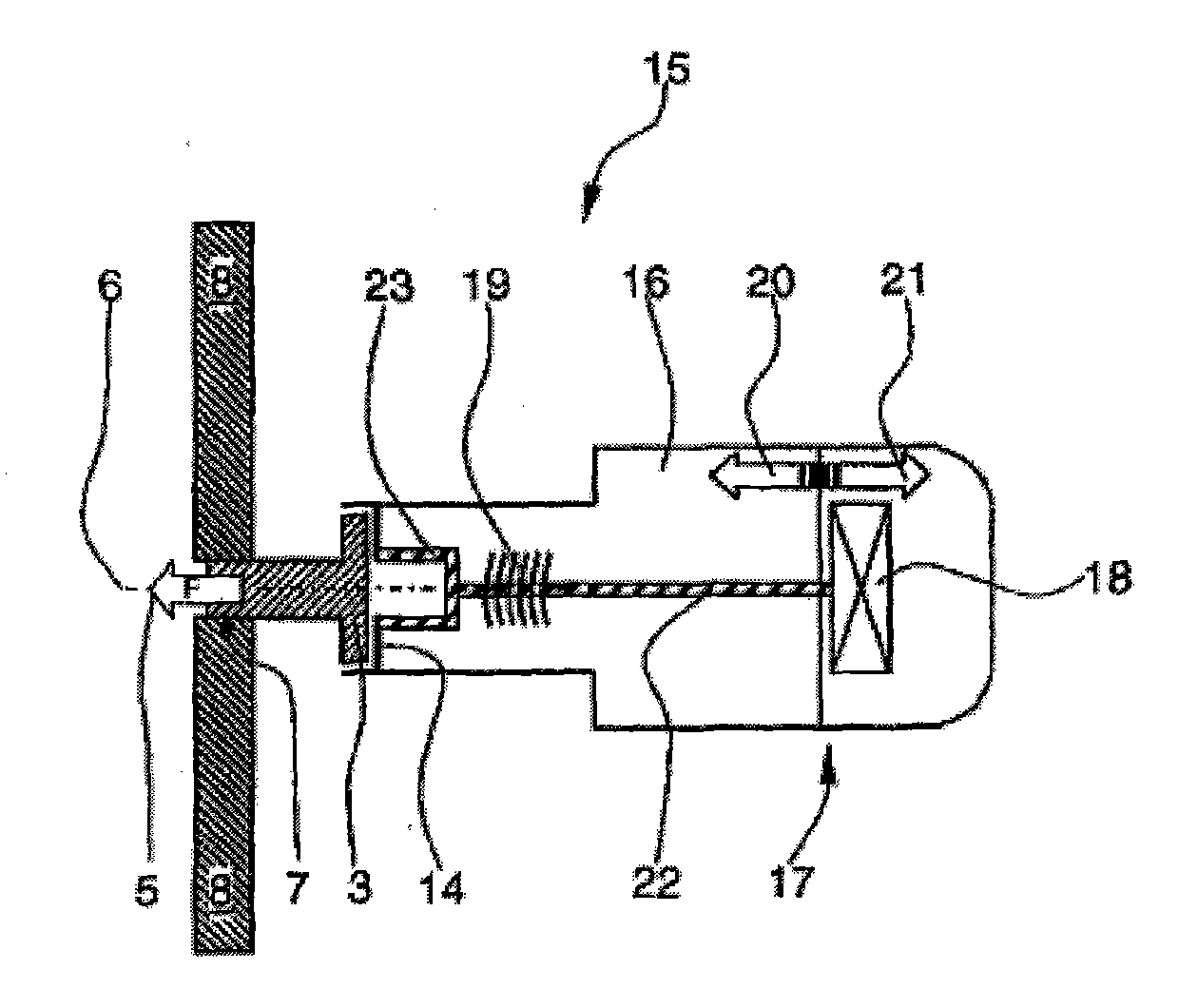

Vibrating rivet tool for pressing and fixing rivets in component holes and method for the use thereof

The invention relates to a vibrating rivet tool (1, 15) for pressing and fixing rivets (3) in component holes (7) in component (8) of aircraft. The vibrating rivet tool (1, 15) comprises a rivet receptacle (2, 14) and a drive unit (4, 16) for producing a high static pressing force (5). According to the invention, the static pressing force (5) is superimposed by a mechanical vibration (11, 19), ofwhich the amplitude acts substantially in the direction of a longitudinal axis (6) of the rivet. As a result, the force necessary to press and fix the rivet (3) in a component hole (7) is reduced in such a way that the overall size and mass of the vibrating rivet tool (1, 15) according to the invention are smaller / lower in comparison with conventional rivet tools. Due to the small overall size and low weight, the vibrating rivet tool (1, 15) can more easily be integrated in automated riveting processes.

Owner:AIRBUS OPERATIONS GMBH

Hydraulic riveting machine for hardware machining

The invention relates to the technical field of riveting machines, and discloses a hydraulic riveting machine for hardware machining, a group of support arms are symmetrically and fixedly mounted on the two sides of a clamp body, a hydraulic balance groove is formed in the top of the clamp body and located between two second hydraulic cavities with the same height, and the middle of the top of the hydraulic balance groove is movably sleeved with a sliding block; a corrugated pipe sleeve is movably connected between the first piston and the inner wall of the first hydraulic cavity, a sliding barrel is fixedly installed at the top of the first piston, a fixing rod with the bottom end extending into the sliding barrel is fixedly installed on the top wall of the first hydraulic cavity, a resistor strip is fixedly installed on the inner wall of the sliding barrel, and a sliding piece in sliding contact with the resistor strip is fixedly installed at the bottom end of the fixing rod. Riveting heads are symmetrically designed at the upper end and the lower end of a clamp body, supporting arms are arranged on the outer sides of the riveting heads, rolling wheels are installed at the ends of the supporting arms in an interactive mode, a sliding block in a hydraulic balance groove is used for controlling on-off of a circuit, a hydraulic system is fed back for adjustment according to resistance changes, and the riveting quality and efficiency are improved.

Owner:扬州盛世模塑科技有限公司

Tapered roller bearing assembling device and working method thereof

The invention provides a tapered roller bearing assembling device. The tapered roller bearing assembling device comprises an operation platform, and further comprises a feeding device, a discharging device, an operation board, a transmission device and a riveting device. Meanwhile, the invention further provides a working method of the tapered roller bearing assembling device. Through a feeding section, a roller is lifted one time and conveyed to the next assembling part, the abrasion to the roller is reduced, a hopper can be lifted and lowered through the effects of a motor and a chain, and discharging is facilitated. Through limiting at two positions, it is guaranteed that the hopper stops moving at the upper position and the lower position. Through the transmission device, an initial product is conveyed to the riveting device, the riveting device presses down automatically, in the whole assembling process, artificial participation is less, human cost is saved, the working efficiencyis improved, rapid riveting of a holder, the tapered roller and an inner sleeve is realized, and the precision of a product is guaranteed.

Owner:山东龙本轴承科技有限公司

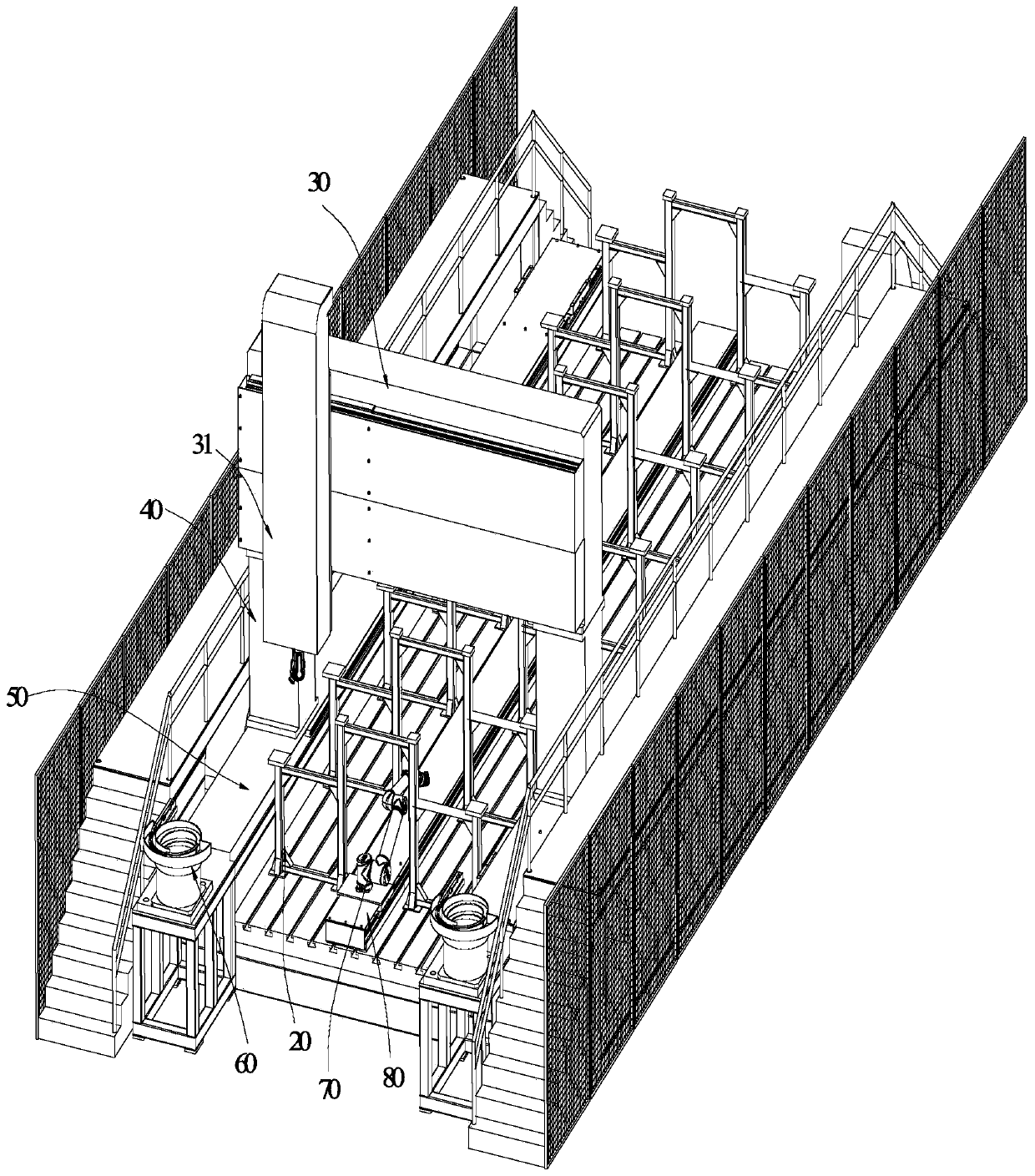

Full-automatic riveting production line

PendingCN111375722AQuick rivetingHigh degree of automationOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses a full-automatic riveting production line which comprises a body, a perforating mechanism, a riveting robot and a first driving robot, wherein a supporting assembly is arrangedon the body and comprises at least two supporting racks; supporting surfaces are arranged at the top ends of the supporting racks; and the at least two supporting surfaces are used for carrying a workpiece; the perforating mechanism is used for perforating the workpiece; the riveting robot is used for clamping and riveting the workpiece to a hole site of the workpiece; and the first driving mechanism is used for driving the perforating mechanism and the riveting robot to move in a conveying direction. The full-automatic riveting production line can carry out automatic riveting and is high inriveting efficiency.

Owner:深圳爱多多智能装备科技有限公司

riveting machine with automatic feeding

ActiveCN105772586BQuick rivetingEasy rivetingMetal-working feeding devicesMetal working apparatusEngineeringMechanical engineering

The invention relates to a squeeze riveter capable of automatically feeding. The squeeze riveter capable of automatically feeding comprises a stand and a mechanical arm; a riveting base module, a gas-liquid booster cylinder and a vibrating disc are arranged on the stand; the gas-liquid booster cylinder is positioned above the riveting base module; a feeding module is arranged in an outlet of the vibrating disc; the riveting base module is provided with a guide base; the feeding module includes a base; a working cavity is formed in the base; an inner end of the working cavity forms a spraying station; a spraying port is formed above the spraying station; a waterproof nut column is provided with a pushing hole on the base below the spraying station; a pushing block is arranged in the pushing hole; an air spraying hole is vertically formed in the pushing block; an outlet of the air spraying hole is positioned on the upper end surface of the pushing block; and an inlet of the air spraying hole is connected with a first air pipe. The squeeze riveter needs no manual operation to load the waterproof nut column, realizes automatic installation of the waterproof nut column, is fast, convenient and safe in the riveting process, and greatly improves the riveting efficiency and quality.

Owner:CHANGZHOU LINGXIE INTELLIGENT EQUIP CO LTD

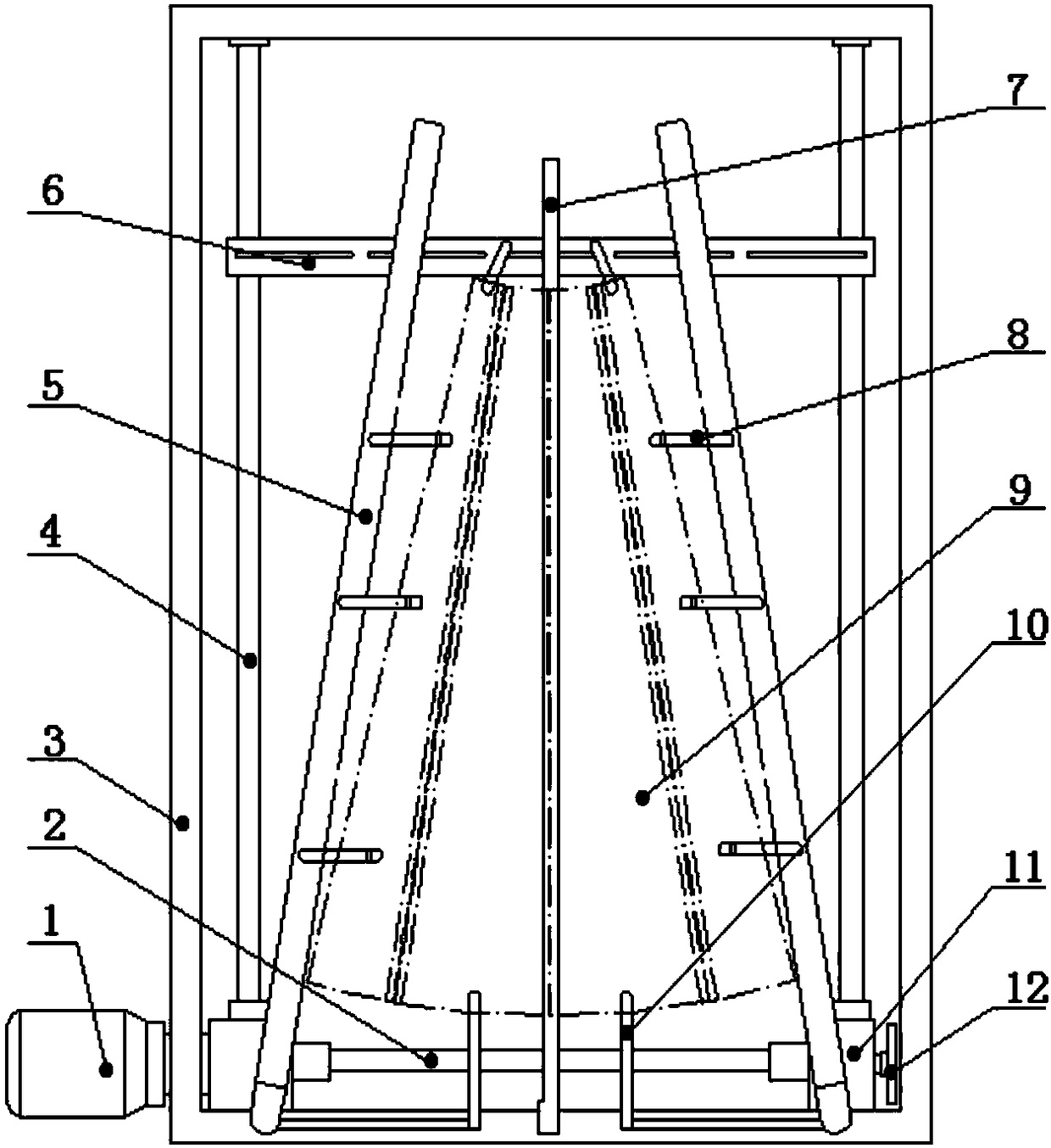

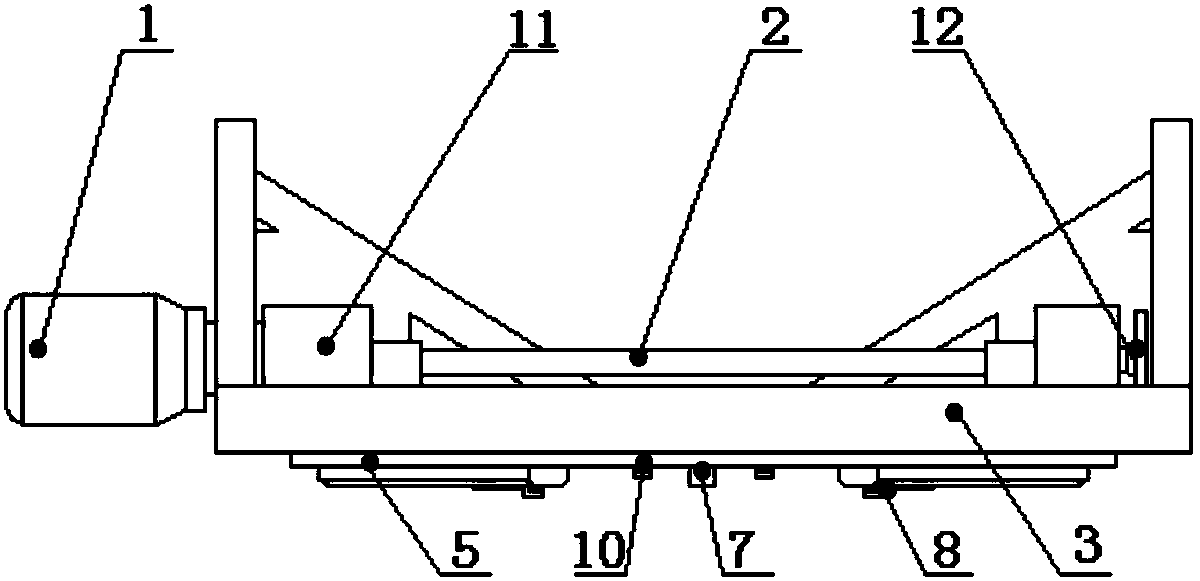

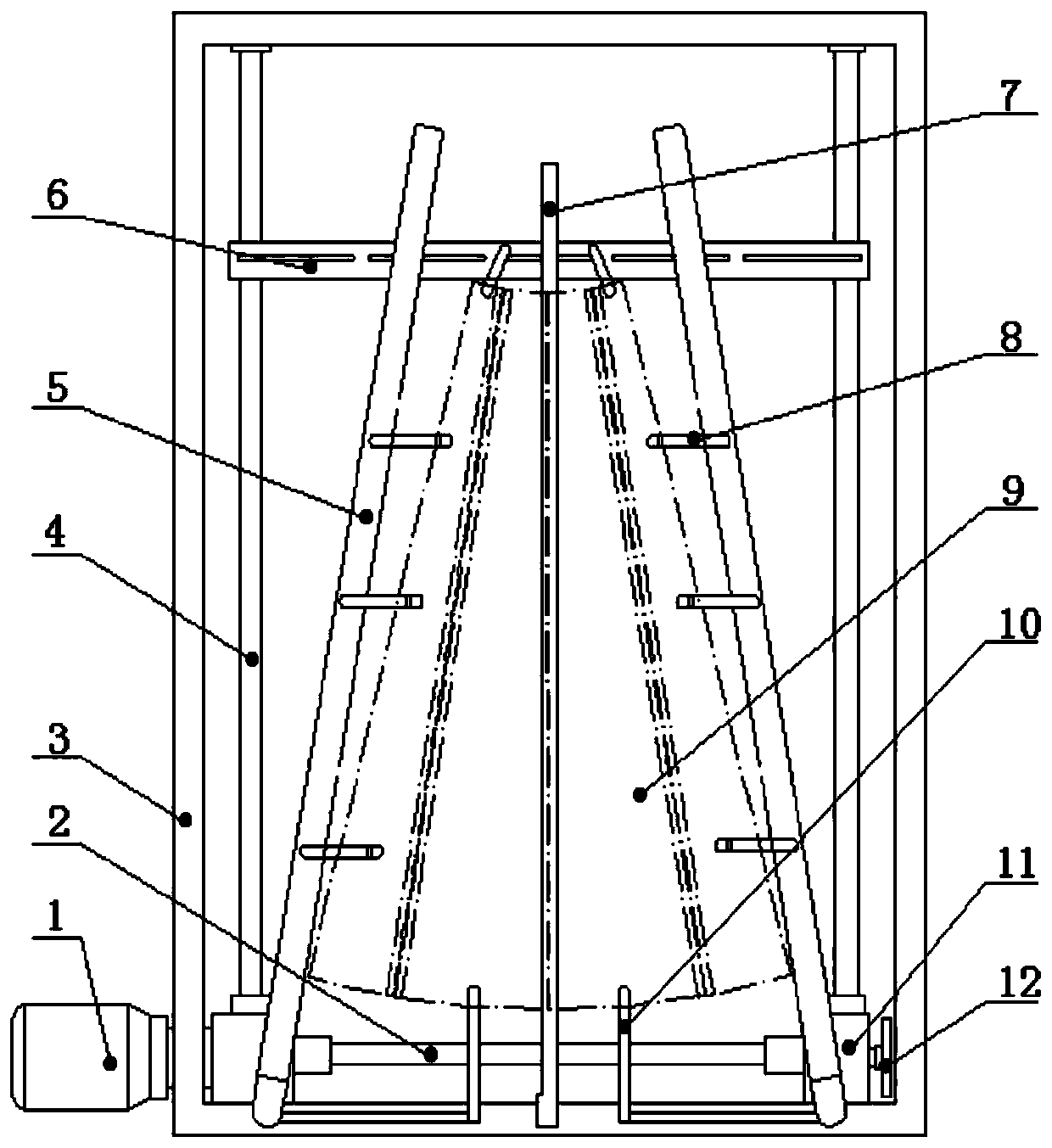

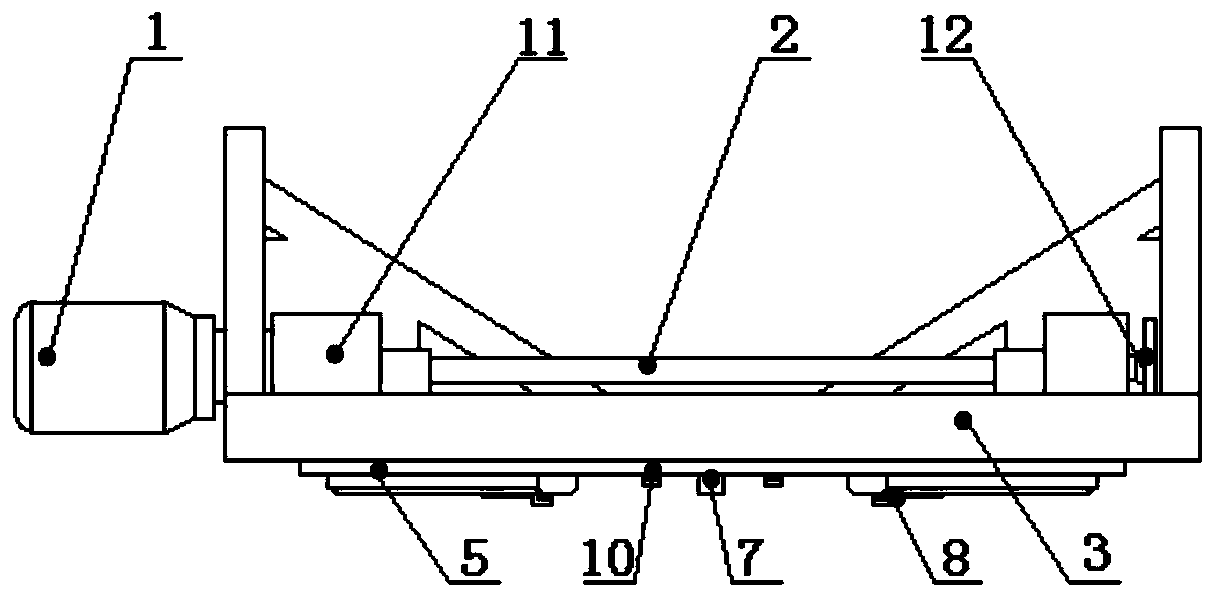

Flexible locating device for riveting cone shell segment wall plate products

The invention provides a flexible locating device for riveting cone shell segment wall plate products. The device comprises a fixed type enclosing frame, a variable swing fixture, a transmission structure and a support clamping part. The fixed type enclosing frame comprises a frame-shaped bracket body and a vertical locating plate. The vertical locating plate is fixed to the center of the bracketbody and is perpendicular to the bottom of the bracket body. The transmission structure comprises a motor, a horizontal transmission shaft, vertical transmission shafts, transmission assemblies and ahand wheel. The variable swing fixture is arranged in the bracket body and comprises a sliding connection plate and swing assemblies. By means of the flexible locating device, the assembling state canbe adjusted according to variation of structural boundary dimensions of the cone shell segment wall plates product so that the flexible locating device can be adapted to the wall plate products of different diameters, heights and taper degrees, and rapid locating and flexible assembling of the cone shell segment wall plate products are achieved.

Owner:CAPITAL AEROSPACE MACHINERY +1

A flexible positioning device for riveting of cone shell section wall plate products

ActiveCN108161787BRealize functionRealize vertical clamping functionWork holdersWall plateCone shell

The invention provides a flexible locating device for riveting cone shell segment wall plate products. The device comprises a fixed type enclosing frame, a variable swing fixture, a transmission structure and a support clamping part. The fixed type enclosing frame comprises a frame-shaped bracket body and a vertical locating plate. The vertical locating plate is fixed to the center of the bracketbody and is perpendicular to the bottom of the bracket body. The transmission structure comprises a motor, a horizontal transmission shaft, vertical transmission shafts, transmission assemblies and ahand wheel. The variable swing fixture is arranged in the bracket body and comprises a sliding connection plate and swing assemblies. By means of the flexible locating device, the assembling state canbe adjusted according to variation of structural boundary dimensions of the cone shell segment wall plates product so that the flexible locating device can be adapted to the wall plate products of different diameters, heights and taper degrees, and rapid locating and flexible assembling of the cone shell segment wall plate products are achieved.

Owner:CAPITAL AEROSPACE MACHINERY +1

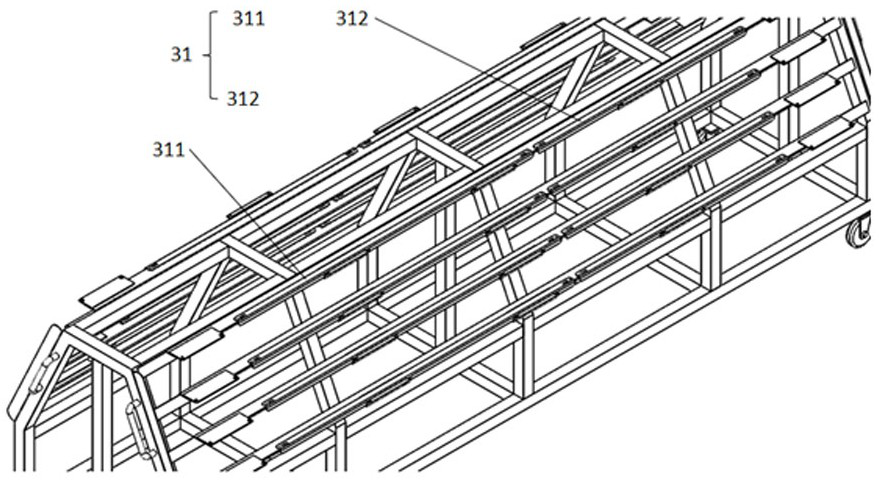

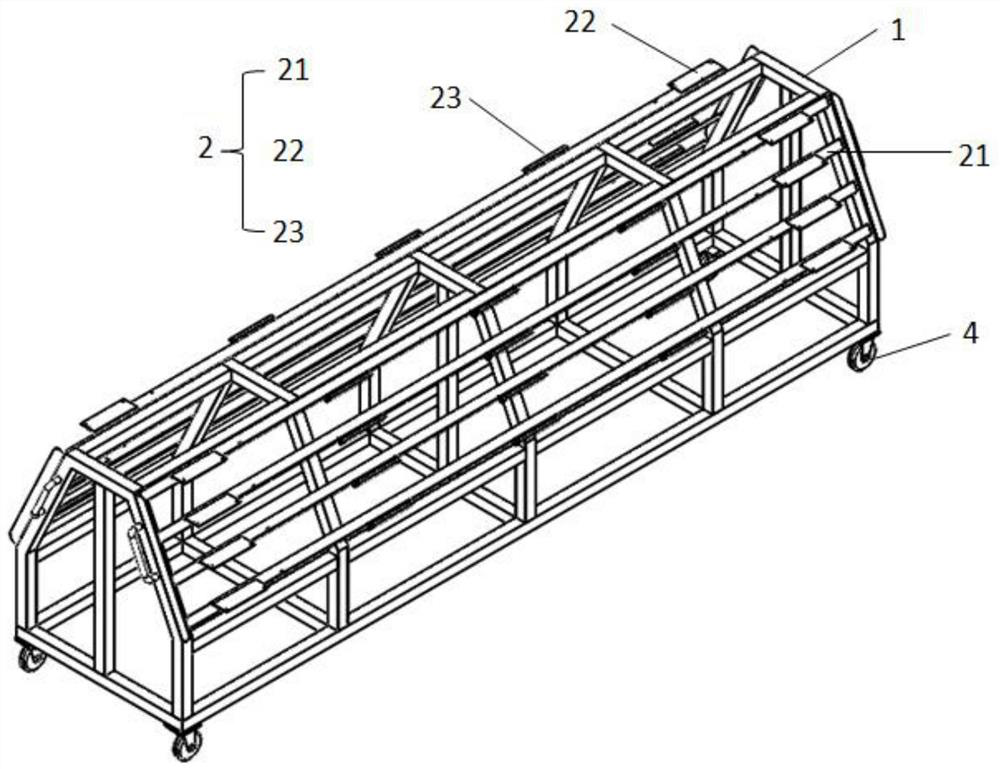

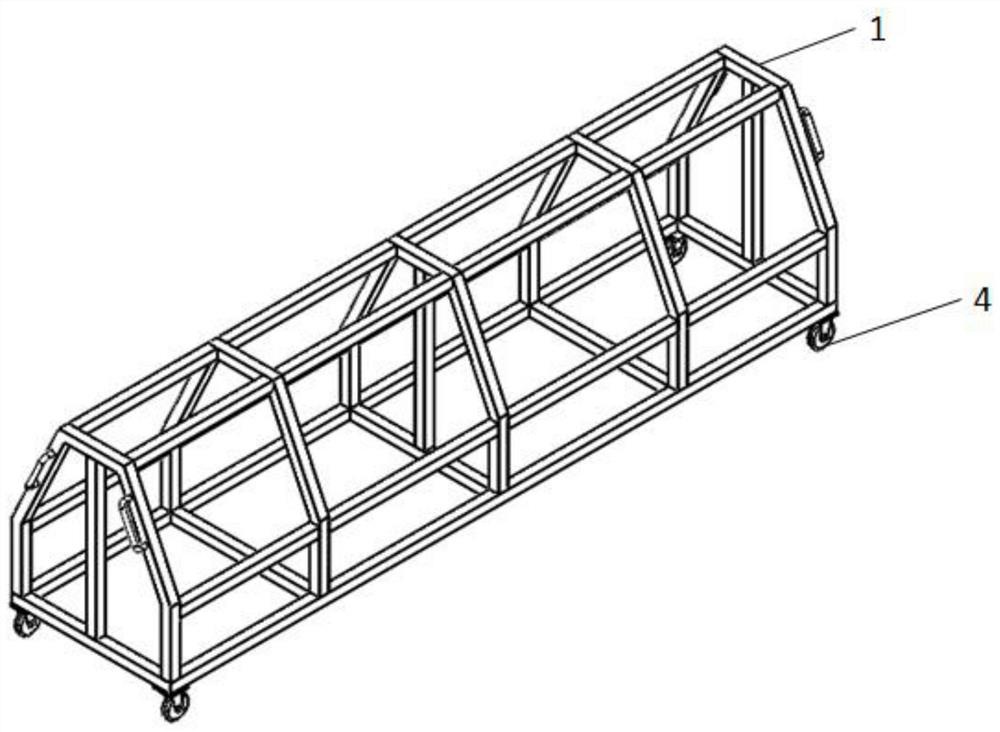

Riveting tooling for sub-beam of heliostat

ActiveCN111308645BQuick rivetingAccurate rivetingSolar heating energyMountingsEngineeringMechanical engineering

The invention discloses a sub-beam riveting tool for a heliostat, which includes a base and at least one set of sub-beam riveting units, wherein the sub-beam riveting unit includes a first support piece, two second support pieces and several first support pieces. Three supporting parts, wherein the first supporting part includes a first connecting plate and a first supporting plate, and the riveting surface of the first supporting plate is provided with a beam positioning structure, and the sub-beam components are sequentially installed on the sub-beam riveting according to their assembly structure unit, and then rivet the riveting holes in turn. By providing a sub-beam riveting tool, the rapid riveting of the sub-beam assembly can be realized, and the labor intensity of the workers can also be reduced. At the same time, the girder positioning structure can be used for different girders. Positioning, preventing misassembly of support beams, and realizing accurate riveting of sub-frame components.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

Fully automatic high speed riveting machine

Owner:东莞市一川金品机械有限公司

A riveting tool for the frame of the automobile sunroof guide rail

A riveting tooling for an automobile sunroof guide rail frame is characterized by comprising a bottom plate used for weighting, wherein bottom columns are arranged below the bottom plate; a mounting plate for mounting guide rails is arranged on the bottom plate; a connecting plate is arranged between the bottom plate and the mounting plate; pushing cylinders for riveting pressing are arranged on the connecting plate. With the adoption of the riveting tooling for the automobile sunroof guide rail frame, the sunroof guide rail frame can be quickly riveted, and meanwhile, structural parts on the sunroof guide rails can be accurately mounted; the riveting tooling applies to the riveting mounting of sunroof guide rail frames with different specification and size.

Owner:ANHUI DIKUN AUTO SKYLIGHT TECH CO LTD HEFEI

A railway freight car 120 valve protective cover rivet riveting equipment

The invention provides a wagon 120-valve protection hood rivet disassembling device. The rivet disassembling device is composed of a riveting device, a splitter and a hand-operated hydraulic pump. The splitter comprises a splitter oil cylinder assembly, a splitter piston, a cutter head assembly, a positioning sleeve, a splitter connection jacket, a C-shaped clamp, a spring, an oil pipe and a quick-change connector. The riveting device comprises a riveting device oil cylinder assembly, a riveting device piston, an inner sleeve, an outer sleeve, a riveting device connection jacket, a clamping section, an upper limiting sleeve, a lower limiting sleeve, a buffering front sleeve, a buffering rear sleeve, a spring, an oil pipe and a quick-change connector. The hand-operated hydraulic pump is provided with a pump body, a reversing valve, the oil pipe and the quick-change connector. The reversing valve is used in a hand-operated mode. The technical scheme is used for riveting and splitting of pultrusion rivets with the diameter being 12 on the wagon 120-valve protection hood portion, the riveting forming is good, splitting is smooth, and the disassembling device is convenient to carry and operate and capable of quickly riveting or splitting rivet lantern rings under the conduction that no electricity, gas and other power sources exist and achieving disassembly of a 120-valve protection hood.

Owner:CRRC MEISHAN

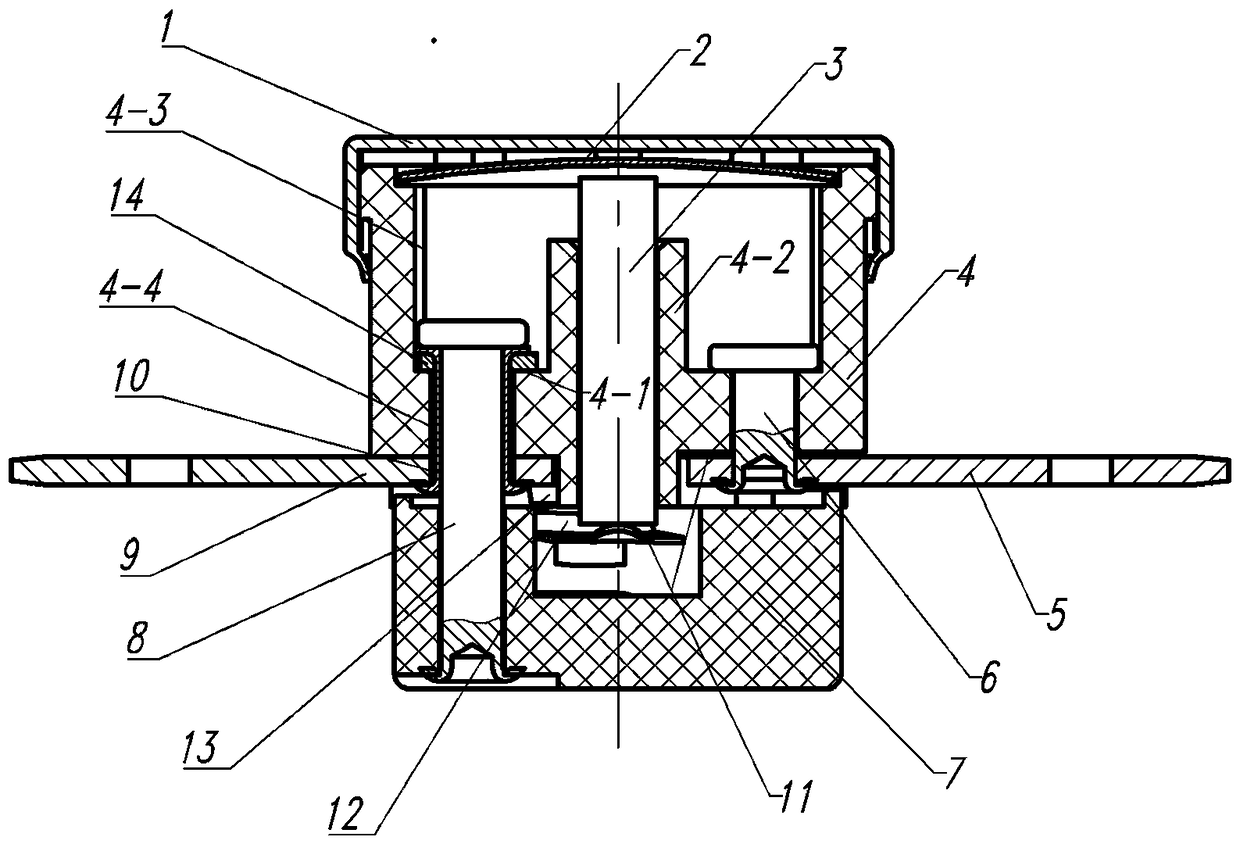

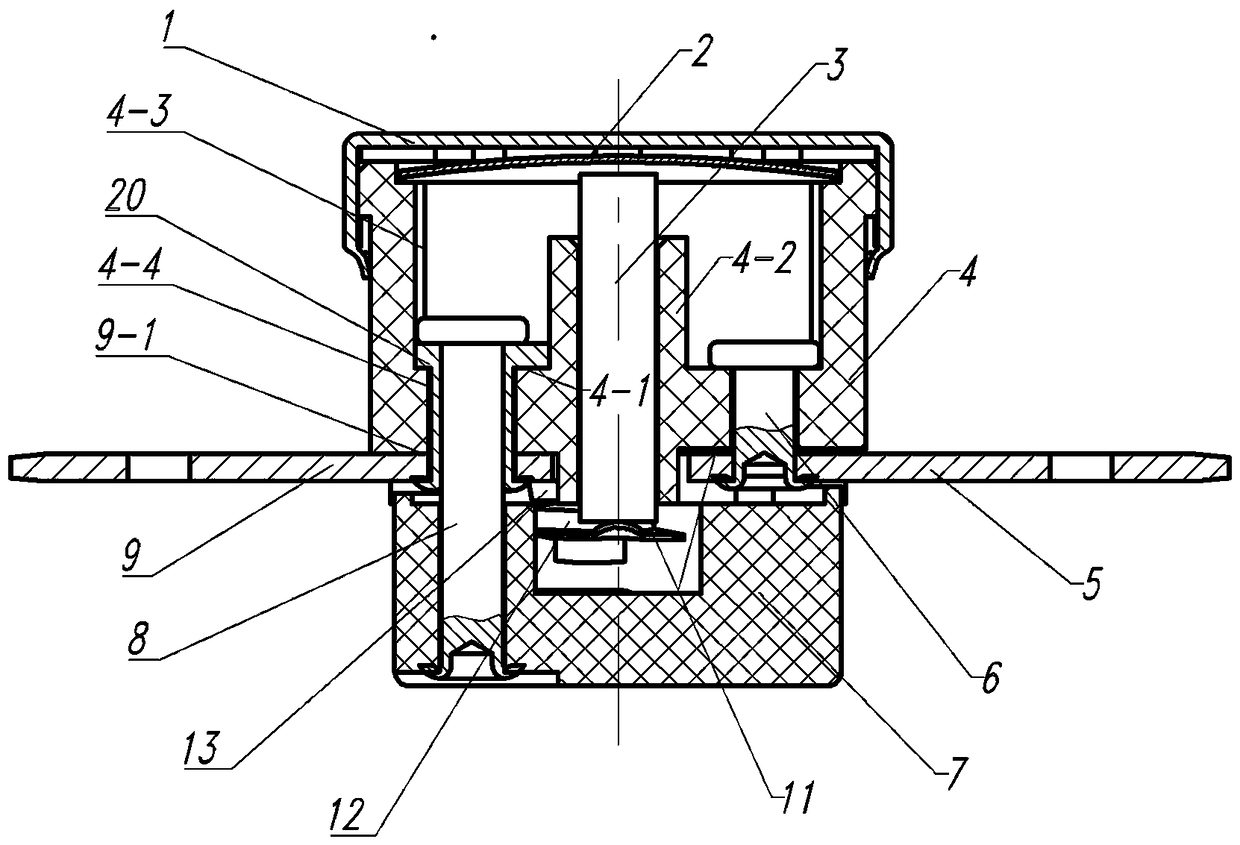

High-efficiency high-quality snap-action temperature controller

PendingCN109119287AQuick rivetingSmooth riveting processThermal switch detailsCentral cylinderEngineering

The invention relates to a high-efficiency high-quality snap-action temperature controller. The temperature controller is provided with a boot-shaped hollow rivet of an integrated structure, a rivet body is vertical to a rivet cap, a first protruded arc in the edge of one side of the rivet cap is connected with an arched groove of a casing in a matched way, a second recessed arc in the edge of theother side of the rivet cap is connected with a outer cylindrical surface of a central cylinder of the casing in the matched way, the bottom side of the rivet cap is tightly connected with a first plane of the casing, and the rivet body is in riveted joint with the inner end portion of a fourth binding post by penetrating a first circular through hole of the casing. The boot-shaped hollow rivet can be used to rivet the fourth binding post to the preset accurate position of the casing rapidly accurately, it is ensured that a static contact is in button joint with a moving contact completely torealize contact in the full surface, riveting crack is eliminated, and the qualified rate and assembling efficiency of products are improved.

Owner:佛山市通宝华龙控制器有限公司

Vibrating rivet tool for pressing and fixing rivets in component holes and method for the use thereof

The rivet tool (1) has a rivet retainer (2) and a drive unit (4), where the drive unit produces a static press-in force (5) in a direction of a rivet longitudinal axis (6). A vibration sensor (9) is provided for producing a mechanical vibration (11), and the static press-in force is overlaid by an amplitude of the mechanical vibration. The amplitude of the vibration runs parallel and / or transverse to the rivet longitudinal axis, and works in a direction of the longitudinal axis. A frequency of the vibration is steplessly adjustable, where the vibration sensor is a piezoelectric element. An independent claim is also included for a method for pressing and fastening of rivets into components drillings of components of aircraft.

Owner:AIRBUS OPERATIONS GMBH

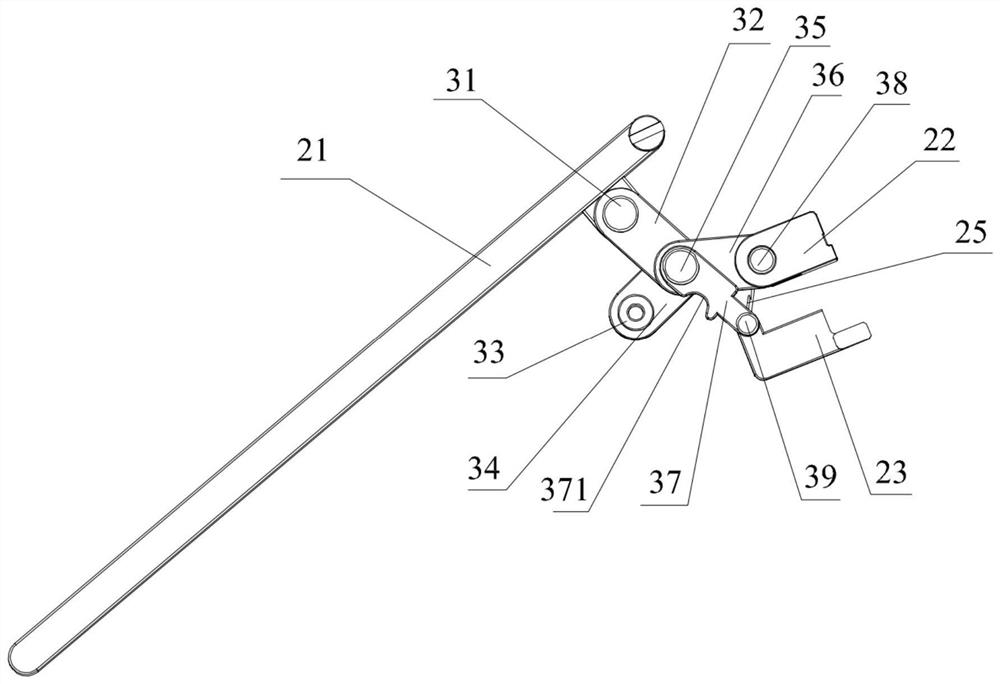

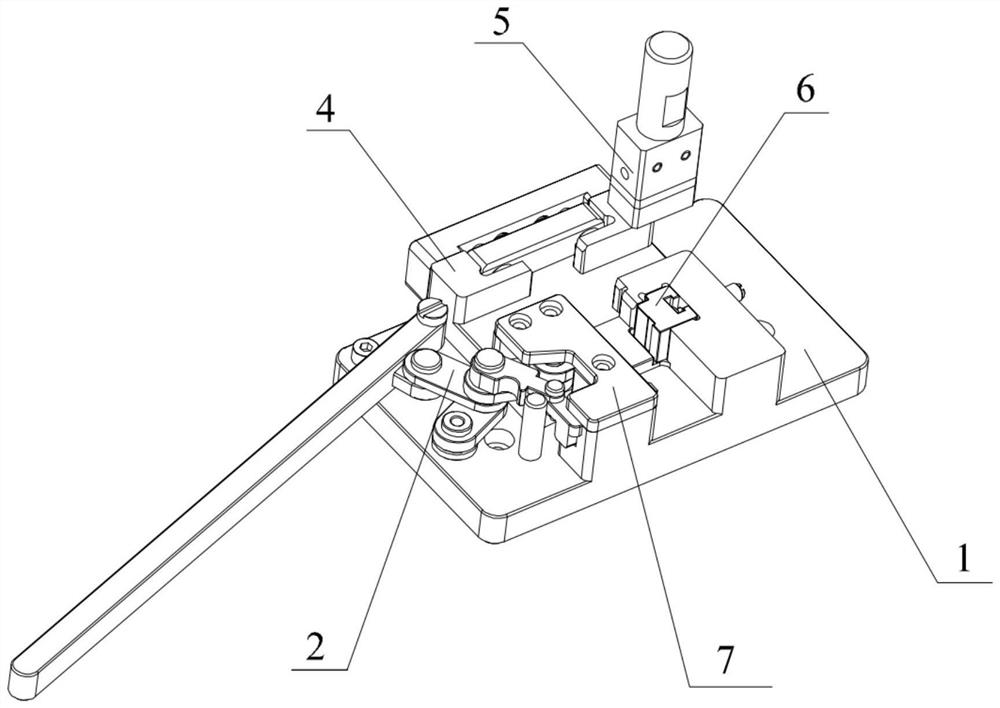

Multi-connecting rod sliding block mechanism for locking machine

ActiveCN112490812ANo lock-upQuick rivetingContact member assembly/disassemblyMetal-working feeding devicesControl engineeringMachine

The invention discloses a multi-connecting rod sliding block mechanism for a locking machine, and belongs to the field of machinery. The multi-connecting rod sliding block mechanism comprises a handle, a multi-connecting rod control mechanism, a first sliding block for fastening an elastic sheet and a second sliding block for longitudinally limiting a connector, and the handle controls the first sliding block and the second sliding block to lock the elastic piece and the connector through the multi-connecting-rod control mechanism. The multi-connecting rod sliding block mechanism has the beneficial effects that the positions of the elastic piece and the connector are fixed through the first sliding block and the second sliding block in the sliding block mechanism, the placement position ofthe connector does not need to be manually adjusted in real time, locking deviation of the elastic piece does not occur, riveting can be fast and accurate, waste of human resources is avoided, and the loss caused by misoperation during product processing is reduced; and after a locking machine manufactured by the multi-connecting rod sliding block mechanism is debugged and used once, the lockingmachine can be repeatedly used by an operator without being debugged again, so that the production efficiency is improved, and the labor cost is reduced.

Owner:AMPHENOL (XIAMEN) HIGH SPEED CABLE CO LTD

Belt cover riveting machine

The invention discloses a belt cover riveting machine. The belt cover riveting machine includes a workbench, a horizontal pressing rod is connected to the workbench through a lifting mechanism in a transmission mode, and an upper pressing wheel assembly is disposed on the bottom side of one end of the horizontal pressing rod. A movable plate is disposed below the upper pressing wheel assembly, andthe movable plate is connected to the top side of the workbench by a sliding mechanism in a transmission mode. A moving pressing wheel assembly is arranged on the top side of the movable plate, and more than one elastic bracket is arranged on the side of the moving pressing wheel assembly. The belt cover riveting machine can improve the processing efficiency of riveting on belt covers, improves the stability of the processing quality, solves the noise problem generated during processing, and is suitable for modern enterprise processing and production.

Owner:FOSHAN CITY NANHAI POPULA FAN

A method for riveting medium and thick metal plates without protrusions on both sides

The invention discloses a riveting method for medium-thick metal plates with no protrusions on both sides, and belongs to the technical field of material connection. A hole with an annular groove is prefabricated on the two medium-thick plates to be connected, and a connecting column with a simple shape is placed, and an external force is applied to both sides of the connecting column through the upper and lower punches to make it plastically deform and fill the ring. The groove method realizes fast and efficient riveting between medium and thick plates. According to the law of constant volume, the connecting column can be filled into the annular grooves of the upper and lower plates after plastic deformation, without obvious protruding high points, reducing the grinding process and improving production efficiency. The parts of the device used have a simple structure, are easy to process, and have good compatibility with conventional equipment. The pretreatment process of the riveted plates is simple, the production efficiency is high, and the cost is low; the surface of the connection part is smooth and has no protrusions, which is more beautiful; and, When the connecting column is plastically deformed, the tensile strength and shear strength of the riveted part increase, and the connection becomes more stable.

Owner:SHAANXI UNIV OF SCI & TECH

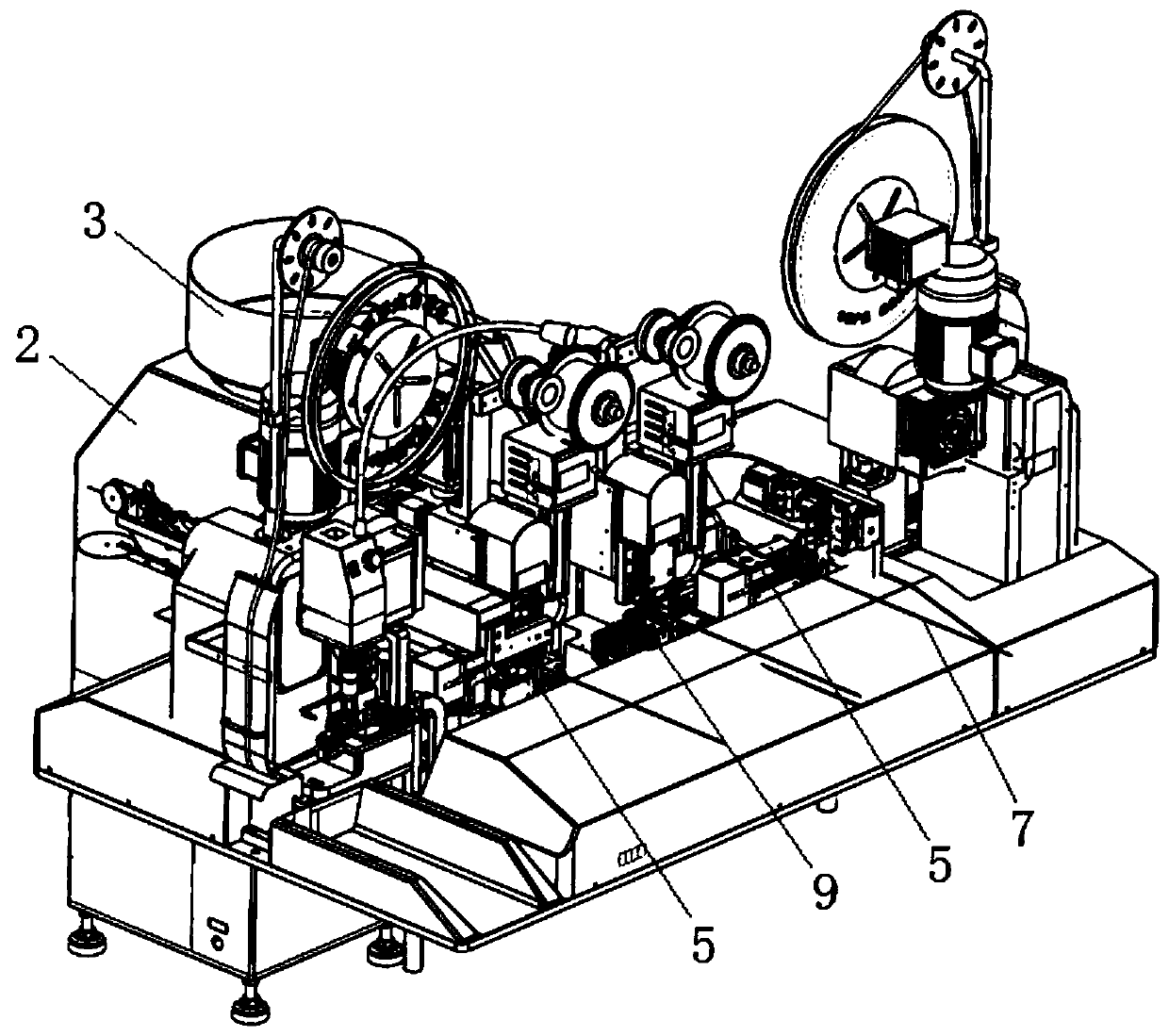

Full-automatic copper strip machine and operation method thereof

PendingCN109904702AImprove processing efficiencyHigh degree of automationConnection formation by deformationElectronic waste recyclingEngineeringCopper

The invention discloses a full-automatic copper strip machine and an operation method thereof. The full-automatic copper strip machine comprises a rack, copper strip loading devices, a vibration device, a cable conveying device, a cable connection device and a terminal formation device, wherein the vibration device, the cable conveying device, the cable connection device and the terminal formationdevice are arranged on one side of the rack; the vibration device is provided with a vibration mechanism and a vibration disk, wherein the vibration disk is provided with a material guiding structureand a material discharging structure; the vibration mechanism vibrates to drive the vibration disk to vibrate, and materials are vibrated and conveyed to a material outlet while the materials are putstraight through the guiding structure and the material discharging structure; two groups of copper strip loading devices are independently arranged on two sides of the board of the rack, each copperstrip loading device is provided with a loading disk, and the side part of the loading disk is provided with a copper strip guiding structure; the cable conveying device is arranged on the upper board of the rack and is used for conveying a cable to a processing position; and the cable conveying device is provided with a cable cutoff mechanism, and the cable is subjected to cutoff processing after the cable finishes being processed. The copper strip machine combines loading and processing into a whole to form the copper strip machine capable of automatically running, and processing efficiencyis improved.

Owner:深圳市瑞峰成机械有限公司

Inner frame riveting machine for bag filter

The invention discloses an inner frame riveting machine for a bag filter, which is simple in structure and reasonable in design and comprises a frame. A conveying mechanism and a riveting mechanism are arranged on the frame, the conveying mechanism comprises a guide rod, a moving frame and a transmission mechanism, the moving frame comprises a first moving frame and a second moving frame, the first moving frame bilaterally slides along the guide rod, the second moving frame vertically slides along the first moving frame, and the transmission mechanism comprises a vertical cylinder and an elastic device. The riveting mechanism comprises a riveting cylinder, a transmission rod and a punching device, the transmission rod is arranged on a fixed bock, one end of the transmission rod is connected with a cylinder rod of the riveting cylinder, the other end of the transmission rod is connected with the punching device, the punching device comprises a riveting punch and an ejector rod, and the transverse axis of the riveting punch is overlapped with that of the ejector rod. The inner frame riveting machine is reasonable in structural design, convenient and practical in operation, high in automation degree, firm and reliable in riveting, stable in product quality, time-saving and labor-saving, an inner frame of a filter bag can be rapidly riveted with the filter bag, production efficiency is improved, and cost is saved.

Owner:张福安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com