Patents

Literature

32results about How to "Easy to position and cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

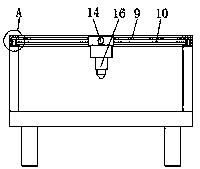

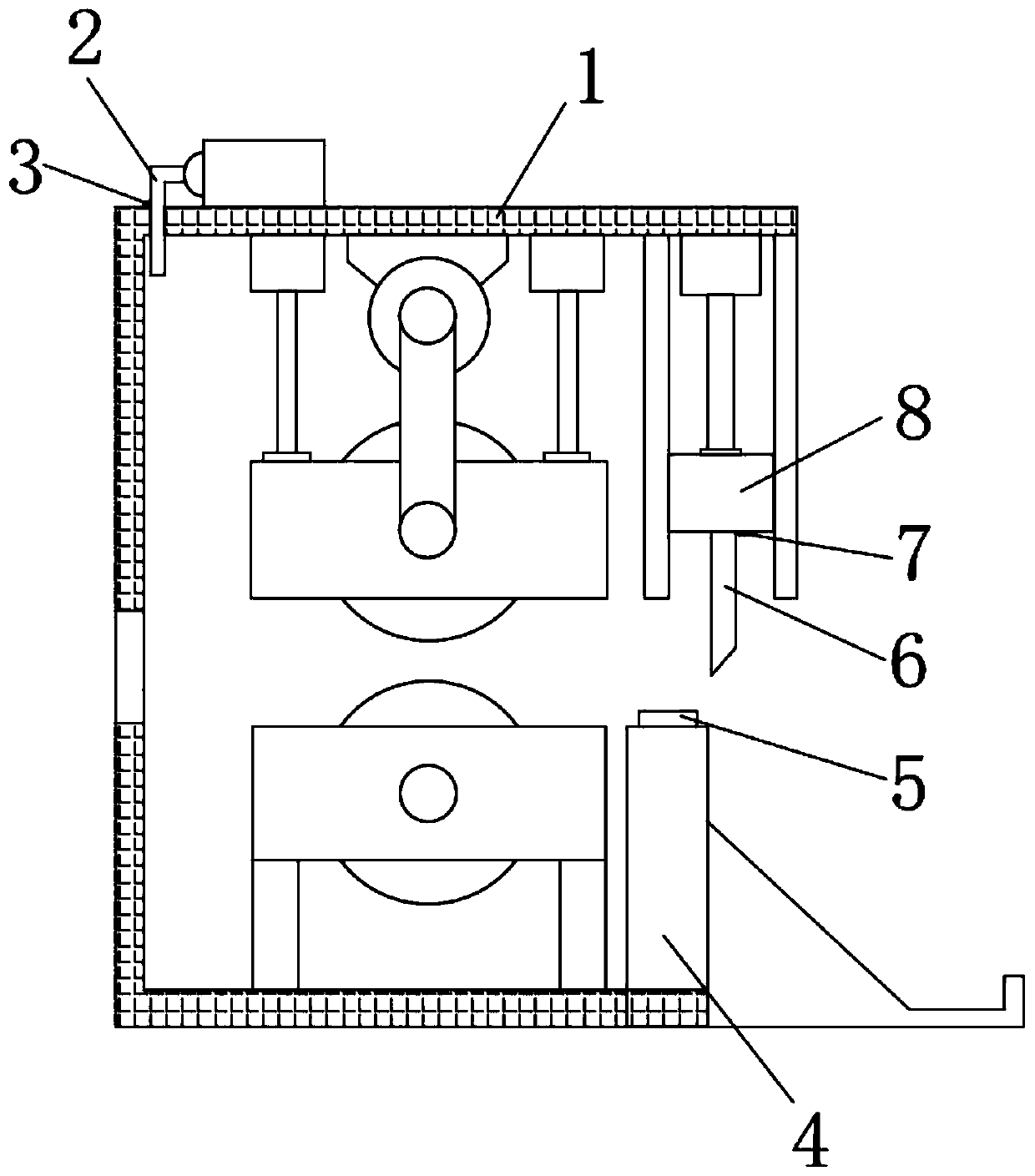

Cutting equipment for garment processing

ActiveCN108842425AImproved cropping accuracyReduce fabric lossSevering textilesEngineeringLeveling mechanism

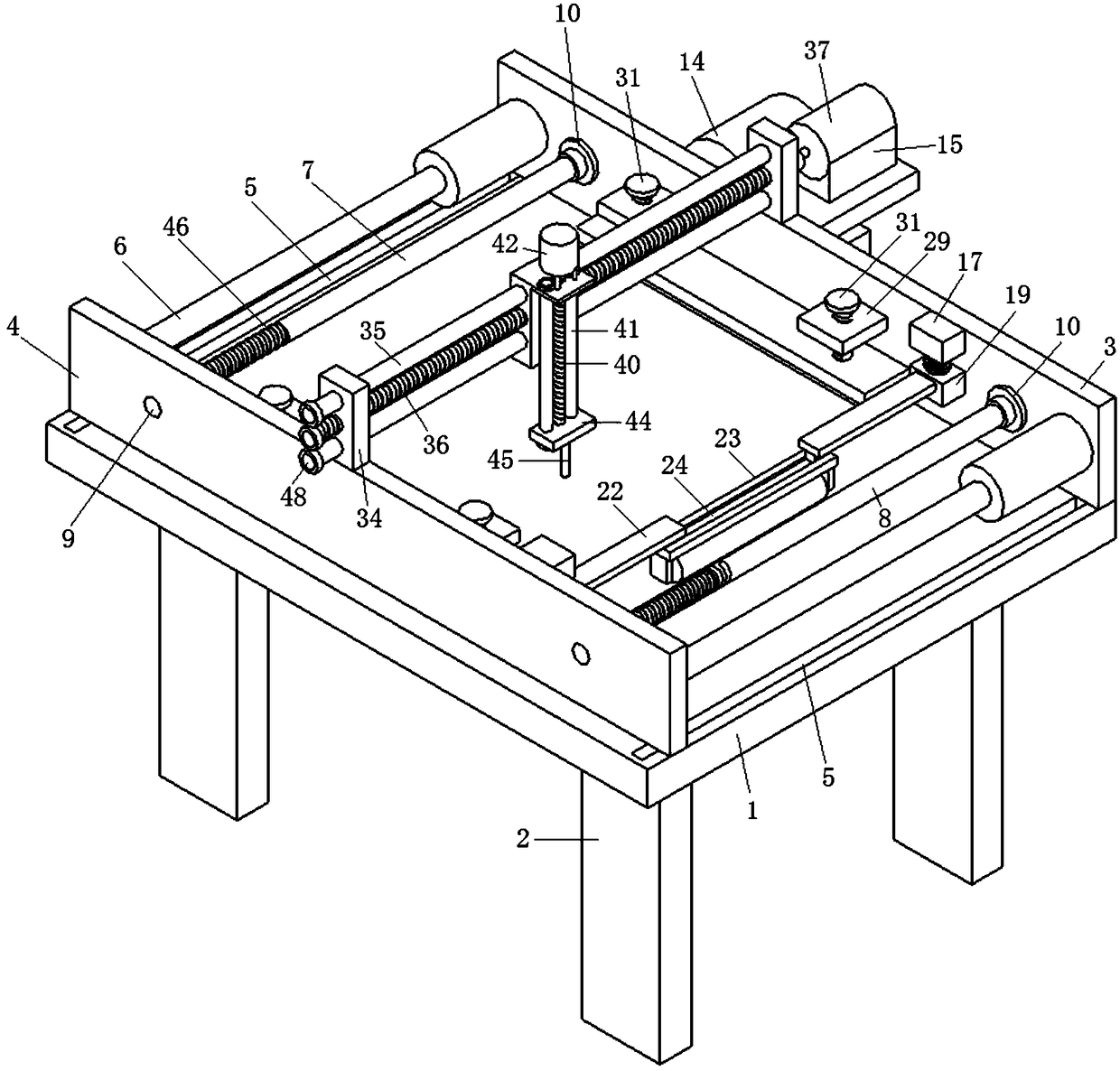

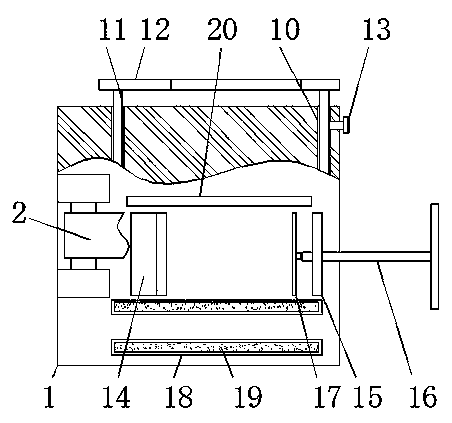

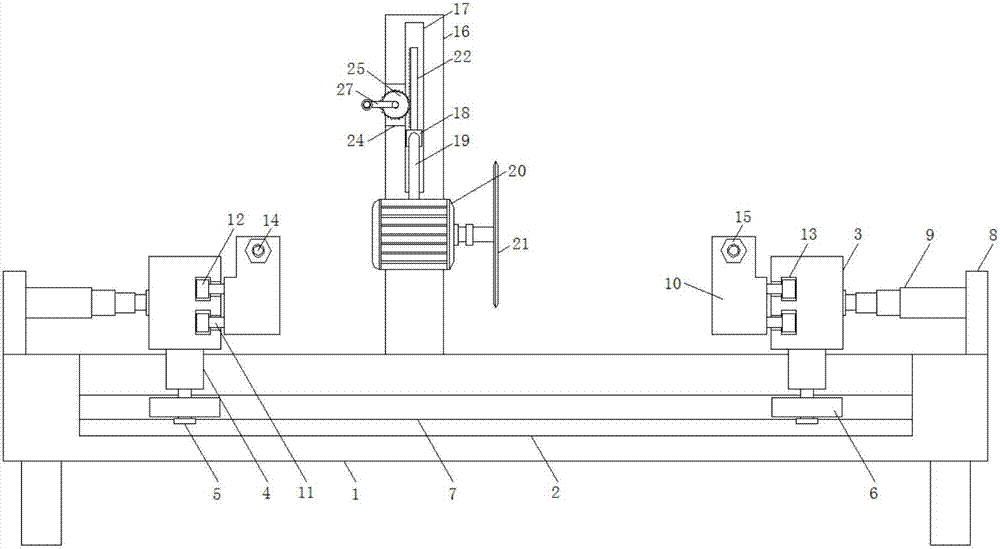

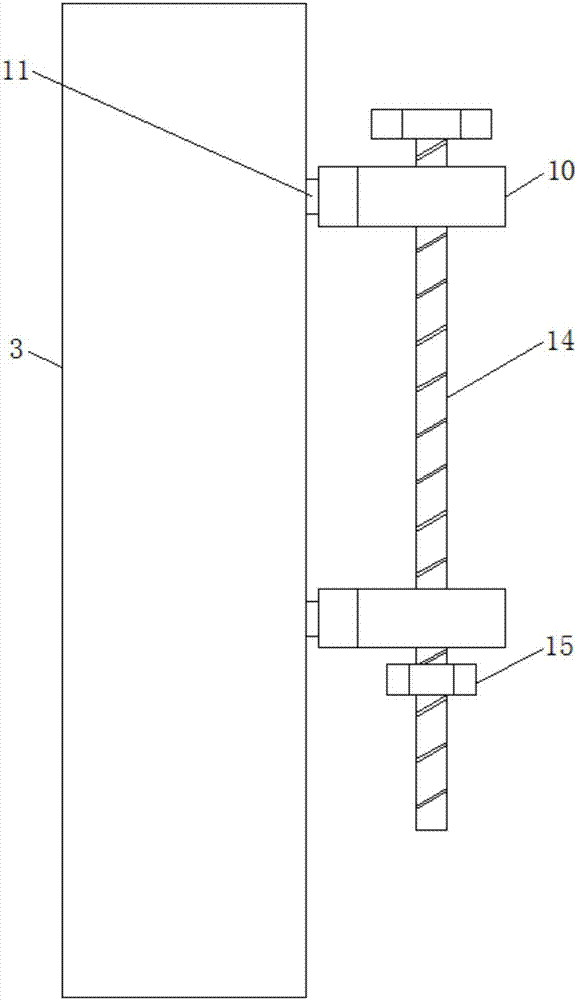

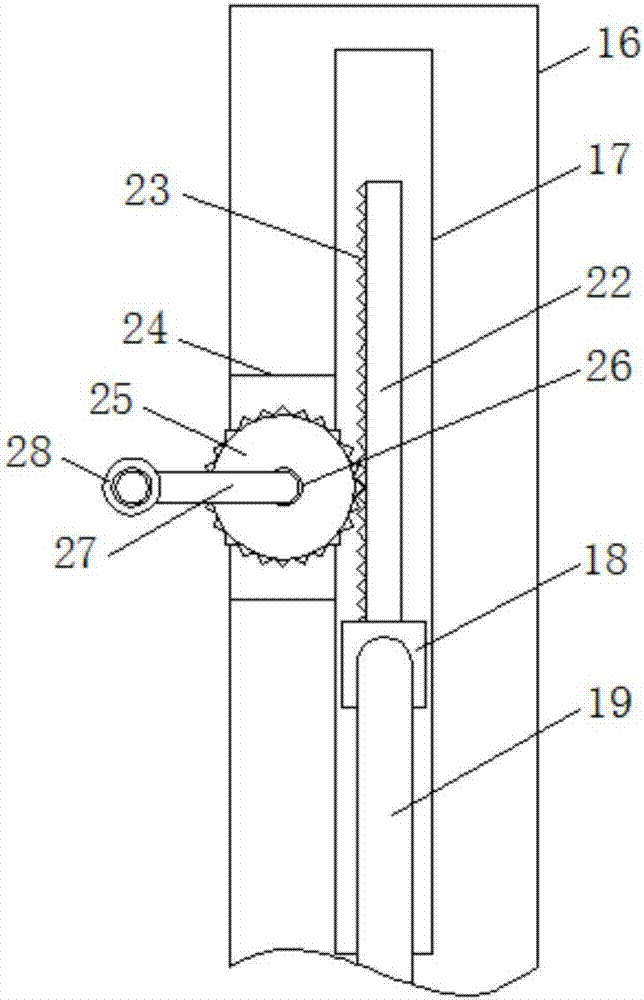

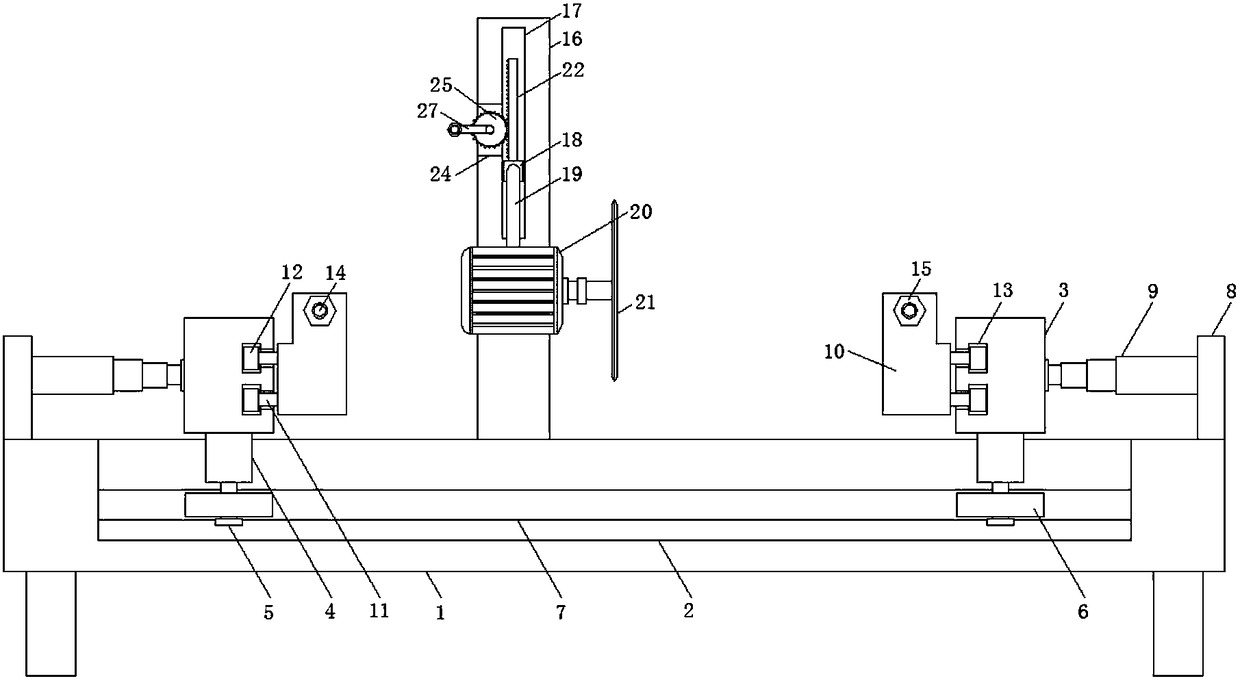

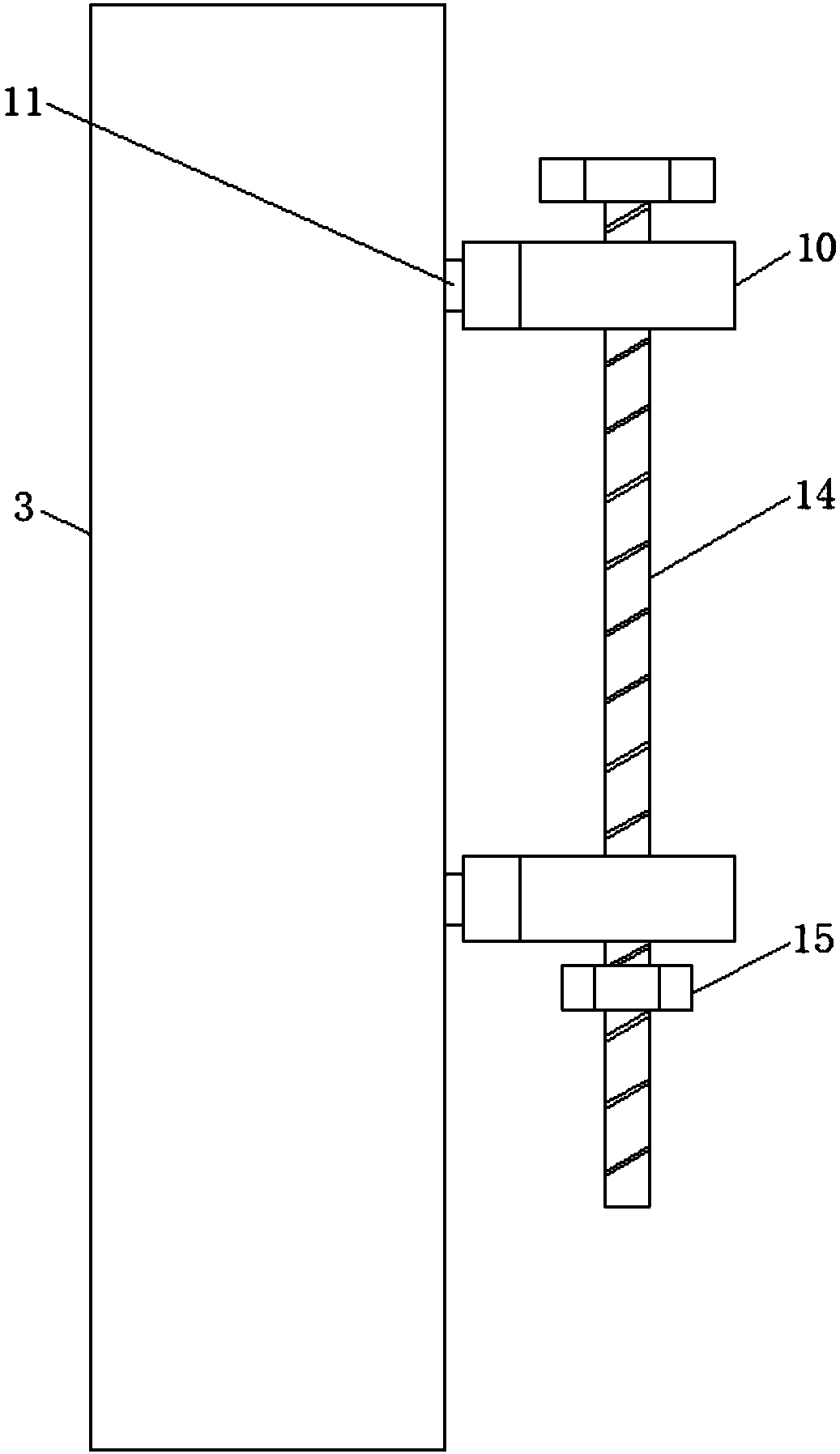

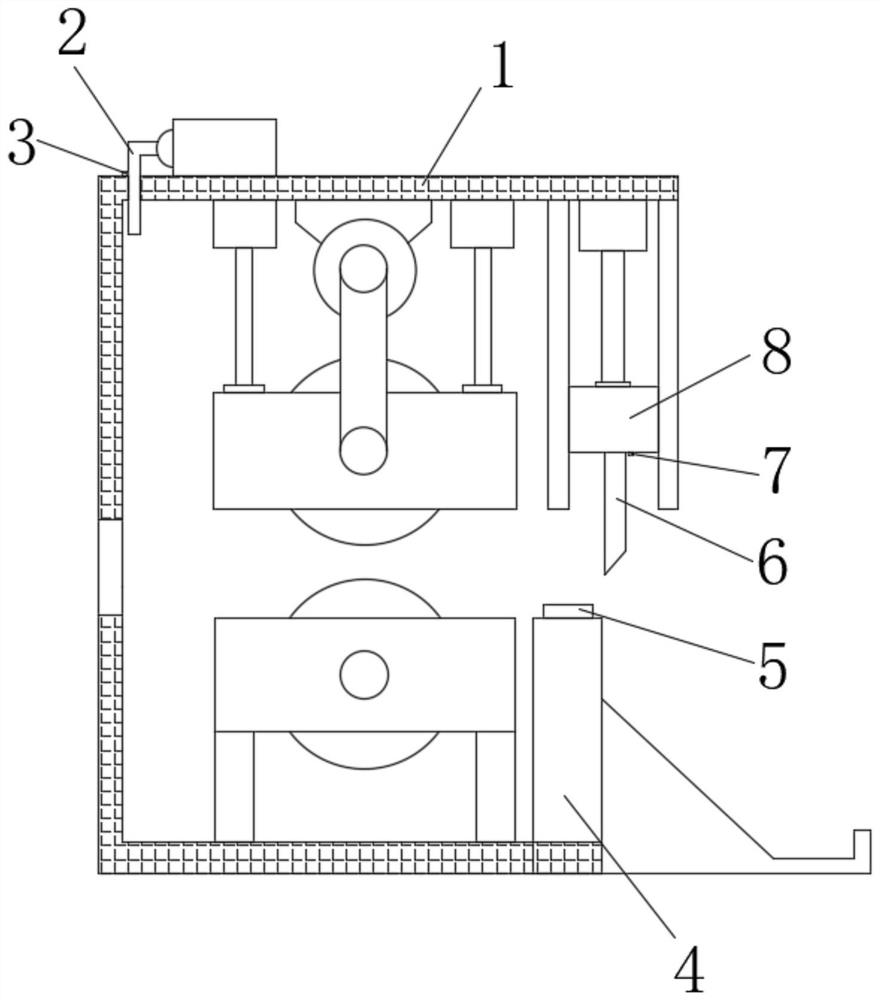

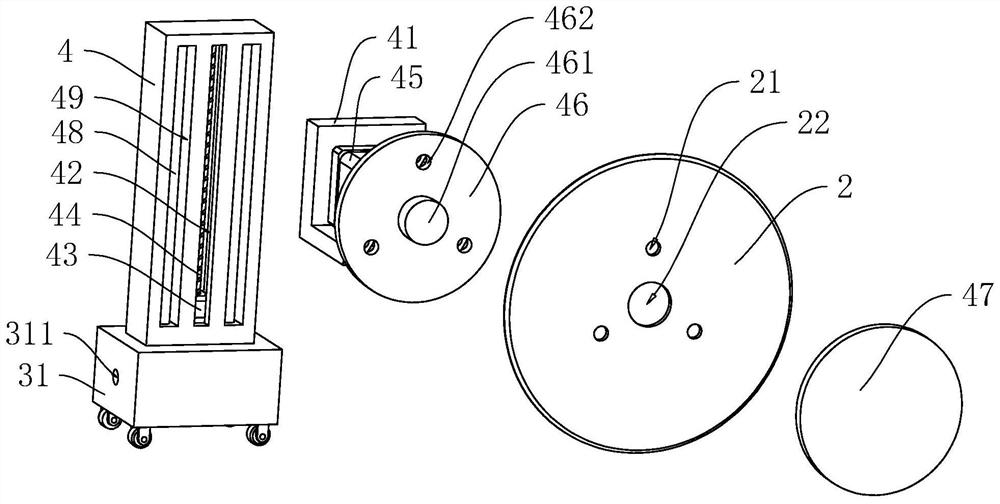

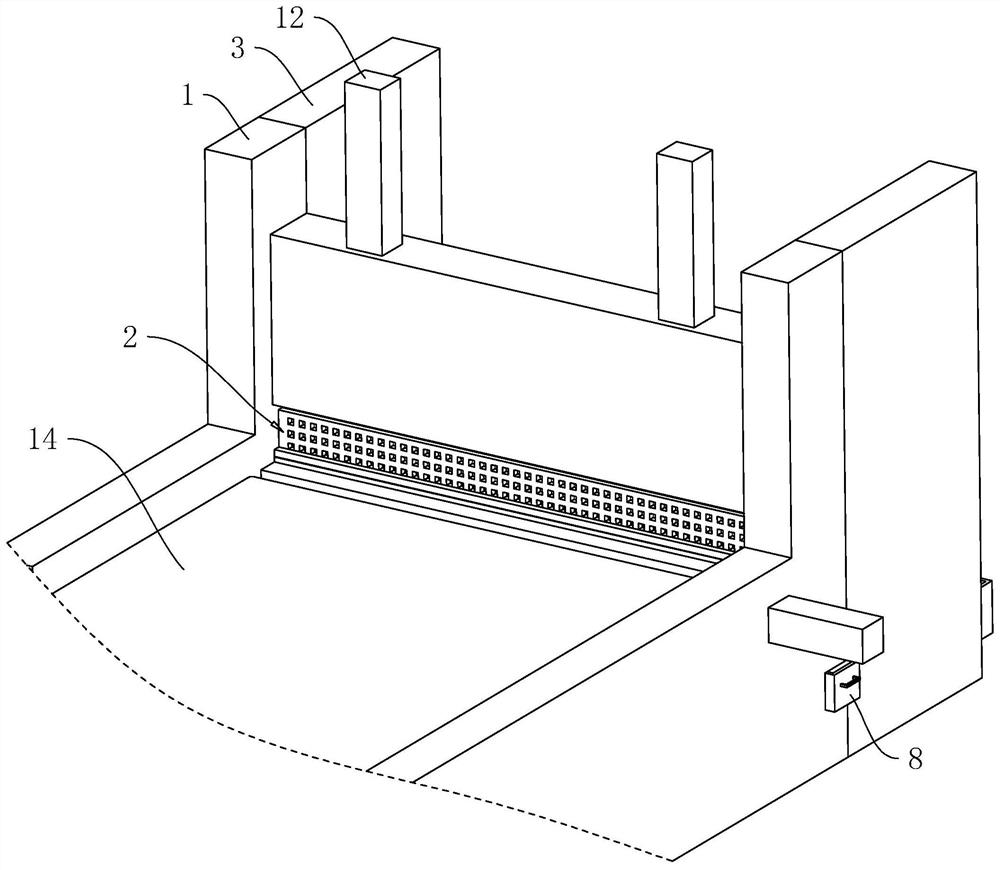

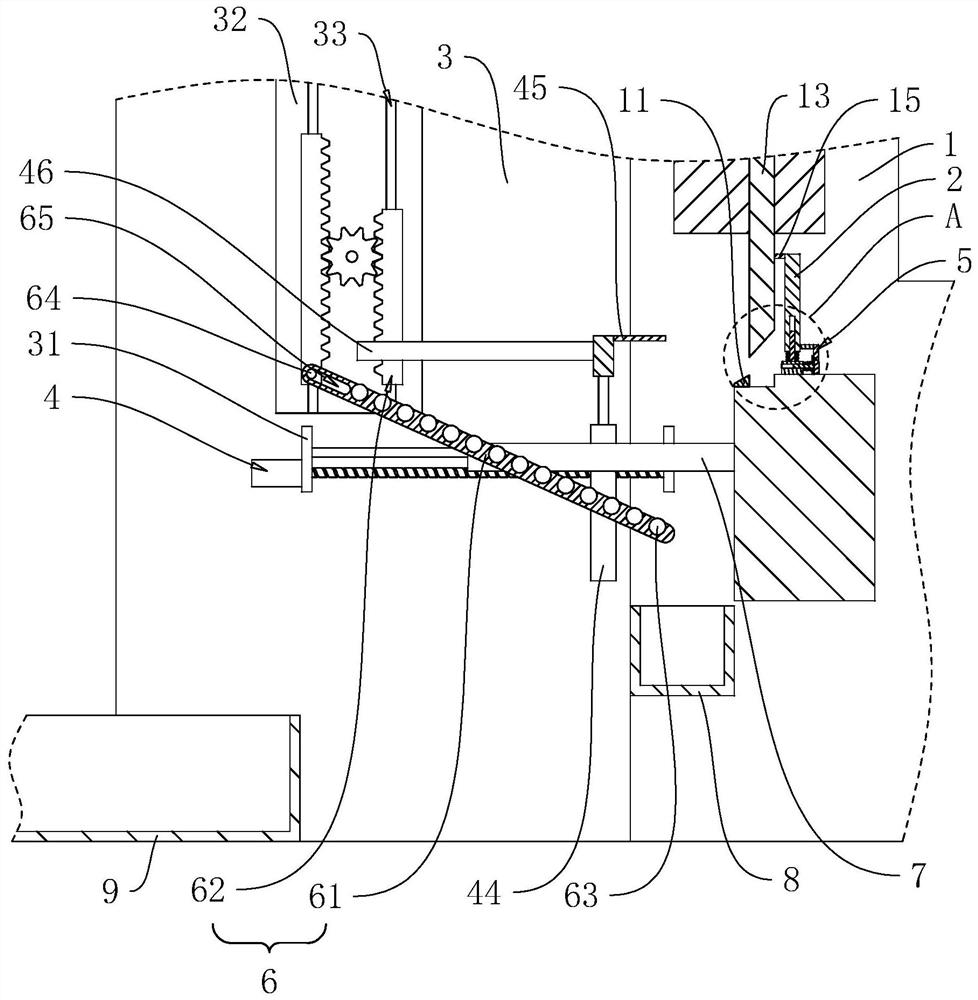

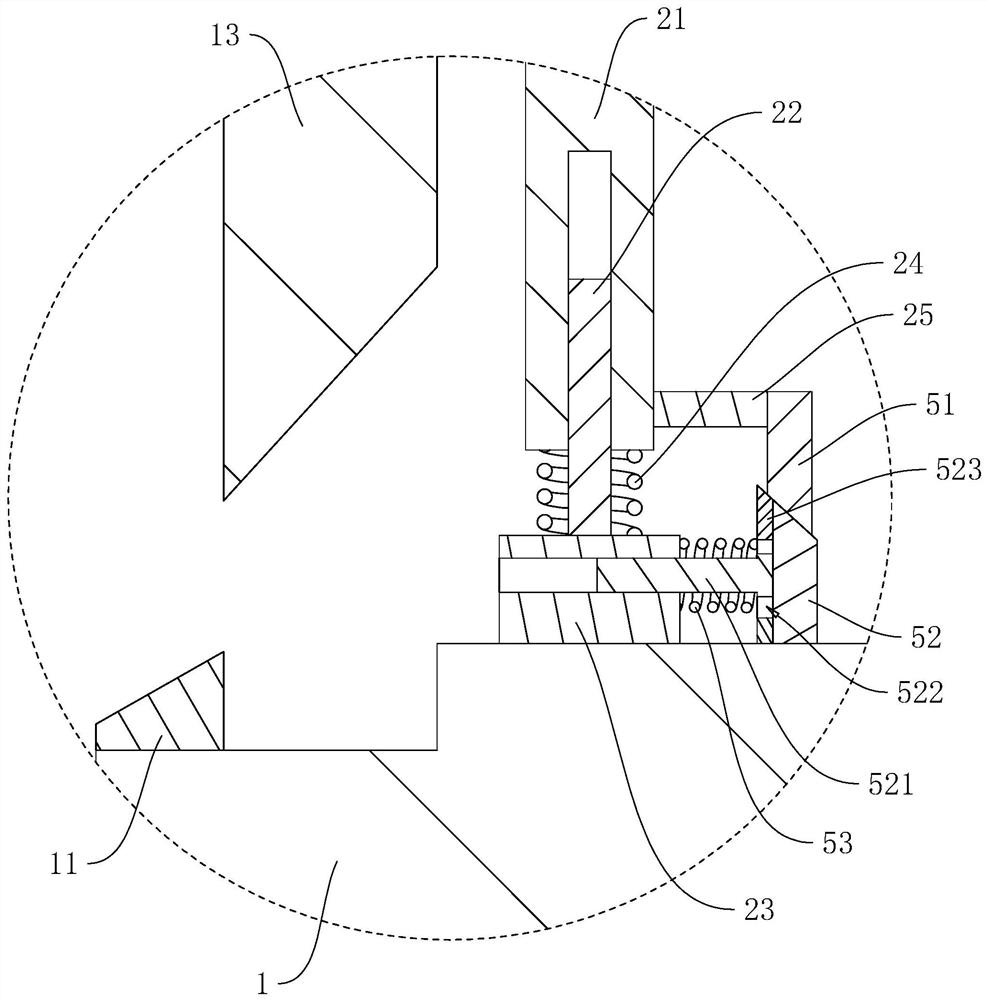

The invention discloses cutting equipment for garment processing. The equipment comprises a workbench, wherein the two ends in the length direction of the workbench are provided with a fixing plate and a moving plate, the other two ends of the workbench are provided with first sliding grooves respectively, the bottom of the moving plate is slidably connected in the first sliding grooves through first sliding blocks, the two ends of the fixing plate are connected with the moving plate through telescopic rods respectively, the sides, close to each other, of the two telescopic rods are provided with a driving roller and a driven roller respectively, two insertion holes provided with first limiting sleeves are formed in the fixing plate, the driving roller and the driven roller run through thefirst limiting sleeves and are in threaded connection with the first limiting sleeves respectively, the end, away from the moving plate, of the driving roller is provided with a driven wheel, a driving wheel is in transmission connection with the driven wheel at one side through a transmission belt, the driving wheel is connected with a first motor, the side, close to the driving roller, of the driven roller is provided with a leveling mechanism, a press mounting mechanism is arranged between the leveling mechanism and the driving roller, and a cutting mechanism is arranged above the press mounting mechanism. The cutting equipment for garment processing can greatly improve the precision of cutting, reduce cloth loss and reduce cost.

Owner:JIXI YUANDAO AGRI IND TECH

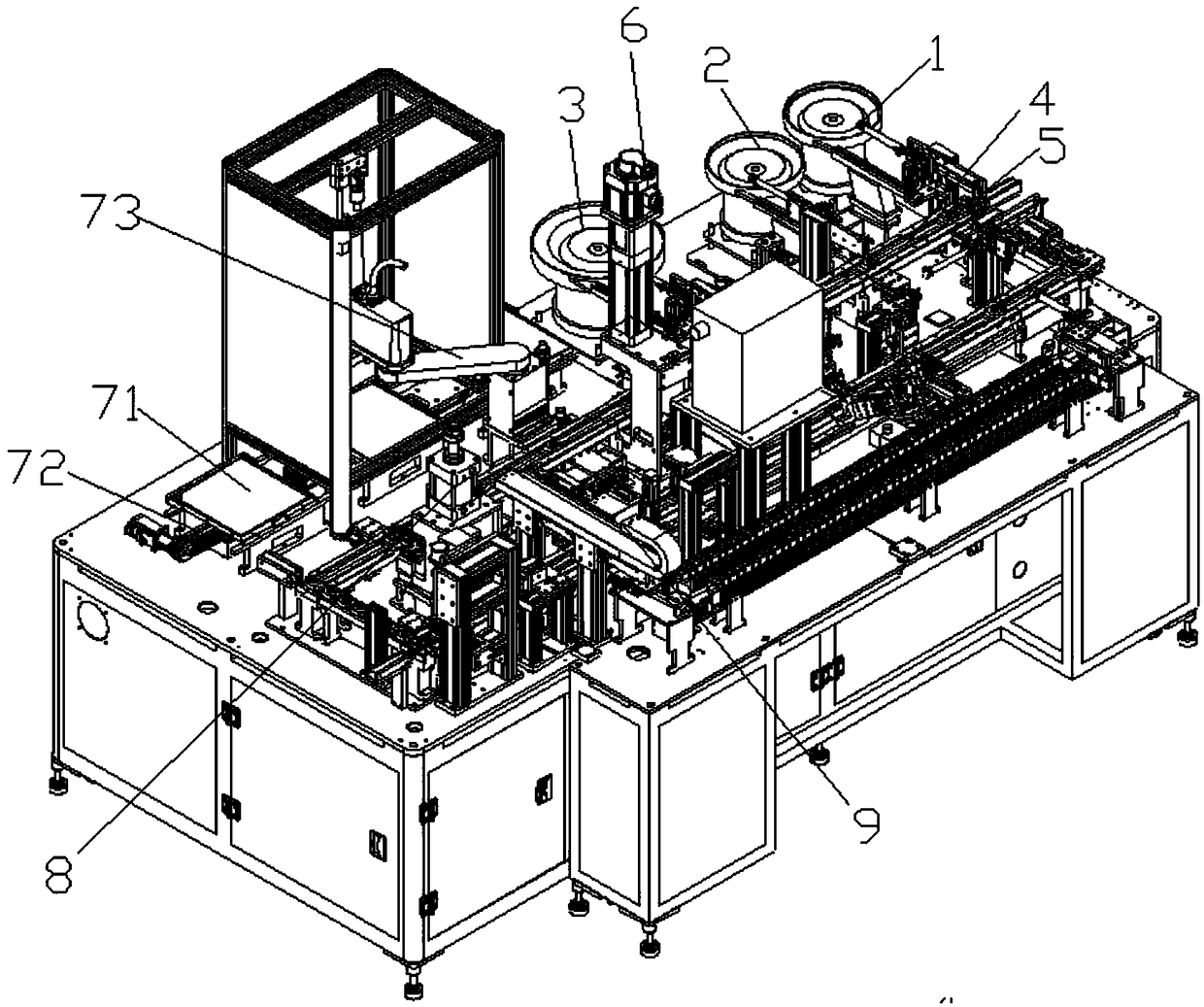

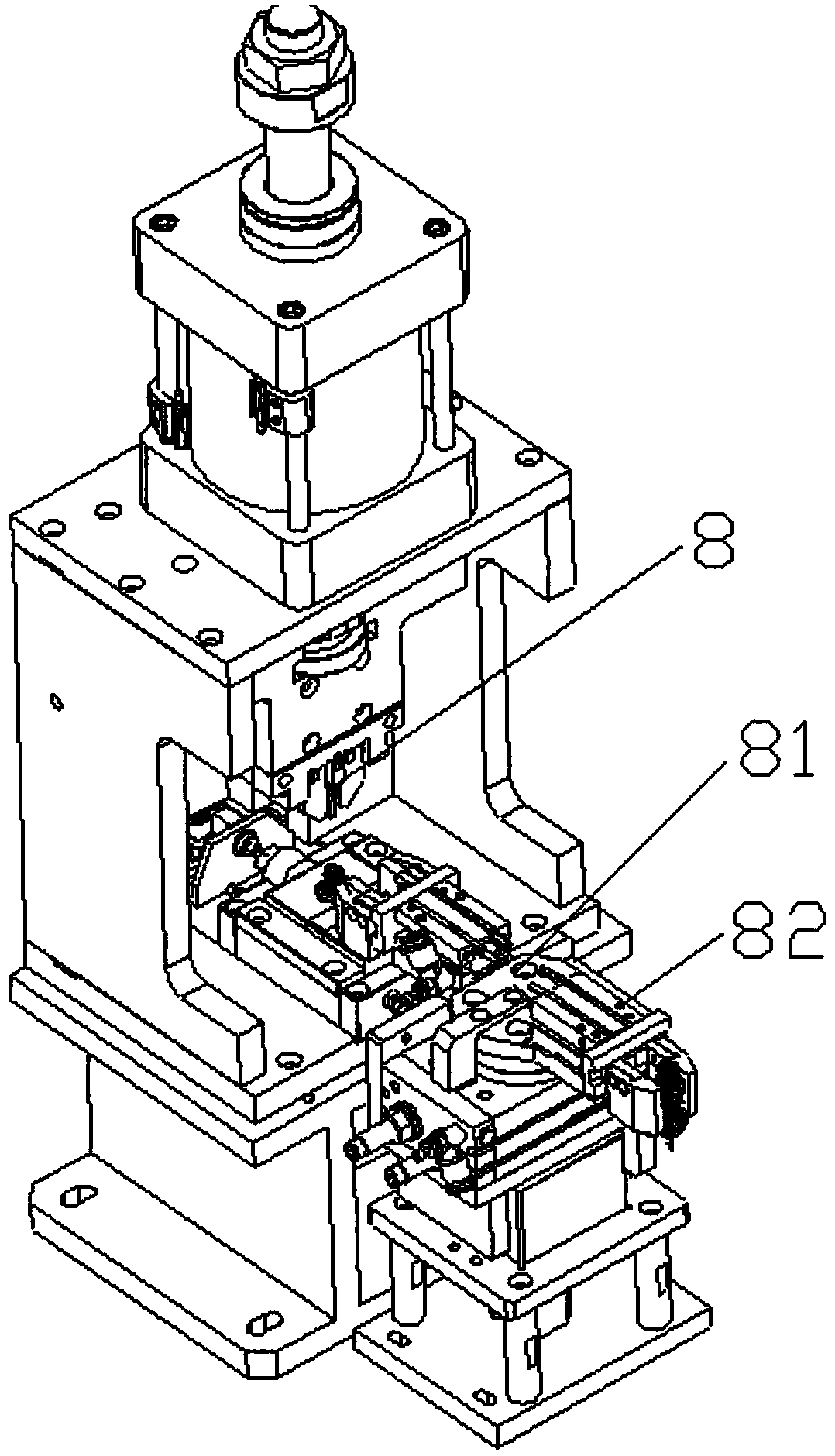

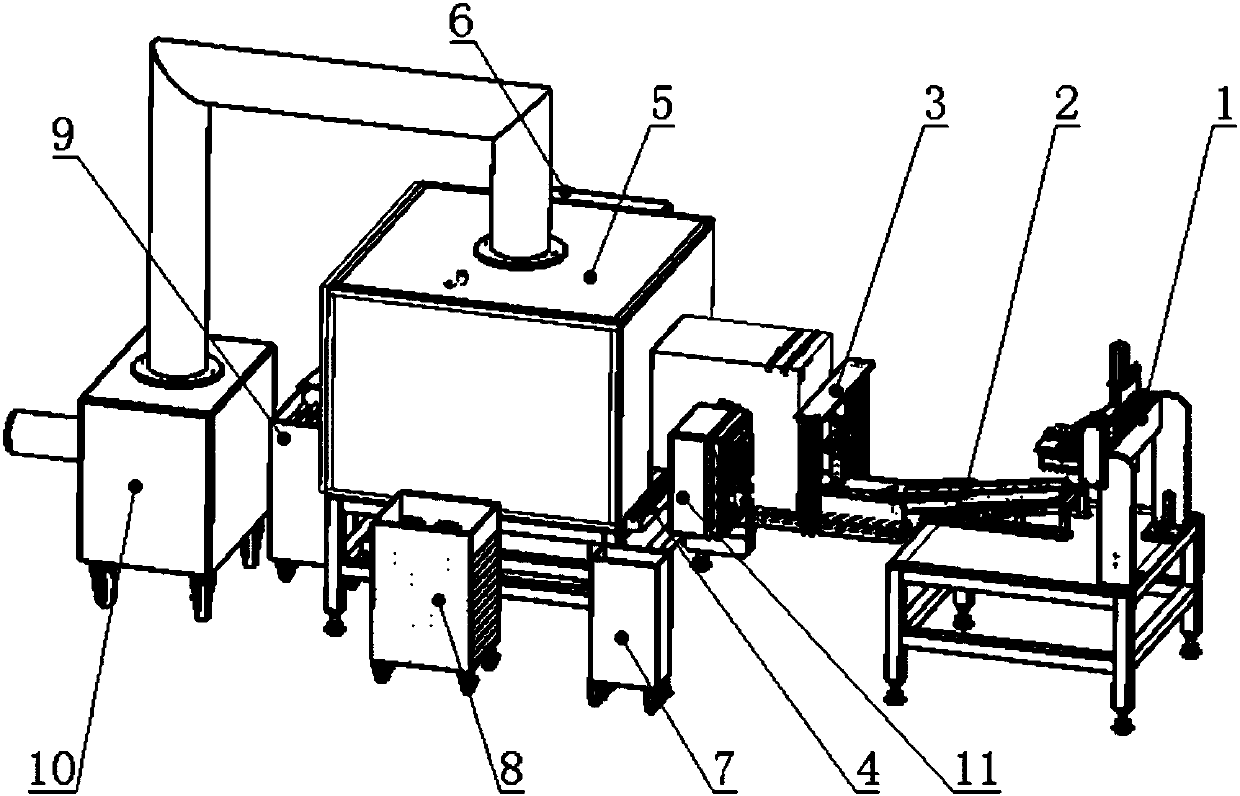

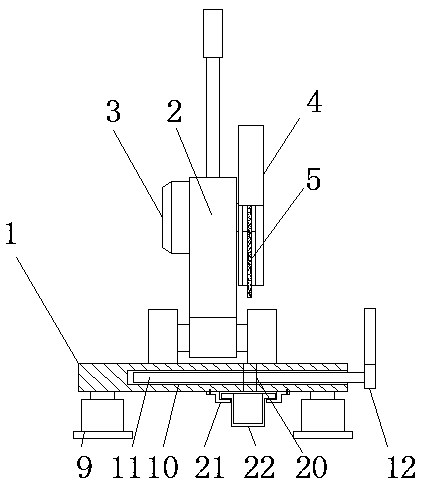

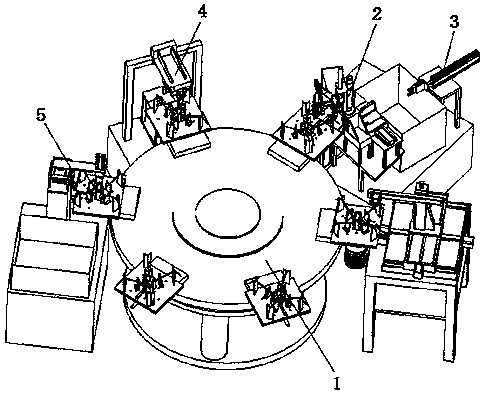

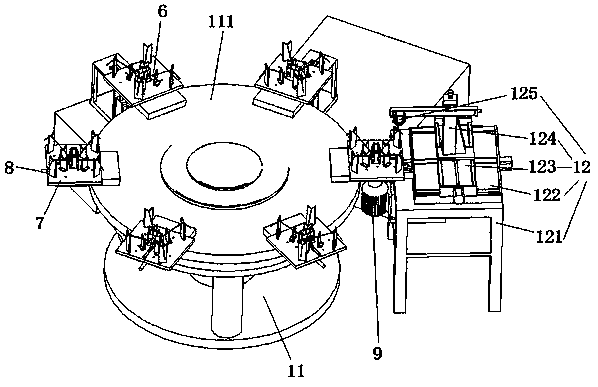

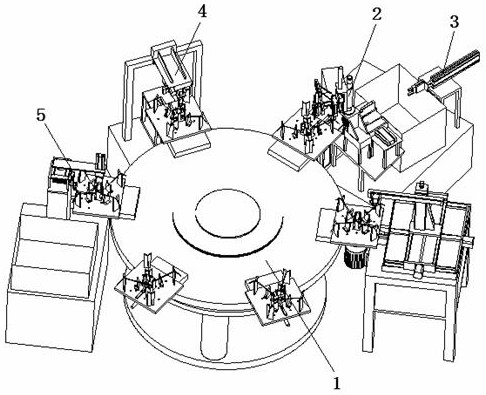

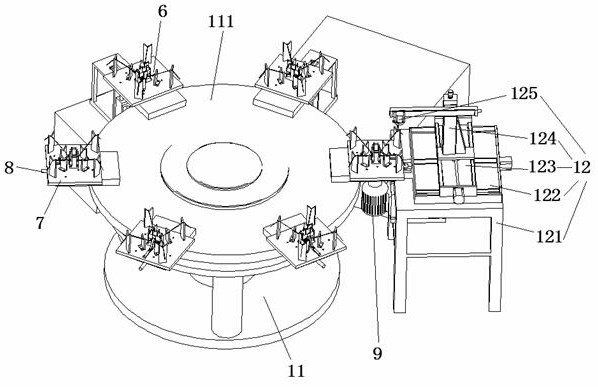

Electromagnetic valve assembling machine

PendingCN108311883AReduce loading spacePrecision weldingAssembly machinesOther manufacturing equipments/toolsEngineeringElectromagnetic valve

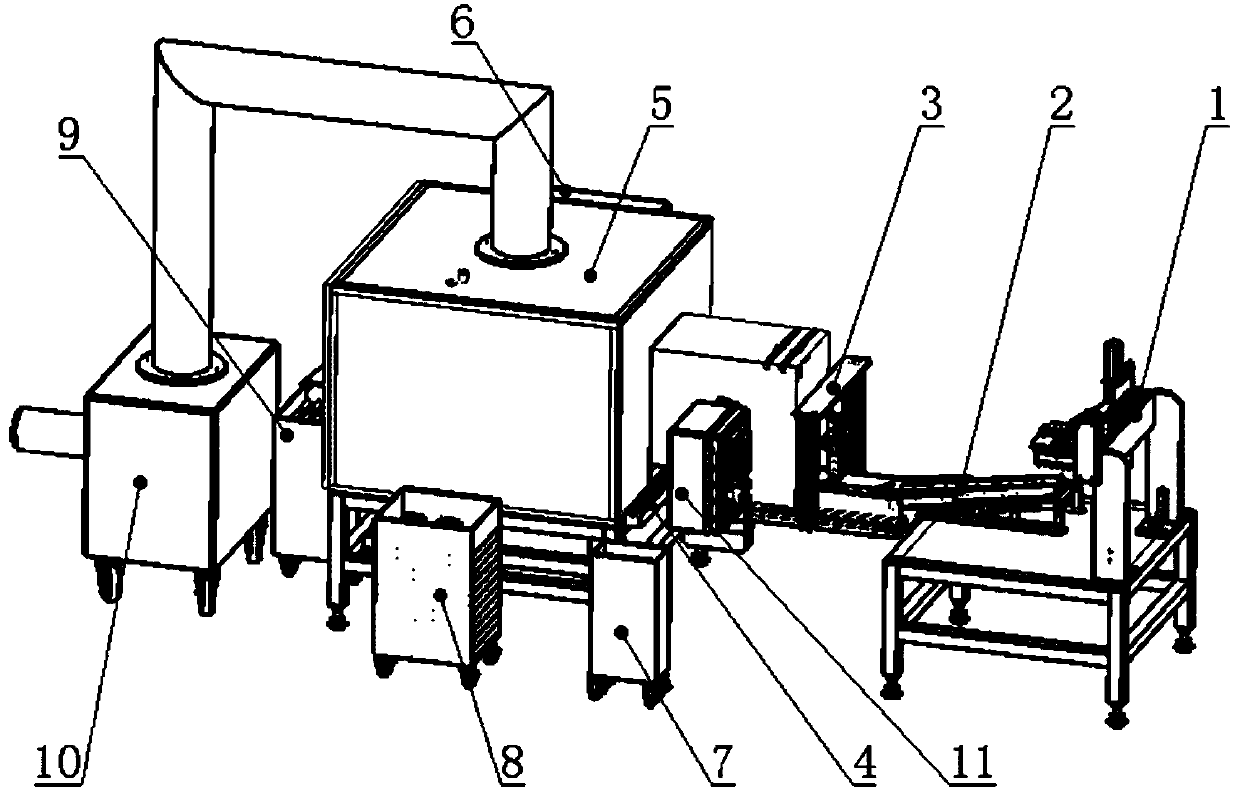

The invention discloses an electromagnetic valve assembling machine. The electromagnetic valve assembling machine comprises a needle vibrating loading mechanism, a gasket vibrating loading mechanism and a valve seat vibrating loading mechanism which are successively arranged, wherein a pin pressing mechanism, a valve element loading mechanism for putting a valve element in a valve seat, a valve seat riveting pressure mechanism for fixing the valve element and the valve seat, a coil assembling mechanism for assembling a coil to an electromagnetic valve body, a coil welding mechanism and a coiltailoring mechanism are successively arranged on two sides of an electric runner; the moving directions of a first coil electric track and a second coil electric track are opposite; a first pushing air cylinder for pushing a coil to the input end of the second coil electric track is arranged at the output end of the first coil electric track; and a second pushing air cylinder for pushing the coilout of the output end of the second coil electric track and a chuck mechanism for conveying the coil to the coil assembling mechanism are arranged at the output end of the second coil electric track.The coil loading space is reduced, and the track is lengthened, so that the coil is manually loaded conveniently.

Owner:KUNSHAN HUAYU AUTOMATION TECH

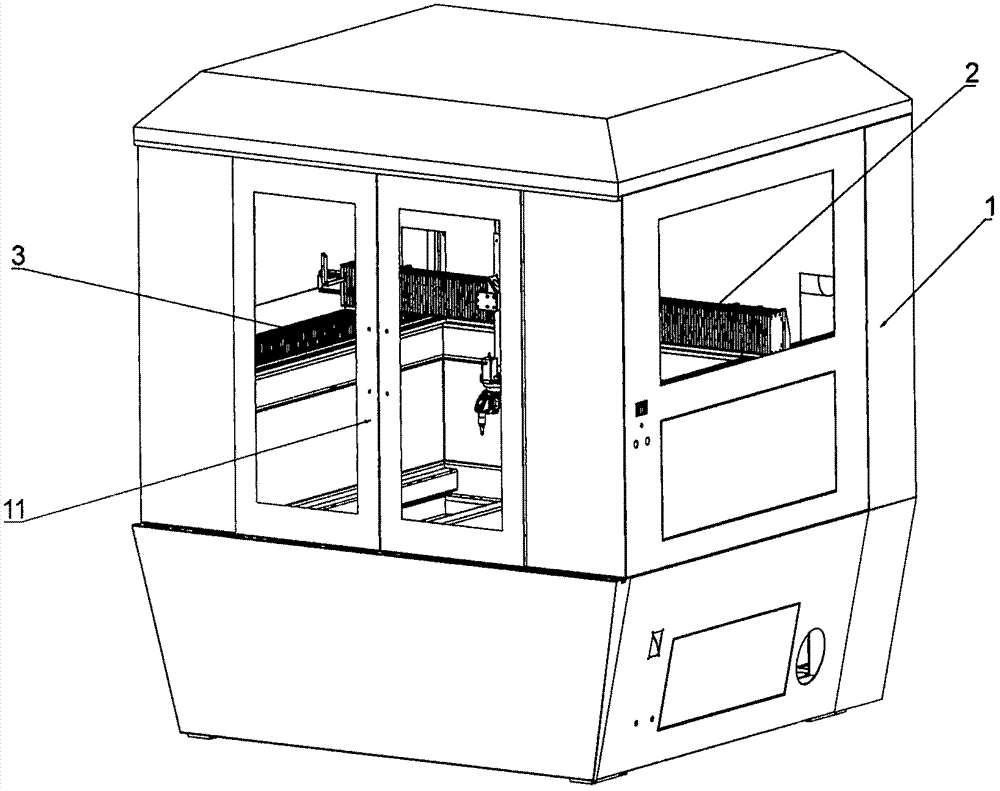

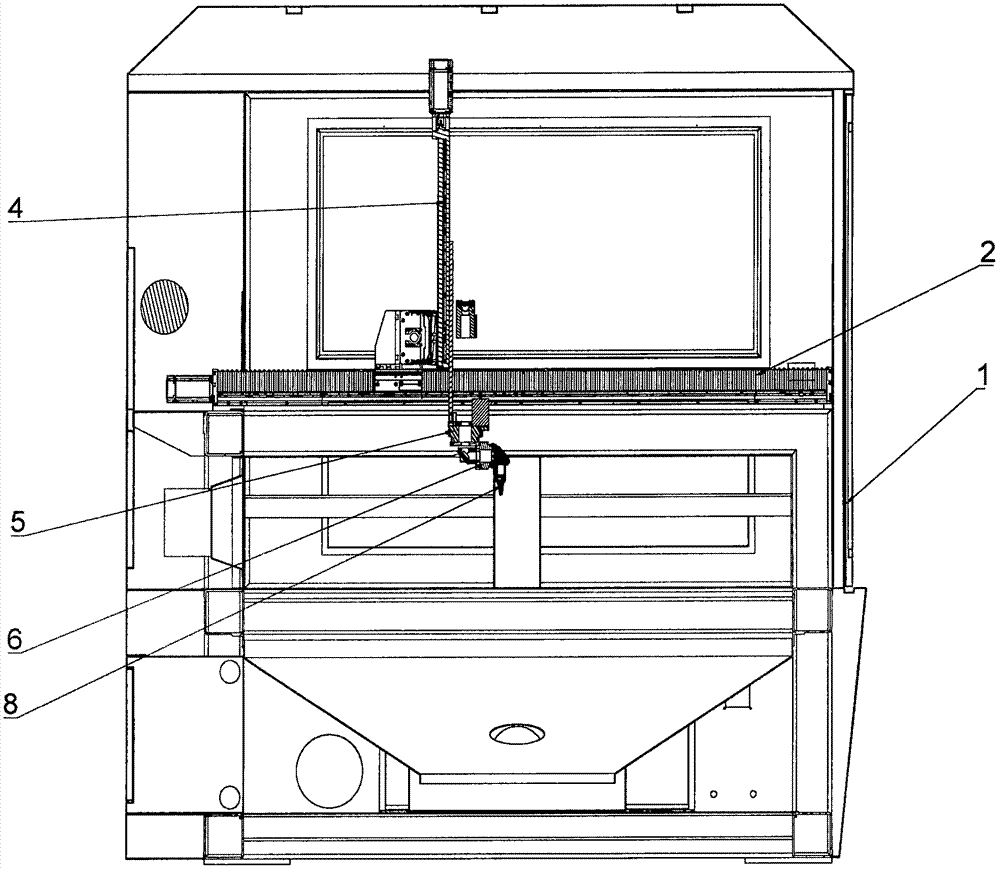

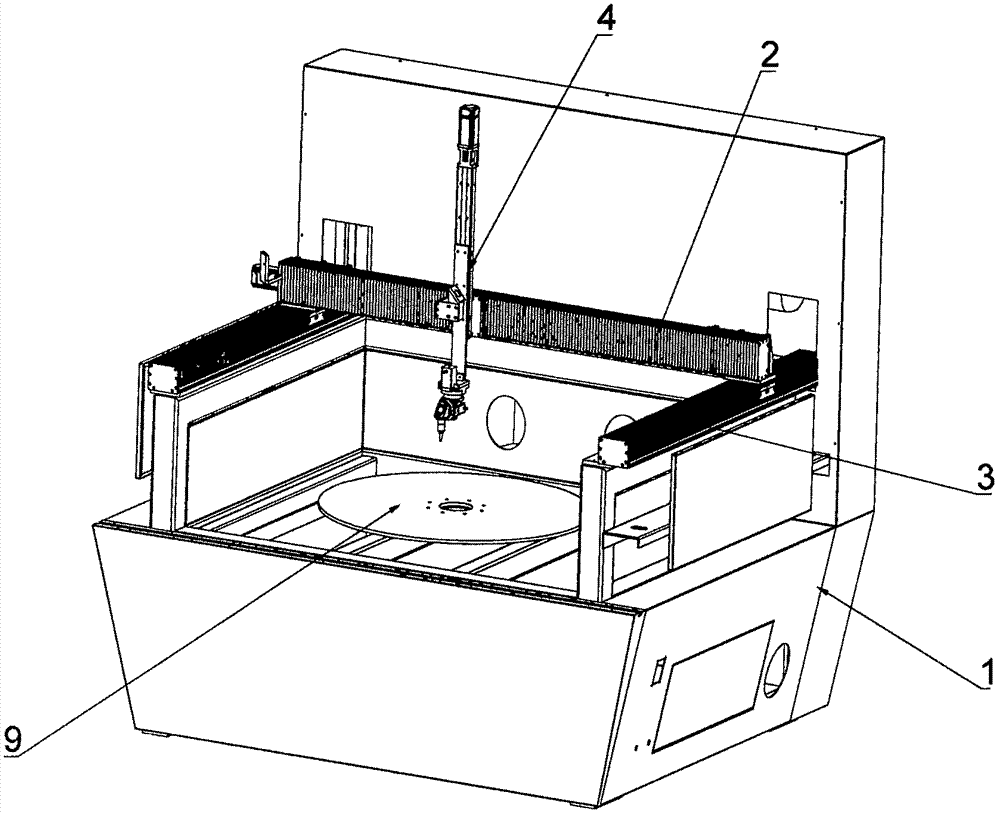

Three-dimensional five-axis laser cutting machine

InactiveCN107030395AImprove cutting efficiencyHigh degree of automationLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a three-dimensional five-axis laser cutting machine, which includes a frame, a laser tube, a reflection assembly, an X-axis assembly, a Y-axis assembly, a Z-axis assembly, a fourth-axis assembly, a fifth-axis assembly, a cutting assembly and a controller ; The cutting assembly includes a condenser lens and a laser cutting head arranged on the fifth-axis rotating disk; the reflection assembly includes several laser mirrors that reflect the laser light emitted by the laser tube to the laser cutting head; the X-axis drive The mechanism, the Y-axis drive mechanism, the Z-axis drive mechanism, the fourth-axis drive mechanism, the fifth-axis drive mechanism, the laser cutting head, and the laser tube are respectively connected with the controller. The invention adopts laser cutting for leather, and passes the laser cutting head through three linear axes and two rotating axes. The laser cutting head can move arbitrarily in the spatial position, the cutting and positioning are accurate, the efficiency is higher, the degree of automation is high, the efficiency is high, and the positioning Accurate, pre-programmed cutting positions reduce scrap and save costs.

Owner:广州喜和喜精密科技有限公司

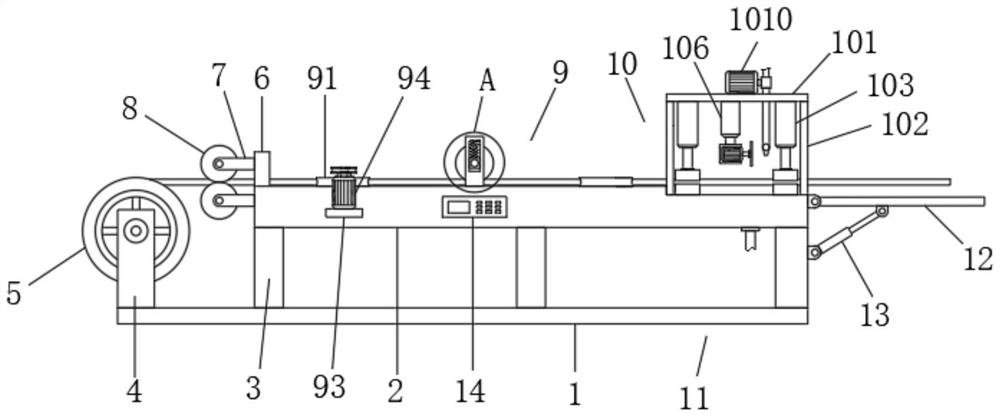

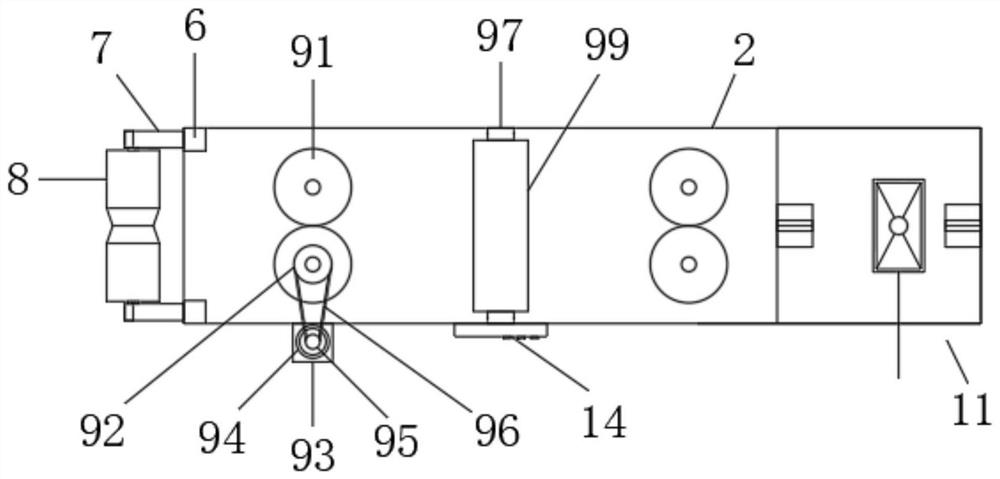

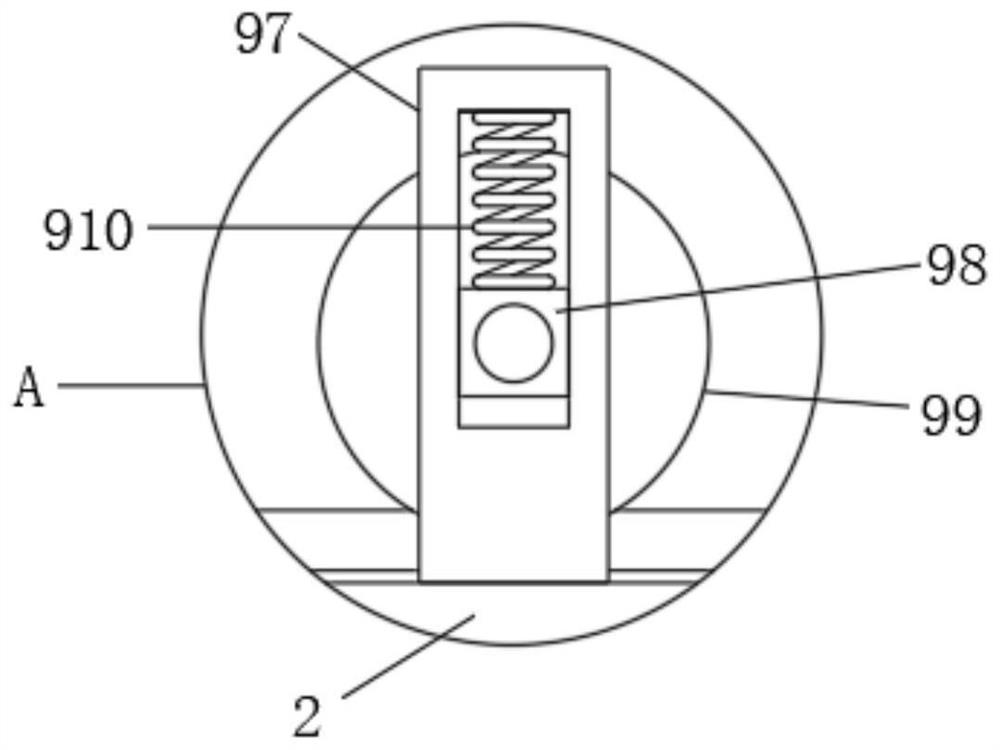

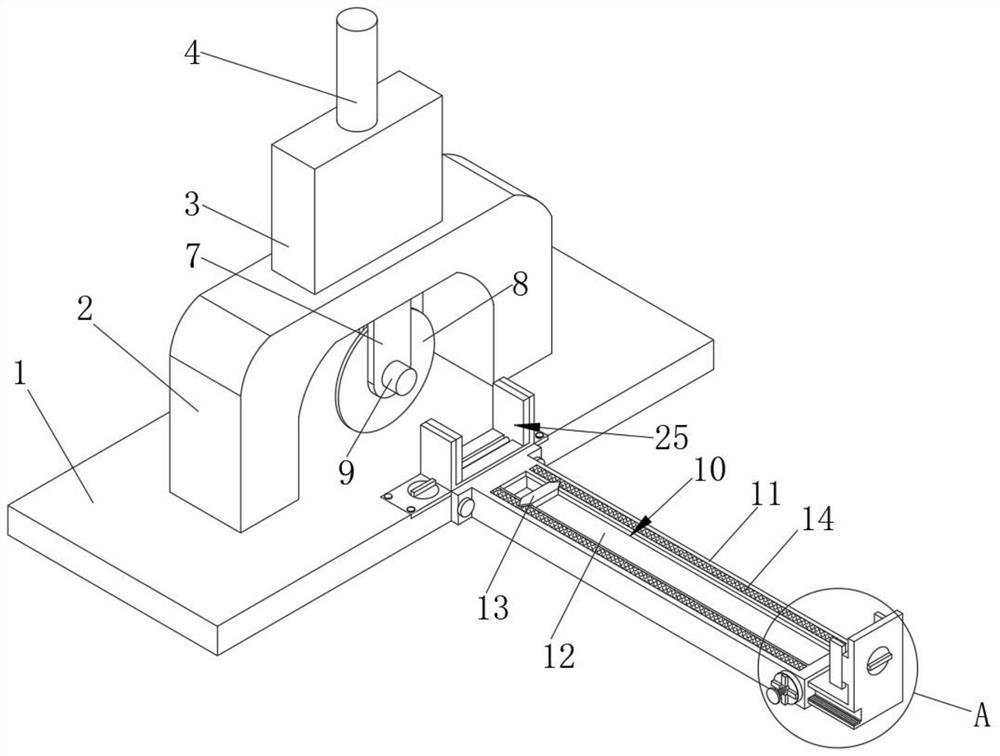

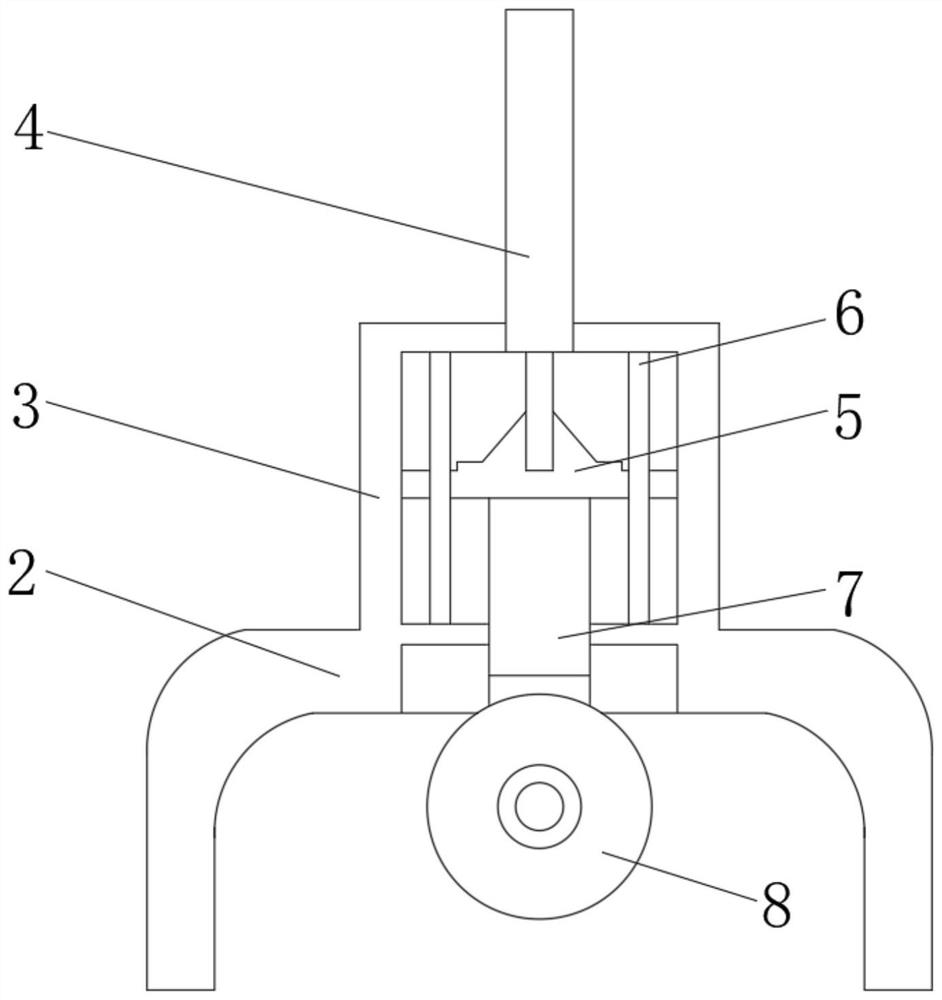

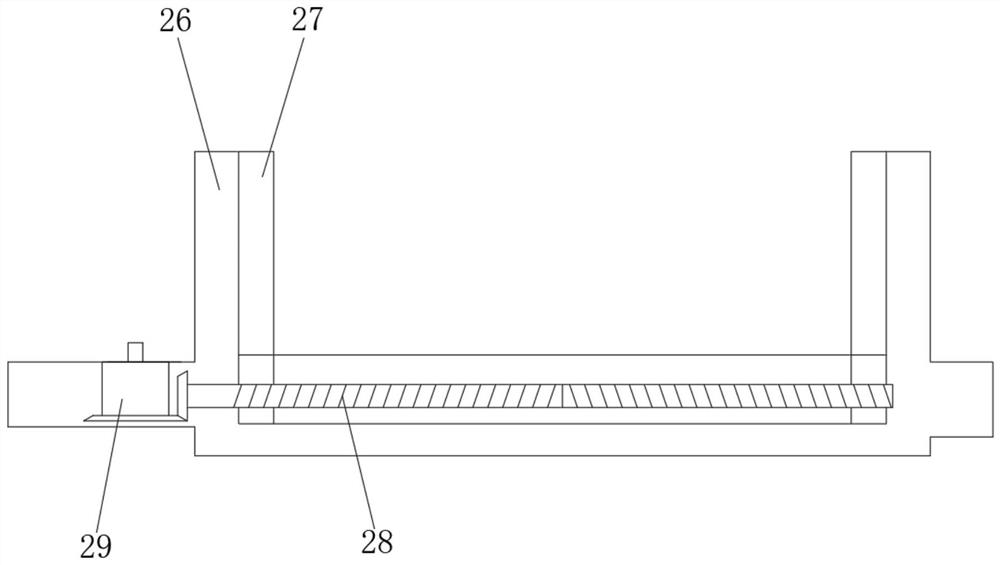

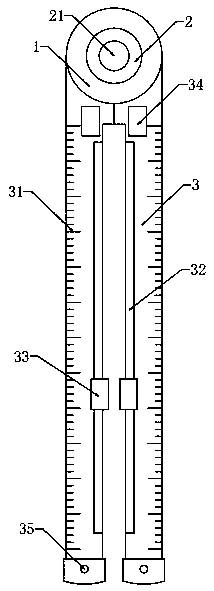

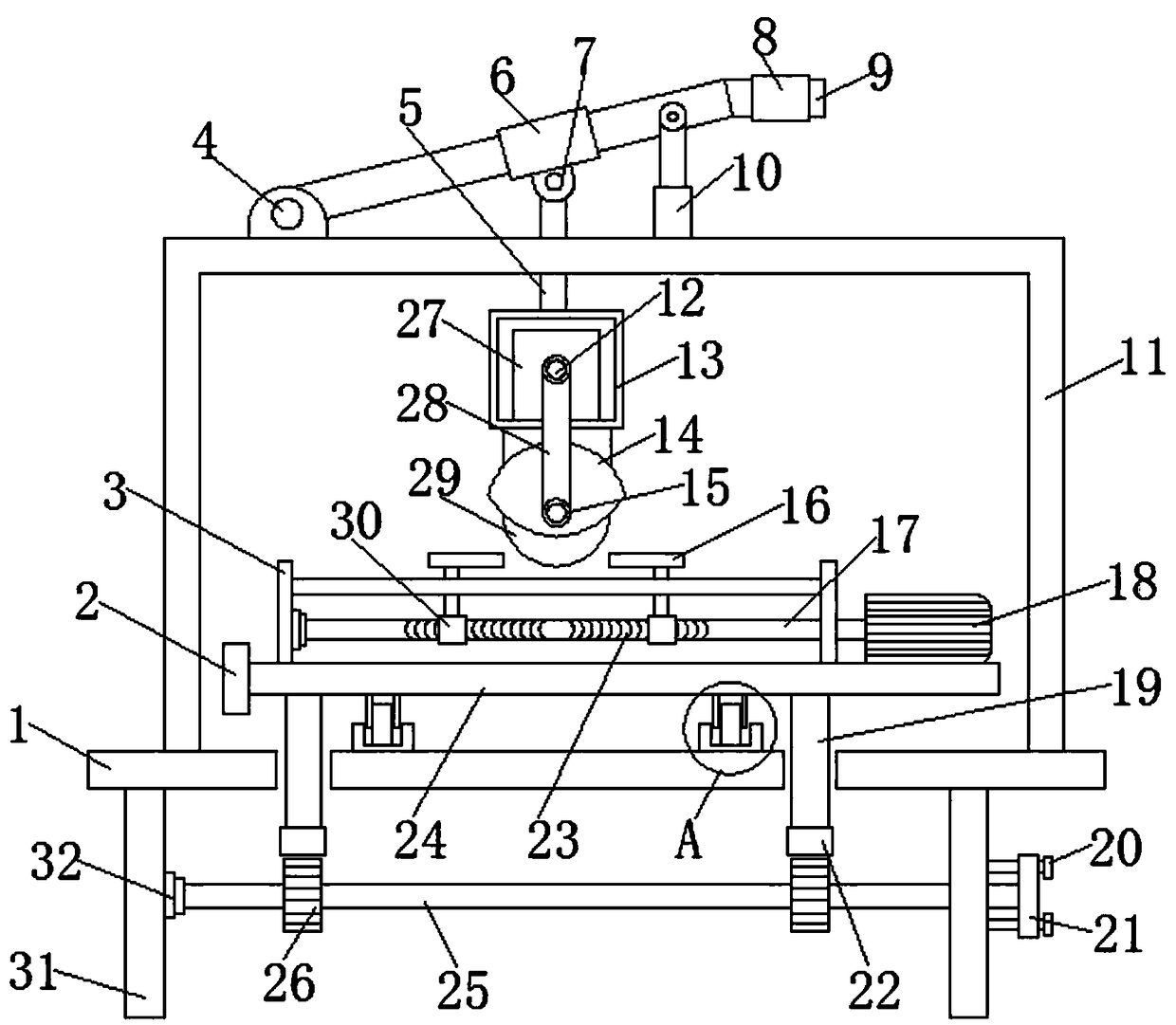

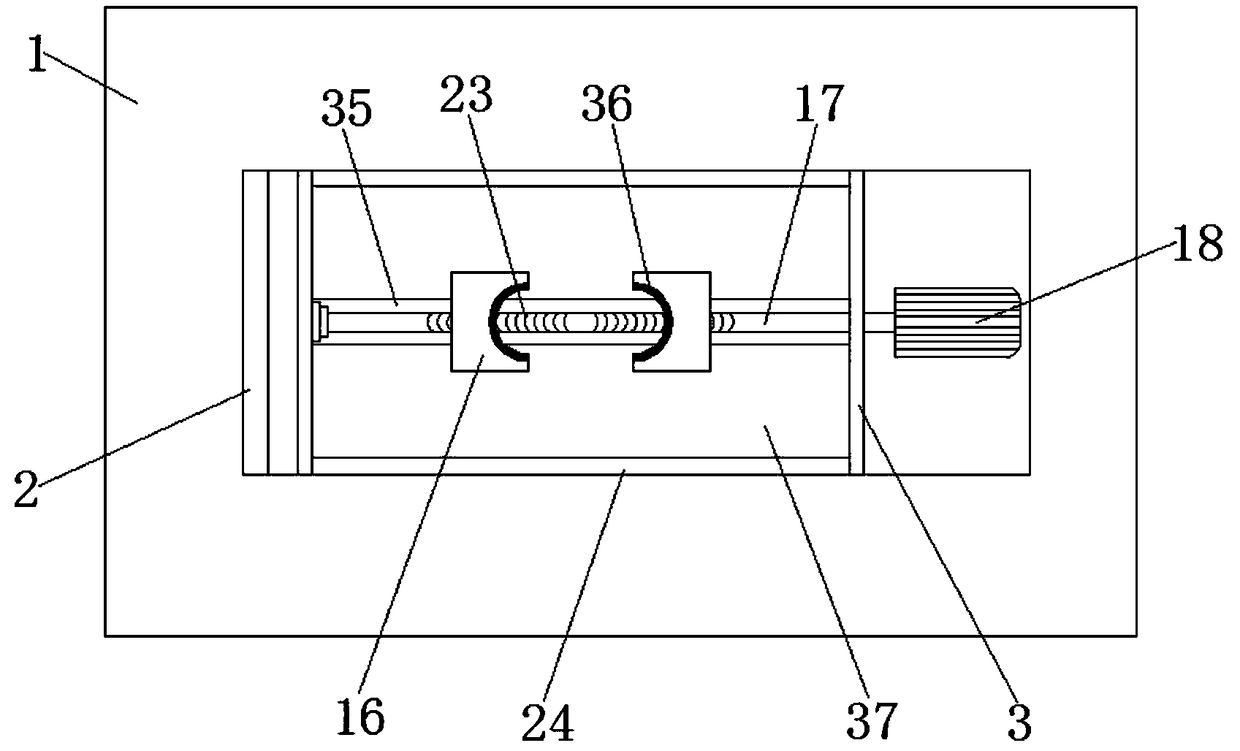

Cutting device for coiled hot-rolled plain round steel bar production and using method thereof

The invention discloses a cutting device for coiled hot-rolled plain round steel bar production and a using method thereof. The cutting device for coiled hot-rolled plain round steel bar production comprises a bottom plate, an operation table is arranged at the top of the bottom plate, supporting legs are fixedly connected to the bottom of the operation table at equal intervals, and the bottoms of the supporting legs are fixedly connected with the top of the bottom plate; and two side plates are fixedly connected to one end of the top of the bottom plate, and a discharging roller is rotationally connected between the two side plates. The cutting device has the beneficial effects that cut steel bars can be better discharged through a rotationally-arranged discharging plate, the steel bars are prevented from being bent, and meanwhile, abrasion generated by direct falling of the steel bars is prevented; the steel bars can be better guided and conveyed through a conveying mechanism, the steel bars are pressed to be straight while being conveyed, the steel bars can be better positioned and cut through a cutting mechanism, tangent point deviation is prevented, and cooling liquid can be better filtered and recycled through a filtering mechanism.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Waste cylinder lithium battery pretreatment device and method

ActiveCN109904547AHigh degree of automationSimple structureWaste accumulators reclaimingProcess efficiency improvementPretreatment methodControl system

The invention discloses a waste cylinder lithium battery pretreatment device and method, and belongs to the technical field of waste lithium battery recycling. The waste cylinder lithium battery pretreatment device includes an automatic sorting device, a conveying mechanism, an electric quantity monitoring actuator, a nondestructive testing system, a flexible clamping jaw mechanism, an automatic cutting mechanism, an automatic detaching mechanism, a recycling dust collecting system, and a control system, wherein the automatic sorting device, the conveying mechanism, the flexible clamping jaw mechanism, the automatic cutting mechanism, the automatic detaching mechanism, and the recycling dust collecting system are connected in sequence, the electric quantity monitoring actuator and the nondestructive testing system are both arranged above the conveying mechanism, and the control system realizes information receiving and instruction sending of the parts. The waste cylinder lithium battery pretreatment device is simple in structure, high in automatic degree, convenient and quick to operate, and high in disassembling efficiency, and has the characteristics of greenization, intellectualization, and flexibility.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

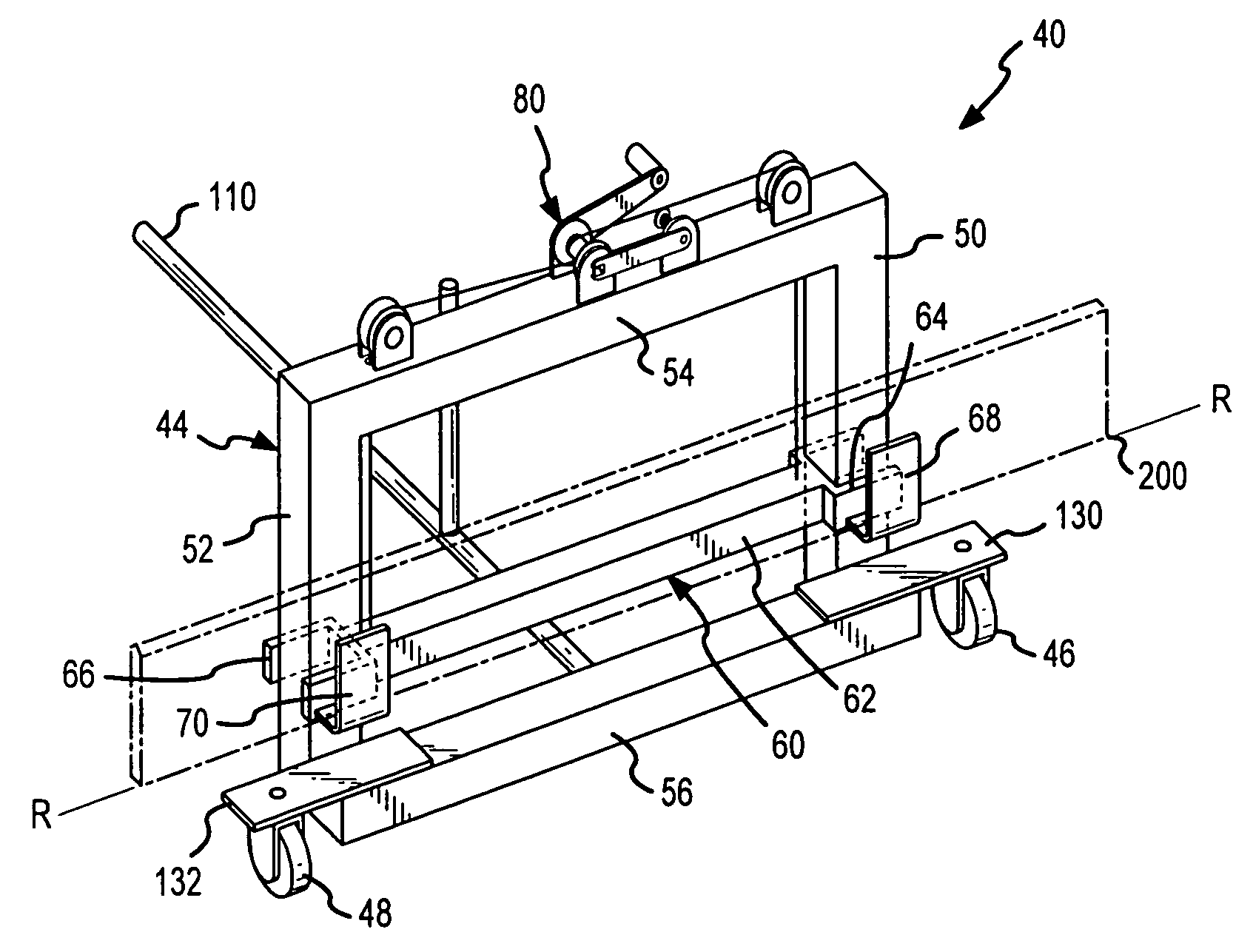

Cutting edge cart

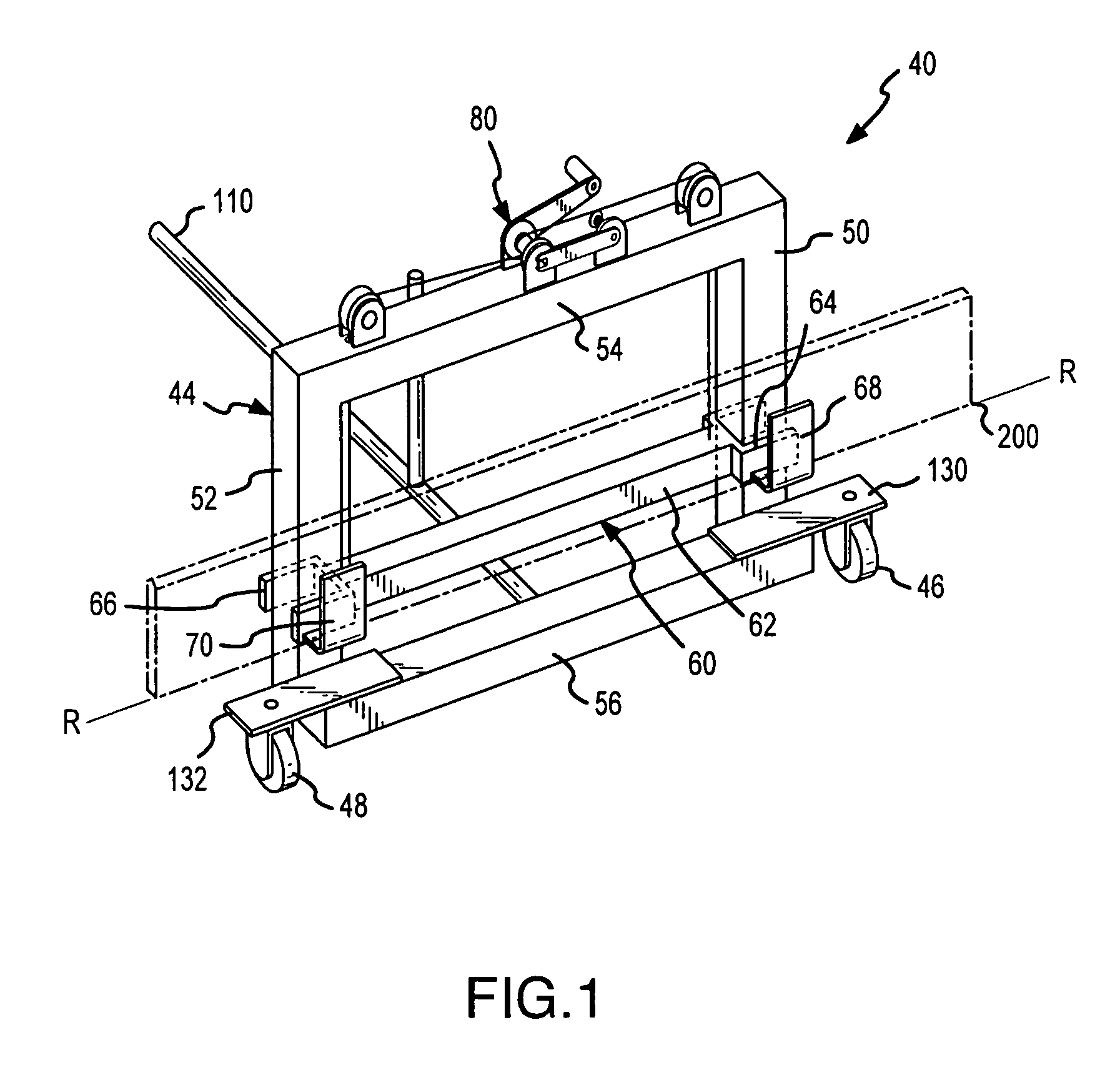

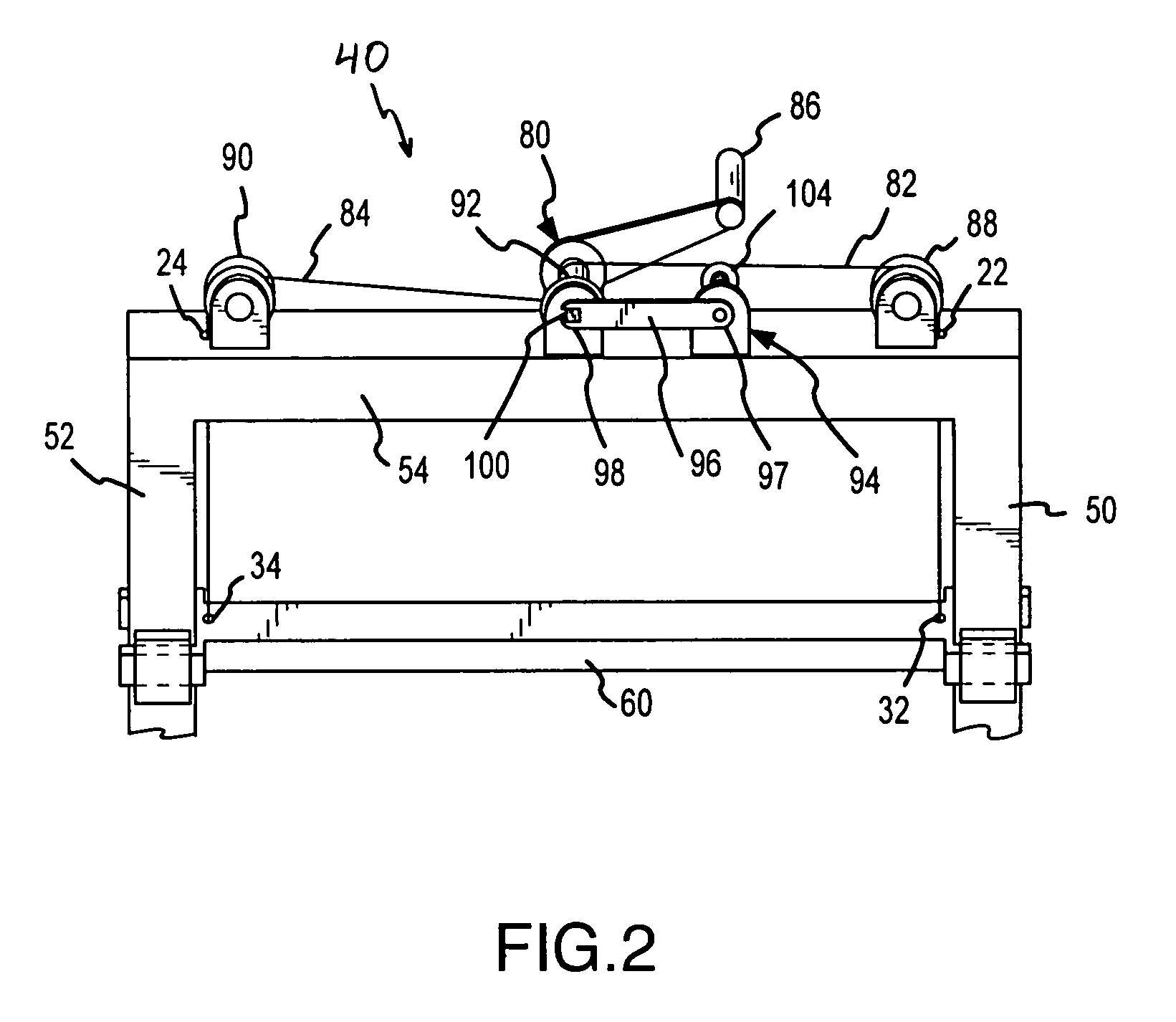

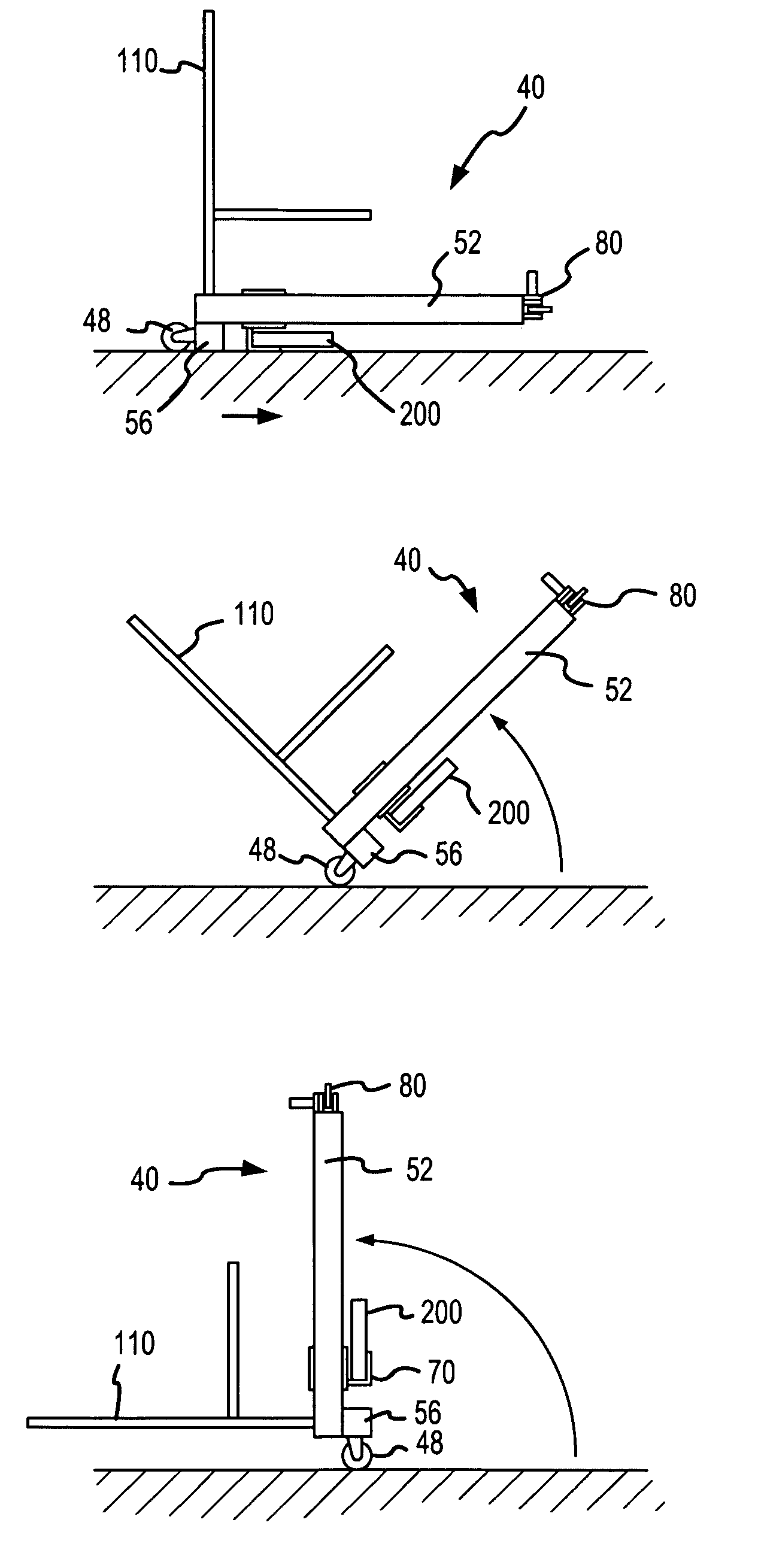

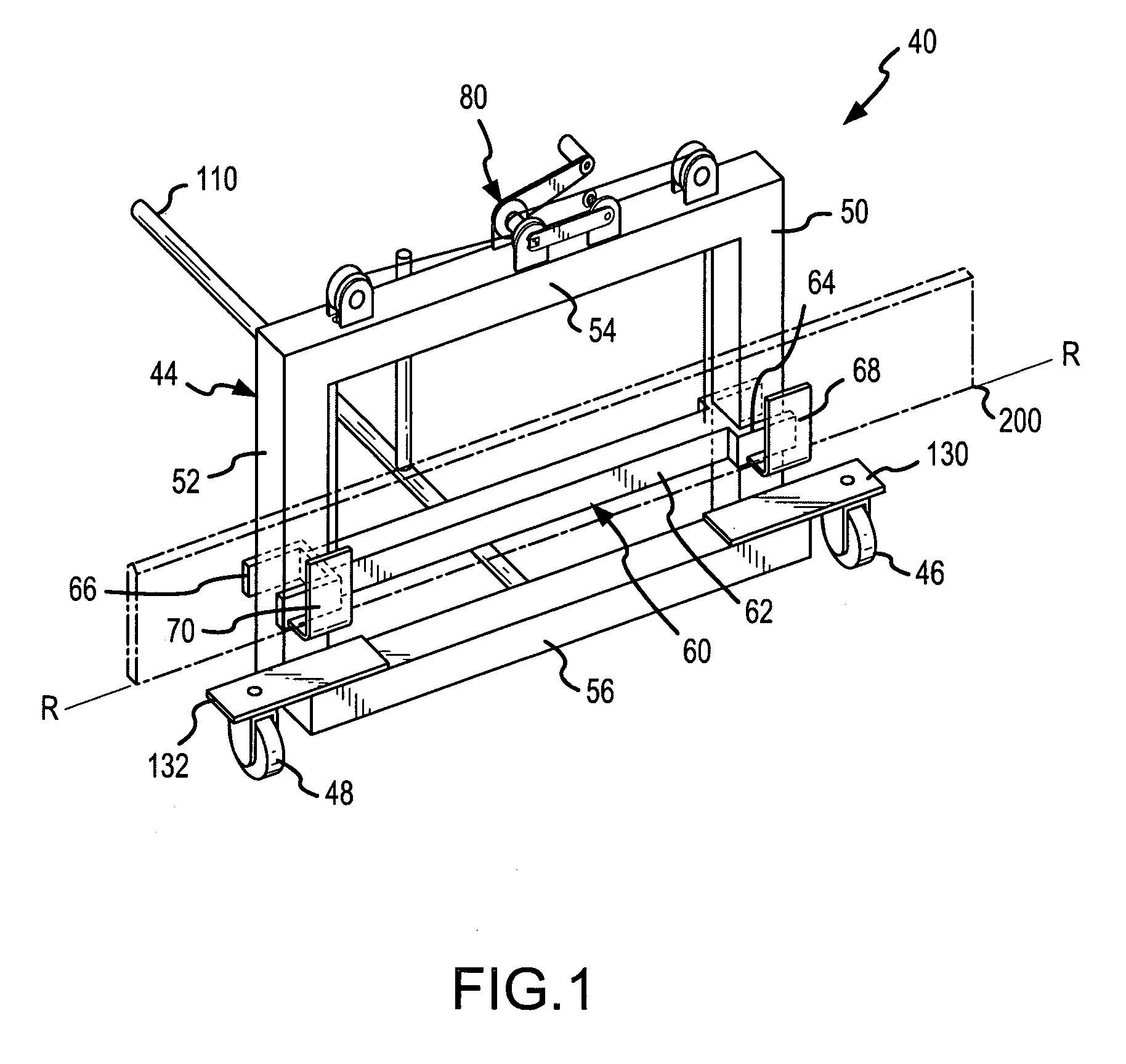

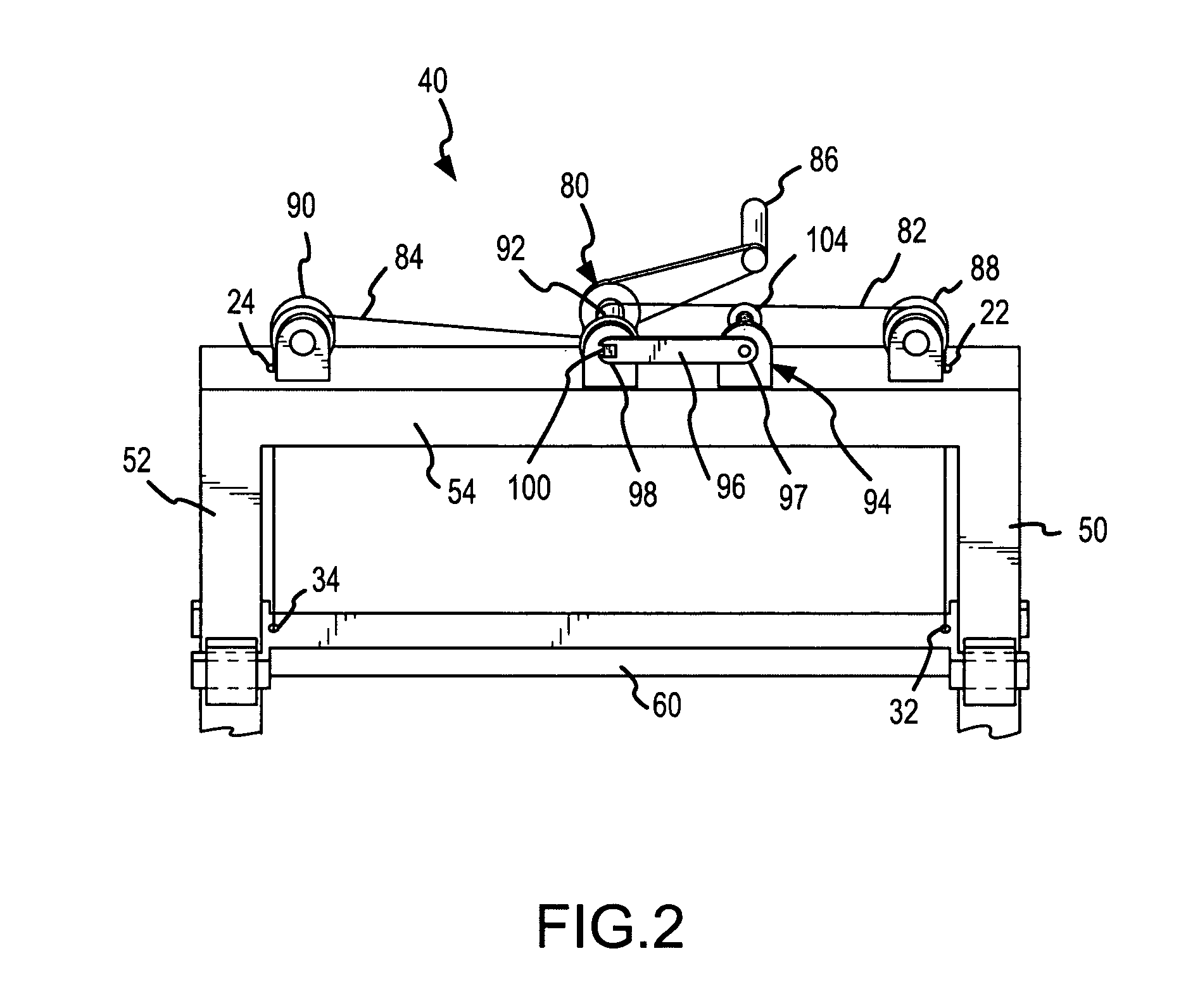

InactiveUS6964092B1Reduce the number of partsEasy to manufactureAutomatic control devicesAssembly machinesEngineeringCart

A cutting edge cart is disclosed that provides an improved means for replacing the replaceable cutting edges on bladed equipment such as road graders and snow plow. The cart allows a single user to retrieve, transport, and position a replacement cutting edge relative to a mold board of the bladed equipment. Generally, the cart contains a frame, two or more transport assemblies attached to the frame, such as wheels, a movable carrier assembly that contains a cutting edge support assembly, and an adjuster. The adjuster is operable to move the carrier assembly between first and second positions relative to the frame allowing the vertical position of a supported cutting edge to be adjusted. The frame and transport assemblies are disposed such that the cart may be rotated or pivoted from a first generally vertical position to a second generally horizontal position. In this horizontal position, a cutting edge may be received within the cutting edge support and the cart rotated back to the generally vertical position.

Owner:BLADE ELEVATOR

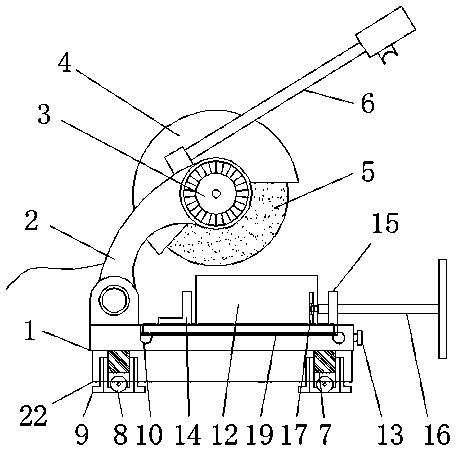

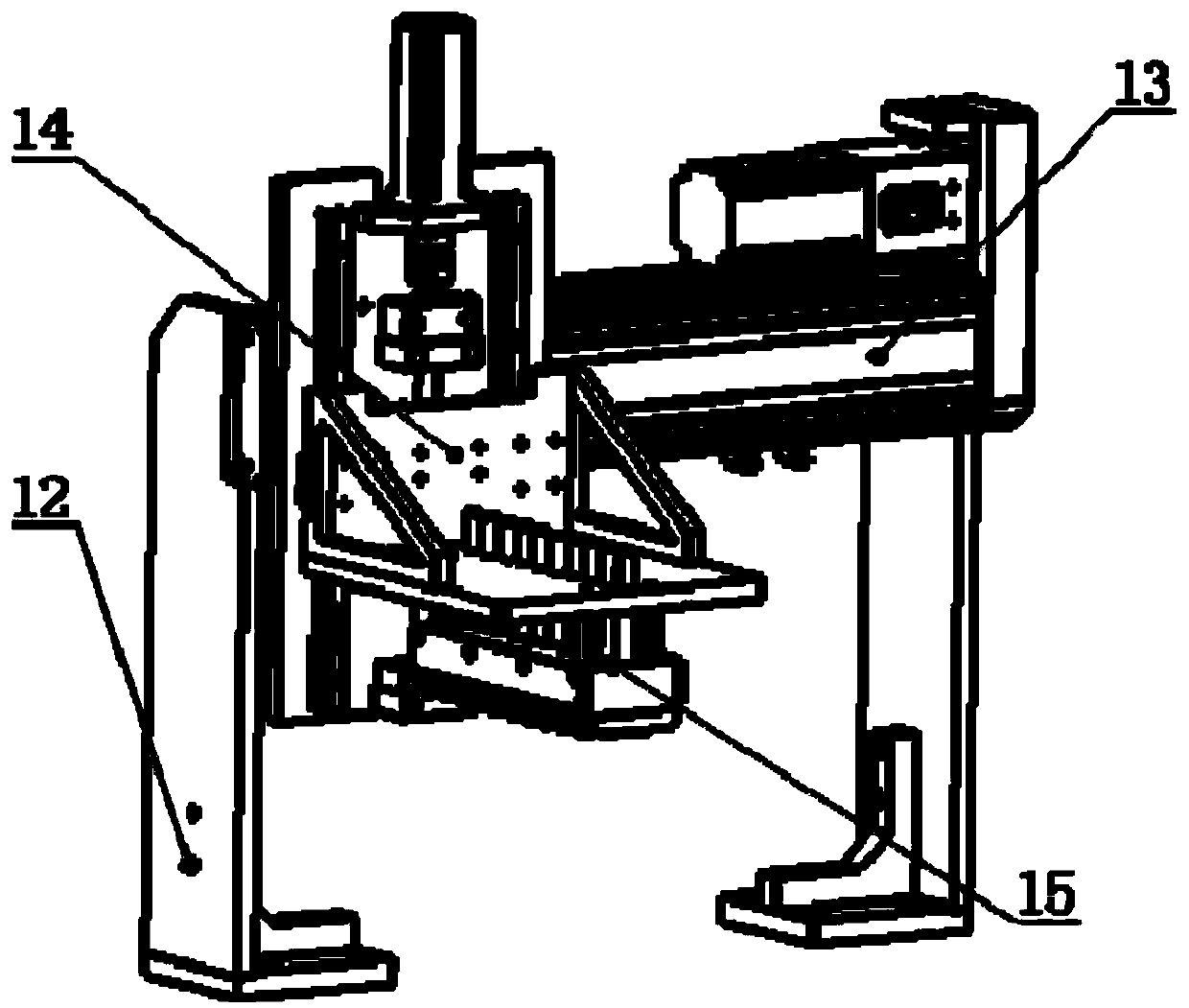

Reinforcement cutting equipment capable of quickly positioning

The invention discloses reinforcement cutting equipment capable of quickly positioning. The equipment comprises a worktable and a holding rod; the left upper side of the worktable is hinged with a movable bracket; a protection shell is mounted on the back side of the movable bracket through a bolt; the holding rod is welded above the movable bracket; a thread rod is welded on the lower surface ofthe worktable; a slide hole is formed in the worktable; the right side of the worktable is in threaded connection with a fixed bolt; a baffle plate is fixed at the middle part of the upper surface ofthe worktable by a screw; an adjusting bolt is in threaded connection with the middle part of a support plate; a clamping plate is mounted at the tail end of the adjusting bolt; a counter bore is formed in the upper surface of the worktable; a rolling shaft is placed in the counter bore; a cutting groove is formed in the middle part of the worktable; and a slide rail is mounted at the middle partof the lower surface of the worktable by a screw. The reinforcement cutting equipment capable of quickly positioning is provided with a collecting box for collecting iron chips, generated in the cutting process, in the use process to guarantee the environmental protection thereof.

Owner:泰州睿之博知识产权运营有限公司

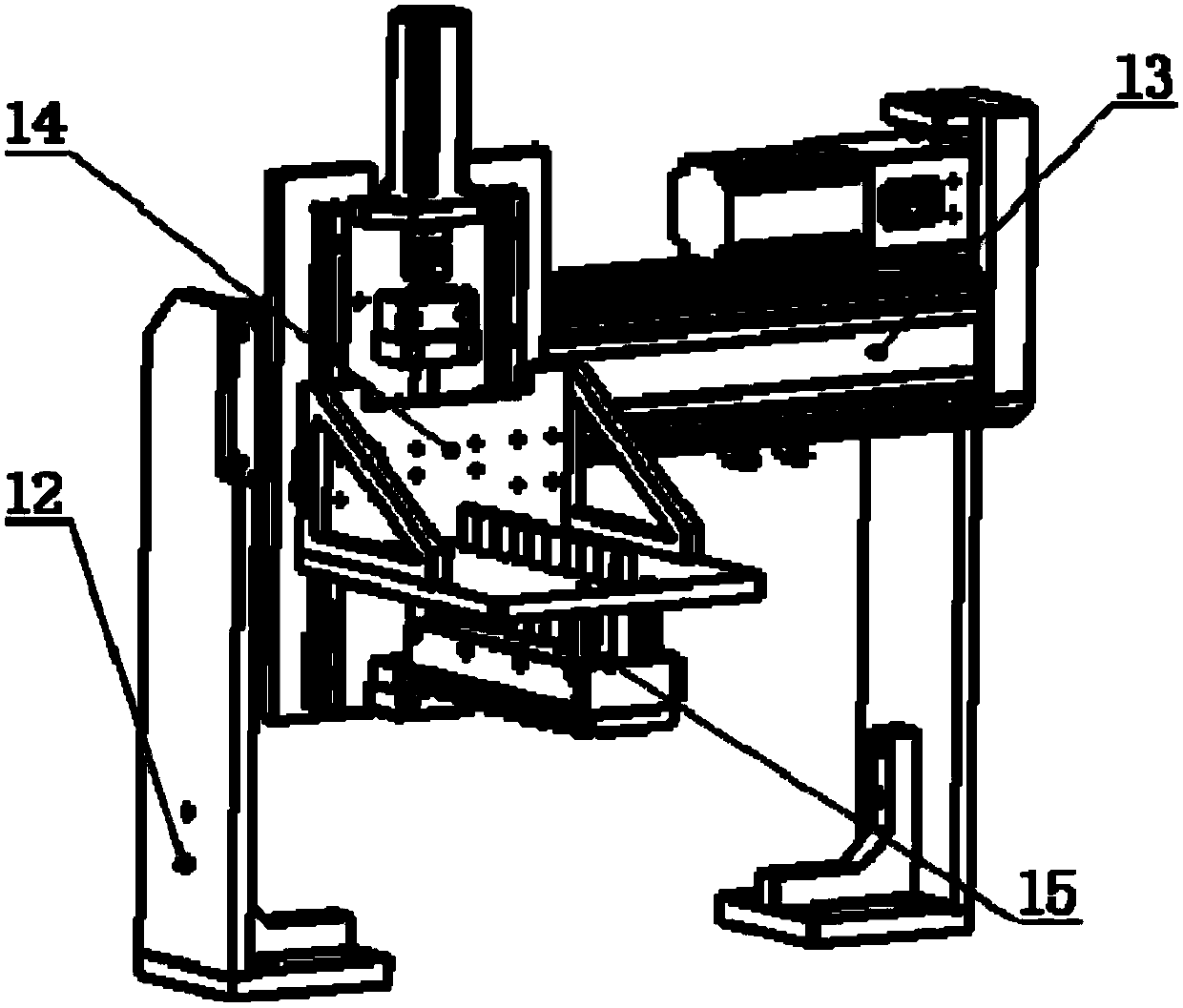

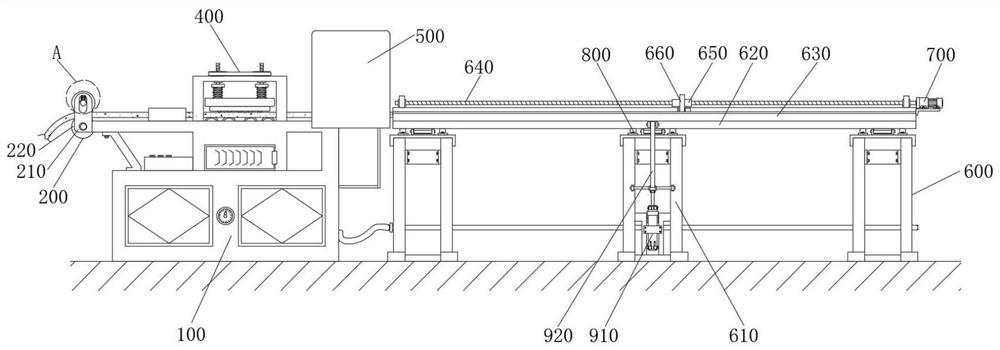

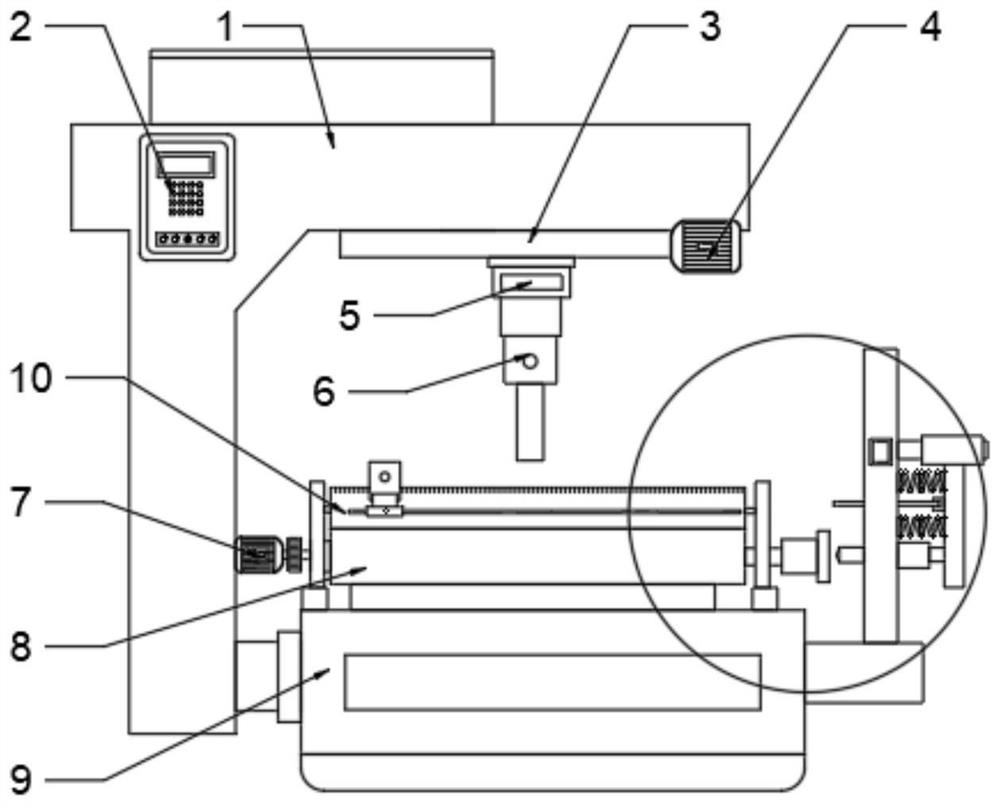

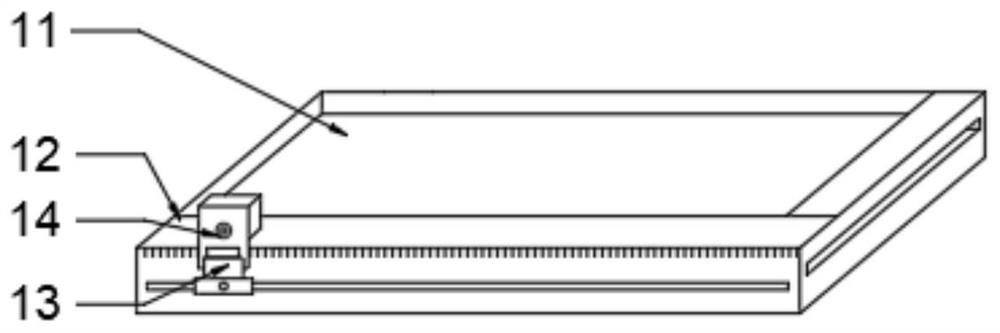

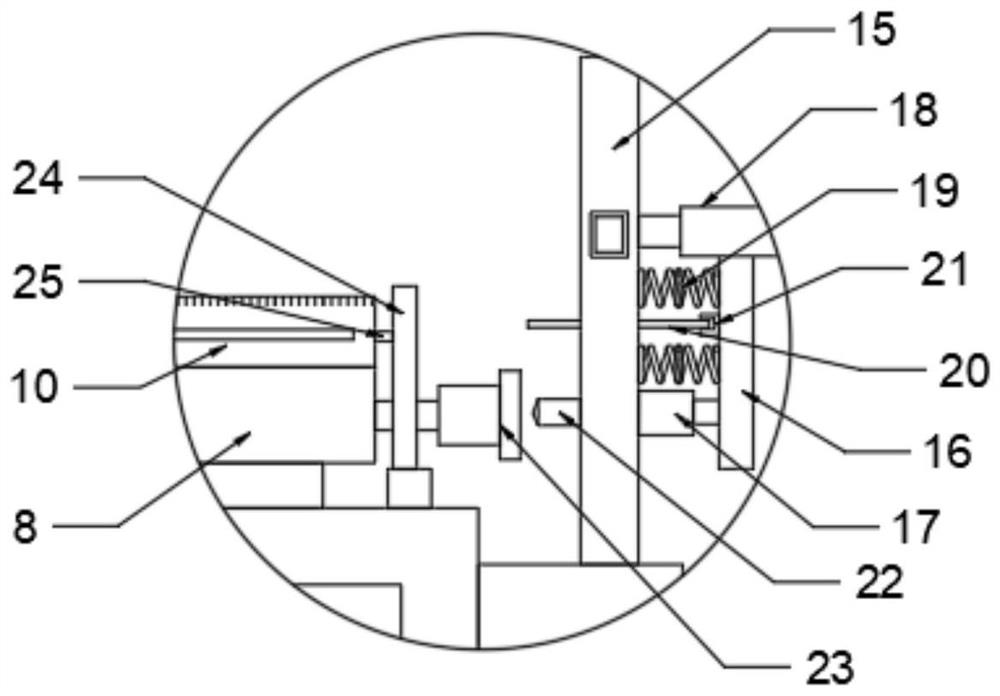

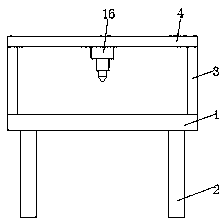

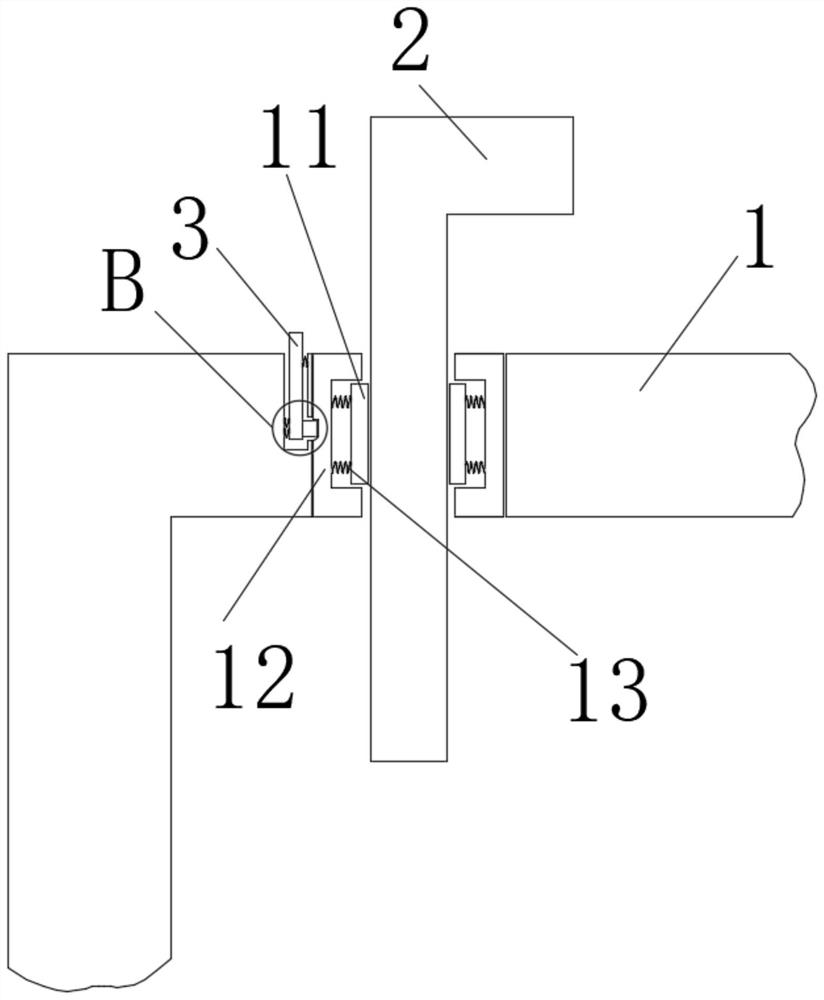

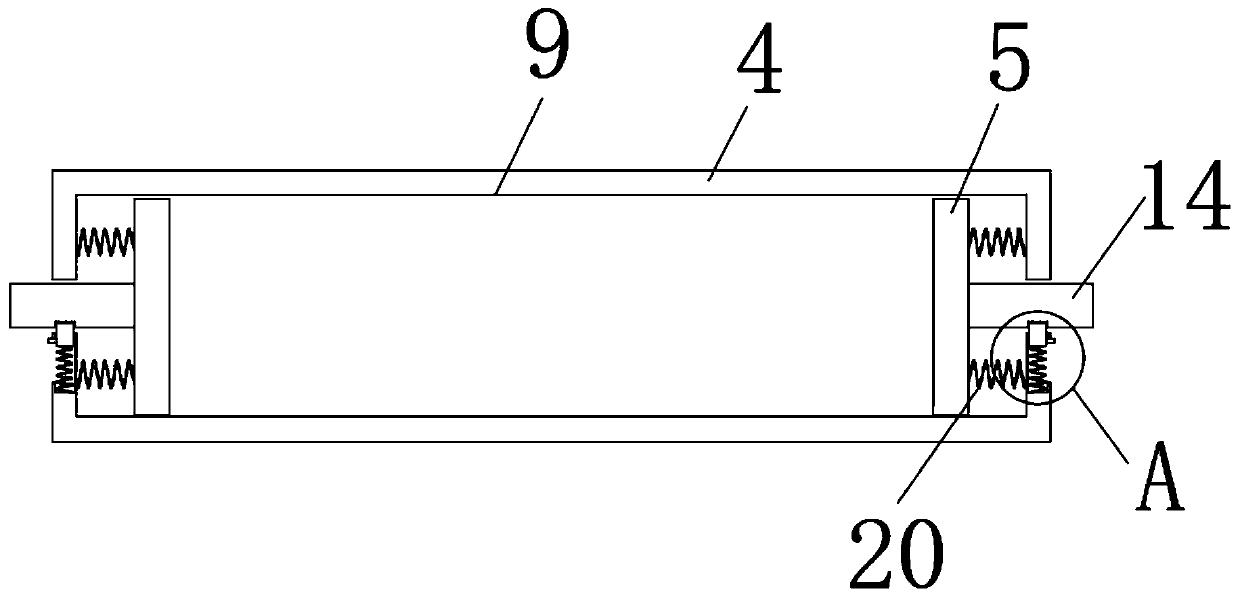

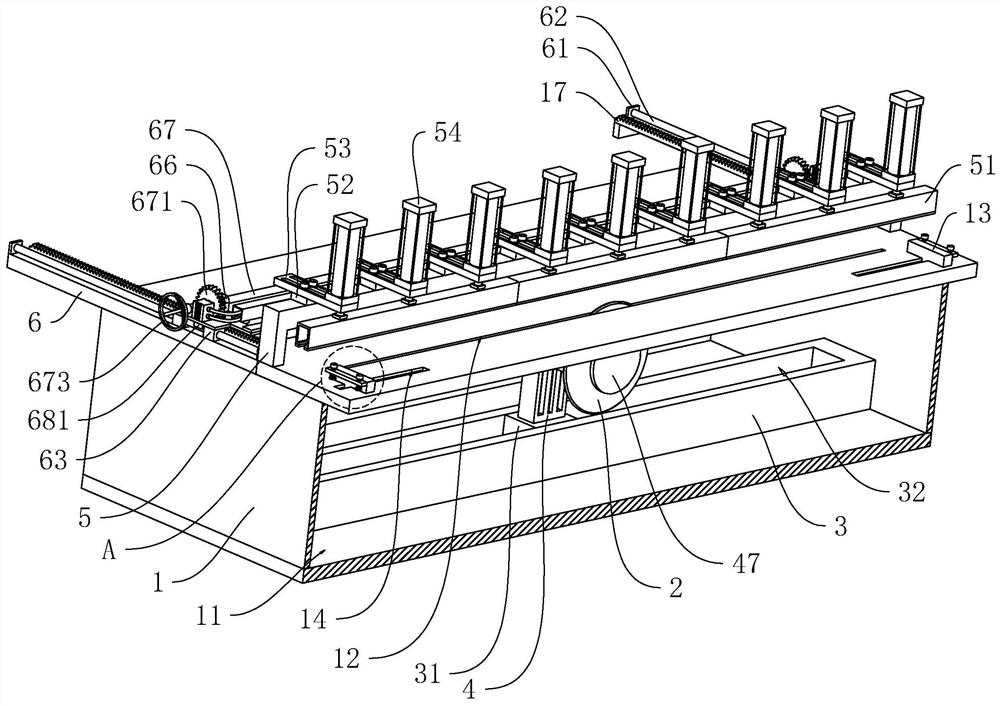

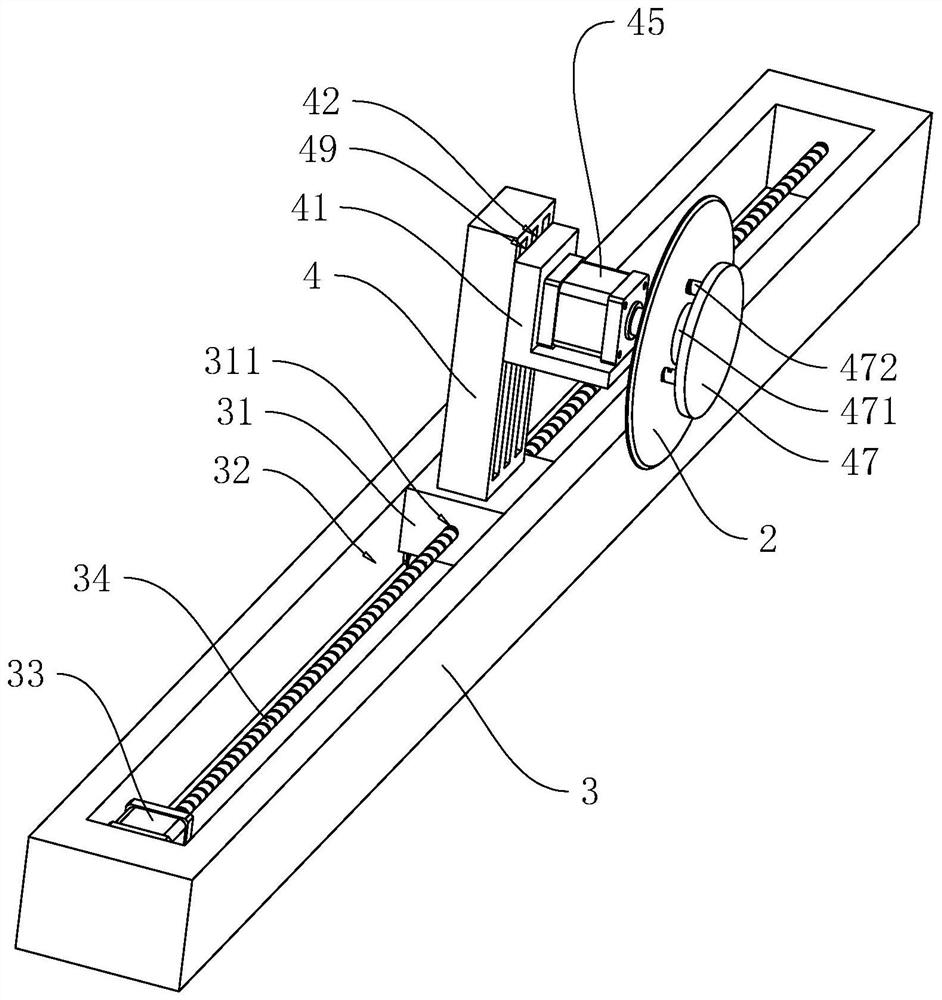

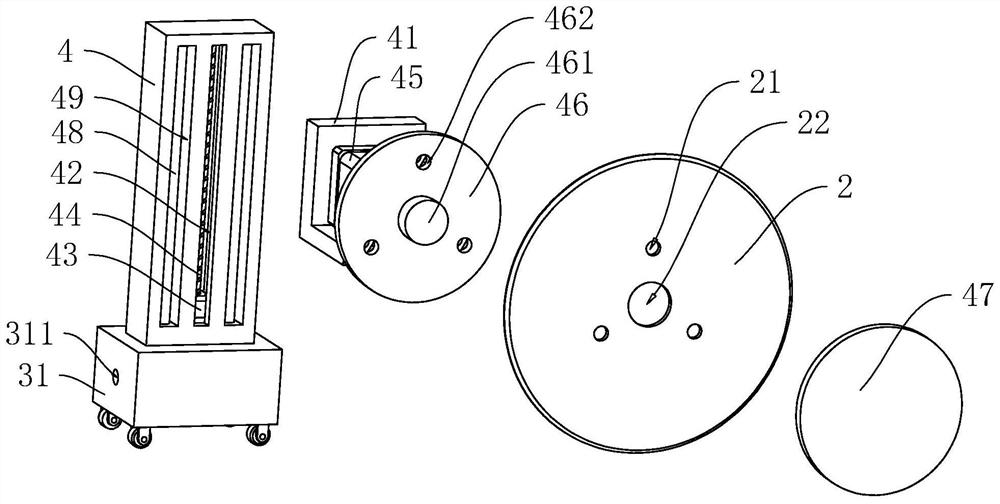

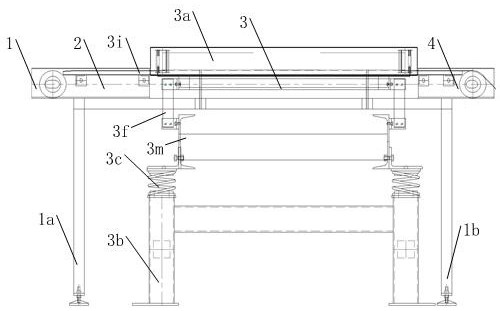

Apparel fabric tailoring machine platform

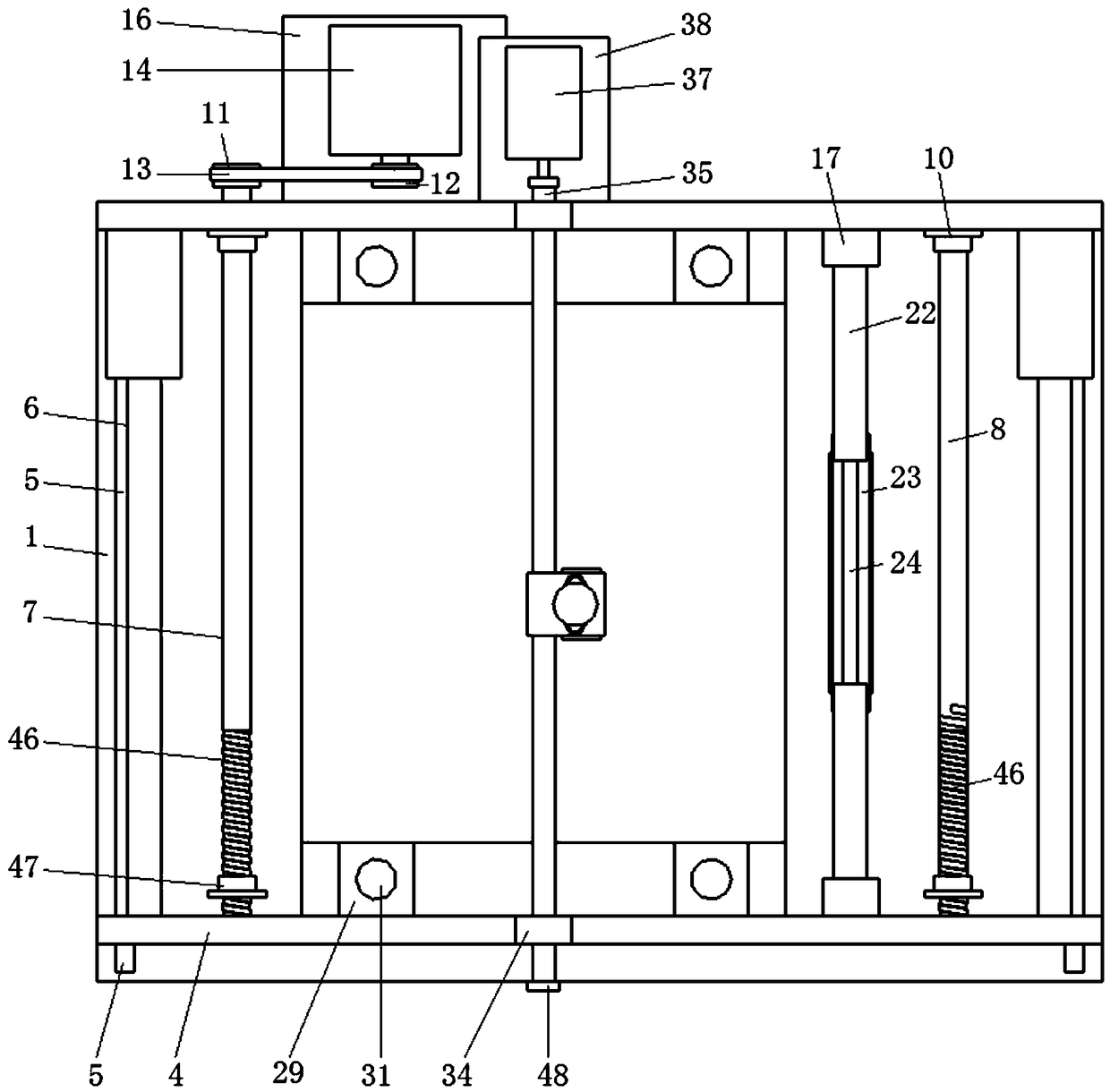

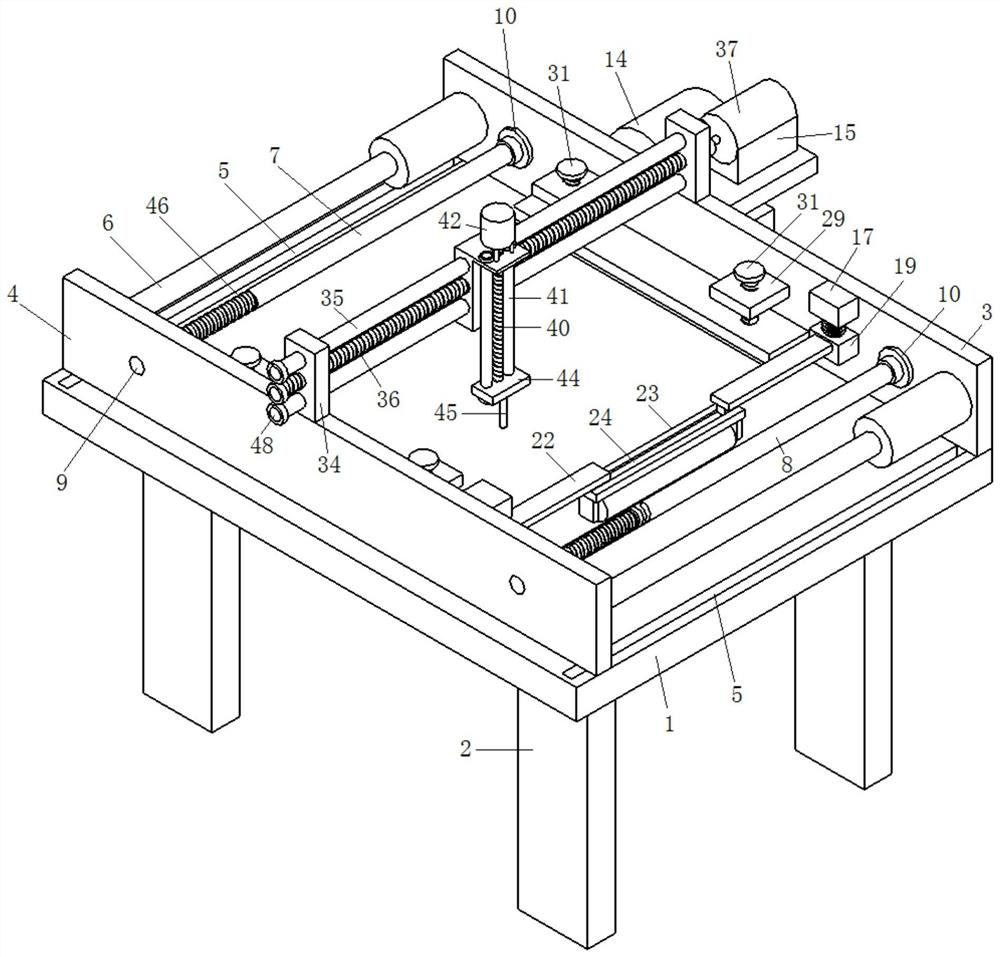

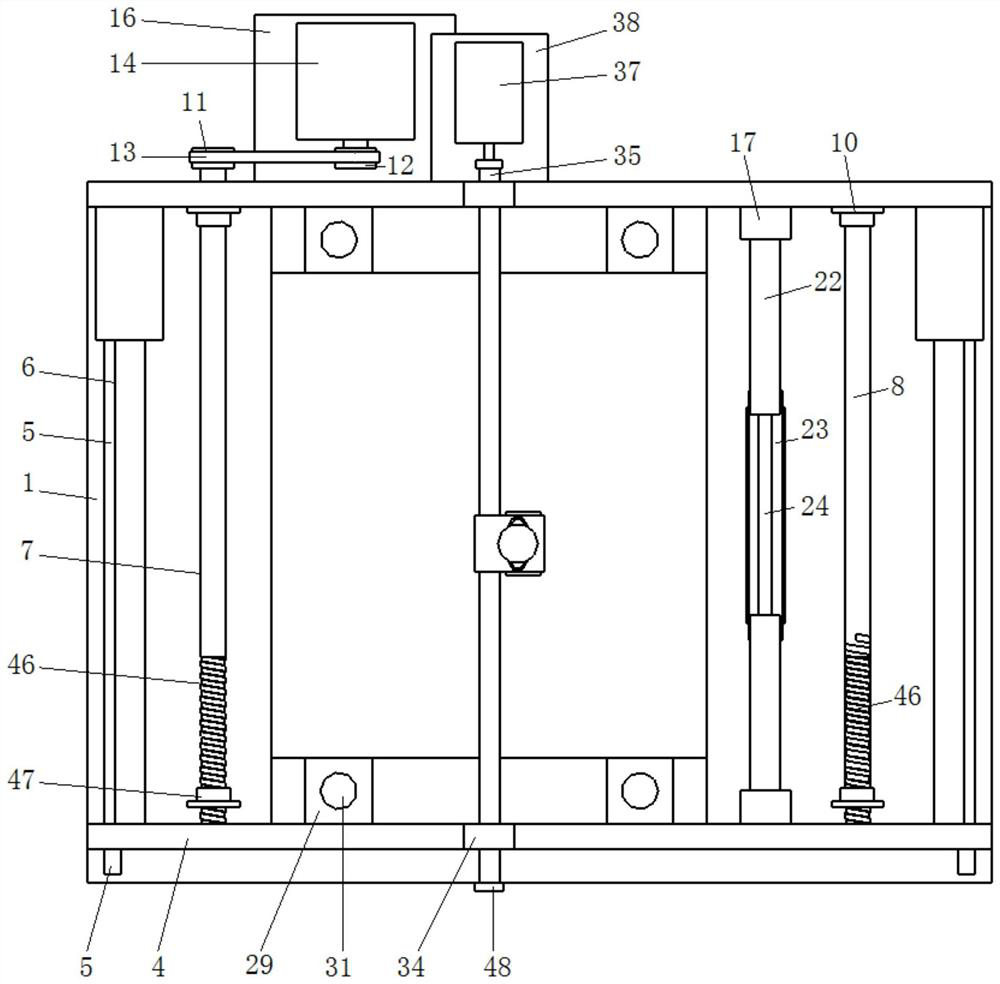

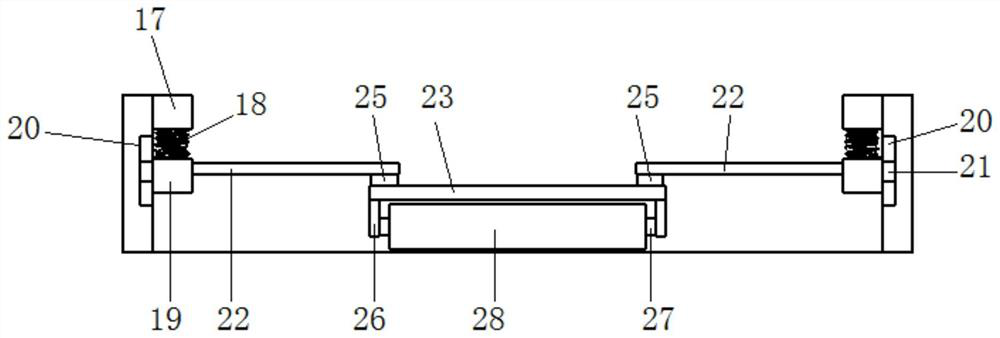

InactiveCN109023904AEasy to position and cutFlexible adjustment of the clamping position of the clothing materialMarking textilesSevering textilesEngineering

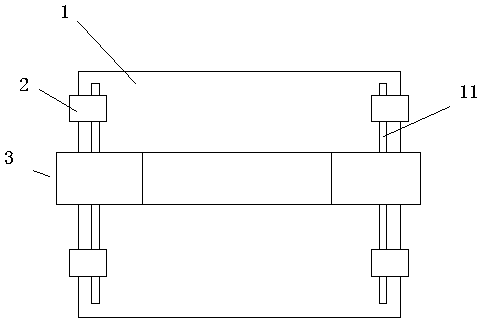

The invention discloses an apparel fabric tailoring machine platform, and belongs to the technical field of apparel design. The apparel fabric tailoring machine platform comprises a platform base, movable clamping parts arranged at the sides of the platform face of the platform base and a movable shelf stretching across the platform base; the movable clamping parts are used for clamping apparels and can adjust the clamping position; a tailoring lineation chalk and a tailoring device are arranged in the middle of the movable shelf; the movable shelf moves in the longitudinal direction of the platform base, and the tailoring device conducts tailoring according to lineation marks of the tailoring lineation chalk on apparel fabric. According to the machine platform, the movable clamping partsare utilized for flexibly adjusting the apparel fabric clamping position, and locating tailoring is facilitated; under the assistance of the movable clamping parts, the tailoring device can automatically follow the cutting lineation marks to conduct automatic tailoring with high efficiency and accuracy.

Owner:湖州棉甜服饰有限公司

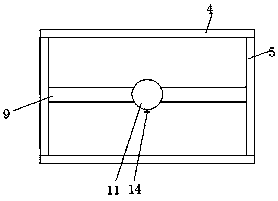

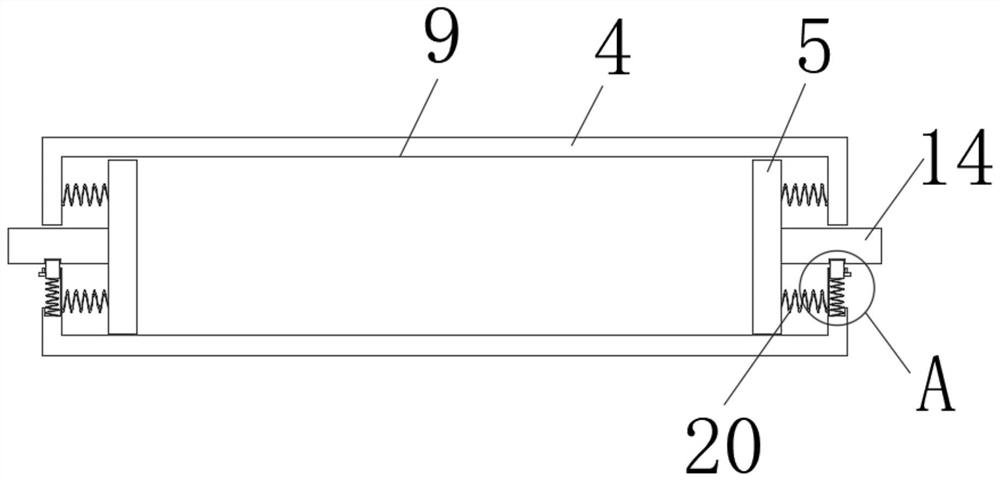

Positioning and cutting device for bridge construction

ActiveCN107059639APrecise positioningEasy to position and cutBridge erection/assemblyEngineeringPositioning system

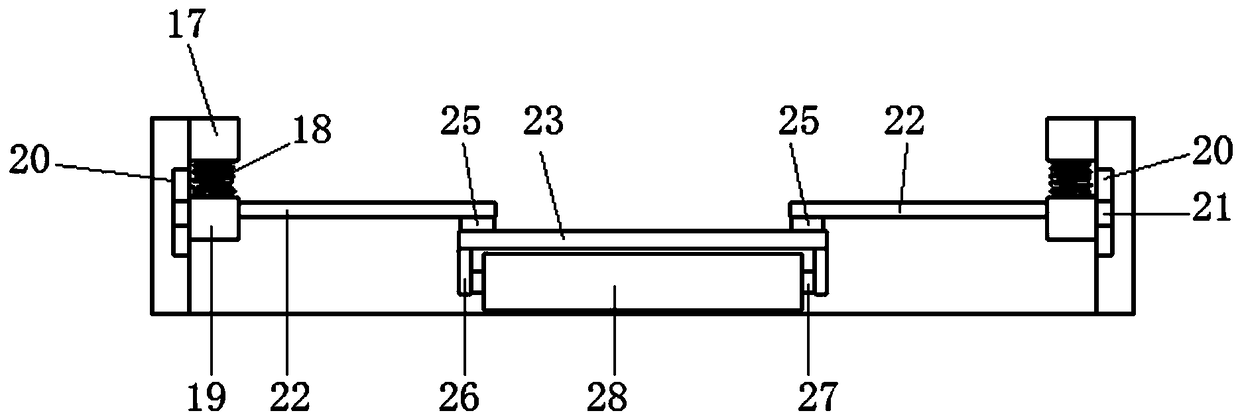

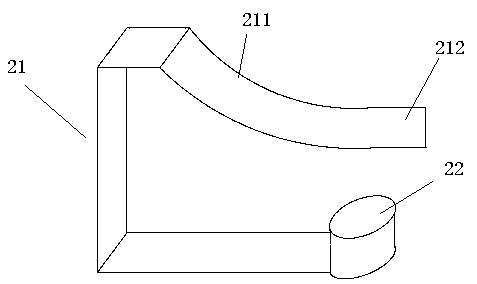

The invention discloses a positioning and cutting device for bridge construction. The positioning and cutting device comprises a working platform. A strip-shaped sliding groove is formed in the working platform; two positioning baffles are arranged on the top of the working platform; connecting sliding blocks corresponding to the strip-shaped sliding groove are arranged at the bottoms of the positioning baffles; connecting shafts are arranged at the bottoms of the connecting sliding blocks; limiting rollers are arranged on the connecting shafts in a penetrating mode; connecting sliding grooves corresponding to the limiting rollers are formed in inner walls of the front face and the back face of the strip-shaped sliding groove correspondingly; supporting plates are arranged on the two sides of the top of the working platform correspondingly; two hydraulic telescopic rods are arranged on the sides, deviated from each other, of the two positioning baffles correspondingly; two positioning plates are arranged on the sides, opposite to each other, of the two positioning baffles correspondingly; and positioning connecting rods are arranged on the sides, close to the positioning baffles, of the positioning plates. According to the positioning and cutting device for bridge construction, it can be more convenient to position pipes needing to be cut and more convenient for constructors to cut, larger convenience is provided for construction.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

A positioning and cutting device for bridge construction

ActiveCN107059639BPrecise positioningEasy to position and cutBridge erection/assemblyEngineeringPositioning system

The invention discloses a positioning and cutting device for bridge construction. The positioning and cutting device comprises a working platform. A strip-shaped sliding groove is formed in the working platform; two positioning baffles are arranged on the top of the working platform; connecting sliding blocks corresponding to the strip-shaped sliding groove are arranged at the bottoms of the positioning baffles; connecting shafts are arranged at the bottoms of the connecting sliding blocks; limiting rollers are arranged on the connecting shafts in a penetrating mode; connecting sliding grooves corresponding to the limiting rollers are formed in inner walls of the front face and the back face of the strip-shaped sliding groove correspondingly; supporting plates are arranged on the two sides of the top of the working platform correspondingly; two hydraulic telescopic rods are arranged on the sides, deviated from each other, of the two positioning baffles correspondingly; two positioning plates are arranged on the sides, opposite to each other, of the two positioning baffles correspondingly; and positioning connecting rods are arranged on the sides, close to the positioning baffles, of the positioning plates. According to the positioning and cutting device for bridge construction, it can be more convenient to position pipes needing to be cut and more convenient for constructors to cut, larger convenience is provided for construction.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

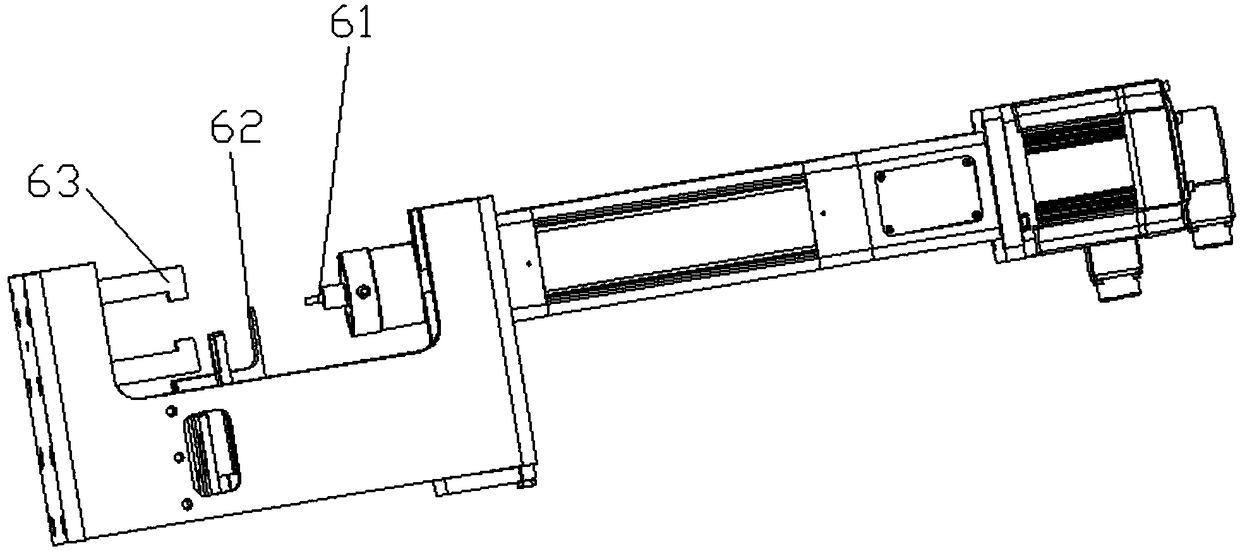

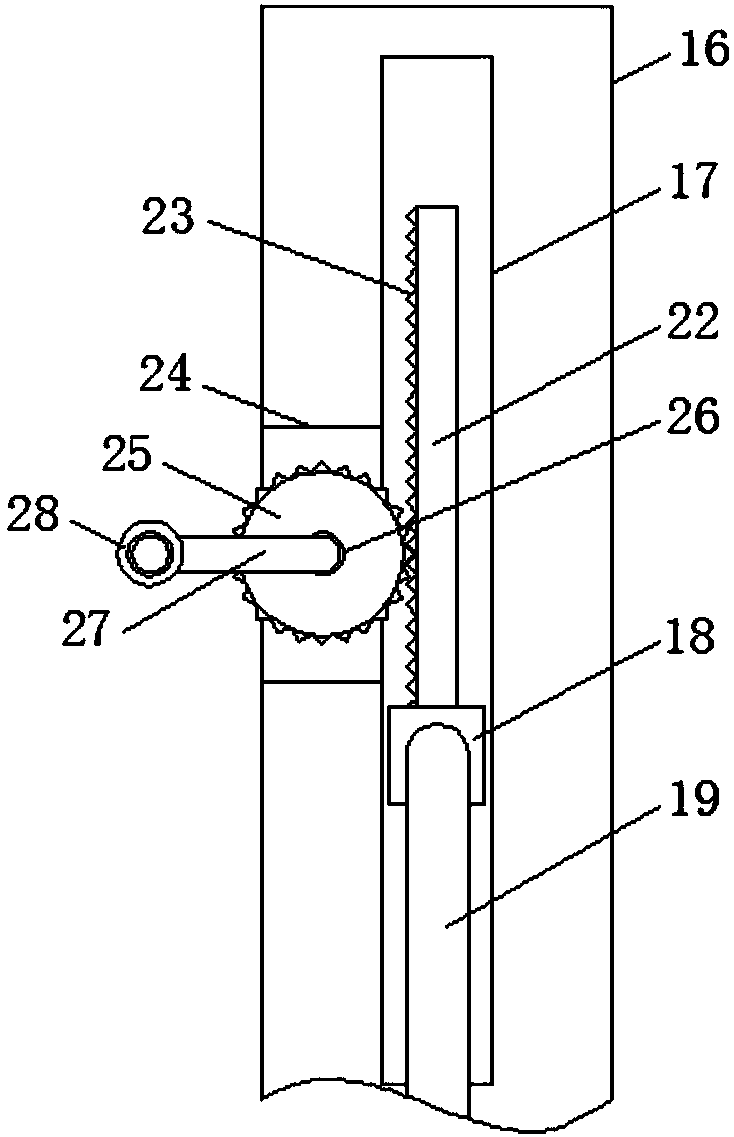

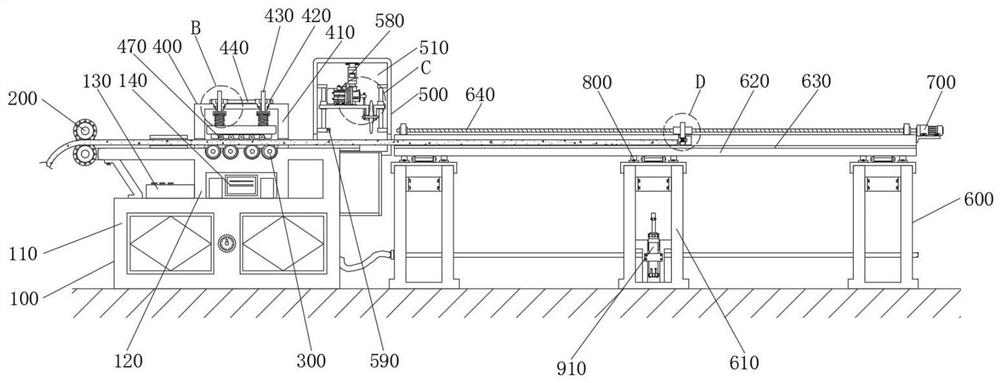

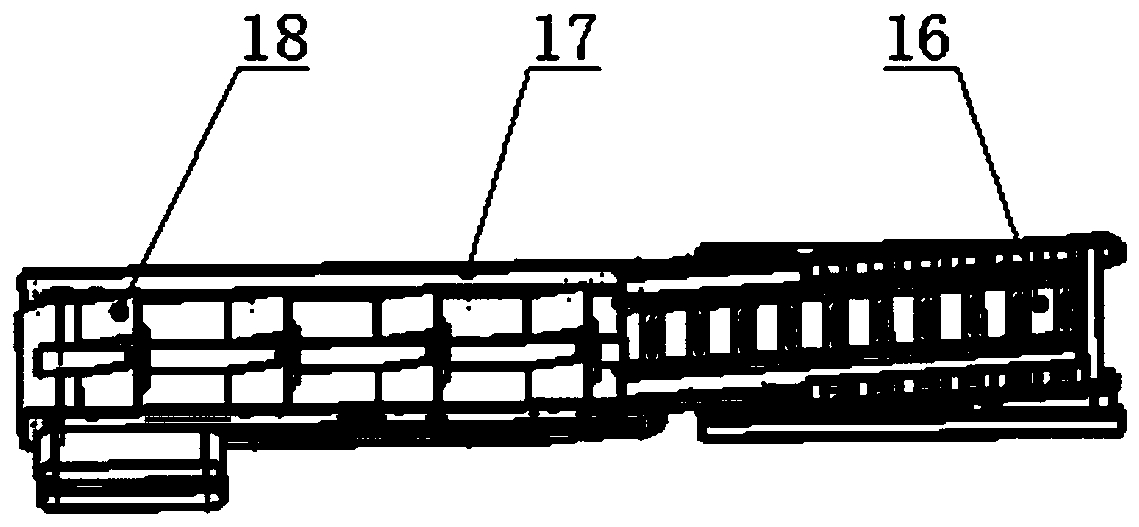

Anchor cable machine with automatic positioning and cutting functions

PendingCN112122687AGuarantee the accuracy of length positioningEasy to position and cutMetal sawing devicesServoPush-button

The invention relates to the technical field of anchor cable machining and production equipment, in particular to an anchor cable machine with automatic positioning and cutting functions. The anchor cable machine comprises an anchor cable machine main body, wherein the anchor cable machine main body comprises a main box body; a supporting table top is fixedly arranged on the top of the main box body; a control button is fixedly welded to one side of the top of the main box body; a control box is fixedly arranged in the supporting table top; a driving mechanism is fixedly arranged inside the top end of the supporting table top; the driving mechanism comprises a conveying roller; and the conveying roller is longitudinally and rotatably connected to the top of the supporting table top. A second contact switch is fixed in a limiting plate; and during work, after an anchor cable moves and abuts against a sliding cover, the second contact switch is pressed through a third spring, so that a control box controls a second servo motor to be started after receiving a signal, and a saw blade is driven to cut a steel cable; and through limitation of the limiting plate, the length positioning accuracy of the device during anchor cable cutting is effectively guaranteed.

Owner:神东天隆集团矿山支护材料有限责任公司

Stainless steel panel cutting and positioning die

InactiveCN112207461AEasy to cutAvoid offsetLaser beam welding apparatusEngineeringSS - Stainless steel

The invention discloses a stainless steel panel cutting and positioning die which comprises a worktable. A working frame is fixedly mounted on one side of the worktable; an operation panel and a lasercutting mechanism are mounted on the working frame; a transmission mechanism is mounted at the top of the worktable; a die shell is arranged on the worktable; and a positioning mechanism corresponding to the transmission mechanism is arranged on one side of the worktable. The stainless steel panel cutting and positioning die is convenient to use, accurate in positioning, high in cutting stabilityduring cutting and good in cutting effect.

Owner:江门市冠奇不锈钢制品有限公司

Method of using a cutting edge cart

InactiveUS7225520B1Reduce the number of partsEasy to manufactureAutomatic control devicesSupporting partsEngineeringCart

A cutting edge cart is disclosed that provides an improved means for replacing the replaceable cutting edges on bladed equipment such as road graders and snow plow. The cart allows a single user to retrieve, transport, and position a replacement cutting edge relative to a mold board of the bladed equipment. Generally, the cart contains a frame, two or more transport assemblies attached to the frame, such as wheels, a movable carrier assembly that contains a cutting edge support assembly, and an adjuster. The adjuster is operable to move the carrier assembly between first and second positions relative to the frame allowing the vertical position of a supported cutting edge to be adjusted. The frame and transport assemblies are disposed such that the cart may be rotated or pivoted from a first generally vertical position to a second generally horizontal position. In this horizontal position, a cutting edge may be received within the cutting edge support and the cart rotated back to the generally vertical position.

Owner:BLADE ELEVATOR

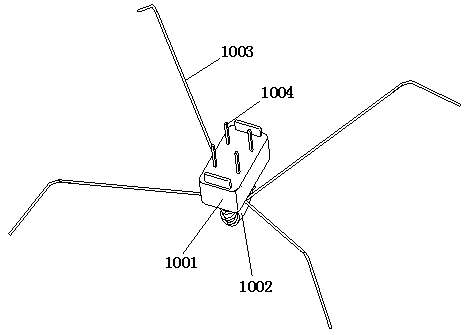

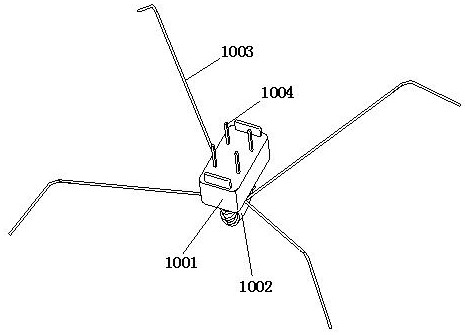

Wire cutting device for inductor

The invention discloses a wire cutting device for an inductor, and belongs to the technical field of inductor processing devices. The device comprises a wire end clamping mechanism and a wire cuttingmechanism, wherein the wire cutting mechanism is arranged beside the wire end clamping mechanism, the wire end clamping mechanism comprises a clamping fixing seat, a rotating conveying assembly, a height adjusting assembly and a wire end clamping assembly, wherein the height adjusting assembly is arranged at the upper end of the rotating conveying assembly, the wire end clamping assembly is fixedly connected with the height adjusting assembly, the wire cutting mechanism comprises a wire cutting base, a wire cutting adjusting assembly, a wire cutting lifting assembly and a wire cutting assembly, wherein the wire cutting adjusting assembly is arranged at the upper end of the wire cutting base, the wire cutting lifting assembly is fixedly connected with the wire cutting adjusting assembly, and the wire cutting assembly is arranged on the wire cutting lifting assembly. According to the device, a copper wire can be straightened by the wire end clamping mechanism, so that the copper wire canbe conveniently positioned and cut, the cut copper wire can be conveniently collected, and the device can further be adjusted to be suitable for processing inductors of different sizes.

Owner:国网甘肃省电力公司临夏供电公司

Metal plate less-cutting machining equipment for mechanical part manufacturing

ActiveCN113751791AReasonable designEasy to position and cutMetal sawing devicesMetal sawing accessoriesForgeMachining

The invention discloses metal plate less-cutting machining equipment for mechanical part manufacturing. The metal plate less-cutting machining equipment for mechanical part manufacturing comprises a fixing plate and an inverted U-shaped support frame mounted at the top of the fixing plate; a measuring assembly for assisting in measuring and positioning a metal part is fixed on one side edge of the fixing plate through bolts; a clamping assembly for assisting in clamping the metal plate is arranged on the top of the fixing plate and corresponds to the measuring assembly; the measuring assembly comprises a fixing box fixed to the side edge of the fixing plate through the bolts and an extending-in plate installed in the fixing box in a penetrating mode; a clamping structure is arranged on the inner side edge of a protruding plate; and a positioning structure for assisting adjustment of the extending-in plate is arranged on the side edge, close to the protruding plate, of the fixing box. The metal plate less-cutting machining equipment for mechanical part manufacturing is reasonable in design; a forge piece can be conveniently and rapidly measured and positioned in the working process; the situation that positioning needs to be conducted again every time cutting is conducted is avoided; and the overall working efficiency is improved.

Owner:苏州乾源涂装有限公司

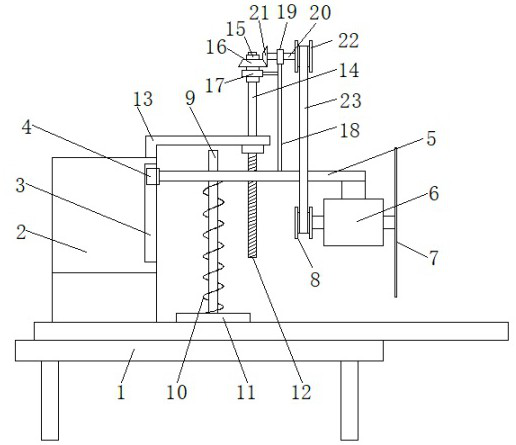

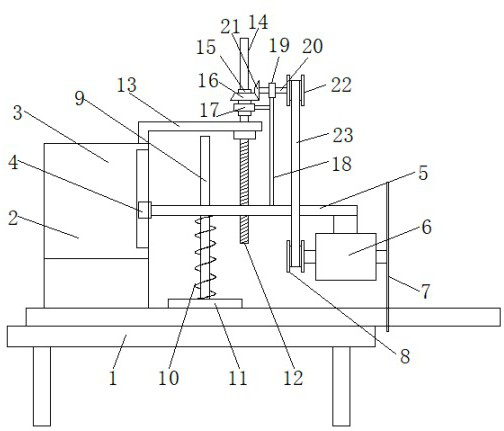

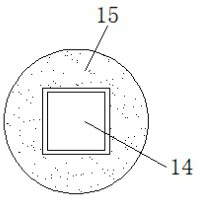

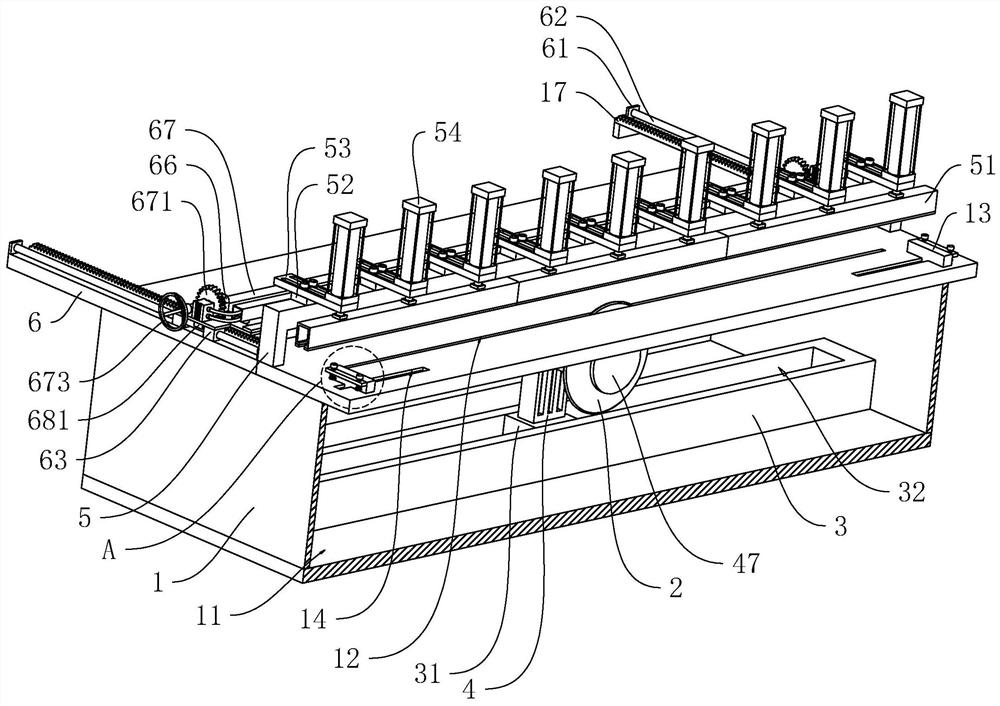

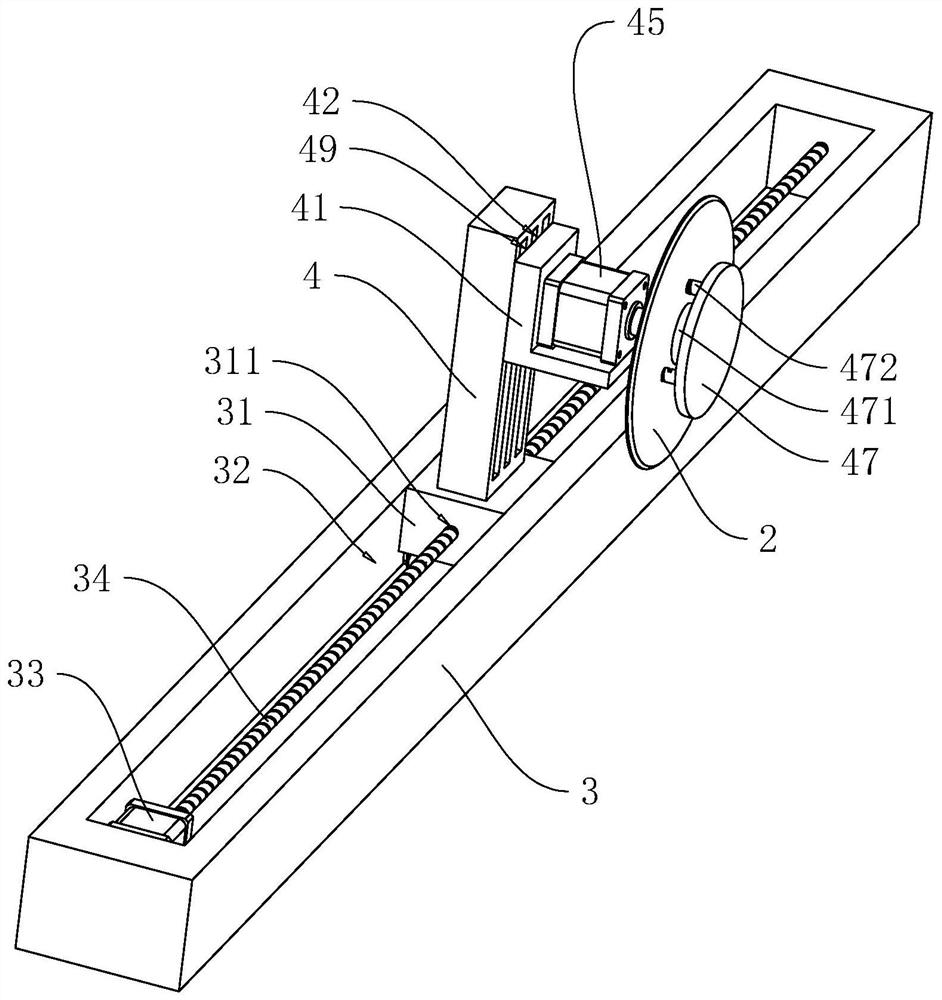

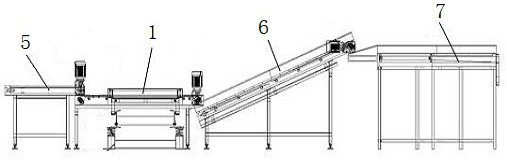

Cutting equipment for three-edged auger stem

InactiveCN112475420AHigh degree of integrationReduce labor costsShearing machinesFeeding apparatusElectric machineryStructural engineering

The invention discloses cutting equipment for a three-edged auger stem, and relates to the technical field of drill stem machining. The following scheme is provided in order to solve the problems thatwhen an existing three-edged auger stem is cut, manual operation is needed, the labor cost of an enterprise is increased, and efficient production of the enterprise is affected. A placement plate isincluded. A fixed seat is fixedly connected to the top of the placement plate, a movable rod is slidably connected to the right side of the fixed seat, a double-shaft motor is fixedly connected to theright side of the bottom of the movable rod, a cutting wheel fixedly sleeves an output shaft at the right end of the double-shaft motor, and a pressing mechanism is movably arranged inside the movable rod in a sleeving mode. A fixed plate fixedly connected with the top of the fixed seat is arranged above a pressing mechanism, and a lifting mechanism is movably arranged in the fixed plate in a sleeved mode. The same motor is conveniently adopted for driving, one machine has multiple purposes, automatic lifting is facilitated to complete positioning cutting, manual operation is not needed, thelabor cost of an enterprise is reduced, and the machining effect is improved.

Owner:HUAIBEI LINGUANG DRILLING ELECTROMECHANICAL ENG

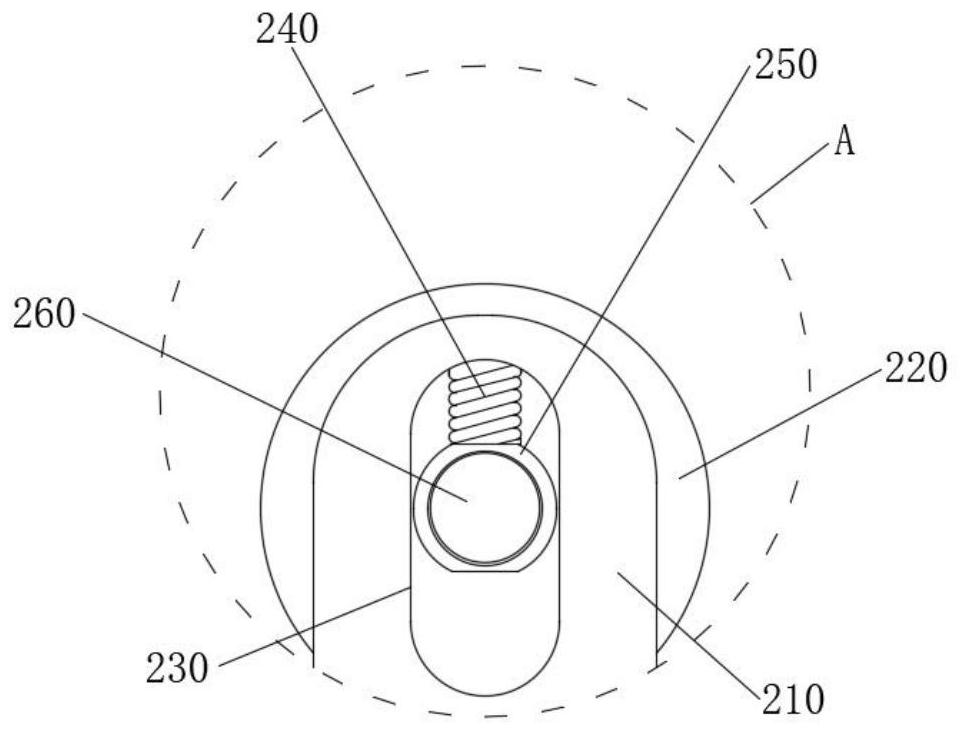

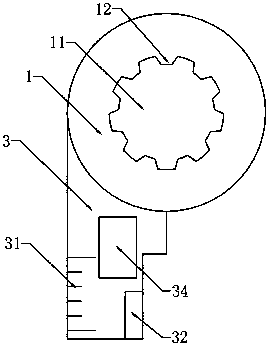

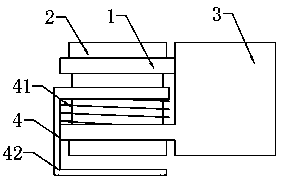

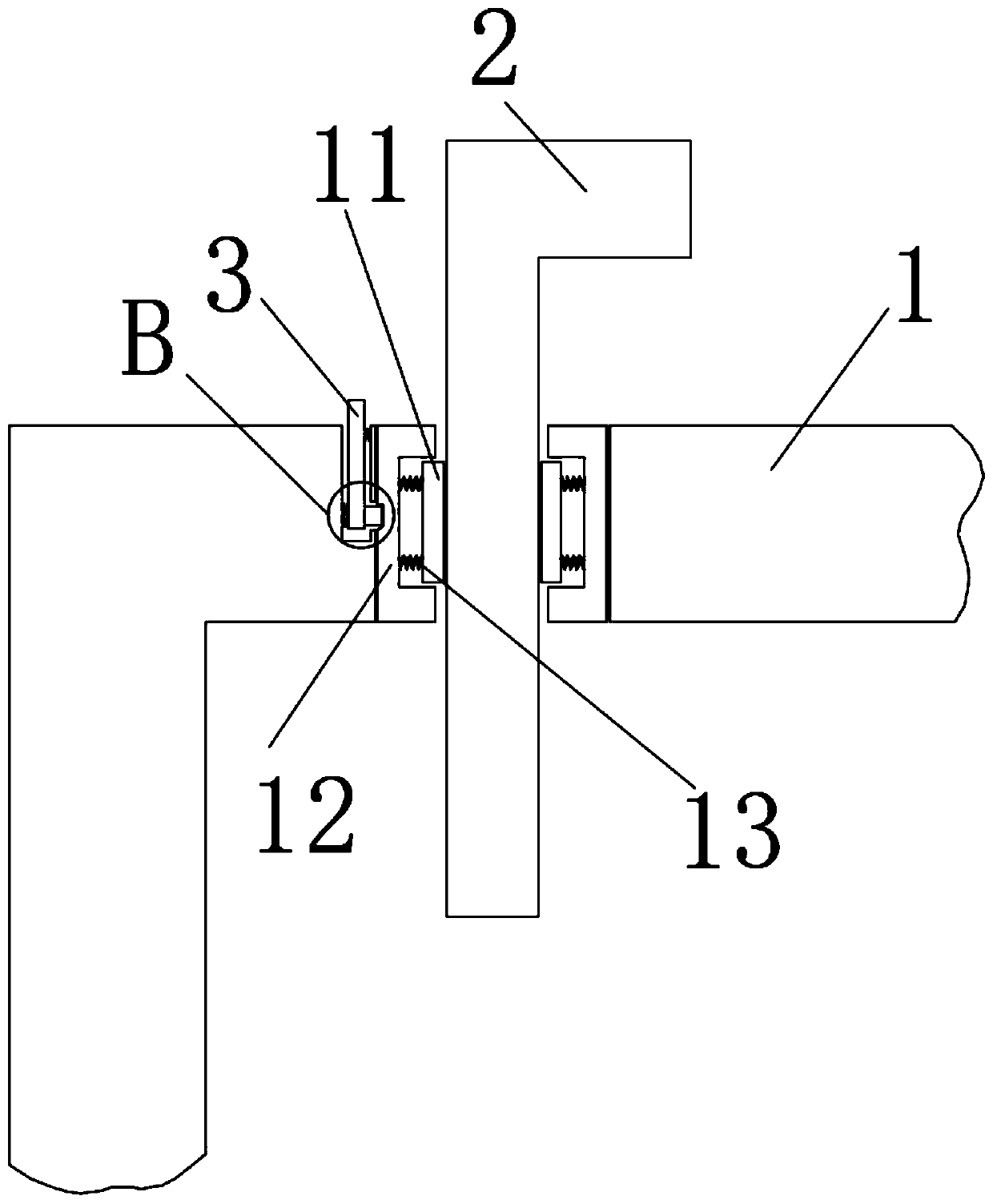

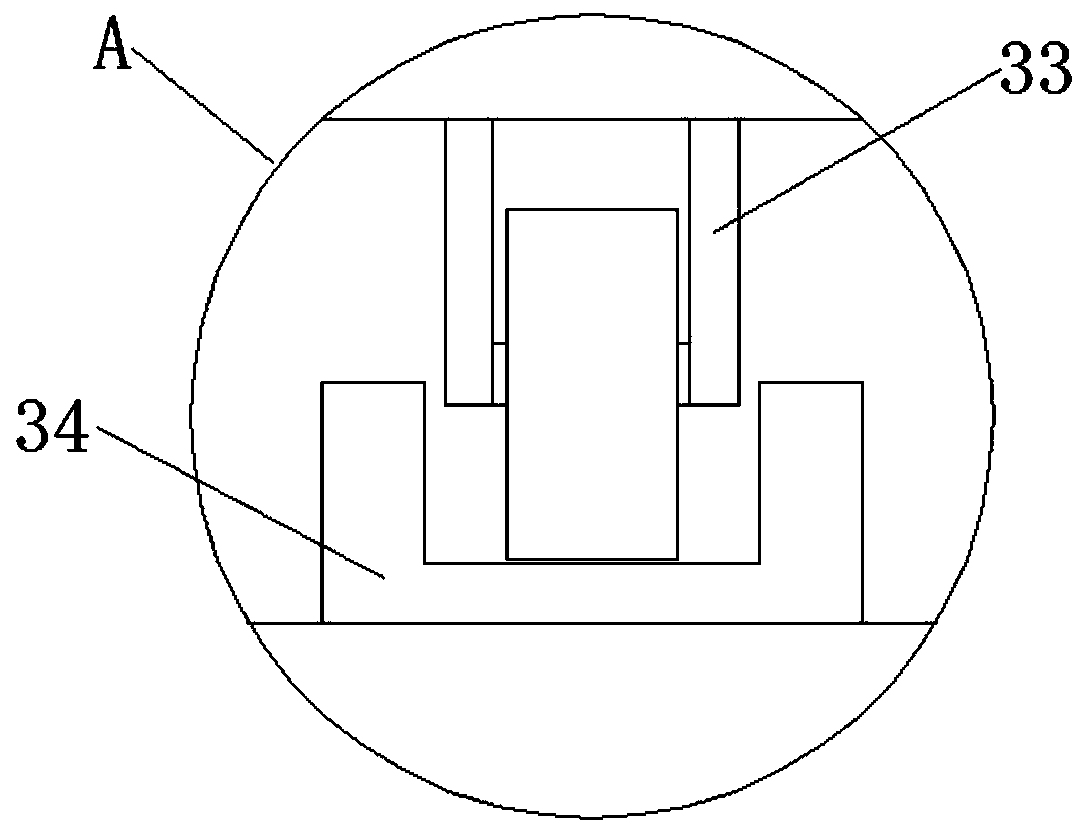

A pressure-sensitive foldable electronic multifunctional grating positioning cutting ruler

InactiveCN107662229BAvoid hurtingSolve the problem of low cutting precisionMetal working apparatusCapacitive pressure sensorGrating

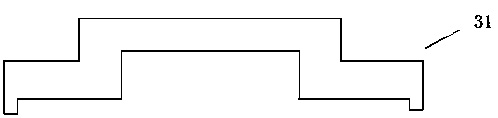

Disclosed is a pressure-sensitive foldable electronic multi-functional optical grating positioning cutting ruler, comprising a connecting plate (1), a connecting shaft (2), a measuring ruler body (3) and a clamping mechanism (4). The connecting shaft (2) comprises an upper shaft (23) of a hollow structure, a lower shaft (25) and a limiting ring (24), the upper shaft (23) and the lower shaft (25) being mutually sleeved, and the connecting plate (1) being engaged with the connecting shaft (2). The measuring ruler body (3) is connected to the connecting plate (1), wherein a T-shaped slide groove (30) and a capacitive pressure sensor (32) are arranged inside the measuring ruler body (3), and a cutting tool carriage (33) is arranged above the T-shaped slide groove (30); an optical grating emitting device (336) is arranged on the cutting tool carriage (33); and the clamping mechanism (4) comprises a tension spring (41) and a C-shaped pressing plate (42). The pressure-sensitive foldable electronic multi-functional optical grating positioning cutting ruler has a rational structure, has the advantages of being simple in structure, being easy to use, being safe and reliable, being convenient to store, being easy to position, and being high precision, etc., and effectively solves the problem of low cutting precision of an existing cutting tool.

Owner:李润开

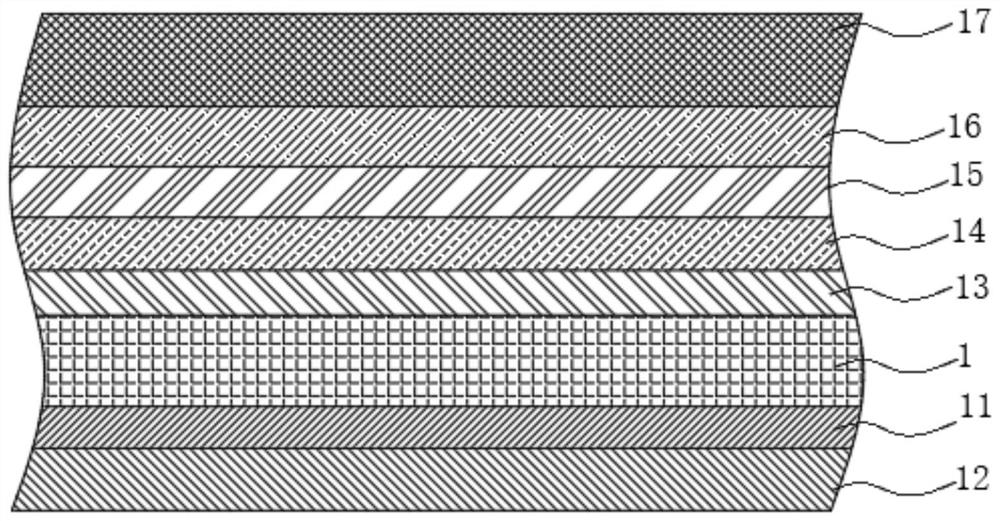

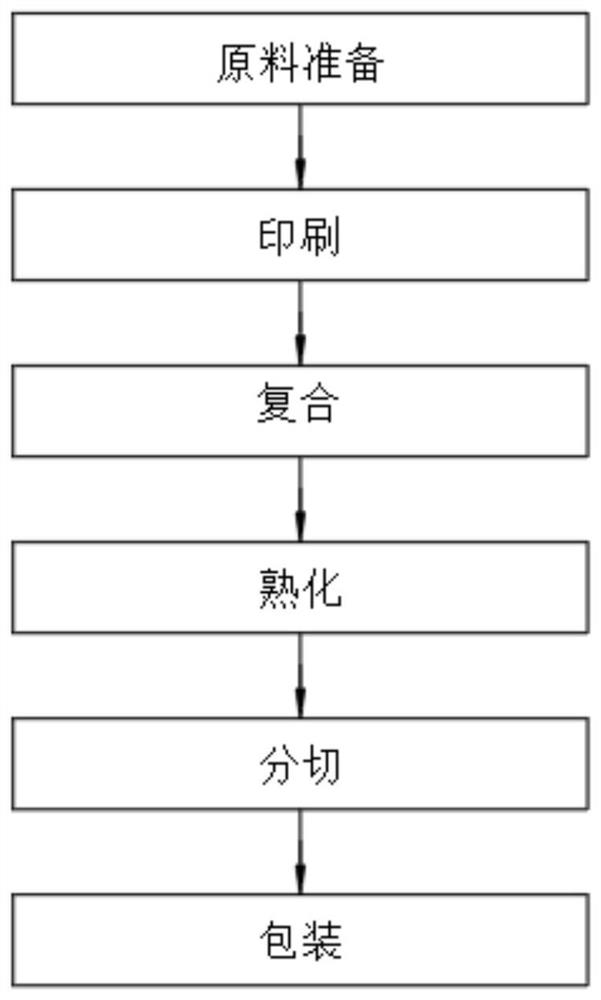

Aluminum-plastic cover film easy to position and cut for blister packaging and preparation method of aluminum-plastic cover film

PendingCN113306233AHigh strengthAvoid breakingLamination ancillary operationsSynthetic resin layered productsPolyesterBlister pack

The invention discloses an aluminum-plastic cover film easy to position and cut for blister packaging and preparation method of the aluminum-plastic cover film. The aluminum-plastic cover film structurally comprises an aluminum foil layer, a reinforcing layer, a heat sealing layer, a first adhesive layer, a polyester film layer, a second adhesive layer, an ink printing layer and a gloss oil layer. The preparation method of the aluminum-plastic cover film easy to position and cut is characterized by comprising the following steps of raw material preparation, printing, compounding, curing and slitting and packaging. The strength of the obtained aluminum-plastic cover film can be improved, the cover film is prevented from being broken, performance is stable, energy is saved, environment friendliness is achieved, positioning cutting and packaging are convenient, and the use requirement can be met.

Owner:上海一可包装制品有限公司

Cutting device with positioning and cutting functions

InactiveCN107695578AEasy to position and cutAvoid shakingWelding/cutting auxillary devicesAuxillary welding devicesComputer engineeringPulley

The invention provides a cutting device with positioning cutting, and relates to the field of cutting devices. The cutting equipment with positioning cutting includes a placing plate, the top four corners of the placing plate are fixedly connected with uprights, two uprights form a group, and the ends of the two sets of uprights away from the placing plate are fixedly connected with the first support As for the cross bar, two second support cross bars are fixedly connected to the side where the two first support cross bars are close to each other, and a chute is provided on the side where the two second support cross bars are close to each other, and the inside of the two chute Both are provided with pulleys, the inner rings of the two pulleys are fixedly sleeved with axles, and a movable crossbar is arranged between the two second support crossbars. The cutting equipment with positioning cutting, the chute opened by the second support bar, and the pulley and wheel shaft arranged inside the chute, the wheel shaft is fixedly connected with the movable cross bar, so that the movable cross bar has the function of moving back and forth, and the movable cross bar The forward and backward movement can make positional cuts on metal.

Owner:无锡宝威焊割设备有限公司

A kind of steel structure automatic forming equipment

ActiveCN111036971BEasy to fixCan't cutShearing machinesMaintainance and safety accessoriesCold airBlade plate

The invention discloses a steel structure automatic forming equipment, which comprises a casing, a support block, a positioning mechanism, a sealing mechanism and a disassembly mechanism, the positioning mechanism is located on the top surface of the support block, the positioning mechanism includes a fixing plate, the support The top surface of the block is provided with a placement groove, and one side of the fixing plate is located inside the placement groove; the present invention effectively prevents the steel from being unable to be fixed on the support block by setting the fixing plate, which is convenient for positioning and cutting, thereby ensuring that the steel Excellent product quality, through the set sealing ring, it can effectively prevent the internal temperature of the equipment from being too high. When the first connecting plate transmits cold air to cool down, the connection between the shell and the cold air pipe is not tight, which will cause the cold air to leak out, ensuring the cooling of the equipment. Efficiency prolongs the service life of the machine. Through the set button, it effectively avoids the cumbersome process of disassembling the blade when the equipment needs to replace the blade on the blade board, saving labor costs.

Owner:XUZHOU NANFANG YONGCI MATERIAL

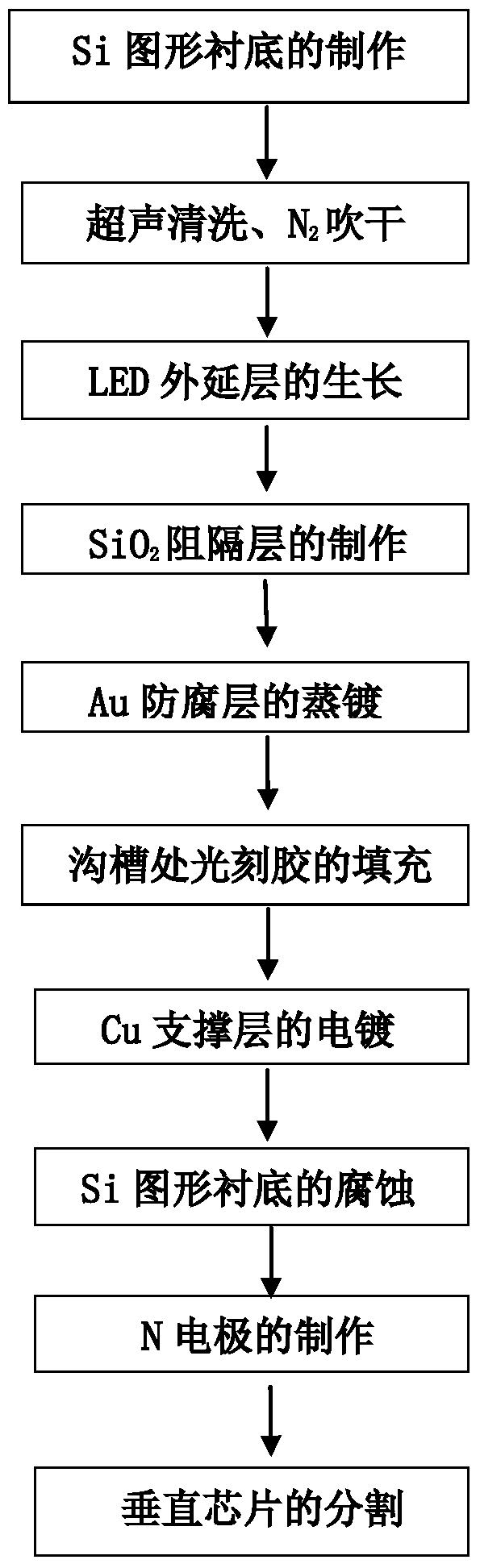

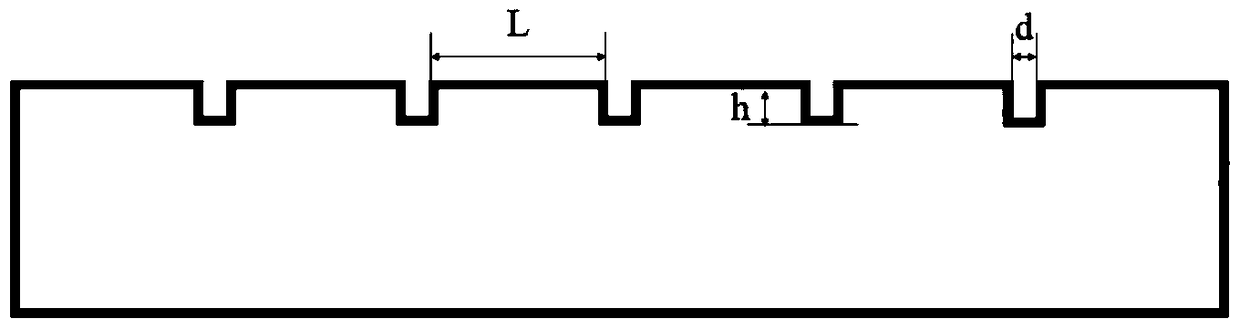

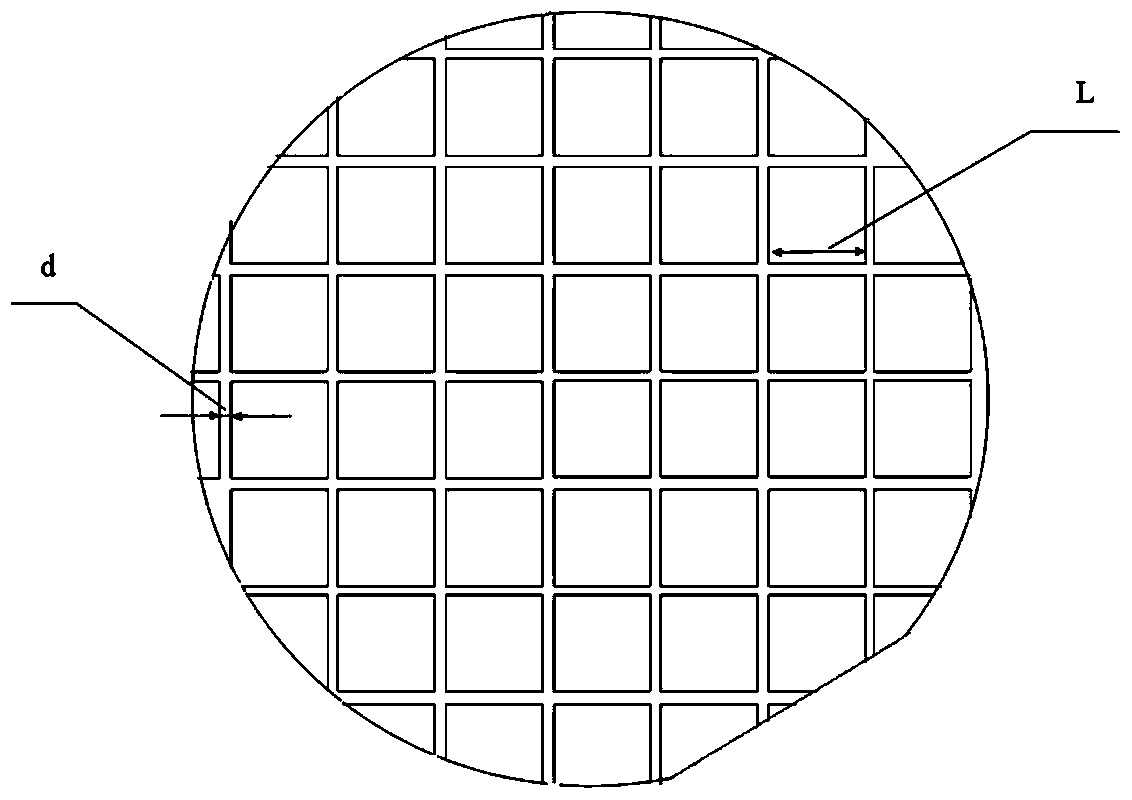

A method of fabricating LED vertical chips using wafer-level Si pattern substrates

ActiveCN105702824BRealize the detection of photoelectric performanceEasy to detectSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsPatterned substrate

The invention discloses a method for manufacturing an LED vertical chip through adoption of a wafer-level Si patterned substrate. The method comprises the following steps of 1, making of a Si patterned substrate; 2, growing of an LED epitaxial layer; 3, making of a Sio[2] barrier layer; 4, making of an anticorrosive layer; 5, filling of photoresist in groove portions; 6, electroplating of a Cu supporting layer; 7, corrosion of the Si patterned substrate; 8, making of N electrodes; and 9 segmenting of the vertical chip. According to the invention, the Si substrate is peeled off to radically solve problems of Si light adsorption; meanwhile, the Sio[2] barrier layers are introduced into the groove portions, so that detection of photoelectric properties of the vertical chip at the dimension of a wafer can be realized without cutting of the chip; and the method is suitable for making of vertical chips of Si patterned substrates of any wafer-level, and has advantages of a simplified detection procedure and good compatibility.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

High-precision aluminum profile plate cutting machine

ActiveCN113385737AEasy to installPlay the effect of automatic cuttingMetal sawing devicesEngineeringWorkbench

The invention relates to a high-precision aluminum profile plate cutting machine. The high-precision aluminum profile plate cutting machine comprises a workbench, a cutting device is arranged on the workbench, the cutting device comprises a cutting saw blade arranged in the workbench through a driving mechanism, a cutting strip hole matched with the cutting saw blade is formed in the bearing face of the workbench, a bearing frame is further arranged on the workbench, the bearing frame is connected with a plurality of limiting pipes used for limiting aluminum profile workpieces through a plurality of lifting mechanisms, limiting strip holes corresponding to the cutting strip hole are formed in the sides, facing the workbench, of the limiting pipes, and the limiting strip holes are matched with the cutting saw blade. According to the high-precision aluminum profile plate cutting machine, the aluminum profile workpieces can be conveniently and fixedly installed on the cutting end face of the workbench, the placed aluminum profile workpieces can be automatically cut, and therefore the stability of the aluminum profile workpieces can be improved, the situation that the aluminum profile workpieces deviate during cutting is reduced, and therefore, the cutting precision of the aluminum profile workpieces can be improved, and potential safety hazards existing in the cutting process are reduced.

Owner:佛山市南海简佳铝业有限公司

A kind of waste cylindrical lithium battery pretreatment device and pretreatment method

ActiveCN109904547BHigh degree of automationSimple structureWaste accumulators reclaimingProcess efficiency improvementControl systemProcess engineering

The invention discloses a waste cylindrical lithium battery pretreatment device and a pretreatment method, belonging to the technical field of waste lithium battery recycling. The waste cylindrical lithium battery pretreatment device of the present invention includes: an automatic sorting device, a transmission mechanism, a power monitoring actuator, a non-destructive testing system, a flexible gripper mechanism, an automatic cutting mechanism, an automatic separation mechanism, a recycling dust collection system and a control system. Among them, the automatic sorting device, transmission mechanism, flexible gripper mechanism, automatic cutting mechanism, automatic separation mechanism and recycling dust collection system are connected in sequence. The power monitoring actuator and non-destructive testing system are all set above the transmission mechanism. Information reception and instruction sending of components. The waste cylindrical lithium battery pretreatment device of the present invention has simple structure, high degree of automation, convenient operation, high dismantling efficiency, and has the characteristics of green, intelligent and flexible.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Cutting equipment for garment processing

ActiveCN108842425BReduce lossesAccurate positioning and croppingSevering textilesDrive wheelTransmission belt

The invention discloses cutting equipment for garment processing. The equipment comprises a workbench, wherein the two ends in the length direction of the workbench are provided with a fixing plate and a moving plate, the other two ends of the workbench are provided with first sliding grooves respectively, the bottom of the moving plate is slidably connected in the first sliding grooves through first sliding blocks, the two ends of the fixing plate are connected with the moving plate through telescopic rods respectively, the sides, close to each other, of the two telescopic rods are provided with a driving roller and a driven roller respectively, two insertion holes provided with first limiting sleeves are formed in the fixing plate, the driving roller and the driven roller run through thefirst limiting sleeves and are in threaded connection with the first limiting sleeves respectively, the end, away from the moving plate, of the driving roller is provided with a driven wheel, a driving wheel is in transmission connection with the driven wheel at one side through a transmission belt, the driving wheel is connected with a first motor, the side, close to the driving roller, of the driven roller is provided with a leveling mechanism, a press mounting mechanism is arranged between the leveling mechanism and the driving roller, and a cutting mechanism is arranged above the press mounting mechanism. The cutting equipment for garment processing can greatly improve the precision of cutting, reduce cloth loss and reduce cost.

Owner:JIXI YUANDAO AGRI IND TECH

An inductor disconnecting pin device

The invention discloses an inductor wire breaking device, which belongs to the technical field of inductor processing equipment and comprises a wire end clamping mechanism and a wire breaking mechanism. It includes a clamping and fixing seat, a rotating transport component, a height adjustment component and a wire end clamping component. The height adjustment component is installed on the upper end of the rotating transport component. The wire base, the wire breakage adjustment assembly, the wire breakage lifting assembly and the wire breakage assembly, the wire breakage adjustment assembly is mounted on the upper end of the wire breakage base, the wire breakage lifting assembly is fixedly connected on the lift assembly. The invention can straighten the copper wire through the work of the wire end clamping mechanism, which is convenient for positioning and cutting the copper wire, and is also convenient for collecting the cut copper wire. The invention can also be adjusted to be suitable for inductors of different sizes processing.

Owner:国网甘肃省电力公司临夏供电公司

Steel structure automatic forming equipment

ActiveCN111036971AEasy to fixCan't cutShearing machinesMaintainance and safety accessoriesBlade plateKnife blades

The invention discloses steel structure automatic forming equipment, which comprises a shell, a support block, a positioning mechanism, a sealing mechanism and a disassembling mechanism. The positioning mechanism is located on the surface of the top end of the support block, and comprises a fixed plate; and a placing groove is formed in the surface of the top end of the support block, and one sideof the fixed plate is located in the inner part of the placing groove. According to the steel structure automatic forming equipment, through arrangement of the fixed plate, inability of steel to be fixed on the support block is effectively avoided, positioning and cutting are convenient, and thus the product quality of the steel is ensured; through arrangement of a sealing ring, the temperature of the inner part of the equipment is effectively avoided to be too high, when a first connecting plate transmits cooling air to cool down, a loose joint between the shell and a cooling air pipe causescool air to leak out, the cooling efficiency of the equipment is ensured, and the use life of a machine is prolonged; and through arrangement of buttons, the problem that when the equipment needs toreplace a blade on a cutter plate, the process of disassembling the cutter plate is tedious is effectively avoided, and the labor cost is saved.

Owner:XUZHOU NANFANG YONGCI MATERIAL

A high-precision aluminum profile cutting machine

ActiveCN113385737BEasy to installPlay the effect of automatic cuttingMetal sawing devicesClassical mechanicsStructural engineering

The application relates to a high-precision aluminum profile cutting machine, which includes a worktable, and a cutting device is arranged on the worktable. The cutting device includes a cutting saw blade arranged inside the worktable through a driving mechanism. The cutting bar hole matched with the cutting saw blade is also provided with a carrier frame. The carrier frame is respectively connected with a plurality of limit tubes for limiting the position of the aluminum profile workpiece through a plurality of lifting mechanisms. The limit tubes face One side of the worktable is provided with a limit bar hole corresponding to the cutting bar hole, and the limit bar hole is matched with the cutting saw blade. The present application can not only facilitate to fasten and install the aluminum profile workpiece on the cutting end face of the worktable, but also can automatically cut the placed aluminum profile workpiece, so that the stability of the aluminum profile workpiece can be improved, so that the In order to reduce the deviation of the aluminum profile workpiece during cutting, it can improve the cutting accuracy of the aluminum profile workpiece and reduce the potential safety hazards during cutting.

Owner:佛山市南海简佳铝业有限公司

A kind of plate shearing machine and the production process of explosion-proof wave valve using the plate shearing machine

ActiveCN112692348BReduce tensionEasy to position and cutShearing machinesShearing machine accessoriesCompression deviceEngineering

The present application relates to a shearing machine and the production process of the explosion-proof wave valve using the shearing machine. Knife and the first driving member that drives the upper cutting knife to slide vertically, a space for plate cutting is formed between the lower cutting knife and the upper cutting knife, and a pressing device is arranged on the upper cutting knife. The pressing device includes a protective net frame arranged on the upper cutting knife, a pressing plate connected to the protective net frame by sliding in the vertical direction, and a pressing spring for maintaining the pressing state of the pressing plate and the sheet material. The protective screen frame is located on the side of the lower cutting knife towards the feeding end, and the surface of the pressing plate close to the lower cutting knife is used to press against the plate. This application has the effect of cutting precision of the sheet.

Owner:浙江银安人防设备有限公司

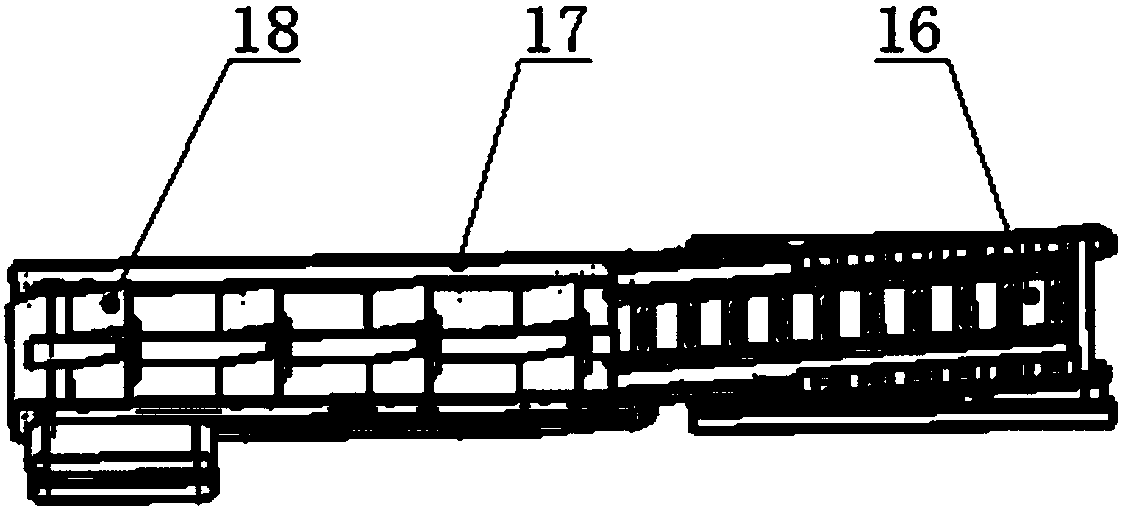

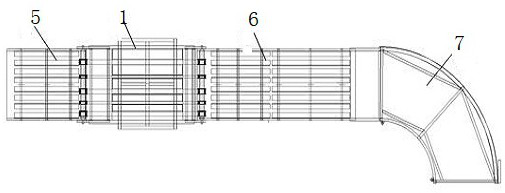

Tobacco leaf bundle head automatic arranging and aligning device

ActiveCN114711453AAlignment EfficientQuality assuranceConveyorsTobacco treatmentElectric machineryEngineering

The invention relates to an automatic tobacco leaf bundle head arranging and aligning device, and belongs to the technical field of threshing and redrying equipment. The tobacco leaf bundle head automatic tidying and aligning device comprises a feeding end conveying device, a bundle head automatic tidying and aligning conveying device, a lifting conveying device and a corner conveying device. The feeding end conveying device, the automatic bundle head arranging, aligning and conveying device, the lifting and conveying device and the corner conveying device are all driven by a motor, and the feeding end conveying device, the automatic bundle head arranging, aligning and conveying device, the lifting and conveying device and the corner conveying device are sequentially arranged in an end-to-end connection mode. According to the tobacco bundle head aligning device, the bundle heads are axially conveyed and aligned in the longitudinal conveying process through the longitudinal conveying of the bundle head aligning device and the axial vibration of the transverse conveying system, efficient alignment of the raw tobacco bundle heads is achieved, the structure is simple, after the tobacco bundle heads are fed in the unified direction, automatic arrangement and alignment of the bundle heads can be rapidly achieved, machining of the subsequent procedure is facilitated, and the production efficiency is improved. And accurate positioning and slitting are achieved, and the quality of the slit materials is guaranteed.

Owner:HONGTA TOBACCO GRP

Rapid positioning and cutting device for sapphire machining

InactiveCN109159310ARapid positioningQuick Position CuttingWorking accessoriesFine working devicesElectric machineryEngineering

The invention relates to the technical field of cutting devices, in particular to a rapid positioning and cutting device for sapphire machining. The device comprises a bottom plate; supporting platesare fixedly installed on the two sides of the lower end of the bottom plate, a manual rotating shaft is rotationally arranged between the supporting plates, and a fixing structure is arranged betweenthe manual rotating shaft and the supporting plates; the two ends of the manual rotating shaft between the supporting plates are provided with second side baffles through first transmission structures, a movable plate is fixedly installed on the second side baffles and at the upper end of the bottom plate, and the lower end of the movable plate is connected to the bottom plate through a sliding structure; and first side baffles are fixedly installed on the two sides of the upper end of the movable plate, and an alternating-current servo motor is fixedly installed on the movable plate which isadjacent to the first side baffle on one side. According to the device, sapphire can be rapidly positioned through clamping plates by means of the rotation of the alternating-current servo motor, meanwhile, the movement of the movable plate can be realized through the rotation of the manual rotating shaft, so that the cutting is facilitated; and a cutting disc can cut the sapphire and can be paused in real time due to the existence of a pressing rod.

Owner:TDG YINXIA NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com