Stainless steel panel cutting and positioning die

A technology for positioning molds and stainless steel, applied in manufacturing tools, welding equipment, laser welding equipment, etc., can solve problems such as insufficient positioning accuracy, insufficient positioning stability, cutting deviation, etc., to achieve good cutting effect, improve cutting accuracy, and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

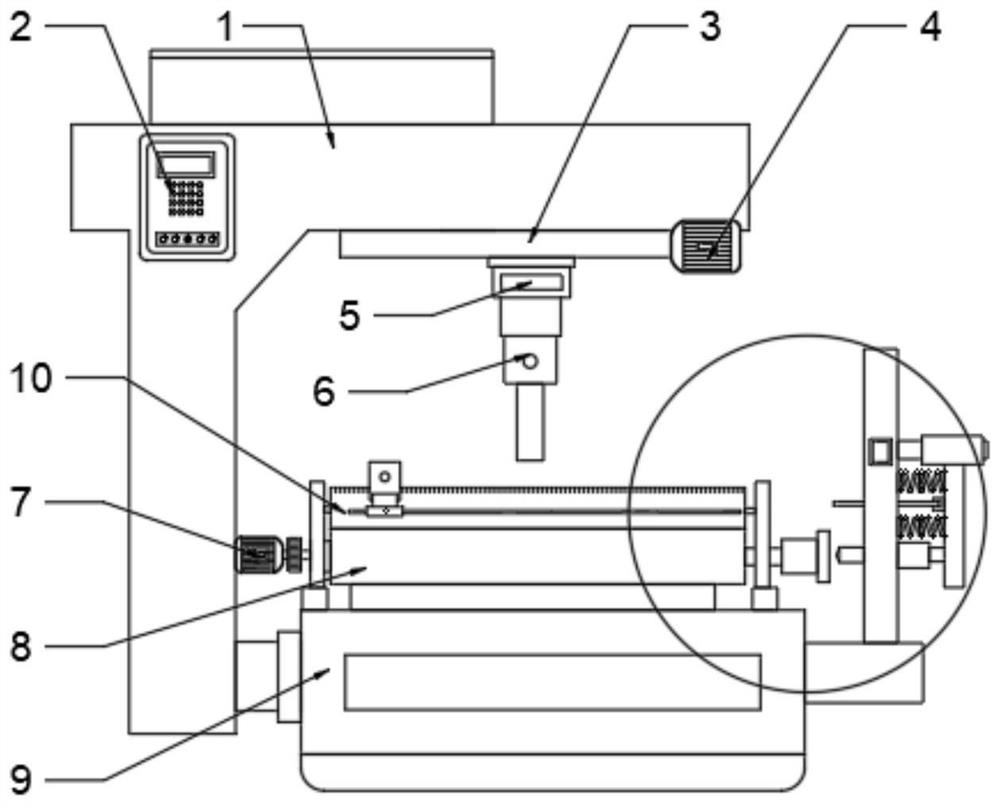

[0021] see Figure 1~3 , in an embodiment of the present invention, a stainless steel panel cutting and positioning mold includes a workbench 9; a work frame 1 is fixedly installed on one side of the work table 9; an operation panel 2 and a laser cutting mechanism are installed on the work frame 1 A transmission mechanism 8 is installed on the top of the worktable 9; a mold shell 10 is provided on the worktable 9; a positioning mechanism is provided on one side of the workbench 9 corresponding to the transmission mechanism 8.

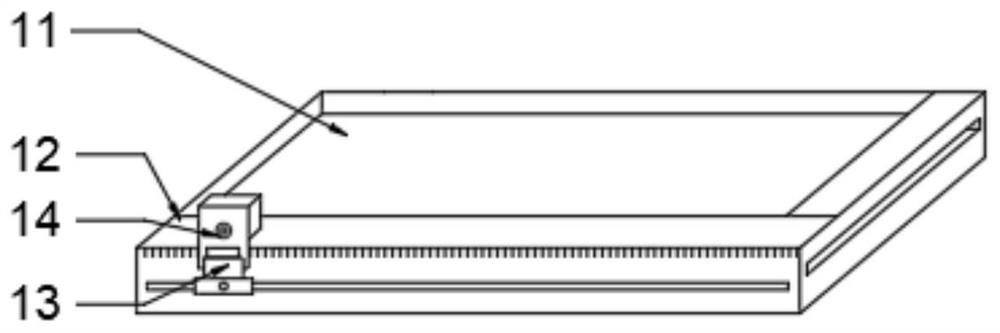

[0022] Further, the mold shell 10 includes a mold cavity 11 and a mounting plate 12; the mold cavity 11 is clamped with a stainless steel plate; the mounting plate 12 is provided with a locator 13; the front of the mold shell 10 is provided with scale.

[0023] Further, the back of the positioner 13 is provided with a limit sliding block; the front of the positioner 13 is provided with an infrared light emitting lamp 14; the corresponding limit slide o...

Embodiment 2

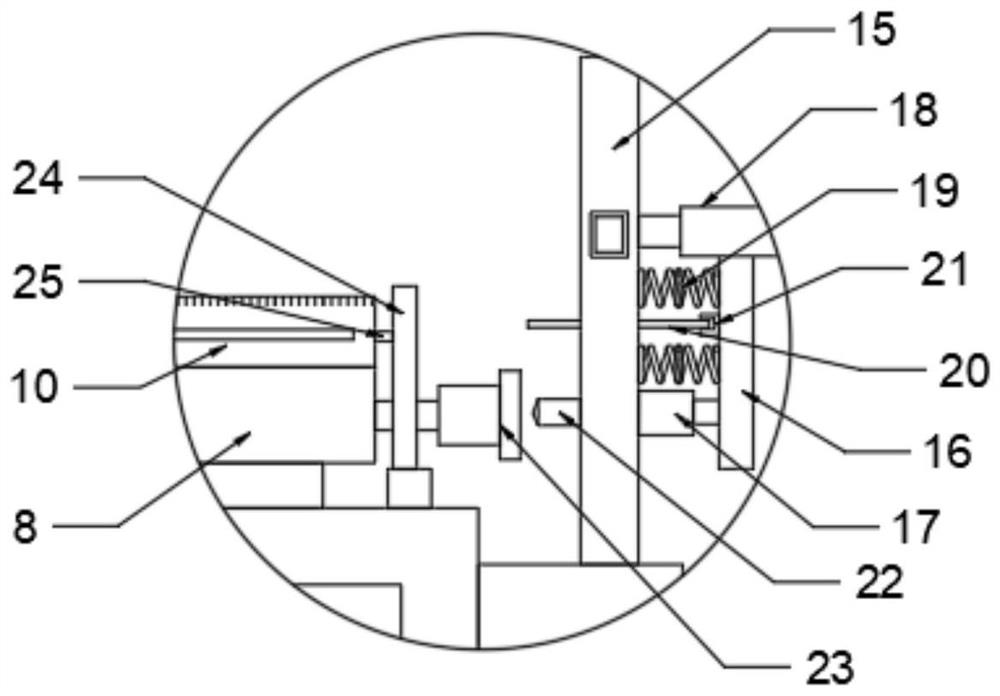

[0028] see image 3 , the top of the workbench 9 is equipped with a guide frame 24; the guide frame 24 is equipped with a guide block 25 near the side of the mold shell 10; the corresponding guide block 25 is provided with a limit chute on the mold shell 10; through the guide The arrangement of the block 25 and the limit chute prevents the mold shell 10 from shifting when cutting.

[0029]The working principle of the present invention is: through the setting of No. 1 guide rail 3, No. 1 servo motor 4 and longitudinal adjustment mechanism 5, it is convenient for laser cutting edge 6 to cut; through the cooperation of photoelectric sensor and infrared light emitting lamp 14, accurate positioning and cutting are performed; The rotation of the eccentric wheel 20 driven by the micro servo motor can change the distance between the installation fixed plate 16 and the fixed plate 15, and then change the position of the positioning head 22. When cutting is required, the positioning hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com