Patents

Literature

37results about How to "Accurate cutting positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic pipe cutting device

InactiveCN105082230AAutomatic cutting workReduce lossMetal working apparatusElectric machineryPosition sensor

The invention discloses a plastic pipe cutting device comprising a fixing mechanism, a base and a sliding platform arranged on the base. The sliding platform is electrically connected with a position sensor. The position sensor is connected with a motor. The sliding platform is further provided with a cutting mechanism. The cutting mechanism comprises a tool rest and a blade fixed to the tool rest. The blade is a reversed-V-shaped blade. The fixing mechanism comprises an air cylinder, an installation frame and a fixing head. The top of the installation frame is connected with the air cylinder. The fixing head is installed on the air cylinder. The installation frame is fixed to the base. The plastic pipe cutting device aims at solving the problems that in the existing pipe cutting process, locating is inaccurate, and cut pipes are prone to deformation.

Owner:CHONGQING XIN CHUAN TA IND

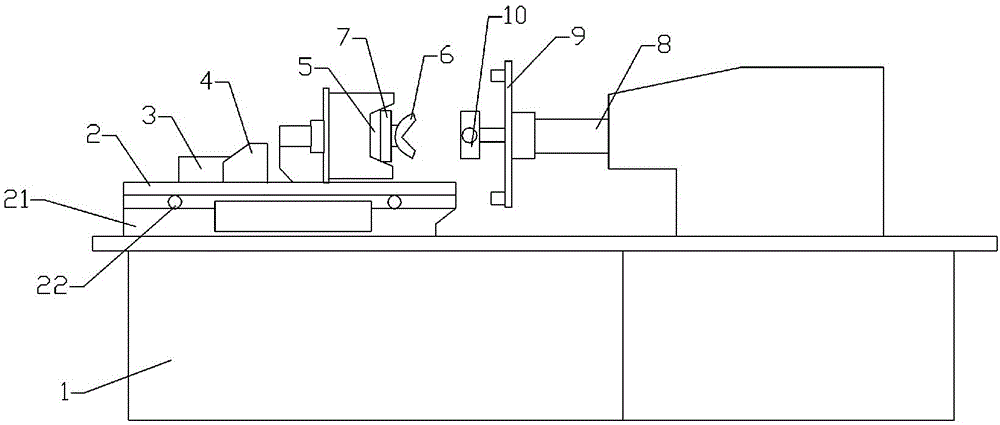

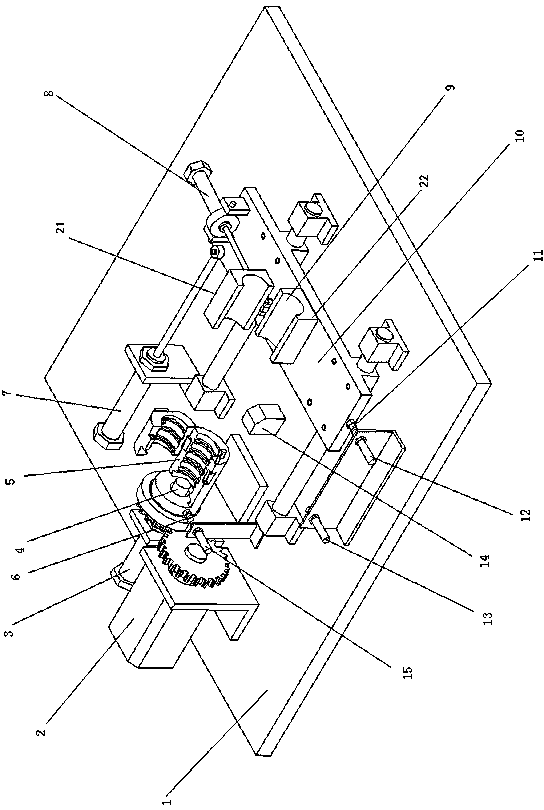

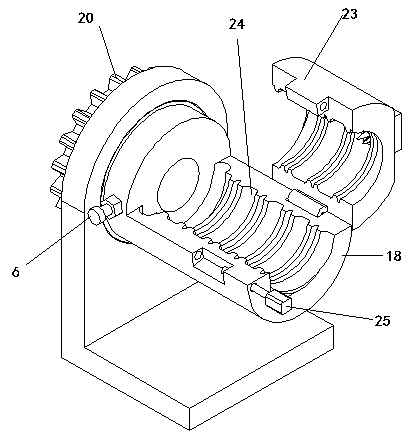

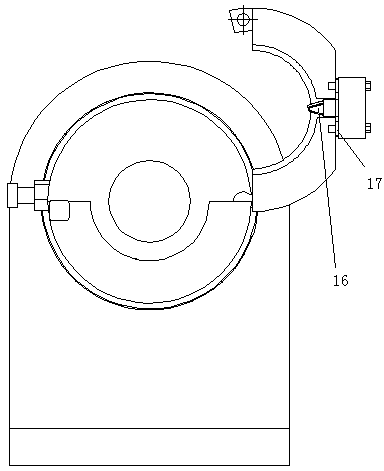

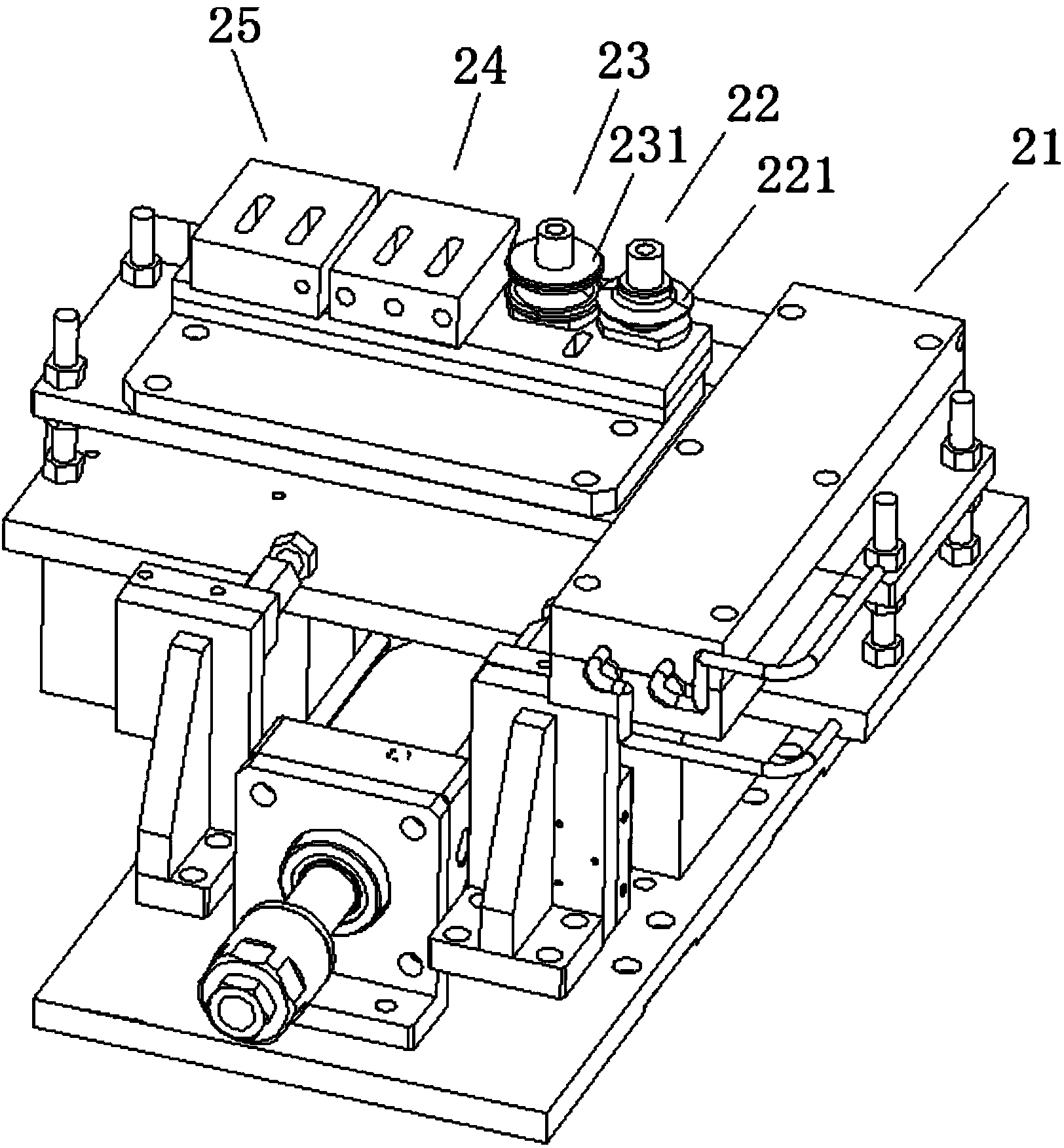

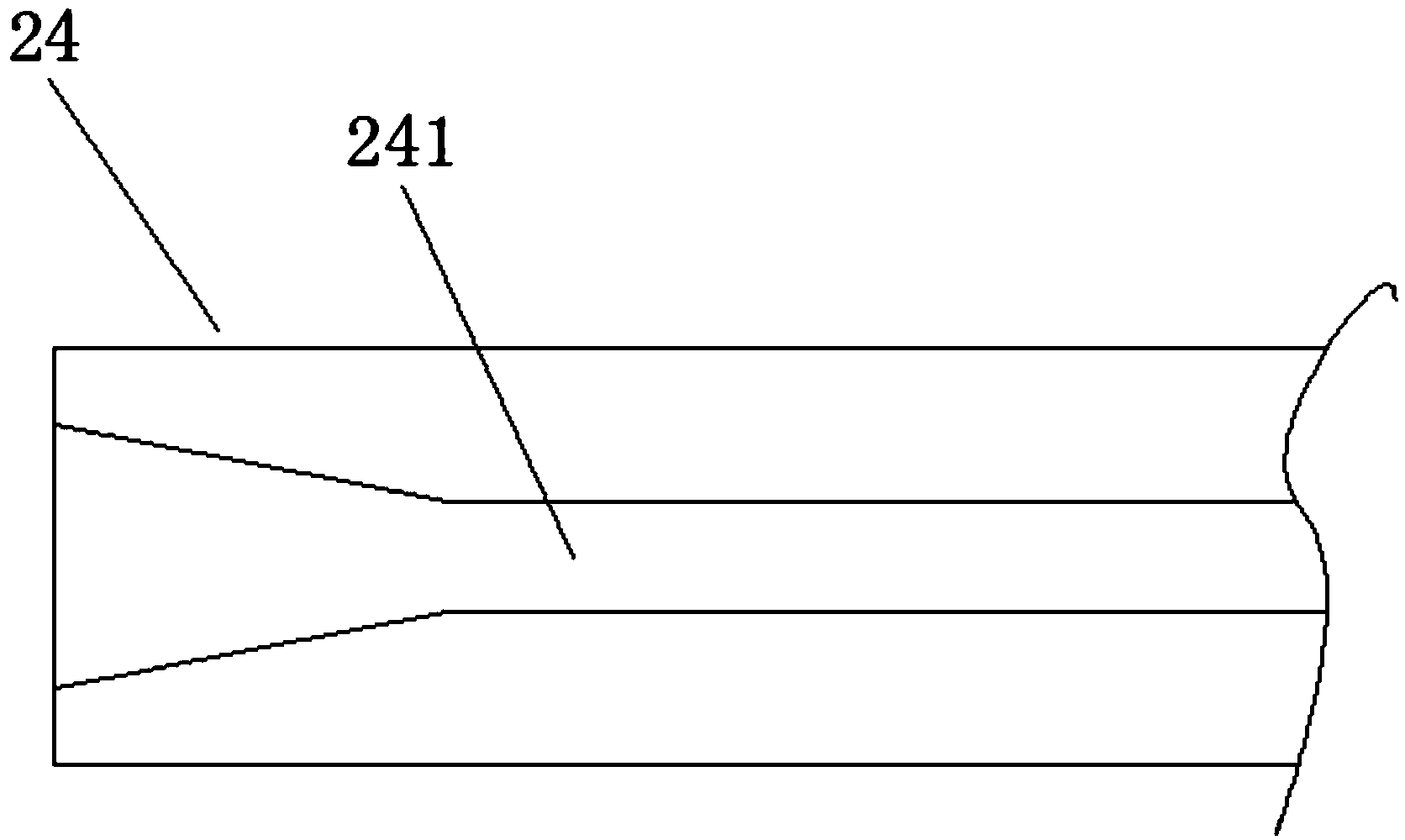

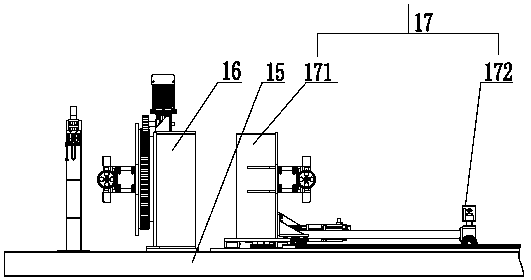

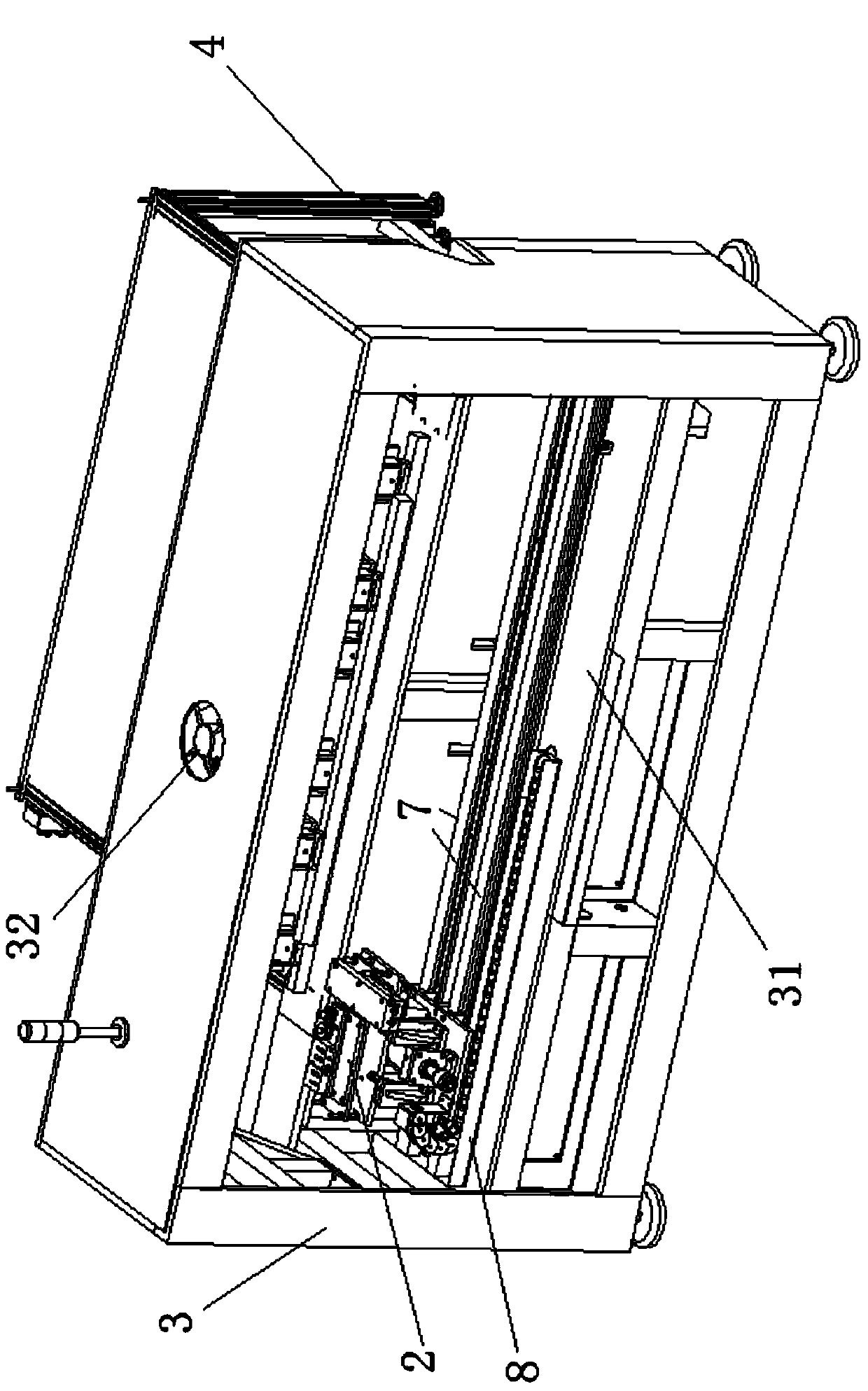

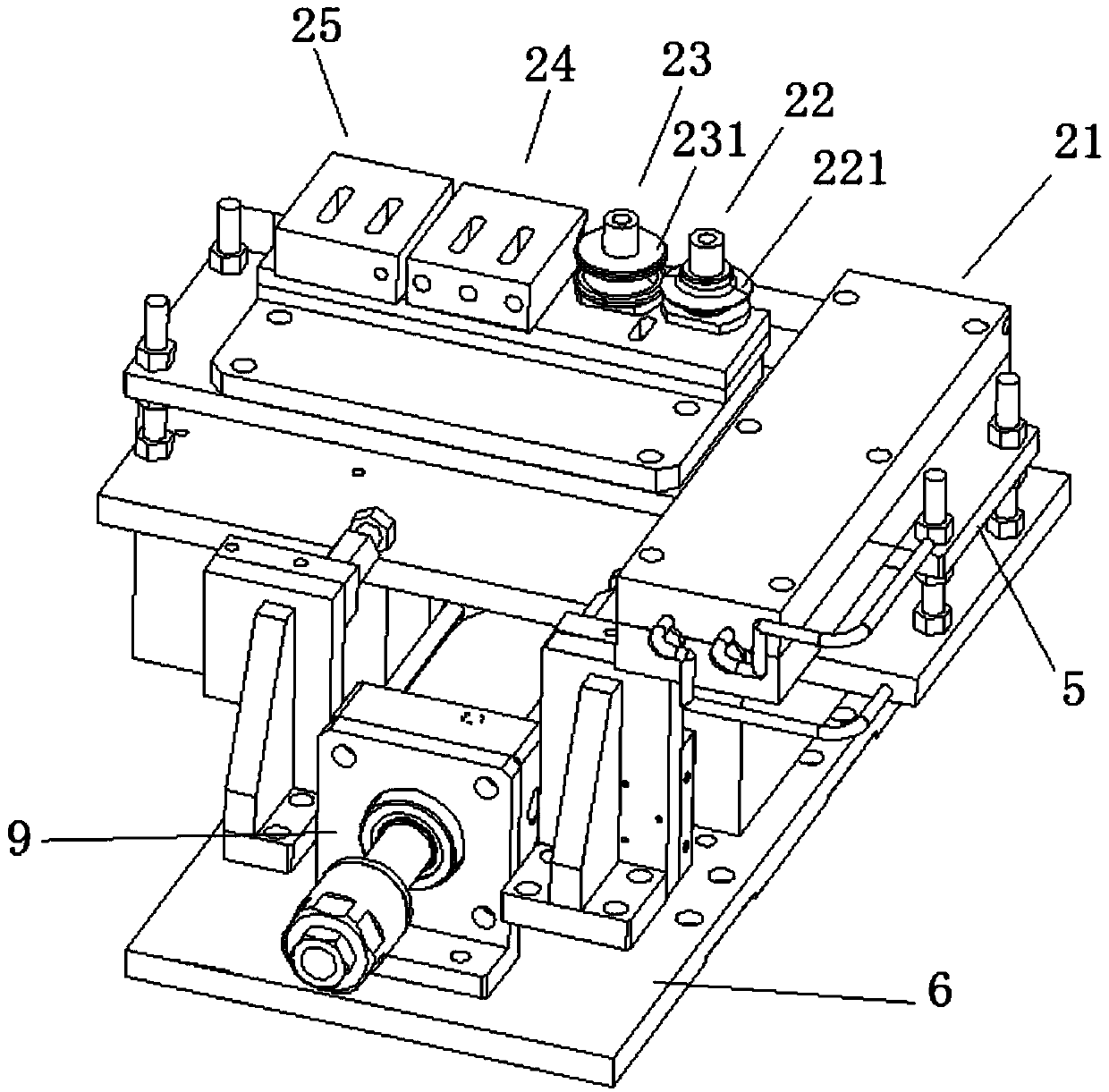

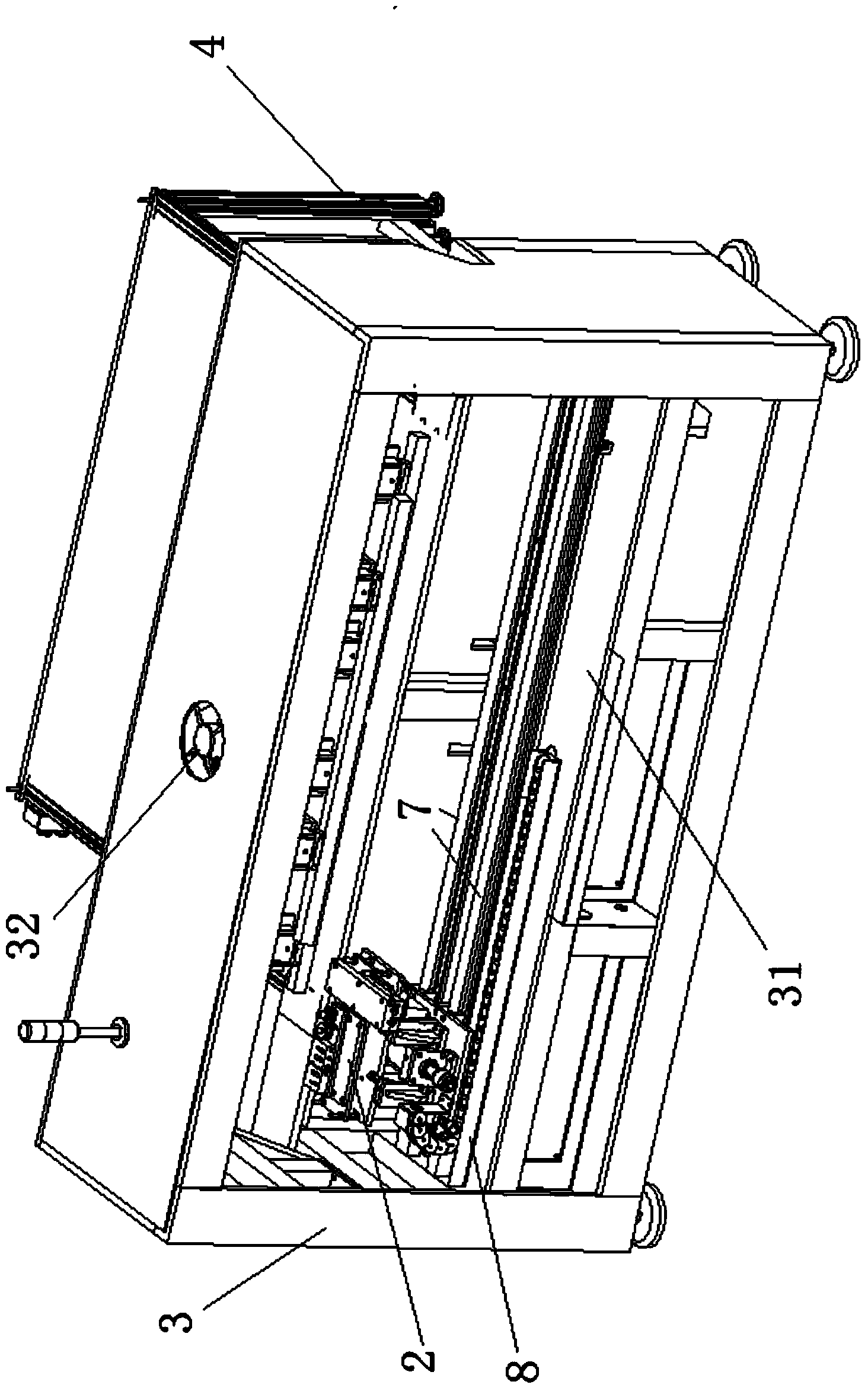

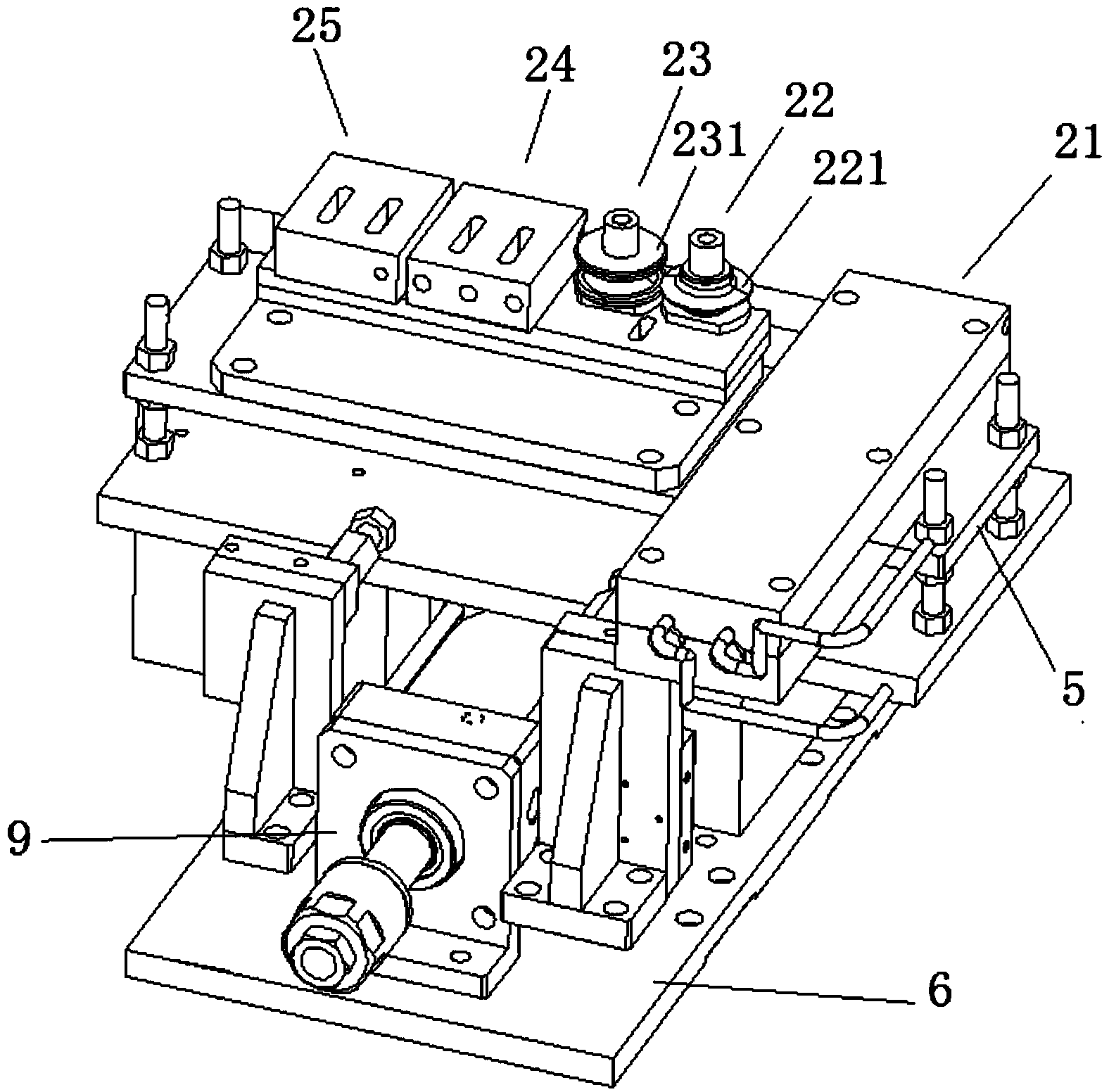

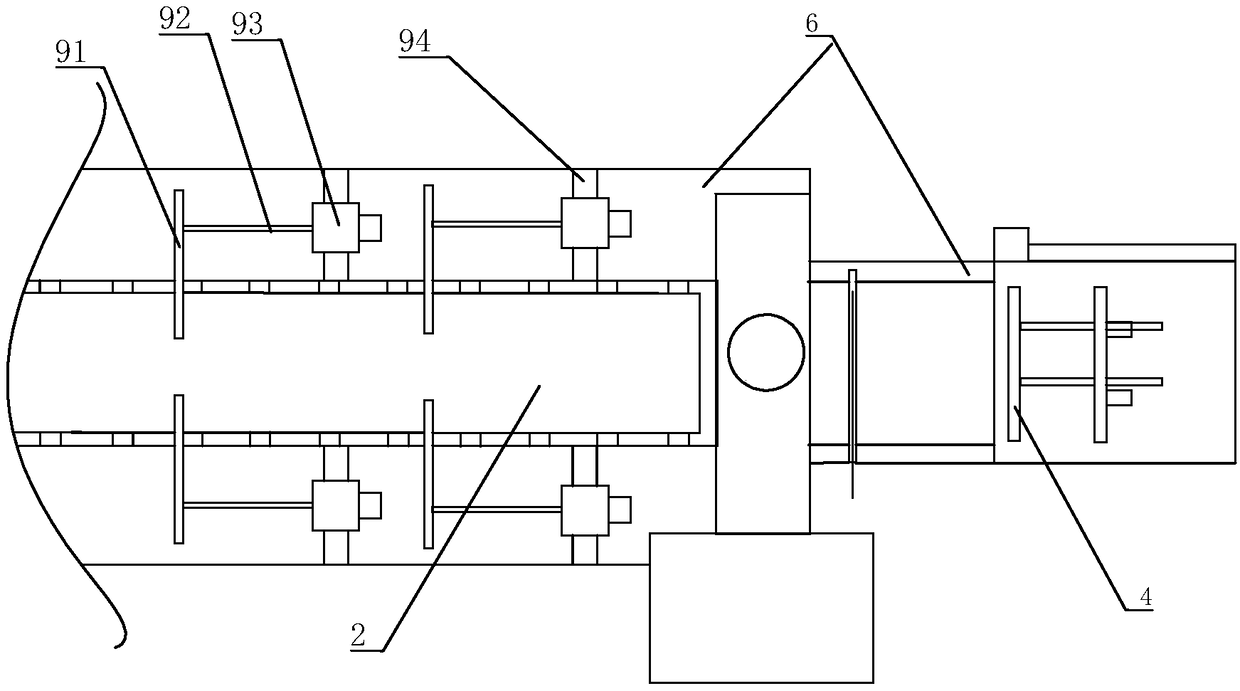

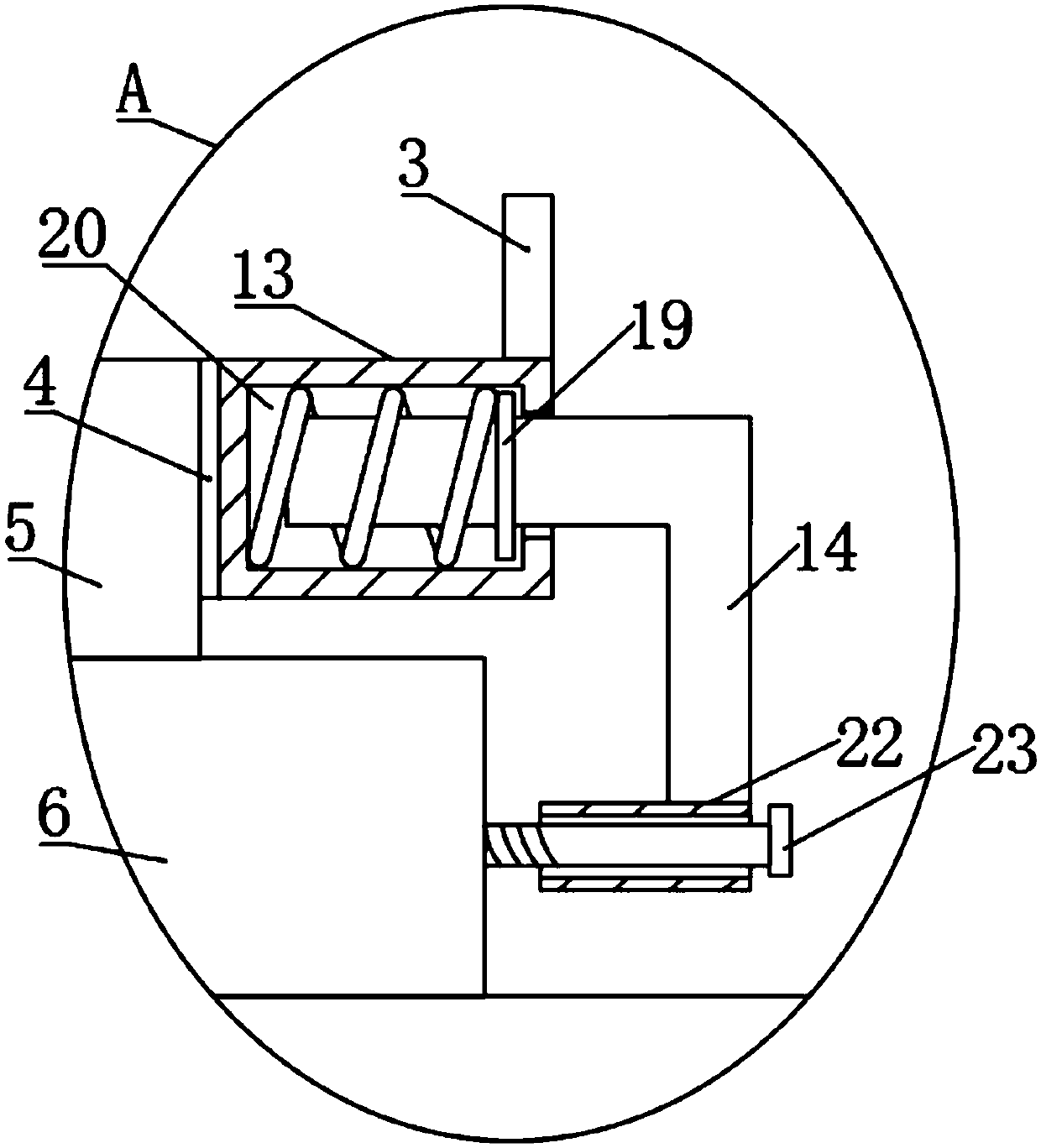

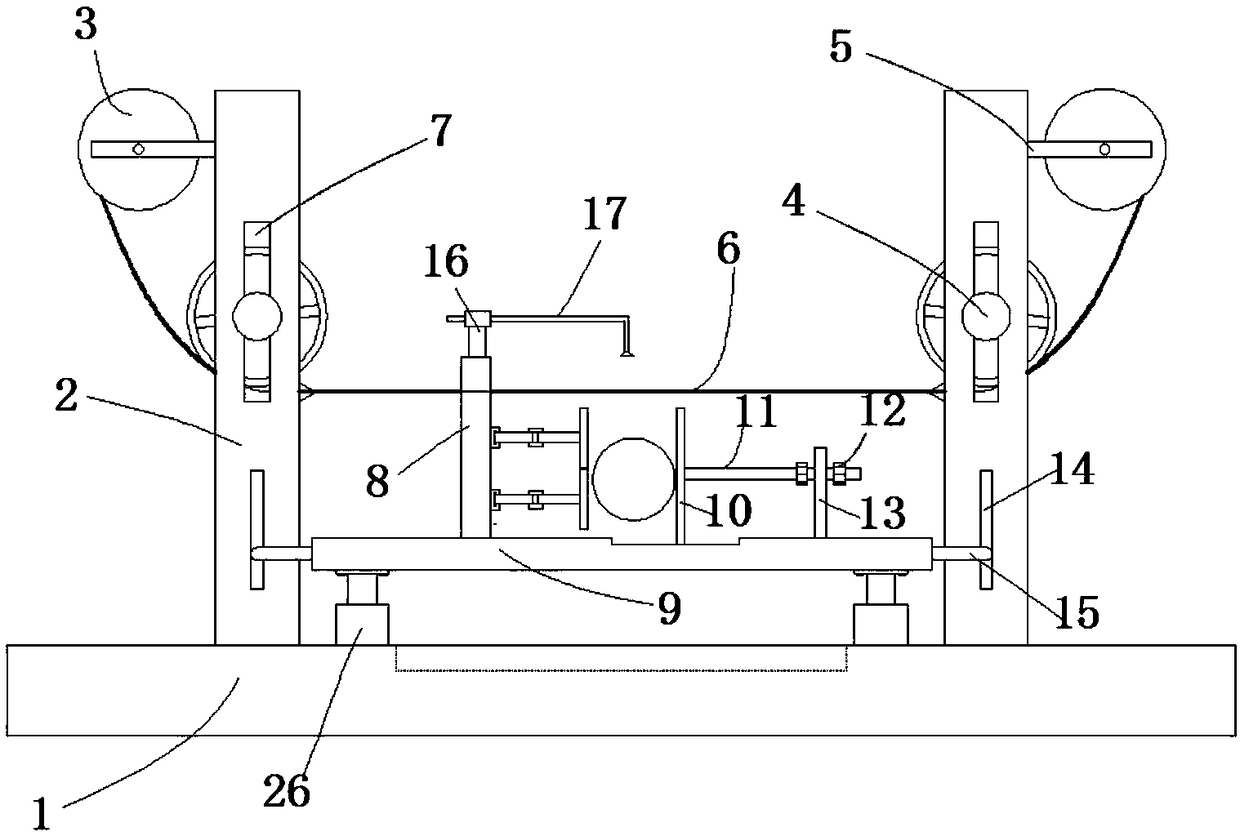

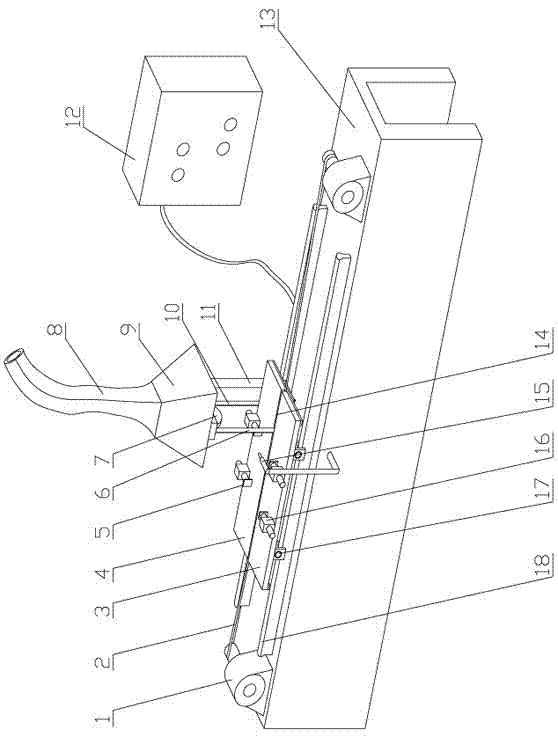

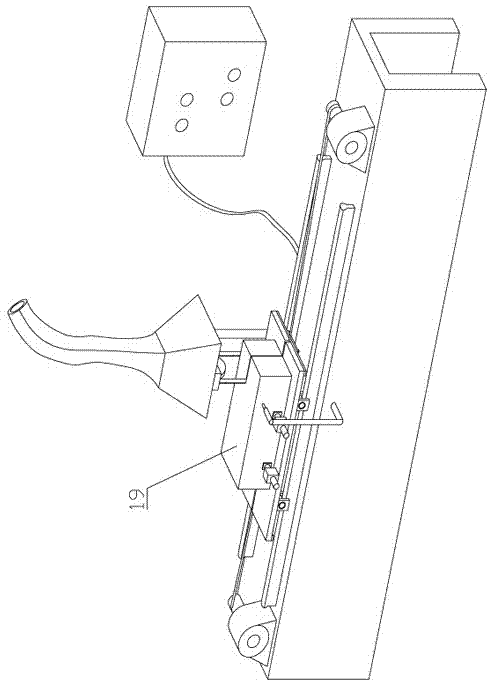

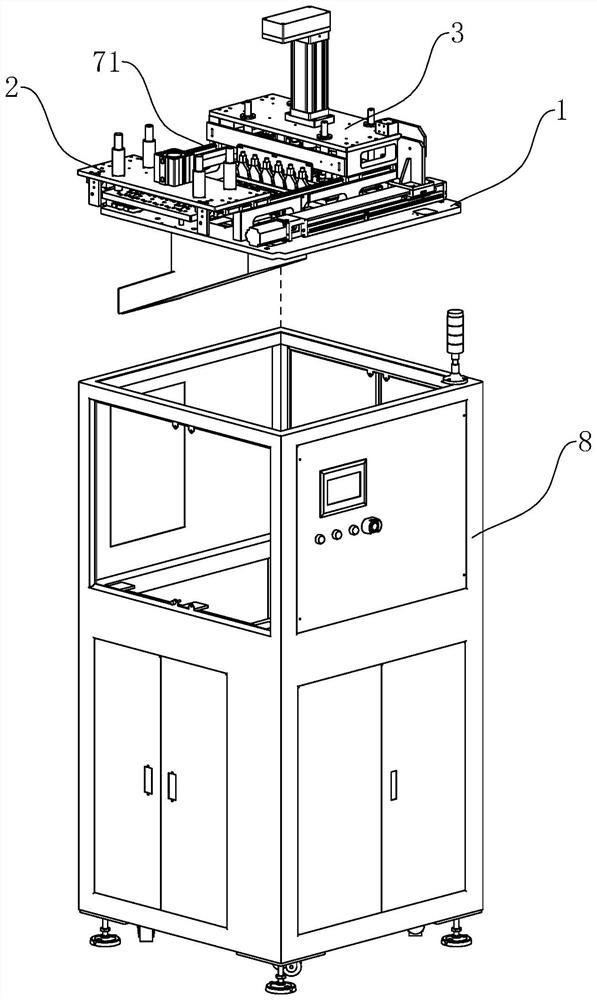

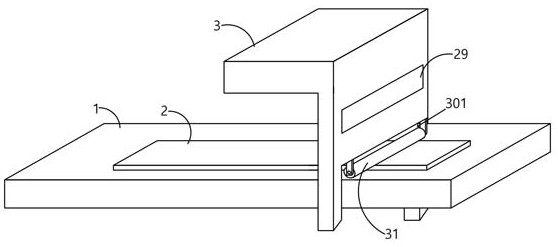

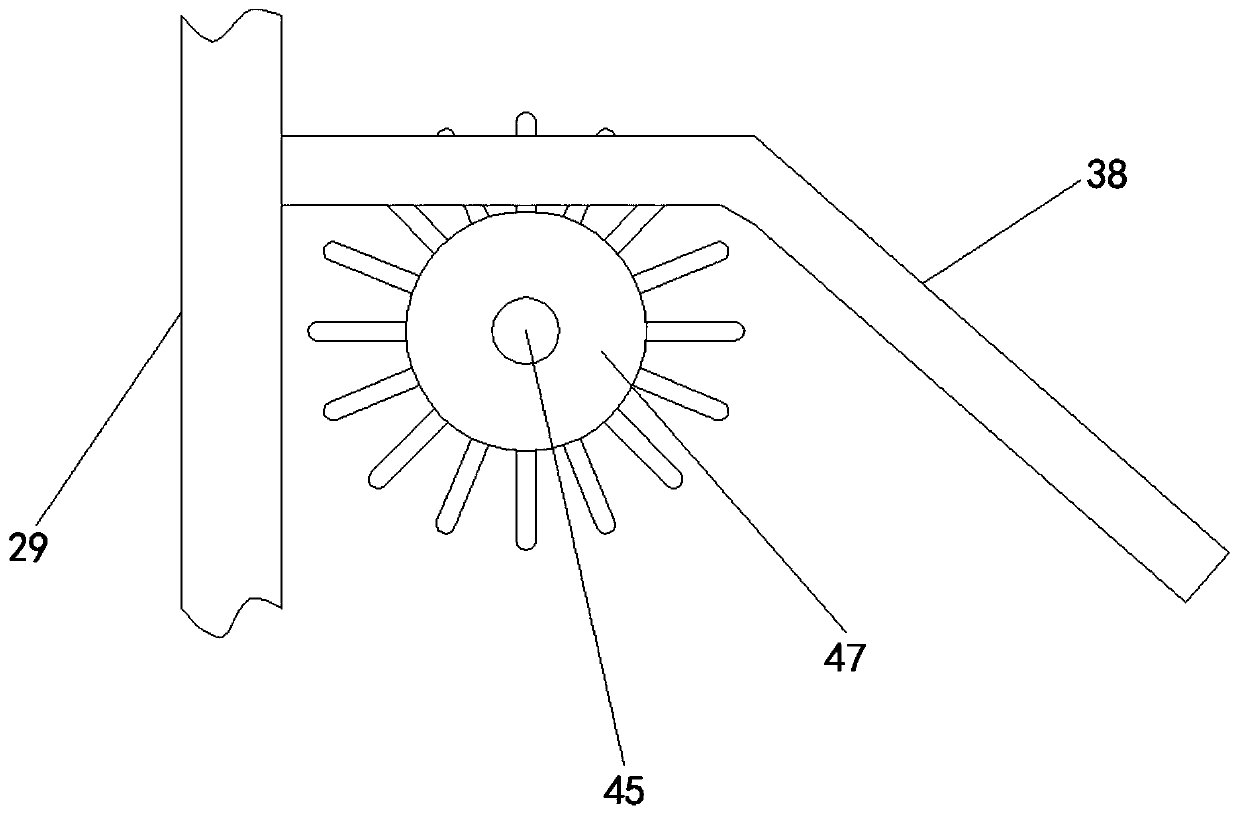

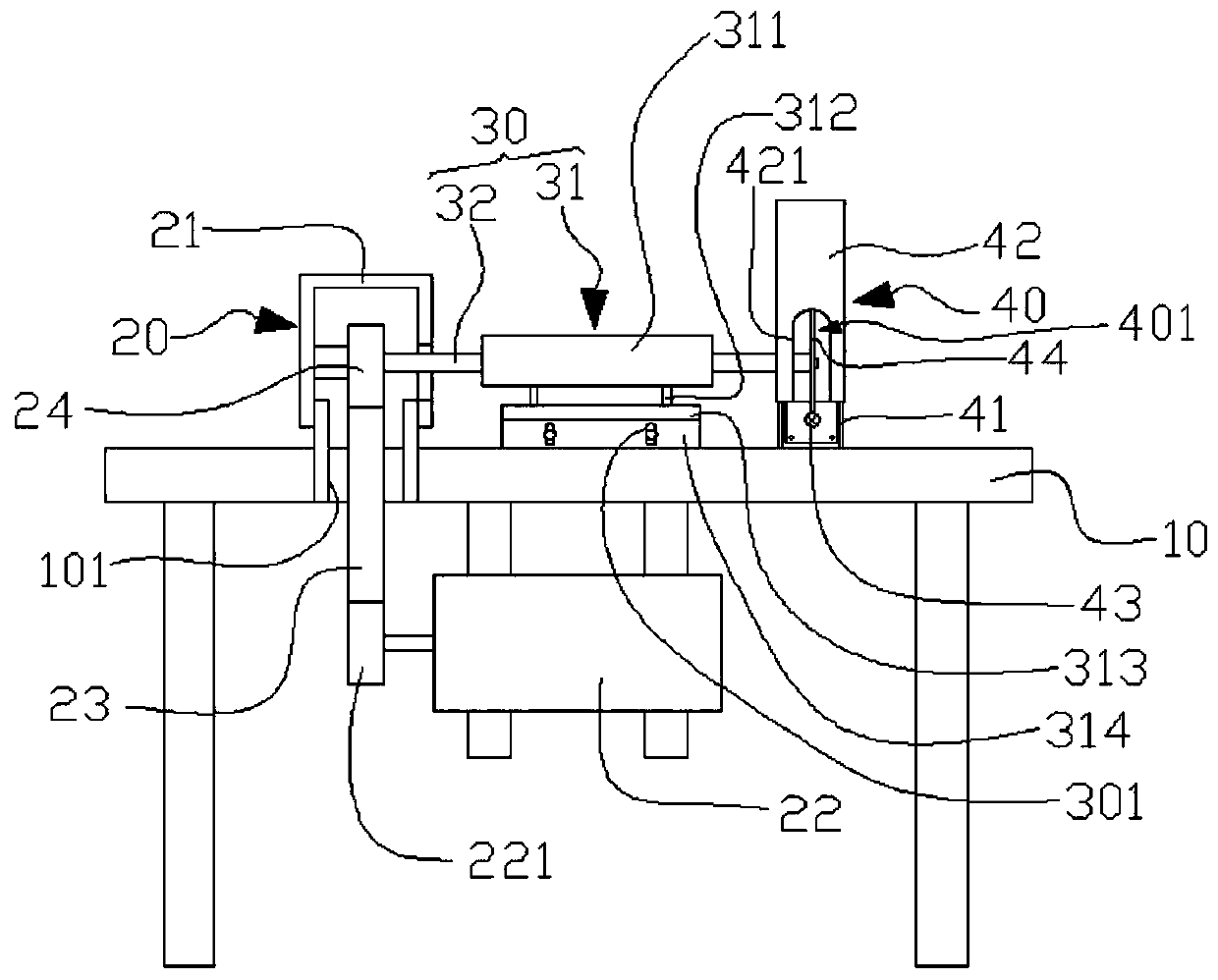

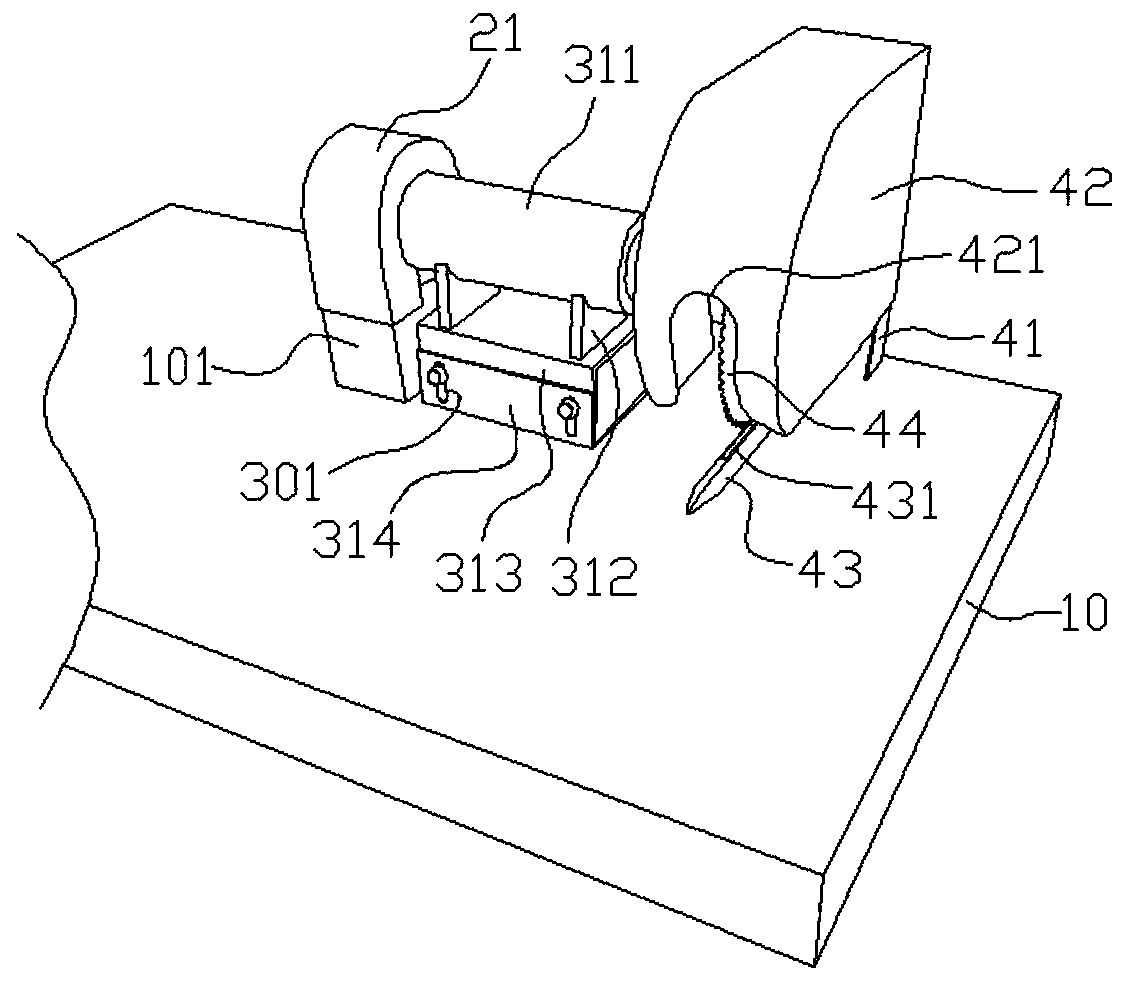

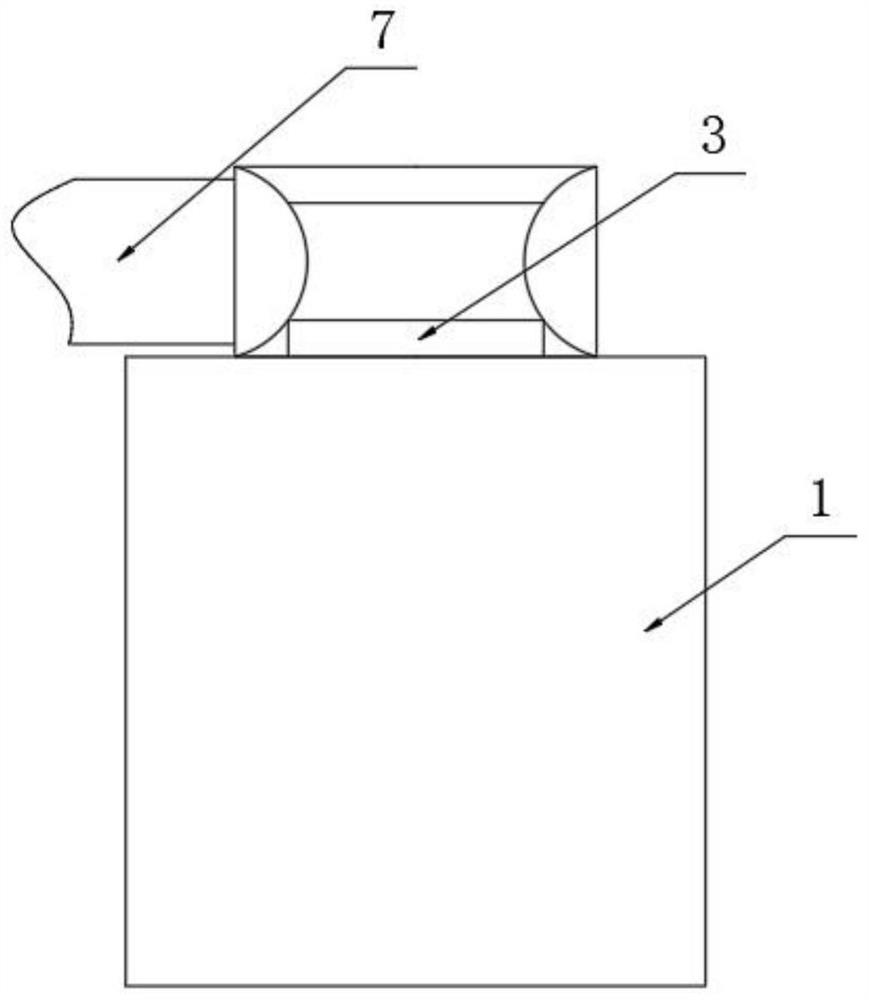

Peeling device for hollow spiral electrifying hose of dust collector and application method thereof

ActiveCN110086125AAchieve reductionRealize accurate positioning of cutting positionApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to the technical field of electrifying hose processing, and relates to a peeling device for a hollow spiral electrifying hose of a dust collector and an application method thereof. The peeling device comprises a base, a rotary cutter, a servo motor, a first cylinder, a second cylinder, a third cylinder, a guide rail sliding table, a hose clamping device, a hose inner jackingrod, a first induction switch, a second induction switch, a third induction switch and a fourth induction switch. The peeling device can accurately position and cut external rubber of the hollow spiral electrifying hose through the cooperation of the devices, accurately controls the cutting length, reduces the difficulty of manual peeling and improves the production efficiency.

Owner:常熟市雷得双金属复合管业有限公司 +1

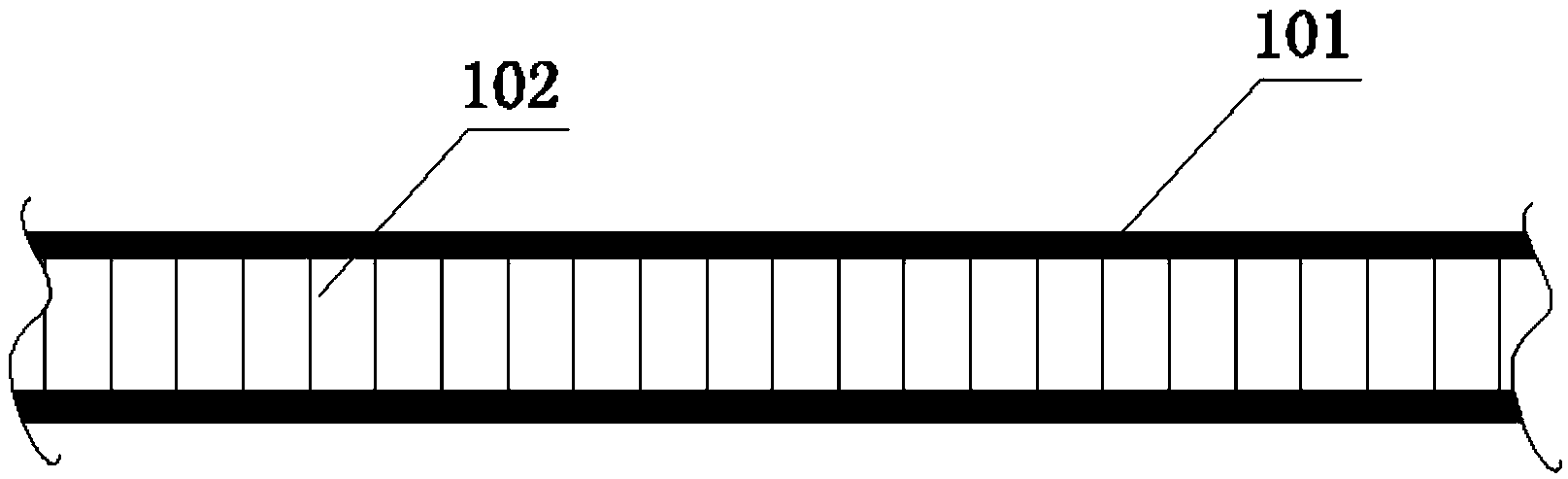

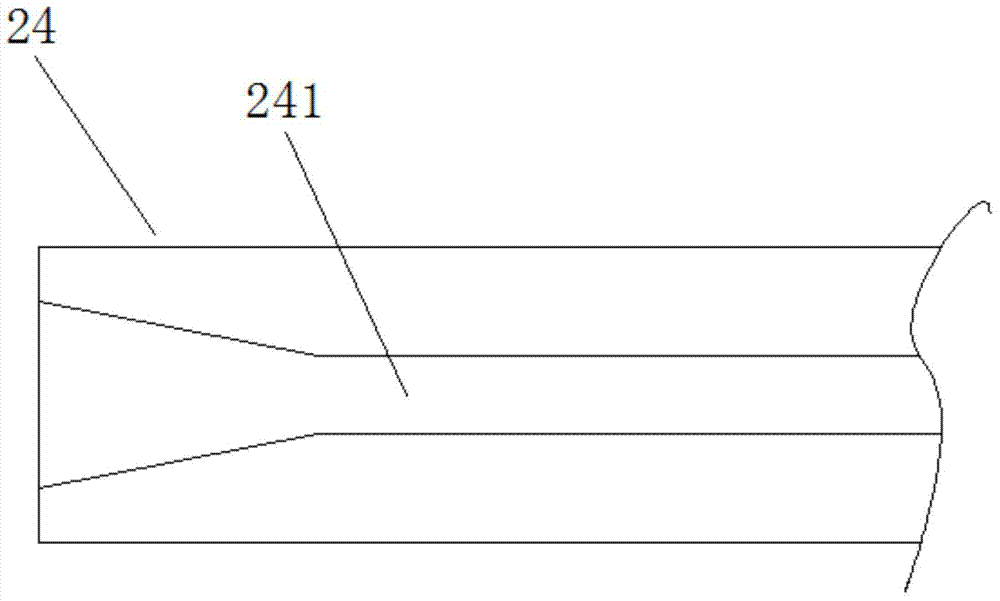

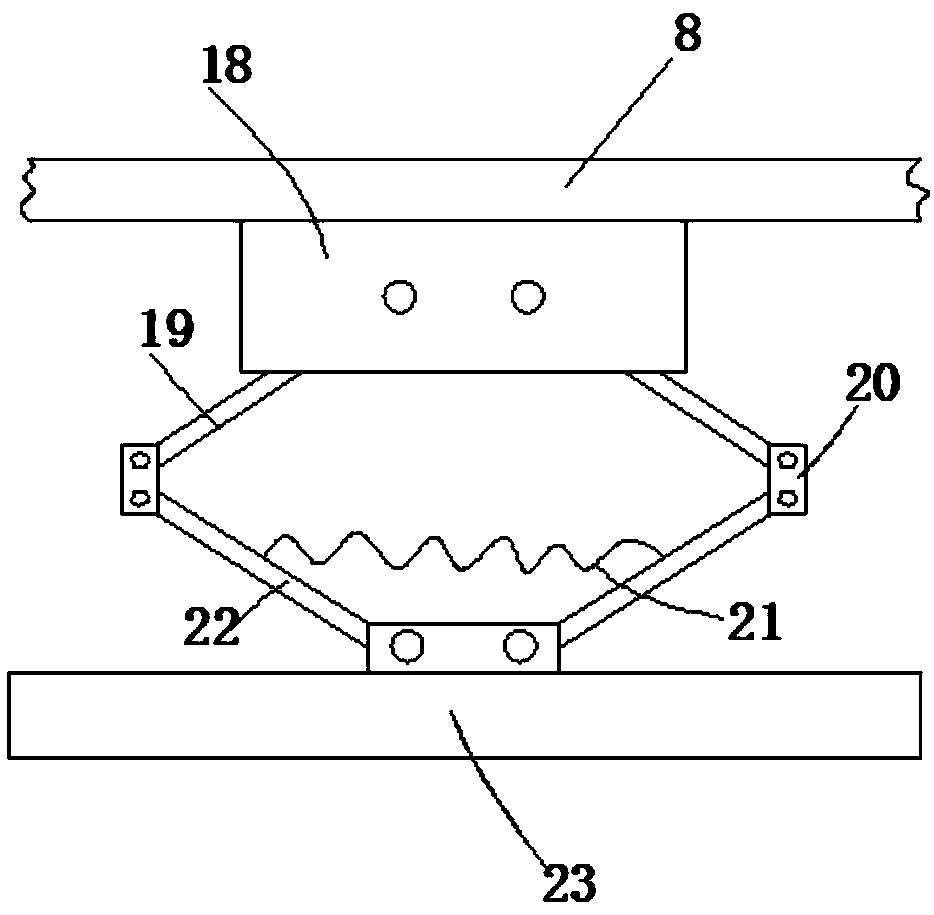

Hollow plate edge bonding forming system

The invention discloses a hollow plate edge bonding forming system. The hollow plate bonding forming system comprises a heating unit which is at least used for heating the side part of a hollow plate until softening, a thermal cutting unit which is at least used for cutting a reinforcing rib in the side part of the softened hollow plate, a hot contracting unit for contracting the side part of the cut hollow plate, a thermal forming unit for processing the side part of the contracted hollow plate to be in a set sealing form and a cooling forming unit for cooling the side part of the hollow plate with a set form for forming. The hollow plate edge bonding forming system has the advantages that the structure is simple, the manufacture cost is low, the cutting location of the hollow plate is accurate, the edge bonding effect is good, the cost is effectively lowered, the product quality is improved, and the yield is increased.

Owner:SUZHOU HOLDEN AUTO

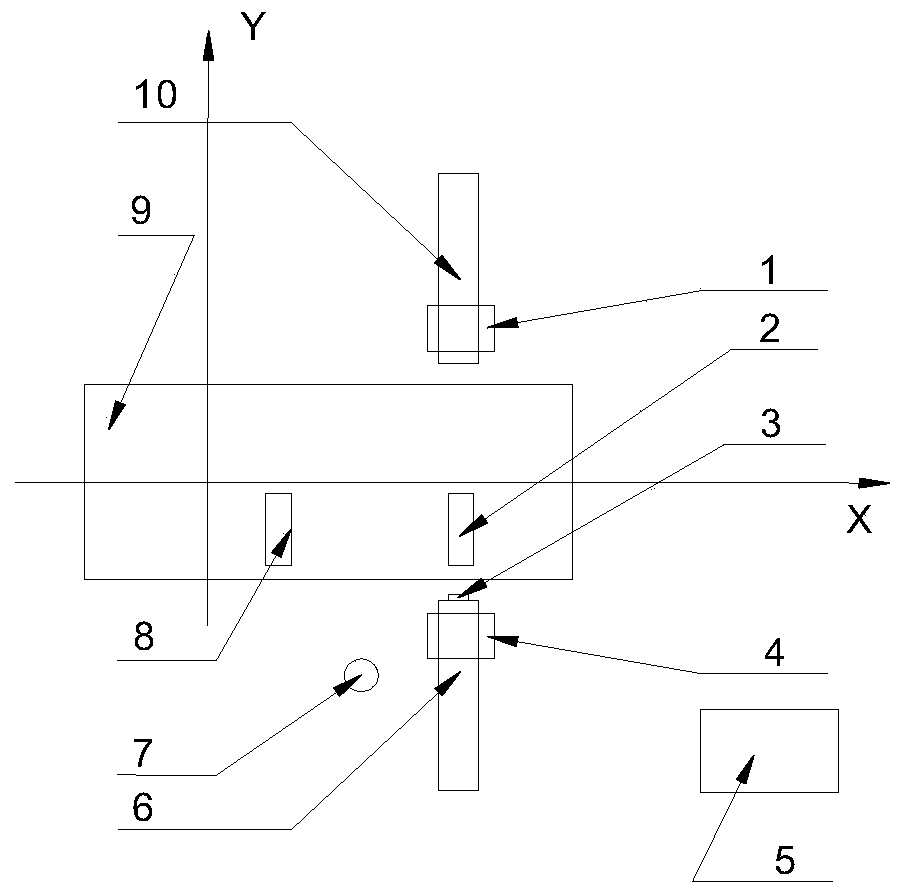

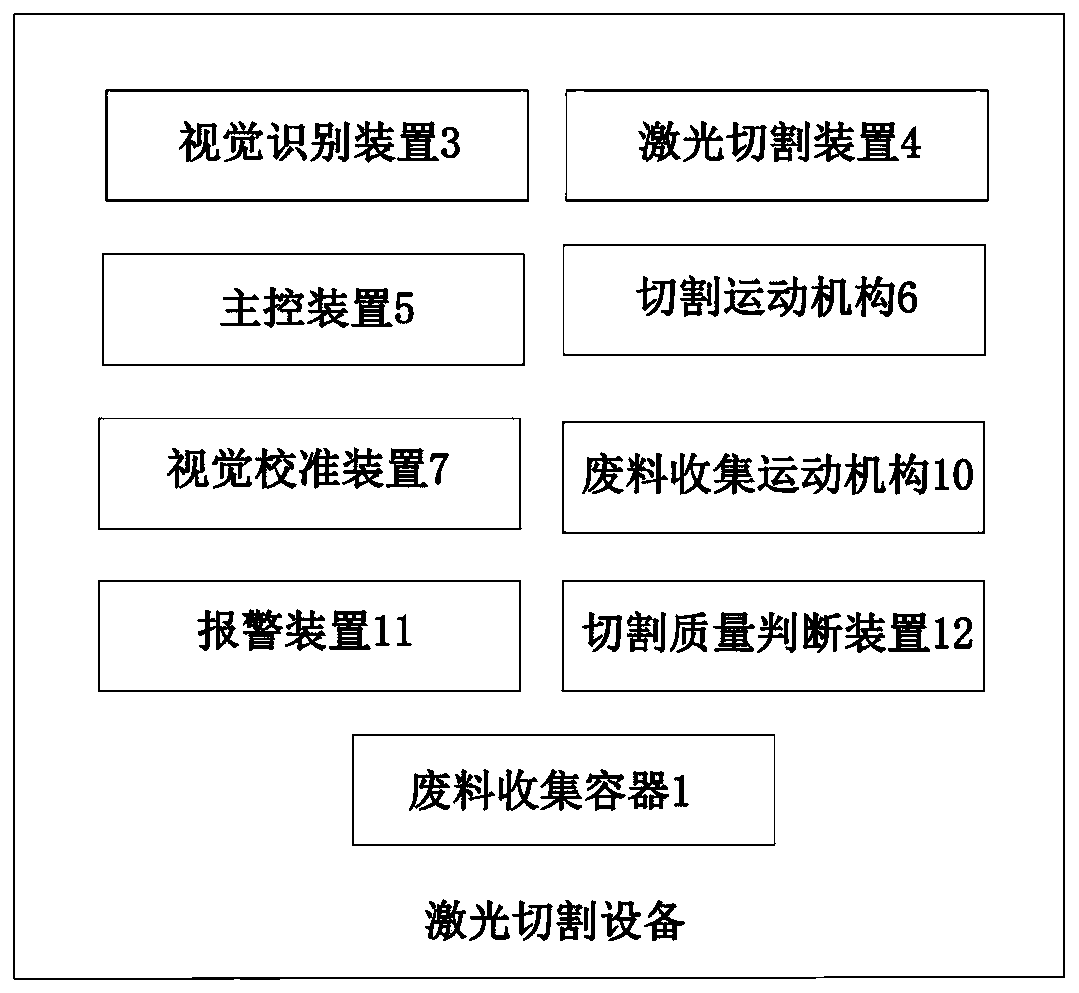

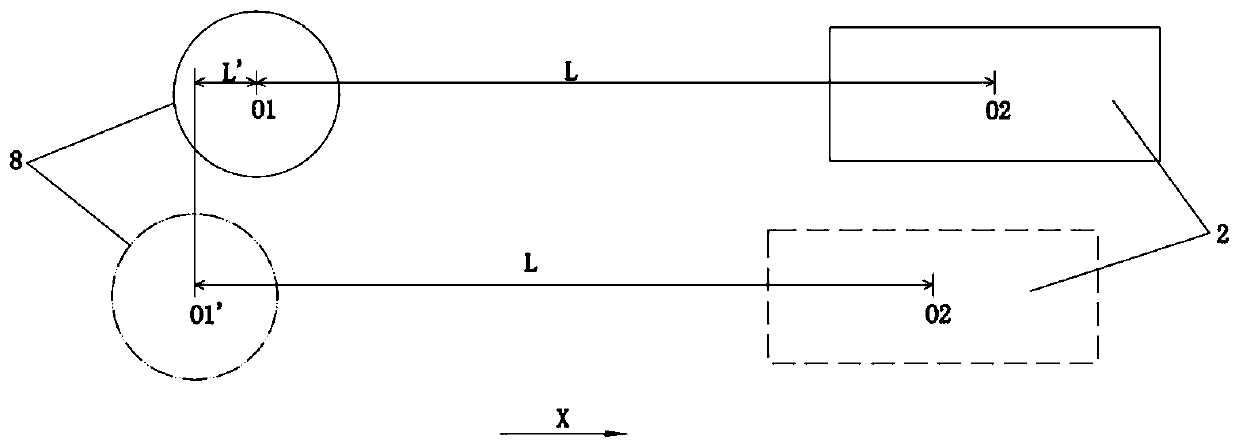

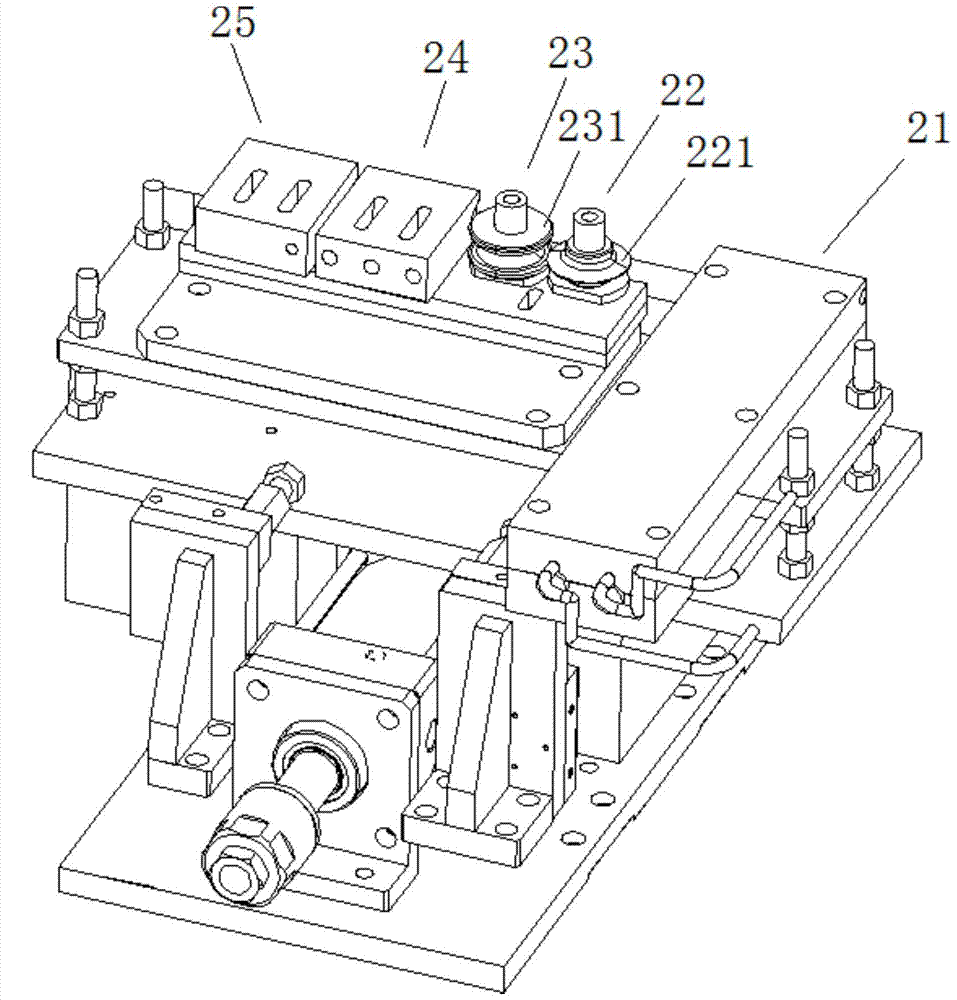

Laser cutting device and laser cutting work method

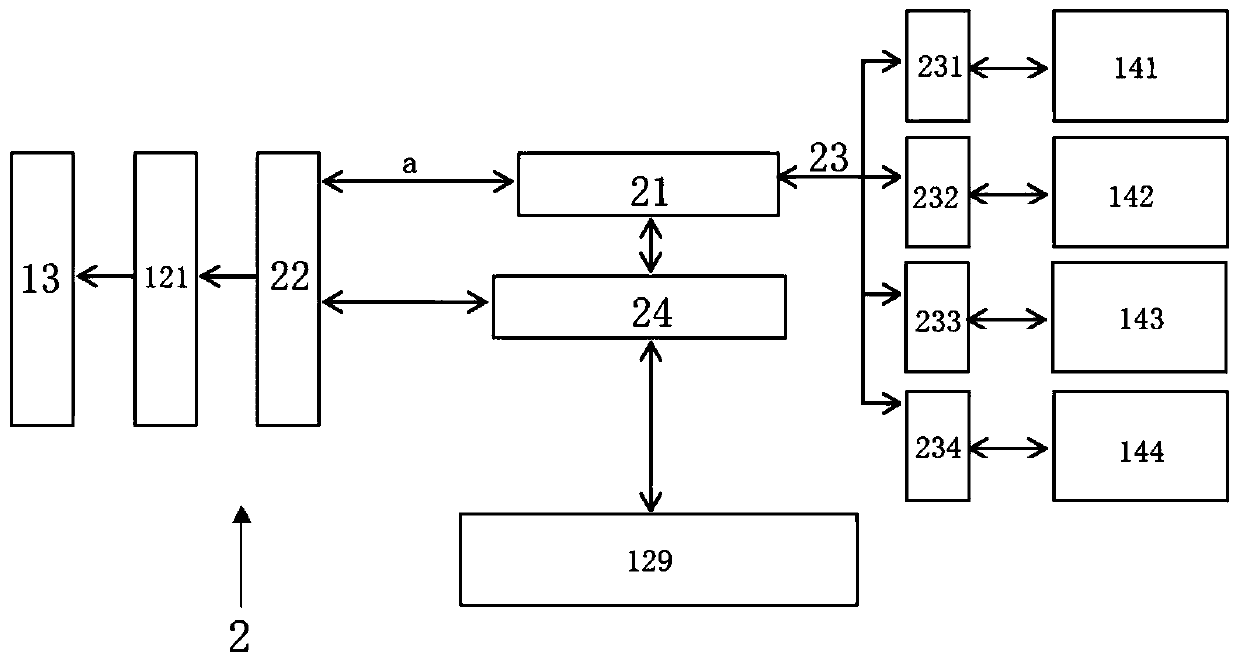

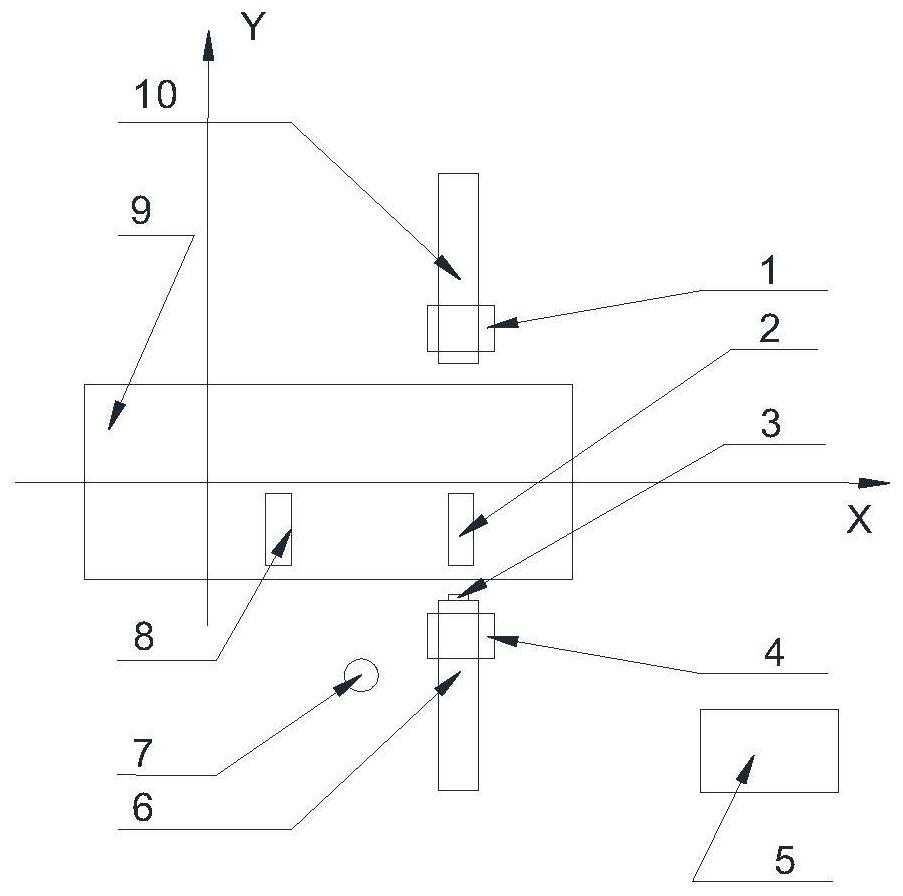

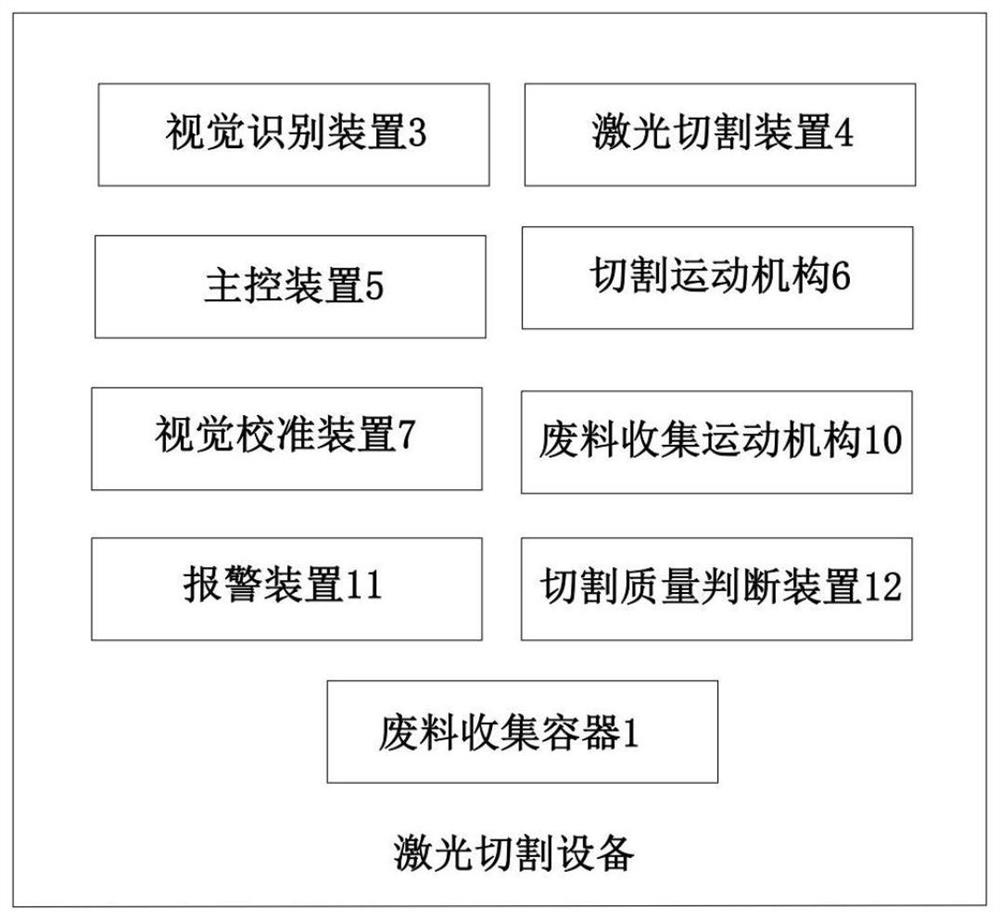

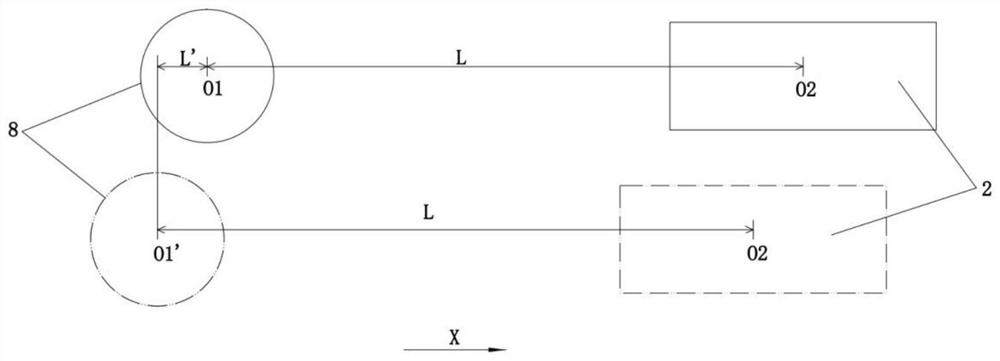

ActiveCN110711953AMeet cutting needsWon't vibrateLaser beam welding apparatusLaser cuttingVisual recognition

The invention relates to a laser cutting device and a laser cutting work method. The laser cutting device comprises a cutting movement mechanism, a laser cutting device, a visual recognition device and a master control device. The laser cutting device is connected with the cutting movement mechanism and generates lasers used for cutting. The visual recognition device is connected with the cuttingmovement mechanism and is used for obtaining image information of a specific structure on a vehicle body. The master control device is connected with the cutting movement device, the laser cutting device and the visual recognition device and is used for obtaining vehicle model information and controlling the laser cutting device to generate lasers used for cutting. The laser cutting device and thelaser cutting method are suitable for production of various vehicle models, the flexible degree is high, in addition, a cutting area can be accurately positioned, the machining precision is improved,the completion quality cutting work is detected online, and it is ensured that subsequent processes are implemented smoothly.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

Edge sealing forming system for hollow plate

The invention discloses an edge sealing forming system for a hollow plate. The edge sealing forming system comprises a heating unit, a heat cutting unit, a heat closing unit, a heat forming unit and a cooling forming unit, wherein the heating unit is at least used for heating the side part of the hollow plate to be softened; the heat cutting unit is at least used for cutting a reinforcing rib inside the side part of the softened hollow plate; the heat closing unit is used for closing the side part of the cut hollow plate; the heat forming unit is used for processing the closed side part of the hollow plate to be in a set sealing state; the cooling forming unit is used for cooling and forming the side part of the hollow plate in the set state. The edge sealing forming system provided by the invention is simple in structure, low in manufacturing cost, accurate in positioning and cutting of the hollow plate and good in edge sealing effect, so that the cost is effectively reduced, and the product quality is improved and the yield is increased.

Owner:SUZHOU HOLDEN AUTO

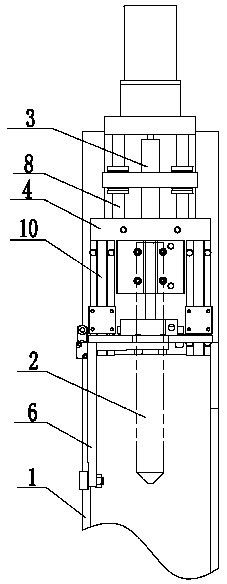

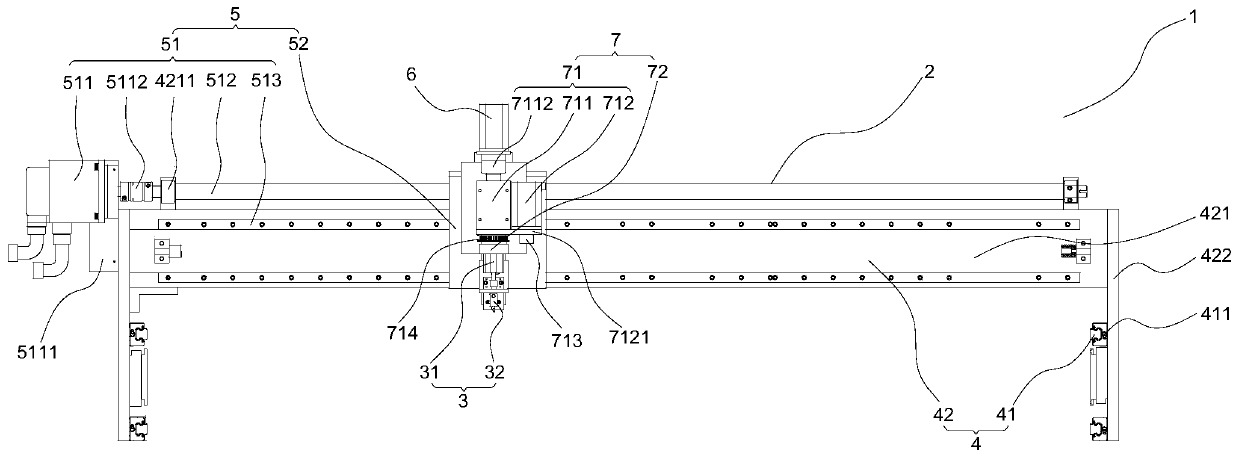

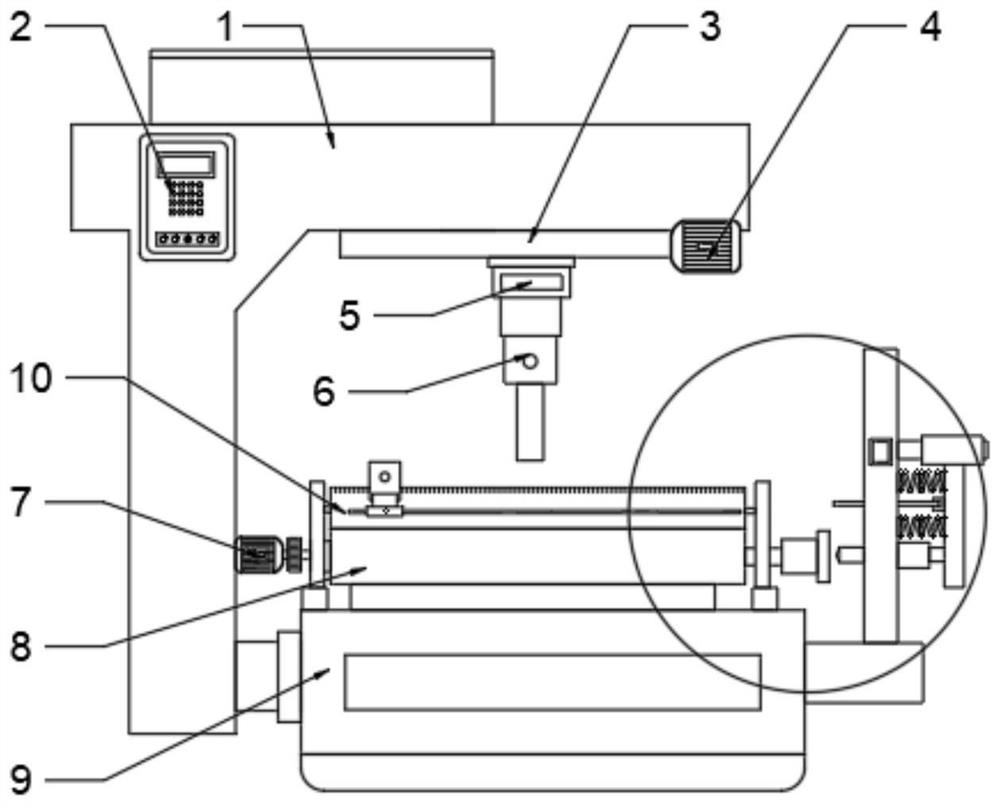

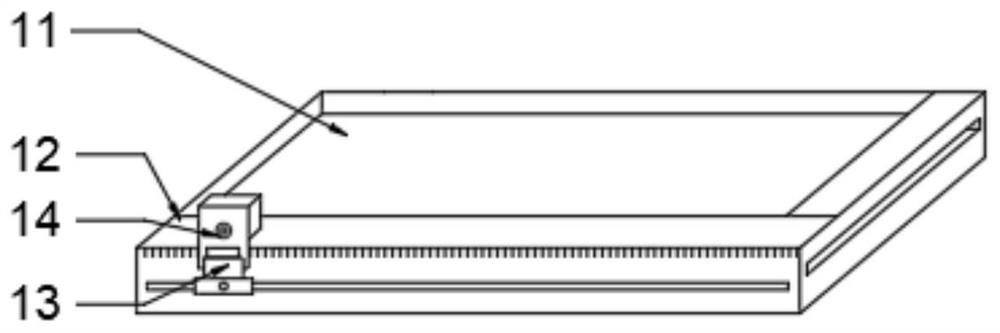

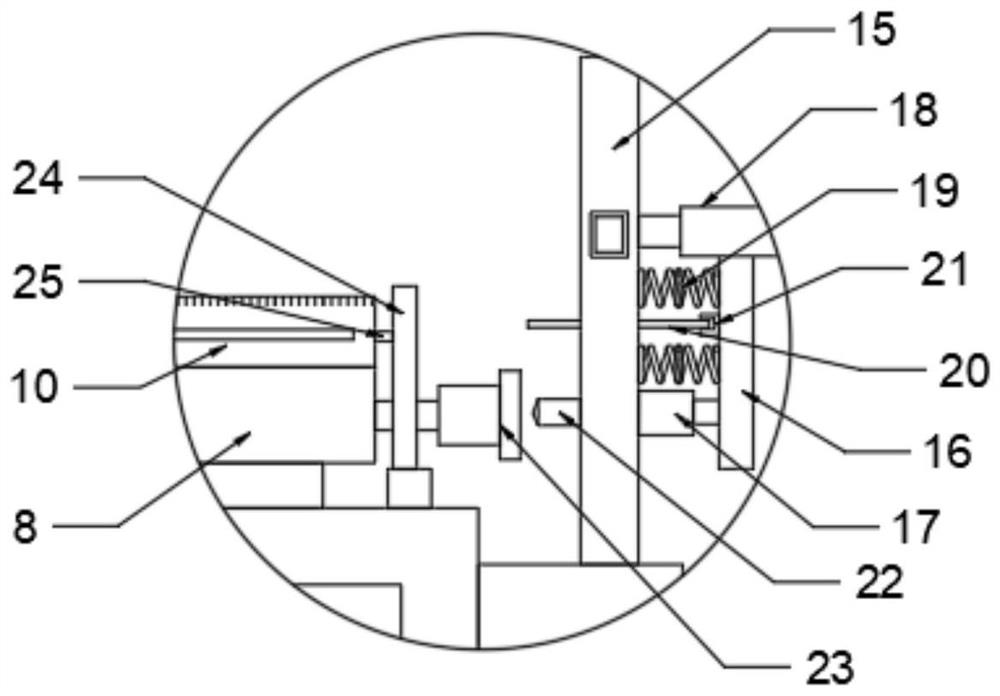

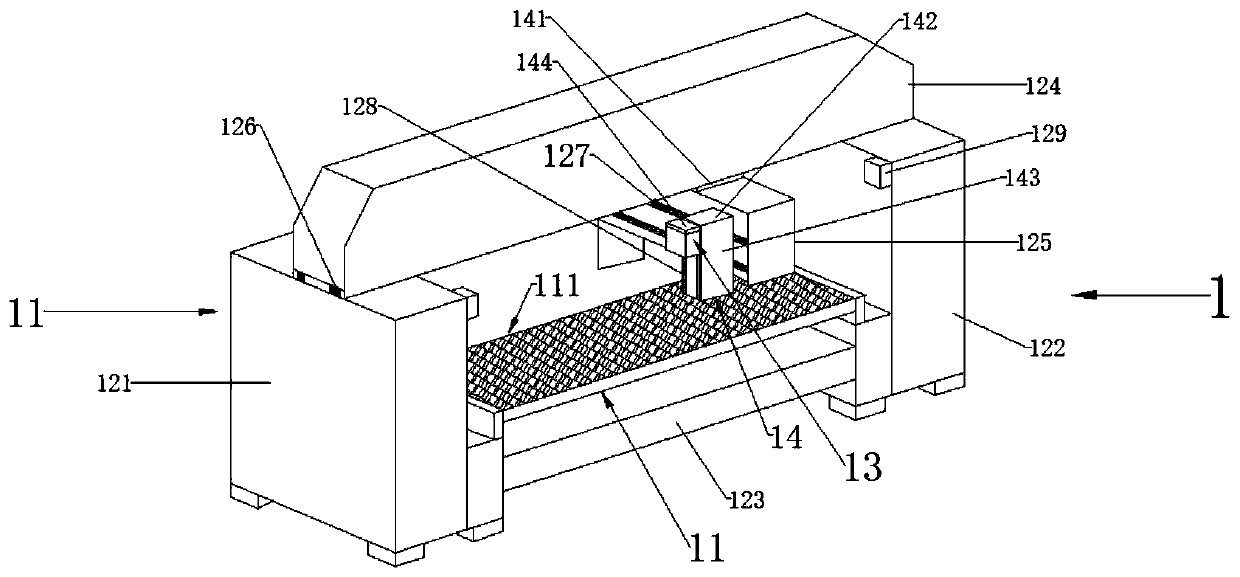

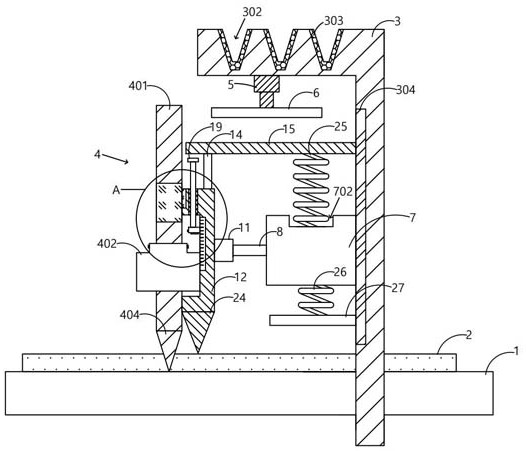

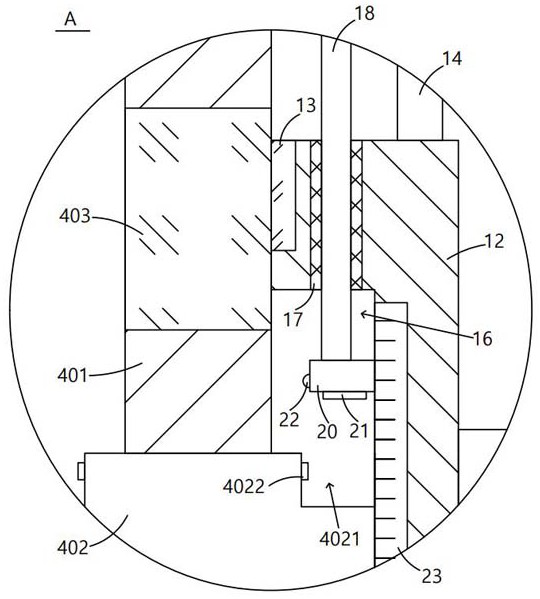

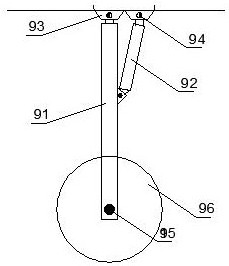

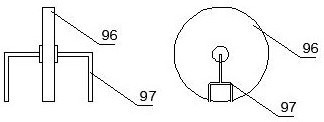

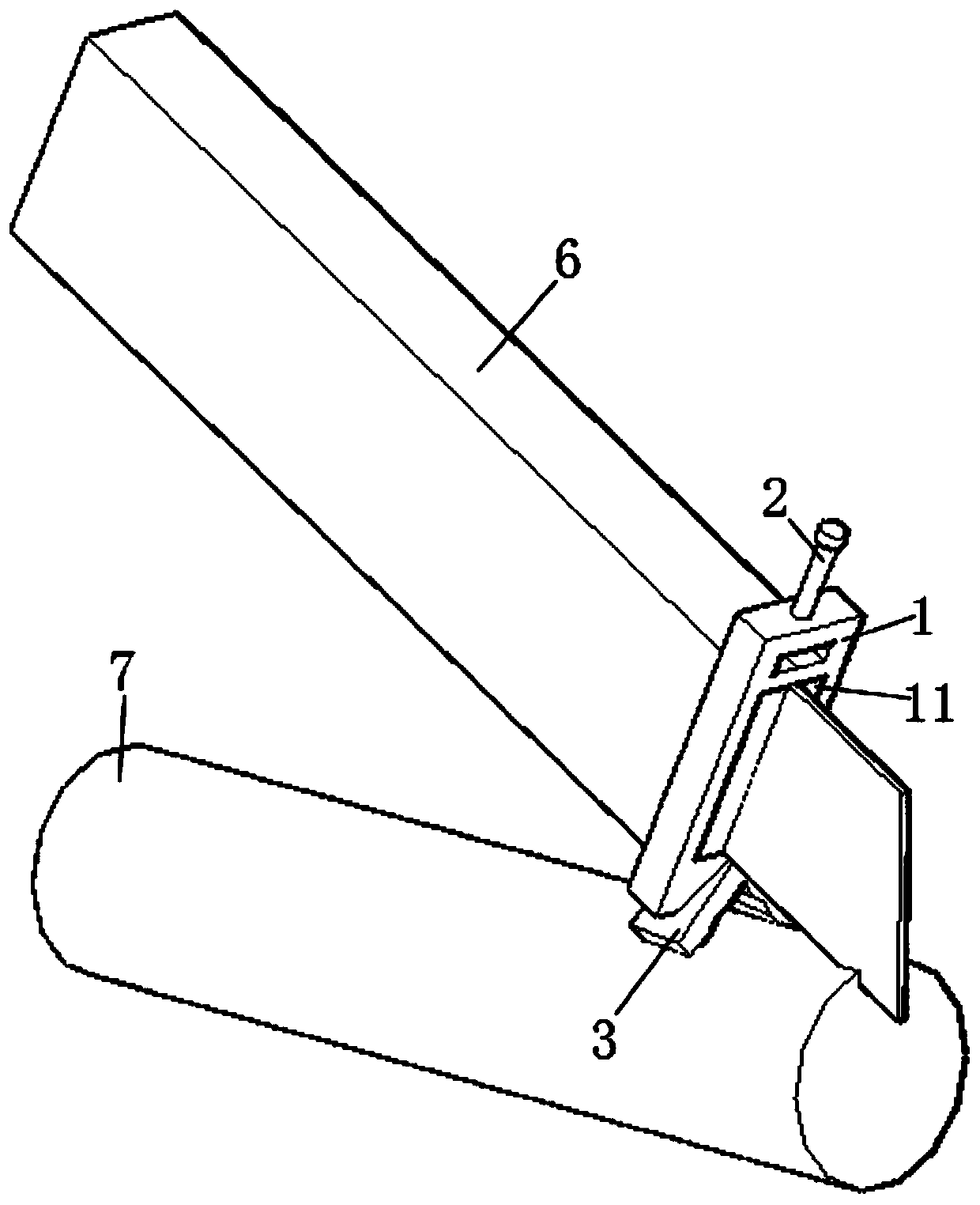

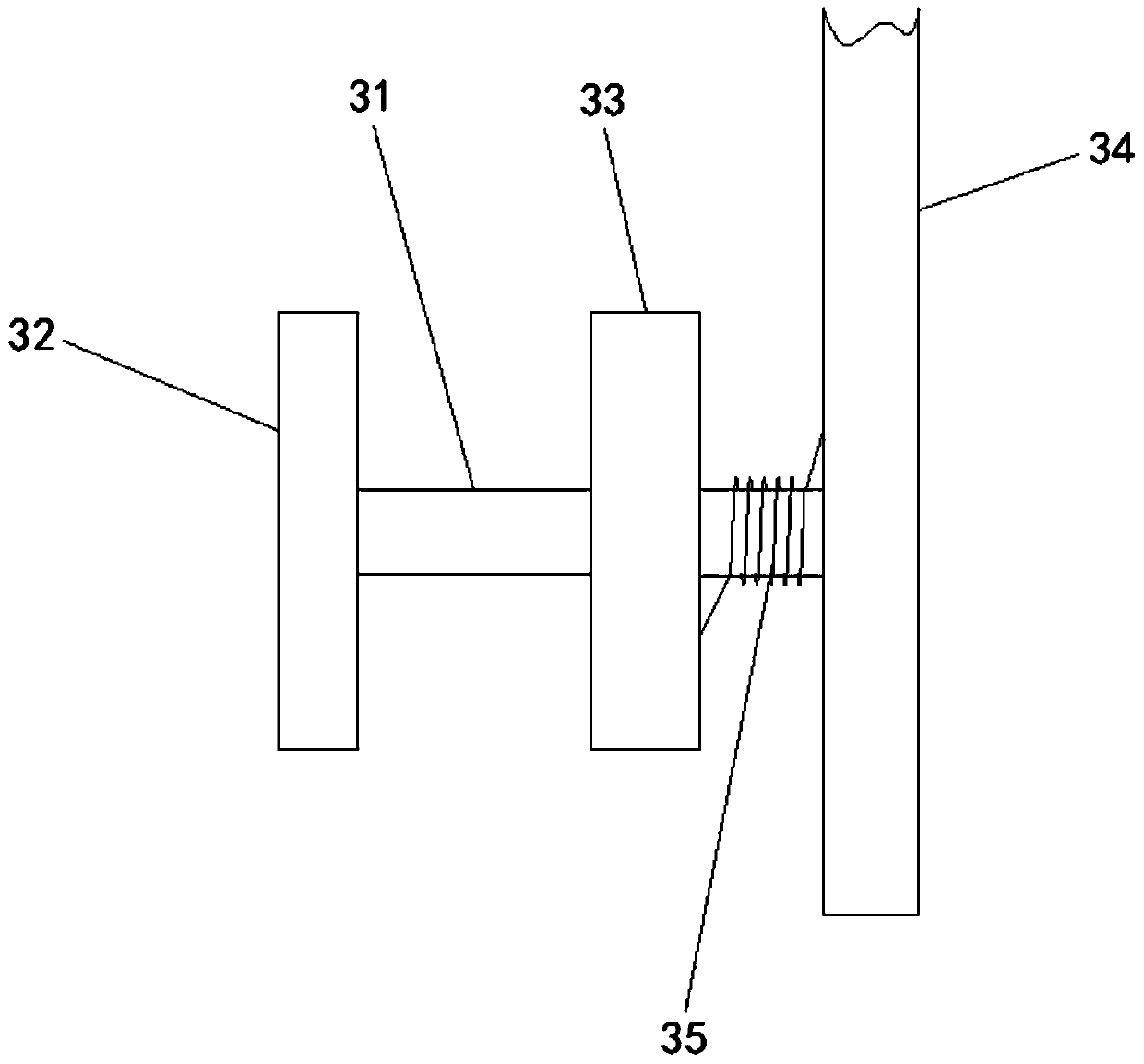

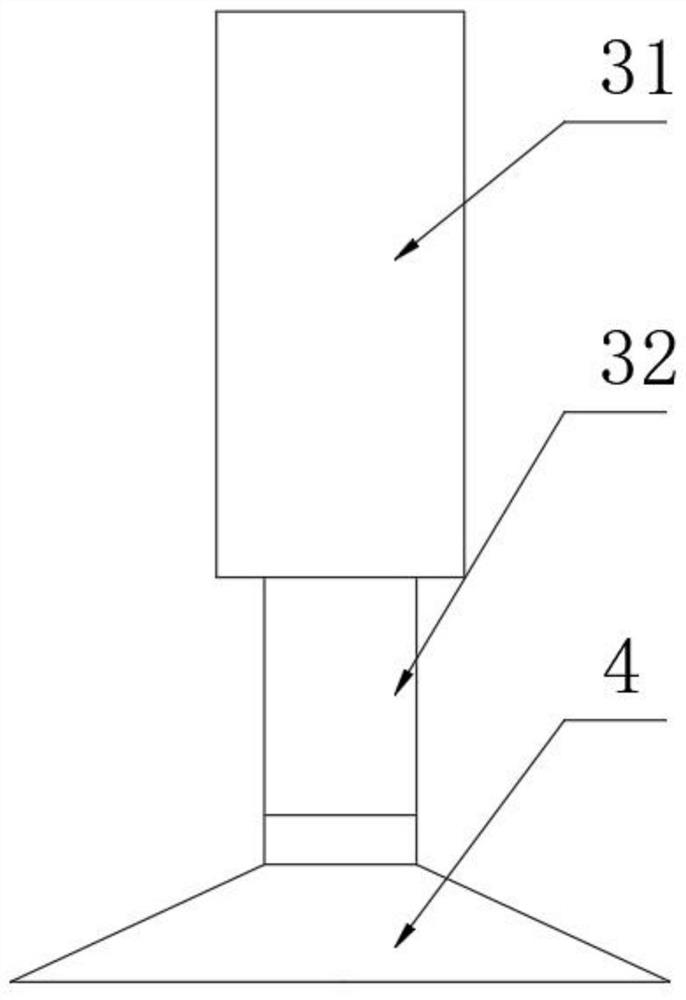

Pipe cutter lifting device and pipe sizing cutting machine

PendingCN108746957AAvoid damageAccurate cutting positioningWelding/cutting auxillary devicesAuxillary welding devicesPower apparatusMechanical engineering

The invention discloses a pipe cutter lifting device and a pipe sizing cutting machine to solve the problem that locating is inaccurate in the cutting process of cutting equipment. The pipe cutter lifting device is characterized by comprising a fixing frame and a cutter. The fixing frame is provided with a first power device which drives the cutter to move up and down. The first power device is connected with a first installing frame. The first installing frame is provided with a second power device which is connected with the cutter. The first installing frame is provided with a limiting block strip parallel to the cutter. According to the pipe cutter lifting device, at first, the first power device drives the cutter to descend, then the second power device drives the cutter to a steel pipe, the limiting block strip can prevent the situation that when driving the cutter, the second power device collides with the steel pipe, and damage to the cutter is caused, when cutting is completed, the second power device is reset, and by arranging the second power device to drive the distance of the cutter, the steel pipe can be accurately located and cut.

Owner:ZHEJIANG INT MARITIME COLLEGE

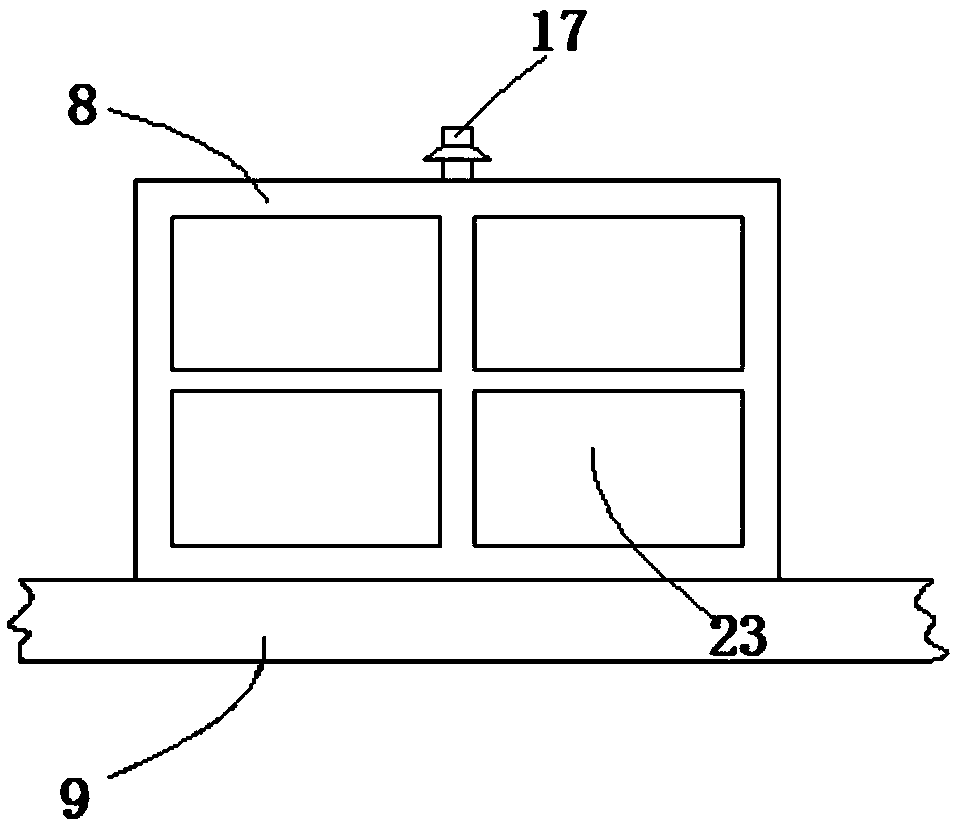

Hollow plate window opener

ActiveCN103737646AAccurate cutting positioningSimple structureMetal working apparatusEngineeringEdge banding

Owner:SUZHOU HOLDEN AUTO

Hollow plate window opening machine

InactiveCN103522325AAccurate cutting positioningSimple structureMetal working apparatusWindow openingEngineering

The invention discloses a hollow plate window opening machine. The hollow plate window opening machine comprises a hot die cutting unit and an edge sealing system, wherein the hot die cutting unit is at least used for cutting a selected portion of a hollow plate, and the edge sealing system is at least used for sealing the side edge portions of the cut hollow plate. The edge sealing system comprises a heating unit, a hot cutting unit, a hot opening shrinking unit, a hot forming unit and a cooling forming unit, wherein the heating unit is at least used for heating the side edge portions of the cut hollow plate until the side edge portions is softened, the hot cutting unit is at least used for cutting reinforcing ribs inside the side edge portions of the softened hollow plate, the hot opening shrinking unit is used for shrinking an opening of the side edge portions of the cut hollow plate, the hot forming unit is used for machining the side edge portions of the opening shrunk hollow plate into a set sealed form, and the cooling forming unit is used for cooling and forming the side edge portions of the hollow plate which is provided with the set form. The hollow plate window opening machine is simple in structure, low in manufacturing cost and good in edge sealing effect, the hollow plate is cut and positioned accurately, cost is effectively reduced, and quality and the yield of products are improved.

Owner:SUZHOU HOLDEN AUTO

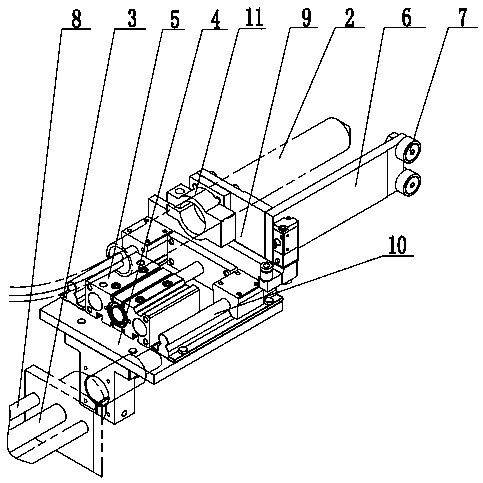

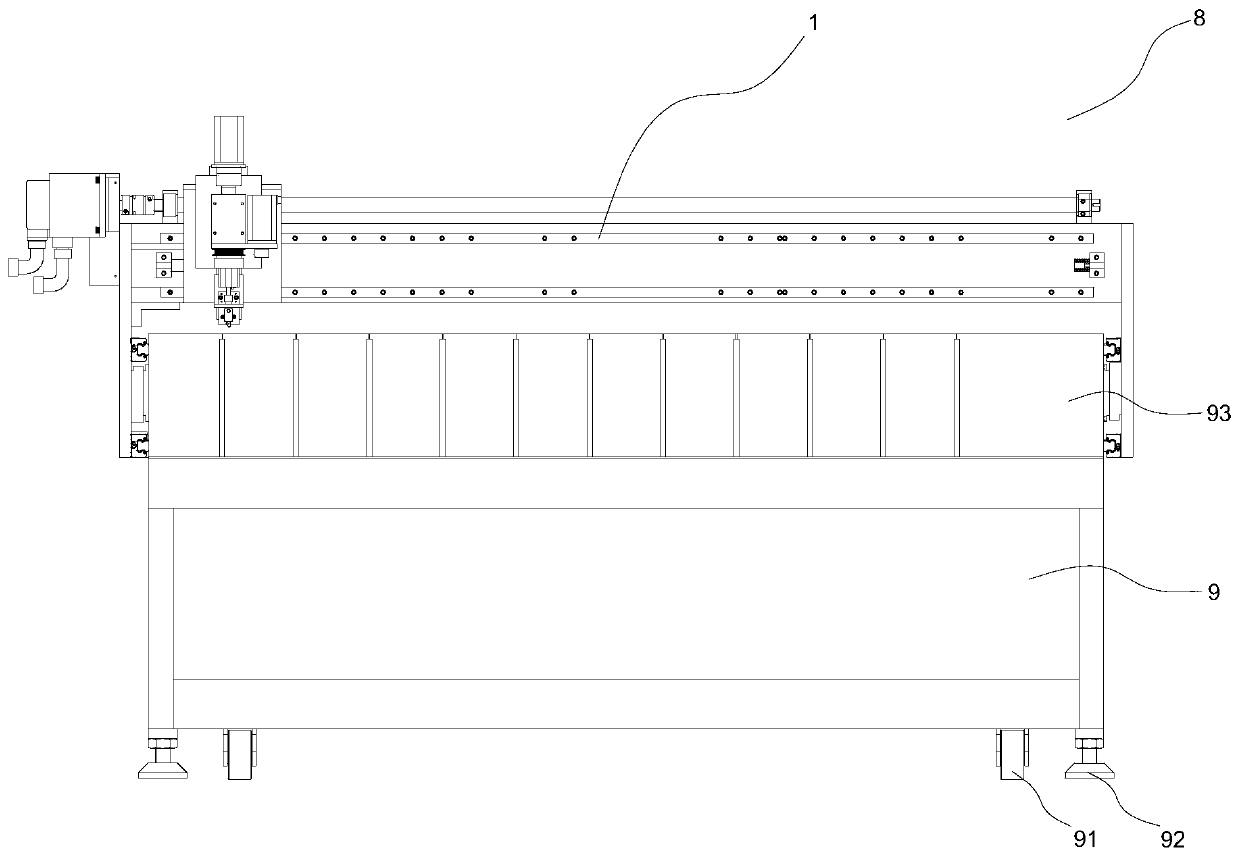

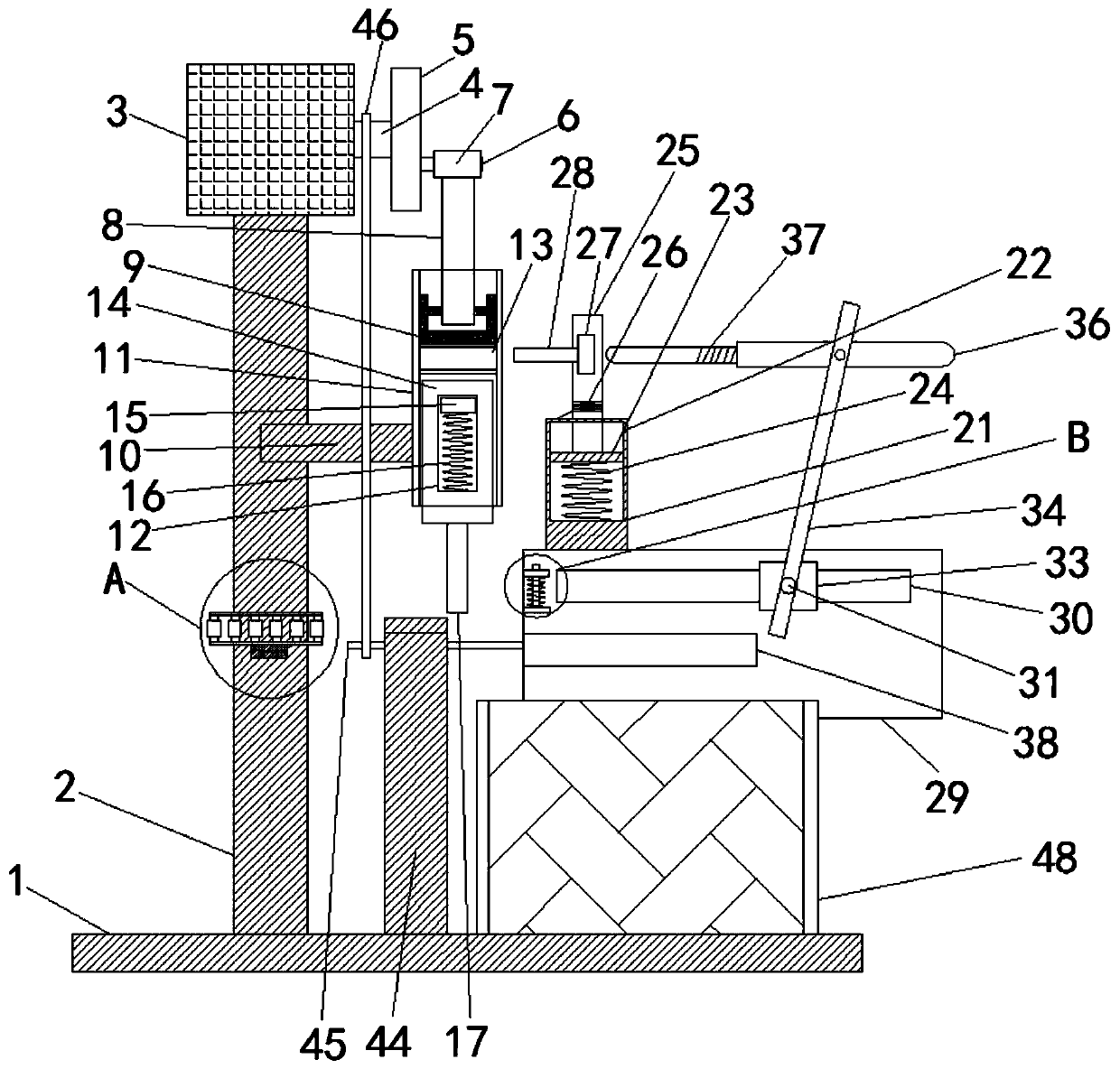

Automatic pushing conveying device

InactiveCN109048456APrecise positioningAccurate cutting positioningMetal working apparatusDrive motorConveyor belt

The invention discloses an automatic pushing conveying device. The automatic pushing conveying device comprises a machine frame and a conveyor belt arranged on the machine frame; the front end of theconveyor belt is provided with a conveying roller; the conveying roller is connected with a driving motor so as to be driven by the driving motor to rotate; the front end of the machine frame is provided with a positioning abutting plate; the positioning abutting plate is perpendicular to the length direction of the conveyor belt; a plurality of positioning pushing devices are sequentially arranged on the machine frame from front to back; each positioning pushing device comprises a pushing plate, a hydraulic device for pushing the pushing plate to move back and forth, and a moving frame for mounting the hydraulic device; the moving frames are slidably connected with the machine frame; the pushing plates of the multiple positioning pushing devices are sequentially driven by the moving frames to move to the position above the conveyor belt, and then driven by the hydraulic devices to move forwards so as to push the side, not abutting against the positioning abutting plate, of profile tomove forward, due to the fact that the multiple positioning pushing devices are sequentially moved and matched, the automatic pushing conveying device can be used for automatic feeding of longer profile on the conveyor belt, and accurate cutting and positioning are ensured.

Owner:江门市森联木业有限公司

Glass cutting apparatus and glass cutting machine based on four-axis linkage

PendingCN110217979ASimple structureScientific and reasonable designGlass severing apparatusMachiningEngineering

The invention belongs to the technical field of glass processing equipment, in particular to a glass cutting apparatus and a glass cutting machine based on four-axis linkage. An X-axis driving assembly drives an X-axis bearing platform to move along the X-axis direction, a Y-axis driving assembly is arranged on the X-axis bearing platform and drives a Y-axis bearing platform to move along the Y-axis direction, a Z-axis driving assembly is arranged on the Y-axis bearing platform and drives a Z-axis bearing platform to move along the Z-axis direction, a C-axis driving assembly is arranged on theZ-axis bearing platform and drives a C-axis bearing platform to rotate around the C-axis, a cutting module is arranged on the C-axis bearing platform, and cutting actions are completed at different positions under linkage of an X-axis moving module, a Y-axis moving module, a Z-axis lifting module, and a C-axis rotating module. The cutting module is driven to process a product by adopting four-axis linkage of X, Y, Z and C, the positioning and cutting is precise and stable and quick, the machining allowance is small, and the use is convenient.

Owner:DONGGUAN YINRUI PRECISION MACHINERY

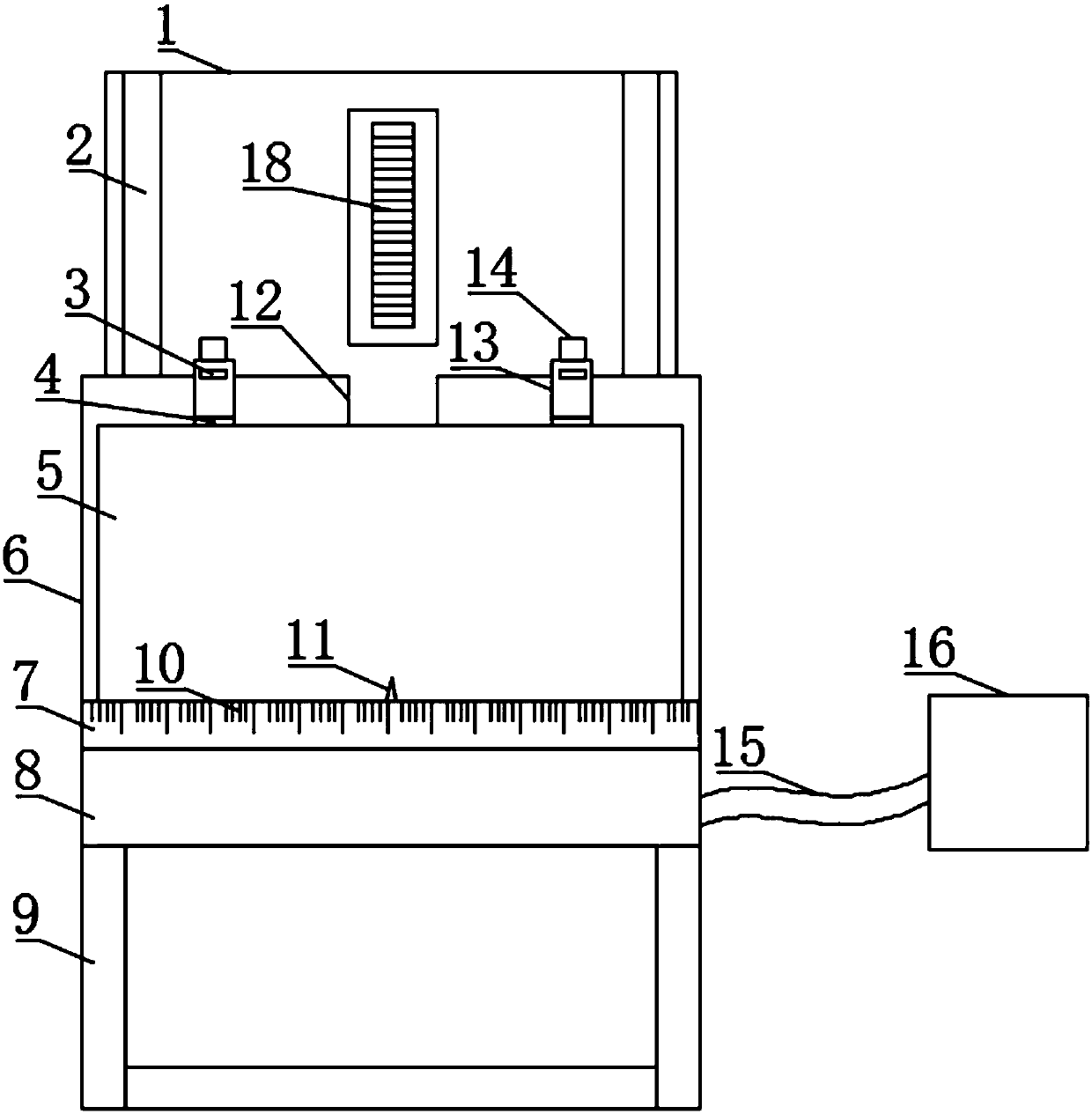

Equipment applied to fixed-distance division of fireproof plate

InactiveCN109591062AEasy to useAccurate cutting positioningMetal working apparatusSlide plateEngineering

The invention discloses equipment applied to fixed-distance division of a fireproof plate. The equipment comprises a cutting platform, the fireproof plate, a movable support plate, a positioning device and a dust suction device. A cutting blade is arranged in a through groove in the cutting platform. Limiting chutes are correspondingly formed in the left side and the right side of the upper surface of the cutting platform. The limiting chutes are in sliding connection with a sliding plate positioned at the bottom of the movable support plate. A rectangular through groove is formed in the position, facing the cutting blade, of the movable support plate. A front baffle is fixedly arranged at the front end of the upper surface of the movable support plate. The bottom of the front baffle is fixedly welded to the upper surface of the movable support plate. A graduated scale is arranged on the upper surface of the front baffle. A dust suction device is movably hinged to the front side face of the movable support plate through a hinge. The fireproof plate is arranged on the portion, on the rear side face of the front baffle, of the upper surface of the movable support plate. A positioningdevice is arranged on the portion, on the rear side face of the fireproof plate, of the upper surface of the movable support plate. In the actual use process of the equipment, the fireproof plate needs to be scribed in advance, and the cutting and positioning are more accurate.

Owner:盐城紫环工业机械有限公司

Water cutting vacuum positioning mechanism of automobile roof

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Stainless steel panel cutting and positioning die

InactiveCN112207461AEasy to cutAvoid offsetLaser beam welding apparatusEngineeringSS - Stainless steel

The invention discloses a stainless steel panel cutting and positioning die which comprises a worktable. A working frame is fixedly mounted on one side of the worktable; an operation panel and a lasercutting mechanism are mounted on the working frame; a transmission mechanism is mounted at the top of the worktable; a die shell is arranged on the worktable; and a positioning mechanism corresponding to the transmission mechanism is arranged on one side of the worktable. The stainless steel panel cutting and positioning die is convenient to use, accurate in positioning, high in cutting stabilityduring cutting and good in cutting effect.

Owner:江门市冠奇不锈钢制品有限公司

Intelligent optical fiber laser cutting system and application method thereof

InactiveCN110900008ASimple structureImprove stabilityLaser beam welding apparatusElectrical controlEngineering

The invention discloses an intelligent optical fiber laser cutting system and an application method thereof. The system comprises a mechanical part and an electrical control part, wherein the mechanical part comprises a machining platform, an equipment overall rack, an optical fiber laser cutter and a moving platform, the machining platform is horizontally arranged in the equipment overall rack, the optical fiber laser cutter is installed on the moving platform and located above the machining platform, the moving platform is installed on the equipment overall rack, the electrical control partcomprises a Galil control card, an industrial personal computer and a servo motion control mechanism, the Galil control card, the industrial personal computer and the optical fiber laser cutter are connected in sequence, and the Galil control card and the servo motion control mechanism motion platform are connected in sequence. The intelligent optical fiber laser cutting system is advantaged in that operation is easy, positioning is accurate, machining precision is high, machining efficiency is high, batch production is met, moreover, CAD drawing files are supported, and the application prospect is wide.

Owner:苏州德吉克激光设备有限公司

A precise positioning cutting device for sapphire processing

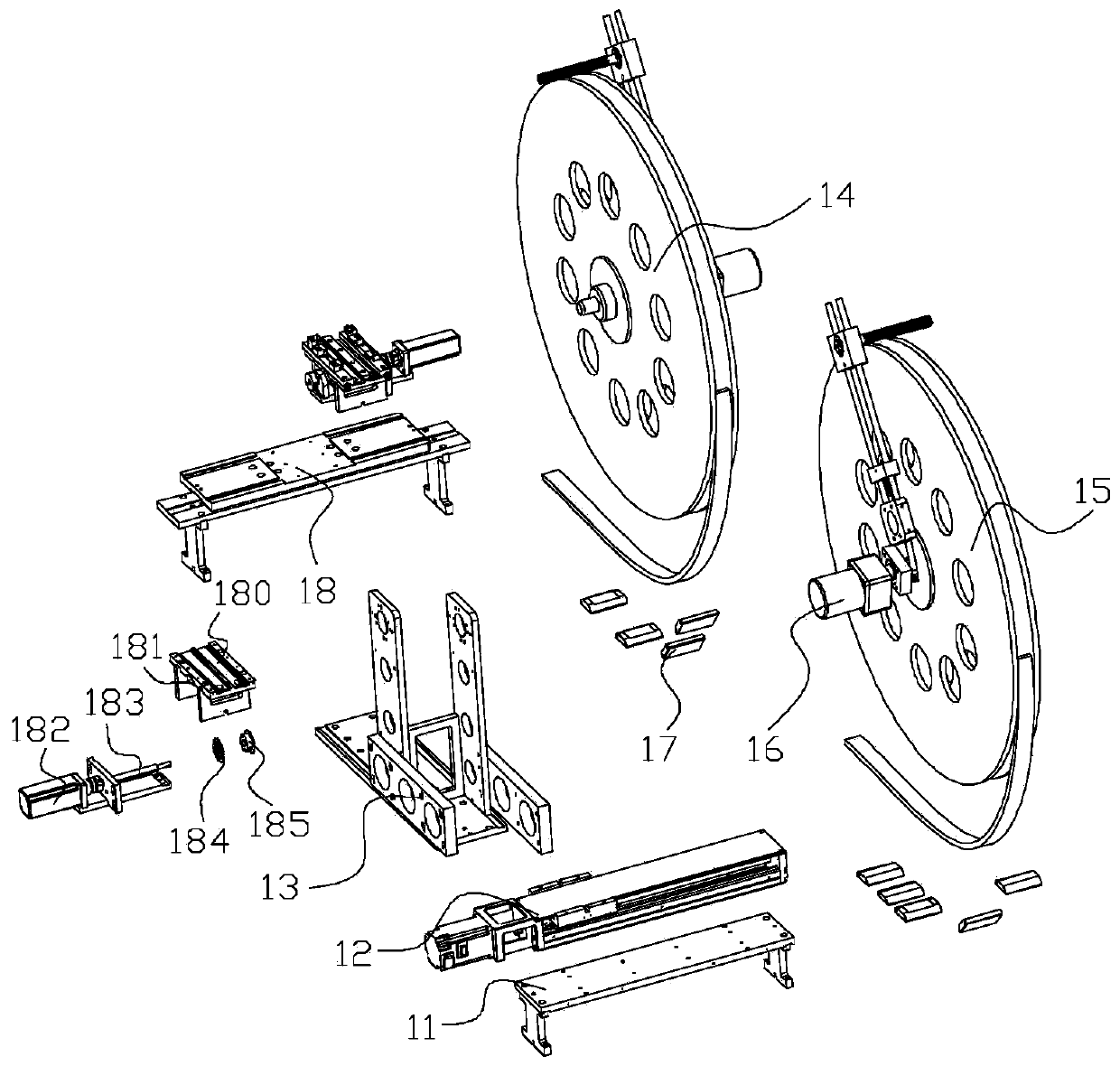

ActiveCN107053502BPrecise positioningAccurate and stable positioningWorking accessoriesFine working devicesEngineeringConductor Coil

The invention relates to the technical field of gem processing, in particular to an accurate positioning and cutting device for sapphire processing. The device comprises a device base; two U-shaped supporting rods are symmetrically arranged on the upper end surface of the device base; a mounting support for mounting an electric winding reel is arranged at one end, far away from the device base, of each U-shaped supporting rod; cutting wires for cutting sapphire wind around the two electric winding reels; electric telescopic rods are symmetrically mounted on the upper end surface of the device base; one end, far away from the device base, of each electric telescopic rod is fixedly connected with a carrying platform; a supporting frame is arranged at one end, far away from the carrying platform, of a fixing plate; and a water spray pipe penetrates through the supporting frame and is used for spraying a cutting fluid to sapphire located between a first clamping plate and a second clamping plate. Compared with an existing cutting device, the accurate positioning and cutting device for sapphire processing can position the sapphire accurately and stably and has the advantages of high cutting quality and stable cutting speed.

Owner:TDG YINXIA NEW MATERIAL CO LTD

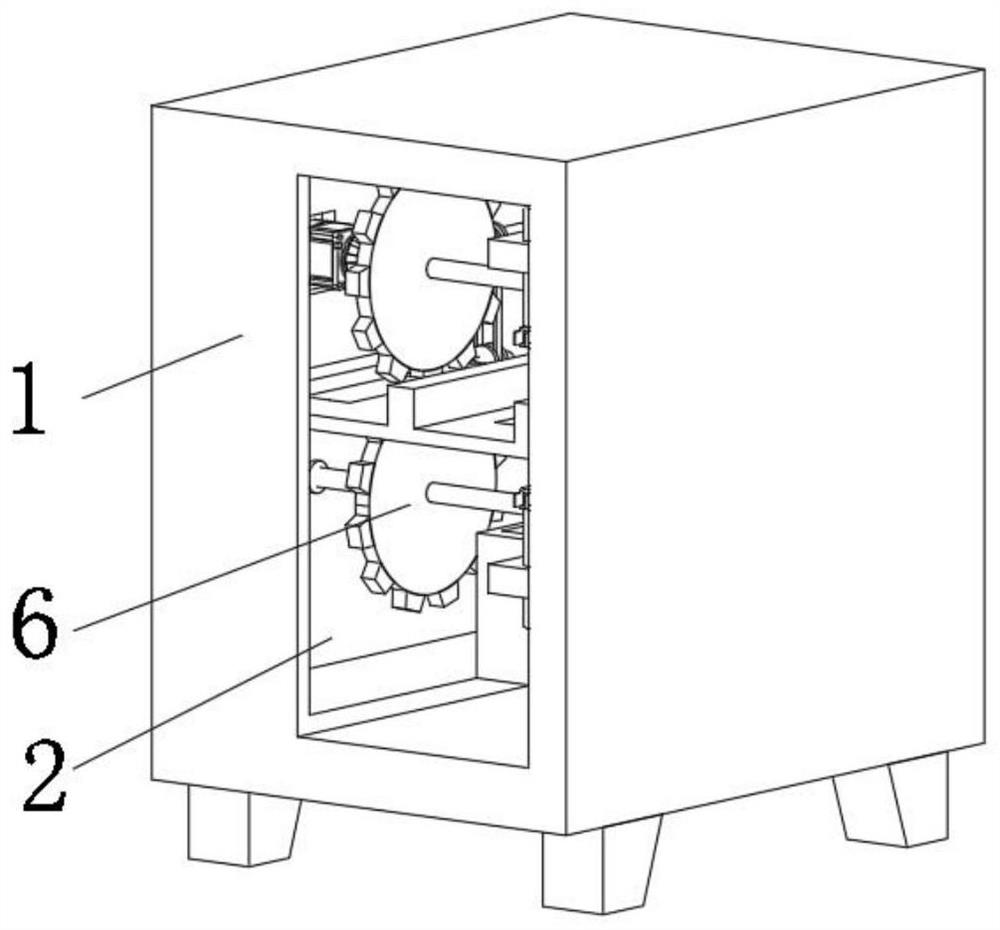

Environment-friendly high-precision autoclaved aerated block cutting machine

InactiveCN106926354ASimple structureAccurate cutting positioningCeramic shaping apparatusEngineeringDrive motor

The invention is an environment-friendly high-precision autoclaved aerated block cutting machine, which has a workbench, and a support frame is arranged in the outer middle part of the workbench. The upper part and the lower part of the support frame are respectively provided with driving wheels, and the driving wheels are driven to rotate by a driving motor. The circular band saw blade is set on the wheel. The circular band saw blade includes an inner section saw blade and an outer section saw blade. There are two symmetrical tracks on both sides. A mobile cutting platform is provided on the track. The mobile cutting platform includes a table. The bottom of the table is provided with rollers. The rollers roll along the rails. A section of cutting seam, located on both sides of the cutting seam on the top of the table, is symmetrically provided with several clamping oil cylinders; a winch is provided at each end of the workbench; the invention has simple structure, precise cutting and positioning, and can realize automatic cutting operation, with great advantages. Good practical application value.

Owner:黄石市神州建材有限公司

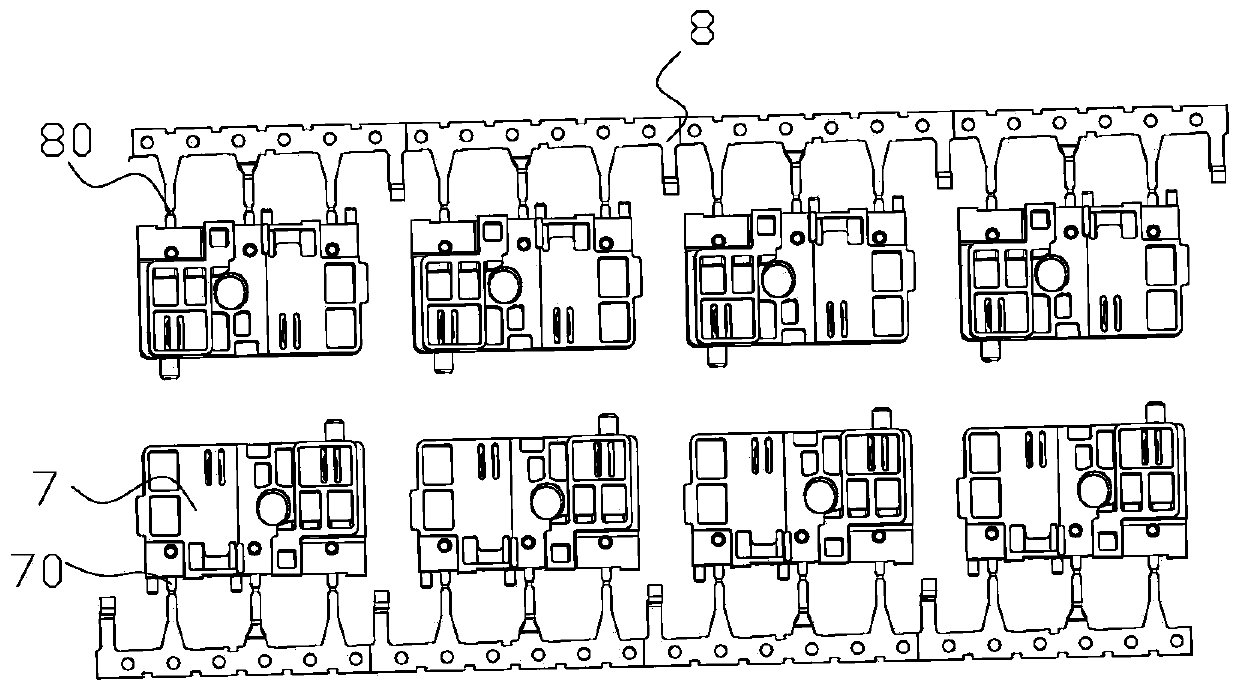

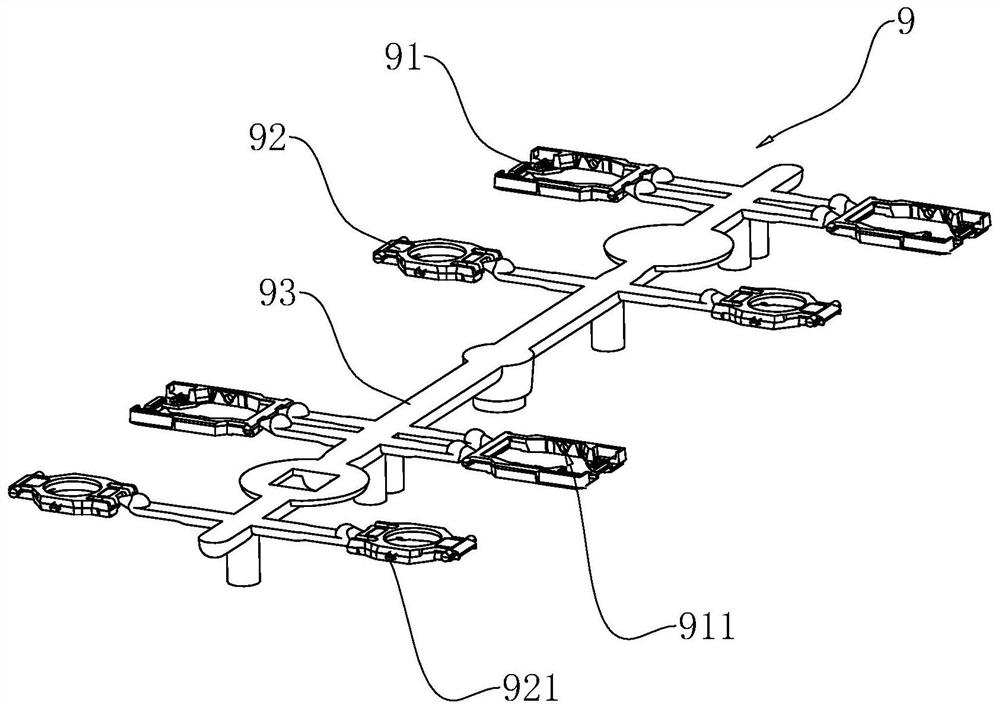

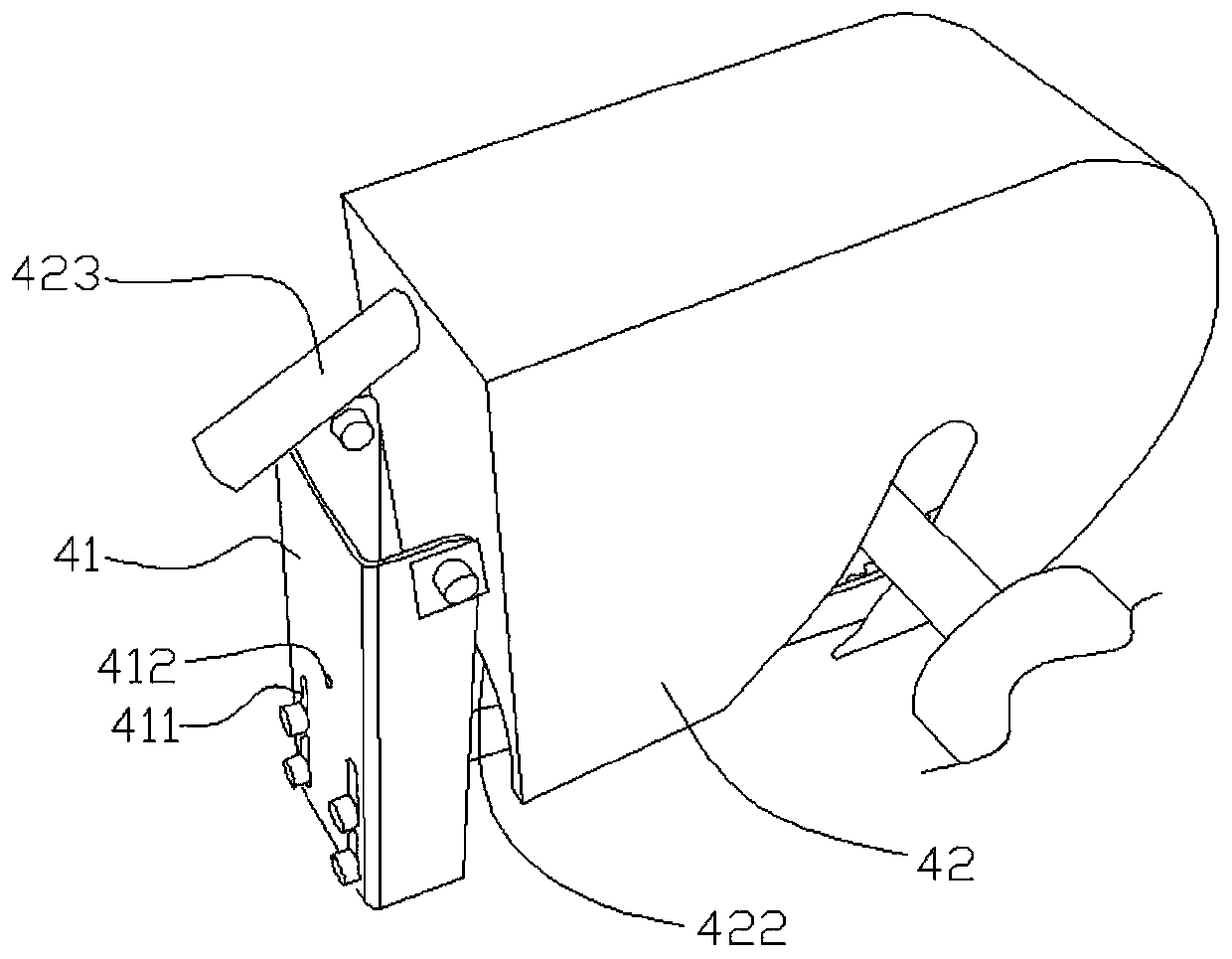

Device and method for cutting wiring terminal of electric connector

ActiveCN111370970APrevents the hassle of unmanageable buildupEasy to cut off and recycleContact member manufacturingElectrical connectionStructural engineering

The invention relates to the technical field of electric connector production. The invention discloses a device for cutting a wiring terminal of an electric connector. The device comprises a cutting bracket, a cutting lifting cylinder, a cutting pressing plate, a first clamping and cutting assembly, a second clamping and cutting assembly and a waste cutting assembly. The device has the advantagesthat the upper end and the lower end of the wiring terminal belt are accurately positioned and cut off, and the cutting-off quality and the cutting-off efficiency of the wiring terminal are improved.

Owner:浙江华西科技有限公司

A kind of laser cutting equipment and laser cutting operation method

ActiveCN110711953BMeet cutting needsWon't vibrateLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a laser cutting device and a laser cutting operation method, which include: a cutting movement mechanism; a laser cutting device, which is connected to the cutting movement mechanism, and generates laser light for cutting; a visual recognition device, which is connected to the cutting The motion mechanism is used to obtain the image information of the specific structure on the vehicle body; and the main control device is connected to the cutting motion mechanism, the laser cutting device and the visual recognition device, and is used to obtain vehicle model information and control the laser cutting device to generate laser for cutting. The invention is applicable to the production of multiple car models, has a high degree of flexibility, can accurately locate the cutting area, improves the processing accuracy, and can detect the quality of the cutting operation on-line to ensure the smooth implementation of the subsequent process.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

Leather shoe fabric cutting equipment for leather shoe processing

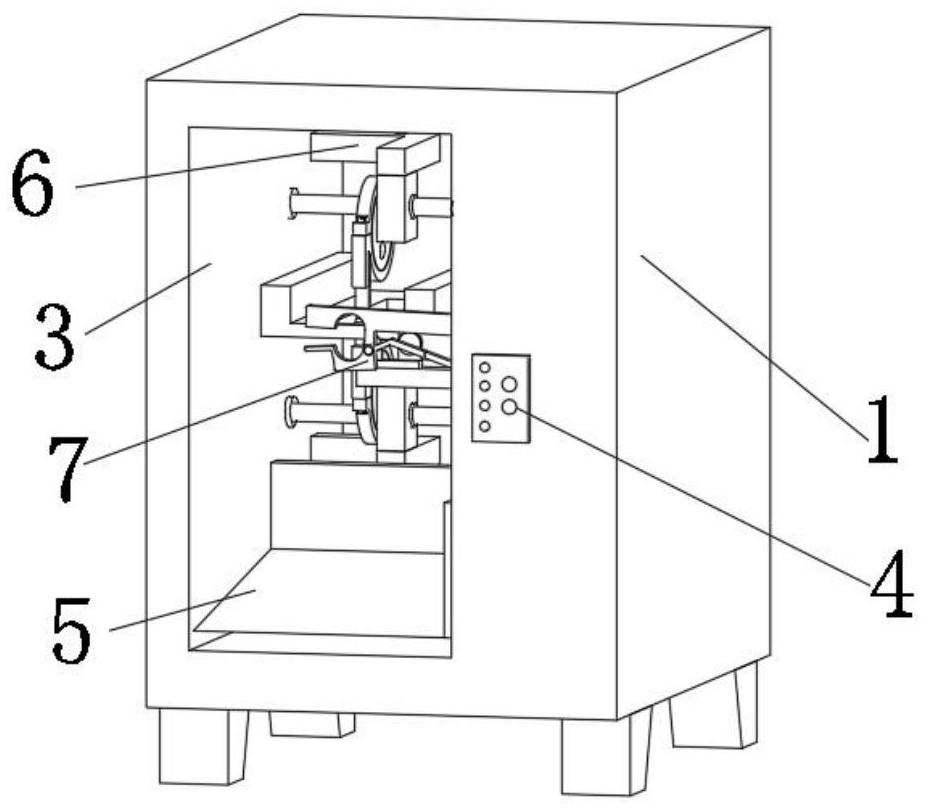

InactiveCN112890374AConvenient fixed conveying operationReduce tiltShoemaking devicesHeelsDrive shaftStructural engineering

The invention relates to the technical field of leather shoe processing equipment, in particular to leather shoe fabric cutting equipment for leather shoe processing, which comprises an outer shell, a feeding port is formed in one side of the outer shell, a discharging port is formed in the other side of the outer shell, an operation button is arranged on the surface of the outer shell on one side of the discharging port, and a conveying plate is fixed in the outer shell. And an open groove is formed in the surface of the conveying plate, a conveying mechanism is installed in the outer shell, and the conveying mechanism comprises a servo motor. The output shaft of the servo motor drives the driving shaft and the auxiliary moving shaft to synchronously rotate, so that the outer sleeve shells arranged on the driving shaft and the auxiliary moving shaft in a sleeving mode eccentrically rotate along the movable shaft pins through the sliding grooves, and pushing pieces on the outer sleeve shells can make contact with leather shoe fabric on the conveying plate at regular time, and the leather shoe fabric is driven to advance forwards in a timed and quantitative mode, so that the cut leather shoe fabric can be fixed and conveyed conveniently, and the overall cutting accuracy can be effectively improved.

Owner:WENZHOU POLYTECHNIC

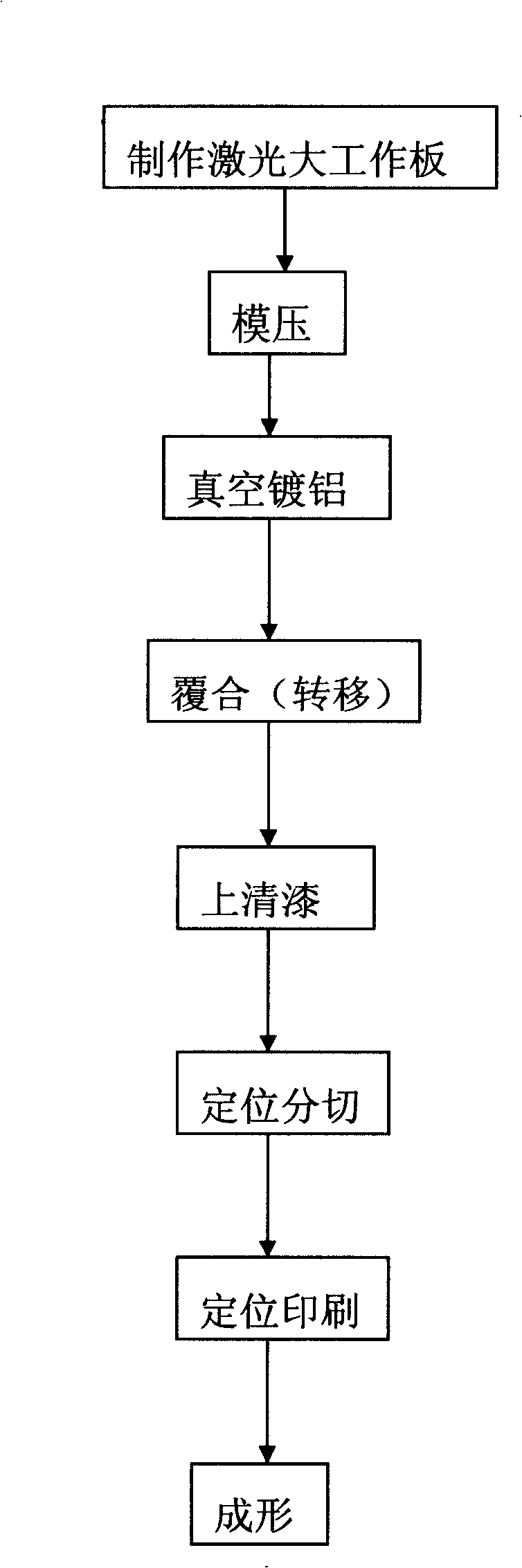

Production technology of laser locating antifalse cigarette box

ActiveCN100431926CStrong anti-counterfeitingHigh technical contentFlexible coversWrappersVarnishMaterials science

Owner:ZHEJIANG MINONG CENTURY GRP

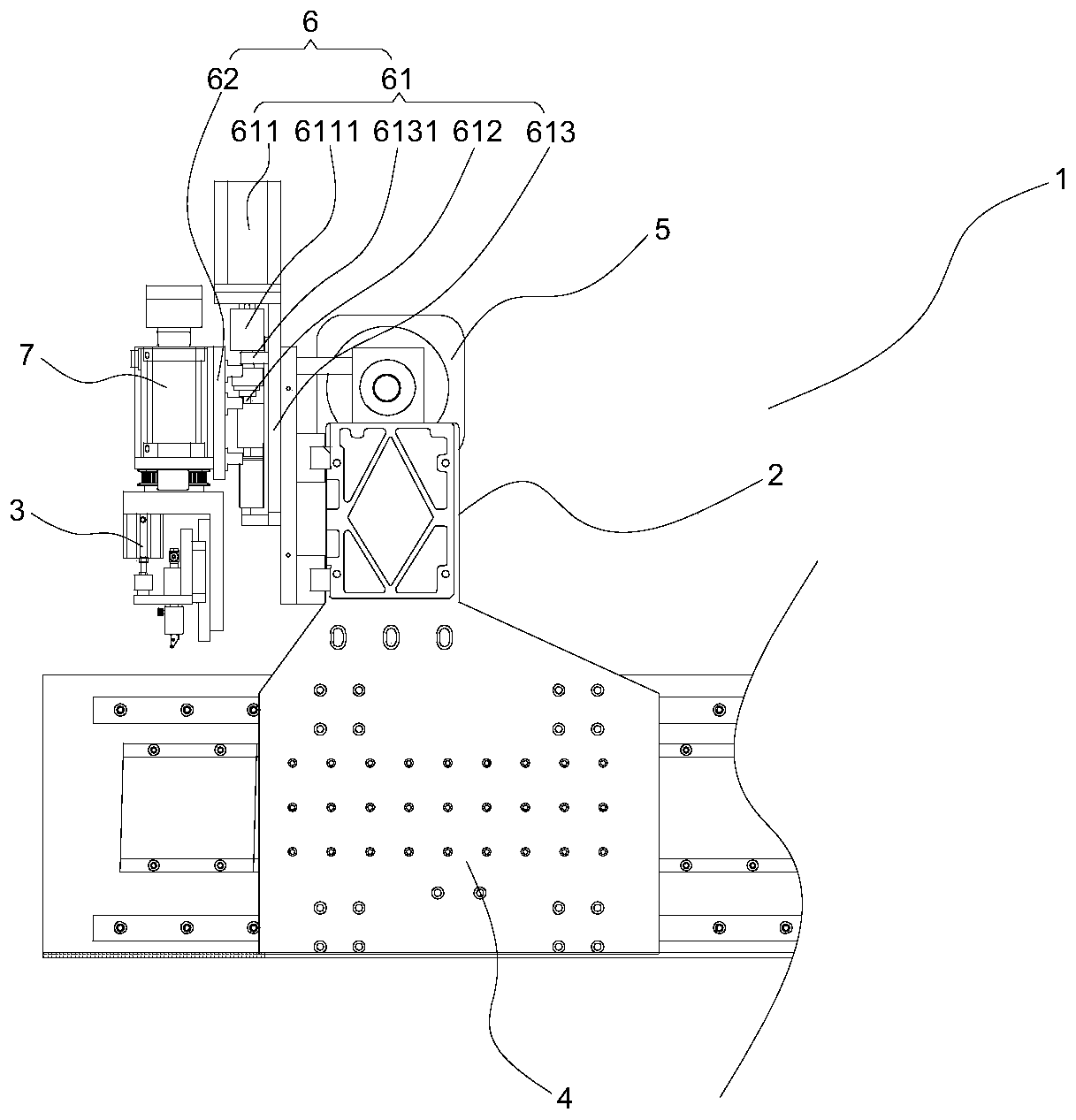

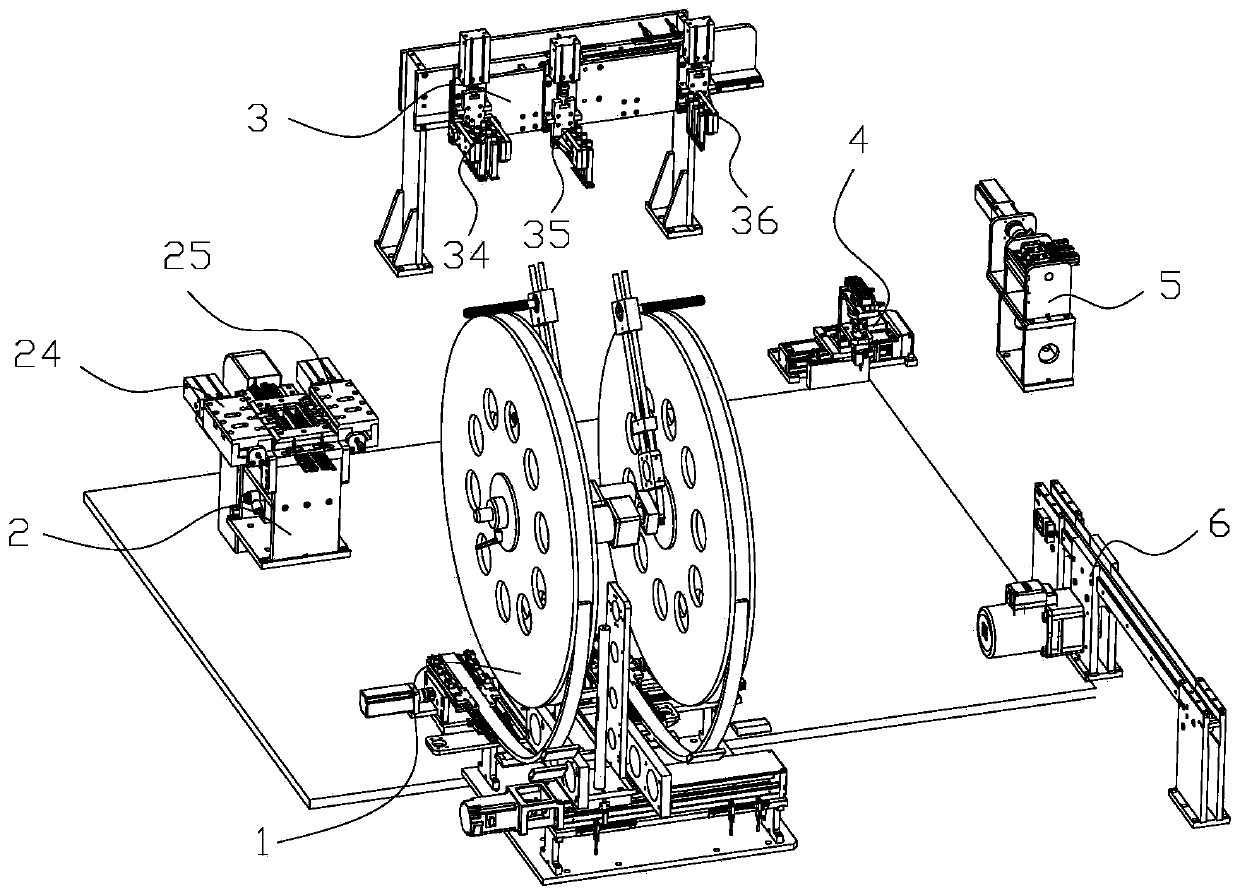

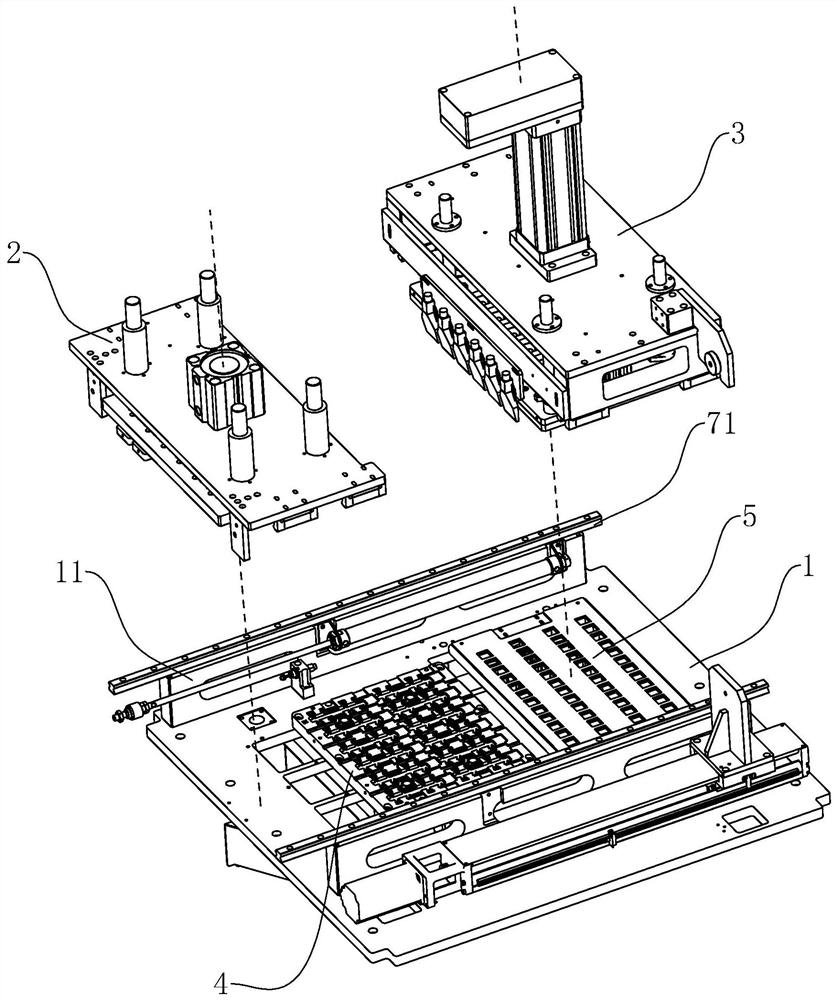

Scissor foot precise assembling system

ActiveCN113352074AImprove assembly efficiencySave manpower and material resourcesMetal working apparatusStructural engineeringWorkbench

The invention relates to a scissor foot precise assembling system. The scissor foot precise assembling system comprises a workbench, a bottom mold plate fixedly connected to the workbench, a cutting assembly and an assembling assembly, wherein the cutting assembly and the assembling assembly are connected to the workbench in a sliding manner and can move to the position above the bottom mold plate. The cutting assembly is provided with guide columns, and guide holes allowing the guide columns to be inserted therein are formed in the bottom mold plate. A batching unit is placed on the bottom mold plate. Outer frames are arranged in inclined bottom grooves and are arranged outside stop blocks in a sleeving manner, and inner frames are arranged in flat bottom grooves. The cutting assembly is provided with a cutter used for cutting the batching unit. The assembling assembly is provided with material taking rods used for being inserted into the inner frames and clamping the inner frames into the outer frames. According to the scissor foot precise assembling system, the inner frames and the outer frames of scissor feet can be assembled in a full-automatic manner, and the assembling efficiency is improved; and meanwhile, due to the fact that the guide columns are inserted into the guide holes, the cutting precision is improved, the size performance of the inner frames and the size performance of the outer frames are improved, and then the quality of the scissor feet after assembling is improved.

Owner:苏州亿源精密模具有限公司

Gray cloth cutting device

ActiveCN114438767APrecise positioningReduce mistakesSevering textilesTextile shapingBlade plateStructural engineering

The invention provides a gray cloth cutting device which is characterized in that gray cloth is placed on a bottom plate, and the bottom plate is clamped and embedded in an opening of an L-shaped plate; the positioning needle can be movably inserted into a positioning groove formed in the top of the L-shaped plate, the positioning needle comprises a positioning needle rod, a magnetic rod section is arranged between the positioning needle rod and the limiting part, and a positioning needle point is arranged at the bottom of the positioning needle rod; the mounting plate is connected with a cutting knife board through an angle adjusting structure, a pressure sensor is fixedly arranged at the bottom of the stopping block, a clamping block is fixedly arranged on the side face of the stopping block, and a cutting knife is fixedly arranged at the bottom of the cutting knife board. A flattening roller is hinged to the center shaft, and an adjusting spring is connected between the movable plate and the top wall of the top groove. The gray cloth cutting device is simple in overall structure, more diversified in function, capable of achieving more accurate positioning and cutting of gray cloth, flexible in operation and quite worthy of popularization.

Owner:江苏松柏纺织品有限公司

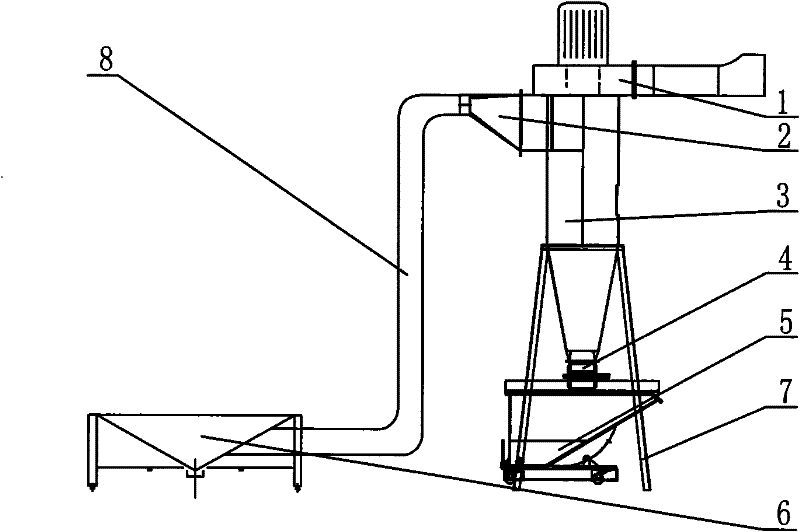

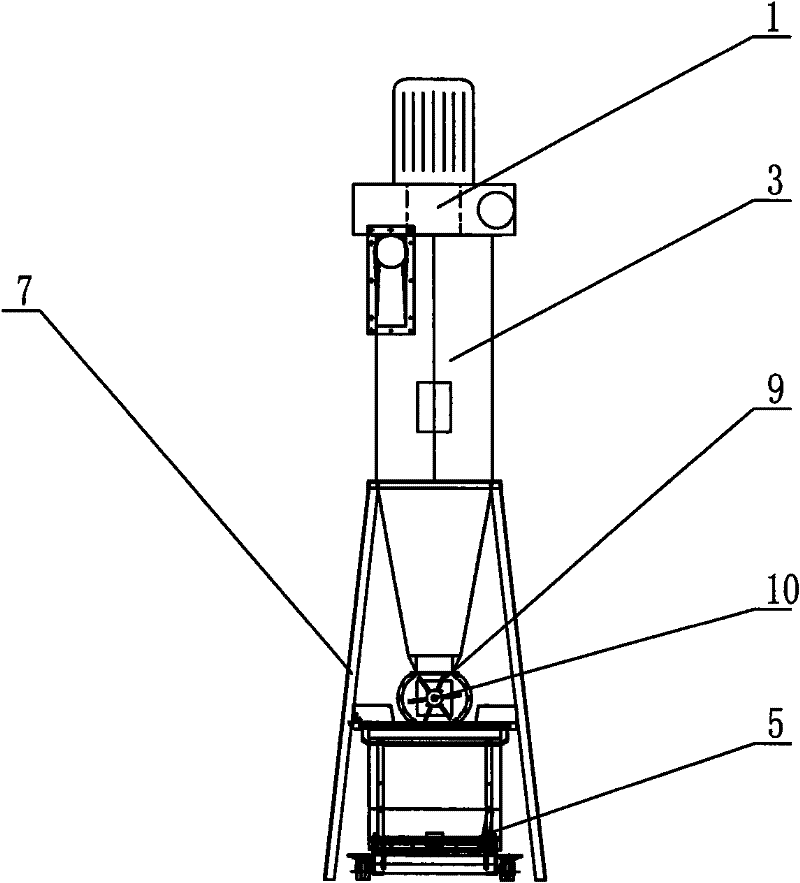

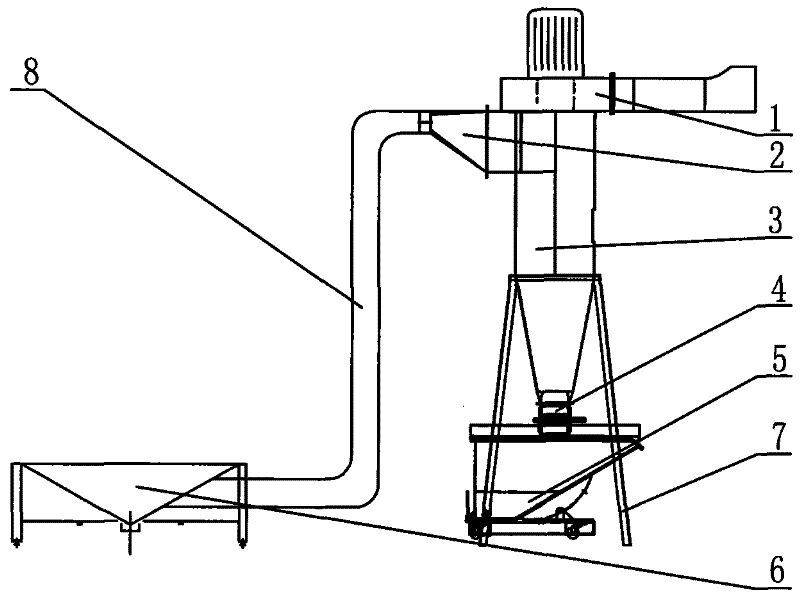

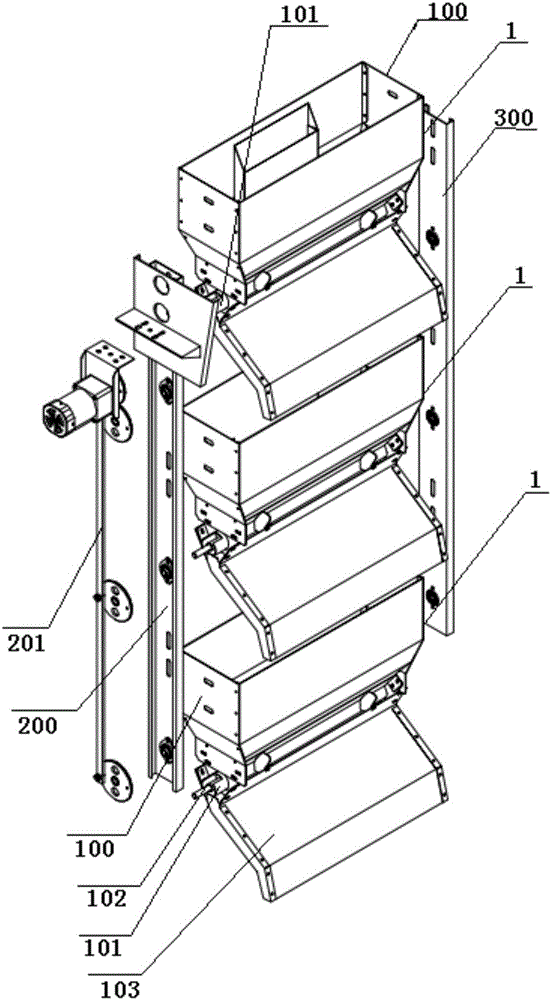

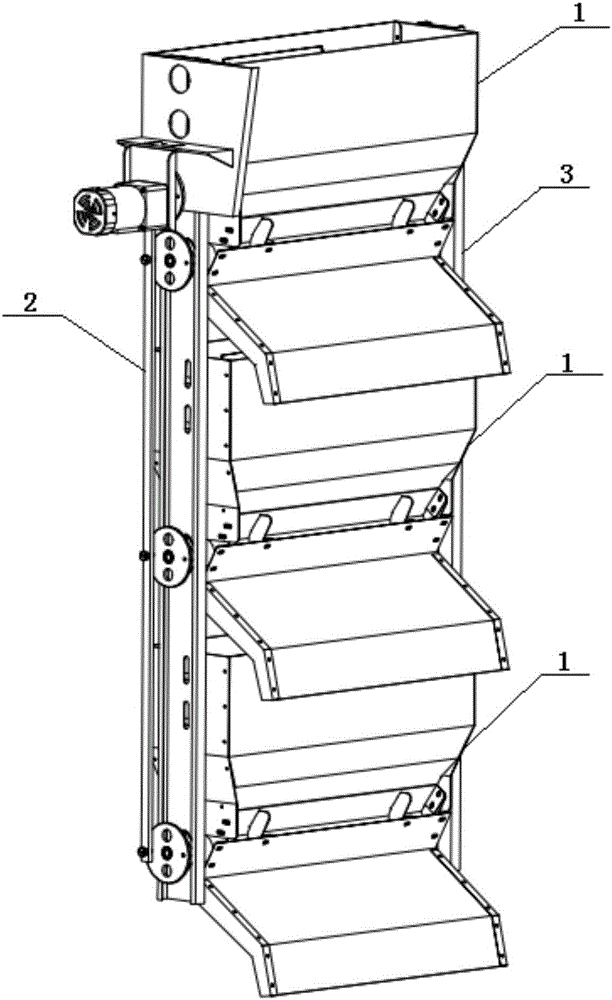

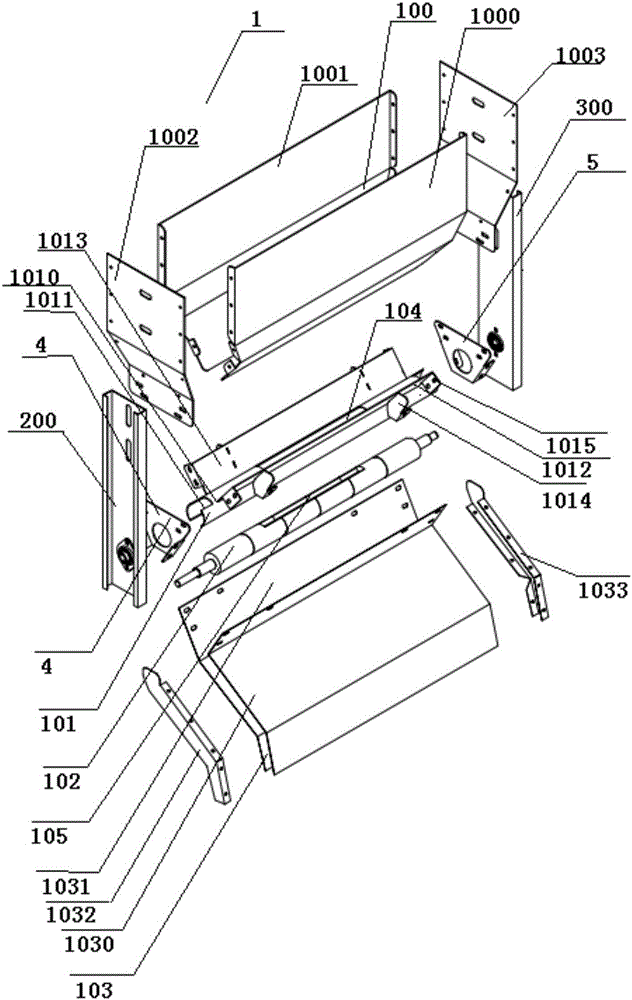

Quantitative location self-propelled hopper device

PendingCN106719093APrecise positioning and cuttingLow costAvicultureEngineeringMechanical engineering

Owner:江苏翠谷鸽业有限公司

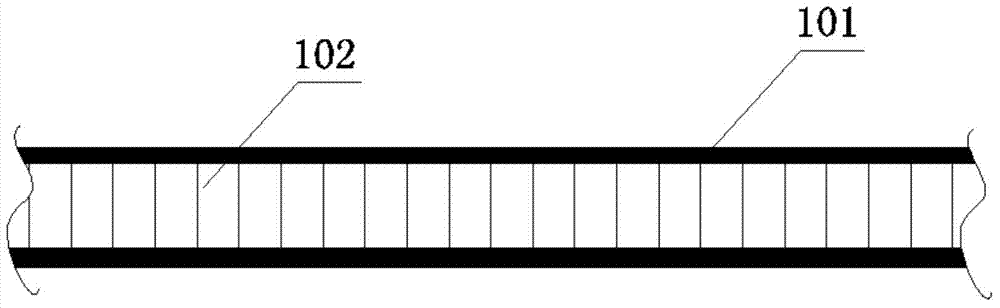

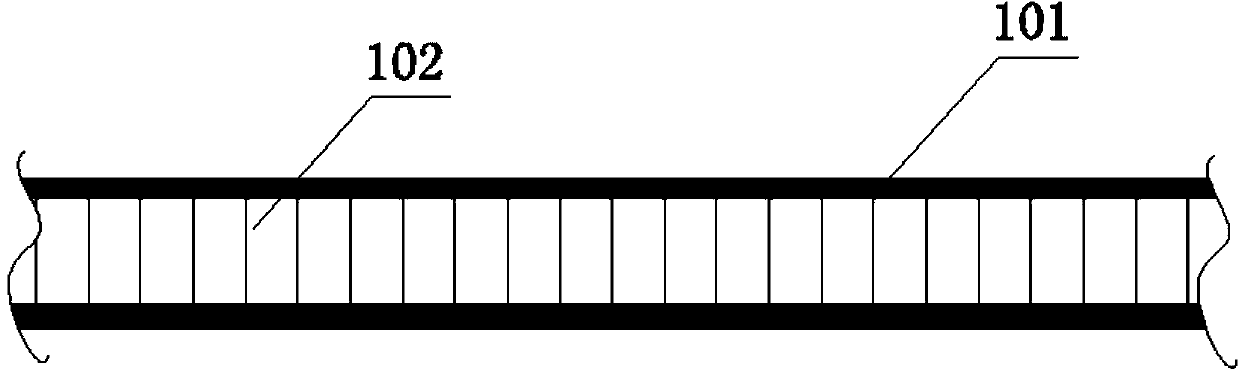

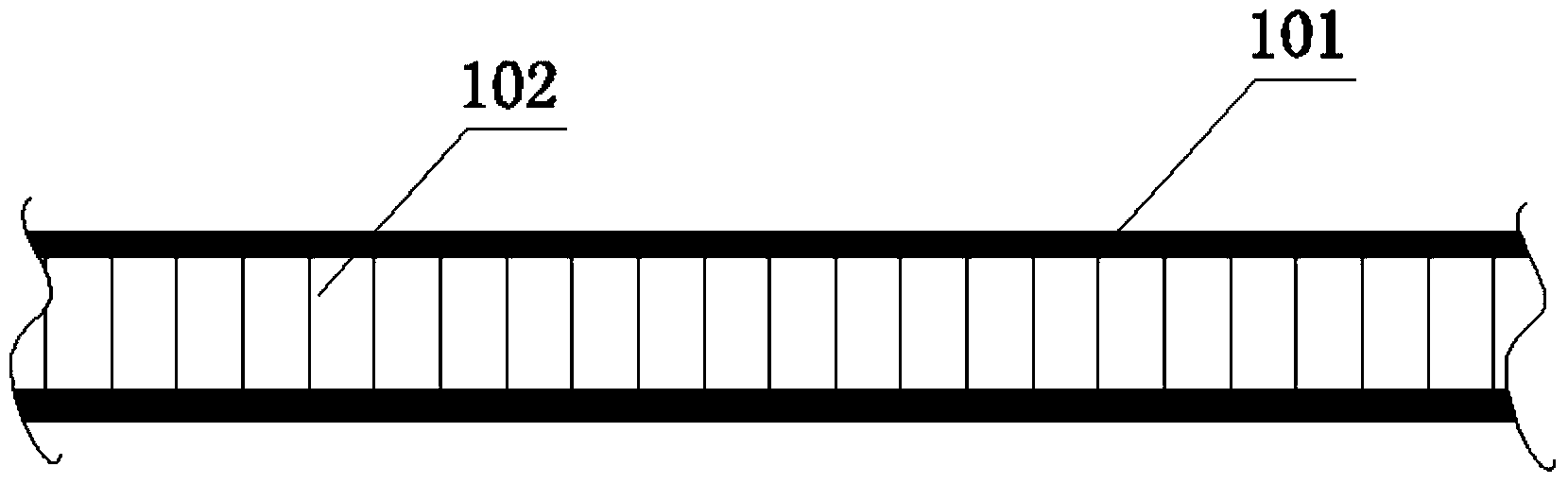

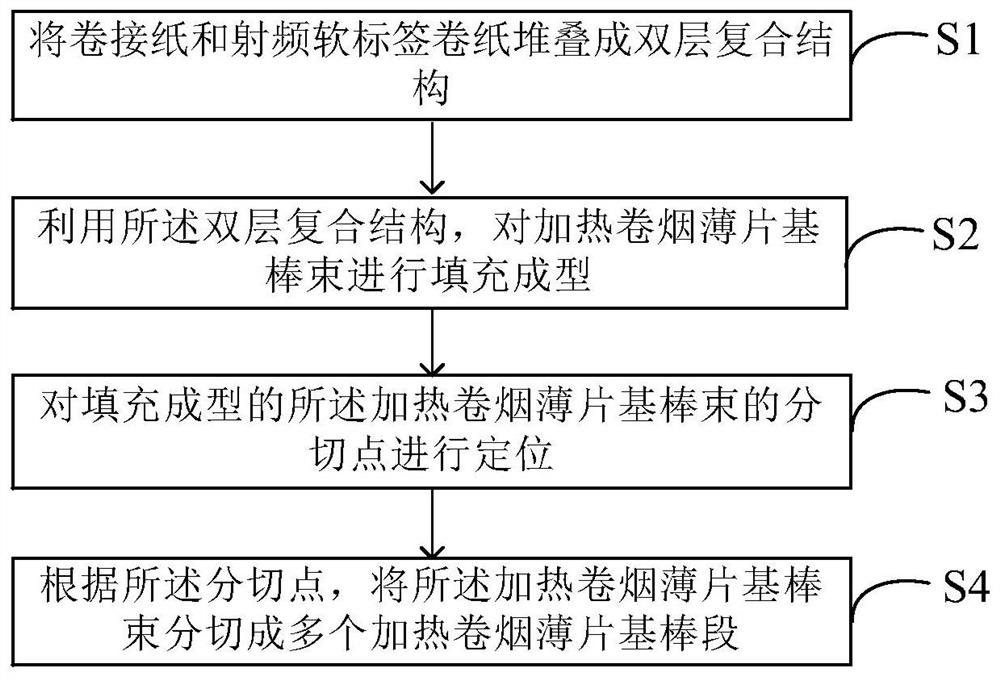

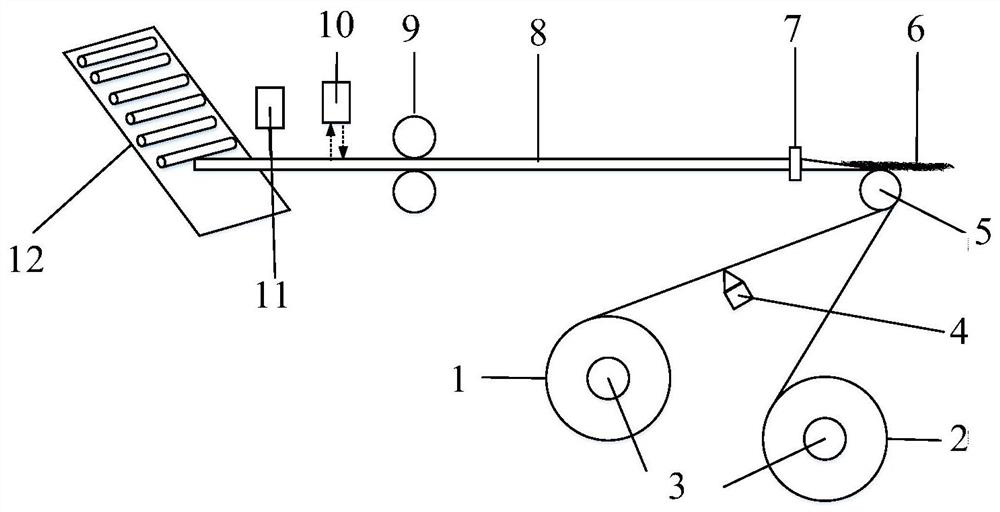

Method for manufacturing heating cigarette sheet base rod

PendingCN113749285AAchieve compositeAccurate cutting positioningCigarette manufactureRolling paperEngineering

The invention discloses a method for manufacturing a heating cigarette sheet base rod. The method comprises the following steps: stacking roll paper and radio frequency soft label roll paper into a double-layer composite structure; using the double-layer composite structure for carrying out filling forming on a heated cigarette sheet base rod bundle; positioning a slitting point of the heated cigarette sheet base rod bundle subjected to filling forming; and according to the cutting points, cutting the heating cigarette slice base rod bundle into a plurality of heating cigarette slice base rod sections. According to the method for manufacturing a heating cigarette sheet base rod, the tobacco sheet tows are filled and formed through double-layer compounding of the radio frequency soft label paper and the rolling paper in the rolling process, then the slitting points are positioned, slitting is conducted, rolling is completed, compounding of the radio frequency soft label and the cigarette can be achieved, the heating cigarette base rod is endowed with the radio frequency characteristic, and a foundation is laid for non-contact identification between the heating cigarette and the appliance and an exclusive adaptation technology.

Owner:CHINA TOBACCO HENAN IND

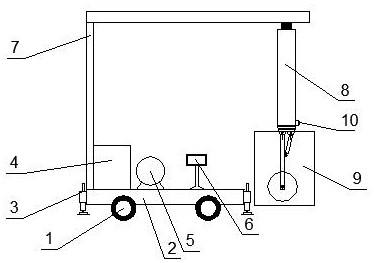

Foundation pit anchor cable cutting machine

PendingCN112663611AMeet cutting construction needsEasy to operateBulkheads/pilesArchitectural engineeringEngineering

The invention belongs to the technical field of foundation pit anchor cable construction, and particularly relates to a foundation pit anchor cable cutting machine used during foundation pit secondary treatment. The foundation pit anchor cable cutting machine comprises a traveling device, a chassis, balance supporting devices, a hydraulic oil tank, a hydraulic oil pump, a telescopic device, a fixed cutting device, a micro camera and an electronic display screen, wherein the fixed cutting device is arranged at one end of the telescopic device, the micro camera is fixed below the telescopic device, the telescopic device is connected with the chassis through an l-shaped cantilever steel component, the l-shaped cantilever steel component is fixed to the left side of the chassis, the balance supporting devices are arranged on the periphery of the chassis, the traveling devices, the hydraulic oil tank and the hydraulic oil pump are arranged at the bottom of the chassis, and the electronic display screen is arranged above the chassis. According to the foundation pit anchor cable cutting machine, a special telescopic and cutting device can directly enter a narrow working face with a limited space for anchor cable cutting, large-range working platform construction is avoided, the working efficiency is improved especially in the secondary treatment environment of an existing foundation pit, and excessive disturbance of the soil body condition of the foundation pit is avoided.

Owner:长沙垚森工程科技有限公司

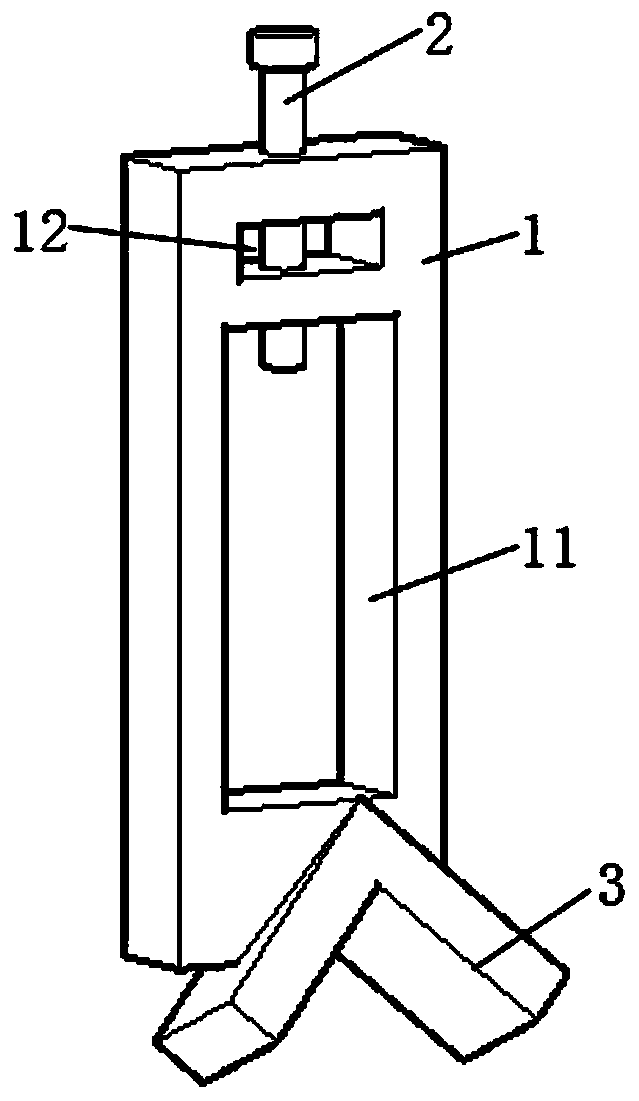

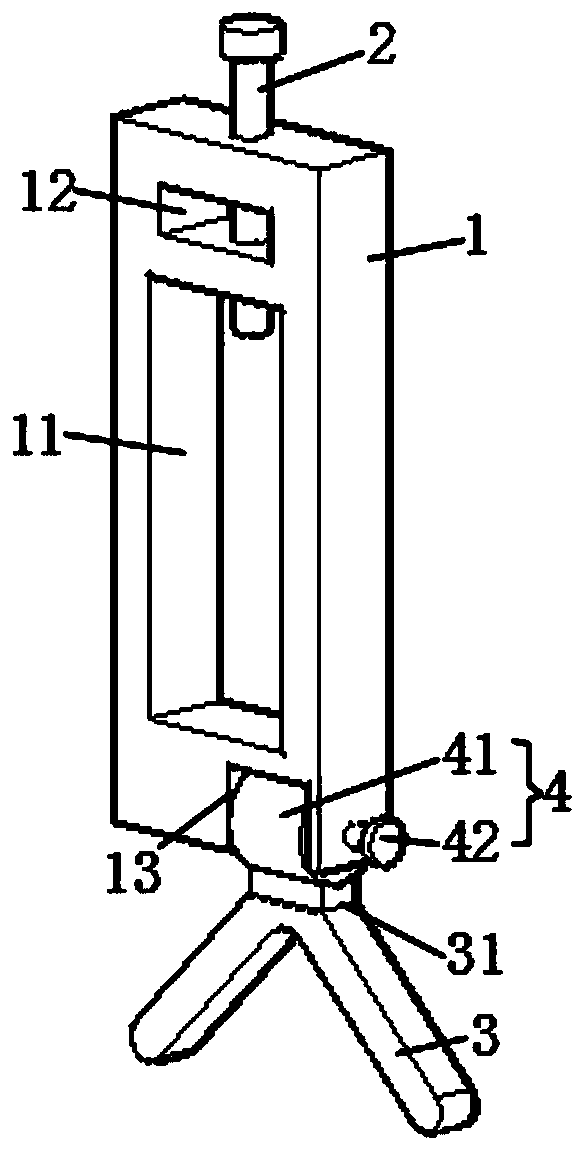

Anti-deviation device for cable cutting

PendingCN111293637AImprove the feelEasy cuttingApparatus for removing/armouring cablesApparatus for joining/termination cablesScrew threadElectric cables

The invention discloses an anti-deviation device for cable cutting. The anti-deviation device comprises an anti-deviation device body, a cutter locking bolt and a triangular clamp. The anti-deviationdevice body is fixed at the top of the triangular clamp; a cutter groove for mounting a cutter runs through the anti-deviation device body along the length direction of the cable; the opening of the clamping groove of the triangular clamp is arranged downwards, and the triangular clamp is vertically clamped at the top of a horizontally placed cable; the cutter locking bolt penetrates through a threaded hole in the anti-deviation device body and is matched with the threaded hole in the anti-deviation device body; and the extrusion end of the cutter locking bolt faces the cutter. The device is simple in structure, low in manufacturing cost and convenient to use.

Owner:HUAINAN MINING IND GRP

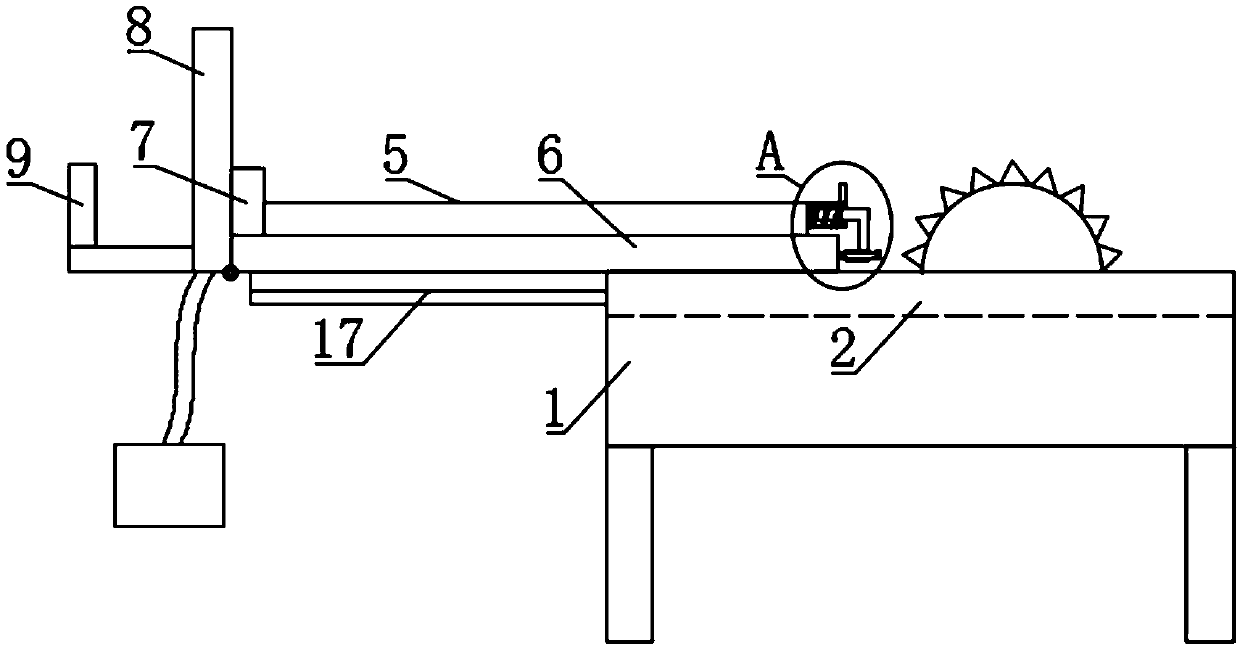

Angle steel cutting device capable of accurately positioning cutting length

ActiveCN110877122AAvoid deformationSimple and fast operationShearing machinesShearing machine accessoriesDrive shaftStructural engineering

The invention relates to the technical field of hardware fittings and discloses an angle steel cutting device capable of accurately positioning the cutting length. The device comprises a base. A column is fixedly installed on the base, a driving device is fixedly installed on the front end of the upper portion of the column, and a driving shaft is arranged on the right side of the driving device.A rotation disc is fixedly connected to the right side of the driving shaft, a horizontal rod is fixedly connected to the front end of the middle of the column, and a plunger cylinder is fixedly connected to the right end of the horizontal rod. A plunger is arranged in an inner cavity of the plunger cylinder, and an angle steel slotter is fixedly connected to the lower portion of the plunger. According to the angle steel cutting device capable of accurately positioning the cutting length, magnetic rollers are used for conveying angle steel, so that the angle steel extrudes a long rod to drivea press plate to be screwed into the plunger cylinder. In cooperation with a rotation piston, the press plate is extruded, so that the angle steel slotter falls down. The angle steel cutting device has the advantages that operation is easily and conveniently performed, the cut angle steel does not easily deform, the cutting end face is in order, the cutting length can be accurately positioned, andthe cut angle steel is automatically stored.

Owner:浙江杭海镀锌钢管有限公司

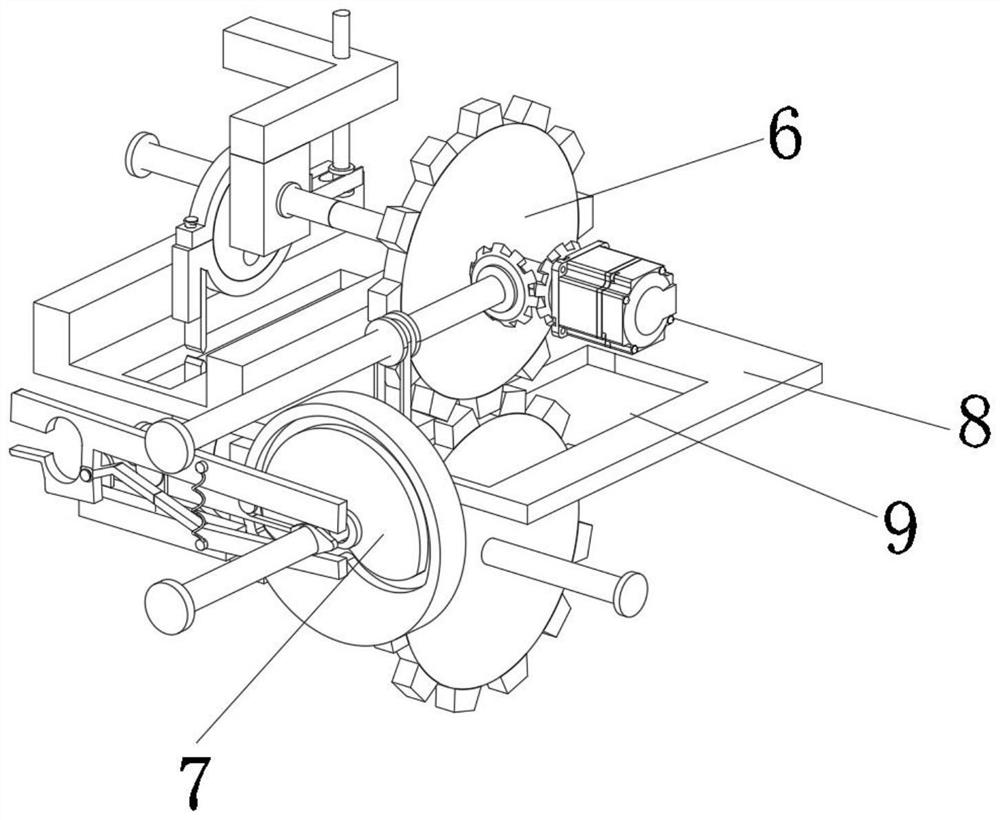

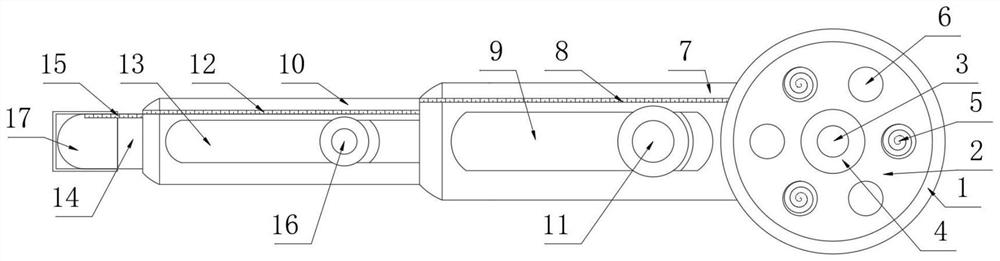

Fish head cutting device and fish head processing method

InactiveCN111387263AAccurate cutting positioningImprove cutting efficiencyFish processingFisheryEngineering

The invention discloses a fish head cutting device. The device comprises an operation table, a driving mechanism, a transmission mechanism and a cutting mechanism; the driving mechanism and the cutting mechanism are oppositely arranged at two ends of the operation table; two ends of the transmission mechanism are respectively arranged on the driving mechanism and the cutting mechanism; the drivingmechanism drives the cutting mechanism to act through transmission of the transmission mechanism, and cutting of a fish head by the cutting mechanism is realized; the cutting mechanism comprises a fixed seat, a protective shell, a fish head positioning piece and a cutting rotary disc; the fixed seat is vertically arranged on the operation table; the protective shell is arranged on the top of thefixed seat; a processing space is formed in the protective shell; the cutting rotary disc is arranged in the processing space; the fish head positioning piece is arranged at the bottom of the fixed seat; and the fish head positioning piece corresponds to the lower part of the processing space. The fish head is fixed through the fish head positioning piece, and the transmission mechanism brings thefish head to the rotary disc, and the rotary disc rotates in the processing space, so that processing of fish head cutting is realized. According to the fish head cutting device and a fish head processing method, the fish head can be accurately positioned and cut.

Owner:广东明基水产集团有限公司 +1

Circular cutting auxiliary device of angle grinder

InactiveCN112643490AAccurate cutting positioningCircle Cutting Standard AccuratePortable grinding machinesPhysicsEngineering

The invention discloses a circular cutting auxiliary device of an angle grinder, and particularly relates to the technical field of circular cutting auxiliary devices of angle grinders. The circle cutting auxiliary device comprises a soft airtight cylinder, wherein a suction cavity is formed in the soft airtight cylinder, a positioning connecting column is fixedly installed in the center of the suction cavity, a positioning sucker is fixedly installed at the end of the positioning connecting column, an elastic separation assembly and a check exhaust valve are fixedly installed in the suction cavity, and a first positioning measurement supporting arm is movably installed outside the soft airtight cylinder. By arranging the soft airtight cylinder, in the working process of the device, point finding and fixing are conducted through the positioning connecting column and the positioning sucker, then the soft airtight cylinder is extruded through external force, internal air of the soft airtight cylinder is exhausted through the check exhaust valve, and the soft airtight cylinder and a cutting machining raw material are tightly attached and fixed, so that a positioning fulcrum is determined for the cutting work of the angle grinder, the cutting positioning accuracy is ensured, and the problem that the machining amount is not qualified due to inaccurate manual positioning is solved.

Owner:无锡博楷电动工具制造有限公司

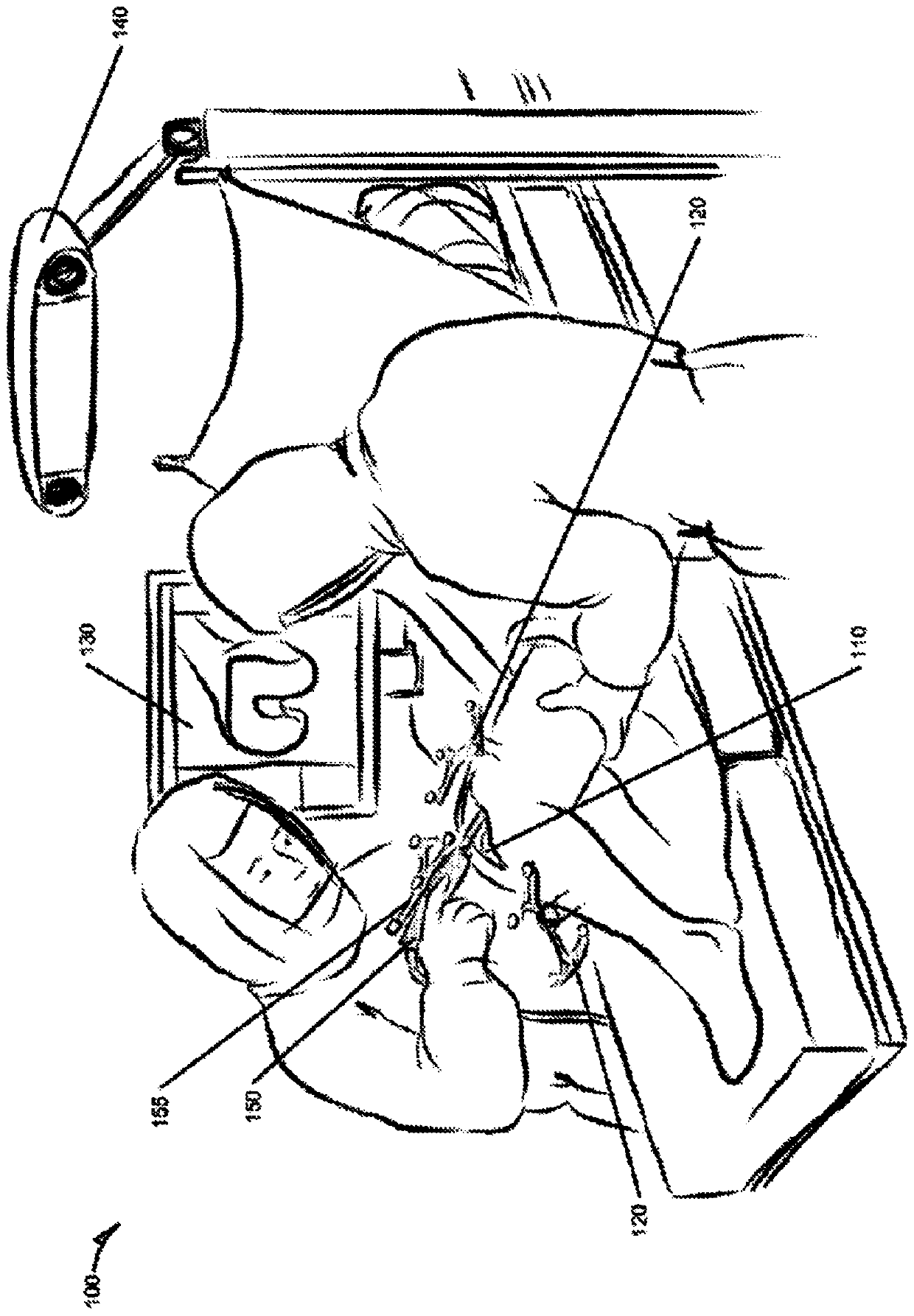

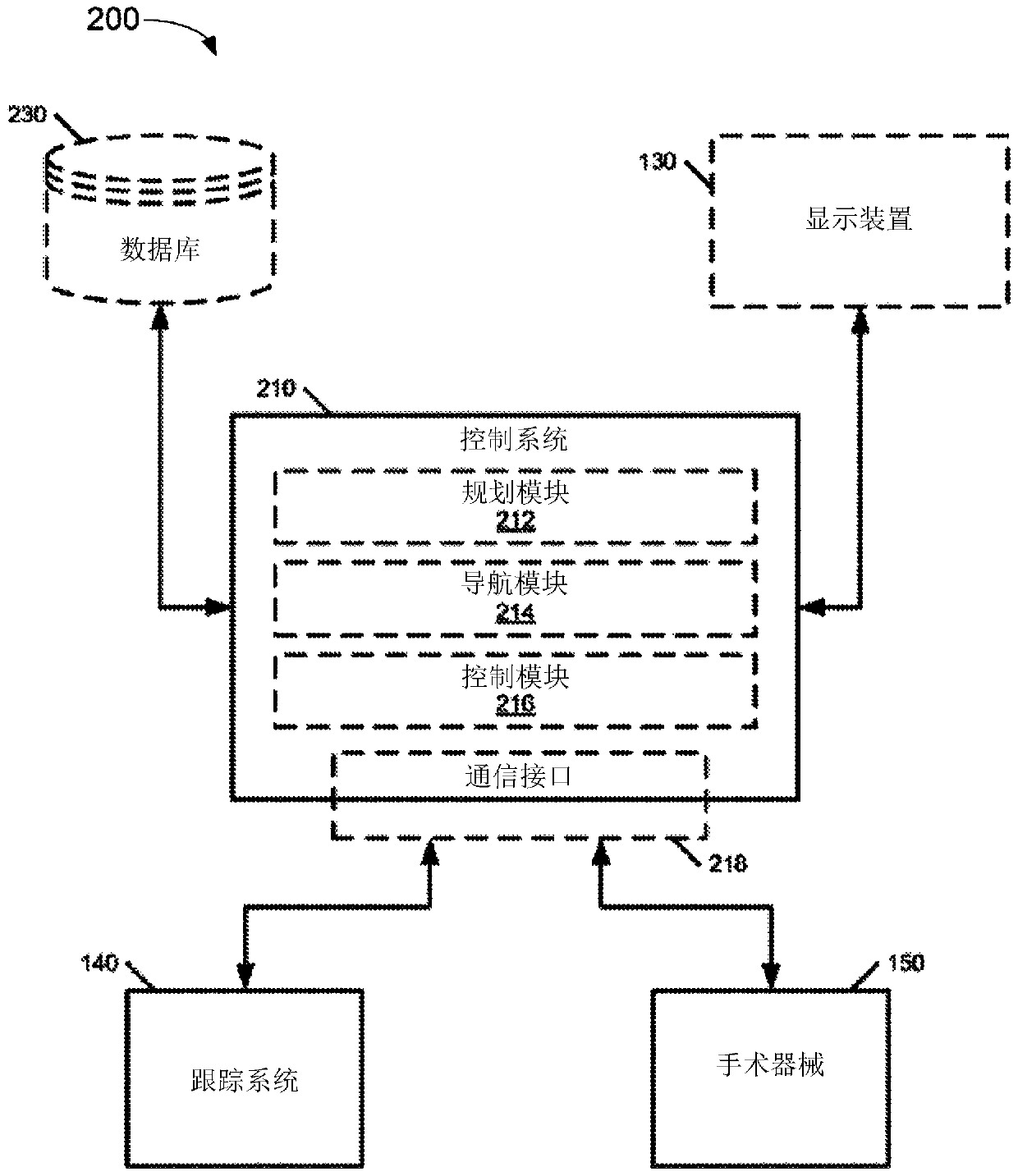

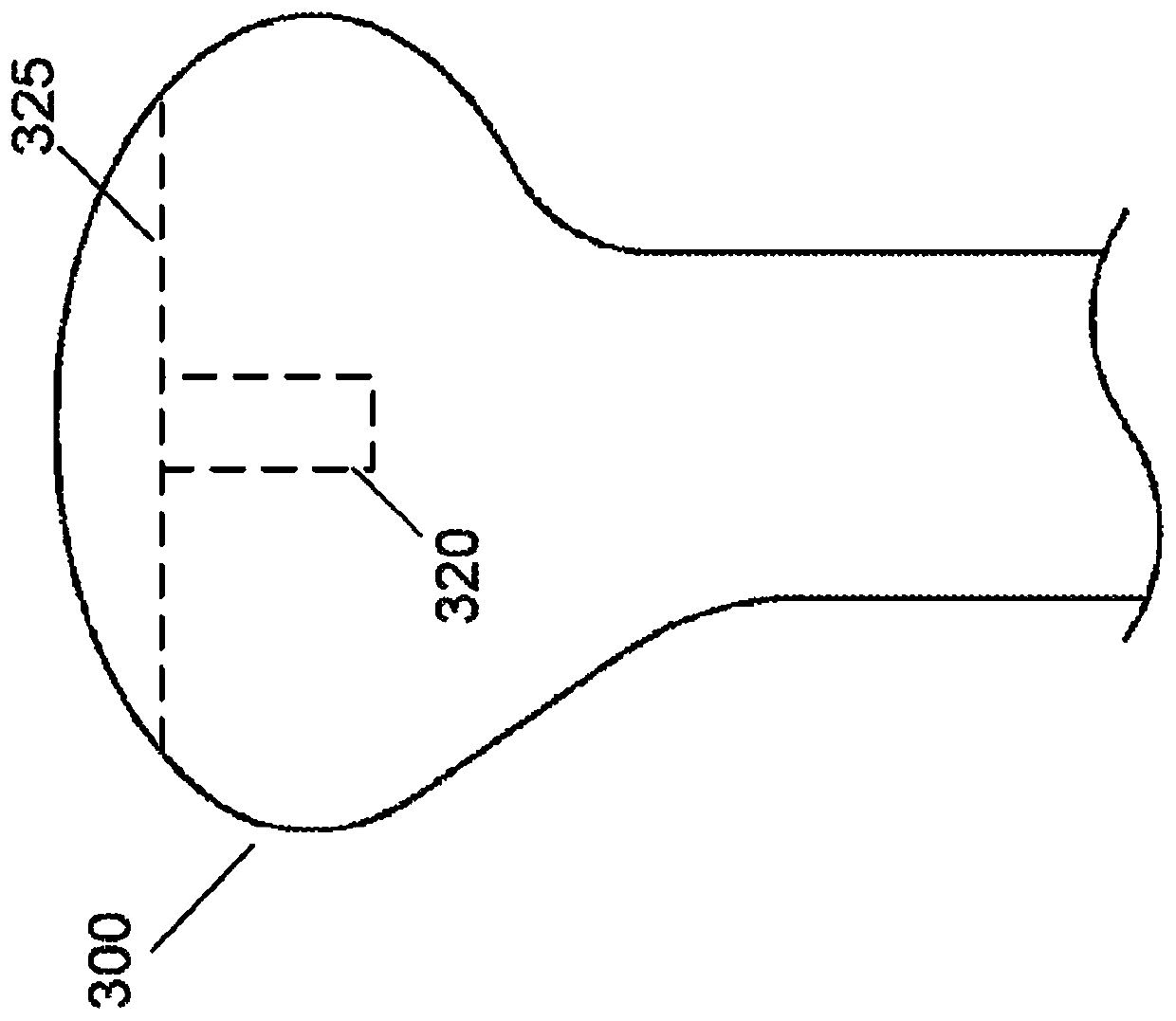

Surgical punch tool for robotically assisted bone preparation for positioning of a cutting block

PendingCN111132624AAccurate cutting positioningEasy to placeSurgical navigation systemsComputer-aided planning/modellingSurgical punchReoperative surgery

Owner:SMITH & NEPHEW INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com