Scissor foot precise assembling system

A technology for assembling system and scissors feet, which is applied in the field of scissors legs, can solve the problems of low efficiency of scissors legs and inability to meet the needs of actual production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

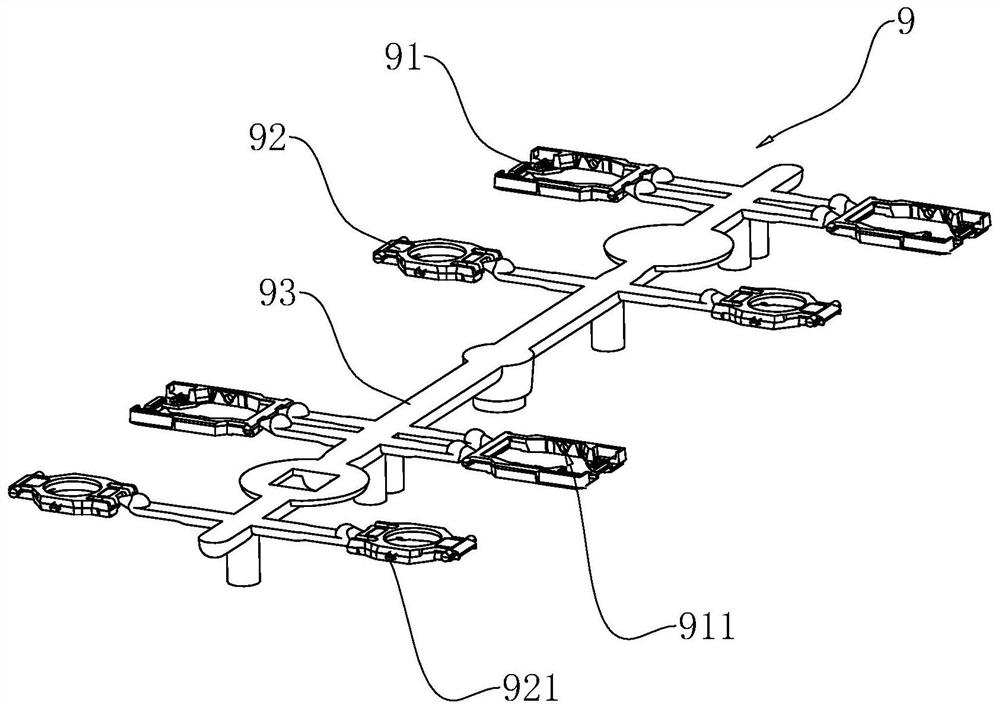

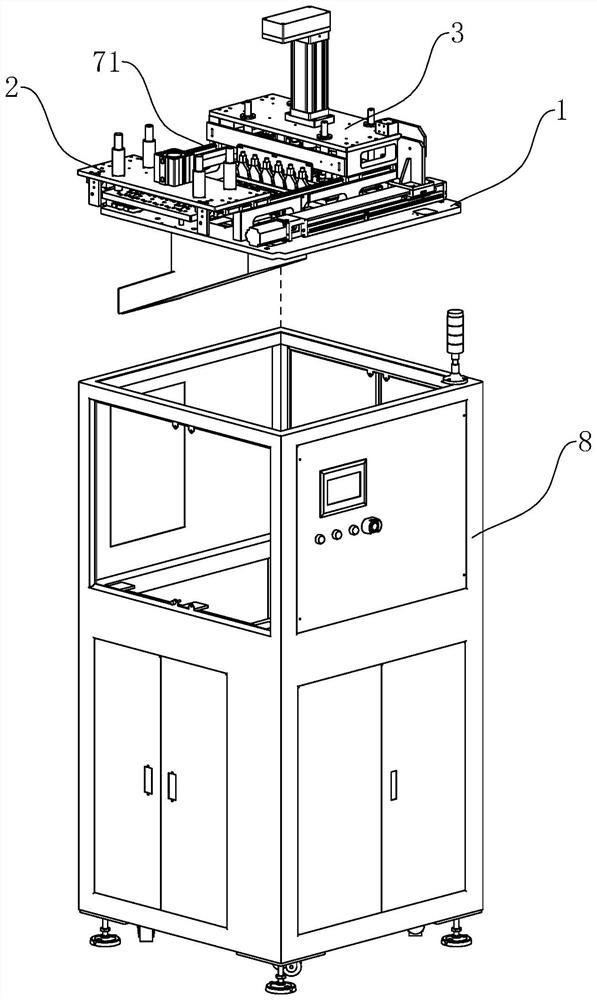

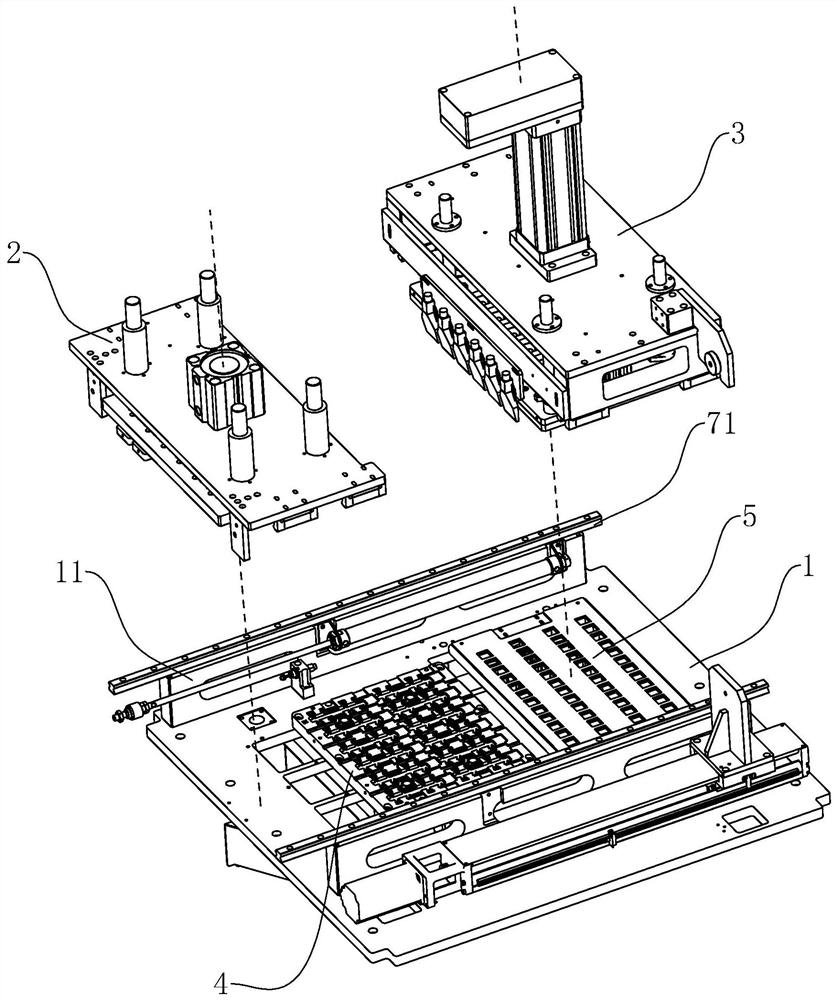

[0060] The embodiment of the present application discloses a precise assembly system of scissor feet, which is used to cut off the outer frame 91 and inner frame 92 on the batching unit 9 from the connecting rod 93 , and snap the inner frame 92 into the outer frame 91 . refer to figure 1 , The batching unit 9 includes a connecting rod 93 and an outer frame 91 and an inner frame 92 connected thereto. In this embodiment, one connecting rod 93 is provided, and four outer frames 91 and inner frames 92 are provided. The outer frames 91 are symmetrically connected in pairs on both sides of the connecting rod 93, and the inner frames 92 are symmetrically connected in pairs on both sides of the connecting rod 93; and the outer frames 91 and inner frames 92 on the same side of the connecting rod 93 are arranged alternately . At the same time, shaft grooves 911 are provided on opposite sides of the inner ring of the outer frame 91 , and correspondingly, rotating shafts 921 matching th...

Embodiment 2

[0096] The embodiment of the present application discloses a precise assembly system for scissor feet. This embodiment is basically the same as Embodiment 1, the difference is that, with reference to Figure 13, this scissor foot precision assembly system is not provided with cylinder 62 but replaces with screw mandrel 64. Specifically, two screw mandrels 64 are horizontally arranged on the workbench 1, and the two screw mandrels 64 are symmetrically arranged on both sides of the cutting assembly 2, and are respectively located inside the corresponding slide rails 71; extending in the length direction. One end of each screw mandrel 64 is connected to the motor 65 fixed on the corresponding bracket 11 and positioned at the receiving plate 5 , and the other end is screwed to the second connection block 29 installed on the lower surface of the first fixing plate 21 . Through the cooperative rotation of the two screw rods 64 , the first fixing plate 21 can be driven, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com