Laser cutting device and laser cutting work method

A laser cutting and equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting production rhythm, positioning accuracy, unqualified cutting hole quality, etc., to ensure continuous and stable production and cutting accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

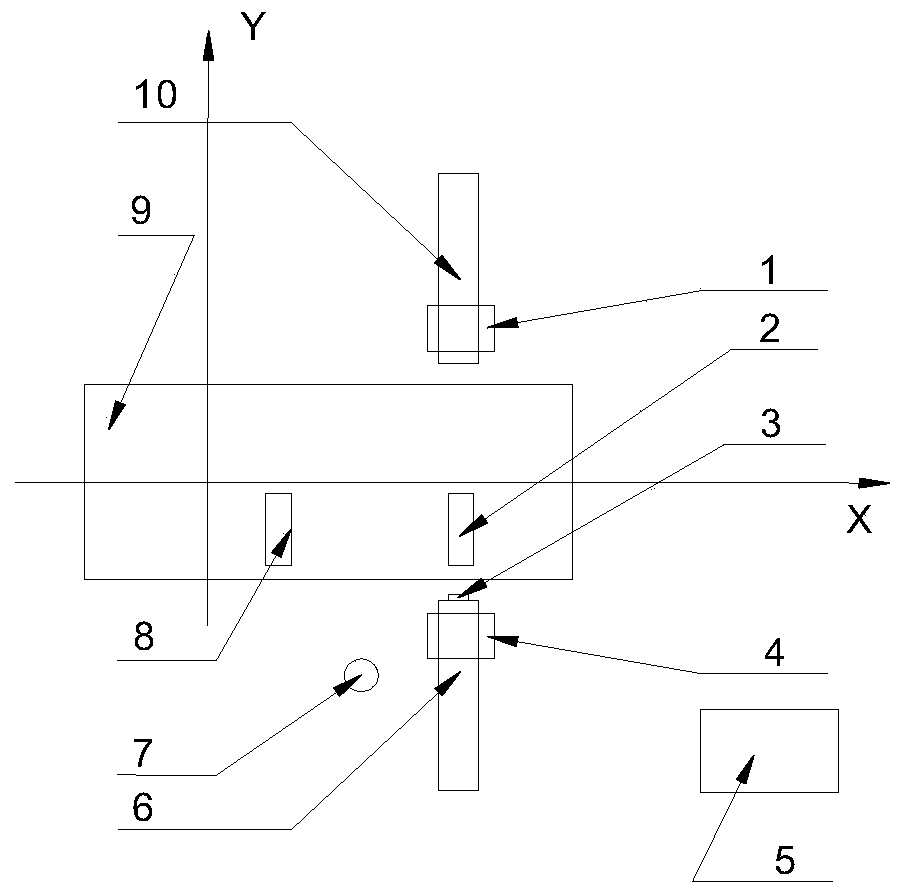

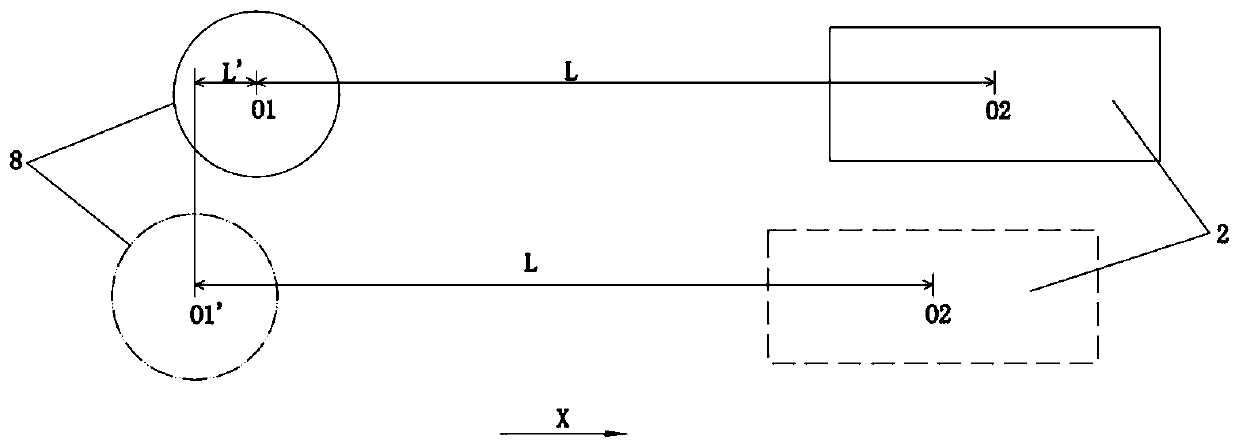

[0033] The laser cutting equipment in this embodiment is suitable for vehicle body processing, such as Figure 1-2 As shown, it includes: a cutting motion mechanism 6, in particular, the cutting motion mechanism 6 is a high-precision multi-axis motion system, and the repetitive motion accuracy is ≤0.05mm;

[0034] Laser cutting device 4, it is connected with described cutting motion mechanism 6, and produces the laser that is used for cutting; Laser cutting device 4 in the present embodiment is three-axis laser cutting cutting device, can finish 50mm in horizontal direction, height direction respectively. ≥10mm moving action, and can cut and form a cutting hole with a diameter of φ0.1mm; since laser cutting is a non-contact processing, it will not cause body vibration during the cutting process, and there is no consumption of the processing head, At the same time, the three-axis laser cutting device can also greatly improve the cutting accuracy, so that the cutting accuracy of...

Embodiment 2

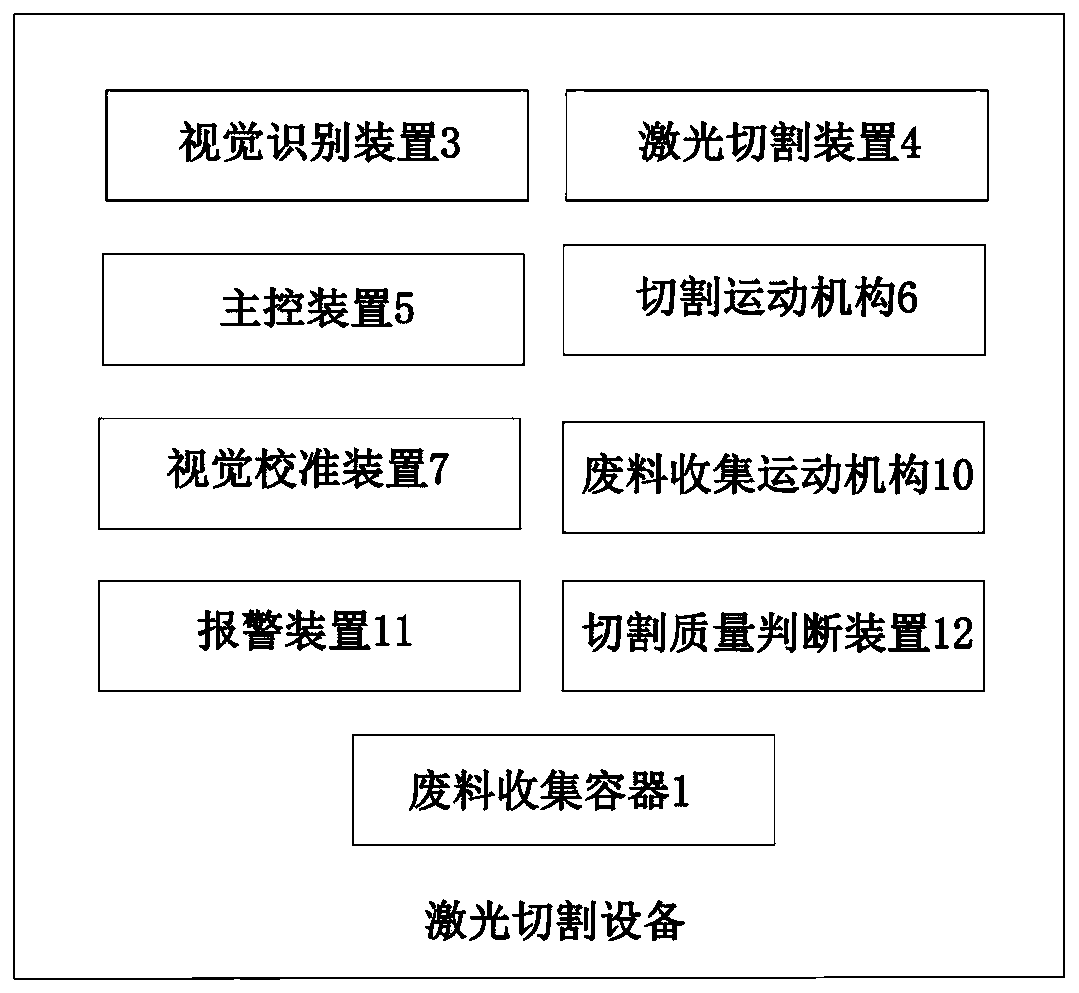

[0041] This embodiment still provides a kind of laser cutting equipment, and its only difference with Embodiment 1 is that, as figure 2 As shown, the laser cutting equipment in this embodiment also includes: a waste material collection motion mechanism 10, which is connected to the main control device 5; and a waste material collection container 1, which is connected to the waste material collection motion mechanism 10; and the waste material collection After receiving the vehicle type information, the motion mechanism 10 invokes the pre-stored waste collection movement path information corresponding to the vehicle type, and drives the waste collection container 1 to move to the vicinity of the cutting area according to the waste collection movement path information, so as to Complete collection of cutting waste.

[0042] Similarly, the waste material collection motion mechanism 10 may also be a high-precision multi-axis motion system, and the waste material collection moveme...

Embodiment 3

[0046] This embodiment still provides a kind of laser cutting equipment, and its only difference with Embodiment 1 or 2 is that, as figure 2 As shown, the laser cutting equipment in this embodiment also includes: a cutting quality judging device 12, which is connected to the visual recognition device 3 and the alarm device, and is used to set the It is compared with the standard image information, and according to the comparison result, it is judged whether the hole and / or contour formed by cutting meets the quality standard, and a judgment result is formed, and the alarm device receives the judgment result, and generates an alarm signal when the judgment does not meet the quality standard; and The image information of the hole and / or contour formed by the cutting is obtained through the visual recognition device.

[0047] Therefore, by checking the cutting quality online after the cutting is completed, the cutting quality data can be obtained in time, fully ensuring the smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com