Lead frame and production process thereof

A lead frame and production process technology, applied in the field of EMC support and its production process, can solve the problems of inability to meet the production of high-precision lead frames, unfavorable integrity of the LED single frame, and bending damage of the LED single frame, etc. Ingenious design, efficient etching, and small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention provides a lead frame and a production process thereof. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

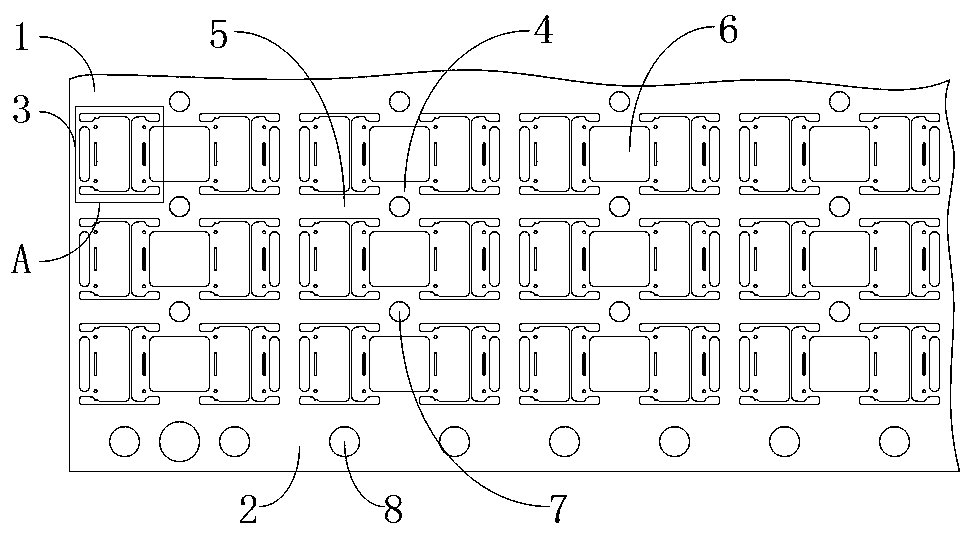

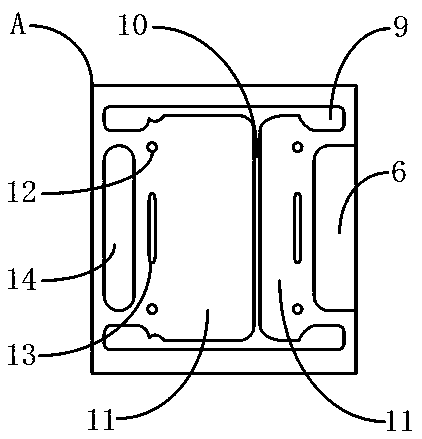

[0040] lead frame, such as figure 1 and figure 2 As shown, it includes a bracket base 1, and the bracket base 1 includes lateral edge bands 2 on both sides, and several LED monomer frames 3 arranged in a horizontal and vertical array between the lateral edge bands 2 on both sides.

[0041] Among them, between adjacent LED monomer frames 3, there are vertically arranged longitudinal connection strips 4 and horizontally arranged transverse connection strips 5, and any adjacent LED monomer frames 3 are provided with a rectangular strip on the longitudinal connection strips 4. In the empty area 6 , a positioning through hole 7 is provided at the intersection of the longitudinal connecting belt 4 and the transverse connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com