Patents

Literature

50results about How to "Ensure shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for rolling thin high-strength steel plate of single-frame steckel mill

ActiveCN102179406ASolve the problem of excessive rolling forceSolve quick stopRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

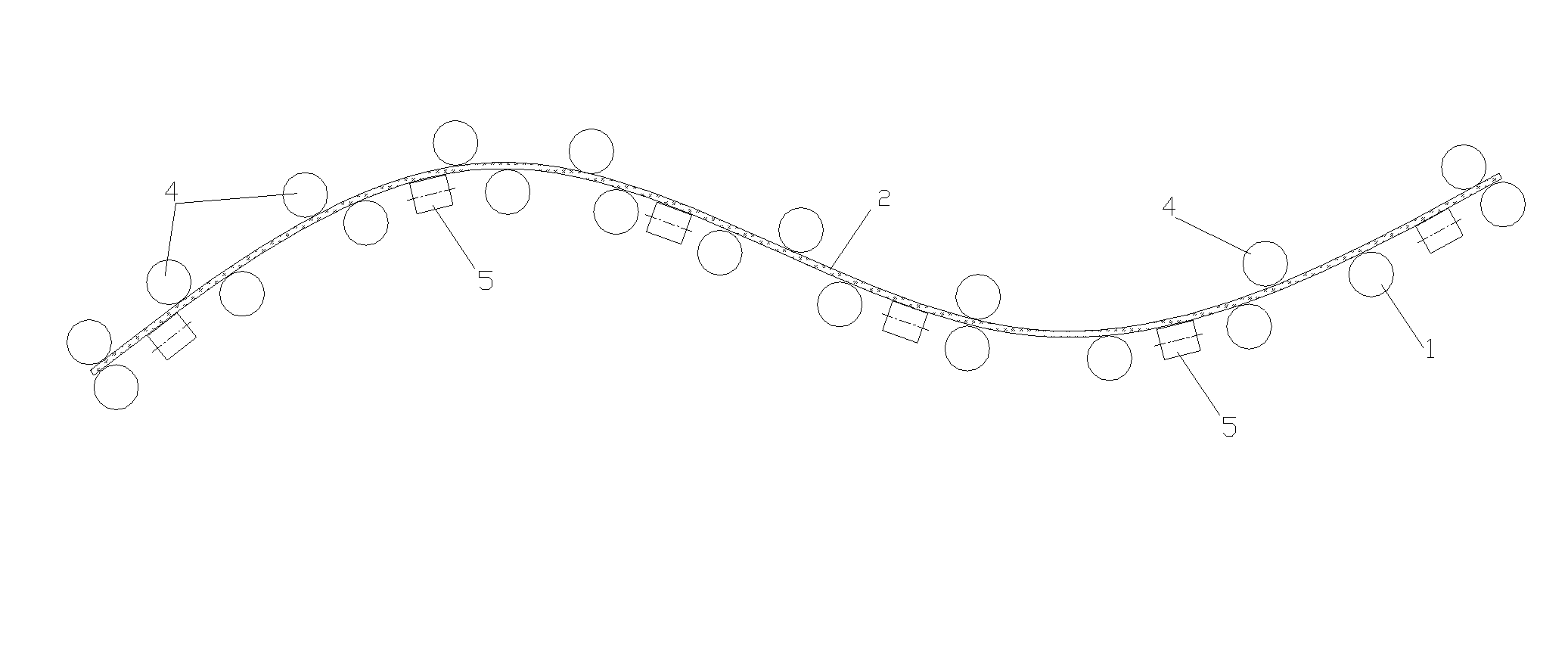

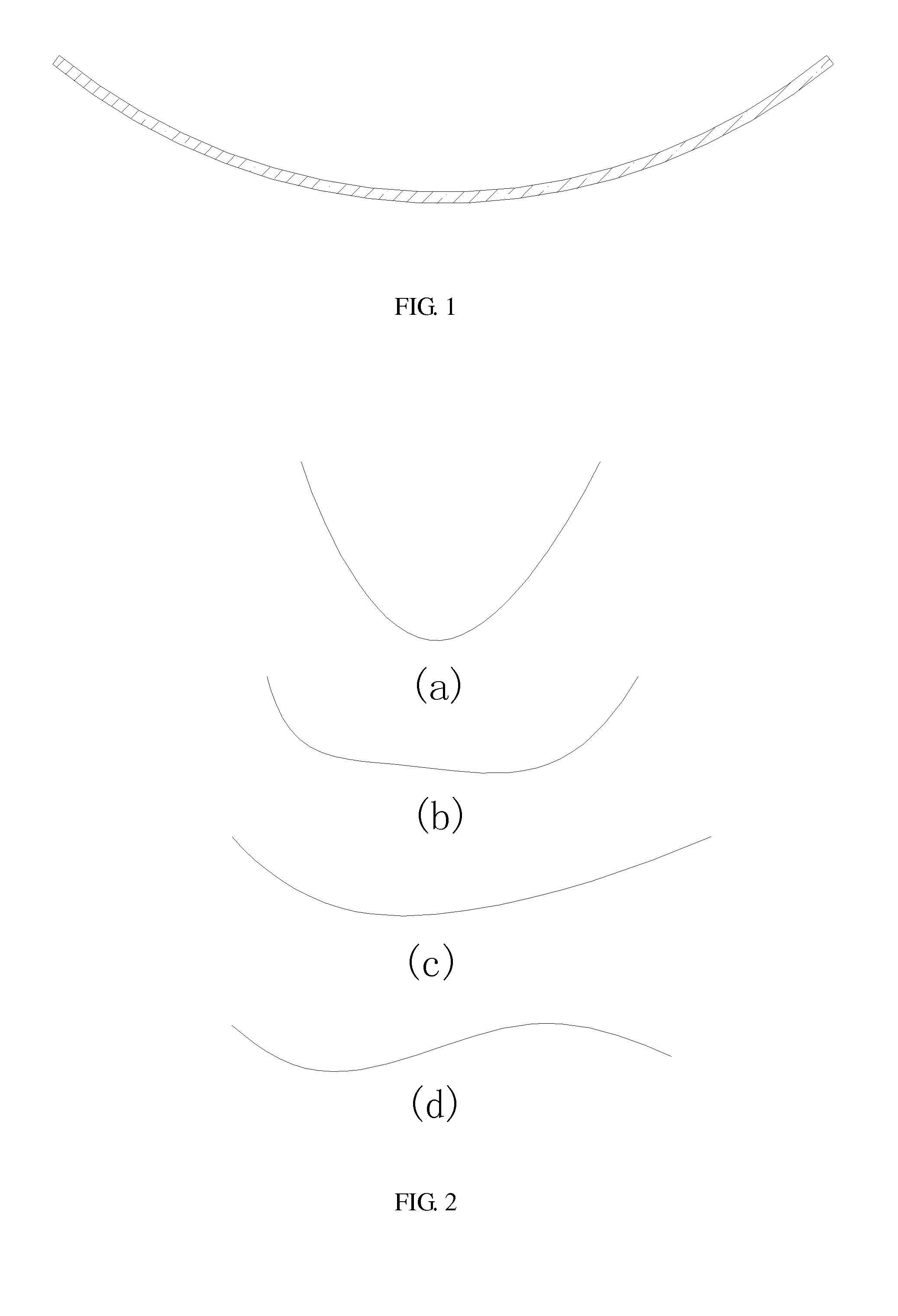

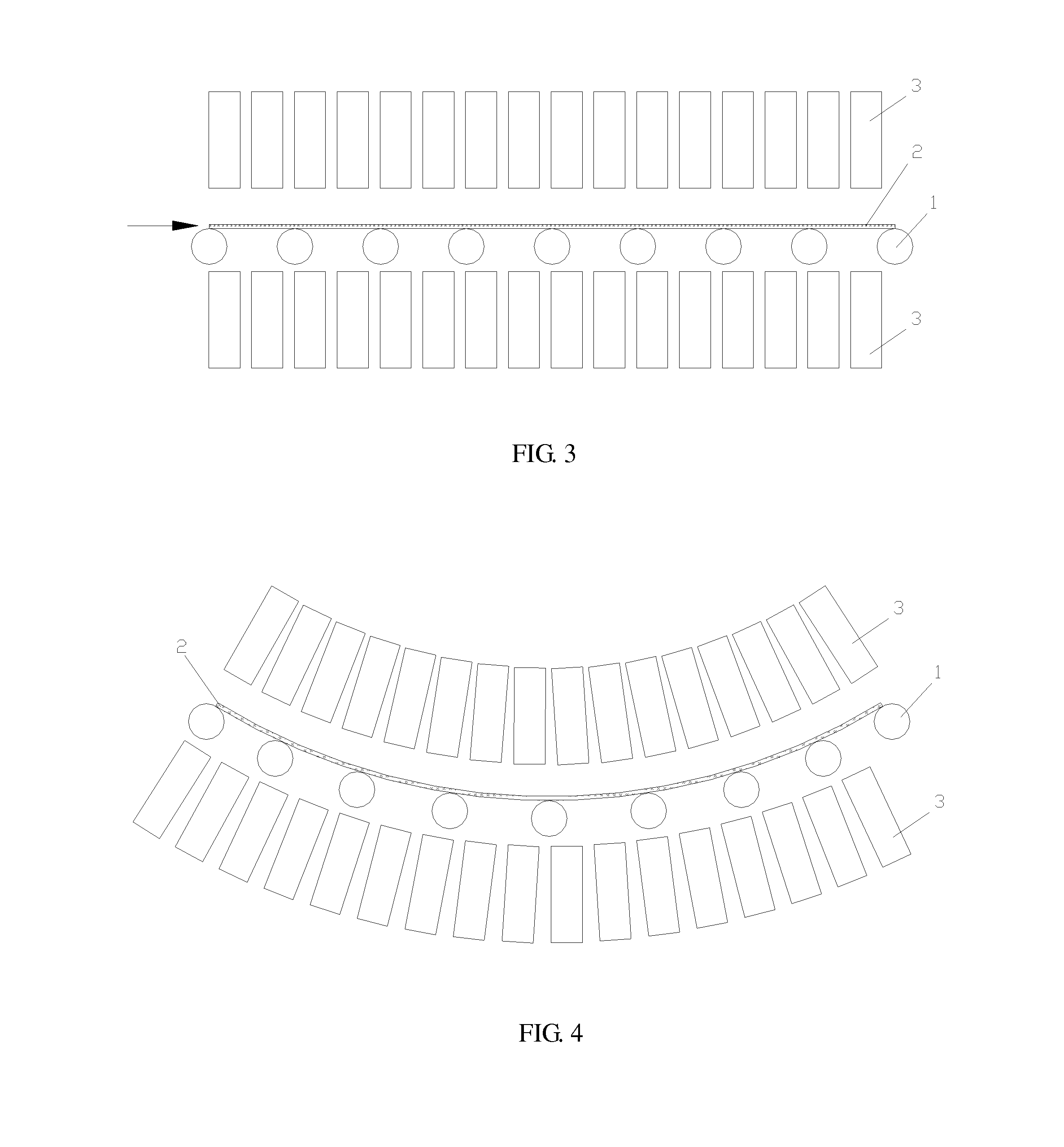

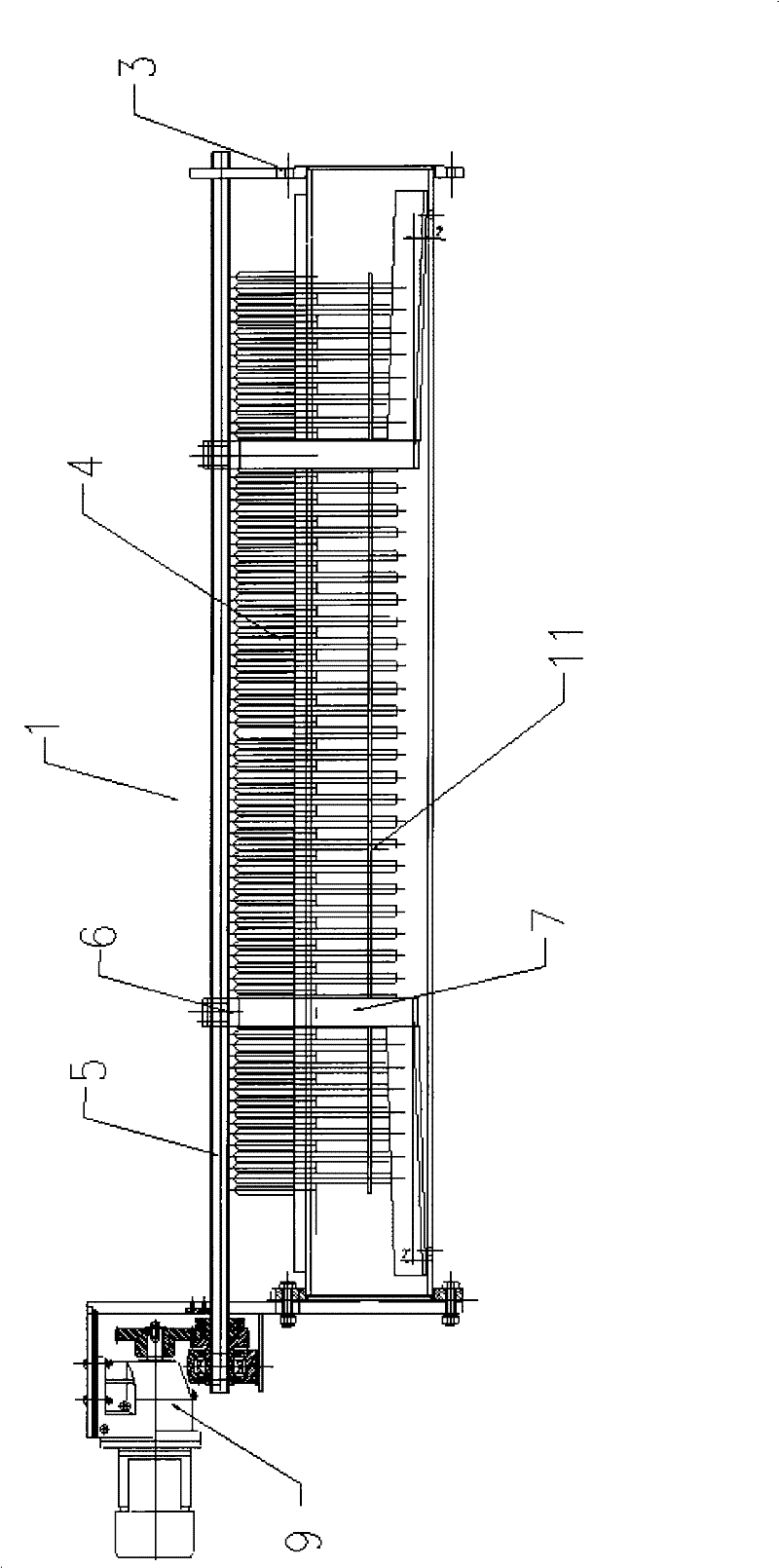

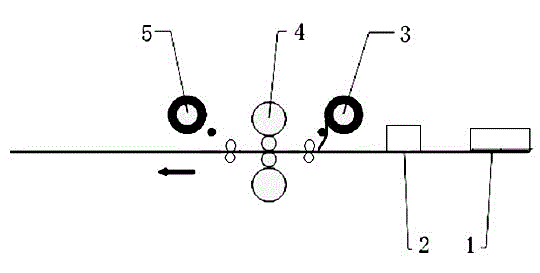

Method for manufacturing columnar curved tempered glass

ActiveUS20150121964A1Smooth transferImprove glass qualityGlass transportation apparatusGlass reforming apparatusFlat glassEngineering

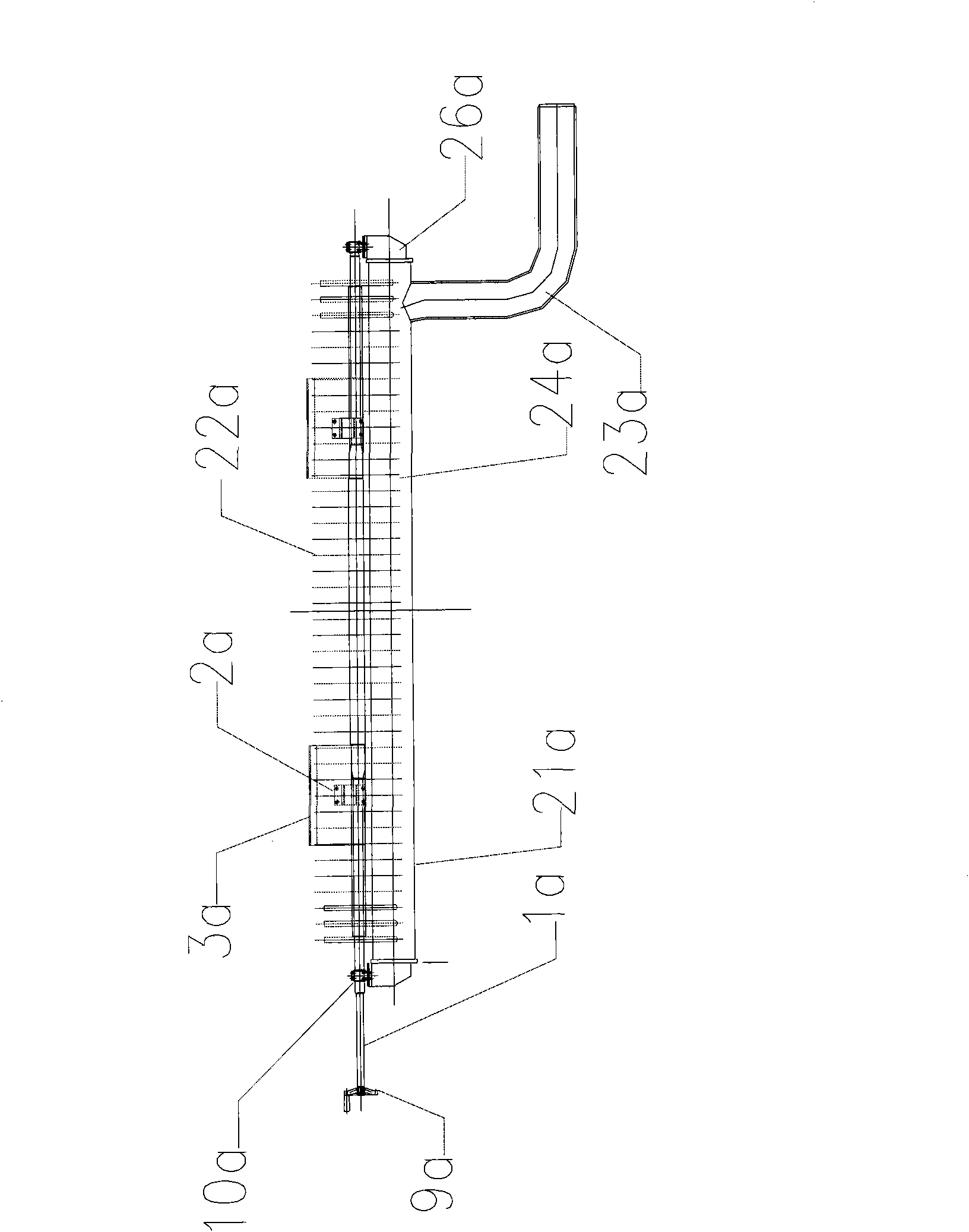

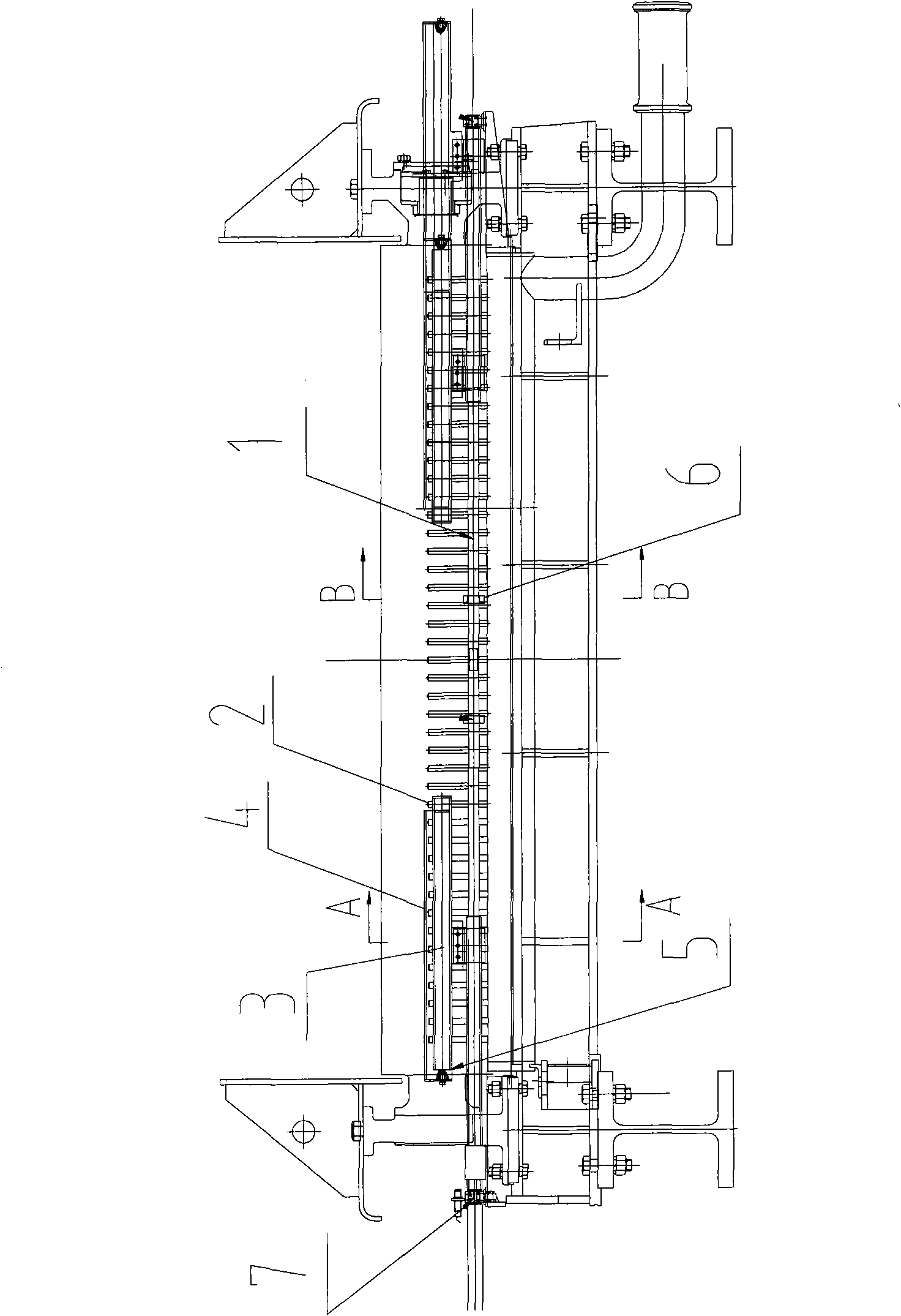

The present invention discloses a device for processing columnar curved tempered glass. The device mainly comprises a glass heating furnace, a glass bending mechanism and a glass tempering mechanism connected sequentially, wherein the arrangement of each supporting roller in the rollers supporting the high temperature flat glass is changed from planar arrangement in space into curved arrangement corresponding to the shape of the glass to be formed, so that the glass bending mechanism enables the glass to suffer bending deformation. Transferring rollers for outputting the formed curved glass in the axial direction of the supporting roller are arranged at the clearance of the rollers of the bending mechanism. In the present invention, bending shaping and tempering of the high temperature flat glass are completed by two stations to break the normal procedure that bending shaping tempering are carried out by one bending appliance intensively, thereby providing a novel technological approach for processing columnar curved tempered glass.

Owner:LUOYANG LANDGLASS TECH CO LTD

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

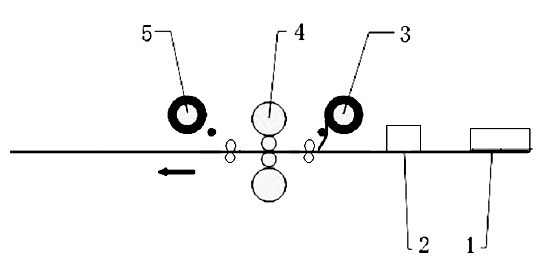

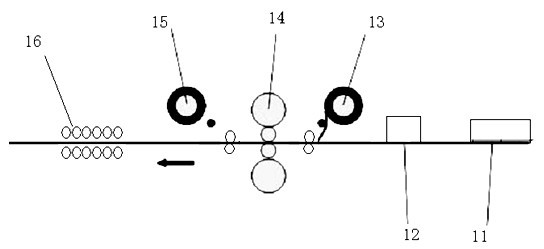

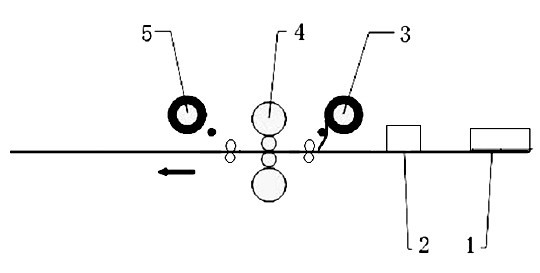

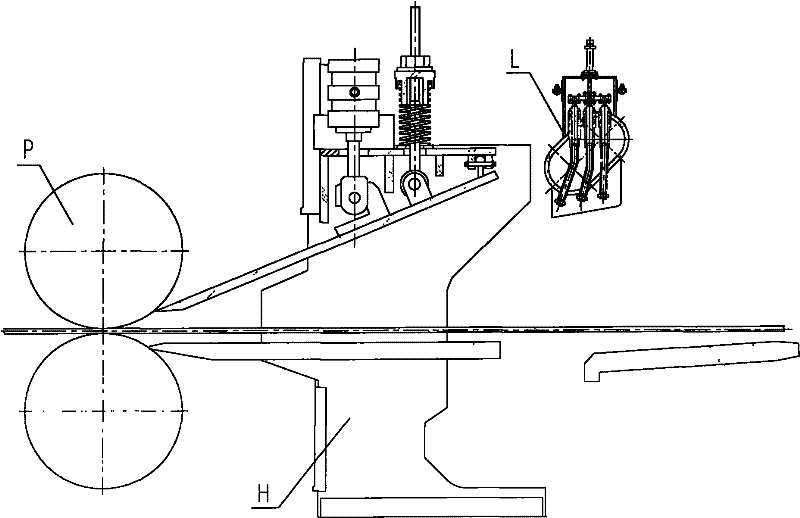

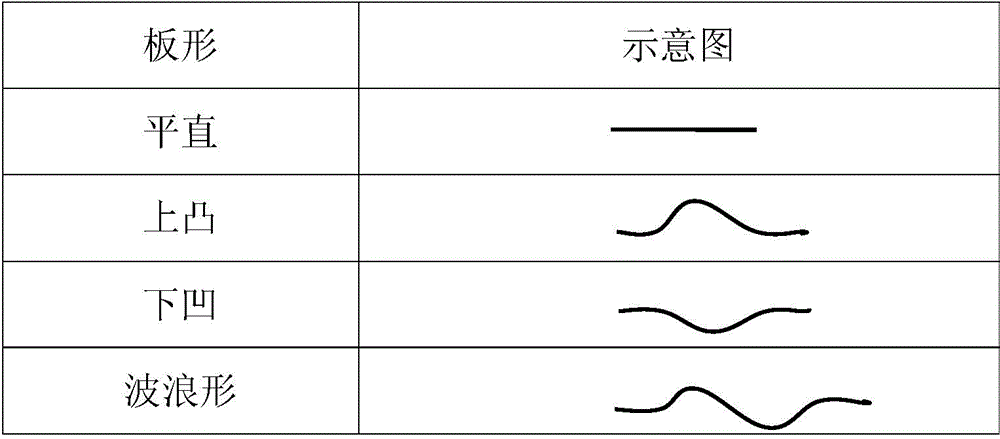

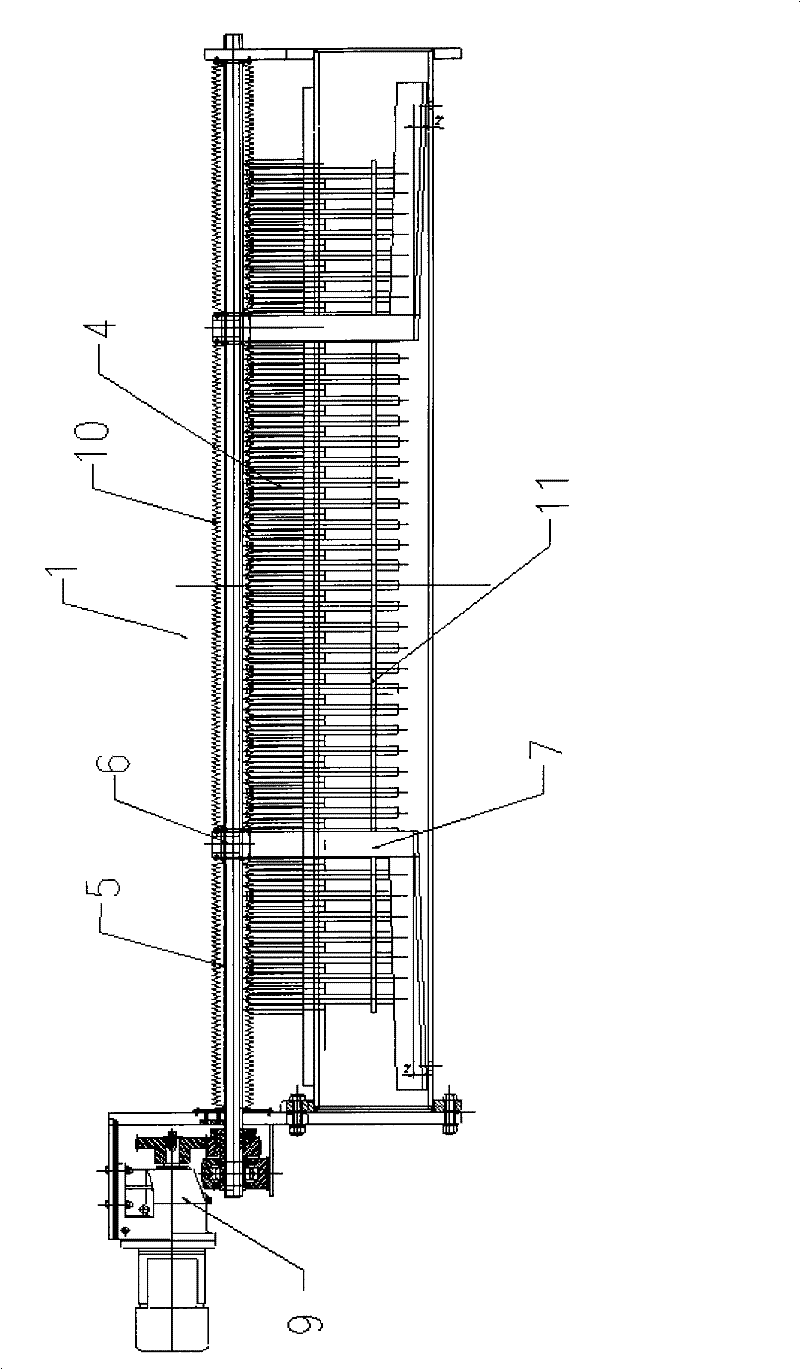

Plate shape control method of hot-rolling and coiled-rolling steel plate of single-rack steekle mill

ActiveCN102699023AImprove the rolling rateSpeed up productionRoll force/gap control deviceTemperature control deviceSteel platesShape control

The invention belongs to the field of steel rolling and discloses a plate shape control method of a hot-rolling and curved-rolling steel plate of a single-rack steekle mill. The plate shape control technology of the hot-rolling and curved-rolling steel plate of the single-rack steekle mill is realized by the steps of adjusting a heating system, optimizing temperature setting of a coiler furnace, adjusting coiled-rolling tension force of the coiler furnace, optimizing a down-pressing system, utilization of bending rolling force of a milling machine and a straightening machine as well as a roller convex degree of a working roller, improving temperature of cooling water which keeps a thin coiled-rolling plate, using an edge shielding function of a laminar flow cooling system, comprehensively adjusting straightening process of edge rollers and bending rollers of a hot straightening machine and the like. When a long billet with a thickness of 150 mm to 220 mm and a steel plate with a rolling thickness not greater than 12 mm are used, the plate shape control method disclosed by the invention has the advantages of synthetically controlling plate shape of the coiled-rolling steel plate and optimizing mechanical properties of the coiled-rolling plate.

Owner:NANJING IRON & STEEL CO LTD

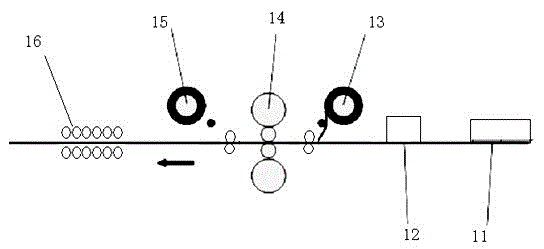

Laminar flow width-offset-adjusting cooling device and control method thereof

ActiveCN101837379AEnsure shapeGuaranteed mechanical propertiesSpray nozzlesRoll mill control devicesStrip steelEngineering

The invention provides a laminar flow width-offset-adjusting cooling device and a control method thereof. The laminar flow width-offset-adjusting cooling device comprises a plurality of groups of spray pipe devices, and each group of spray pipe device comprises a collecting pipe, two screw rods, two pistons and two motors, wherein the collecting pipe is provided with a plurality of evenly distributed spray pipes and a water inlet pipe; the two screw rods are respectively arranged at the two ends of the collecting pipe along the central axis of the collecting pipe, and can move inside the collecting pipe along the central axis of the collecting pipe; the two pistons are respectively positioned at the two adjacent ends of the screw rods, the external diameters of the pistons are matched with the internal diameter of the collecting pipe, the sides of the pistons are respectively provided with at least one locating key along the axial direction, and the at least one locating key is meshedwith at least one locating groove arranged on the inner wall of the collecting pipe along the axial direction; the two motors are respectively used for driving the screw rods; and the water inlet pipe is positioned in the middle of the collecting pipe. According to the requirements of the cooling technique of the strip steel with different widths, the invention can be used for adjusting the area of cooling water along the width direction of a channel, thus reducing the temperature reduction of the side of the strip steel, and ensuring the uniformity of the profile shape, the mechanical performance, the temperature and the phase change of the strip steel along the width direction.

Owner:BAOSHAN IRON & STEEL CO LTD +2

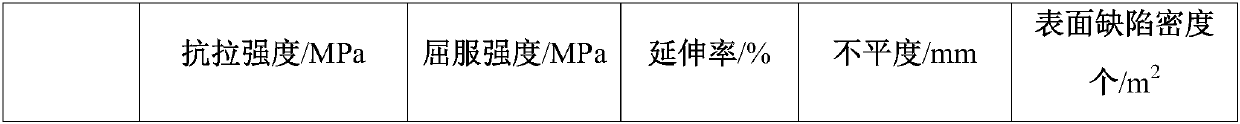

Preparation process of high-performance 7-series aluminum alloy sheet

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a preparation process of a high-performance 7-series aluminum alloy sheet. The alloy comprises smaller thanor equal to 0.10% of Si, smaller than or equal to 0.15% of Fe, 1.7-1.9% of Cu, 2.4-2.55% of Mg, 5.8-6.0% of Zn, smaller than or equal to 0.24% of Cr, smaller than or equal to 0.04% of Ni, smaller than or equal to 0.03% of Ti, smaller than or equal to 0.05% of Mn, and smaller than or equal to 0.15% of impurities (with a single impurity being smaller than or equal to 0.05%), with the balance beingAl. By improving the formula and the process, the unevenness and the performance uniformity of the prepared aluminum alloy sheet in the width direction are guaranteed, and the problem that an ultra-large-width aluminum alloy coil prepared by an existing rolling process has poor performance uniformity and flatness in the width direction is solved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

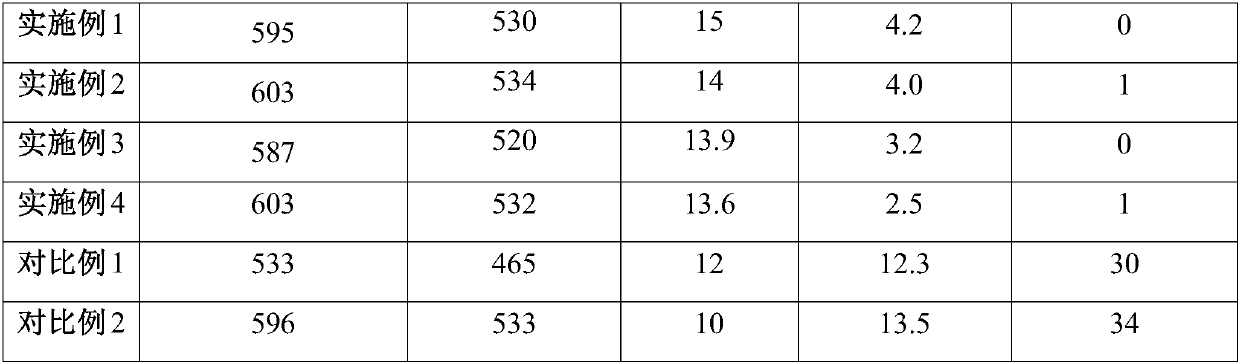

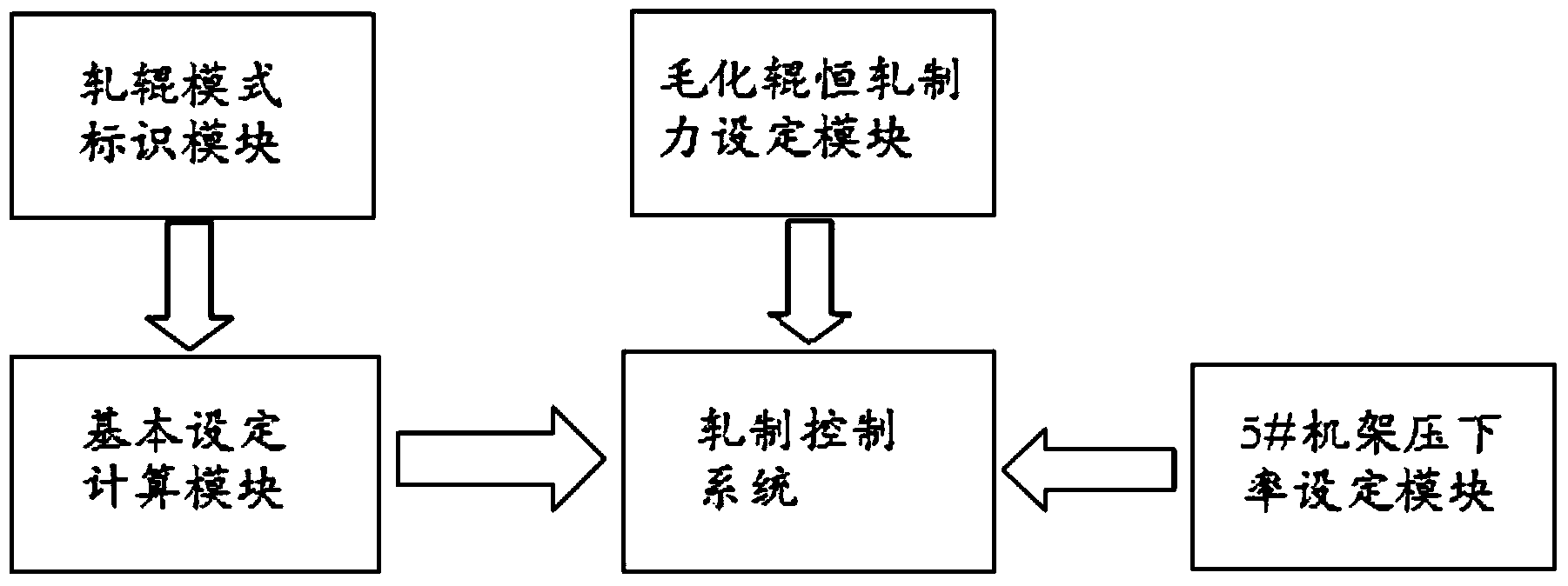

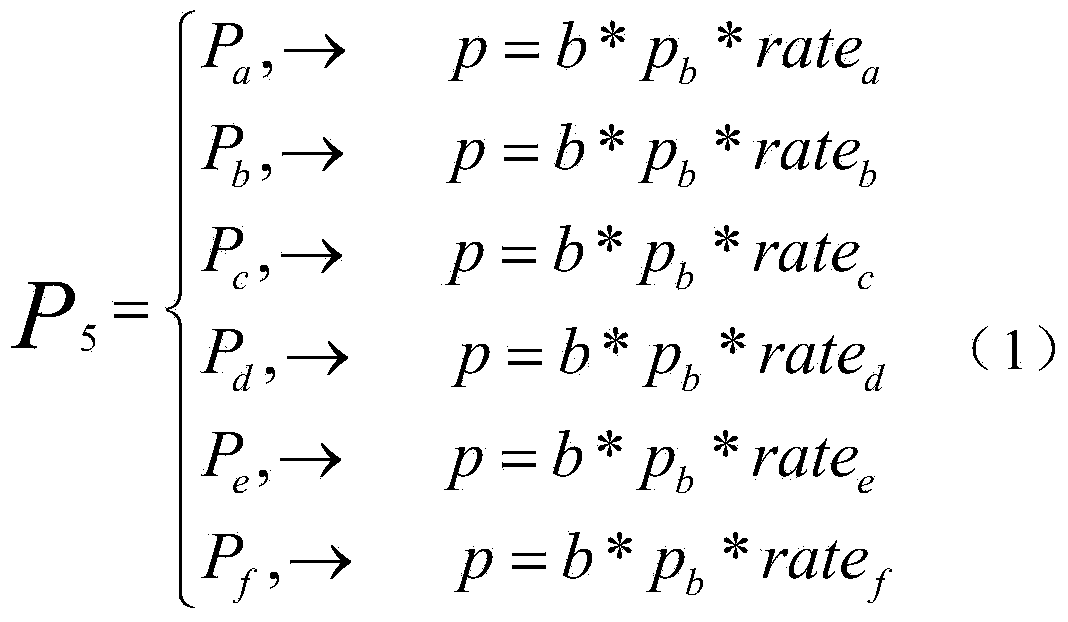

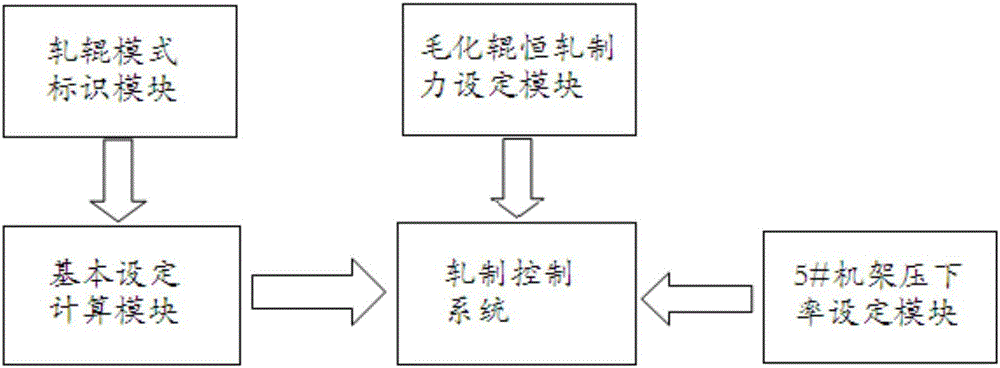

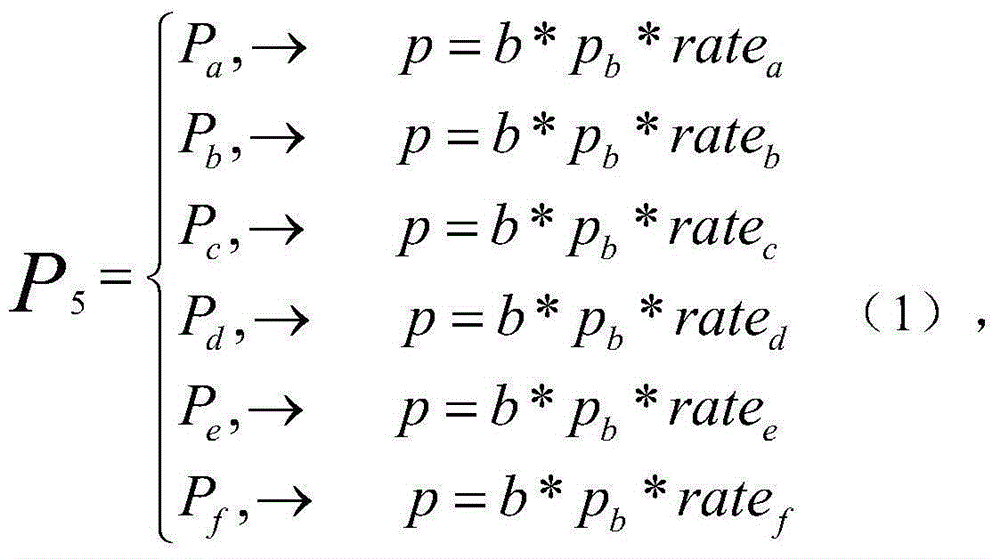

Texturing roll rolling system and method of UCMW tandem cold rolling mill

ActiveCN103861873AEnsure shapeGuaranteed dimensional accuracyRoll mill control devicesMetal rolling arrangementsControl systemEngineering

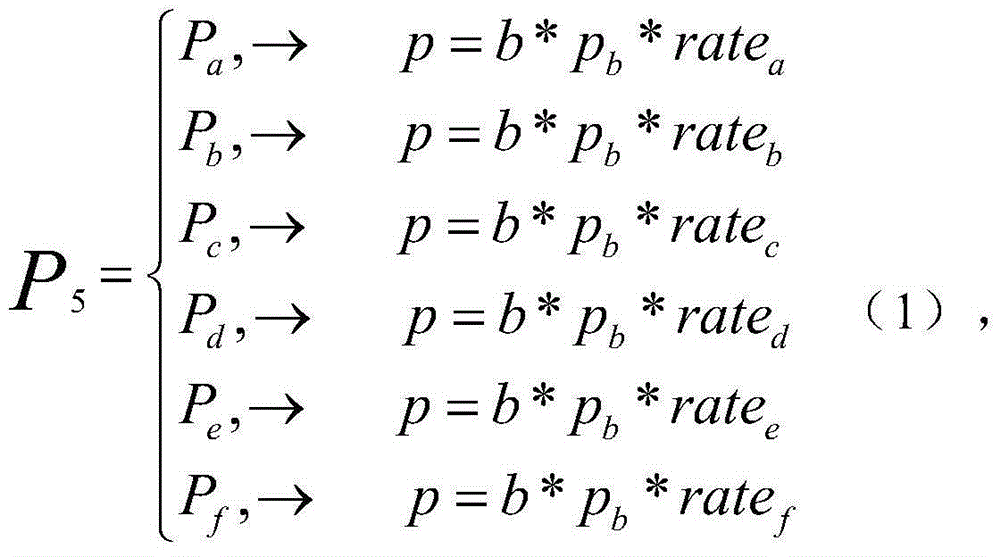

The invention relates to a texturing roll rolling system and method of a UCMW tandem cold rolling mill. The texturing roll rolling system and method of the UCMW tandem cold rolling mill comprises a rolling mode identity module, a basic setting and calculation module, a texturing roll constant-rolling-force setting module, a No.5 rack reduction ratio setting module and a rolling control system, wherein the rolling mode identity module is used for judging a roll mode; the basic setting and calculation module is used for obtaining required rolling parameters from a reduction ratio constant table corresponding to the texturing roll mode; the texturing roll constant-rolling-force setting module is used for calculating rolling force in the texturing roll mode according to the type, the width and thickness specifications and the rolling speed of strip steel; the No.5 rack reduction ratio setting module is used for selecting No.5 rack reduction ratio from the reduction ratio constant table corresponding to the texturing roll mode according to the type and the width and thickness specifications of a set steel coil. The invention additionally relates to a method using the system. The rolling system and the method provided by the invention have the advantages that the rolling mill can realize stable rolling in the texturing roll mode, the shape and dimension accuracy of finished strip steel plates can be guaranteed and especially the surface quality of the strip steel can be guaranteed.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

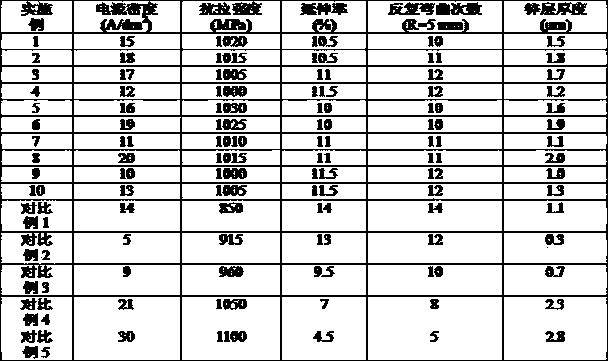

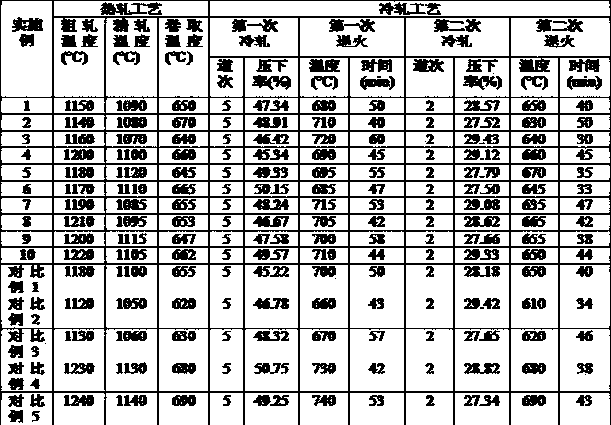

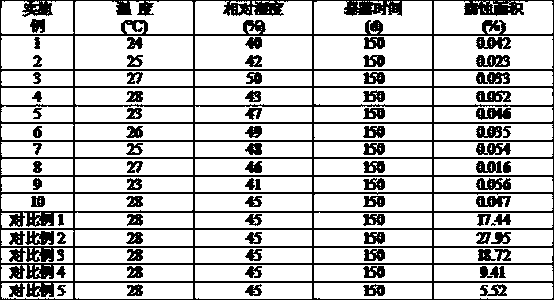

High-strength cold-rolled electrogalvanized binding strip and production method thereof

InactiveCN104046916AStrong adhesionMeet the requirements of bundling and packagingCellsMetallurgyHigh intensity

The invention discloses a high-strength cold-rolled electrogalvanized binding strip, which comprises the following components in percentage by weight (wt%): 0.05-0.10% of C, 0.40-1.0% of Mn, no more than 0.010% of Si, no more than 0.010% of P, no more than 0.010% of S, 0.40-0.60% of Ti, 0.30-0.70% of Cr, 0.50-0.80% of Ni, and 0.030-0.060% of Als; the production method comprises the following steps: melting and continuously casting into blanks, and conducting conventional cast blank heating; conducting hot rolling; conducting conventional pickling; carrying out secondary cold-rolling and secondary annealing; producing strips. The binding strip is 1.0mm thick, the tensile strength is no less than 1000MPa, the elongation rate is no less than 10%, the number of repeated bending times is no less than 10 (R=5mm), an electrogalvanized layer which is uniform and compact, strong in adhesion strength and is 1.0-2.0mu m thick is formed on the surface of the strip, the strip cannot have obvious rusting for 150 days after being placed in interior atmospheric environment, thus being good in profile, and completely meeting the binding and packaging requirement of a precise and ultrathin cold-rolled steel strip.

Owner:武汉钢铁有限公司

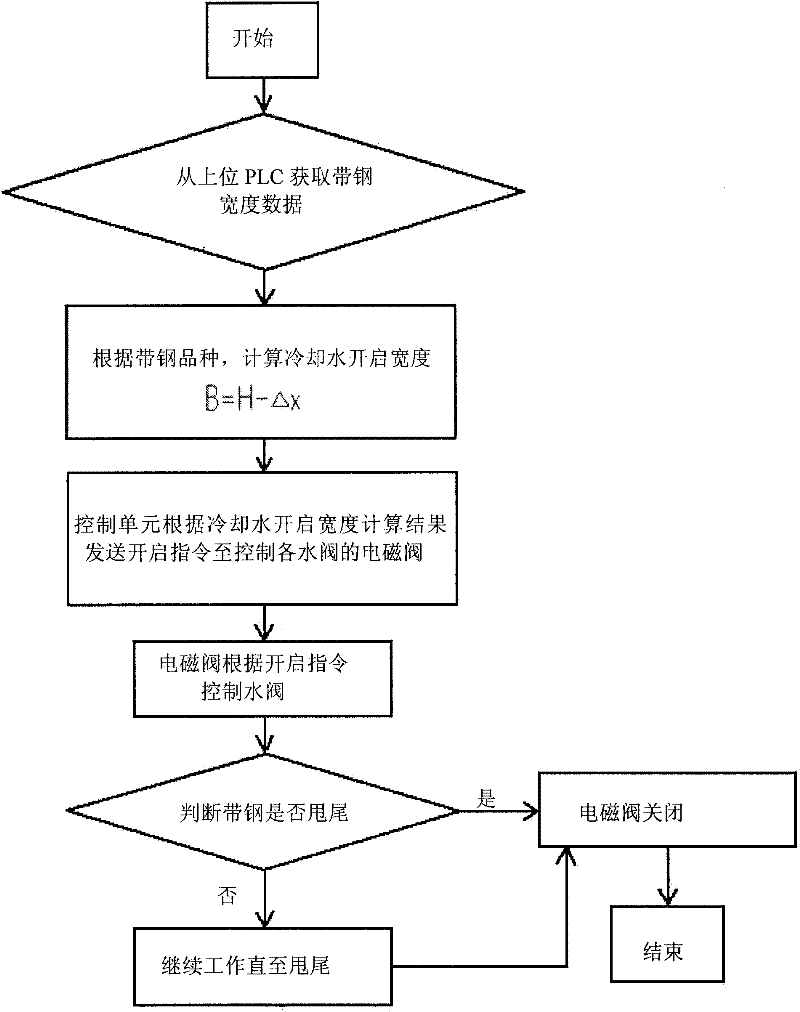

Laminar flow water cooling device and control method

ActiveCN101811144AEnsure shapeGuaranteed mechanical propertiesTemperature control deviceWork treatment devicesStopped workWater storage

The invention relates to a laminar flow water cooling device and a control method. The laminar flow water cooling device comprises a plurality of water storage pipes, the arrangement direction of the water storage pipes is the same as the operating direction of strip steel, the water storage pipes are symmetrically distributed, water inlet ends of the water storage pipes are respectively provided with a water valve, and bodies of the water storage pipes are respectively provided with a plurality of cooling water pipes distributed at equal intervals. The control method comprises the following steps of: (1) starting; (2) acquiring width data of the strip steel from an upper PLC; (3) calculating the width of cooling water; (4) using a control unit to send opening command to all the water valves; (5) using an electromagnetic valve to control the water valves according to the opening command; (6) judging whether the strip steel throws the tail; (7) leading the laminar flow water cooling device to stop working; and (8) finishing laminar flow cooling control process. The invention adjusts the area of the cooling water along the channel width direction according to the cooling technique requirements of different widths of the strip steel, reduces the temperature reduction at the side of the strip steel, and guarantees the profile shape, the mechanical performance, the temperature and the uniformity of phase change along the width direction of the strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

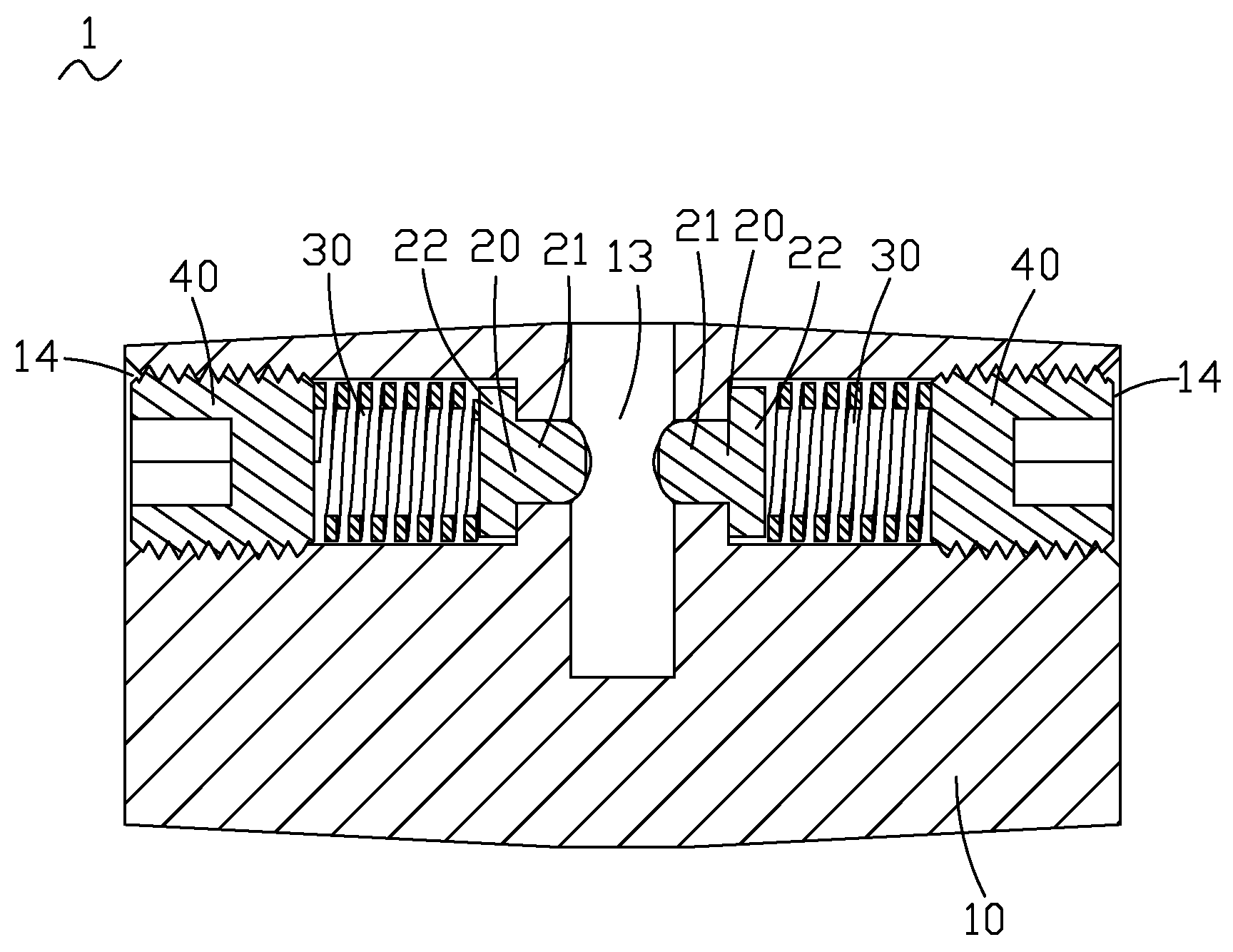

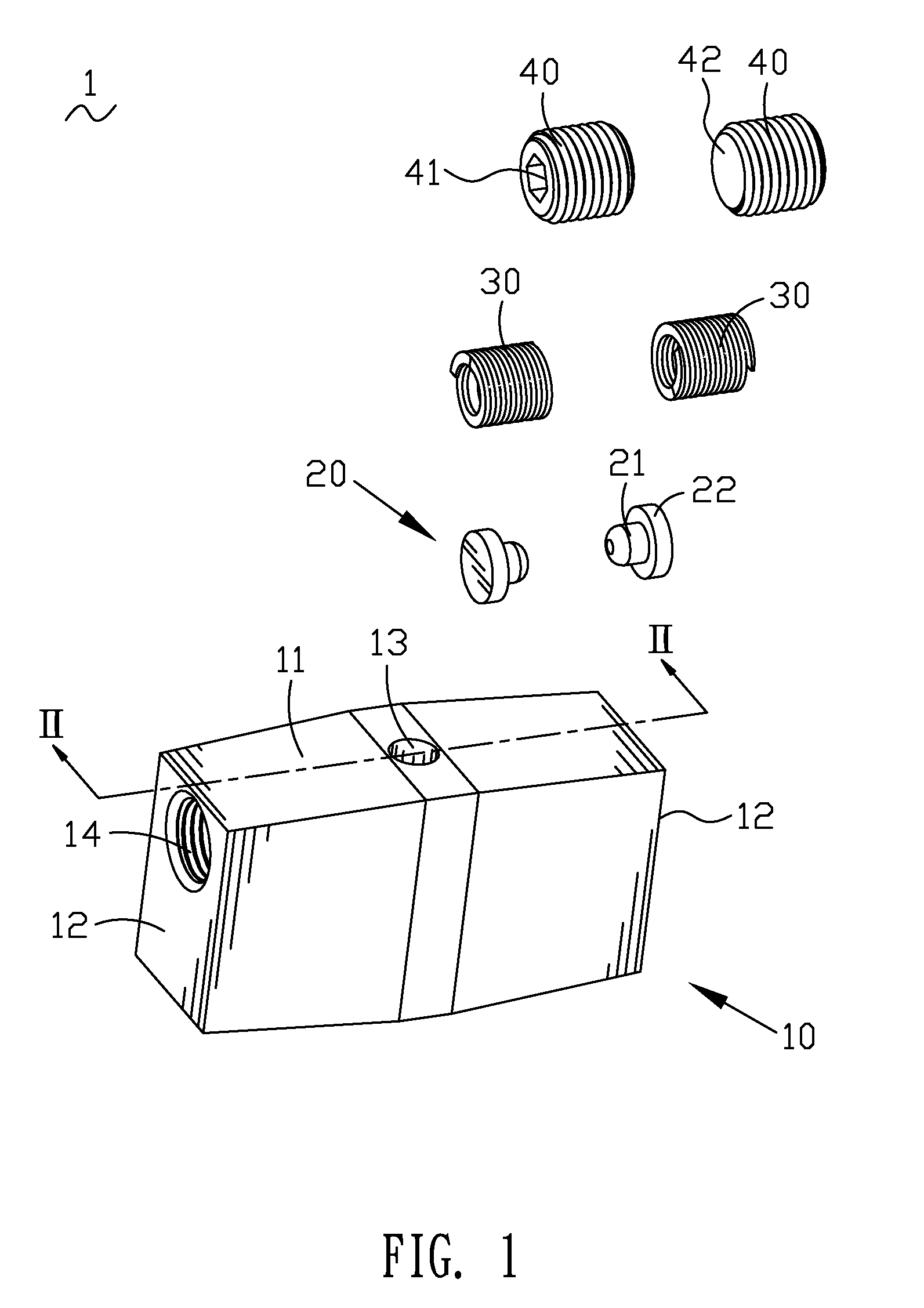

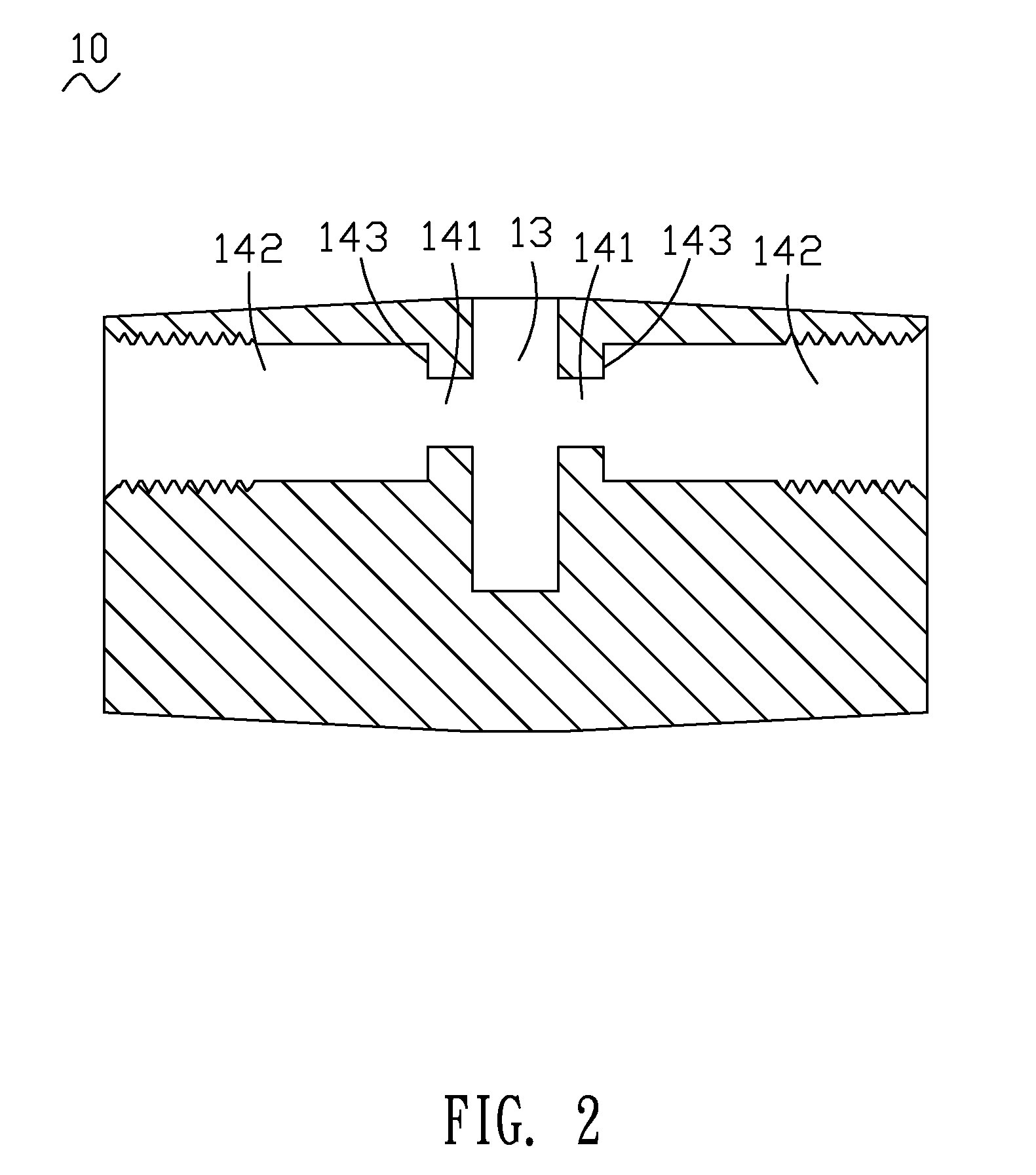

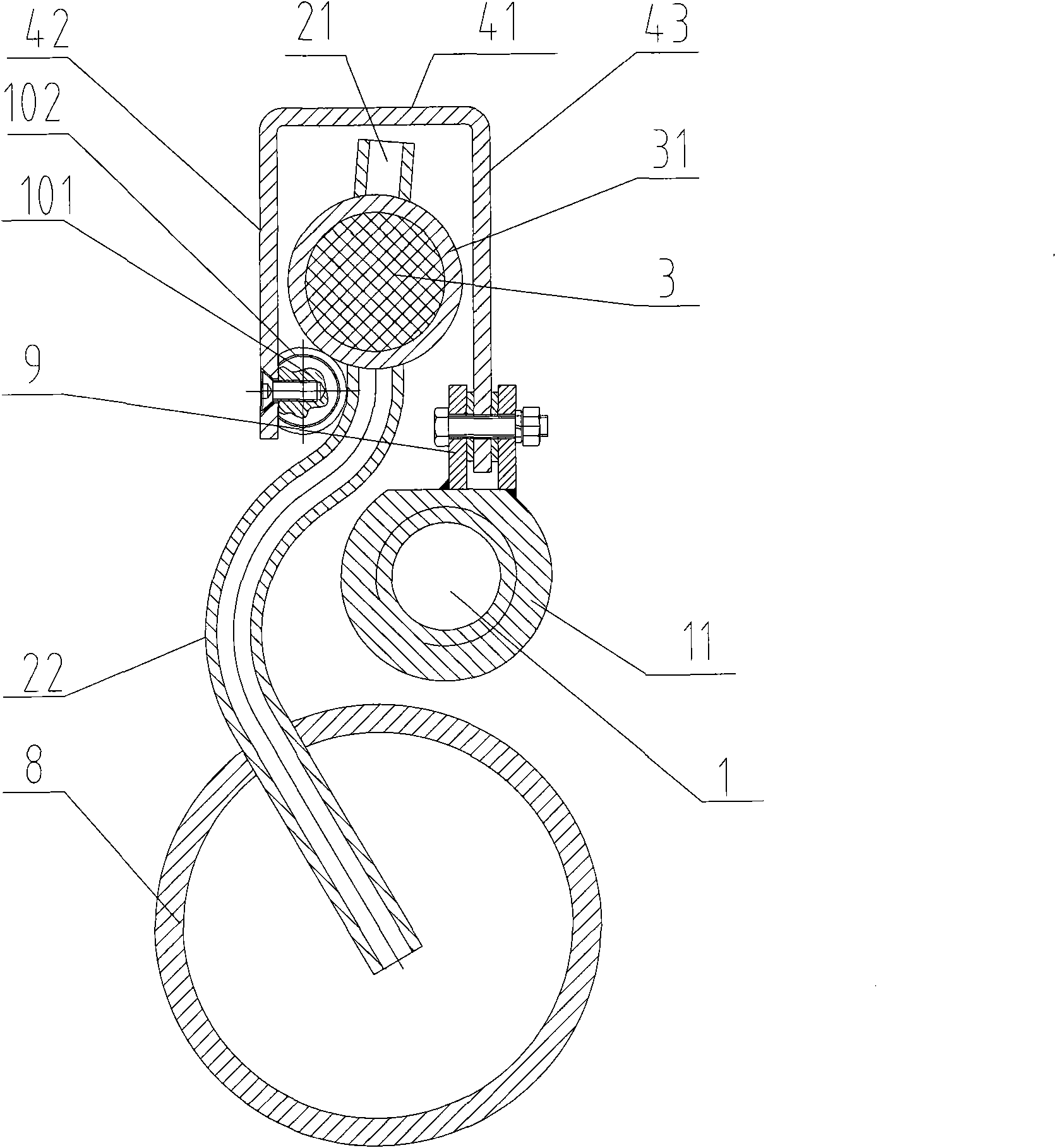

Position mechanism

InactiveUS20090263526A1Ensures shaping qualityPrecise positioningTailstocks/centresConfectioneryEngineeringElastic component

The present invention provides a position mechanism including a locating body. The locating body defines a locating cavity and a receiving chamber communicating with the locating cavity. A locating stopper is received in the receiving chamber of the locating body with an end thereof toward the locating cavity, and an elastic component is received in the receiving chamber of the locating body and resiliently biases the locating stopper into the locating cavity.

Owner:CHENG UEI PRECISION IND CO LTD

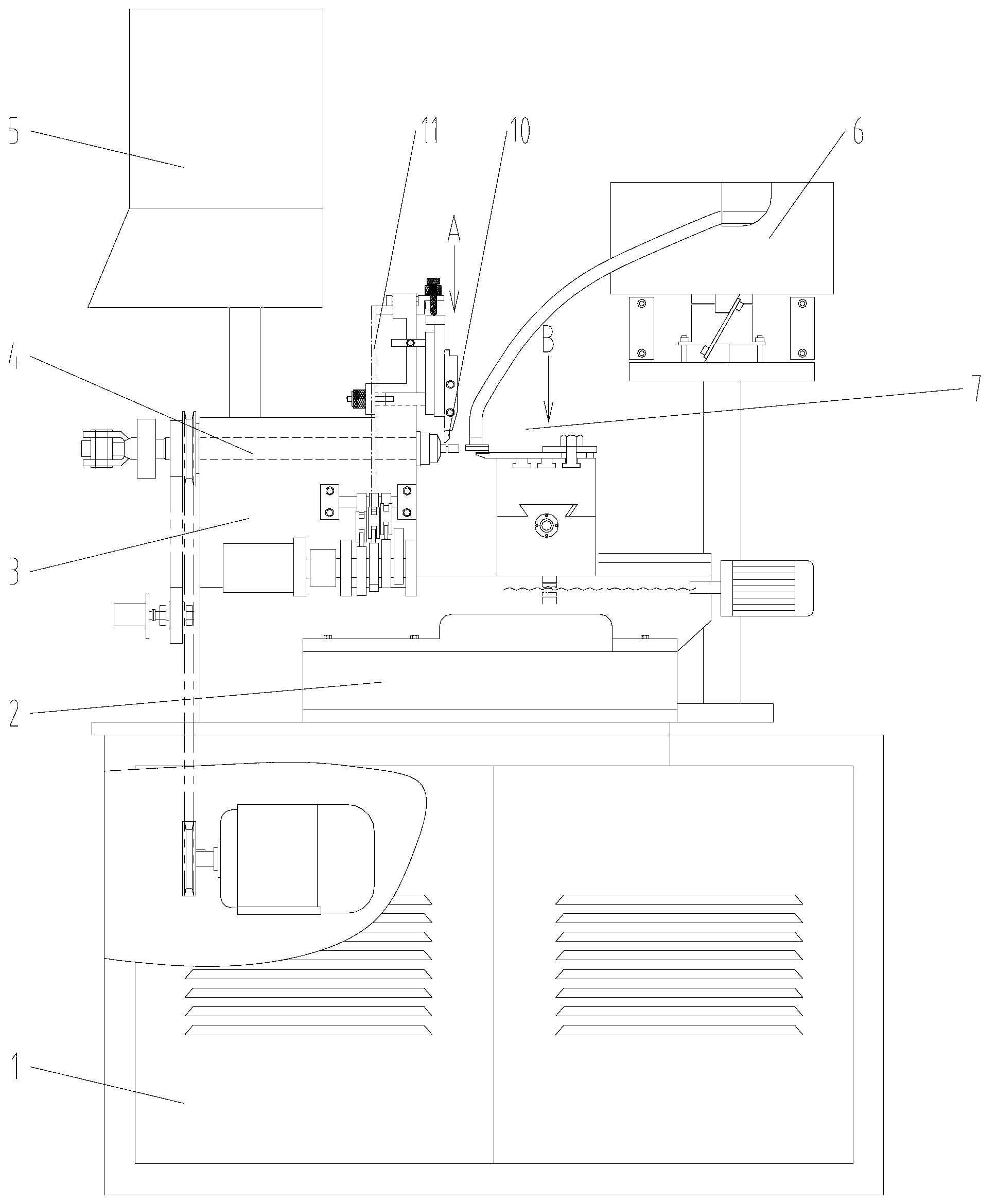

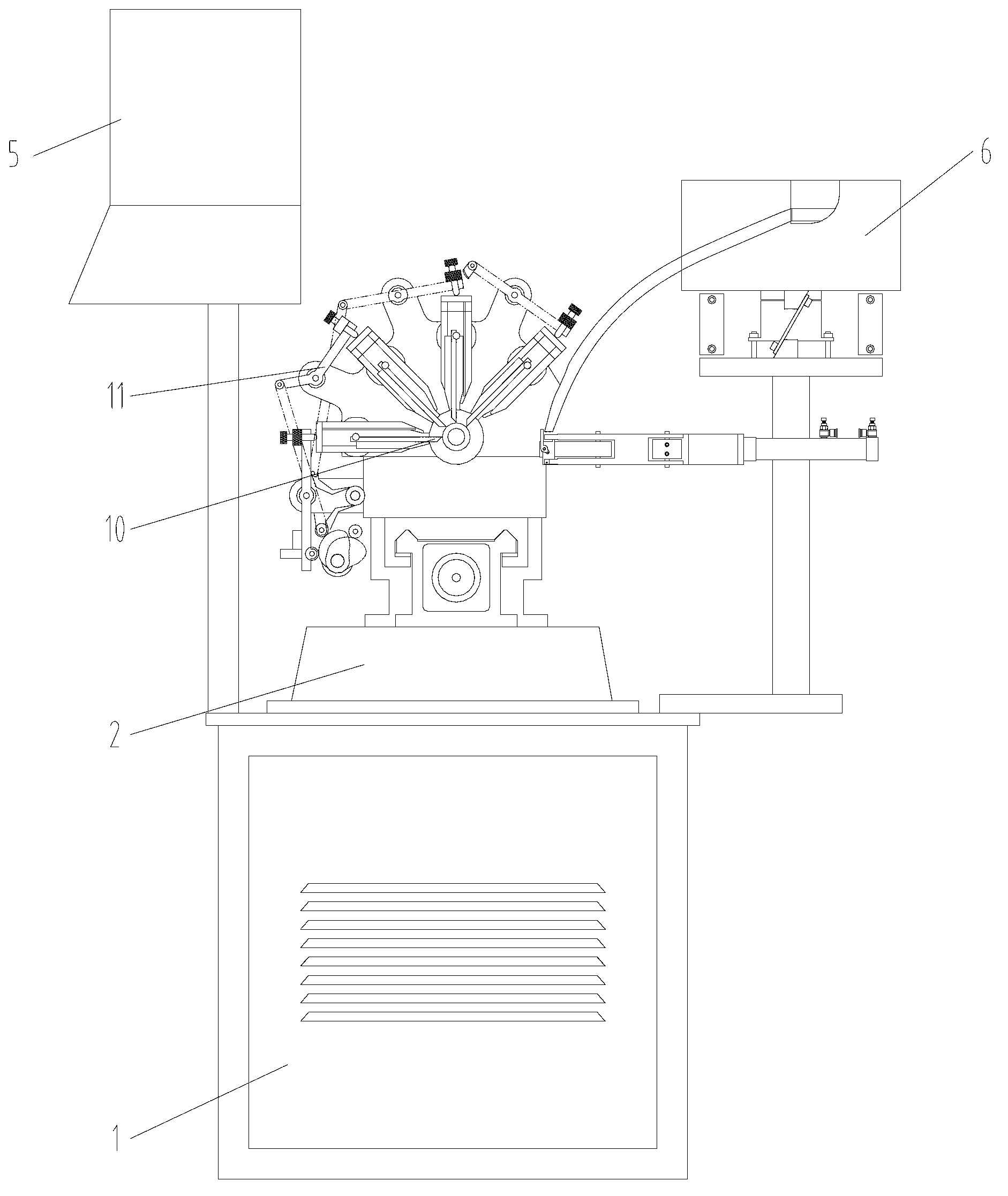

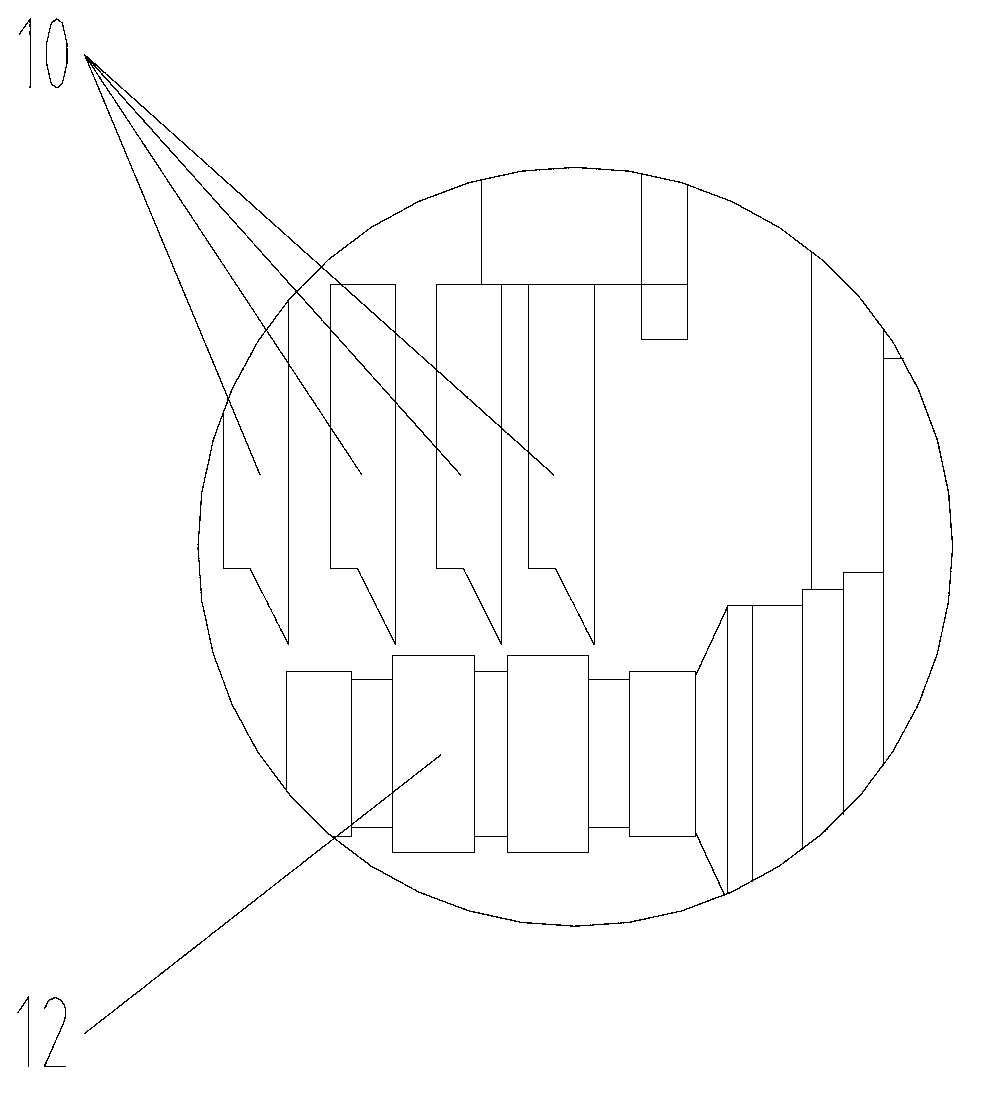

Numerical-control automatic cam lathe

InactiveCN103286327AGuaranteed processing sizeEnsure shapeAutomatic/semiautomatic turning machinesFeeding apparatusPosition toleranceNumerical control

The invention discloses a numerical-control automatic cam lathe comprising a frame, an engine base, a nose, a spindle, a numerical-control operator, a feed device and a numerical-control cutter rest. The numerical-control cutter rest is provided with an X-axis cutter, a Y-axis cutter and a Z-axis cutter, and the Z-axis cutter is driven by an eccentric cam connecting rod mechanism. The numerical-control automatic cam lathe has the advantages that the eccentric cam connecting rod mechanism controls cutter feed, is combined with numerical control and the like to perform fine operation and guarantee size accuracy in product processing; workpiece clamping is completed through automatic feeding, labor is reduced and labor efficiency is improved; cut workpieces are automatically fixed, multi-directional cutting can be realized, cutting requirements of different shapes are met, the same workpiece can be processed and formed on the lathe at one step without frequent changing devices, full-automatic cutting process is realized, processing size and shape and position tolerance of the workpiece are guaranteed, and production efficiency and product processing speed are effectively improved.

Owner:JIANGSU TANGYIN PHOTOELECTRIC

Laminar cooling edge shielding device and control method

InactiveCN110270598ASolve the phenomenon of uneven cooling distributionReduce cross-sectional temperature differenceTemperature control deviceWork cooling devicesHydraulic cylinderLaminar cooling

The invention relates to a laminar cooling edge shielding device which comprises an upper laminar manifold device, the two ends of the upper laminar manifold device are fixedly connected with a water tank supporting beam, the two sides of the water tank supporting beam are provided with a transmission side water collecting tank and a work side water collecting tank correspondingly, the water tank supporting beam comprises an upper fixing beam and a lower fixing beam, the upper fixing beam and the lower fixing beam are connected through a connection support, the connection support is provided with a water tank hydraulic cylinder, the transmission side water collecting tank and the work side water collecting tank are pushed by respective water tank hydraulic cylinders to slide on the water tank supporting beam, the transmission side water collecting tank and the work side water collecting tank are connected through a corrugated telescopic water pipe, and the bottom of the transmission side water collecting tank is provided with a drainage hose. The spraying area of cooling water in the width direction of strip steel is adjusted, the phenomenon that cooling distribution of a laminar cooling system in the width direction of strip steel is solved, strip steel edge temperature drop is reduced, and the strip steel cross section temperature difference is reduced.

Owner:ANGANG STEEL CO LTD

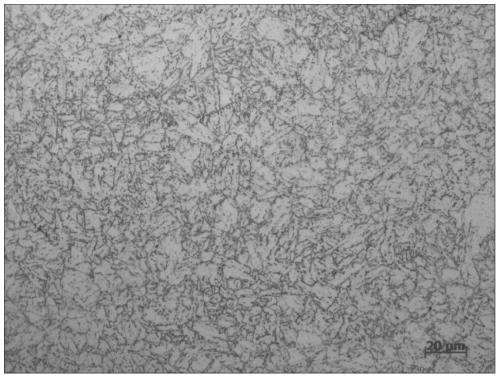

Manufacturing method of marine 5Ni steel plate with low remanence and excellent surface quality

ActiveCN111440990AGuaranteed hardenabilityGuaranteed low temperature impact toughnessFurnace typesQuenching agentsTemperingSurface cleaning

The invention relates to a manufacturing method of a marine 5Ni steel plate with low remanence and excellent surface quality. The technological process is converter smelting -> LF refining -> RH highvacuum degassing -> Ca treatment -> continuous casting -> casting blank slow cooling treatment -> casting blank surface cleaning -> heating -> rolling -> quenching twice -> tempering. According to component design, low carbon, low silicon and 5% of Ni are adopted, and V and Nb are added, so that hardenability is improved, low-temperature toughness is improved, austenitic amorphous starting temperature is raised, the steel plate can be subjected to high-temperature rolling and high-temperature quenching, then the shape of the steel plate is remarkably improved, and the steel plate is suitable for production of thin specification products. According to the manufacturing method, optimization is performed from the perspectives of element design, technology control, base material organization,center segregation, quenching and tempering temperature and time and the like, and therefore it is guaranteed that the steel plate has good ductility, -130 DEG C low-temperature impact toughness, excellent surface quality and low remanence while high strength of the 5Ni steel plate is realized.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

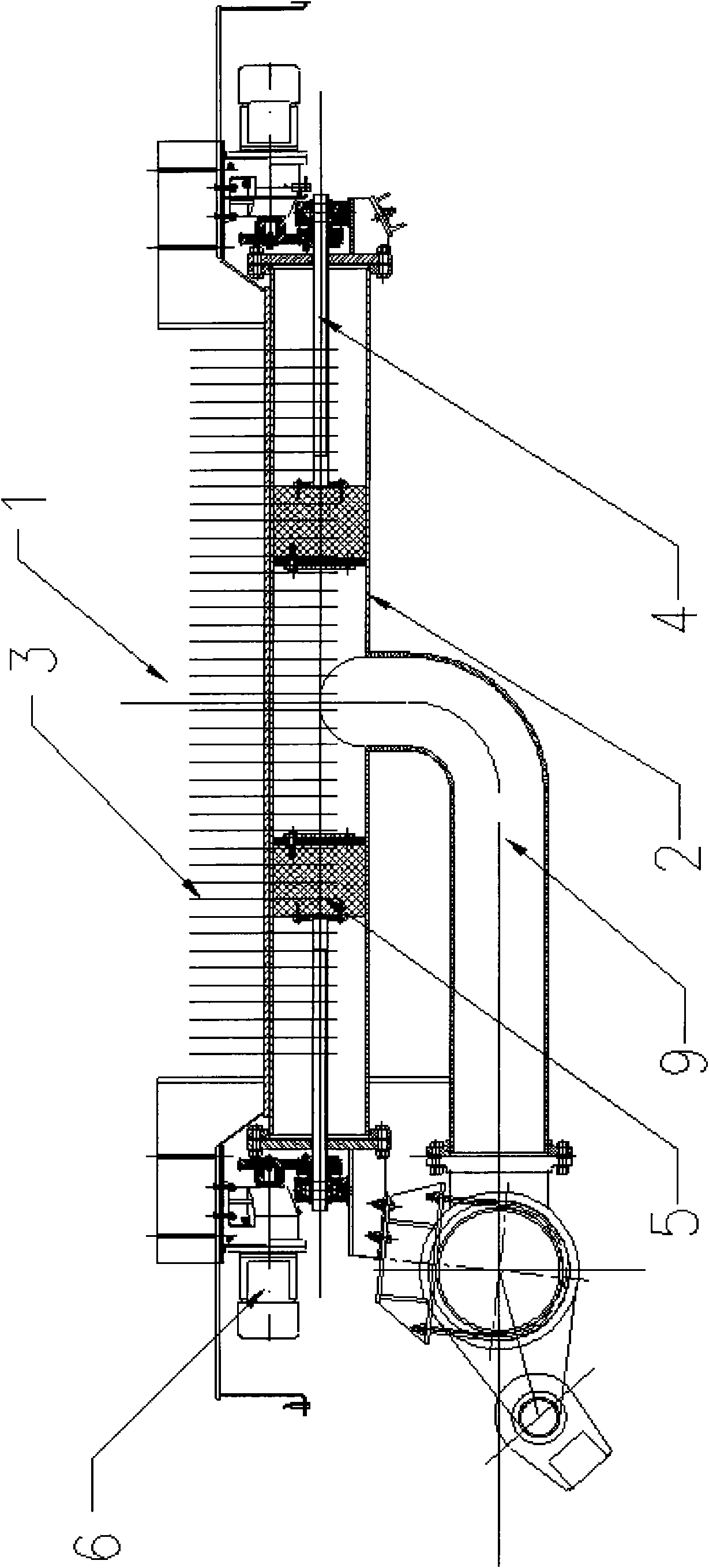

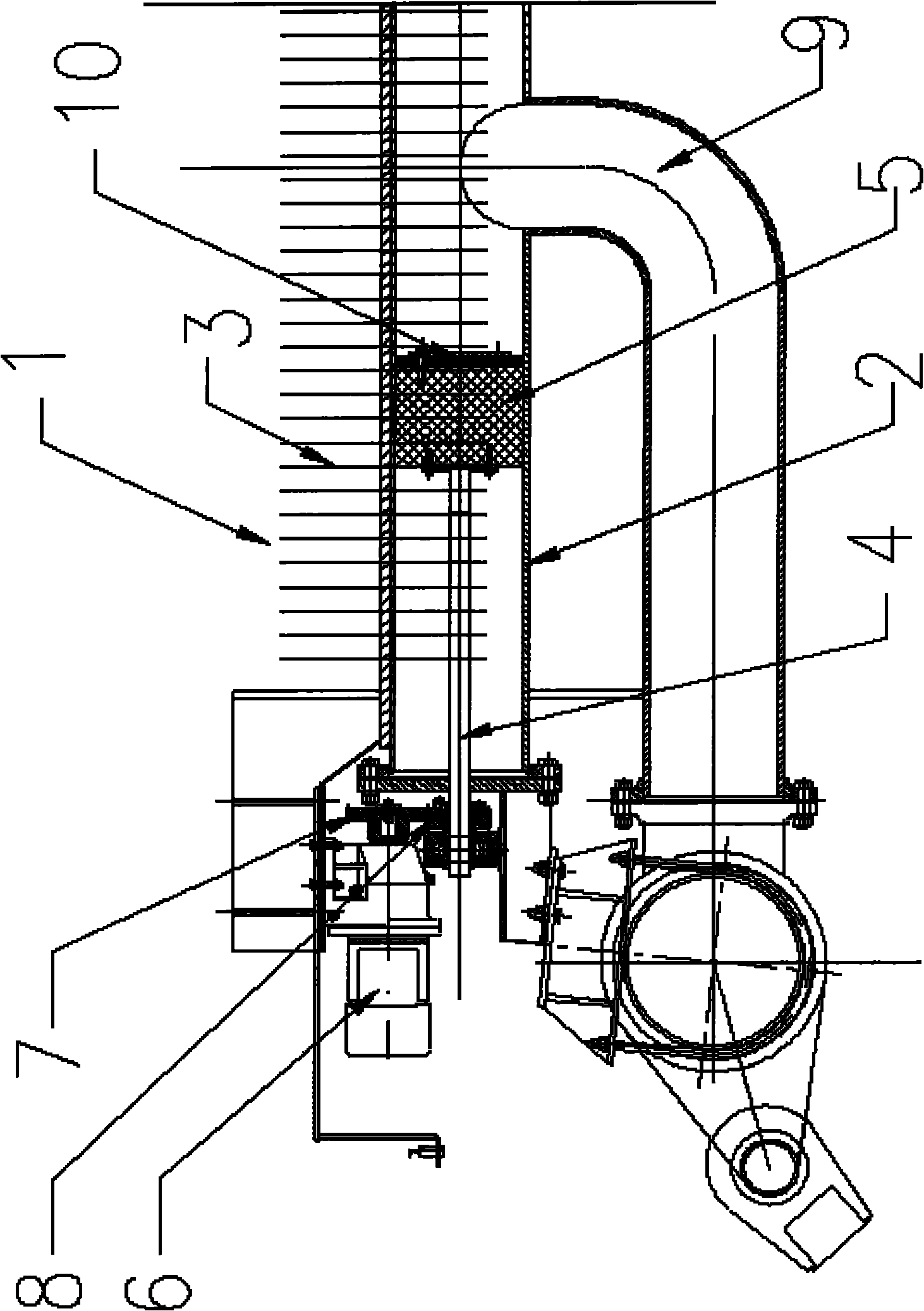

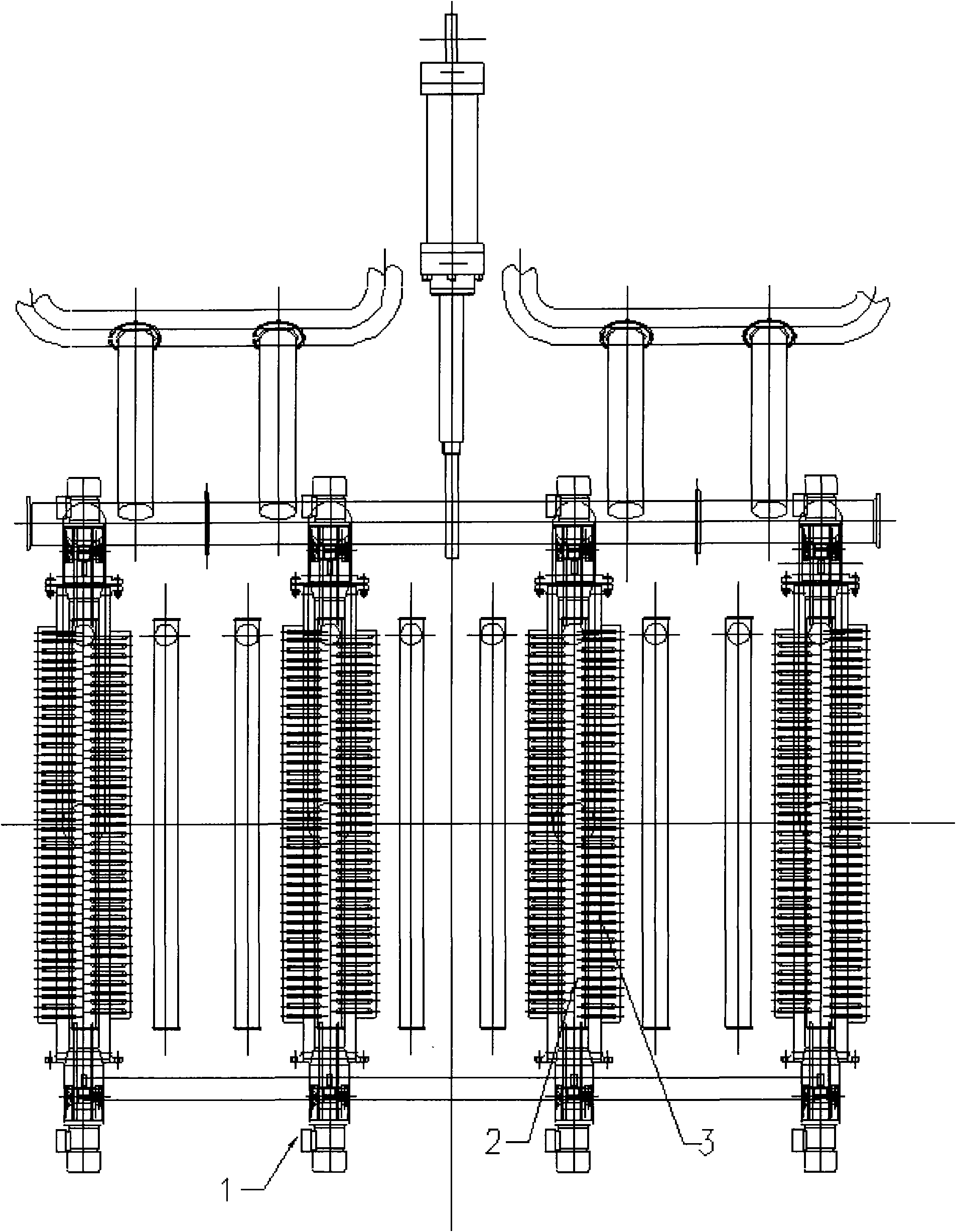

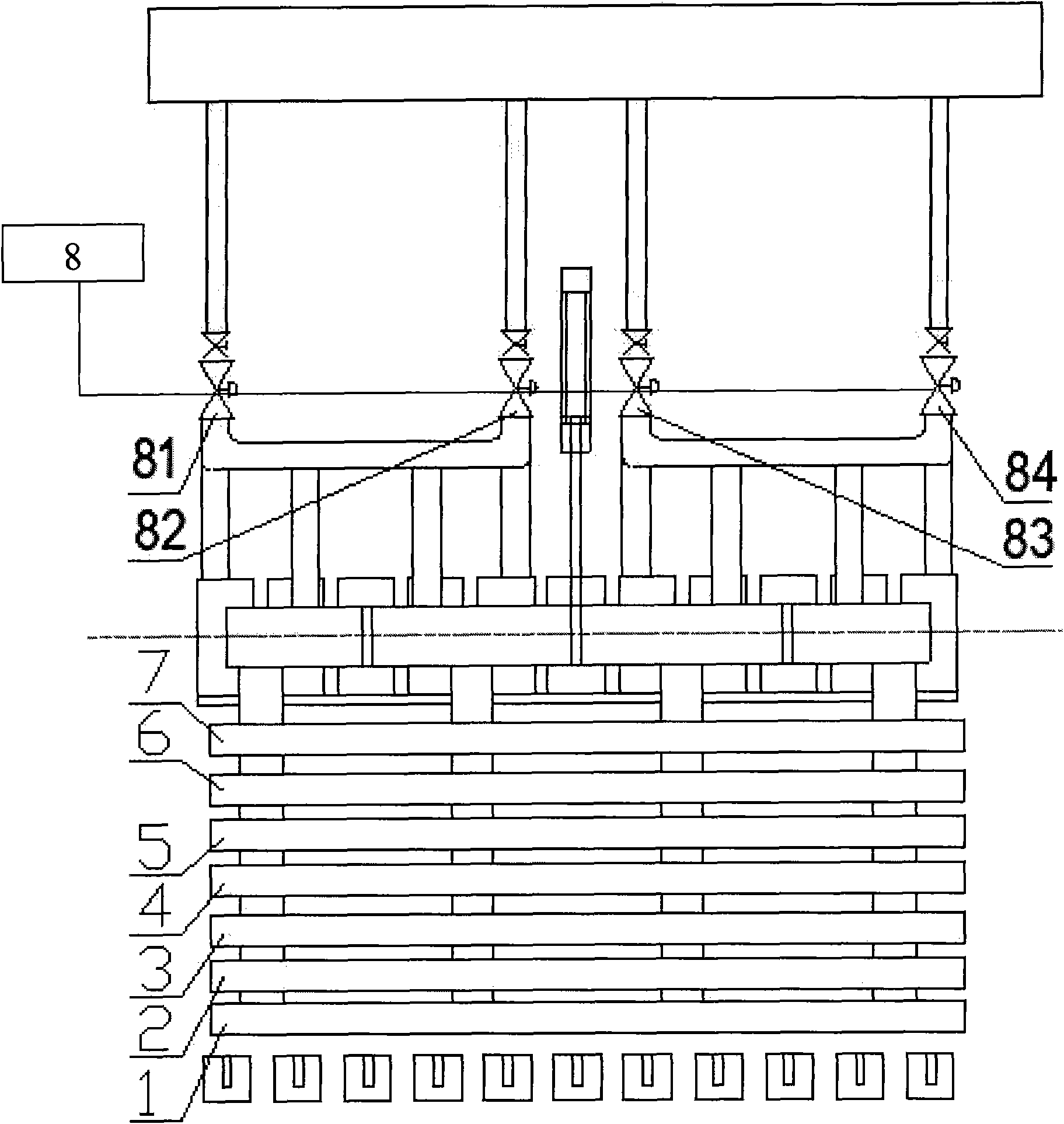

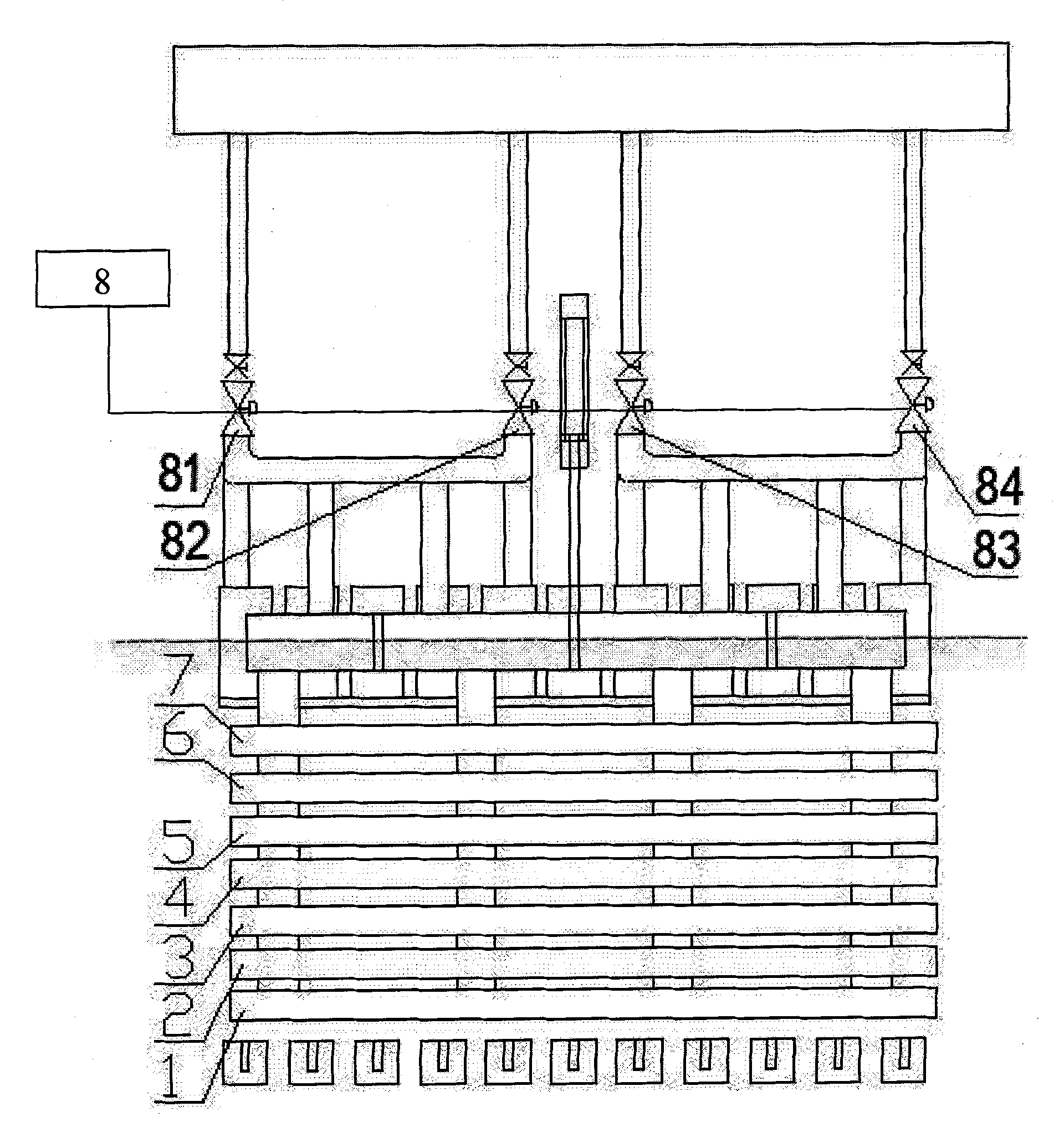

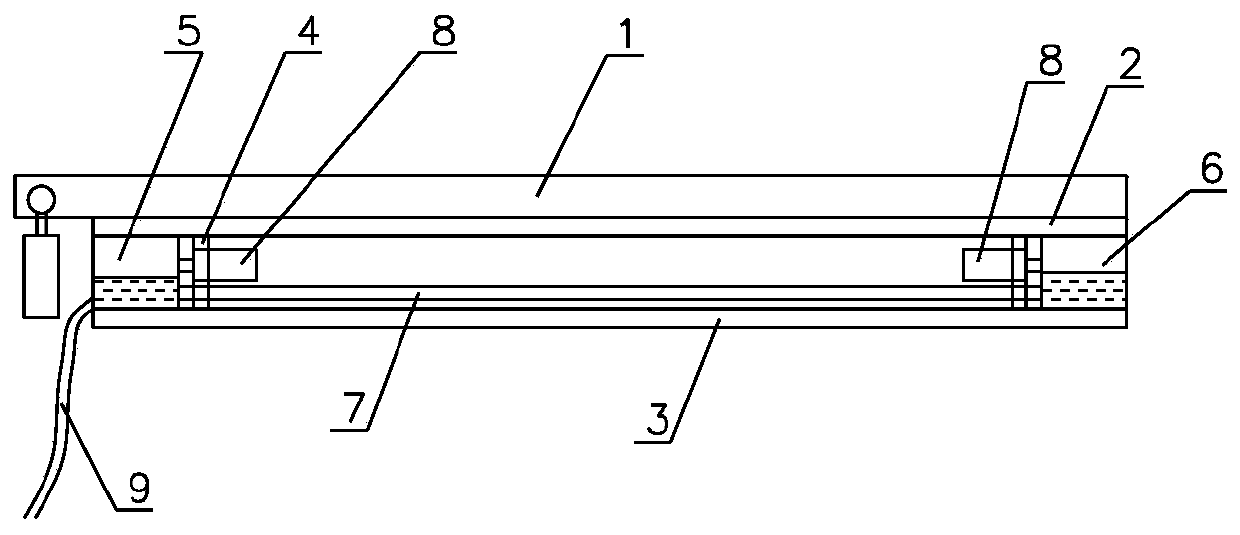

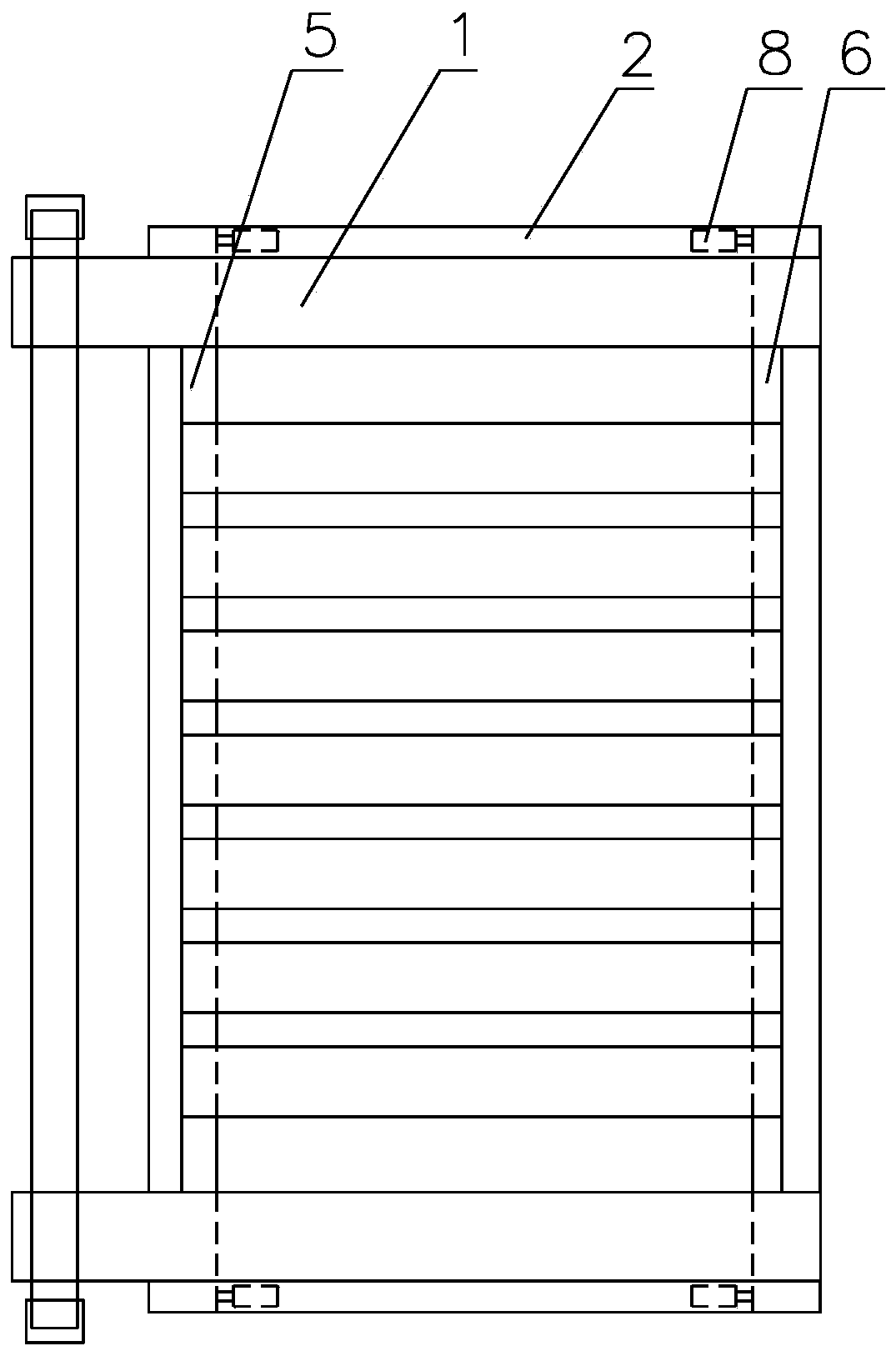

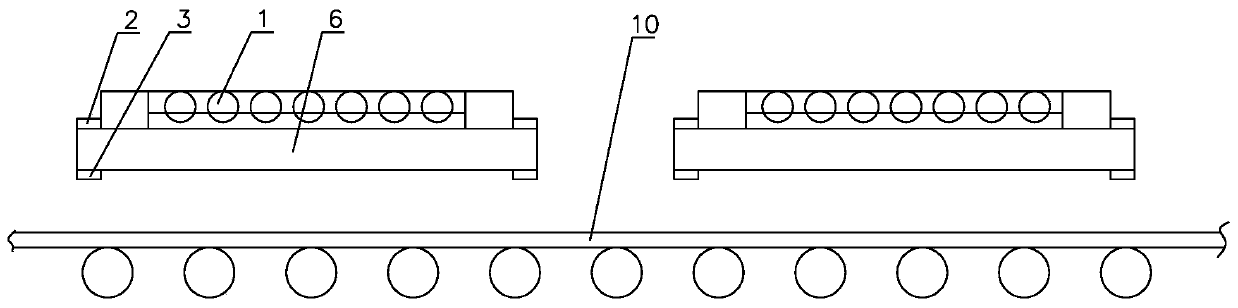

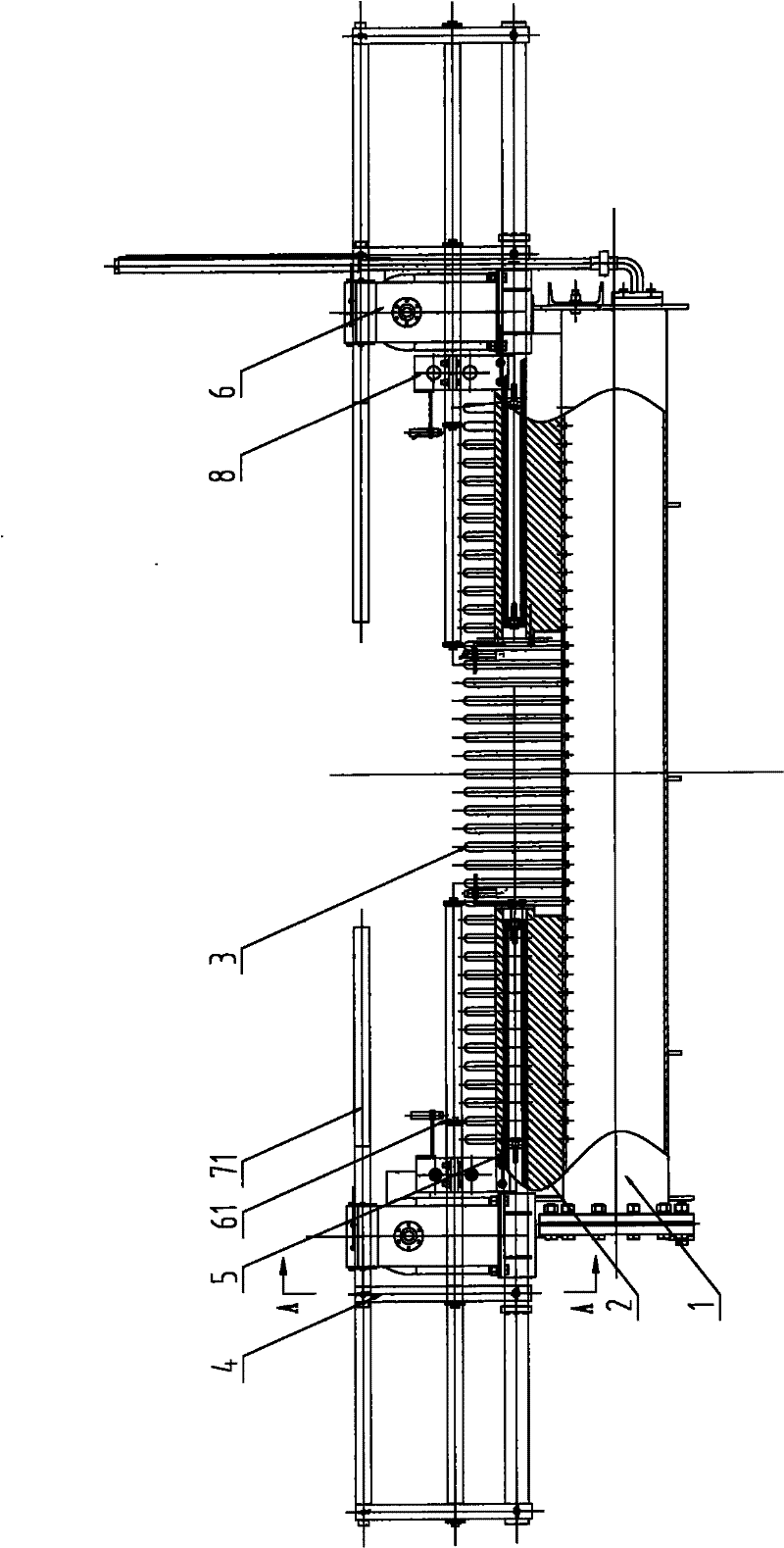

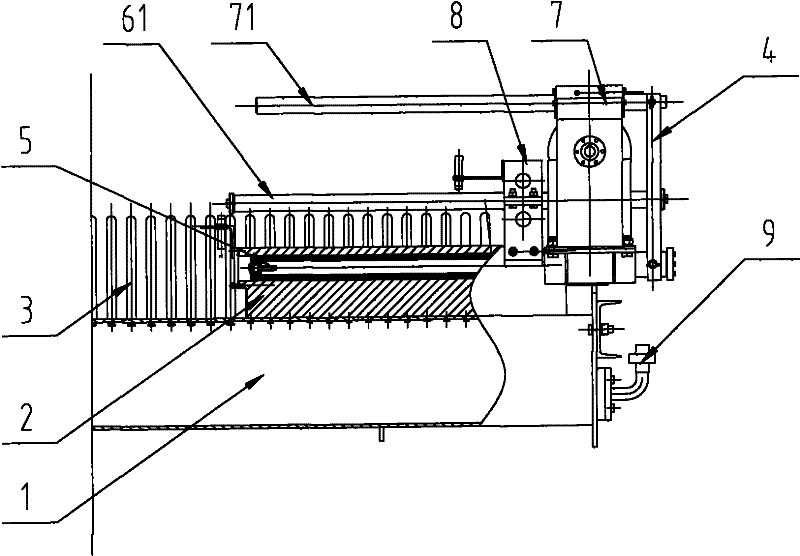

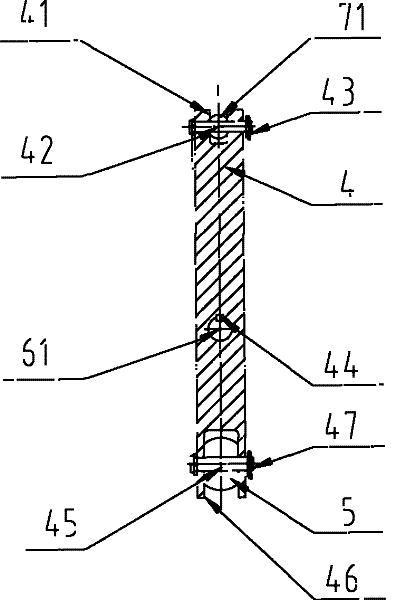

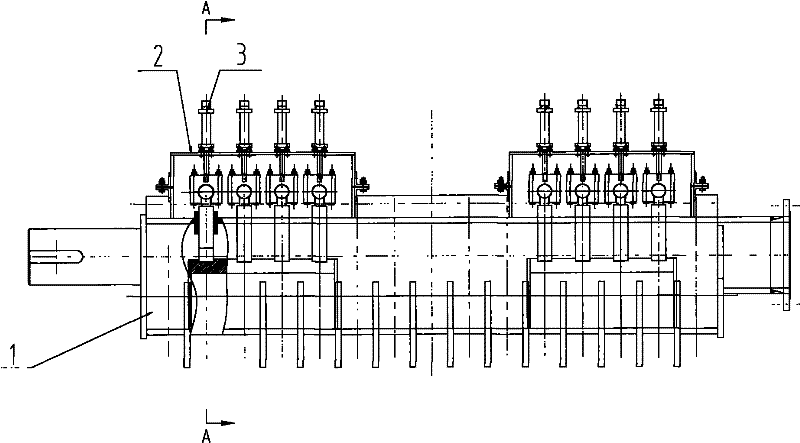

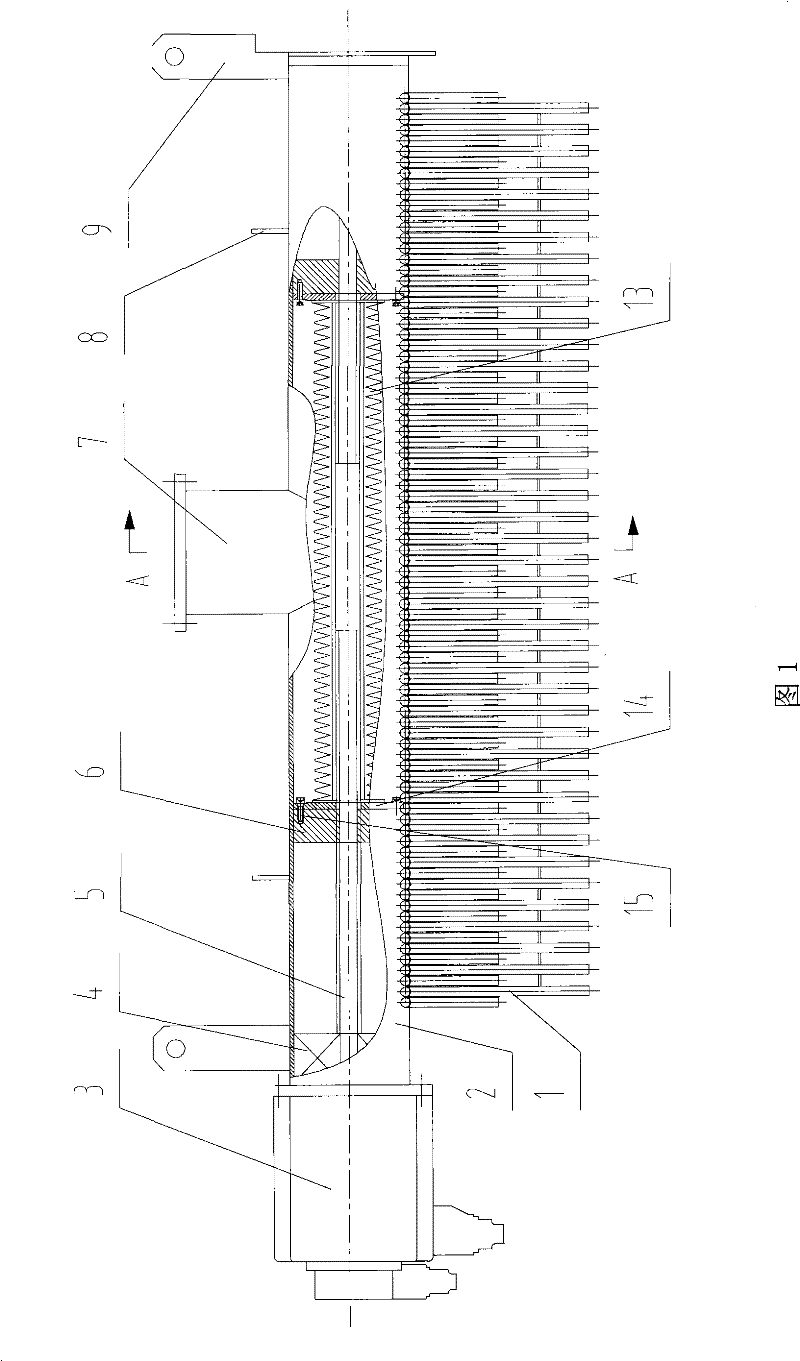

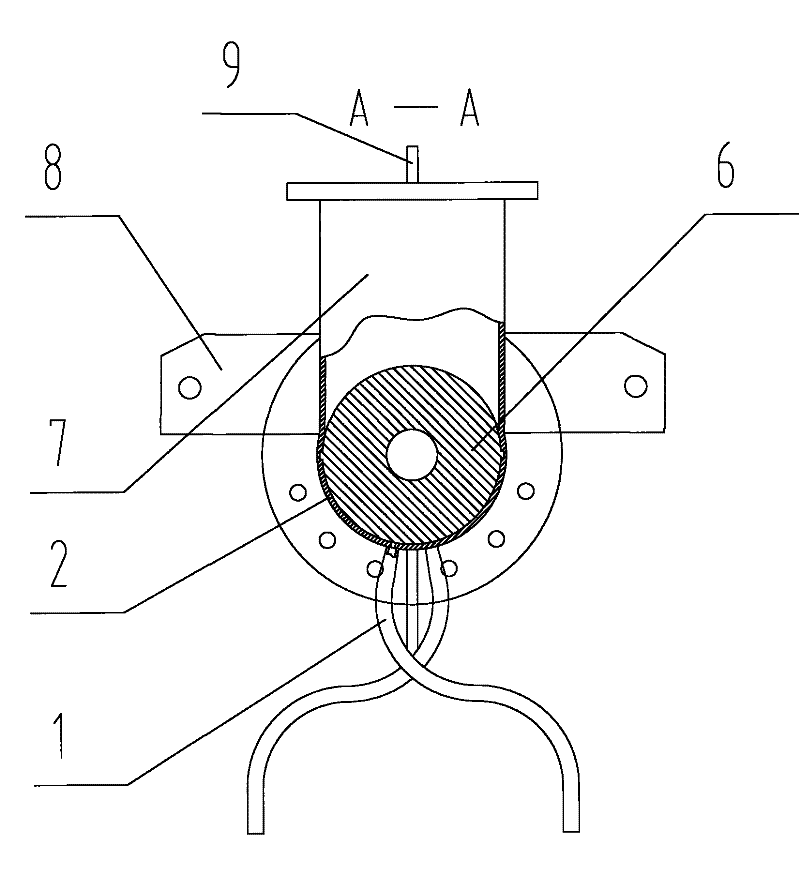

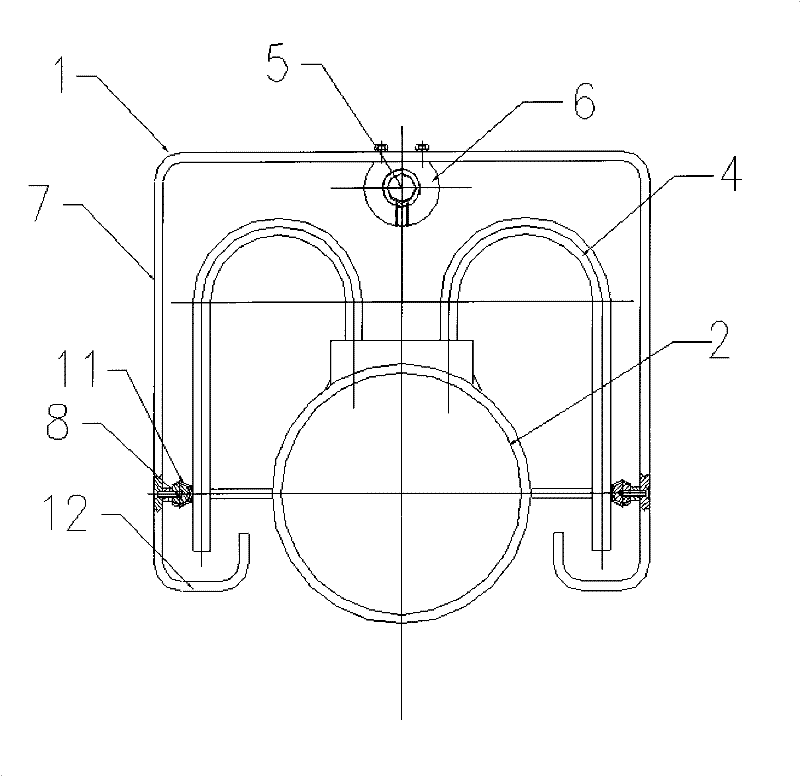

A self-balancing plunger-type upper spraying laminar flow cooling device

ActiveCN102189130AGuaranteed force balanceEnsure shapeWork treatment devicesMetal rolling arrangementsControl theoryForce balance

The invention discloses a self-balancing plunger-type upper spraying laminar flow cooling device which comprises a plurality of groups of upper spraying devices. Each group of upper spraying device comprises a collecting pipe, a plurality of spraying pipes, a cross beam, two plungers , two sets of driving devices and two sets of balancing devices, wherein the cross beam is arranged at both ends of the collecting pipe; a plunger hole is arranged in the cross beam along the horizontal direction; the two plungers are respectively arranged at both ends of the plunger hole; the two sets of drivingdevices are respectively arranged at both ends of the collecting pipe and connected with the two plungers; and the two sets of balancing devices are respectively arranged above the two sets of driving devices, each set of balancing device is correspondingly and fixedly connected with each set of driving device and the plunger through a synchronization board. Compared with the prior art, the self-balancing plunger-type upper spraying laminar flow cooling device can automatically guarantee the force balance of the driving devices when regulating the laminar flow cooling width, thereby improvingthe work stability, and avoiding the deflection torque which is caused by the single-side force of the driving devices and can affect the stability of plunger drive.

Owner:BAOSHAN IRON & STEEL CO LTD

Upper spray cooling device arranged among finishing mill racks

InactiveCN102189132AEnsure shapeGuaranteed mechanical propertiesWork treatment devicesMetal rolling arrangementsEngineeringStrip steel

The invention discloses an upper spray cooling device arranged among finishing mill racks. The device is arranged above strip steel and at an inlet side of a finishing mill rack. The device comprises a split-type collecting pipe, a plurality of rows of spray pipes, a plurality of opening and closing values and a plurality of driving devices, wherein the split-type collecting pipe is arranged perpendicular to the operating direction of the steel strip; the spray pipes are uniformly arranged along the axial direction of the collecting pipe, each row of spray pipes comprises a plurality of spray pipes arranged along the radial direction of the collecting pipe, and the spray pipes are communicated with the collecting pipe through the upper ports of the spray pipes; the opening and closing values are correspondingly arranged above the plurality of rows of spray pipes and vertically move to break the upper ports of the plurality of rows of spray pipes; and the driving devices are fixedly arranged in a plurality of supports on the split-type collecting pipe, respectively and correspondingly arranged above the plurality of opening and closing values and correspondingly connected with the plurality of opening and closing values so as to realize the driving motion on the opening and closing values. The upper spray cooling of the finishing mill rack has a simple structure, and meanwhile, the adjustment of cooling water along the width direction of the strip steel can be realized.

Owner:BAOSHAN IRON & STEEL CO LTD +1

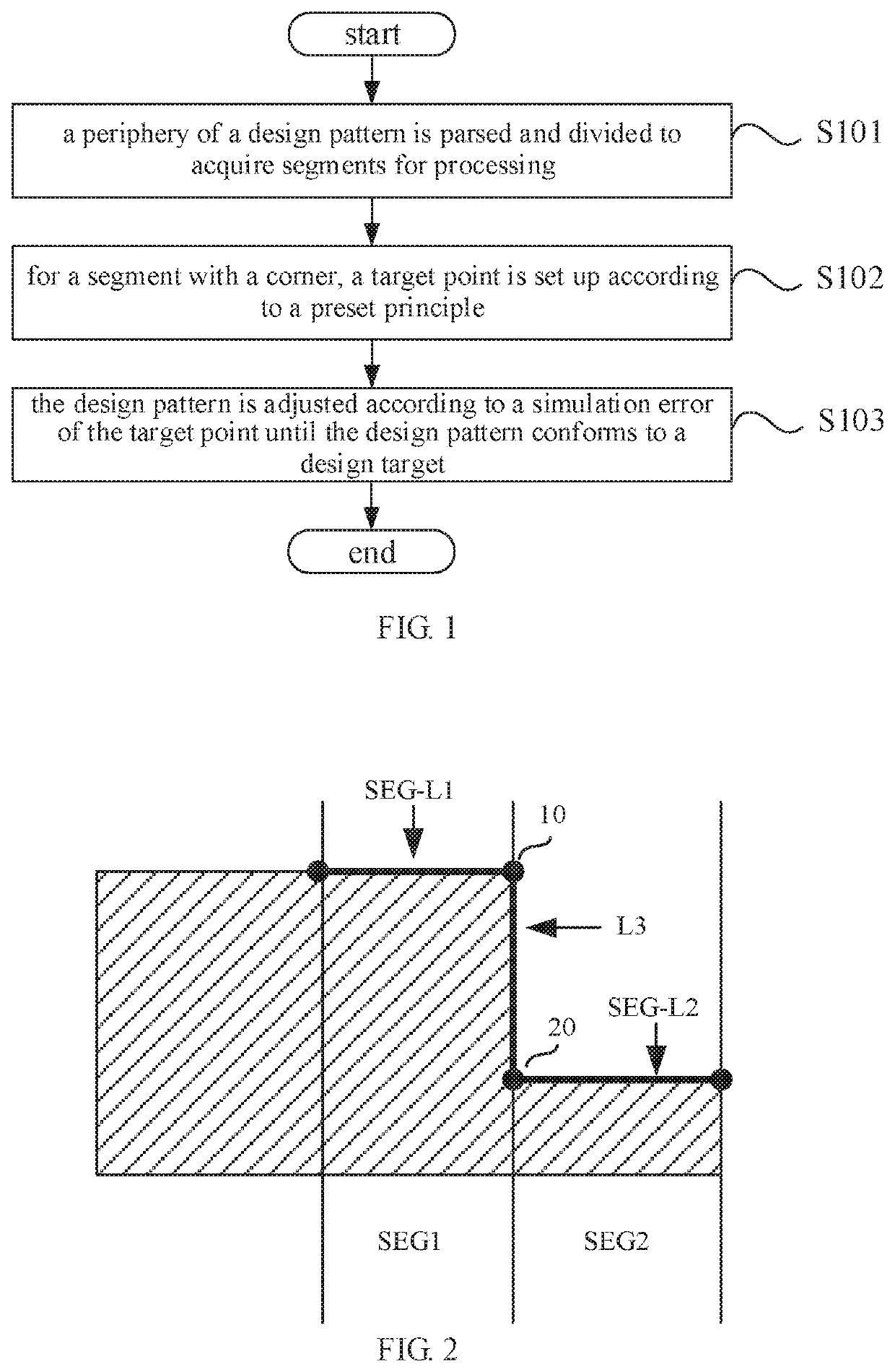

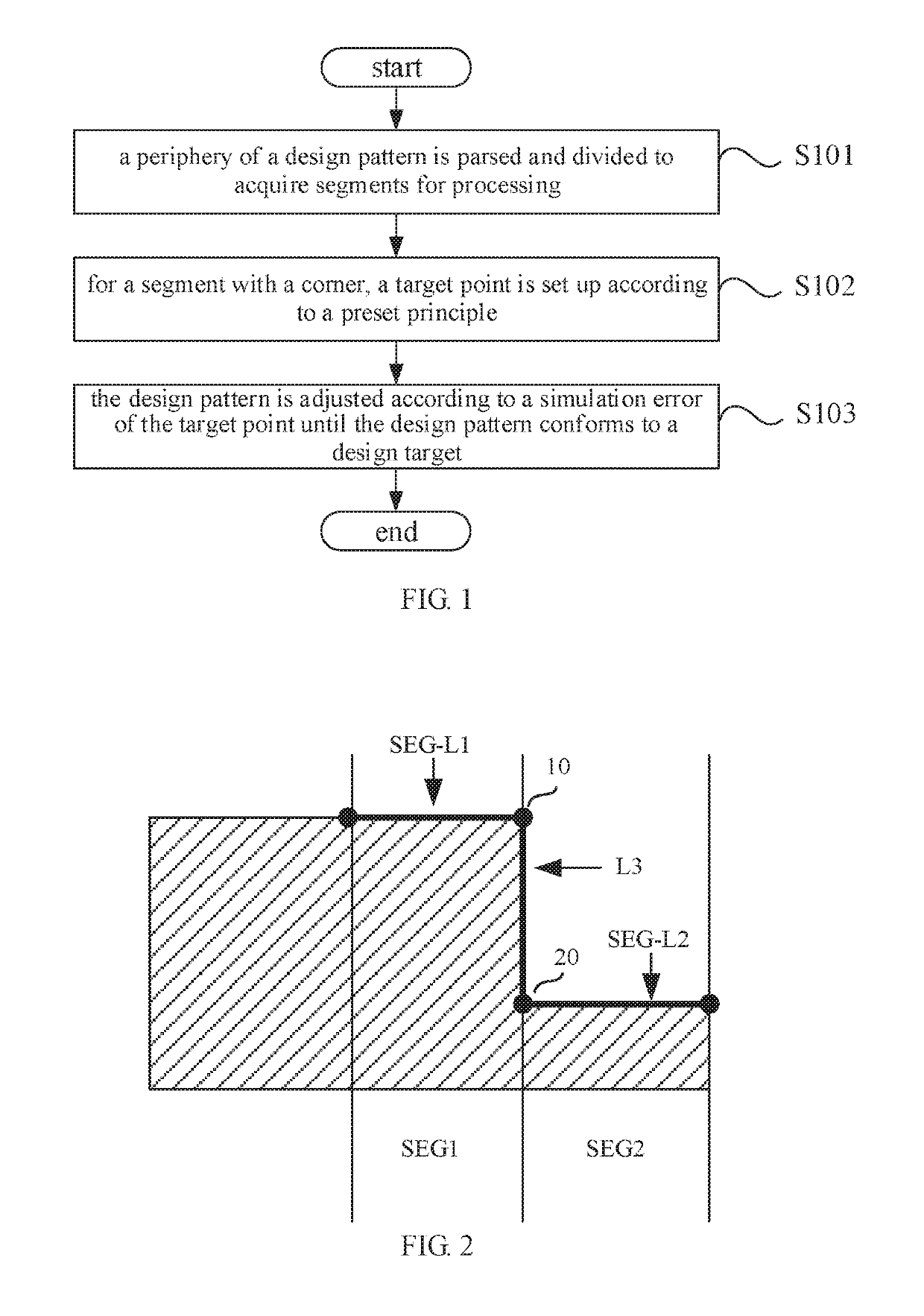

Method and system for correction of optical proximity effect

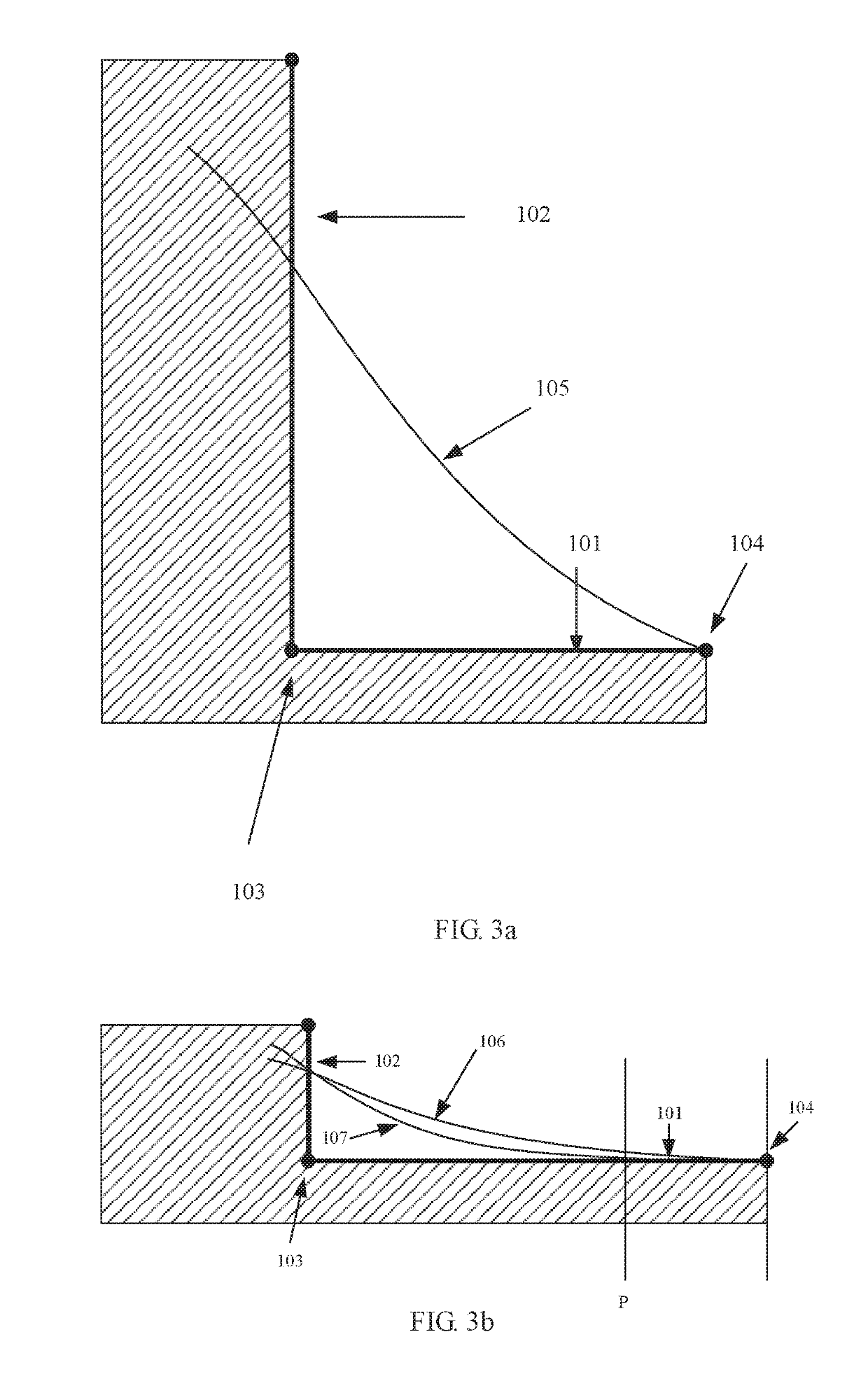

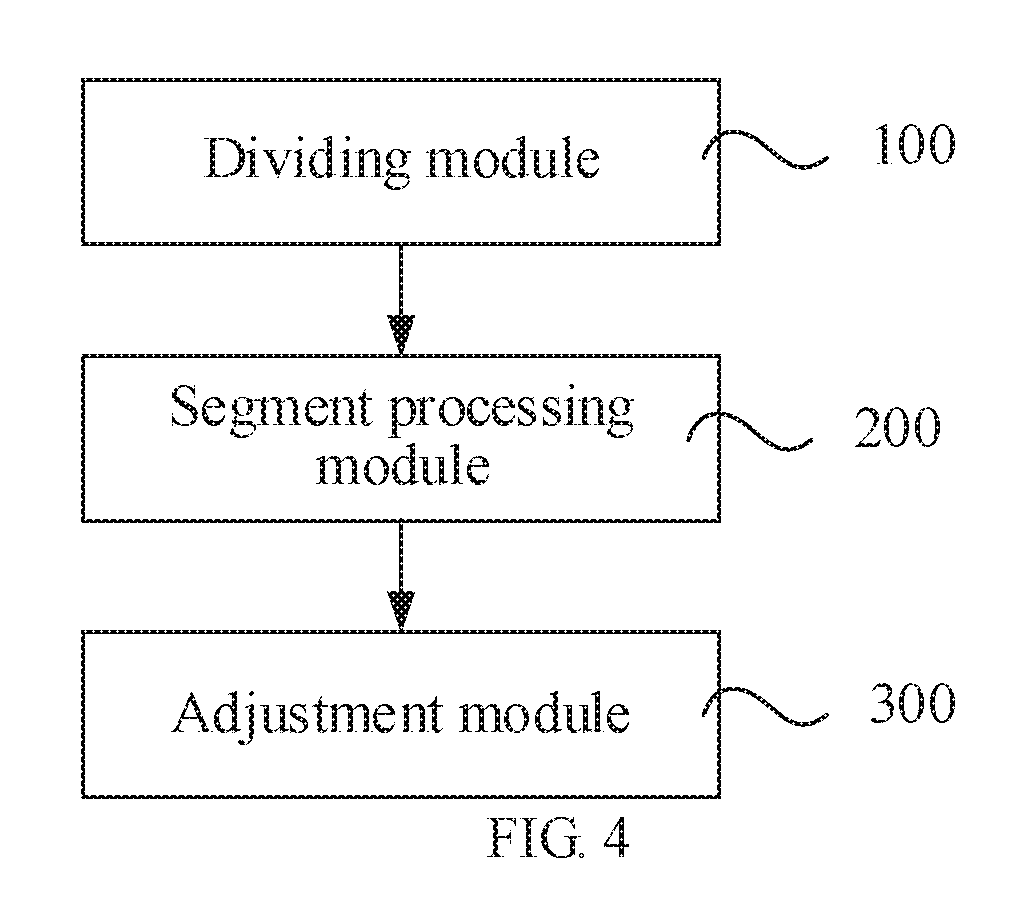

ActiveUS10816893B2Improve performanceEnsure shapeDesign optimisation/simulationOriginals for photomechanical treatmentEngineeringDesign pattern

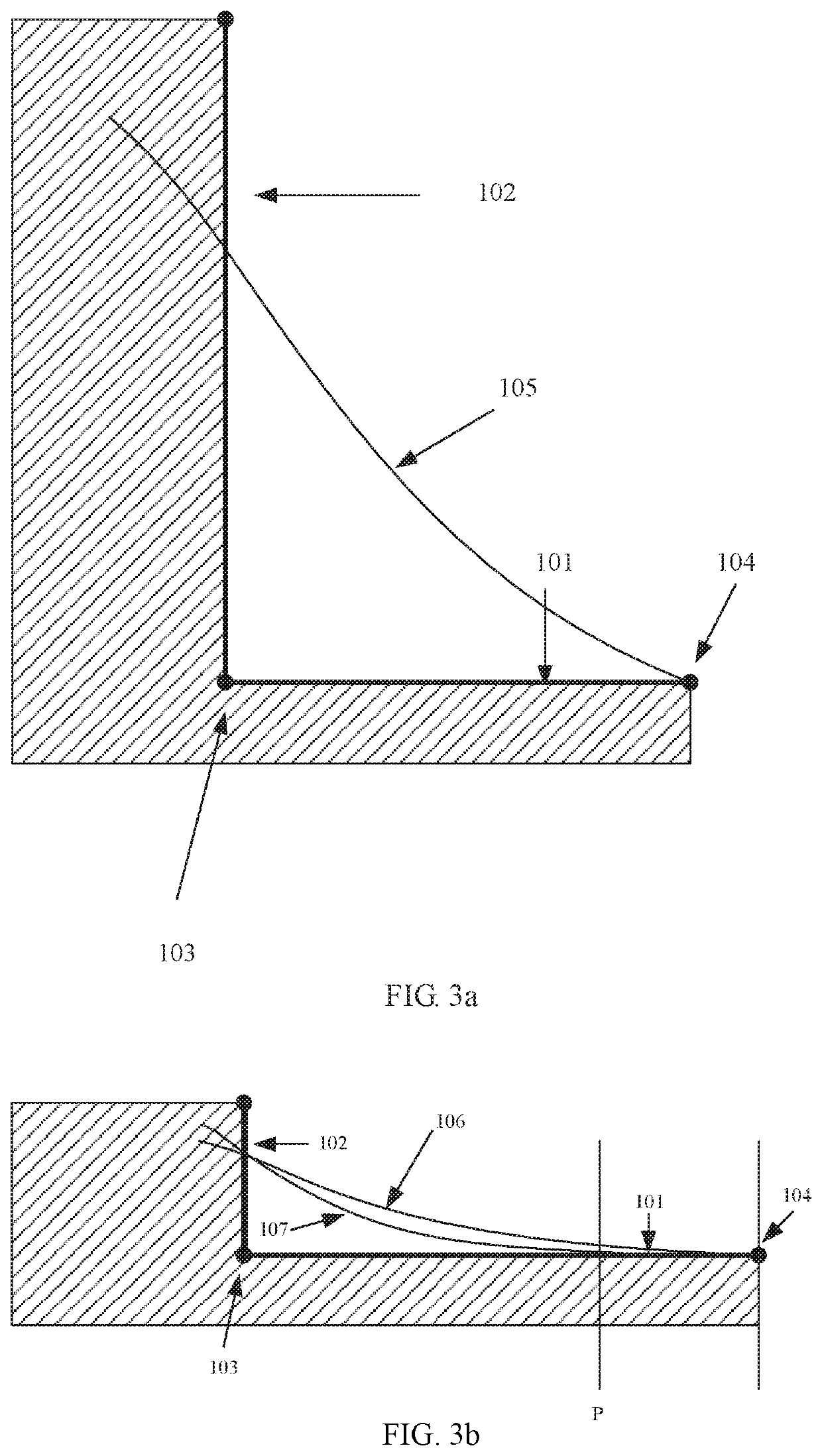

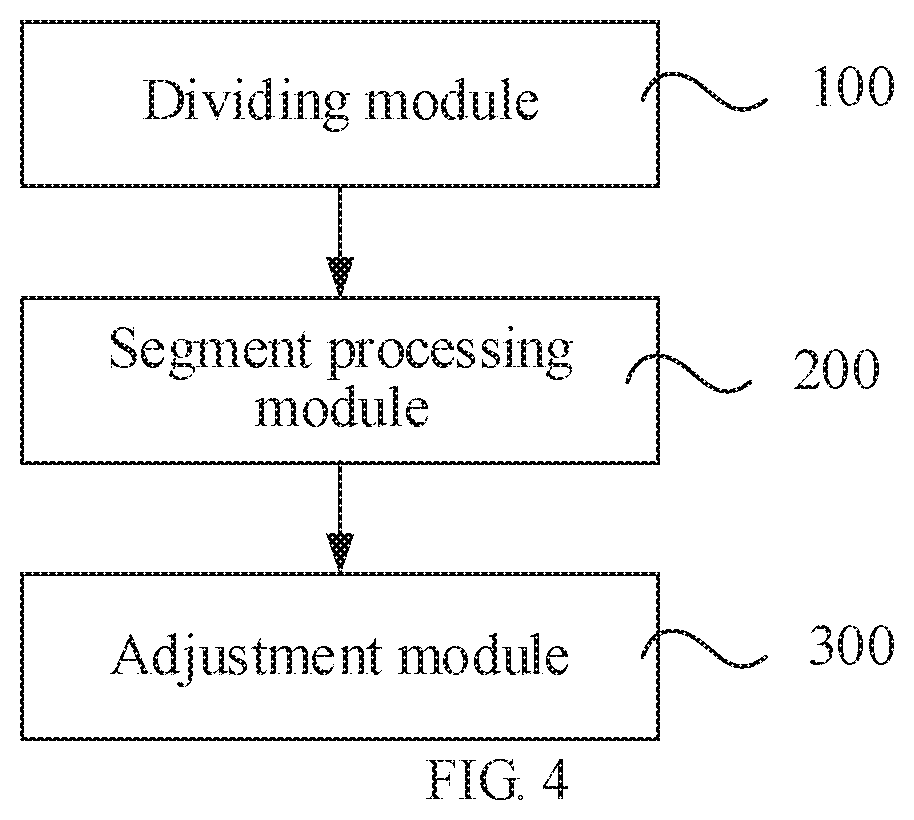

A method for correction of an optical proximity effect, comprising: parsing and dividing the periphery of a design pattern to obtain segments to process; for a segment having a corner comprising a segment side (101) and an adjacent side (102) forming a corner relation with the segment side, setting a target point according to the following principle: when the length of the adjacent side (102) is greater than a preset length, the target point is set at the location of the outer end point (104) of the segment side; when the length of the adjacent side (102) is less than or equal to the preset length, the target point is set between the vertex (103) of the corner and the outer end point (104) of the segment side, and the less the length of the adjacent side (102), the further the target point from the location of the outer end point (104); and adjusting, according to a simulation difference of the target point, the design pattern until it conforms to a design target.

Owner:CSMC TECH FAB2 CO LTD

nm300 wear-resistant steel for high-silicon and high-alumina concrete mixer truck and production method

The invention discloses a kind of NM300 wear-resistant steel for high-silicon and high-aluminum concrete mixer trucks and a production method, which controls the mass percentage content of each element in the steel and the carbon equivalent of the steel. The desulfurized pre-treated molten iron enters the converter for smelting. The qualified molten steel is continuously cast into steel billets after being treated with LF+RH+calcium. The steel billets are heated to 1150~1300°C in a soaking furnace or heating furnace and then rolled into intermediate billets through rough rolling mills and finish rolling. The final rolling temperature is 820~920℃. The 2.0~5.0mm steel plate after final rolling is cooled in sections by water cooling. The steel plate is cooled to 100~300℃ and then rolled into steel coils. The steel coils with a temperature lower than 70℃ are then cooled. The rolled cover is backfired at a temperature of 150 to 300°C and a holding time of 10 to 30 hours. The rolled steel plate is cross-cut and straightened to a fixed length. Wear-resistant steel plate Rm≥1000MPa, A50≥8%, HBW≥300HB, yield-to-strength ratio ≤0.75, has good wear resistance and processing performance, and the production process is simple. As a lightweight material for concrete mixer trucks, its practical value is obvious.

Owner:湖南华菱涟源钢铁有限公司 +1

A rolling system and method for textured rolls of UCMW cold tandem rolling mill

ActiveCN103861873BEnsure shapeGuaranteed dimensional accuracyRoll mill control devicesMetal rolling arrangementsControl systemReduction ratio

The invention relates to a texturing roll rolling system and method of a UCMW tandem cold rolling mill. The texturing roll rolling system and method of the UCMW tandem cold rolling mill comprises a rolling mode identity module, a basic setting and calculation module, a texturing roll constant-rolling-force setting module, a No.5 rack reduction ratio setting module and a rolling control system, wherein the rolling mode identity module is used for judging a roll mode; the basic setting and calculation module is used for obtaining required rolling parameters from a reduction ratio constant table corresponding to the texturing roll mode; the texturing roll constant-rolling-force setting module is used for calculating rolling force in the texturing roll mode according to the type, the width and thickness specifications and the rolling speed of strip steel; the No.5 rack reduction ratio setting module is used for selecting No.5 rack reduction ratio from the reduction ratio constant table corresponding to the texturing roll mode according to the type and the width and thickness specifications of a set steel coil. The invention additionally relates to a method using the system. The rolling system and the method provided by the invention have the advantages that the rolling mill can realize stable rolling in the texturing roll mode, the shape and dimension accuracy of finished strip steel plates can be guaranteed and especially the surface quality of the strip steel can be guaranteed.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

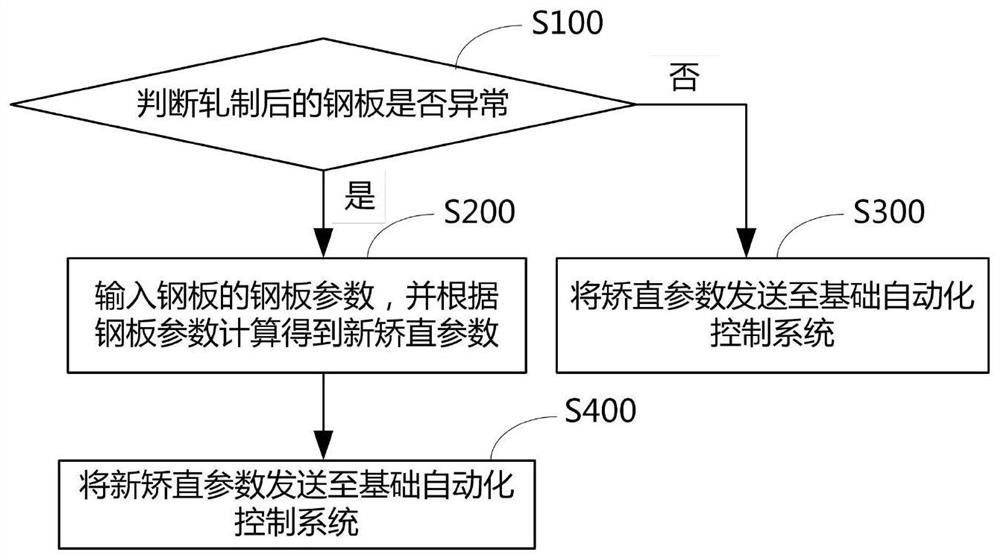

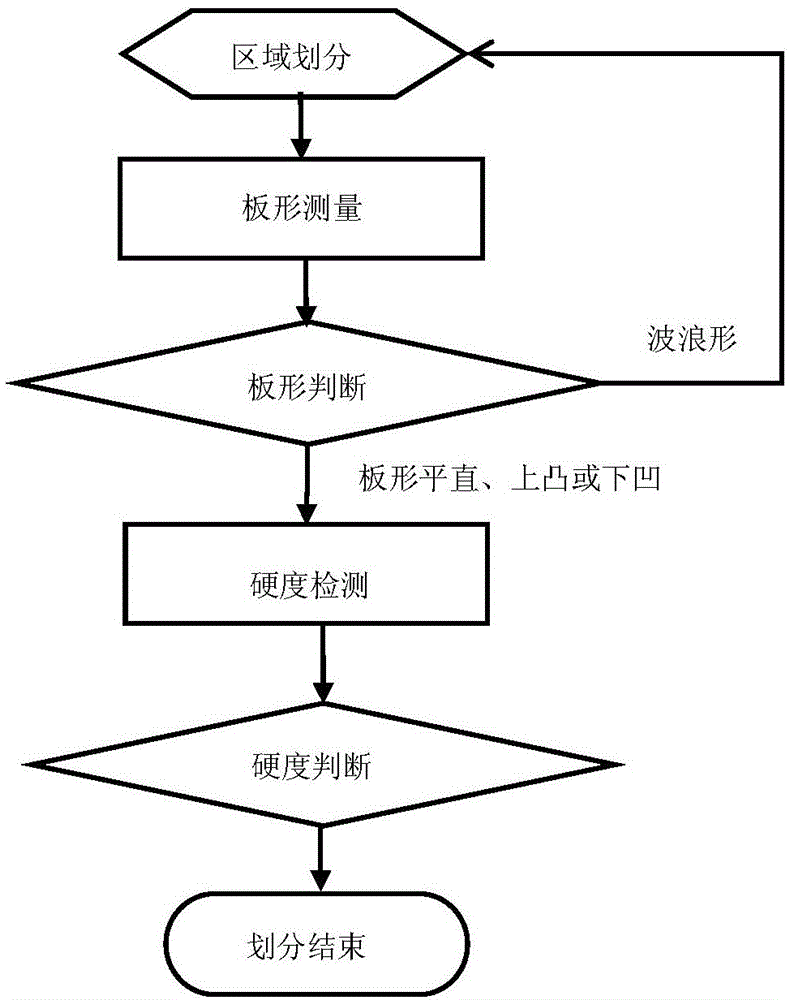

Steel plate straightening method

The invention provides a steel plate straightening method. The steel plate straightening method comprises the steps that whether a rolled steel plate is abnormal or not is judged, if the rolled steelplate is abnormal, steel plate parameters of the steel plate are input, new straightening parameters are obtained through calculation according to the steel plate parameters, the new straightening parameters are sent to a basic automatic control system, and the basic automatic control system controls a straightener to straighten according to the new straightening parameters. According to the steelplate straightening method, calculating the steel plate parameters of the abnormal steel plate is carried out to obtain the new straightening parameters, the straightener is controlled to straightenaccording to the new straightening parameters, and the straightened abnormal steel plate is obtained, so that the shape of the steel plate is guaranteed, and the waste quantity is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

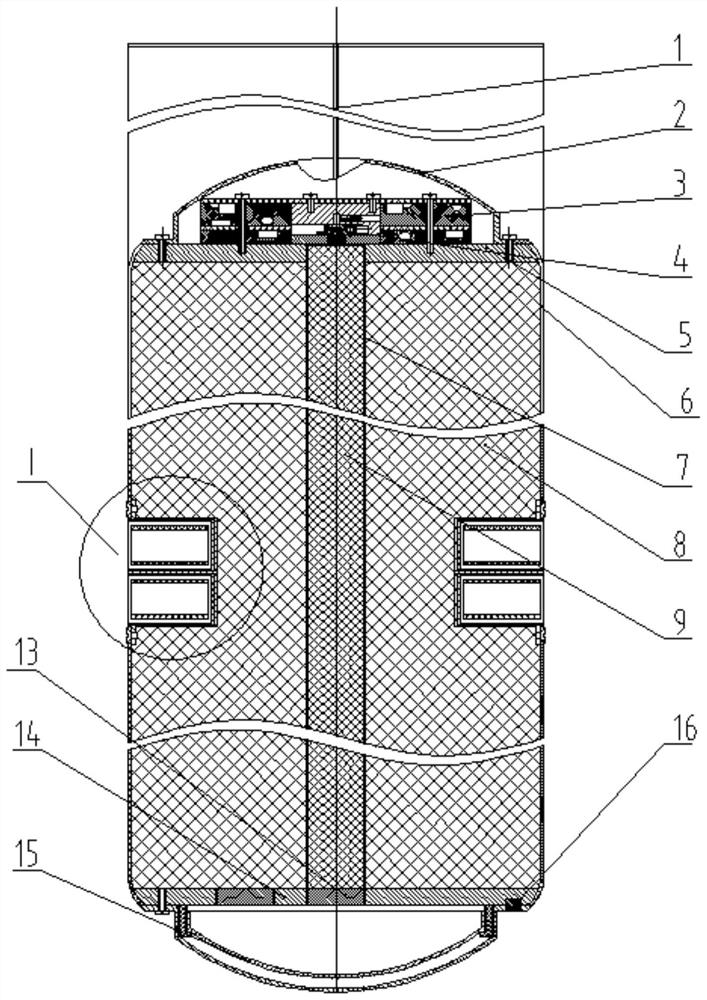

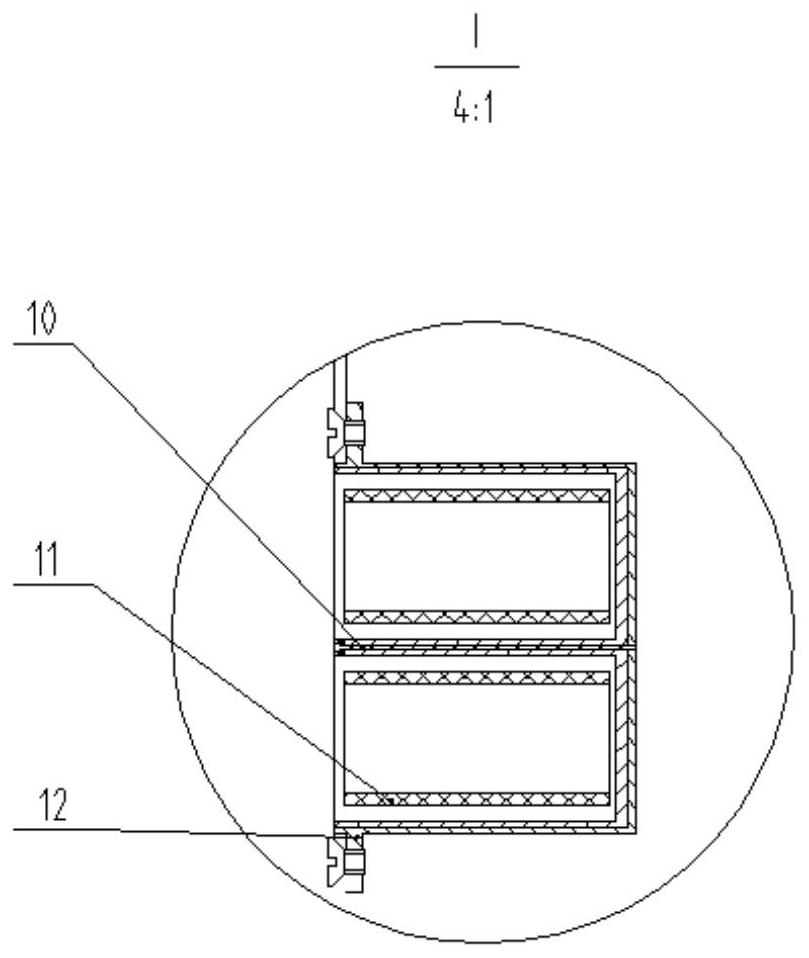

Fire extinguishing bomb with fine control function

The invention discloses a fire extinguishing bomb with a fine control function, and belongs to the technical field of forest fire extinguishing. The fire extinguishing bomb comprises a barrel type empennage, a rear cover, a control module, a safety detonating device, a tail baffle, a warhead shell, a preset protection barrel, a fire extinguishing agent, a main explosive, a connecting body, a pulseengine shell, a pulse engine shell, a blocking piece, a front baffle, a closing switch and a heat detector. According to the fire extinguishing bomb, the advantages that the pulse engine is fast in reaction and can be started in situ are utilized, the low-speed flying bomb can accurately control and correct the flying posture of the bomb at the tail end of a trajectory, air shock waves generatedby explosion of the main explosive rapidly scatter forest big fire into small fire, the fire extinguishing agent forms a covering layer within the range of being exploded into the small fire in a firescene under pushing of air waves generated after explosion of the explosive, continuous combustion of the small fire can be weakened, and reburning of remaining fire can be inhibited. The fire extinguishing bomb further has the advantages of being simple in structure, safe, reliable, high in fire extinguishing efficiency, small in environmental pollution and the like.

Owner:HUAIHAI IND GRP

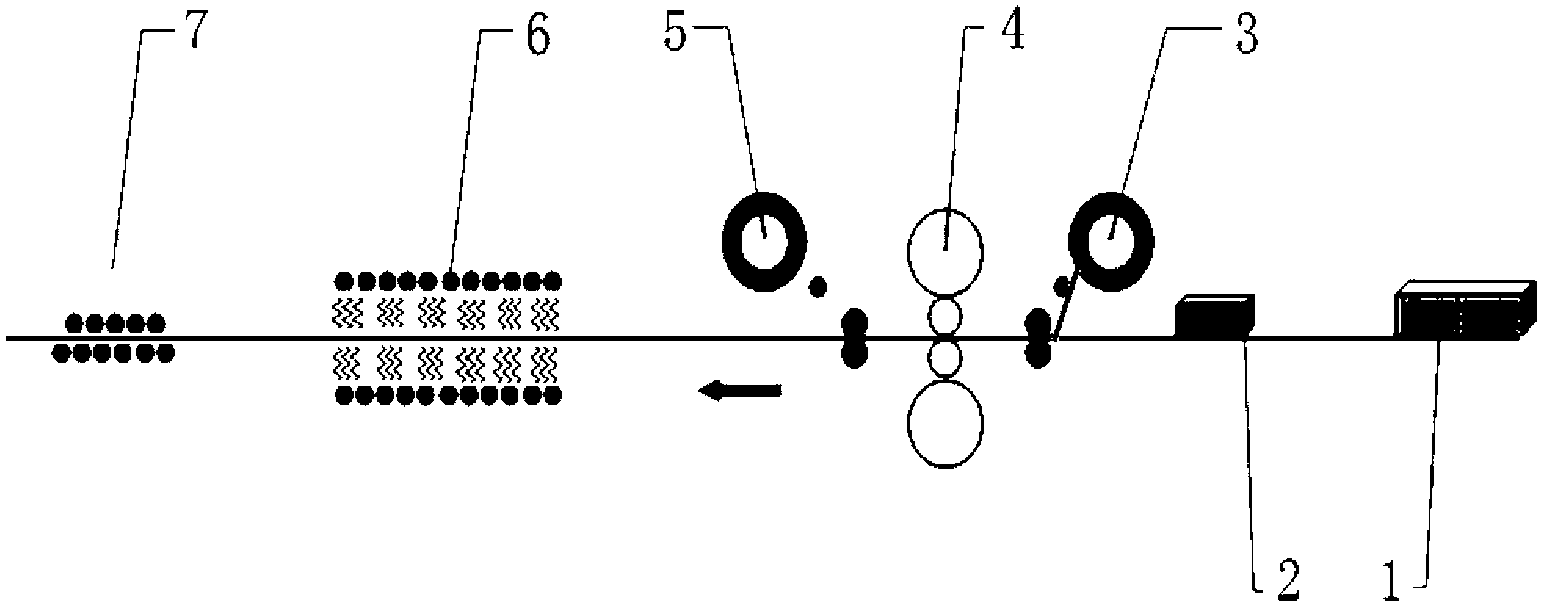

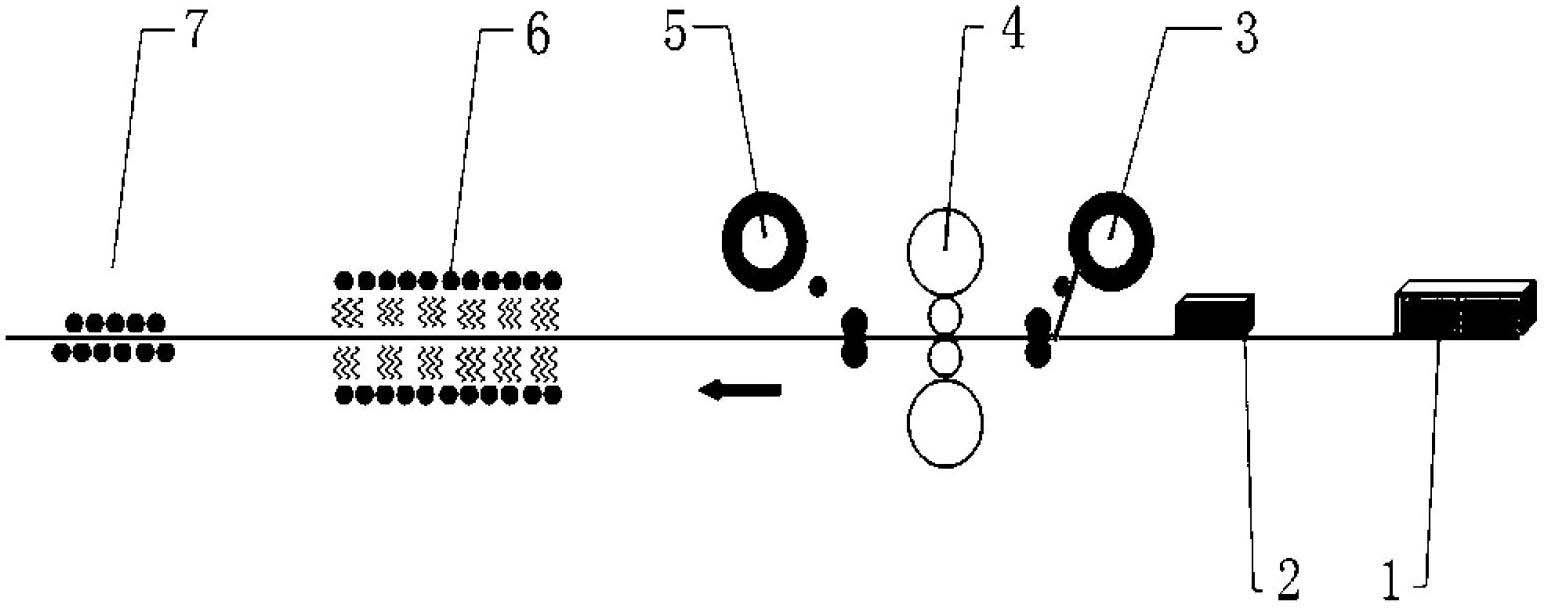

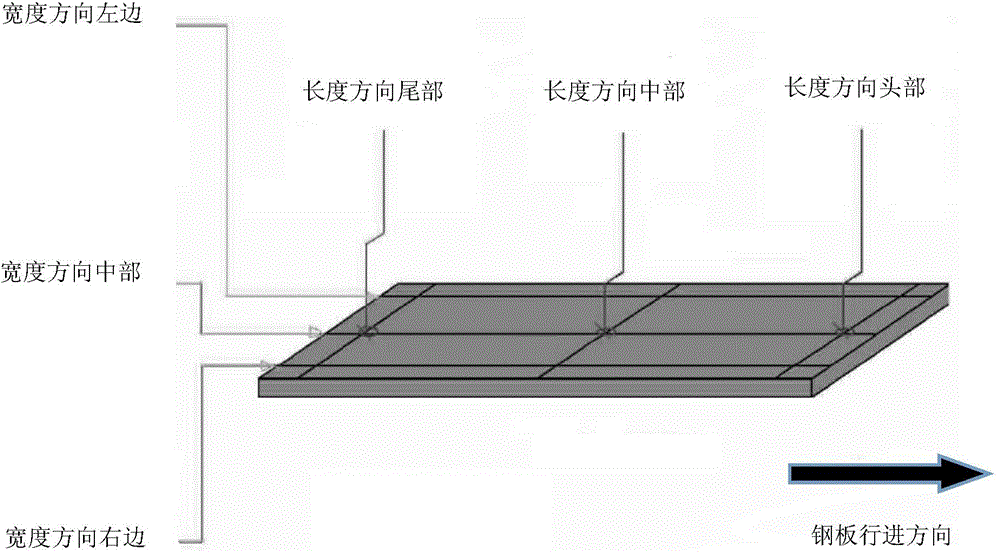

Three-dimensional full-flow control method for online steel plate solution treatment

ActiveCN105695729AEnsure hardnessEnsure shapeHeat treatment process controlProfile control deviceSolution treatmentHardness

The invention provides a three-dimensional full-flow control method for online steel plate solution treatment, and belongs to the field of control. According to the three-dimensional full-flow control method, to solve the bottleneck problem that the plate shape is not good after a steel plate is rolled and cooled during application of the online solution treatment technology, a post-rolling cooling device capable of being controlled in a three-dimensional full-flow mode in the longitudinal direction, the transverse direction and the vertical direction is utilized, three-dimensional full-flow control over the cooling device is carried out according to the hardness and the plate shape of the cooled steel plate, and therefore the hardness and the plate shape of the rolled and cooled steel plate subjected to online solution treatment are ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

Method and system for correction of optical proximity effect

ActiveUS20190212643A1Improve performanceRounding performance be improveDesign optimisation/simulationOriginals for photomechanical treatmentDesign patternDesign objective

A method for correction of an optical proximity effect, comprising: parsing and dividing the periphery of a design pattern to obtain segments to process; for a segment having a corner comprising a segment side (101) and an adjacent side (102) forming a corner relation with the segment side, setting a target point according to the following principle: when the length of the adjacent side (102) is greater than a preset length, the target point is set at the location of the outer end point (104) of the segment side; when the length of the adjacent side (102) is less than or equal to the preset length, the target point is set between the vertex (103) of the corner and the outer end point (104) of the segment side, and the less the length of the adjacent side (102), the further the target point from the location of the outer end point (104); and adjusting, according to a simulation difference of the target point, the design pattern until it conforms to a design target.

Owner:CSMC TECH FAB2 CO LTD

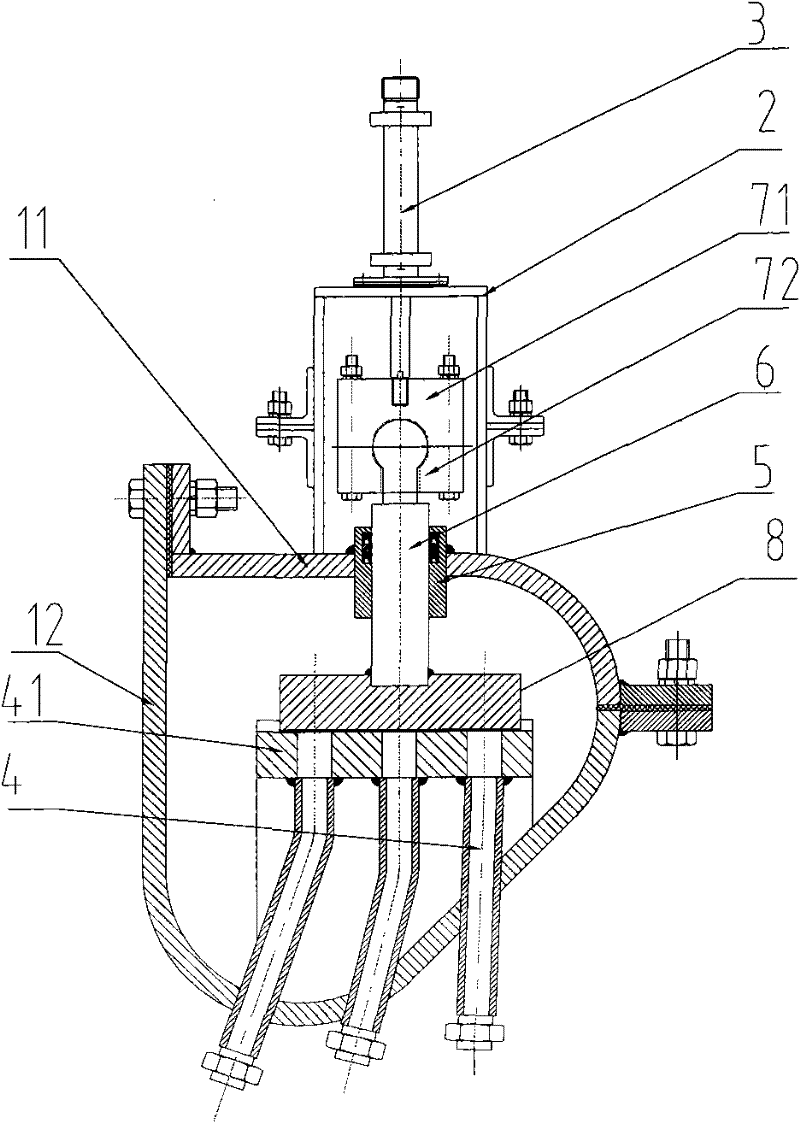

Lower spraying laminar flow cooling device

ActiveCN102189131BReduce consumptionAvoid wastingWork treatment devicesMetal rolling arrangementsLaminar coolingSpray nozzle

The invention discloses a lower spraying laminar flow cooling device. The device comprises a plurality of groups of lower spraying devices, wherein each group of lower spraying device comprises a collecting pipe, two plunger pipes, two plungers and two U-shaped covers; the collecting pipe is fixedly arranged along a direction vertical to the operation direction of strip steel; a plurality of goose neck spray pipes are uniformly distributed on the collecting pipe along the axial direction; the two plunger pipes are fixedly arranged above the two ends of the collecting pipe respectively, pass through the plurality of goose neck spray pipes which are uniformly distributed at the two ends of the collecting pipe respectively, divide the goose neck spray pipes into upper nozzles and lower spraypipes, and are communicated with the upper nozzles and the lower spray pipes of the goose neck spray pipes through a plurality of through holes; the two plungers are arranged in the two plunger pipesrespectively; the two U-shaped covers are covered outside the two plungers in a mode that openings are downward; and the plungers are connected with driving devices through the U-shaped covers, so that movement in the axial direction is realized, the through holes are blocked, and cooling water quantity is adjusted.

Owner:BAOSHAN IRON & STEEL CO LTD

Automobile engine cylinder cover casting material

The invention discloses an automobile engine cylinder cover casting material, which is prepared from the following ingredients (by weight): 2.32-2.35% of carbon, 1.2-1.4% of silicon, 0.32-0.68% of manganese, 0.01-0.03% of titanium, 0.10-0.30% of aluminium, 0.22-0.28% of chromium, 0.22-0.28% of vanadium, 0.12-0.14% of molybdenum, 0.02-0.05% of tin, 0.012-0.014% of cerium, sulfur being less than or equal to 0.001%, phosphor being less than or equal to 0.004%, and the rest of iron. Mechanical properties of the automobile engine cylinder cover casting material are effectively improved. The cost is low, and the efficiency is high.

Owner:马鞍山顺发机械制造有限公司

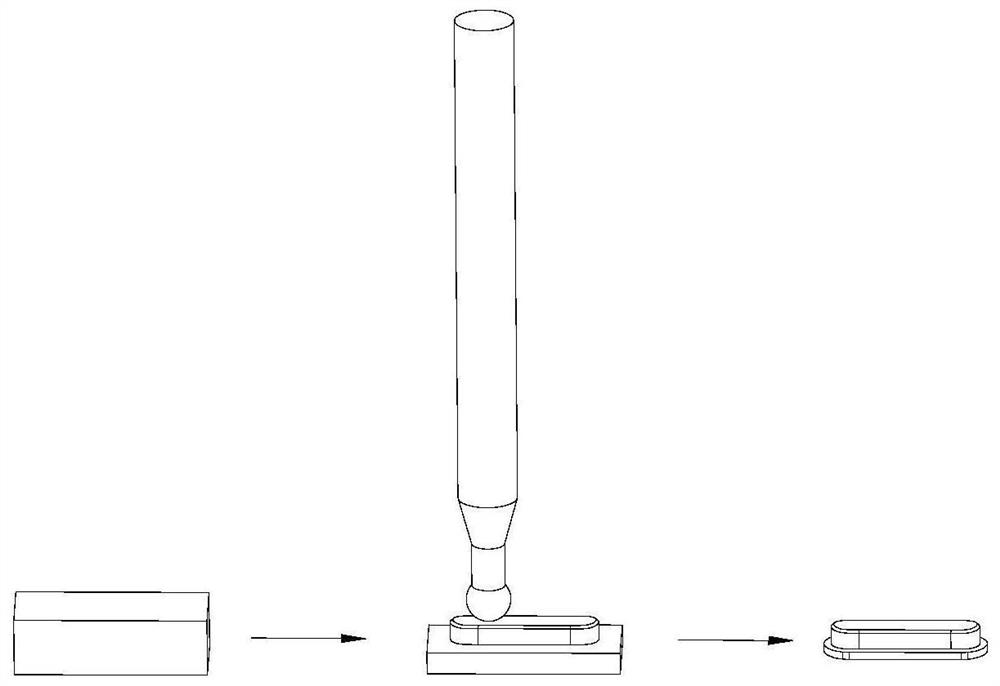

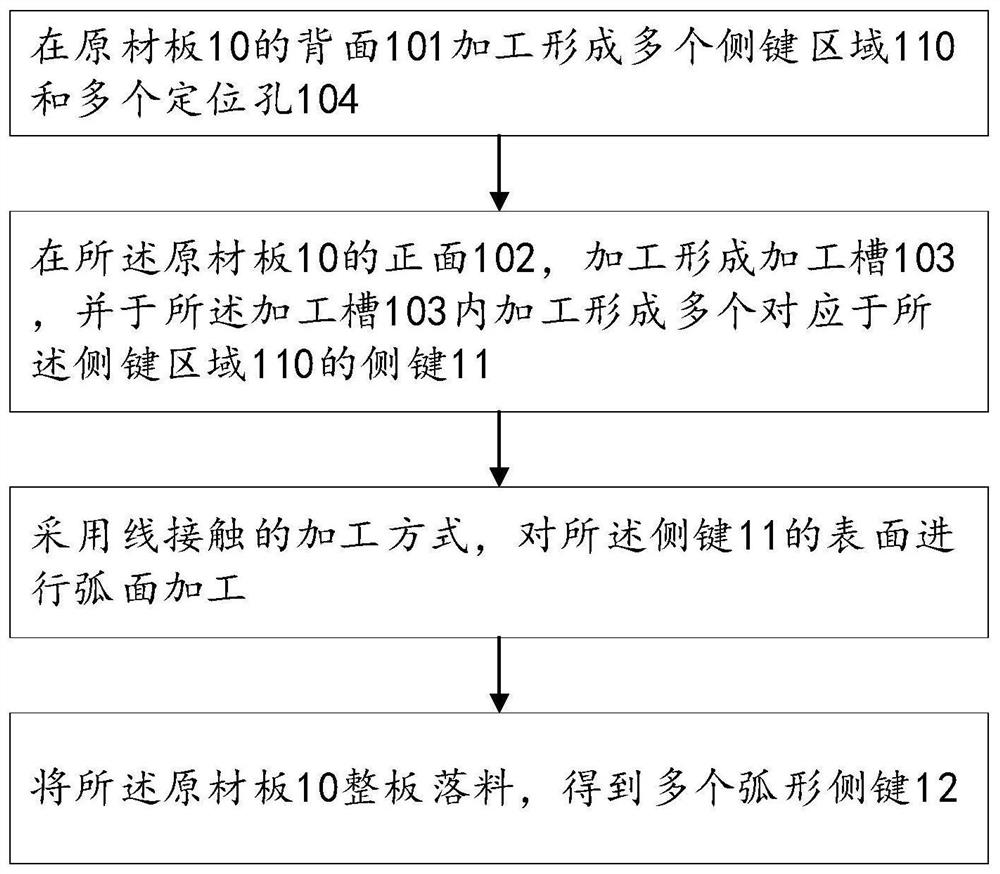

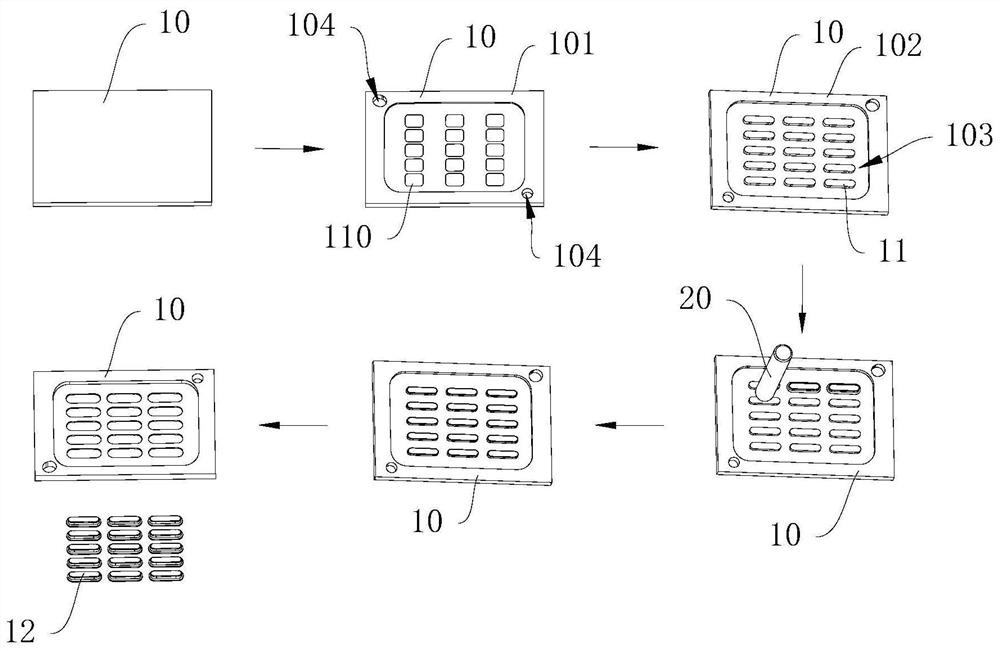

Batch machining method for arc-shaped side keys and machining tool

ActiveCN113118710AReduce lossImprove processing efficiencyMilling cuttersMilling equipment detailsStampingLaser cutting

The invention relates to a batch production method of arc-shaped side keys and a machining tool. By adopting a line contact machining mode, one machining tool can be adopted to conduct arc surface machining on a plurality of side keys at the same time, the machining efficiency is high, the tool loss is small, and the machining cost is low; blanking of the whole raw material plate is achieved in a stamping or laser cutting mode, the machining efficiency of the arc-shaped side keys is improved, and batch production of the arc-shaped side keys is achieved; and in addition, the side keys are machined and formed in the mode that a plurality of side key areas are distributed in the rectangular array mode, and the accuracy of the shapes and the positions of the arc surfaces formed when the arc surfaces of the side keys are machined through the machining tool is ensured.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD

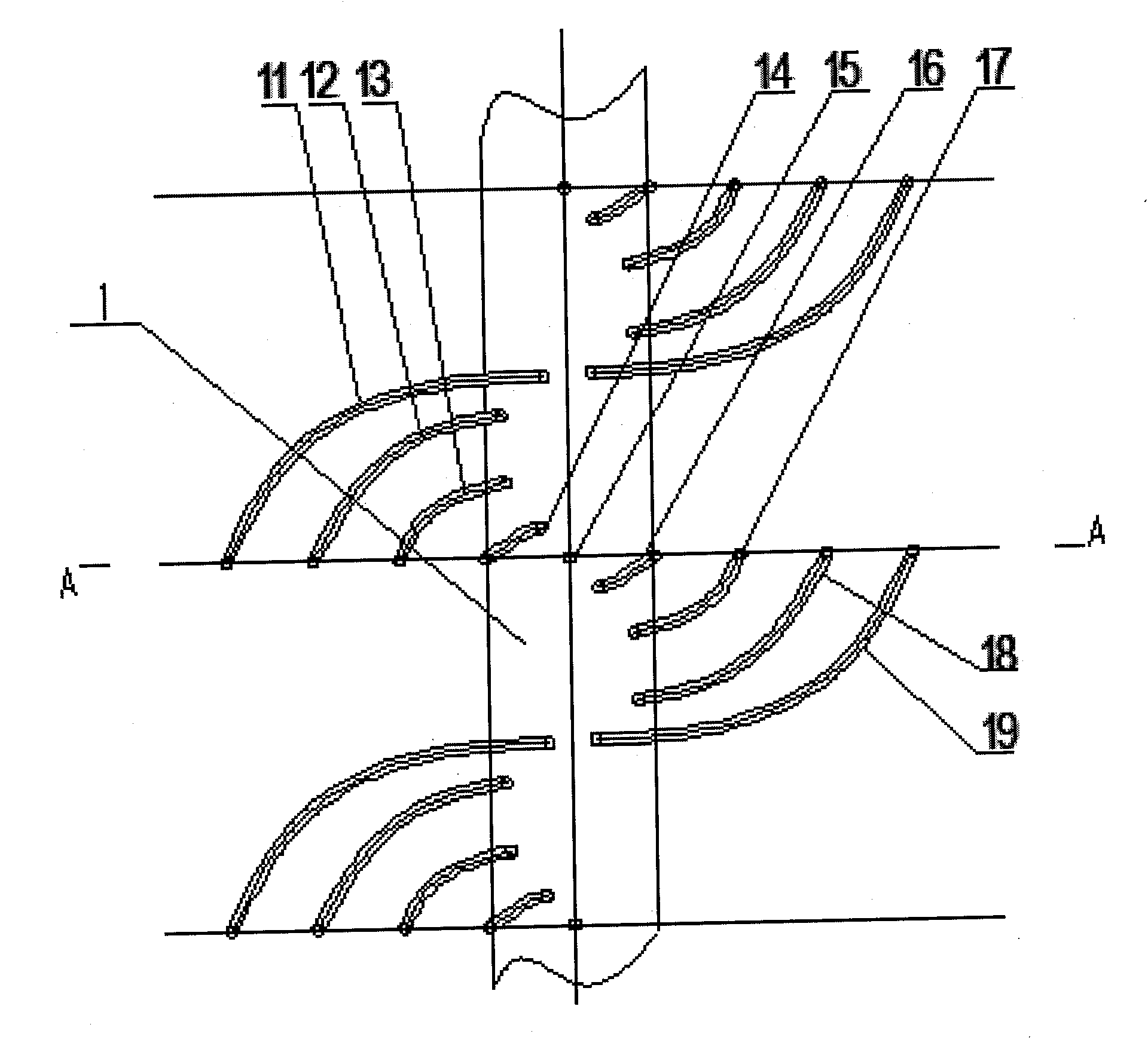

Laminar flow width-adjusting cooling device and control method thereof

ActiveCN101837378BEnsure shapeGuaranteed mechanical propertiesWork treatment devicesRoll mill control devicesStrip steelEngineering

The invention relates to a laminar flow width-adjusting cooling device and a control method thereof. The laminar flow width-adjusting cooling device comprises a plurality of groups of spray pipe devices, and each group of spray pipe device comprises a collecting pipe, a screw rod and two pistons, wherein the middle part of the collecting pipe is provided with a water inlet pipe, and the collecting pipe is provided with a plurality of spray pipes which are evenly distributed; the screw rod is arranged in the center of the collecting pipe along the axial direction; and the two pistons are respectively arranged on the screw rod and can move in the collecting pipe along the length direction of the screw rod, and the external diameters of the pistons are matched with the internal diameter of the collecting pipe. According to the requirements of the cooling technique of the strip steel with different widths, the invention can be used for adjusting the area of cooling water along the width direction of a channel, thus reducing the temperature reduction of the side of the strip steel, and ensuring the uniformity of the profile shape, the mechanical performance, the temperature and the phase change of the strip steel along the width direction.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of non-oriented electrical steel hot rolled plate

The invention relates to the field of steel making, in particular to a production method of a non-oriented electrical steel hot rolled plate. According to the production method of the non-oriented electrical steel hot rolled plate, molten steel is cast into a plate blank first, the plate blank is heated in a heating furnace, and then the heated plate blank is subject to roughing to obtain an intermediate blank, and the intermediate blank is subject to finishing rolling to obtain the hot rolled plate, wherein the thickness of the plate blank is 160-240mm, the plate blank is heated to 1120-1250DEG C in the heating furnace, the temperature of the plate blank in the roughing process is 1080-1230 DEG C, and the thickness of the intermediate blank is 36-40mm. By means of the production method of the non-oriented electrical steel hot rolled plate, the production of the non-oriented electrical steel hot rolled plate can be realized by adopting a common steel hot rolled plate production line,a special electrical steel hot rolled plate production line can be omitted, the production cost of the non-oriented electrical steel hot rolled plate is obviously reduced, and the production method has great popularization and application prospects.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

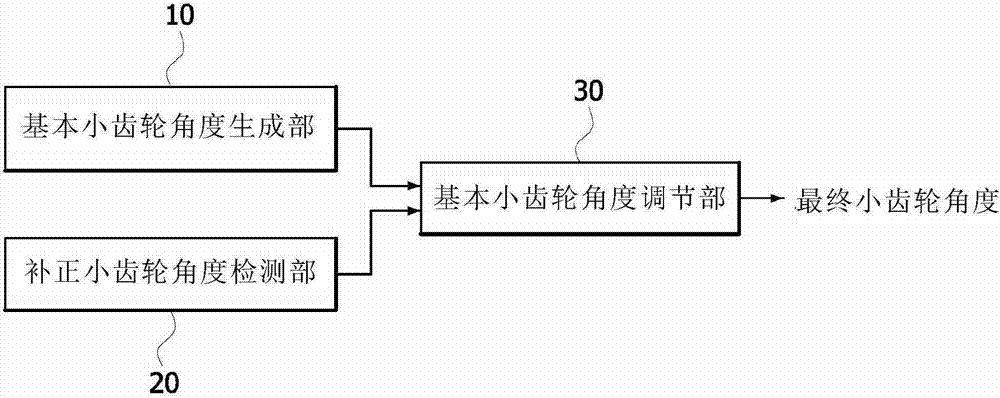

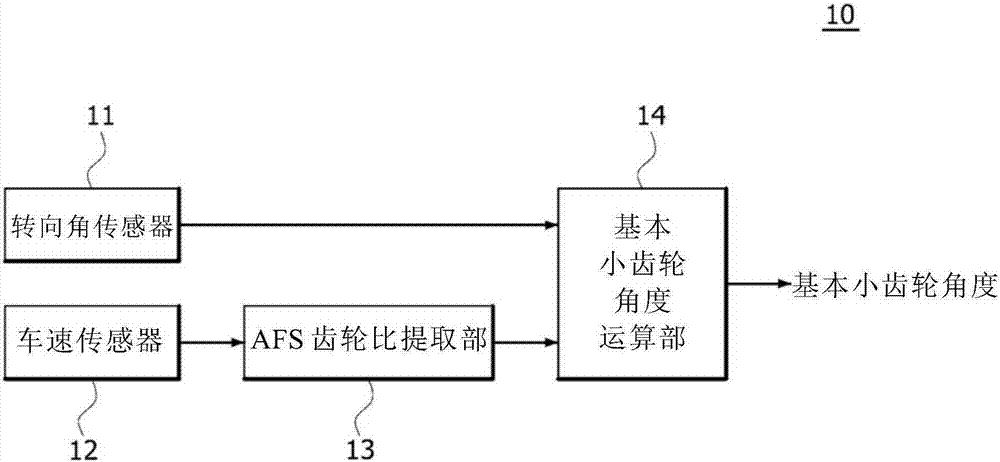

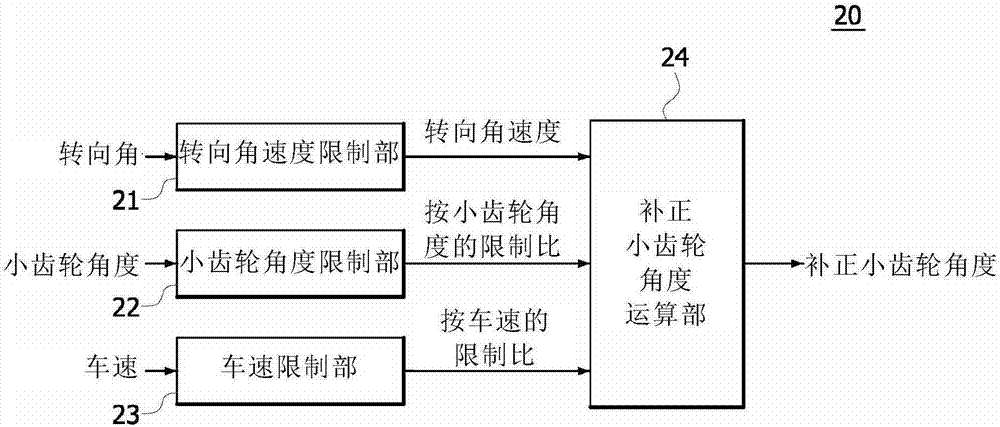

Active steering device of vehicle

ActiveCN105438258AQuick responseEnsure high-speed stabilitySteering linkagesAutomatic steering controlSteering angleEngineering

The present invention provides an active steering device of a vehicle, comprising a basic small pinion angle generation part configured to generate a basic pinion gear angle with respect to the steering angle of a driver according to the gear ratio of the active steering device with respect to the vehicle speed; a correction pinion angle detection part configured to detect a preset correction pinion angle according to the steering angle; and a basic pinion angle regulation part configured to receive the basic pinion angle and the correction pinion angle from the pinion angle generation part and the correction pinion angle detection part, and the correction pinion angle is used for regulating the basic pinion angle and output the final pinion angle. The active steering device of a vehicle is able to improve the response speed of the vehicle and ensure the high speed stability when steering in emergency in the high speed emergency condition, besides, whatever how about the steering angle area, the increased steering with a preset amount is generated, so that the steering linearity of a vehicle is ensured.

Owner:HYUNDAI MOBIS CO LTD

Laminar flow cooling upper spray blocking device

ActiveCN101837377BEnsure shapeGuaranteed mechanical propertiesWork treatment devicesSpray nozzlesLaminar coolingStrip steel

The invention relates to a laminar flow cooling upper spray blocking device which comprises a plurality of groups of lower spray devices, and each group of lower spray device comprises a collecting pipe, a plurality of spray pipes, at least one screw rod, two sliding blocks and two blocking plates, wherein the spray pipes are evenly distributed on the collecting pipes; the at least one screw rod is arranged at the upper part of the collecting pipe in a spanning way along the length direction of the collecting pipe; the two sliding blocks are provided with internal screw and are respectively connected with the screw rods by screw thread; the two blocking plates are respectively fixed with the sliding blocks, extend to an outlet of the collecting pipe; and the collecting pipe is movably shielded by a sliding mechanism. The laminar flow cooling upper spray blocking device can correspondingly build lower spray gap laminar flow corresponding to the width of a belt material channel according to the requirements of the cooling technique of the strip steel with different widths, and reduces the temperature reduction of the side of the strip steel by the corresponding change of a laminar flow cooling area along the width direction; and by adopting automatic lubrication, the device has the structure which is convenient for maintenance, and ensures the uniformity of the profile shape, the mechanical performance, the temperature and the phase change of the strip steel along the width direction.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for rolling thin high-strength steel plate of single-frame steckel mill

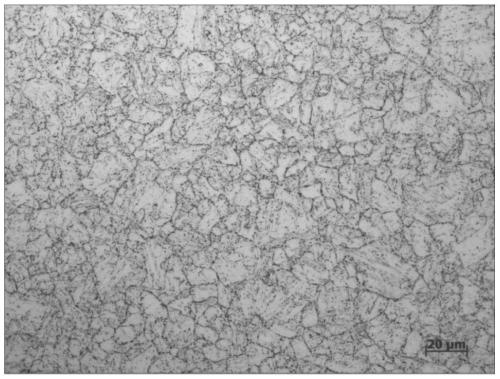

ActiveCN102179406BGrain refinementEliminate temperature differenceRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com