Three-dimensional full-flow control method for online steel plate solution treatment

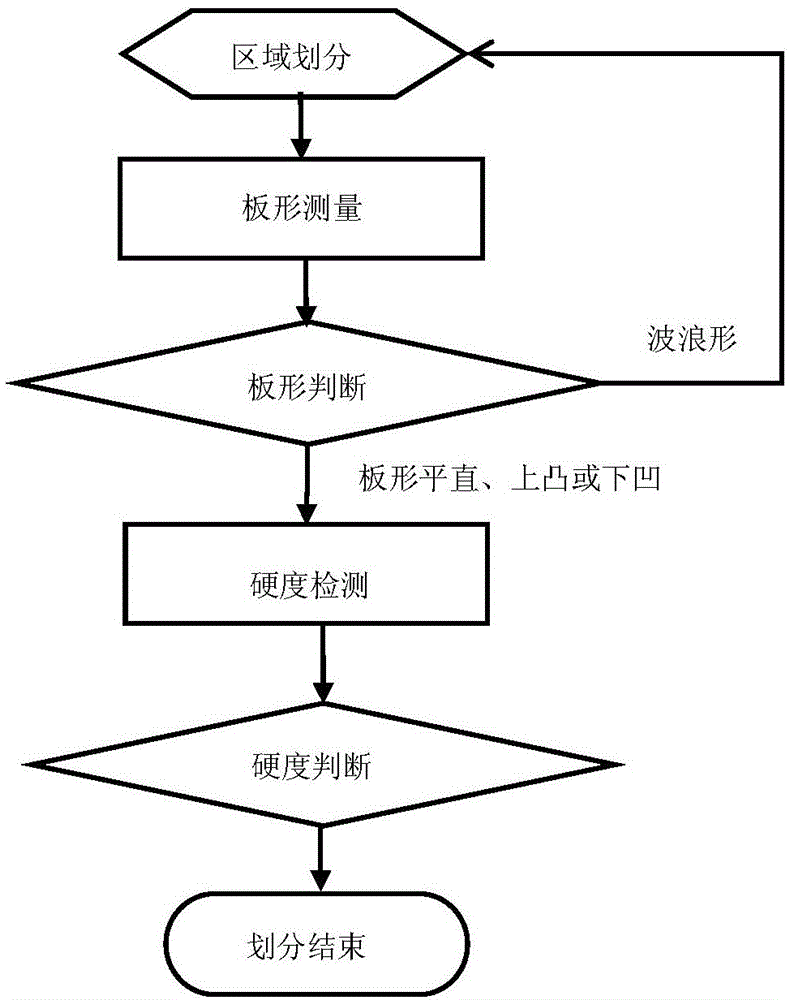

A control method and solid solution treatment technology, applied in the field of control, can solve problems such as poor cooling plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The main parameters of a specific embodiment of the technical solution of the present invention are as follows:

[0068] Take the solution treatment of a 20mm thick steel plate of a certain steel grade as an example.

[0069] 1) Valve group design

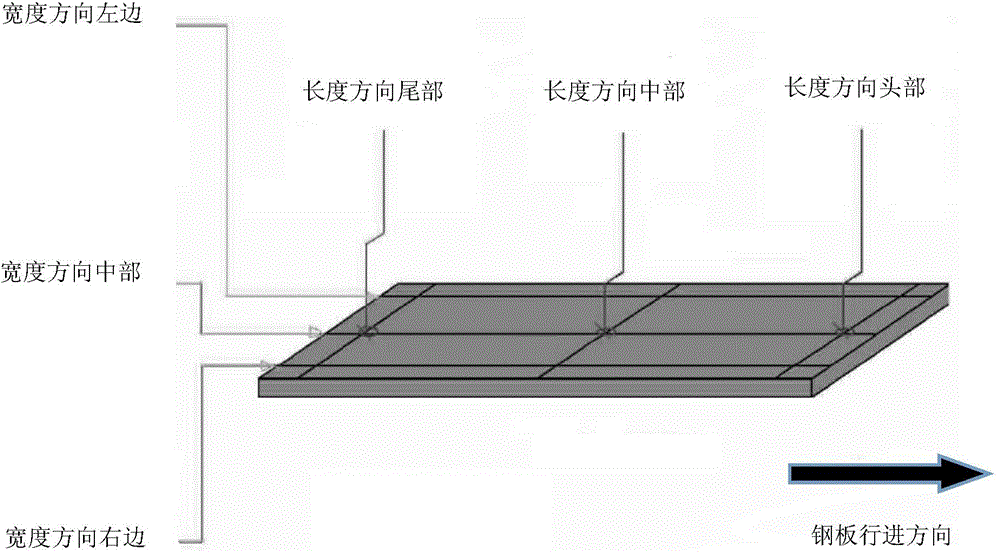

[0070] In this example, according to the actual cooling plate shape control needs, the water cooling zone is divided into 8 water zones longitudinally, and each water zone is divided into 3 zones on the left, middle and right horizontally, separated up and down, so that a total of 6×8=48 control valve groups are designed , Each group includes a set of flow control valve and switch valve, etc., and the water flow is set separately according to the needs of the cold zone.

[0071] 2) Initial water ratio and flow setting

[0072] Water ratio

[0073] Flow rate (m 3 / h)

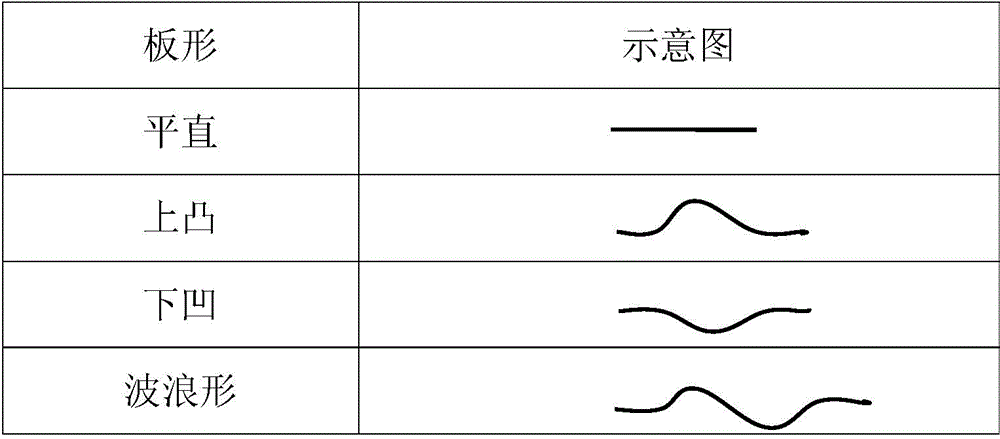

[0074] 3) Actual measurement of steel plate hardness and shape

[0075]

[0076] 4) Head water ratio and flow rate setting correction

[0077] Water ratio

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com