Multifunctional oxygenation reamer

A hole reamer and multi-functional technology, applied in the field of metallurgy, can solve problems such as easy blockage, poor slag discharge, inconvenient replacement of cutter heads, etc., to achieve the effect of speeding up, improving work efficiency, and solving problems of hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

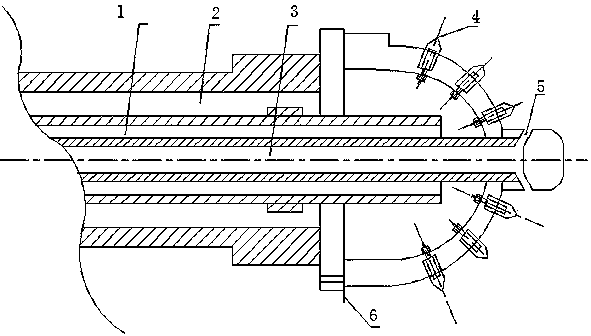

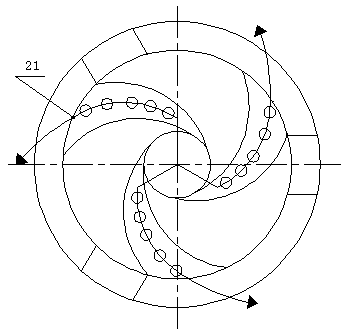

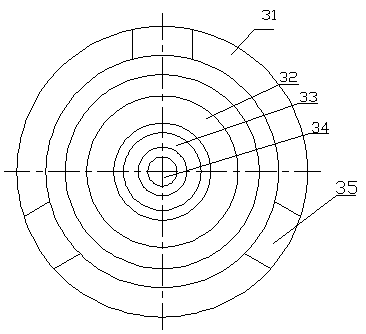

[0027] Such as figure 1 As shown, an oxygen-filling multifunctional reamer, the outermost layer in the spindle drill rod of the reamer is set as the backwater cavity (2), and the second layer is set as the water inlet cavity (1), the innermost The layer is set as an oxygenation chamber (3), three oxygenation holes (5) evenly arranged along the circumference are set on the top of the drill bit. The cutter head assembly is fixed on the reamer drill bit by bolts, and the drill bit and the spindle drill rod are connected The connecting flanges (31) are connected together. During the reaming work, as the drill bit is drilled, automatic oxygenation is performed at the same time, which solves the problem of no "cold steel" reaming, circulating water cooling setting, lowering the working temperature, and thus Ensure the mechanical strength of the drill bit and drill pipe components. The generated waste slag is quickly flushed out along the automatic slag discharge slot (6) under the imp...

Embodiment 2

[0031] Such as figure 1 As shown, an oxygen-filling multifunctional reamer, the outermost layer in the main shaft drill rod of the reamer is set as the pipe of the return water cavity (2), and then enters the pipe of the water inlet cavity (1). The innermost layer of the pipeline is set as the oxygenation chamber (3). On the top of the drill bit, there are 4 oxygenation holes (5) evenly arranged along the circumference. The cutter head assembly is fixed on the reamer drill bit by bolts. The drill bit and the spindle drill rod are connected by a connecting flange (31). When the drill bit is drilled, oxygen is automatically filled at the same time as the drill bit is drilled. This solves the problem of no "cold steel" reaming and circulating water cooling settings. The working temperature is lowered to ensure the mechanical strength of the drill bit and the drill pipe components. Under the impact of the airflow, the generated waste residue is quickly flushed out along the automati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com